#diaphragmpump

Text

Elevate your textile and carpet production with AODD Pumps – the ultimate solution for seamless fluid transfer. From dyeing to finishing, achieve precision and efficiency at every stage of your manufacturing process.

0 notes

Text

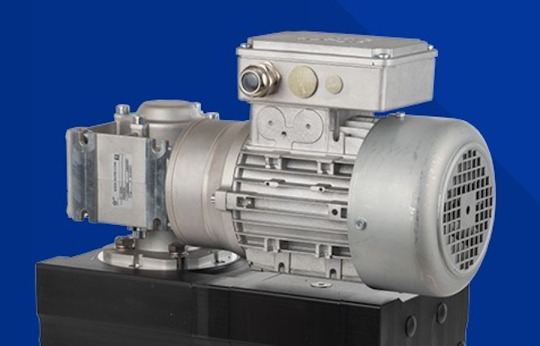

Electric driven diaphragm pump now Atex certified

The Verderair e-Pure, a fully electric driven pump, is now able to transfer fluids in potentially explosive environments without any concerns. The fluid moves through the pump horizontally. The electric drive ensures the reciprocating movement of the diaphragms so that the diaphragm chambers are alternately filled and pressed. This pump design utilises flapper valves instead of ball valves, a reduced number of flow bends and moving parts resulting in less friction losses. The speed of the fluid and the energy efficiency of these pumps is therefore optimised. High speed low stroke technology enables low pulsation. The e-Pure is available in 3 models:

- flow 30 l/min

- flow 50 l/min

- flow 100 l/min

More details in this YouTube video

https://youtu.be/-y57l6A_NXk

www.verderliquids.com

Read the full article

0 notes

Text

Diaphragm Vacuum Pump

A diaphragm vacuum pump uses a flexible diaphragm to adjust the volume within a pumping chamber, creating a vacuum on one side while maintaining atmospheric pressure on the other. It operates continuously, without oil, and produces minimal noise, achieving an ultimate vacuum pressure of 0.08 MPa. The pump's PTFE-based design makes it suitable for handling toxic substances, and its non-stick surface prevents the buildup of solid materials and contaminants.

With an evacuation rate of 30 L/min, it provides high-cost performance, reliable quality, and a unique structure tailored to the diverse needs of laboratories, hospitals, and industries. This pump is commonly used for various tasks such as vacuum filtration, distillation under reduced pressure, rotary evaporation, vacuum concentration, and solid-phase extraction.

#vacuumpump, #diaphragmpump, #labmate

0 notes

Text

In search of a trash pump rental? Look no further than Rentalex for all your equipment needs. We offer an extensive range of trash pumps, including the rugged Wacker Neuson PDT3A 3" Diaphragm Trash Pump, perfectly suited for tasks that challenge other pumps. Engineered to tackle solids of up to 1-3/4″ (45 mm), it's the ideal choice for dewatering mud slurries and seepage areas. Contact us now at (813) 971-9990 to receive a personalized quote!

See the Wacker PDT3A Diaphragm Pump here: https://www.rentalex.com/rental_equipment/tampa-pumps/back-to-pumps-plumbing-equipment/

0 notes

Text

Nirmala Pumps provides a reliable Diaphragm Dosing Pump that requires minimal maintenance. It is designed to move fluids by utilizing a flexible diaphragm that is alternately compressed and expanded, resulting in a pumping action. These pumps are frequently utilized to dispense small amounts of liquids, such as chemicals, dyes, and pharmaceuticals.

#diaphragmdosingpump#diaphragmpump#industrialpump#nirmalapumps#industry#products#equipments#ahmedabad#gujarat#india

0 notes

Photo

TOPSFLO continues to diaphragm pumps RD & production,

Self-designed TM40 series diaphragm air pumps ,

Solve real needs for the medical device industry,

Serve global high-end customers with high-quality products.

http://www.topsflo.com/mini-diaphragm-pump/tm40a-b-brush-air-pump.html

0 notes

Text

Discover reliability and safety with our ATEX compliant diaphragm pumps! Designed to meet stringent standards, our pumps ensure efficiency and peace of mind in hazardous environments. Explore unparalleled performance for your industrial needs.

