#electromagnetic flow sensors

Explore tagged Tumblr posts

Text

How to Select the Perfect Measurement Solution for Your Fluid Processing System

In today's industrial landscape, selecting the right fluid measurement solution can make or break your processing system's efficiency, accuracy, and overall operational costs. With countless options available in the market, finding the perfect fit for your specific application requires careful consideration of numerous factors. This comprehensive guide will walk you through the essential steps to ensure you make an informed decision when choosing measurement tools for your fluid processing needs.

Understanding Your Process Requirements First

Before diving into the various measurement technologies available, you must thoroughly understand what you're measuring and why. A successful fluid system measurement strategy begins with clearly defining your process parameters:

Process Media Characteristics

Viscosity (Is your fluid thick like honey or thin like water?)

Corrosiveness (Will your fluid potentially damage measurement equipment?)

Temperature and pressure ranges

Presence of solids or bubbles

Conductivity properties

Performance Requirements

Required measurement accuracy (±0.2%, ±0.5%, or ±1%)

Flow rate range (minimum and maximum expected rates)

Pressure drop limitations

Repeatability needs

Response time

Installation Environment

Available space constraints

Straight pipe run availability

Ambient conditions (temperature, humidity, vibration)

Hazardous area classifications

Taking the time to document these requirements will significantly narrow your options and prevent costly mistakes down the road.

Exploring Common Fluid Measurement Technologies

Each measurement technology has its unique strengths and limitations. Let's explore the most common options and when they shine:

Electromagnetic Flow Meters

Electromagnetic flowmeters excel when measuring conductive fluids. By generating a magnetic field across the pipe and measuring the voltage produced as the conductive fluid passes through, these meters deliver exceptional accuracy.

Best suited for:

Water-based solutions

Slurries and wastewater

Chemical processing

Food and beverage applications

Key advantages:

No moving parts means minimal maintenance

No pressure drop

Unaffected by fluid density, viscosity, or temperature

Available in sanitary designs for hygienic applications

However, electromagnetic flow sensors cannot measure non-conductive fluids like oils or gases, so they're not universal solutions.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to determine flow rates, either through transit-time or Doppler methods. The transit-time approach measures how long it takes for sound waves to travel between transducers, while Doppler systems measure frequency shifts caused by reflections off particles in the fluid.

Best applications:

Clean liquids (transit-time)

Dirty liquids with suspended particles (Doppler)

Large diameter pipes

Non-invasive measurement needs

Strengths:

Clamp-on options available (no pipe cutting required)

No pressure drop or flow obstructions

Suitable for corrosive applications

Bidirectional measurement capabilities

Ultrasonic flow meter accuracy can be affected by fluid consistency and pipe condition, so proper installation is crucial.

Coriolis Flow Meters

When ultimate accuracy is non-negotiable, coriolis flow meters often provide the solution. Using the Coriolis effect, these meters measure mass flow directly rather than volumetric flow, eliminating concerns about temperature and pressure effects on density.

Ideal for:

Custody transfer applications

High-value products

Multi-phase fluids

Applications requiring density or concentration measurement

Benefits:

Exceptional accuracy (typically ±0.1% to ±0.5%)

Direct mass flow measurement

Independent of flow profile and fluid properties

Can measure multiple parameters simultaneously (flow, density, temperature)

The primary drawbacks include higher initial cost and larger installation footprints, especially for larger pipe sizes.

Rotameter Flowmeters

For applications where simplicity, reliability, and visual indication are priorities, rotameter flowmeters remain popular choices. These variable area meters use a float in a tapered tube to indicate flow rate.

Commonly used for:

Low-flow applications

Local flow indication without power

Simple proportional control

Purge and blanketing systems

Advantages:

No power required for basic models

Visual indication without instruments

Simple operation and maintenance

Cost-effective for smaller applications

Accuracy tends to be lower than other technologies (typically ±2-5%), making rotameters less suitable when precision is paramount.

Critical Selection Factors Beyond Technology Type

While understanding the different measurement technologies is important, several other factors should influence your final decision:

Total Cost of Ownership

Initial purchase price is just one component of the total cost. Consider:

Installation complexity and costs

Power requirements

Calibration frequency and expense

Spare parts availability and cost

Expected service life

Maintenance requirements

A higher upfront investment in a premium flow meter might deliver substantial savings over its operational lifetime through reduced maintenance and higher accuracy.

Integration with Existing Systems

Your measurement solution should seamlessly integrate with your current control and monitoring systems:

Compatible output signals (4-20mA, HART, Fieldbus, etc.)

Communication protocol support

Software compatibility

Power supply requirements

Ensuring proper integration prevents costly rework and communication issues after installation.

Regulatory and Compliance Requirements

Many industries face strict regulatory oversight regarding fluid measurement:

Industry-specific certifications (FDA, 3A, EHEDG for food and pharma)

Hazardous area approvals (ATEX, IECEx, FM)

Custody transfer approvals (OIML, NTEP, MID)

Environmental compliance documentation

Non-compliance can result in production shutdowns, fines, or rejected products, making this a critical consideration.

Supplier Expertise and Support

The right measurement partner offers more than just hardware:

Application engineering support

Commissioning assistance

Training programs

Responsive technical support

Calibration services

Global presence for multinational operations

Working with experienced measurement solution providers like XINSIER TECHNOLOGY ensures you benefit from 15+ years of industry knowledge and support across 53 countries worldwide.

Decision-Making Framework: A Practical Approach

To systematize your selection process, consider implementing this step-by-step framework:

Document process requirements (fluid properties, accuracy needs, environmental conditions)

Screen technologies based on compatibility with your application

Evaluate qualified options using weighted criteria important to your operation

Request detailed specifications from shortlisted suppliers

Perform cost-benefit analysis including total cost of ownership

Check references from similar applications

Conduct site assessment to verify installation feasibility

This structured approach narrows options progressively while ensuring all critical factors receive proper attention.

Real-World Considerations From Industry Experience

After working with thousands of fluid processing systems across diverse industries, we've observed several practical considerations often overlooked during selection:

Future-proofing: Select measurement solutions that can accommodate potential process changes or expansions

Standardization benefits: Using consistent meter types across your facility simplifies maintenance and reduces spare parts inventory

Redundancy needs: Critical measurements might warrant backup measurement systems

Local support availability: Even the best technology fails without proper support infrastructure

Environmental impact: Consider energy consumption and end-of-life disposal impacts

Conclusion: Making Your Final Decision

Selecting the perfect measurement solution for your fluid processing system requires balancing technical requirements, financial considerations, and practical implementation factors. By thoroughly understanding your process needs, evaluating the strengths and limitations of different technologies, and considering the total cost of ownership, you'll be well-positioned to make an informed decision.

Remember that the cheapest option rarely delivers the lowest long-term cost, and the most expensive isn't automatically the best fit for your application. Instead, focus on finding the right match for your specific requirements while ensuring proper installation and maintenance.

With over 15 years of experience providing scientific and cost-effective measuring solutions, XINSIER TECHNOLOGY has helped thousands of facilities optimize their fluid measurement systems. Our team of specialists can guide you through the selection process to ensure you achieve the precision, reliability, and performance your operation demands.

