#coriolis mass flow

Explore tagged Tumblr posts

Text

Unveiling Precision: Nagman Flow's Coriolis Mass Flow Meter

Welcome to Nagman Flow, where precision instrumentation meets cutting-edge technology. In this blog post, we dive into the world of flow measurement with a focus on the Coriolis Mass Flow Meter. We will explore the intricacies of this innovative device, its applications, and how Nagman Flow's expertise ensures unparalleled accuracy in mass flow measurement.

Coriolis Mass Flow Meter: A Breakthrough in Flow Measurement

The Coriolis Mass Flow Meter represents a revolution in flow measurement technology. Operating on the principle of the Coriolis effect, this meter offers unparalleled accuracy in measuring mass flow rates. Nagman Flow's Coriolis Mass Flow Meter is engineered to deliver precise measurements across various fluid mediums, from liquids to gases.

Advantages of Nagman Flow's Coriolis Mass Flow Meter

Precision Measurement: Nagman Flow's Coriolis Mass Flow Meter provides precise measurement of mass flow rates, ensuring accuracy and reliability in critical processes.

Versatility: Whether measuring liquids or gases, Nagman Flow's Coriolis Mass Flow Meter offers unmatched versatility, making it suitable for a wide range of applications.

Low Maintenance: Built with robust construction and advanced technology, Nagman Flow's Coriolis Mass Flow Meter requires minimal maintenance, reducing downtime and operational costs.

Coriolis Gas Flow Measurement: With specialized configurations for gas flow measurement, Nagman Flow's Coriolis Mass Flow Meter excels in accurately measuring gas flow rates, providing valuable insights for various industries.

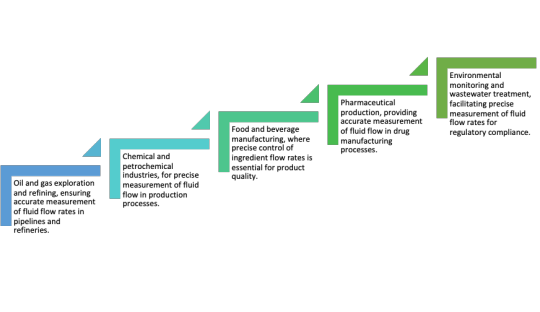

Applications of Coriolis Mass Flow Meter

Nagman Flow's Coriolis Mass Flow Meter finds applications across diverse industries, including:

In the realm of flow measurement, Nagman Flow's Coriolis Mass Flow Meter stands as a beacon of precision and reliability. With its advanced technology and unparalleled accuracy, Nagman Flow ensures that industries can rely on precise mass flow measurements for optimal performance and efficiency. Trust Nagman Flow to deliver exceptional solutions for all your flow measurement needs. Contact us today to learn more about Nagman Flow's Coriolis Mass Flow Meter and experience the difference in precision instrumentation.

0 notes

Text

Types Of Flow Measurement Devices

In the dynamic realm of industrial processes, the accurate measurement of fluid flow is crucial for efficiency and performance. In this article, we delve into the different types of flow measurement devices that play a pivotal role in optimizing processes across various sectors.

Electromagnetic Flow Meters: In applications where the fluid is conductive, electromagnetic flow meters shine. These devices utilize Faraday's law of electromagnetic induction to measure the velocity of the fluid. The resulting data, combined with the pipe's cross-sectional area, provides a precise measurement of the flow rate, making them ideal for industries dealing with water or other conductive liquids.

Ultrasonic Flow Meters: Employing ultrasonic waves to determine the velocity of fluid, these non-intrusive devices are gaining popularity. Transit-time and Doppler are two common types within this category. Transit-time ultrasonic meters measure the time it takes for ultrasonic signals to travel with and against the flow, while Doppler meters use the frequency shift of reflected waves to calculate flow velocity.

Coriolis Flow Meters: Renowned for their accuracy, Coriolis flow meters operate on the principle of the Coriolis effect. As fluid flows through a vibrating tube, the Coriolis effect induces a phase shift, which is proportional to the mass flow rate. This technology is particularly effective for measuring both liquids and gases with high precision.

Vortex Shedding Flow Meters: Capitalizing on the phenomenon of vortices forming downstream of a bluff body placed in the fluid stream, vortex Shedding flow meters are apt for measuring the flow of gases and liquids. The frequency of vortices shed is directly proportional to the flow rate, enabling accurate measurements.