0 notes

Text

MTR

Machine Tool Repair.

952 E Ramsey St.

Banning, CA 92220

(800) 988-2724

Nicholas Clark

(949)537-1008

I emailing you a brochure on our company into regards of rebuilding and repairing on all types of:

• Diaphragm Pumps

•Control valves

• Vacuum Pumps,

•Boiler feed Pumps •Centrifugal Pumps

•Drum Motors,

•Hydraulic pumps

•Gearboxes,

•Hydraulic cylinders.

•Drum Motors Van De Graaf,

•Electric Motors

•Machinery and equipment

• Cylinder Repair, Bobcats, excavators,Forklifts,

Specialize in doing emergency rush service repair we have a full machine shop for gear cutting, welding, machining

Feel free to contact us at

Visit our website

mtrservice.com

#CentrifugalPumps

#ScrewPumps

#DiaphragmPumps

#GearPumps

#HydraulicGearPumps

#VacuumPumps

# LobePumps

#VanePumps

#SUMPPUMPS

#ProgressingCavityPumps

#SplitCasePumps

#HydraulicPumps

#EndSuctionPumps

#SelfPrimingPumps

#JetPumps

#PlungerPumps

#MultistagePumps

#Sulzarpump gearboxrepair#CentrifugalPumps ScrewPumps DiaphragmPumps GearPumps HydraulicGearPumps VacuumPumps LobePumps VanePumps SUMPPUMPS#ProgressingCavityPumps SplitCasePumps HydraulicPumps EndSuctionPumps SelfPrimingPumps JetPumps PlungerPumps MultistagePumps

1 note

·

View note

Text

MTR Repair’s

(800)987-2724

mtrservice.com

I am writing to introduce you to our repair service, MTR Repair, which specializes in repairing a variety of equipment and machinery for the food and beverage industry. Our team of certified technicians has extensive training and experience in repairing slurry pumps, Aodd pumps, positive displacement pumps, gearboxes, blowers, and other equipment.

At MTR Repair, we understand the importance of minimizing downtime and maximizing productivity. That's why we focus on reducing the Mean Time to Repair (MTR) of your equipment. MTR is the average time it takes for equipment to be diagnosed, repaired, and recovered after experiencing a failure

. By proactively improving the MTR, we can reduce availability losses due to repairs and speed up the equipment's rate of recovery from failures and breakdowns

Our comprehensive repair services ensure that your equipment is repaired efficiently and reliably. We use original spare parts and closely monitor operational data to detect possible causes of failure before they occur

. Our local service technicians conveniently bring the repair solution to your facility, providing fast response time and factory training

#CentrifugalPumps

#ScrewPumps

#DiaphragmPumps

#GearPumps

#HydraulicGearPumps

#VacuumPumps

#LobePumps

#VanePumps

#ProgressingCavityPumps

#SplitCasePumps

#HydraulicPumps

#EndSuctionPumps

#SelfPrimingPumps

#JetPumps

#PlungerPumps

#MultistagePumps

#pumprepair#mining gearbox plasticmolding sandgravel#mtrrepair#aoddpump#positivedisplacementpump#alfalaval#cherrybernell#slurrypump#vertical pump

0 notes

Photo

Established in the year Of 2017, We “Aadiushmaa Engineers Pvt. Ltd.” are the leading, Manufacturer, Trader, And Exporter with an extensive array of AODD Pumps, Plate Heat Exchanger, Air Compressor, Metering Pump, Rotary Lob Pumps, Vapour Absorption Machine, etc. We are committed to our customers by putting our efforts which can fulfill their expectations as per their requirement.

#dealer#authorized#distributor#diaphragmpump#aircompressor#manufacture#heatexchanger#platetype#seperator#decanter

2 notes

·

View notes

Text

Revolutionize your operations with Semiconductor AODD Pumps – the cutting-edge solution for precision fluid transfer in semiconductor manufacturing. Efficiency meets reliability for superior performance in your high-tech processes.