Whether you need electromagnetic flowmeters for water treatment, ultrasonic flow meters for large pipelines, or coriolis flow meters for high-accuracy custody transfer applications, partnering with experienced measurement professionals ensures you'll get the perfect solution for your unique requirements.

0 notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

5 notes

·

View notes

Text

Swarm detects ocean tides' magnetic signatures

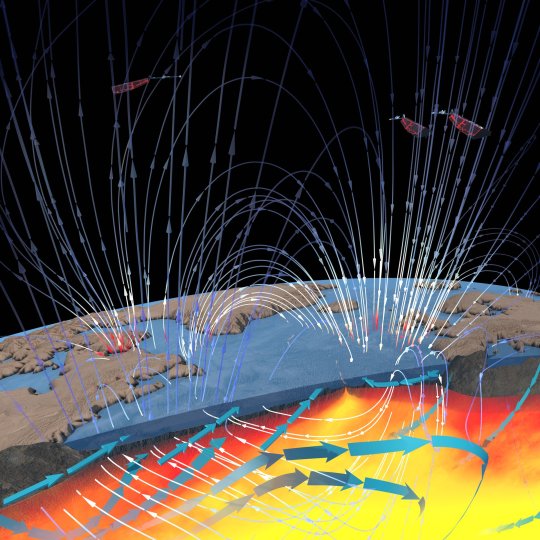

A study using data from ESA's Swarm mission suggests that faint magnetic signatures created by Earth's tides can help us determine magma distribution under the seabed and could even give us insights into long-term trends in global ocean temperatures and salinity.

Swarm is a constellation of three satellites that study Earth's geomagnetic field. This magnetic field that extends from Earth's interior into space is thought to be produced largely by an ocean of liquid iron in the planet's outer core. Other sources of magnetism include magnetized rocks in the crust.

And although we might not normally think of oceans as generating magnetism, the salty sea water is a moderate electrical conductor. This means that as tides flow across Earth's magnetic field, they generate weak electric currents, which in turn induce small magnetic signals that can be detected from space.

With its satellites flying at an altitude between 462 km and 511 km, Swarm measures Earth's magnetic field more accurately than ever before. It can detect faint tidal signatures and distinguish them from other stronger magnetic field sources from Earth's interior.

"This study shows that Swarm can provide data on properties of the entire water column of our oceans." says Anja Strømme, ESA's Swarm Mission Manager.

Swarm's data can also provide insights into the distribution of magma, which could in future support better understanding of events such as the Hunga-Tonga volcanic eruption of 2022.

The study of these signatures made the front cover of the world's oldest scientific journal, Philosophical Transactions of the Royal Society A, and was conducted by a team from the University of Cologne and the Technical University of Denmark.

Swarm gets better with age

The mission, launched in 2013, was only meant to fly for four years but is now in its 12th year. Anja adds, "This is one of the benefits of flying missions for longer than originally planned. So, by flying as long as the scientific output is of excellent quality and resources allow, you can tackle scientific questions that weren't originally envisaged."

Swarm is, however, slowly nearing the natural end of its lifespan as drag gradually brings the satellites physically closer to Earth. This has enabled the mission's instruments—the satellites carry state-of-the-art sensors including magnetometers that measure the strength, magnitude and direction of the magnetic field—to capture faint signals that would be more difficult to detect from the higher orbits at the start of the mission.

Less solar interference

Swarm's ability to detect the faint ocean signals was also helped by the sun's less active period around 2017. "These are among the smallest signals detected by the Swarm mission so far," says lead author Alexander Grayver, of the University of Cologne.

"The data are particularly good because they were gathered during a period of solar minimum, when there was less noise due to space weather."

The "minimum" period of the sun's 11-year solar cycle is when the sun's surface is least active. During this "quiet" period, it emits less solar matter—including electromagnetic radiation and charged particles—so "space weather" phenomena such as the Northern Lights are less frequent. And with less electromagnetic radiation from the sun, the geomagnetic signals from Earth are more easily detectable by Swarm's magnetometers and other instruments.

The hope is that, when the next solar minimum comes around after 2030, Swarm might still be flying—albeit at a lower altitude—and will be able to continue detecting the faint signals that can help us understand more about the temperatures and salinity deep within our oceans.

IMAGE: The tidal flows of Earth’s salty seawater across Earth’s magnetic field lines generate electric currents within the ocean. These in turn induce secondary magnetic fields that form part of the planet’s complex magnetic field signal that can be detected from space. ESA’s Swarm satellites can measure these tiny oceanic magnetic fields and distinguish them from other magnetic fields such as those from the core, ionosphere, magnetosphere and magnetized crust. Credit: Lina Jakaitė

2 notes

·

View notes

Text

Custom mech for my Lancer campaign. Balance feedback appreciated!

LEVIER

STRIKER/ARTILLERY

Like an old-world ship-of-the-line, the Levier is an figurehead of national pride; an large, intimidating mech that's as effective in propaganda shoots as on the battlefield, although it will excel in both. Typically seen wielding large, high-caliber weapons, Leviers are typically deployed in groups of three, five, or seven. These units- or “fleets”, as they are called -work together to fire in “broadsides”- enormous eschatological moments when the arduous loading process is completed, and the world holds still as the Levier takes aim and brings the Cohesive’s metaphorical fist down onto their enemies.

Phys. Description. Replace with art if/when it becomes available

A large, imposing mech. Its face-on profile is boxy, black, industrial, with sheer edges and various decals in a chinese-adjacent (replace when found with actual space language), almost resembling a shipping container.

Side profile reveals an enormous gun that juts through the mech’s torso, resembling a naval cannon. It penetrates through to both front and back. The rear section houses a complicated network of gangways, small ladders, and carbon fibre spools and ropes. Four Power Monkeys clamber about it, carrying enormous shells under their arms. The front of the gun is huge, blackened, like an industrial chimney. Yellow smoke billows from it following a firing. A curved shield protrudes from the base, giving the side profile the impression of the front prow of a ship. The entire mech is covered with shibari-like overhull drydock netting, which power Monkeys use to get around.

HP: 10

Evasion: 7

Speed: 4

Heat Cap: 5

Sensors: 20

Armor: 1

E-Defense: 7

Size: 2

Repair Cap: 2

Tech Attack: -1

Save Target: 8

License:

I. Broadside Cannon, Downtime Propagator

II. LEVIER FRAME, Bonny Ship the Diamond, Virulent Phosphorus Charge

III. Divine Fist, Santiana Gained a Day

TRAITS:

Trait One: Terracotta Soldier

Your weapons begin unloaded.

Trait Two: Broadside Tactics

Whenever you attack with a Heavy Loading weapon, you may choose to incur -2 difficulty on your attack and take heat 0. If you do so, you may make another attack with another heavy loading weapon, dealing half damage on a hit. You may take this action any number of times, but the heat gain increases by two for each use.

Trait Three: Shoulder-to-Shoulder Mutual Bracing

For every other friendly character in an continguous row with the Mech tag that is size two or larger, your attacks with heavy weapons gain +1 accuracy, 1d6 extra damage, and Reliable 4. (In this case, three continguous mechs would gain reliable 12.) (this is the only part of this ability that stacks.)