In conclusion, the world of flow measurement devices is as diverse as the industries they serve. Each type has its strengths and applications, catering to specific needs and scenarios. As industries continue to evolve, the synergy of these devices with cutting-edge technologies ensures that accurate flow measurement remains a cornerstone for optimizing processes and enhancing overall efficiency.

2 notes

·

View notes

Text

0 notes

Text

Intelligent Flow Meter Market Set to Surge on Digitalization in Process Control

Intelligent flow meters integrate advanced sensing technologies, smart algorithms, and communication protocols to deliver precise and reliable flow measurement across industries. These devices leverage ultrasonic, electromagnetic, Coriolis, and thermal mass sensing principles to monitor liquid and gas flows, enabling real-time data acquisition, remote diagnostics, and predictive maintenance. Advantages such as reduced downtime, enhanced process efficiency, and improved regulatory compliance drive adoption in oil & gas, water treatment, chemical processing, food & beverage, and pharmaceutical sectors. The increasing focus on Industry 4.0 and IoT-driven automation has expanded the market scope for intelligent flow meters, offering actionable market insights and contributing to better market share and business growth for Intelligent Flow Meter Market Insights OEMs. Manufacturers are investing in R&D to develop compact, low-power, and corrosion-resistant variants that cater to harsh environments, further supporting market opportunities and strengthening competitive dynamics. As end users demand accurate mass flow measurements to optimize energy consumption and minimize losses, the intelligent flow meter market revenue is poised for steady expansion.

#Intelligent#Intelligent Flow#Intelligent Flow Meter Market Insights#Intelligent Flow Meter#Intelligent Flow Meter Market#Coherent Market Insights

0 notes

Text

How Flow Meters Facilitate Middle East Biofuel And Renewable Energy Production

The UAE is witnessing growth in the industrial sector. To achieve efficiency, safety and compliance, accurate measurement and control of fluid flow is a must. With oil & gas, water treatment, chemical processing, and manufacturing industries picking up, demand for quality flow meters has never been more so. Ali Yaqoob has emerged as a leading supplier, having a comprehensive line of flow meters for business in the UAE to cater to the different requirements.

The Importance of Flow Meters in the UAE

Flow meters are crucial devices that measure the flow of liquid or gas whether it be a volume or a mass. The flow measurement is significant and fundamental in the UAE, which has some quality industries that use high quality standards as well as safety measures, accurate flow measurement gives:

Billed accurately and inventory reported

Environmental and safety rules are met

Better control of process and related operating costs

Early detection of leaks or inefficiencies in the system

Full Range of Flow Meters

Ali Yaqoob is also known as one of the best Flow Meter Suppliers in the region, offering solutions for a vast range of applications. They have the following product offerings:

Positive Displacement Flow Meters

Turbine Flow Meters

Electromagnetic Flow Meters

Ultrasonic Flow Meters

Coriolis Mass Flow Meters

Every category is tailored for special applications, from the measurement of water and fuel to chemicals and industrial gases, so customers can receive the most appropriate technology for their purpose.

Special Offers on Best Brands

Ali Yaqoob is an official distributor of the global top-branded products, such as the most sought-after Liquid Controls M7 & M15 flow meter. Such systems are reputed for precision, reliability, and little or no maintenance required, and thus fit well in harsh environments. Ali Yaqoob also provides special promotions and offers periodically, thus providing extra value to enterprises requiring addition or upgrade in flow measurement capacity.

Value-Added Services

Besides providing top-notch flow meters, Ali Yaqoob provides:

Expert technical assistance to assist clients to choose the appropriate flow meter for their application

Installation services and after-sales services

Calibration and maintenance services to ensure long-term accuracy and reliability

Conclusion

For companies looking for dependable flow meter UAE solutions, Ali Yaqoob is an excellent partner. With a wide line of products, alliances with top global brands, and a focus on customer satisfaction, they have emerged as one of the best Flow Meter Suppliers in the region. Whether you need a stocked flow meter or an engineered-to-order solution, Ali Yaqoob is well placed to deliver as per your needs with skill and speed

0 notes

Text

0 notes

Text

0 notes

Text

Understanding the Role of a Fuel Flow Meter in Modern Industry

In the world of precision and efficiency, the Fuel Flow Meter has become a silent workhorse across industries. Whether in aviation, marine, automotive, or industrial applications, this device plays a critical role in measuring the accurate flow of fuel. With rising fuel costs and increasing environmental concerns, monitoring fuel consumption has never been more vital.