0 notes

Text

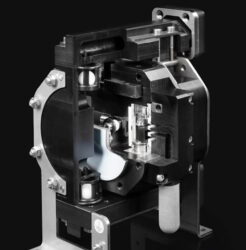

Double diaphragm pumps for greater reliability in chemical processes

Product Manager Stefan Anstöter knows the requirements of the chemical industry and knows what users value.

"From the material to the design and the accessibility for repairs: Chemical pumps must function flawlessly in practical application," says Stefan Anstöter, Product Manager at Timmer GmbH. "We know: Here there is no room for error. That's why we have optimised our pumps so that they meet – and even exceed – all industry requirements. This starts with deliberate use of suitable pump materials. For example, stainless steel, which has proven to be effective in other industries, is often not suitable for chemical applications because it is subject to attack by alkalis and acids. Instead, the pumps in the ‘Tim Chem’ product line are equipped with a plastic housing. The polytetrafluoroethylene (PTFE) that we use is compatible with the chemicals that are used.”

External influences such as significant temperature fluctuations change the shape of the material, and the housing then tends to leak at the connections. “We use a design for our pumps that connects the highly-resistant plastic components that are in contact with media, by means of tie rods. The force exerted by the tie rods is distributed by the large-area reinforcement plates – a measure that significantly minimises deformation of the plastic,” says Anstöter.

The Tim Chem series chemical pumps come factory-standard with a sensor that monitors the status of the pump and that can be integrated directly into the user's process control system.

To ensure maximum protection, stainless steel sheets encompass the pump and provide stability for the entire construction. Metal does not come into contact with the medium. Plastic, and plastic only, which has been tested for resistance, completely encloses the processed medium. The material is FDA-compliant and thus it is food-safe.

Optimal sealing of a pump is a major aspect of process reliability. It is a characteristic that plays a central role in product development at Timmer. In this regard, the design follows a simple rule: The fewer sealing surfaces, the fewer possibilities of a leak. Consequently, chemical pumps from Timmer have only four sealing points – and these pumps are Atex-compliant.

Easy access for repairs

A look inside the pump shows the sealing concept, which significantly minimises the risk of leaks. The design enables easy access for repairs and fast on-site service.

These double diaphragm pumps come factory-standard with an intelligent sensor for condition monitoring. The sensor can be integrated directly into the user's process control system. Integrated in a process control system the sensor shows the real-time status of the pump and by means of an additional system, immediately sounds an alarm should an error occur. The company decides how the pump should be integrated into the system and what data it should display. If an error message occurs and if repairs are required, service technicians benefit from the easy accessibility offered by the pumps. For example, valve balls and valve cages can be replaced without dismounting the side covers. Use of special tools is not necessary.

The heart of the pump, a special, extremely low-wear, ceramic latching valve, ensures smooth operation. All of the valve's friction pairs are made of ceramics in conjunction with precision-ground, high-performance plastics. The result is minimum wear in the valve itself. The reduced stroke path provides long-term protection of the diaphragm.

www.timmer.de

Read the full article

0 notes

Photo

QIWEI PUMP-DBY3 EODD PUMP

Learn more>>> www.chinadiaphragmpump.com/

0 notes

Text

The Wacker Neuson PDT2A 2" Diaphragm trash pump is ideal for moving almost anything that flows. Water with mud, slurries, and seepage can be moved efficiently with these pumps, which are 2-inch pumps capable of handling solids up to 1.5 inches and up to 50 gpm. Solid rubber tires provide excellent traction and smooth rolling over rough terrain due to their high quality components. Rent the Wacker PDT2A Diaphragm Pump by calling Rentalex at (813)971-9990.

Learn more about the Wacker PDT2A Diaphragm Pump here: https://www.rentalex.com/rental_equipment/newequipment/wacker-pdt2a-diaphragm-pump/

0 notes

Text

Air Diaphragm Pumps utilize compressed air to transfer fluids. These pumps consist of two chambers, both equipped with a flexible diaphragm. Air Diaphragm Pumps are highly versatile and can pump a wide range of fluids, including liquids, slurries, and gases. They are self-priming and require minimal maintenance.