SYSTEM POINTS: 8

MOUNTS:

Flex mount

Heavy mount

Integrated

CORE system

Drydock Overshield Hull Netting

The Drydock Overshield Hull Netting is a tightly- wrapped net of four-centimeter-thick cabling that covers the entirety of the Levier. On each intersection is an electromagnetically active node that can snap to another node in a matter of seconds. This allows the net to move dynamically by swapping whether each node is attracting or repelling the others, creating a movement not unlike birds flying in a flock. When active, the net floats about a foot away from any mechs it is protecting, ready to bunch up around an incoming projectile, creating dynamic armour that is strongest everywhere because it only needs to be strong in small bursts, in very specific areas.

(PASSIVE) When yer Crit, minus Grit.

Active (requires 1 Core Power): Cast Drydock Overshield Netting

Any allies in Burst four around you gain Overshield eight. You gain Overshield equal to two times the number of allies that were affected by this effect. You take four energy damage as the sudden voltage flows through your systems.

Integrated Mount: Gun-of-the-Line

Gun-of-the-Line

Weapon

Heavy

Cannon, Loading, Ordnance, reliable 5, knockback self 1, accurate

Range 20

3d6 kinetic damage

Bonny Ship the Diamond

System fluff

6 SP

Gain the Diamond Fleet of Fame reaction

Diamond Fleet of Fame

Reaction, once per round

Trigger: another allied mech of size two or greater would make an attack with an heavy weapon

You may either reload one loading weapon, or grant them +2 accuracy on their attack.

Virulent Phosphorous Charge

Popularised by its legendary use to bring down the Lucky Duck destroyer-cruiser in the battle of Najkta, Virulent Phosphorous is an incredibly volatile and explosive substance produced by an genetically modified strain of bacteria originally native to the backwater world Mudd. Most barrels are not sufficiently strong to so much as direct the blast away from the user, but you never know… maybe you're built different!

Mod, limited two

When you load this weapon, you may choose to expend a charge. If you do, the next shot fired becomes cone 5, stunning all enemies inside the area if they fail an ENGINEERING check and dealing burn 8 instead of the regular damage.. Destroy the weapon on the mount that fired the Flashpowder charge and take 5 heat.

Downtime Propagator

Harnessing the power of the Cohesive's Power Monkey robotic assistants, time spent loading is not wasted! Direct them to manually aim an auxillary weapon, replace and repair damaged systems, or spray coolant and chaff manually from canisters from the comfort of your cockpit. The CWCC reserves the right to remotely revoke access to this product if it detects that it is attached to an Smith-Shimano frame.

4 SP

Whenever you expend a full action to Stablilize, choose one:

Make an attack with an auxillary weapon for half damage on a hit

Repair up to one system, mount, or gain half your maximum HP repaired

Grant yourself and up to two adjacent allies soft cover until the beginning of your next turn.

Divine Fist

Superheavy CQB, loading, knockback 5

Cone 3

4d6 kinetic damage. On hit, targets are knocked prone and suffer from Shredded.

Santiana Gained a Day

8 sp

As long as there are four allies of size two or above adjacent to you who have not taken damage or have not moved involuntarily since their last turn or two other Leviers adjacent to you who have not taken damage or have not moved involuntarily since their last turn, your Drydock Overshield Hull Netting flares out behind you, connecting you to your allies. You gain the following benefits:

You and the others affected by this ability may reload loading weapons as an quick action.

Any damage (excepting heat) dealt to you or any allies affected is spread evenly amongst the group as heat. If the number of damage is uneven, you take the largest portion. This effect takes place after all other damage calculation.

You may fire weapons with Ordnance as though they did not have Ordnance.

You gain immunity to the Shredded condition and +1 armour.

If any mech benefiting from Santiana Gained a Day takes stress damage, instantly end the effect. Take heat 2.

5 notes

·

View notes

Text

Thin film reveals origins of pre-superconducting phase

RIKEN physicists have found an ideal platform for exploring the behavior of electrons in a material as it approaches superconductivity. This could help to develop new superconductors that operate at more convenient temperatures than existing ones. The study is published in the journal Physical Review B. Superconductors carry electrical current without any resistance, and are used in powerful electromagnets and magnetic sensors, for example. But superconductivity generally only occurs at low temperatures, so researchers are seeking high-temperature superconductors that could open up a much wider range of applications. The ultimate goal is to find materials that superconduct at room temperature. Superconductivity in so-called conventional superconductors occurs when electrons pair up. This pairing prevents the electrons from scattering as they flow through a material.

Read more.

#Materials Science#Science#Superconductivity#Superconductors#Thin films#Nematic#Iron selenide#Iron#Selenium

8 notes

·

View notes

Text

Top 10 Projects for BE Electrical Engineering Students

Embarking on a Bachelor of Engineering (BE) in Electrical Engineering opens up a world of innovation and creativity. One of the best ways to apply theoretical knowledge is through practical projects that not only enhance your skills but also boost your resume. Here are the top 10 projects for BE Electrical Engineering students, designed to challenge you and showcase your talents.

1. Smart Home Automation System

Overview: Develop a system that allows users to control home appliances remotely using a smartphone app or voice commands.

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Wi-Fi or Bluetooth module

Sensors (temperature, motion, light)

Learning Outcome: Understand IoT concepts and the integration of hardware and software.

2. Solar Power Generation System

Overview: Create a solar panel system that converts sunlight into electricity, suitable for powering small devices or homes.

Key Components:

Solar panels

Charge controller

Inverter

Battery storage

Learning Outcome: Gain insights into renewable energy sources and energy conversion.

3. Automated Irrigation System

Overview: Design a system that automates the watering of plants based on soil moisture levels.

Key Components:

Soil moisture sensor

Water pump

Microcontroller

Relay module

Learning Outcome: Learn about sensor integration and automation in agriculture.

4. Electric Vehicle Charging Station

Overview: Build a prototype for an electric vehicle (EV) charging station that monitors and controls charging processes.

Key Components:

Power electronics (rectifier, inverter)

Microcontroller

LCD display

Safety features (fuses, circuit breakers)

Learning Outcome: Explore the fundamentals of electric vehicles and charging technologies.

5. Gesture-Controlled Robot

Overview: Develop a robot that can be controlled using hand gestures via sensors or cameras.

Key Components:

Microcontroller (Arduino)

Motors and wheels

Ultrasonic or infrared sensors

Gesture recognition module

Learning Outcome: Understand robotics, programming, and sensor technologies.

6. Power Factor Correction System

Overview: Create a system that improves the power factor in electrical circuits to enhance efficiency.

Key Components:

Capacitors

Microcontroller

Current and voltage sensors

Relay for switching

Learning Outcome: Learn about power quality and its importance in electrical systems.

7. Wireless Power Transmission

Overview: Experiment with transmitting power wirelessly over short distances.

Key Components:

Resonant inductive coupling setup

Power source

Load (LED, small motor)

Learning Outcome: Explore concepts of electromagnetic fields and energy transfer.

8. Voice-Controlled Home Assistant

Overview: Build a home assistant that can respond to voice commands to control devices or provide information.

Key Components:

Microcontroller (Raspberry Pi preferred)

Voice recognition module

Wi-Fi module

Connected devices (lights, speakers)

Learning Outcome: Gain experience in natural language processing and AI integration.

9. Traffic Light Control System Using Microcontroller

Overview: Design a smart traffic light system that optimizes traffic flow based on real-time data.

Key Components:

Microcontroller (Arduino)

LED lights

Sensors (for vehicle detection)

Timer module

Learning Outcome: Understand traffic management systems and embedded programming.

10. Data Acquisition System

Overview: Develop a system that collects and analyzes data from various sensors (temperature, humidity, etc.).

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Multiple sensors

Data logging software

Display (LCD or web interface)

Learning Outcome: Learn about data collection, processing, and analysis.

Conclusion

Engaging in these projects not only enhances your practical skills but also reinforces your theoretical knowledge. Whether you aim to develop sustainable technologies, innovate in robotics, or contribute to smart cities, these projects can serve as stepping stones in your journey as an electrical engineer. Choose a project that aligns with your interests, and don’t hesitate to seek guidance from your professors and peers. Happy engineering!

5 notes

·

View notes

Text

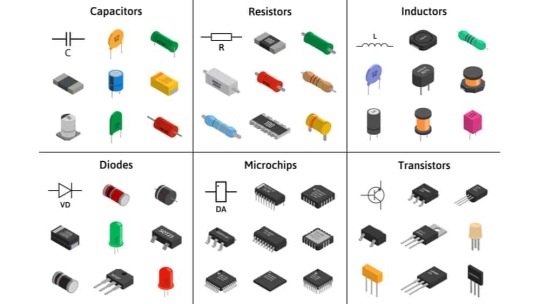

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

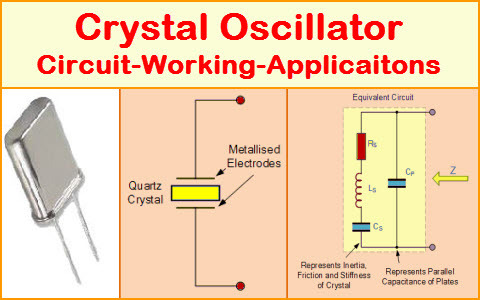

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

A Complete Guide to Endress+Hauser Products for Industrial and Marine Applications

The Role of Precise Measurement in Industrial Automation Industrial automation has transformed manufacturing and process industries, helping firms save costs, enhance efficiency, and provide increased safety. Precise and reliable measurement instrumentation is one of the chief facilitators of this change, making it possible to monitor and control various process variables like flow, level, pressure, and temperature in real time. Endress+Hauser’s product range is built to address these and other requirements, providing state-of-the-art technology to provide precision, reliability, and performance in even the toughest environments.

1. Flow Measurement Solutions

Flow measurement is perhaps the most important parameter in industrial automation. Across most industries, from oil and gas to food and beverage, accurate flow control is needed to sustain production consistency, avoid waste, and ensure safety. Endress+Hauser has a series of electromagnetic and ultrasonic flowmeters that are superior in terms of both performance and reliability. To cite an example, their Proline series of electromagnetic flowmeters are extremely accurate and provide real-time data of conductive liquids’ flows. They would be most suitable for the water treatment, chemical processing, and food production industries, where accurate fluid control is essential.

2. Liquid Analysis and Measurement

Apart from flow measurement, liquid analysis is also a crucial element in industrial automation. The product portfolio of Endress+Hauser consists of sophisticated instruments to measure parameters like pH, turbidity, conductivity, and dissolved oxygen. These sensors are indispensable for the quality of the end product while being compliant with environmental and safety regulations. Pharmaceutical, food and beverage, and power generation industries depend upon these instruments to measure vital parameters and ensure product uniformity.

3. Level Measurement, Pressure, and Temperature

Temperature, pressure, and level measurement form the building blocks of industrial automation. Precise measurement in these respects is necessary for the control of heating systems, pressure vessels, and storage tanks. Endress+Hauser offers a range of sensors and transmitters, including the iTEMP range for temperature measurement and the Liquiphant series for level measurement. These instruments assist in enabling industries to check their processes efficiently, with the equipment running within safety limits and the products made to the desired standards.

4. Process Control and Data Integration

Measurement is not enough for Endress+Hauser, which provides integrated process control solutions. Their automation solutions gather data from multiple instruments, giving operators real-time information about their processes. Endress+Hauser’s solutions optimize the performance of industries, reduce downtime, and maintain stability in processes within operating parameters. The automation solutions of Endress+Hauser are extremely versatile and can be tailored to suit industries from chemical production to water management.

Endress+Hauser Solutions for Marine Industry

The marine industry, as with industrial applications, demands accurate control and measurement for the safe and efficient performance of its vessels. From tracking fuel efficiency to ensuring there are no emission contraventions, Endress+Hauser solutions play a crucial role in enabling marine operators to deliver the increasing requirements of sustainability, efficiency, and safety. Let’s explore how Endress+Hauser helps the marine industry.

1. Marine Emission Monitoring

With increasingly strict environmental regulations, sea operators are required to meet emissions standards in order to minimize their environmental footprint. Endress+Hauser’s Maritime Suite provides leading-edge digital solutions in emission monitoring, condition diagnostics, and greenhouse gas monitoring. The Maritime Suite tools make it possible for ship owners and fleet operators to track real-time information about their fleet’s performance and monitor emissions and regulatory compliance. These are solutions such as redundant emission monitoring, analyzer condition monitoring, and emissions mass flow rate calculations.

2. Marine Steam and Water Analysis Systems (SWAS)

For power generation equipment and marine boilers onboard ships, monitoring water quality is vital to ensure efficient operation. Endress+Hauser’s steam and water analysis systems (SWAS) are engineered to measure water quality in marine conditions, and assist in monitoring important parameters such as pH, conductivity, and dissolved oxygen. These systems play a critical role in optimizing boiler performance, minimizing fuel consumption, and maintaining safe operation with low chances of corrosion or scaling in critical equipment.

3. Integrated Marine Automation Solutions

Endress+Hauser provides integrated marine automation systems that assist in optimizing operations on board ships. The systems are geared to automate different processes, including engine management, ballast control, and fuel efficiency optimization. Through real-time data and analytics, marine operators are able to make more informed decisions, increase fuel usage, lower emissions, and maximize overall vessel performance. The solutions are important in bringing down operating costs and ensuring maximum efficiency, particularly in long-distance commercial shipping.

The Endress+Hauser Advantage: Why Use Their Products?

1. Innovation and Reliability

Endress+Hauser is the market leader in innovation, continuously innovating beyond what is possible in process automation and measurement. Their products are built to last, with long-term reliability even in the harshest environments. From extreme temperatures to high-pressure systems to marine conditions, Endress+Hauser’s products are designed to deliver at the highest levels.

2. Tailored Solutions for Any Industry

One of the most impressive aspects of Endress+Hauser’s solution is that it is capable of delivering customized solutions that meet the unique demands of each industry. The company collaborates extensively with customers to learn about their unique needs, providing tailored solutions that deliver maximum performance, minimize costs, and maintain compliance with regulations.

3. In-depth Customer Support

Endress+Hauser does not merely supply products; they supply the complete package of customer support to ensure that their solutions perform at their best in the long term. Throughout the installation and commissioning process, through maintenance and calibration, Endress+Hauser provides a complete range of services to maintain systems at peak efficiency.

Explore Our Endress+Hauser Products Collection At Aeliya Marine Tech.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter

0 notes

Text

Plug-In Productivity for Mobile Operations

As industries worldwide adapt to rising energy demands and increasingly unpredictable operational environments, the industrial socket box has become a critical component in modern power infrastructure. Engineered to withstand extreme conditions while optimizing energy distribution, these systems empower businesses to maintain productivity, safety, and adaptability across diverse applications—from automated factories to temporary outdoor installations.

Weather-Resistant Power Hubs for Modern Challenges

With climate volatility disrupting workflows globally, industrial operations require solutions that defy environmental stressors. Advanced socket boxes employ corrosion-resistant alloys and multi-layered sealing to repel moisture, dust, and chemical exposure. Reinforced casings endure impacts from debris or accidental drops, while UV-stabilized materials prevent degradation in sun-exposed areas. Ideal for offshore rigs, desert mining sites, or flood-prone warehouses, these units ensure uninterrupted power flow even during extreme weather events.

Intuitive Design for Rapid Deployment

Time-sensitive projects demand plug-and-play efficiency. Modular socket boxes feature tool-free assembly, allowing workers to reconfigure outlets, circuit breakers, and surge protectors in minutes. Color-coded connectors and transparent access panels simplify troubleshooting, reducing downtime during equipment swaps or voltage adjustments. Compact variants integrate seamlessly into mobile units, providing instant power for disaster relief teams or film crews operating in remote locations.

Built-In Safety for High-Risk Environments

Electrical hazards in volatile settings—oil refineries, chemical plants, or construction zones—can escalate quickly. Modern socket boxes incorporate self-monitoring sensors that detect overheating wires or insulation faults, triggering automatic shutdowns before fires ignite. Tamper-proof locks and child-resistant covers prevent accidental contact, while anti-spark coatings minimize risks in flammable atmospheres. These innovations align with global safety protocols,ensuring compliance without compromising operational speed.

Versatility Across Industries

The adaptability of industrial socket boxes transcends traditional applications:

·Manufacturing: Streamline assembly lines with centralized power hubs for robotic arms and conveyor systems.

·Renewable Energy: Manage solar farm connections or wind turbine maintenance with weatherproof units.

·Urban Development: Power smart streetlights and EV charging stations using submersible models resistant to rainwater.

·Entertainment: Safeguard outdoor concerts or festivals with silent-operating boxes that eliminate electromagnetic interference.

Sustainable Engineering for Eco-Conscious Operations

As industries prioritize green practices, socket boxes now leverage recycled polymers and chrome-free metal finishes. Modular designs extend product lifespans—replace individual components instead of discarding entire units. Solar-ready models integrate with renewable energy grids, reducing reliance on fossil fuels while maintaining peak performance.

Elevate your power management strategy with solutions designed for tomorrow’s challenges at www.nante.com , where innovation fuels industrial resilience.

0 notes

Text

Variable Area Measurement Technology: What Engineers Need to Know in 2025

In today's industrial landscape, accurate measurement of fluid flow is crucial for maintaining efficient operations, ensuring product quality, and meeting regulatory requirements. Variable area measurement technology has stood the test of time as a reliable solution for flow measurement needs across industries. As we progress through 2025, engineers face new challenges and opportunities when implementing these measurement systems. This comprehensive guide explores the latest developments in variable area measurement technology and provides practical insights for engineering professionals.

Understanding Variable Area Flow Measurement Principles

At its core, variable area flow measurement operates on a straightforward principle: as fluid flows through a tapered tube, it exerts force on a float, causing it to rise until the upward force of the fluid equals the downward force of gravity on the float. The position of the float corresponds to a specific flow rate, which can be read directly from calibrated markings on the tube.

This elegant principle has made rotameter flowmeters one of the most widely used variable area instruments in industrial settings. Their reliability in challenging environments continues to make them relevant even as digital alternatives emerge.

Key Advantages in Modern Industrial Applications

Variable area technology offers several distinct advantages that explain its endurance in the competitive flow meter market:

Visual indication: Operators can quickly assess flow rates with a glance at the device, making troubleshooting more efficient

Operation without external power: Unlike electromagnetic flow sensors, basic variable area devices function without electricity

Cost-effectiveness: Lower acquisition and maintenance costs compared to more complex flow measurement technologies

Versatility: Suitable for liquids, gases, and steam applications with appropriate configurations

Durability: Well-constructed units can operate reliably for decades with minimal maintenance

When comparing variable area technology to other options like ultrasonic flow meters, engineers must consider these inherent advantages alongside specific application requirements.

Recent Innovations in Variable Area Measurement

The traditional variable area meter has evolved significantly in recent years. Modern versions now incorporate:

Digital Integration Capabilities

Today's advanced rotameter flowmeters often feature digital outputs that can interface with plant control systems. This bridges the gap between traditional visual indication and modern digital monitoring requirements. Engineers can now enjoy the reliability of variable area principles combined with the convenience of remote monitoring and data logging.

Enhanced Materials for Extreme Conditions

Manufacturers have developed specialized materials for both floats and tubes that can withstand increasingly challenging industrial environments. PTFE-lined units resist highly corrosive chemicals, while titanium components allow operation in high-pressure, high-temperature scenarios that would have been impossible for earlier designs.

Improved Accuracy Specifications

While traditional variable area devices typically offered accuracy in the 2-5% range, recent engineering improvements have pushed accuracies to within 0.5% for premium units. This development has expanded the application range for these instruments, making them viable for processes requiring higher precision without resorting to more expensive measurement technologies.

Selection Criteria for Engineering Applications

When evaluating variable area measurement devices for specific applications, engineers should consider:

Fluid Properties

The viscosity, density, corrosiveness, and cleanliness of the process fluid directly impact the performance and longevity of the measurement device. For highly aggressive chemicals, glass-tube rotameter flowmeters with corrosion-resistant floats often provide the best combination of visibility and durability.

Flow Range Requirements

Variable area devices perform best when sized appropriately for the expected flow range. Oversized units sacrifice resolution at lower flows, while undersized units create excessive pressure drop and may suffer premature wear. The optimal selection provides readable resolution across the entire expected operating range.

Installation Considerations

Proper installation significantly impacts measurement accuracy. Engineers must ensure:

Sufficient straight pipe runs before and after the device

Proper orientation (typically vertical with flow upward)

Protection from external mechanical vibration

Appropriate temperature conditions to maintain calibration accuracy

Integration Needs

Modern industrial settings increasingly demand connected instruments. When selecting a variable area measurement device, engineers should evaluate:

Protocol compatibility with existing control systems

Data logging requirements

Alarm notification capabilities

Remote monitoring needs

Comparison with Alternative Flow Measurement Technologies

Understanding how variable area measurement compares with other common flow meter types helps engineers make informed decisions:

Technology

Strengths

Limitations

Best Applications

Variable Area

Visual indication, no power required, cost-effective

Limited accuracy, requires vertical installation

Simple monitoring, backup systems, budget-conscious applications

Electromagnetic

High accuracy, no moving parts, no flow obstruction

Requires power, limited to conductive fluids

Precise measurement of conductive liquids, bidirectional flow

Ultrasonic

Non-invasive options, works with large pipes

Higher cost, sensitive to fluid properties

Clean liquids, existing pipelines where cutting is impractical

Air Flow Sensors

Specialized for gas applications

Limited to specific media

HVAC, compressed air systems, gas monitoring

Maintenance Best Practices for Long-Term Reliability

To maximize the service life of variable area measurement devices, engineers should implement:

Regular visual inspections - Check for float movement restrictions, tube discoloration, or damage

Periodic cleaning - Remove buildup that can affect float movement or reading accuracy

Calibration verification - Compare readings against a reference standard annually

Gasket and seal replacement - Prevent leakage by replacing wear components according to manufacturer guidelines

These maintenance routines typically require minimal downtime while significantly extending instrument life and preserving measurement accuracy.

Future Trends in Variable Area Measurement

Looking ahead, several developments are shaping the future of variable area flow measurement:

IoT integration enabling predictive maintenance and performance optimization

Augmented reality interfaces for easier commissioning and troubleshooting

Advanced materials further extending chemical compatibility and temperature ranges

Hybrid designs combining variable area principles with digital sensing technologies

These innovations will likely expand applications for variable area technology while maintaining its fundamental advantages of simplicity and reliability.

Conclusion

Variable area measurement technology remains a valuable tool in the industrial engineer's toolkit for 2025 and beyond. By understanding its principles, advantages, and recent innovations, engineers can effectively apply this proven technology to meet modern measurement challenges. When properly selected, installed, and maintained, variable area devices offer an excellent balance of reliability, visibility, and cost-effectiveness for a wide range of fluid measurement applications.

Whether you're considering a basic rotameter flowmeter for visual indication or an advanced variable area system with digital integration, this technology continues to evolve to meet the changing needs of industrial measurement applications while maintaining its fundamental simplicity and dependability.

0 notes

Text

Digital Water Meters vs Mechanical Water Meters - what best suits your needs?

Ali Yaqoob provide an extensive range of digital water meters, water flow meters and related accessories and services for the full potential applications in the region. Ali Yaqoob are an industry thought leader in next-generation water flow measurement. With the region still emphasizing water conservation and maximum resource utilization, the demand for reliable and accurate water metering technology has never been higher.

Digital Water Meter: The New Benchmark

The Digital water meters represent a significant advancement in water management technology. Unlike traditional mechanical meters, digital water meters use electronic sensors and digital displays to accurately and precisely report instantaneous water flow and consumption. Digital water meters are equipped with features like:

High accuracy (typically within 0.25% to 0.5% margin of error)

Large flow rates and pipe diameter ranges (DN2 to DN2000)

Digital output for easy interfacing with data loggers and building automation systems

Optional options of batch control, low-flow alert, and remote monitoring

Digital water meters can be used for residential and industrial applications, where precise billing, leak detection, and efficient water use monitoring can be provided.

Water Flow Meter

Water flow meters are devices specifically designed to meter water flow through a pipe, and they are also extremely purposeful for balancing the system, ensuring supply, and monitoring infrastructure. The primary types of water flow meters are:

Mechanical Water Flow Meters: They utilize moving components such as impellers or turbines to detect flow. They are robust and once again, are the best option for measuring bulk in high-flow meters.

Electromagnetic and Ultrasonic Meters: with virtually no moving parts, these have the benefit of durability and consistent accuracy, especially if often impacted by water quality which would affect mechanical meters.

Digital Meters: these possibly have the most advanced sensors with digital readouts and communication for remote reading, automatic data collection, and communication to smart city systems.

They find application in residential, commercial, and industrial sectors to deliver precise measurement for metering, resource management, and system upkeep.

UAE Water Flow Meter Suppliers

There are several acknowledged water flow meter suppliers in the region, with Ali Yaqoob being prominent for its wide product range and technical expertise. The company offers:

Digital and mechanical meters for cold and hot water

Electromagnetic and ultrasonic flow meters

Industrial, commercial, and residential area meters

Installation, calibration, and maintenance support, and accessories

Ali Yaqoob's commitment to quality and customer service has made it an go-to partner for water utilities, facility managers, and industrial customers looking for reliable water metering in Dubai and across the UAE.

B Meters Water Meter: A trusted name

Ali Yaqoob is proud to offer B Meters' range of water Meters that are known around the world for their accuracy, durability and conformity to International Standards. B Meters products provide users with an array of models for various flow rates and installation situations suitable to both domestic and overseas plumbing setups. The meters can be used in new installations as well as retrofitting and supplement the nation's initiative toward smart metering and efficient water management.

Conclusion

As the UAE continues to advance water conservation and smart infrastructure initiatives, the role of accurate and reliable water flow measurement becomes increasingly important day by day. Ali Yaqoob is at the forefront with its extensive array of digital water meters, mechanical meters, smart water flow measurement options, including the proven B Meters brand, that is assisting the change ahead. With partnerships to the leading water flow meter suppliers within the UAE, businesses and utilities are now equipped to ensure efficient monitoring, optimal use of resources, and a secure future of water consumption in the country.

#digital water meter#Water Flow Meter#water flow meter suppliers in UAE#Digital Flow Meter#Water Meters

0 notes

Text

Automotive Ethernet Market Insights: Disruptions, Challenges, and Recovery Paths

The automotive industry is undergoing a significant transformation, with Ethernet technology playing a pivotal role in enabling the next generation of connected, autonomous, and software-defined vehicles. Automotive Ethernet provides high-speed, reliable communication networks essential for Advanced Driver Assistance Systems (ADAS), infotainment systems, and vehicle-to-everything (V2X) connectivity.

Key Drivers:

Adoption of Autonomous Vehicles: The increasing deployment of ADAS and autonomous driving technologies necessitates high-speed data transfer capabilities, driving the demand for automotive Ethernet.

Growth of Connected Vehicles: The proliferation of connected vehicle services, including real-time diagnostics, over-the-air updates, and V2X communication, requires robust networking solutions.

Transition to Zonal Architectures: OEMs are shifting towards zonal vehicle architectures, consolidating ECUs and reducing wiring complexity, which Ethernet facilitates effectively.

Download a Free Sample Report: - https://tinyurl.com/5febk3er

Technology & Application Insights

Bandwidth Segments:

100 Mbps (100BASE-T1): Dominated the market in 2023, suitable for basic control functions and less demanding data transmission needs.

1 Gbps (1000BASE-T1): Projected to witness significant growth, supporting high-speed communication required by ADAS, high-definition cameras, and real-time data processing modules.

Component Segments:

Hardware: Comprises Ethernet switches, connectors, cables, and ICs, and was the largest revenue-generating component in 2023.

Software & Services: Include network management, security protocols, and testing solutions, supporting the integration and maintenance of Ethernet networks.

Application Segments:

ADAS: Led the market in 2023, with Ethernet enabling high-speed data transfer for sensors and cameras essential for safety features.

Infotainment: Expected to witness significant growth, driven by the demand for advanced in-car entertainment and connectivity features.

Commercial Vehicles: Increasing adoption for fleet management, telematics, and operational efficiency.

🌍 Regional Insights

Asia Pacific:

Market Size: Generated USD XXX million in 2023, accounting for XX% of the global market share.

Growth Rate: Projected to grow at a CAGR of XX% from 2024 to 2030.

Key Drivers: Increasing sales of passenger cars with intelligent connectivity and safety features.

Europe:

Market Size: Expected to reach USD XXX billion by 2030, becoming the fastest-growing regional market.

Key Drivers: Stringent safety standards and a strong emphasis on technology innovation in the automobile sector.

North America:

Market Size: Projected to reach USD XXX billion by 2028, growing at a CAGR of XX% during the forecast period.

Key Drivers: Rising demand in premium cars with connected car features and a strong push from OEMs for transition towards zonal architecture in automotive networking.

Challenges

High Installation Costs: The initial cost of automotive Ethernet solutions, encompassing hardware, software development, testing, security implementation, and retrofits for older vehicles, poses a significant challenge to widespread adoption.

Network Complexity: Managing increasingly complex automotive networks with numerous ECUs and data flow requires expertise in high-speed networking protocols, network security, and mitigating electromagnetic interference.

Integration with Legacy Systems: Integrating Ethernet into existing vehicle architectures can require significant modifications and upgrades, posing a financial hurdle for manufacturers.

Future Outlook

The automotive Ethernet market is poised for significant growth, driven by advancements in vehicle technology and the increasing demand for connected and autonomous vehicles. Key trends shaping the future include:

Adoption of Zonal Architectures: OEMs are consolidating ECUs and reducing wiring complexity, with Ethernet facilitating effective communication within these architectures.

Integration with 5G and V2X: The convergence of automotive Ethernet with 5G networks and V2X communication will enable real-time data exchange, enhancing vehicle-to-vehicle and vehicle-to-infrastructure interactions.

Focus on Cybersecurity: As vehicles become more connected, ensuring robust cybersecurity measures in Ethernet networks will be paramount to protect against potential threats.

Industry News

BMW and Analog Devices Collaboration: In May 2024, BMW Group announced the adoption of Analog Devices' E²B™ technology, utilizing 10BASE-T1S Ethernet to facilitate edge bus connectivity in automotive applications.

SMK Corporation's Ethernet Connector: In April 2023, SMK Corporation developed the SE-R1, the industry's smallest Ethernet connector for automotive applications, supporting both 100BASE-T1 and 1000BASE-T1 standards.

Read Full Report: - https://www.uniprismmarketresearch.com/verticals/automotive-transportation/automotive-ethernet

0 notes

Text

Eaton Fire Leaves California Landscape Charred

On the afternoon of January 11, 2025, NASA’s AVIRIS-3 (Airborne Visible/Infrared Imaging Spectrometer-3) flew aboard a B200 aircraft over Los Angeles County, where it captured images of several areas affected by wildland fires.

These false-color images show areas burned by the Eaton fire in Altadena and parts of Pasadena, Arcadia, and Sierra Madre. Charred trees and buildings in developed areas appear dark brown, whereas the burned wildland areas, particularly in Angeles National Forest, are shades of orange.

The Eaton fire ignited in the hills of Eaton Canyon, near Altadena, on the evening of January 7. By 10:30 a.m. the next day, the fire had quickly grown to cover more than 10,000 acres (40 square kilometers), according to Cal Fire. Around the time of this image on January 11, it had expanded to 14,117 acres (57 square kilometers), and the Los Angeles County Fire Department reported it was about 15 percent contained.

The AVIRIS-3 optical sensor collects data in 286 bands in the electromagnetic spectrum, ranging from visible violet light at a wavelength of 380 nanometers to shortwave infrared at 2,500 nanometers. In the past, AVIRIS images have been useful for investigating fire behavior and the effects of fire emissions. They are also used for post-fire analyses, such as fire severity, area burned, soil erosion, and other environmental change.

“In addition to assisting with damage assessments, these data may help us understand the chemical composition and toxic nature of ash in the post-fire environment and how it redistributes over time via wind and water flows, with subsequent data acquisitions,” said Michael Falkowski, manager of NASA’s wildland fire program.

As of the morning of January 15, the Eaton fire had stopped expanding, and it was 45 percent contained. Preliminary estimates indicate that thousands of structures were destroyed, according to Cal Fire.

NASA’s Disasters Response Coordination System has been activated to support agencies responding to the fires, including the California Governor’s Office of Emergency Services. Response activities are centered on two primary requests from the local emergency managers: damage assessment information on built infrastructure, and impacts of air quality and human health risks. The team will be posting maps and data products on its open-access mapping portal as new information becomes available.

Explore interactive maps of these images on the AVIRIS data portal.

NASA Earth Observatory images annotated by Lauren Dauphin using data from Airborne Visible / Infrared Imaging Spectrometer-3 (AVIRIS-3) instrument, via NASA Earthdata Search. Story by Emily Cassidy.

1 note

·

View note

Text

Applications of Pressure Transducers in Aerospace Systems

In aerospace engineering, precision, reliability, and safety are non-negotiable. Every component used in an aircraft or space-bound system must meet the highest standards of performance. Pressure transducers are one such component—playing a crucial role in monitoring and controlling fluid and gas pressures throughout various aerospace systems.

These devices convert pressure into electrical signals, enabling real-time monitoring of critical systems such as hydraulic circuits, engine control modules, cabin pressurization, and fuel lines. Any fluctuation in pressure can impact the safety or efficiency of an aircraft, which is why dependable sensors are essential.

Pressure Transducers in Real-World Aerospace Use

Aerospace systems operate in extreme conditions—high altitudes, rapid pressure changes, and exposure to vibrations and temperature fluctuations. In such environments, pressure transducers must not only deliver precise readings but also remain stable and accurate over time.

Applications include:

Monitoring hydraulic pressure in landing gear and control surfaces

Regulating fuel flow and ensuring safe engine performance

Managing environmental systems to maintain cabin pressure

Supporting altitude sensing and air data systems

Advanced TK-U5 Pressure Transducers are designed specifically for such high-performance applications. These sensors are qualified as per MIL-STD-461G and MIL-STD-810H, confirming their suitability for demanding aerospace operations.

A Reliable Alternative to the P700 and P900 Pressure Sensors

Many aerospace systems still rely on legacy models like the P700 pressure sensor and P900 pressure sensor. These models have served well in the past but are now obsolete or difficult to source. Replacing them with modern equivalents often presents challenges in compatibility and system integration.

The TK-U5 series by Telektron India offers a dependable solution. These sensors are engineered as direct replacements for the P700 and P900 pressure sensor, ensuring seamless integration without requiring major design modifications. They maintain mechanical and electrical compatibility while providing enhanced accuracy, improved durability, and better signal stability.

This makes the TK-U5 series an ideal upgrade for organizations looking to maintain legacy systems without compromising on performance or reliability.

Designed for Harsh Aerospace Environments

Meeting stringent aerospace standards, the TK-U5 transducers are built to withstand:

Extreme vibration and shock during flight operations

Wide temperature ranges and rapid thermal cycling

Electromagnetic interference from complex onboard electronics

Their rugged design and proven reliability reduce the risk of failure and support long-term, maintenance-free operation in mission-critical scenarios.

In aerospace systems, the importance of accurate and stable pressure measurement cannot be overstated. As older models like the P700 pressure sensor and P900 pressure sensor become outdated, adopting reliable replacements is essential to maintain safety and performance.

TK-U5 pressure transducers by Telektron are engineered to meet the current and future needs of the aerospace industry. With military-grade certifications and compatibility with legacy systems, they offer a future-ready solution grounded in reliability and precision.

0 notes

Text

What Is an Industrial Sensor? Complete Guide + Types and Applications

Industrial sensors, also known as industrial detectors, are essential components used in various industries to convert physical, mechanical, or chemical parameters—such as temperature, pressure, humidity, and liquid levels—into analog or digital electrical signals. These sensors play a key role in quality control, safety assurance, and optimizing operational performance across different industrial processes.

In this guide, we’ll answer the commonly asked question, “What is an industrial sensor?” and help you get familiar with the different types of industrial sensors and their applications.

What Are the Main Applications of Industrial Sensors?

Before choosing to خرید سنسور صنعتی for your factory or automation system, it's important to first evaluate the needs of your industry. Here are 5 major industries where industrial sensors are widely used:

Food and beverage industry

Robotics and automation

Automotive manufacturing

Pharmaceutical and medical industries

Assembly and material handling sectors

Why Use Industrial Sensors? Key Benefits!

Using industrial sensors in sectors such as automotive, food processing, or pharmaceuticals brings multiple benefits:

Enhanced workplace safety

High operational accuracy

Cost savings through process optimization

Improved product quality and consistency

Reduced equipment wear and extended machine lifespan

Real-time monitoring of temperature, pressure, and humidity

Types of Industrial Sensor; Complete Overview

Industrial sensors can be broadly categorized into two main types:

1. Contact Sensors

These sensors require direct physical contact to detect objects or measure variables. Pressure Sensors is Ideal for measuring pressure in gases and liquids within open or closed systems.

Force Sensors: Measure applied force or load in various industries, especially automotive.

⚠️ Contact sensors have a shorter lifespan due to constant exposure to physical forces such as shock or impact. They are more prone to wear and failure over time.

2. Non-Contact Sensors

These sensors operate without direct contact, making them more durable and reliable in harsh environments.

Advantages of Non-Contact Sensors:

Precise conversion of physical/chemical parameters into analog or digital signals

Reliable in a wide range of industrial environments

Fast switching and response time

Noise-free operation

Long service life

Let’s explore the main types of non-contact sensors used in industry:

1. Inductive Sensors

Inductive sensors operate based on Faraday’s law of electromagnetic induction. They are commonly used to detect metal objects and measure dimensions or movement.

Applications:

Automotive: Detecting metallic parts in production lines

Metal Processing: Measuring thickness or locating parts in welding and cutting

Packaging: Identifying metal items in assembly lines

Robotics: Object detection in automated systems

Electronics: Separating and detecting metal parts

2. Capacitive Sensors

Capacitive sensors detect objects by sensing changes in capacitance. They work with conductive, non-conductive, and semi-conductive materials.

Industries That Use Capacitive Sensors:

Manufacturing: Monitoring levels, weights, and humidity

Automotive: Used in braking, suspension, and autonomous systems

Electronics: Measuring voltage, frequency, and electrical parameters

Energy and Petrochemicals: Monitoring pressure and flow

Medical: Tracking vital parameters like heart rate, oxygen levels, and more

3. Magnetic Sensors

These sensors work by detecting changes in magnetic fields and are non-contact, making them highly durable.

Who Uses Magnetic Industrial Sensors?

Electronics: Used in compasses and magnetic navigation

Automotive: Applied in braking, steering, and positioning systems

Steel and Metalworks: Monitoring welding and magnetic anomalies

Oil and Gas: Detecting faults in pipelines and equipment

Medical Imaging: MRI and other diagnostic technologies

4. Ultrasonic Sensors

Ultrasonic sensors are non-contact devices that operate using high-frequency sound waves (above the human hearing range). These sensors are used for distance measurement, presence or absence detection of objects, and level control of liquids or solids.

How Ultrasonic Sensors Work:

The sensor emits an ultrasonic pulse toward the target. After the pulse hits the object, it reflects back to the sensor. The time it takes for the echo to return is measured, and using the speed of sound, the distance to the object is calculated.

Applications of Ultrasonic Sensors:

Industrial automation (for detecting the presence of objects on production lines)

Liquid level measurement in tanks and containers

Obstacle detection in robotics and automated vehicles

Packaging and bottling systems

Advantages:

Non-contact measurement

High accuracy in detecting transparent, shiny, or irregular surfaces

Not affected by color or material of the object

Limitations:

May be affected by temperature and humidity

Less effective in environments with heavy dust or sound-absorbing materials

5. Photoelectric Sensors

Photoelectric sensors are non-contact sensors that detect the presence, absence, or distance of an object using a beam of light, usually infrared or visible red light.

How Photoelectric Sensors Work:

These sensors emit a light beam from a transmitter toward a receiver. When an object interrupts or reflects the beam, the sensor detects the change and outputs a signal. There are three common types of photoelectric sensors:

Through-Beam (Opposed Mode): Transmitter and receiver are in separate units. The sensor detects when the object blocks the light beam.

Retroreflective: Transmitter and receiver are in one housing. A reflector is placed opposite the sensor. When the object interrupts the beam between the sensor and reflector, it is detected.

Diffuse Reflective: Transmitter and receiver are in one housing. The sensor detects the light reflected back from the object itself.

Applications of Photoelectric Sensors:

Detecting small or transparent objects on conveyor belts

Counting products on a line

Position detection in packaging machinery

Safety and security systems (e.g., automatic doors)

Advantages:

Fast response time

Long sensing range (especially in through-beam type)

Reliable detection of small and fast-moving objects

Limitations:

May be affected by dirt, dust, or misalignment

Performance can vary depending on surface reflectivity and color

6. Proximity Sensors

Proximity sensors are non-contact sensors that detect the presence or absence of an object within a specific range without any physical contact. Unlike photoelectric sensors, they do not use light beams, and instead rely on electromagnetic fields or capacitive effects.

Types of Proximity Sensors:

Inductive Proximity Sensors:

Detect metallic objects.

Operate based on the electromagnetic induction principle.

Common in industrial automation for detecting machine parts or fasteners.

Capacitive Proximity Sensors:

Detect both metallic and non-metallic materials (e.g., glass, plastic, wood).

Work based on changes in capacitance caused by nearby objects.

7. Ultrasonic Proximity Sensors:

Use ultrasonic waves to detect the presence and distance of an object.

Ideal for liquid level measurement or detecting irregularly shaped objects.

Applications:

Detecting objects on conveyor belts

Position detection in robotics