This blog dives deep into what a Fuel Flow Meter is, its importance, applications, and why businesses and operators should consider integrating this technology.

What Is a Fuel Flow Meter?

A Fuel Flow Meter is a device designed to measure the rate at which fuel is delivered or consumed. Installed in fuel lines, it provides real-time data on flow rates, which can then be used for performance monitoring, fuel management, and cost optimization.

There are various types of Fuel Flow Meters including:

Positive displacement meters

Turbine meters

Coriolis mass flow meters

Ultrasonic meters

Each type has its own advantages depending on the fuel type, flow range, and required accuracy.

Why Are Fuel Flow Meters Important?

Accurate fuel measurement is critical for several reasons:

✅ Cost Control: Knowing the exact amount of fuel used helps businesses identify inefficiencies and reduce unnecessary consumption.

✅ Environmental Responsibility: With stricter emission standards, accurate fuel data helps track carbon footprints and optimize fuel use.

✅ Performance Monitoring: For engines and machinery, monitoring fuel consumption allows operators to detect early signs of wear or malfunction.

✅ Compliance: Certain industries require detailed fuel records for compliance and reporting. A Fuel Flow Meter ensures these records are accurate.

Real-World Applications

The versatility of the Fuel Flow Meter means it finds use in various industries:

Aviation: Ensuring aircraft engines are performing efficiently while maintaining safety.

Marine: Tracking ship fuel usage to comply with international maritime regulations.

Automotive: Used in fleet management to monitor fuel use and improve route planning.

Industrial Equipment: Monitoring heavy machinery to optimize fuel consumption and reduce downtime.

Testimonial

“After installing a Fuel Flow Meter on our fleet, we saw a measurable reduction in fuel waste. Not only did it improve our bottom line, but it also helped us meet our sustainability goals.” — Logistics Manager, National Transport Company

Frequently Asked Questions (FAQs)

What is the accuracy of a Fuel Flow Meter?

Accuracy depends on the type and model, but many modern Fuel Flow Meters can achieve up to ±0.2% accuracy under ideal conditions.

Can it handle different fuel types?

Yes, there are meters designed for diesel, gasoline, aviation fuel, and even biofuels. It’s crucial to choose a meter compatible with your specific fuel type.

Is installation complicated?

Most Fuel Flow Meters are designed for easy installation and integration into existing systems. However, for best performance, professional installation is recommended.

How do I maintain a Fuel Flow Meter?

Regular calibration and cleaning are essential. Many modern meters come with self-diagnostic features to alert operators when maintenance is required.

How to Choose the Right Fuel Flow Meter

Selecting the right Fuel Flow Meter depends on several factors:

Fuel type

Flow rate range

Required accuracy

Environmental conditions

Budget

Consulting with a reputable supplier or technical expert can ensure you select the best meter for your needs.

Final Thoughts

The Fuel Flow Meter and Diesel Bowser is no longer just a nice-to-have; it is a critical tool for businesses looking to improve efficiency, reduce costs, and meet environmental standards. By offering real-time, accurate fuel data, it empowers operators to make smarter, data-driven decisions.

0 notes

Text

Accurate Flow Measurement For All Applications — ADD VALUE Coriolis Flow Meter

Qingdao Add Value Flow Metering Co., Ltd. is a trusted manufacturer and supplier in pulp processing, petroleum & oil measuring, chemical processing and wastewater handling and commercial applications.

Here are the advantages of our ADD VALUE Coriolis mass flow meters.

High mass flow accuracy, measurement error is better than ± 0.1%;

High density accuracy, measurement error is better than ± 0.0005g / cm³;

High temperature accuracy, measurement error is better than ± 0.2 ºC;

Good zero stability to ensure long-term stable operation;

Fast response time, suitable for small batch and short time filling;

Wide turndown ratio, the turndown ratio can reach 20:1;

Long service life, product design service life is 10 years;

More warning functions.