Features:

-> Self-priming

-> Easy installation

-> Easy for maintenance

-> Low noise level

-> Durable and long-lasting

#airdiaphragmpump#diaphragmpump#industrialpump#nirmalapumps#industry#products#equipments#ahmedabad#gujarat#india

0 notes

Text

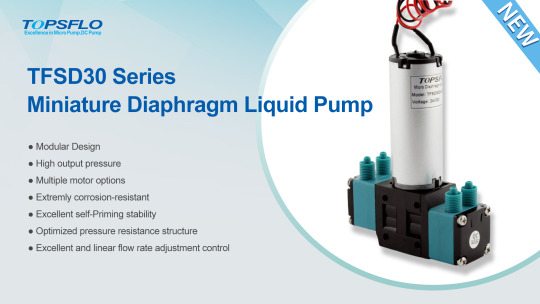

【New Product】| TFSD30 Series New-Generation High Performance Diaphragm Liquid Pump

Currently, in the fields of IVD and analytical instruments, high performance liquid pumps have long relied on imports. After the occurrence of global trade disputes and the COVID-19, issues such as the price and supply cycle of high-performance liquid pumps have significantly impacted the production of high-end medical and analytical instruments in China.

TOPSFLO has been deeply involved in the field of micro diaphragm pumps for more than ten years. In response to the above problems, the R&D center established a special project in 2020. After countless improvements and upgrades, it will finally launch a high-performance diaphragm liquid pump suitable for a variety of medical scenarios in the second half of 2022—TFSD30 Series. The launch of TFSD30 Series marks that domestically independently developed diaphragm liquid pumps have fully reached and surpassed German and Japanese products in performance, reliability and other fields.

High-performance diaphragm pumps face multiple challenges during operation, such as lifespan and reliability under high working pressure, tolerance to various corrosive chemical media, sealing performance under high pressure, the impact of noise and vibration on instruments, and issues related to valve plate adhesion and suction reliability when extracting viscous liquids.

To meet a wide range of customer needs and application scenarios, TOPSFLO focused on independent research and innovation in the development of TFSD30 Series pump. In the early stages of technical development, new technologies, structures, materials, and processes were employed. Multiple high-precision devices accumulated test data, and with collaboration from various sources, TFSD30 Series achieved another leap in product quality and performance.

1. Modular Design: TOPSFLO diaphragm pumps is designed with modularity, allowing flexible combinations of core components, materials, and processes. This enables rapid customization and production delivery with the shortest development cycle and minimal cost:

Miniature diaphragm pumps need to be integrated into fluid systems in various industries. Customers' working points, conditions, media, pipe types, power supply, and control systems vary significantly across different application industries. Even the same customer will have different requirements for fluid properties in different projects and systems. Our rapid customized services based on customer needs have always been well received and recognized by customers.

From the inception of the TFSD30 Series, TOPSFLO adopted a product mindset based on modular design, planning and designing the components, materials, and structure of the product. This approach allows us to provide customers with various high-quality and rapid customization services at the minimum cost. Customers can choose different pump heads, connectors, materials, and motors as needed, obtaining customized models with corrosion resistance, pressure, and flow characteristics. TOPSFLO sample line immediately customizes production based on customer choices, ensuring that customized products have fast delivery times and cost advantages comparable to standard products.

2. High output pressure for continuous operation in high-pressure conditions, providing a continuous power source for inkjet and cleaning applications:

TFSD30 Series is a liquid pump with a wide range of operating pressures. It can operate under -35kPa negative pressure, drawing liquid from a negative pressure container or from a location below the pump body installation position of 3.5m. It can also output liquid under +600kPa positive pressure, achieving a liquid lift of over 60 meters. Specially designed and pressure-resistant diaphragms and pump bodies, with optimized processes, not only enable the output of high-pressure liquid but also ensure continuous operational lifespan under rated high output pressure. When TFSD30 Series is connected to a micro atomizing nozzle, sufficient working pressure can produce ideal micro-sized mist droplets. When connected to a needle nozzle, it can output a strong high-pressure water column.