0 notes

Text

A Closer Look at Flow Meters: Enhancing Accuracy and Efficiency in Fluid Measurement

Introduction:

In industries where fluid flow plays a critical role, accurate measurement is essential for process optimization, quality control, and cost management. Flow meters are the unsung heroes in these operations, providing vital data and insights into fluid dynamics. In this blog post, we will delve into the world of flow meters, exploring their significance, working principles, types, and the benefits they offer in various applications. So, let's dive in and unravel the mysteries of flow meters!

1. The Importance of Flow Meters:

Fluid flow is a fundamental aspect of many industries, including oil and gas, chemical processing, water management, and manufacturing. In this section, we will discuss why flow meters are crucial for these sectors and how they contribute to enhanced productivity, safety, and resource utilization.

2. Understanding Flow Meter Principles:

To comprehend the intricacies of flow meters, we must grasp their underlying principles. In this section, we will explore the four main types of flow meters: differential pressure, positive displacement, velocity, and mass flow meters. We'll explain the working mechanisms of each type and highlight their strengths and limitations.

3. Differential Pressure Flow Meters:

One of the most common types of flow meters is the differential pressure flow meter. In this section, we will take a closer look at orifice plates, venturi tubes, and flow nozzles - three widely used differential pressure flow meter variants. We'll explain their construction, working principles, and discuss their applications and considerations for accurate measurements.

4. Positive Displacement Flow Meters:

Positive displacement flow meters are known for their precise measurements of low flow rates. In this section, we will examine the working principles of gear meters, nutating disc meters, and oval gear meters. We'll explore their advantages, limitations, and typical applications in industries such as food and beverage, pharmaceuticals, and fuel distribution.

5. Velocity Flow Meters:

Velocity flow meters, such as turbine and electromagnetic meters, rely on the fluid's velocity to measure flow rates. In this section, we will delve into their working principles, installation considerations, and applications. We'll also discuss the challenges associated with fluid properties, calibration, and maintenance.

6. Mass Flow Meters:

For applications where mass measurement is crucial, mass flow meters provide accurate results by directly measuring the mass of the flowing fluid. We will explore thermal mass flow meters, Coriolis flow meters, and their working principles, advantages, and limitations. This section will highlight their significance in industries like pharmaceuticals, chemical processing, and HVAC systems.

7. Selecting the Right Flow Meter:

Choosing the appropriate flow meter for your specific application is vital for accurate and reliable measurements. In this section, we will discuss the key factors to consider, such as fluid characteristics, flow range, accuracy requirements, installation constraints, maintenance needs, and cost considerations. By understanding these factors, you can make an informed decision when selecting a flow meter.

8. The Future of Flow Meter Technology:

As technology advances, so does the field of flow meters. In this section, we will explore emerging trends and innovations, including digitalization, Internet of Things (IoT) integration, and advancements in sensor technology. We'll discuss how these developments are shaping the future of flow meter technology and the potential benefits they offer.

9. Conclusion:

Flow meters are indispensable tools for accurate fluid measurement in various industries. By understanding their principles, types, and considerations for selection, you can optimize processes, reduce costs, and ensure safe operations. We hope this blog post has shed light on the world of flow meters and provided you with valuable insights into their significance and applications. Remember, precision in flow measurement leads to efficiency and success!

#flow meters#water meter test bench#gas meter calibration#flow meter#coriolis mass flow meters#flow meter calibration#liquid flow calibration system

0 notes

Text

Innovate systems is best Flow Meter Supplier, Flow Meter Manufacturer, Dealer, Exporter in Pune, Bangalore, Mumbai, Ahmadabad, Chennai, Gujarat, Hyderabad. We provideGas Flow Meter, Portable Ultrasonic Flow Meter, Oil Flow Meter, Vortex Flow Meter, Ultrasonic Level Transmitter, Mass Flow Meters, Online Digital Ph Meter, Hanna Ph Meter, Abb Electromagnetic Flow Meter, Coriolis Mass Flow Meter, and Hydraulic Flow Meterat best price

0 notes

Text

The Micro Motion 20001827 Flow Meter F025S113CQBZEZ1ZZ is a reliable and accurate solution for liquid and gas flow measurement. Built with Coriolis technology, it ensures precise mass flow, density, and temperature readings in one compact unit. Its robust stainless-steel construction makes it ideal for harsh industrial environments. The F025S113CQBZEZ1ZZ model is known for its high performance, easy integration, and minimal maintenance. Whether used in chemical processing, oil & gas, or food industries, this flow meter delivers consistent and efficient results. Choose Auto2mation for quality flow measurement solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Meter#Micro Motion#Flow Meter

0 notes

Text

How to Select the Perfect Measurement Solution for Your Fluid Processing System

In today's industrial landscape, selecting the right fluid measurement solution can make or break your processing system's efficiency, accuracy, and overall operational costs. With countless options available in the market, finding the perfect fit for your specific application requires careful consideration of numerous factors. This comprehensive guide will walk you through the essential steps to ensure you make an informed decision when choosing measurement tools for your fluid processing needs.

Understanding Your Process Requirements First

Before diving into the various measurement technologies available, you must thoroughly understand what you're measuring and why. A successful fluid system measurement strategy begins with clearly defining your process parameters:

Process Media Characteristics

Viscosity (Is your fluid thick like honey or thin like water?)

Corrosiveness (Will your fluid potentially damage measurement equipment?)

Temperature and pressure ranges

Presence of solids or bubbles

Conductivity properties

Performance Requirements

Required measurement accuracy (±0.2%, ±0.5%, or ±1%)

Flow rate range (minimum and maximum expected rates)

Pressure drop limitations

Repeatability needs

Response time

Installation Environment

Available space constraints

Straight pipe run availability

Ambient conditions (temperature, humidity, vibration)

Hazardous area classifications

Taking the time to document these requirements will significantly narrow your options and prevent costly mistakes down the road.

Exploring Common Fluid Measurement Technologies

Each measurement technology has its unique strengths and limitations. Let's explore the most common options and when they shine:

Electromagnetic Flow Meters

Electromagnetic flowmeters excel when measuring conductive fluids. By generating a magnetic field across the pipe and measuring the voltage produced as the conductive fluid passes through, these meters deliver exceptional accuracy.

Best suited for:

Water-based solutions

Slurries and wastewater

Chemical processing

Food and beverage applications

Key advantages:

No moving parts means minimal maintenance

No pressure drop

Unaffected by fluid density, viscosity, or temperature

Available in sanitary designs for hygienic applications

However, electromagnetic flow sensors cannot measure non-conductive fluids like oils or gases, so they're not universal solutions.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to determine flow rates, either through transit-time or Doppler methods. The transit-time approach measures how long it takes for sound waves to travel between transducers, while Doppler systems measure frequency shifts caused by reflections off particles in the fluid.

Best applications:

Clean liquids (transit-time)

Dirty liquids with suspended particles (Doppler)

Large diameter pipes

Non-invasive measurement needs

Strengths:

Clamp-on options available (no pipe cutting required)

No pressure drop or flow obstructions

Suitable for corrosive applications

Bidirectional measurement capabilities

Ultrasonic flow meter accuracy can be affected by fluid consistency and pipe condition, so proper installation is crucial.

Coriolis Flow Meters

When ultimate accuracy is non-negotiable, coriolis flow meters often provide the solution. Using the Coriolis effect, these meters measure mass flow directly rather than volumetric flow, eliminating concerns about temperature and pressure effects on density.

Ideal for:

Custody transfer applications

High-value products

Multi-phase fluids

Applications requiring density or concentration measurement

Benefits:

Exceptional accuracy (typically ±0.1% to ±0.5%)

Direct mass flow measurement

Independent of flow profile and fluid properties

Can measure multiple parameters simultaneously (flow, density, temperature)

The primary drawbacks include higher initial cost and larger installation footprints, especially for larger pipe sizes.

Rotameter Flowmeters

For applications where simplicity, reliability, and visual indication are priorities, rotameter flowmeters remain popular choices. These variable area meters use a float in a tapered tube to indicate flow rate.

Commonly used for:

Low-flow applications

Local flow indication without power

Simple proportional control

Purge and blanketing systems

Advantages:

No power required for basic models

Visual indication without instruments

Simple operation and maintenance

Cost-effective for smaller applications

Accuracy tends to be lower than other technologies (typically ±2-5%), making rotameters less suitable when precision is paramount.

Critical Selection Factors Beyond Technology Type

While understanding the different measurement technologies is important, several other factors should influence your final decision:

Total Cost of Ownership

Initial purchase price is just one component of the total cost. Consider:

Installation complexity and costs

Power requirements

Calibration frequency and expense

Spare parts availability and cost

Expected service life

Maintenance requirements

A higher upfront investment in a premium flow meter might deliver substantial savings over its operational lifetime through reduced maintenance and higher accuracy.

Integration with Existing Systems

Your measurement solution should seamlessly integrate with your current control and monitoring systems:

Compatible output signals (4-20mA, HART, Fieldbus, etc.)

Communication protocol support

Software compatibility

Power supply requirements

Ensuring proper integration prevents costly rework and communication issues after installation.

Regulatory and Compliance Requirements

Many industries face strict regulatory oversight regarding fluid measurement:

Industry-specific certifications (FDA, 3A, EHEDG for food and pharma)

Hazardous area approvals (ATEX, IECEx, FM)

Custody transfer approvals (OIML, NTEP, MID)

Environmental compliance documentation

Non-compliance can result in production shutdowns, fines, or rejected products, making this a critical consideration.

Supplier Expertise and Support

The right measurement partner offers more than just hardware:

Application engineering support

Commissioning assistance

Training programs

Responsive technical support

Calibration services

Global presence for multinational operations

Working with experienced measurement solution providers like XINSIER TECHNOLOGY ensures you benefit from 15+ years of industry knowledge and support across 53 countries worldwide.

Decision-Making Framework: A Practical Approach

To systematize your selection process, consider implementing this step-by-step framework:

Document process requirements (fluid properties, accuracy needs, environmental conditions)

Screen technologies based on compatibility with your application

Evaluate qualified options using weighted criteria important to your operation

Request detailed specifications from shortlisted suppliers

Perform cost-benefit analysis including total cost of ownership

Check references from similar applications

Conduct site assessment to verify installation feasibility

This structured approach narrows options progressively while ensuring all critical factors receive proper attention.

Real-World Considerations From Industry Experience

After working with thousands of fluid processing systems across diverse industries, we've observed several practical considerations often overlooked during selection:

Future-proofing: Select measurement solutions that can accommodate potential process changes or expansions

Standardization benefits: Using consistent meter types across your facility simplifies maintenance and reduces spare parts inventory

Redundancy needs: Critical measurements might warrant backup measurement systems

Local support availability: Even the best technology fails without proper support infrastructure

Environmental impact: Consider energy consumption and end-of-life disposal impacts

Conclusion: Making Your Final Decision

Selecting the perfect measurement solution for your fluid processing system requires balancing technical requirements, financial considerations, and practical implementation factors. By thoroughly understanding your process needs, evaluating the strengths and limitations of different technologies, and considering the total cost of ownership, you'll be well-positioned to make an informed decision.

Remember that the cheapest option rarely delivers the lowest long-term cost, and the most expensive isn't automatically the best fit for your application. Instead, focus on finding the right match for your specific requirements while ensuring proper installation and maintenance.

With over 15 years of experience providing scientific and cost-effective measuring solutions, XINSIER TECHNOLOGY has helped thousands of facilities optimize their fluid measurement systems. Our team of specialists can guide you through the selection process to ensure you achieve the precision, reliability, and performance your operation demands.

Whether you need electromagnetic flowmeters for water treatment, ultrasonic flow meters for large pipelines, or coriolis flow meters for high-accuracy custody transfer applications, partnering with experienced measurement professionals ensures you'll get the perfect solution for your unique requirements.

0 notes

Text

What are the benefits of Flow Meter?

In a time when there is a lot of dependency on accurate measurement in industries like water treatment, oil and gas, medicine, and manufacturing, the value of a flow meter cannot be overstated. But what then is a flow meter, and why should it matter so much?

A flow meter is a device used to measure the rate of flow of a liquid or gas within a pipe. It is utilized to control and monitor the volume of fluid flowing in an attempt to ensure efficiency, accuracy, and safety in industrial and commercial use.

We will introduce the key benefits of using a flow meter in many industries.

1. Accurate Measurement

Accuracy is one of the advantages of possessing a flow meter. Water, gas, steam, or chemicals, a flow meter provides you with real numbers. Quality control, process optimization, and billing require precise flow measurement.

In businesses like water utilities or fuel delivery, any error in the measurement of flow by even a small amount can translate to astronomical losses. A calibrated flow meter guarantees risk avoidance.

2. Operation Efficiency

Flow meters enhance operational efficiency through real-time measurement and flow rate control. Operations can, based on flow data:

Maximize energy usage

Identify leaks or clogging

Automate the operation

Enhance overall productivity

For example, in irrigation systems or HVAC equipment, use of flow meters guarantees control of air or water flow as per requirement without wastage, resulting in efficiency.

3. Cost Savings

By using a flow meter, one can eschew tremendous operating expenses in the long term. By bypassing product loss, which reveals system inefficiencies, and decreased downtime, business firms can eschew maintenance, repair, and material expense.

Flow meters also enable billing with precision, especially in the utilities and service business. Precise reading ensures no over-charging or under-charging, winning customer confidence and enhancing business reputation.

4. Enhanced Safety

In steam, chemical, or pressurized gas processes, flow measurement must be sustained to prevent accidents. Immediate change or reduction in flow could indicate system failure or hazard.

Smooth operations could be realized immediately with fast measurement through flow meters with instant response to prevent leakage, equipment destruction, or environmental risk and ensure personnel and asset safety.

5. Data Collection and Reporting

Flow meters today may also have digital interfaces and may be interfaced with SCADA and IoT systems. They may be stored and transmitted for use for:

Process analysis

Compliance with regulations

Inspection and audits

Predictive maintenance

Flow meters, therefore, are not only measurement devices but also business intelligence providers.

6. Versatility Across Industries

Flow meters are also versatile and come in many types to be used for different purposes:

Electromagnetic flow meters – for conductive fluids

Ultrasonic flow meters – for clean and dirty liquids

Turbine flow meters – for precise measurement in pipes

Thermal mass flow meters – ideal for gases

Coriolis flow meters – for high precision in liquids and gases

From water supply management in municipalities to fluid measurement in the production of food and beverages, there's a flow meter for the job.

Final Thoughts

The benefit of a flow meter is greater than just measuring—it's accuracy, efficiency, cost savings, and safety. With the rapid-paced industry era we have today, fluid flow measurement in real-time is making businesses smarter, safer, and more responsible.

If you care about maximizing process control or loss prevention in your company, an investment in the right flow meter could be the one that will give you the edge.

0 notes

Text

Overview of Digital Flow Meters: Accurate Flow Measurement for Modern Industries

Flow meters are essential tools in many industries, used to measure the volume or mass of a fluid moving through a pipeline. With the growing demand for more precise, reliable, and real-time data, digital flow meters have become increasingly popular. These advanced instruments offer enhanced accuracy, easy integration with digital systems, and lower maintenance needs compared to traditional mechanical meters.

This blog will provide a clear overview of digital flow meters, how they work, their types, benefits, and where they are used.

What is a Digital Flow Meter?

A digital flow meter is a device that measures the flow of liquids or gases and displays the results in a digital format. It uses sensors and electronic components to monitor flow rates with high precision and often includes features such as:

Digital displays for real-time monitoring

Remote data transmission

Integration with SCADA, PLC, or IoT systems

Alarm settings and data logging

These meters are commonly used in water treatment plants, oil & gas industries, chemical processing, and HVAC systems, among others.

Types of Digital Flow Meters

There are several types of digital flow meters, each suited for different applications based on the type of fluid and required accuracy:

1. Electromagnetic Flow Meters

Ideal for conductive liquids like water, slurries, and chemicals. These meters use electromagnetic fields to measure flow without any moving parts.

2. Ultrasonic Flow Meters

Use high-frequency sound waves to measure the velocity of the fluid. They are perfect for both clean and dirty liquids and work well in large pipes.

3. Turbine Flow Meters

Contain a spinning rotor that turns with the flow. The rotational speed is proportional to the flow rate. These are used in clean, low-viscosity liquids.

4. Coriolis Flow Meters

Measure mass flow directly using the Coriolis effect. Known for their high accuracy and are used in chemical and pharmaceutical industries.

5. Thermal Mass Flow Meters

Used mainly for gases, these measure flow by detecting heat loss from a heated sensor placed in the flow path.

Benefits of Using Digital Flow Meters

✅ High Accuracy: Digital sensors reduce human error and provide exact measurements.

✅ Easy to Read: Digital displays are user-friendly and easy to interpret.

✅ Remote Monitoring: Many models support wireless or wired connectivity for remote data access.

✅ Low Maintenance: With fewer moving parts, these meters are durable and require minimal upkeep.

✅ Data Storage: Many meters come with memory functions for storing historical data for analysis.

Applications of Digital Flow Meters

Digital flow meters are used across various industries, including:

Water & Wastewater Management: For monitoring distribution and treatment systems.

Oil & Gas: For controlling the flow of fuels and gases.

Food & Beverage: Ensures precise ingredient mixing and quality control.

Pharmaceutical: For high-accuracy dosage and mixing applications.

HVAC Systems: For measuring water and air flows for better energy efficiency.

Conclusion

Digital flow meters have revolutionized how industries measure and manage fluids. Their combination of accuracy, reliability, and advanced features makes them an essential part of modern process control systems. Whether you are managing water resources, producing chemicals, or ensuring clean air flow, a digital flow meter can greatly improve your operational efficiency.

If you’re searching for reliable Digital flow meter manufacturers in India, it’s important to choose a company with proven expertise, quality products, and excellent service support to match your industry’s specific needs.

Looking for the right digital flow meter for your application? Connect with a trusted supplier today and discover how digital technology can enhance your flow measurement systems.

#flow meters#electromagnetic water meter#digital water flow meter#digital flow meters#digital water flow meter manufacturer in india#digital water flow meter india#electromagnetic flow meters#digital water meter#electromagnetic flow meter suppliers in india#electromagnetic flow meter manufacturers in india

0 notes

Text

The Science of Accuracy: Understanding Modern Flow Meters

In industries where precise measurement is crucial, flow meters play a significant role in ensuring accuracy and efficiency. From monitoring gas usage to optimizing industrial processes, flow meters provide essential data that helps businesses reduce waste, improve productivity, and enhance safety. With technological advancements, modern flow meters are now more accurate, reliable, and efficient than ever before.

Looking for high precision flow meters from leading flow meter manufacturers? Explore our wide range of advanced flow measurement solutions and find the perfect fit for your industry. Contact us today for expert guidance!

The Importance of Accurate Flow Measurement

Flow meters are essential tools for measuring the flow rate of liquids and gases in various industries such as oil and gas, chemical processing, and water treatment. Accurate flow measurement ensures optimal performance, regulatory compliance, and cost control. Whether it is a thermal mass flow meter for gas applications or an RPD gas meter for precise volumetric measurements, choosing the right flow meter is vital for operational success.

Types of Modern Flow Meters

With numerous types of flow meters available in the market, selecting the best one depends on the specific application. Some of the most commonly used flow meters include:

Thermal Mass Flow Meters: Ideal for measuring gas flow, these meters are highly accurate and do not require moving parts, reducing maintenance costs.

RPD (Rotary Positive Displacement) Gas Meters: Used in industrial and commercial applications, these meters provide precise volume measurement of gas.

Ultrasonic Flow Meters: These meters use sound waves to measure flow and are widely used in water and wastewater management.

Coriolis Flow Meters: Known for their high accuracy, they measure mass flow directly and are useful in chemical and food industries.

Each type of flow meter has unique benefits, and working with reliable flow meter manufacturers ensures that businesses get the best product suited for their needs.

Choosing the Right Flow Meter Supplier

Selecting the right flowmeter suppliers is just as important as choosing the right flow meter. A trusted supplier provides not only high-quality products but also technical support, calibration services, and guidance on installation. When looking for flow meter suppliers, consider factors such as industry experience, product range, accuracy standards, and after-sales support.

The Future of Flow Measurement

Partner with a trusted suppliers to stay ahead in the ever evolving world of flow measurement technology. Get in touch with us now to find the best solution for your needs!

In conclusion, modern flow meters are the backbone of accurate fluid measurement in various industries. Whether you need a thermal mass flow meter, RPD gas meter, or any other type of flow meter, working with the right flow meter manufacturers and suppliers ensures long-term efficiency, accuracy, and reliability. Choose wisely and stay ahead in the competitive industrial landscape!

0 notes