3. Adopt high-end corrosion-resistant materials to meet chemical compatibility requirements for various corrosive media applications:

Facing various corrosive media, TOPSFLO, in the selection of rubber and sealing materials, introduced not only conventional EPDM rubber but also fluororubber. Collaborating with leading suppliers of special rubber materials, TOPSFLO developed perfluoroether rubber (FFKM) valve plates and sealing systems with excellent corrosion resistance. Additionally, corrosion-resistant materials widely praised in the industry, such as polytetrafluoroethylene (PTFE), were also applied. The variety of corrosion-resistant material choices allows TFSD30 Series to be compatible with strong oxidizing agents, strong acids, strong bases, and organic solvents. It can be widely used in the transfer, washing, disinfection, cleaning, and inkjet applications involving highly corrosive liquids.

4. Optimized pressure resistance structure, elevating the pressure resistance capability of the micro diaphragm pump from 500kPa to 800kPa:

To meet the sealing and pressure resistance requirements for high-pressure applications, TOPSFLO R&D team comprehensively referred to the design features of various domestic and foreign high-pressure liquid pumps in the structural design, and made multiple improvements. Such as using glass fiber-reinforced polyphenylene sulfide (PPS) engineering plastic as the pressure-resistant pump body. This not only optimized the part structure but also reduced points of seal failure. The pressure-resistant pump body components' sealing and fastening pressure were optimized and strengthened, achieving a comprehensive pressure resistance performance of TFSD30 Series surpassing similar products at the 800kPa (0.8mPa) level. In addition to enhancing the pump body's pressure resistance, TFSD30 Series has undergone specific optimizations for pipe connection reliability and prevention of pipe detachment under high pressure. When used in high-pressure conditions, it can be equipped with a sleeve-type pipe sealing joint to enhance pipe pressure connection reliability.

5. Non-adhesive one-way valve structure for excellent self-Priming stability:

In order to minimize the industry-wide issue of self-priming failure caused by one-way valve adhesion when extracting viscous liquids, TOPSFLO significantly enhanced and improved the product structure during the development of TFSD30 Series. For example, the surface-sealing structure of the one-way valve plate was changed to a line-sealing structure to reduce medium retention and adhesive surface area. Fluid structure calculation simulations and 3D printing technology were introduced to minimize the working dead zone of the volumetric pump. This achieved higher suction negative pressure than similar imported foreign products, resulting in more stable and reliable self-priming performance.

6. Multiple motor options covering a wide range of lifespan and price ranges:

TFSD30 Series offers various motor options, including DC brushed motors, conventional brushless motors, and enhanced bearing custom brushless motors. These options cater to intermittent users, customers working under long-term continuous low loads, and those operating under long-term high-pressure and high-load conditions. This provides the most suitable configuration options, meeting the high reliability demands of challenging conditions and the cost-effective options for applications prioritizing cost. The diverse motor options also give users a broader range of choices in terms of power supply voltage, speed control mode, electromagnetic compatibility, and more.

7. Excellent and linear flow rate adjustment control characteristics:

To achieve stable liquid output flow rate control, TFSD30 Series can control motor speed through PWM signals. Optimizations were made for speed-flow characteristics. With the combined effect of the motor controller control program and optimized internal structure, the speed control curve of TFSD30 Series exhibits superior linearity compared to conventional diaphragm pumps. This enables customers to easily adjust and control the pump's output flow rate through programming and control signals in various applications.

The new generation high performance diaphragm pump TFSD30 Series has started prototype testing for initial users and will continue to iterate and improve based on customer feedback. TOPSFLO adheres to the core value of "creating value for customers" and is willing to work together with all customers to advance the continuous improvement of diaphragm pump technology and product quality. If you would like further information on TFSD30 Series high-performance diaphragm pump or apply for prototype testing, please contact our pre-sales engineers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes