#digital ph sensor

Explore tagged Tumblr posts

Text

Reliable Ammonium and Ammonia Nitrogen Sensors for Water Quality Monitoring

Our high-performance ammonium sensor and ammonia nitrogen sensor are specially designed for precise and real-time water quality monitoring in various environments. Ideal for use in aquaculture, wastewater treatment, environmental monitoring, and industrial processes, these sensors provide accurate measurement of ammonia-related compounds that are critical to maintaining safe and balanced water systems.

The ammonium sensor accurately detects NH₄⁺ levels, an essential parameter in understanding nutrient content and pollution in water. Theammonia nitrogen sensor measures NH₃-N, a key indicator of water toxicity and treatment efficiency. Both sensors are engineered for long-term deployment with durable, waterproof housings and advanced anti-interference features.

Our water quality ammonium sensor solutions are easy to install, integrate seamlessly with digital data systems, and require minimal maintenance. With high sensitivity and stability, they ensure dependable results even in harsh or fluctuating environmental conditions.

Whether you're managing aquaculture systems, monitoring natural water bodies, or optimizing wastewater treatment, our sensors deliver the accuracy and reliability needed for effective decision-making. Enhance your water monitoring capabilities with our trusted ammonium and ammonia nitrogen sensors today.

#environmentalmonitoring#digital ph sensor#AmmoniumSensor#AmmoniaNitrogenSensor#WaterQualityMonitoring#WaterQualityAmmoniumSensor#EnvironmentalSensors#WastewaterTreatment#AquacultureMonitoring#WaterTesting#SmartWaterSensor#RealTimeWaterMonitoring#NH4Sensor#IndustrialWaterQuality#EnvironmentalMonitoring#WaterTech#SensorTechnology#CleanWaterSolutions#IoTWaterMonitoring#WaterAnalysis

0 notes

Text

Pocket TDS meter

Pocket TDS meter is a handheld unit with a dual measurement function. Hold function saves and records measurement readings. Automatic power off post ten minutes of last operation prolongs battery life. It determines the temperature and concentration of dissolved solids in a solution.

#pocket tds meter#oakton ecotestr cts#hanna hi98131#tds meter#tds tester#tds water tester#zero water tester#ph ec meter#tds meter digital water tester#tds 3#tds ec meter#tds sensor#ph and ec meter#total dissolved solids meter#best tds meter#tds metre#ec meter hydroponics#water tds meter#hanna ec meter#hi98129#tds meter price#ppm water tester#hm digital tds meter#groline ph meter#inline tds meter#hanna tds meter#tds monitor#ph and tds meter#hanna hi98129#vivosun ph meter

0 notes

Text

Titanic Mission To Map Wreck In Greatest-Ever Detail

— By Jonathan Amos & Alison Francis | 12 July 2024

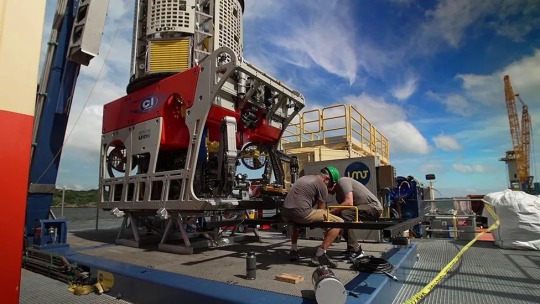

Six-tonne robots will spend up to 20 days mapping and cataloguing the wreck site

A team of imaging experts, scientists and historians set sail for the Titanic on Friday to gather the most detailed photographic record ever made of the wreck.

The BBC had exclusive access to expedition members in the US city of Providence, Rhode Island, as they made preparations to leave port.

They'll be using state of the art technology to scan every nook and cranny of the famous liner to gain new insights into its sinking.

This is the first commercial mission to Titanic since last year's OceanGate tragedy. Five men died while trying to visit the lost ship in a novel submersible.

A joint memorial service will be held at sea in the coming days for them and the 1,500 passengers and crew who went down with Titanic in 1912.

The new expedition is being mounted by the US company that has sole salvage rights and which to date has brought up some 5,500 objects from the wreck.

But this latest visit is purely a reconnaissance mission, says RMS Titanic Inc, based in Atlanta, Georgia.

Two robotic vehicles will dive to the ocean bottom to capture millions of high-resolution photographs and to make a 3D model of all the debris.

"We want to see the wreck with a clarity and precision that's never before been achieved," explained co-expedition lead David Gallo.

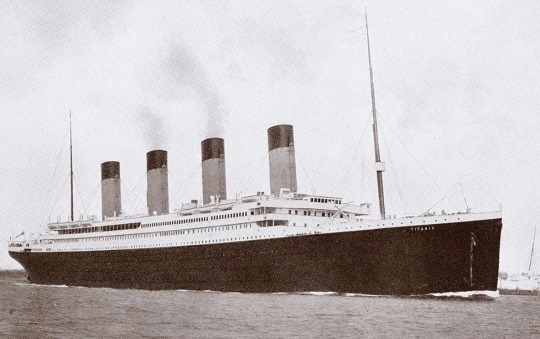

Titanic was the largest and most luxurious passenger ship of its day

The logistics ship Dino Chouest is going to be the base for operations out in the North Atlantic.

Weather permitting, it should spend 20 days above the wreck, which lies in 3,800m (12,500ft) of water.

It will be a poignant few weeks for all involved.

One of the five who died on the OceanGate sub was Frenchman Paul-Henri ("PH") Nargeolet. He was the director of research at RMS Titanic Inc and was due to lead this expedition.

A plaque will be laid on the seabed in his honour.

"It's tough but the thing about exploration is that there's an urge and a drive to keep going. And we're doing that because of that passion PH had for continuous exploration," explained friend and historian Rory Golden, who will be "chief morale officer" on Dino Chouest.

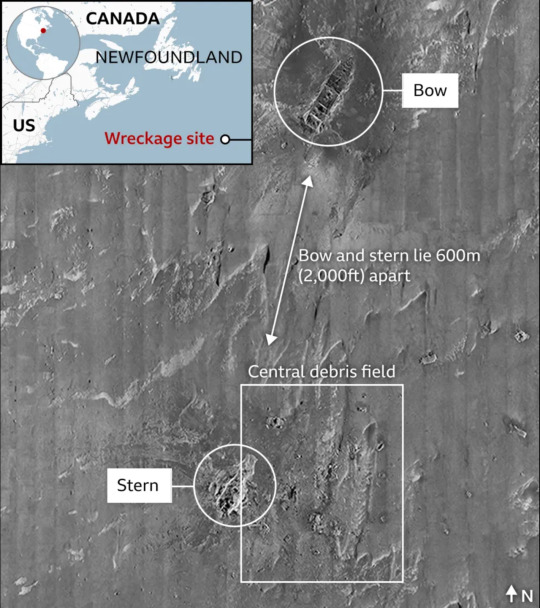

On its last visit in 2010, RMS Titanic Inc made a sonar map of the wreck site

There can be few people on Earth who don't know the story of the supposedly unsinkable Titanic and how it was holed by an iceberg, east of Canada, on the night of 15 April 1912.

There are countless books, movies and documentaries about the event.

But although the wreck site has been the target of repeated study since its discovery in 1985, there still isn't what could be described as a definitive map.

And while the bow and stern sections of the broken ship are reasonably well understood, there are extensive areas of the surrounding debris field that have received only cursory inspection.

There is still much to learn about Titanic, even its famous bow

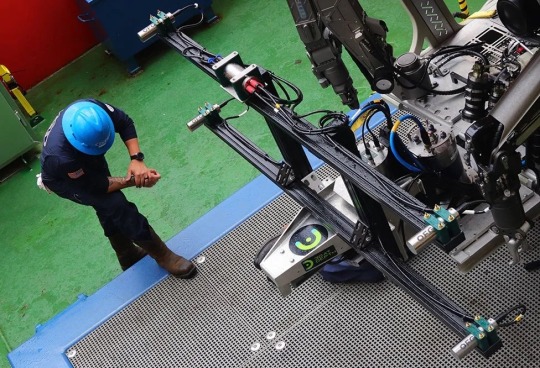

Two six-tonne remotely operated vehicles (ROVs) intend to put that right. One will be fitted with an array of ultra-high-definition optical cameras and a special lighting system; the other will carry a sensor package that includes a lidar (laser) scanner.

Together, they'll track back and forth across a 1.3km-by-0.97km section of seafloor.

Evan Kovacs, who's in charge of the imaging programme, says his camera systems should produce millimetre resolution.

"If all of the weather gods, the computer gods, the ROV gods, the camera gods - if all those gods align, we should be able to capture Titanic and the wreck site in as close to digital perfection as you can get. You would be able to quite literally count grains of sand," he told BBC News.

Powerful cameras should return unprecedented detail from the deep

There's huge anticipation for what the magnetometer aboard the sensor ROV might produce. This is a first for Titanic.

The instrument will detect all the metals at the wreck site, even material that is buried out of sight in the sediment.

The sensor instruments, including the magnetometer, will return fascinating new data

"It would be an absolute dream to determine what has happened with Titanic's bow below the seafloor," explained geophysics engineer Alison Proctor.

"Hopefully, we'll be able to deduce whether or not the bow was crushed when it hit the seabed, or if it might actually extend down well into the sediment intact."

The team wants to review the state of some well known objects in the debris field, such as the boilers that spilled out as the opulent steamliner broke in half.

A rendering of what the electric candelabra might have looked like

There's the desire, too, to locate items thought to have been sighted on previous visits. These include an electric candelabra, which in its day would have been a fascinating curio, as well as the possibility of a second Steinway grand piano.

The musical instrument's wooden surround would have long since decayed away, but the cast iron plate, or frame, that held the strings should still be there, and perhaps even some of the keys.

"For me, it's the passengers' possessions, especially their bags, that are of greatest interest," said Tomasina Ray, who curates the collection of Titanic artefacts held by the company.

"It's their belongings - if we are able to retrieve more in the future - that help flesh out their stories. For so many passengers, they are just names on a list, and it's a way to keep them meaningful."

Rory Golden says the memorial plaque for PH will be placed upright in the sediment

This will be RMS Titanic Inc's ninth visit to the wreck site. The firm has attracted controversy in recent years with its stated desire to try to bring up part of the Marconi radio equipment that transmitted the distress calls on the night of the sinking.

It won't happen on this expedition but if and when it does occur, it would mean extracting an object from inside the disintegrating ship.

For many, Titanic is the gravesite to the 1,500 who died that night in 1912 and should not be touched, its interior especially.

"We get that and understand it," said company researcher James Penca.

"We dive to Titanic to learn as much as we can from her; and like you should with any archaeological site, we do it with the utmost respect. But to leave her alone, to just let her passengers and crew be lost to history - that would be the biggest tragedy of all."

It is the personal items, some preserved inside bags, that tell the stories of the dead

James Penca has the famous ship's radio call sign - "MGY" in morse code - tattooed on his arm

— Additional Reporting By Rebecca Morelle and Kevin Church

#Science & Environment#Shipwrecks#Photography#RMS Titanic#Atlantic Ocean 🌊#Titanic Mission#Map Wreck#Greatest-Ever Detail

2 notes

·

View notes

Text

Common Challenges in Operating an Affluent Treatment Plant

Effluent treatment plants (ETPs) play a vital role in managing industrial wastewater, ensuring that harmful chemicals do not enter water bodies. ETPs are a popular and essential treatment plant across various industries, such as pharmaceuticals, textiles, chemicals, and the food processing industry. Any reliable effluent treatment plant manufacturer provides the best quality ETPs that meet your industrial standards and offer environmental benefits. However, it is not easy to maintain ETPs properly for industrial use, as there are common challenges associated with the operation of an effluent treatment plant. Let's discuss the common challenges in detail through this blog.

Common Challenges in Operating an Effluent Treatment Plant

In this segment, we will discuss the most common challenges associated with operating an effluent treatment plant for various industrial applications.

Fluctuating wastewater composition

Different industries generate wastewater with highly harmful elements. However, it is not possible to generate the same quality of wastewater from a particular industry. A sudden change in chemical composition and pH balance can create problems in the operation of effluent treatment plants. In such cases, industrialists must adopt personalised treatment strategies to make the wastewater treatment process effective.

Unskilled manpower

Operating an effluent treatment plant requires a knowledgeable team to manage the treatment process. Inappropriate use of effluent treatment plants can lead to degradation of the plant's quality. Operators must understand chemical dosing, equipment maintenance, and safety protocols to operate this device effectively. Otherwise, it will be damaged within a short time.

Inadequate maintenance

If you buy ETPs from renowned effluent treatment plant manufacturers, but unless you take proper maintenance of pumps, aerators, and clarifiers, the effluent treatment plant will lose its capacity within a few days. Neglected maintenance leads to equipment breakdown and a reduction in plant efficiency.

Higher operating cost

The operating cost of ETPs is very high and includes chemical usage, skilled labour, and equipment maintenance. For any small-scale industry, the cost of operating an ETP is such a big investment.

Lack of automation

Some ETPs do not include a digital monitoring system; instead, they feature a manual operating system. Without sensors, it is challenging to detect faults within machinery, resulting in significant problems for the industry.

Conclusion

Managing an effluent treatment plant for an industrial wastewater treatment process is a significant challenge for small-scale industries. In such a case, you must think logically about how to utilize the effluent treatment plants for the ultimate benefits of the industrial wastewater treatment process in a budget-friendly manner.

youtube

#effluent treatment plant manufacturers#effluent treatment plant suppliers#effluent treatment plant manufacturer#best effluent plant providers#Youtube

0 notes

Text

Modern Technologies Driving Fisheries Growth in Gujarat Marine

Gujarat, a state boasting India’s longest coastline of over 1,600 kilometers, is emerging as a frontrunner in marine innovation. From modernizing ports to revolutionizing fisheries with smart technologies, Gujarat’s marine sector is evolving rapidly. The fisheries industry, in particular, is experiencing a remarkable transformation, supported by advancements in infrastructure, digital integration, and world-class marine services.

The synergy between traditional maritime practices and new-age technology is empowering Gujarat’s coastal communities, boosting exports, ensuring sustainability, and positioning the state as a vital player in India’s blue economy. At the heart of this revolution are stakeholders like Gujmar Group – a trusted Ship Chandler and one of the best ship supply companies in India, ensuring vessels and fishery operations remain fully supported and equipped.

Let’s dive deep into the modern technologies that are propelling Gujarat’s fisheries toward sustainable and profitable growth.

1. Satellite-Based Vessel Monitoring Systems (VMS)

One of the most significant technological leaps in Gujarat’s fisheries management has been the adoption of VMS. These GPS-powered systems are installed on fishing vessels and allow authorities to monitor their real-time movement.

This technology not only enhances safety by tracking boats during rough weather or emergencies, but also aids in sustainable fishing practices by ensuring vessels don’t enter restricted or overfished zones. VMS is particularly useful in identifying fishing patterns and deploying enforcement where needed.

For marine services providers like Gujmar Group, VMS helps predict vessel arrivals at ports, making it easier to plan ship supplies, maintenance, and bunkering efficiently.

2. Cold Chain & Refrigeration Logistics

Previously, one of the major challenges in Gujarat’s fisheries was the lack of a seamless cold chain. Spoilage during transportation caused significant losses to fishers and exporters.

Today, smart cold storage units, temperature-controlled containers, and real-time monitoring tools have transformed how seafood is stored and shipped. These advancements ensure catch quality is maintained from sea to shore, enabling Gujarat to meet global seafood export standards.

Efficient cold chain integration has also boosted the demand for ship store suppliers like Gujmar Group, who provide not just marine essentials but also temperature-sensitive provisions required by fishing fleets.

3. e-Fish Markets and Traceability Systems

Digital fish marketplaces are gaining ground in Gujarat, enabling fishermen to sell their catch directly to buyers across the country through mobile apps and web portals. These platforms cut down the involvement of middlemen, ensuring better margins for fishers.

Additionally, traceability systems using QR codes or RFID tags are being adopted. These allow consumers to verify where their seafood came from, how it was caught, and when – a major step toward transparency and sustainable sourcing.

This digitization indirectly supports marine services companies by streamlining inventory planning, order management, and on-board provisioning for fishing vessels that are increasingly digitized.

4. Sustainable Aquaculture with IoT & AI

The introduction of smart aquaculture systems is another milestone. Fish farms in coastal Gujarat now use Internet of Things (IoT) sensors to monitor water quality, pH levels, feed distribution, and fish health. AI algorithms analyze this data to optimize feeding schedules, reduce disease risk, and improve yields.

Such precision fish farming is not only more profitable but also environmentally sustainable. And as aquaculture infrastructure grows, so does the demand for quality marine supplies — creating more opportunities for top ship store suppliers and ship chandlers in the region.

Gujmar Group has been instrumental in providing marine-grade equipment, safety gear, and maintenance tools to aquaculture operations — a testament to its role as one of the best ship supply companies in India.

5. Drone & Underwater Surveillance Technology

In marine conservation and fisheries management, drones are being used to track fish migration patterns, survey aquatic health, and even monitor illegal fishing activity. Underwater ROVs (Remotely Operated Vehicles) are used for seabed mapping, checking fish stock density, and inspecting submerged aquaculture cages.

These innovations improve resource management, ensure safety, and assist authorities in crafting data-driven policies.

For companies offering marine services, drone and ROV support is becoming a specialized vertical, where prompt parts supply, repair, and technical support is key. Here again, reliable ship chandlers like Gujmar Group provide a competitive edge.

6. Upgraded Marine Infrastructure

The Gujarat Maritime Board (GMB) and state government are investing heavily in port modernization, harbor construction, and smart landing centers. These centers are designed to support advanced fishing vessels with berthing, ice plants, processing units, and fuel supplies.

This infrastructure uplift strengthens the ecosystem for marine services — allowing companies like Gujmar Group to provide end-to-end provisioning, ship repairs, bonded stores, and supply chain support across Gujarat’s strategic ports.

As a trusted name among ship store suppliers, Gujmar not only caters to merchant vessels but also supports hundreds of fishing boats with tools, ropes, spare parts, paints, and protective gear.

7. Blockchain for Supply Chain Transparency

As global seafood buyers become more quality-conscious, blockchain technology is being explored to ensure tamper-proof records of a fish’s journey from catch to consumer. Gujarat’s marine stakeholders are piloting blockchain projects that help build consumer trust and comply with export regulations.

Ship suppliers, port operators, and fisheries can now share verified data on a decentralized platform — minimizing fraud and maximizing visibility.

Gujmar Group: Enabling Gujarat’s Blue Tech Transformation

Whether it's provisioning high-seas fishing vessels, supplying cold chain essentials, or providing technical marine support, Gujmar Group is at the forefront of India’s marine modernization.

Recognized among the top ship chandlers and the best ship supply company in India, Gujmar combines decades of industry experience with a customer-first mindset. Operating across South Asian and African ports, the company ensures timely delivery of high-quality goods, spare parts, and marine essentials that keep Gujarat’s fisheries and maritime sector thriving.

Conclusion

The fusion of traditional marine practices with modern technologies is shaping the future of Gujarat’s fisheries. From AI-driven aquaculture to satellite-based vessel monitoring, the transformation is as deep as it is wide.

As Gujarat sails ahead on its marine tech journey, the role of trusted ship store suppliers and marine service providers like Gujmar Group becomes even more crucial. They aren’t just supplying goods — they’re powering a sustainable, technologically advanced marine economy.

#Ship Chandler#Marine Services#Best ship supply company in India#ship store suppliers#ship repair#ship supplier#ship provisions#ship stores suppliers in india#marine paints#marine fuel suppliers in india#top ship chandlers in india

0 notes

Text

A Complete Guide to Endress+Hauser Products for Industrial and Marine Applications

The Role of Precise Measurement in Industrial Automation Industrial automation has transformed manufacturing and process industries, helping firms save costs, enhance efficiency, and provide increased safety. Precise and reliable measurement instrumentation is one of the chief facilitators of this change, making it possible to monitor and control various process variables like flow, level, pressure, and temperature in real time. Endress+Hauser’s product range is built to address these and other requirements, providing state-of-the-art technology to provide precision, reliability, and performance in even the toughest environments.

1. Flow Measurement Solutions

Flow measurement is perhaps the most important parameter in industrial automation. Across most industries, from oil and gas to food and beverage, accurate flow control is needed to sustain production consistency, avoid waste, and ensure safety. Endress+Hauser has a series of electromagnetic and ultrasonic flowmeters that are superior in terms of both performance and reliability. To cite an example, their Proline series of electromagnetic flowmeters are extremely accurate and provide real-time data of conductive liquids’ flows. They would be most suitable for the water treatment, chemical processing, and food production industries, where accurate fluid control is essential.

2. Liquid Analysis and Measurement

Apart from flow measurement, liquid analysis is also a crucial element in industrial automation. The product portfolio of Endress+Hauser consists of sophisticated instruments to measure parameters like pH, turbidity, conductivity, and dissolved oxygen. These sensors are indispensable for the quality of the end product while being compliant with environmental and safety regulations. Pharmaceutical, food and beverage, and power generation industries depend upon these instruments to measure vital parameters and ensure product uniformity.

3. Level Measurement, Pressure, and Temperature

Temperature, pressure, and level measurement form the building blocks of industrial automation. Precise measurement in these respects is necessary for the control of heating systems, pressure vessels, and storage tanks. Endress+Hauser offers a range of sensors and transmitters, including the iTEMP range for temperature measurement and the Liquiphant series for level measurement. These instruments assist in enabling industries to check their processes efficiently, with the equipment running within safety limits and the products made to the desired standards.

4. Process Control and Data Integration

Measurement is not enough for Endress+Hauser, which provides integrated process control solutions. Their automation solutions gather data from multiple instruments, giving operators real-time information about their processes. Endress+Hauser’s solutions optimize the performance of industries, reduce downtime, and maintain stability in processes within operating parameters. The automation solutions of Endress+Hauser are extremely versatile and can be tailored to suit industries from chemical production to water management.

Endress+Hauser Solutions for Marine Industry

The marine industry, as with industrial applications, demands accurate control and measurement for the safe and efficient performance of its vessels. From tracking fuel efficiency to ensuring there are no emission contraventions, Endress+Hauser solutions play a crucial role in enabling marine operators to deliver the increasing requirements of sustainability, efficiency, and safety. Let’s explore how Endress+Hauser helps the marine industry.

1. Marine Emission Monitoring

With increasingly strict environmental regulations, sea operators are required to meet emissions standards in order to minimize their environmental footprint. Endress+Hauser’s Maritime Suite provides leading-edge digital solutions in emission monitoring, condition diagnostics, and greenhouse gas monitoring. The Maritime Suite tools make it possible for ship owners and fleet operators to track real-time information about their fleet’s performance and monitor emissions and regulatory compliance. These are solutions such as redundant emission monitoring, analyzer condition monitoring, and emissions mass flow rate calculations.

2. Marine Steam and Water Analysis Systems (SWAS)

For power generation equipment and marine boilers onboard ships, monitoring water quality is vital to ensure efficient operation. Endress+Hauser’s steam and water analysis systems (SWAS) are engineered to measure water quality in marine conditions, and assist in monitoring important parameters such as pH, conductivity, and dissolved oxygen. These systems play a critical role in optimizing boiler performance, minimizing fuel consumption, and maintaining safe operation with low chances of corrosion or scaling in critical equipment.

3. Integrated Marine Automation Solutions

Endress+Hauser provides integrated marine automation systems that assist in optimizing operations on board ships. The systems are geared to automate different processes, including engine management, ballast control, and fuel efficiency optimization. Through real-time data and analytics, marine operators are able to make more informed decisions, increase fuel usage, lower emissions, and maximize overall vessel performance. The solutions are important in bringing down operating costs and ensuring maximum efficiency, particularly in long-distance commercial shipping.

The Endress+Hauser Advantage: Why Use Their Products?

1. Innovation and Reliability

Endress+Hauser is the market leader in innovation, continuously innovating beyond what is possible in process automation and measurement. Their products are built to last, with long-term reliability even in the harshest environments. From extreme temperatures to high-pressure systems to marine conditions, Endress+Hauser’s products are designed to deliver at the highest levels.

2. Tailored Solutions for Any Industry

One of the most impressive aspects of Endress+Hauser’s solution is that it is capable of delivering customized solutions that meet the unique demands of each industry. The company collaborates extensively with customers to learn about their unique needs, providing tailored solutions that deliver maximum performance, minimize costs, and maintain compliance with regulations.

3. In-depth Customer Support

Endress+Hauser does not merely supply products; they supply the complete package of customer support to ensure that their solutions perform at their best in the long term. Throughout the installation and commissioning process, through maintenance and calibration, Endress+Hauser provides a complete range of services to maintain systems at peak efficiency.

Explore Our Endress+Hauser Products Collection At Aeliya Marine Tech.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter

0 notes

Text

pH Sensors Market Future Trends Reflect Advancements in Automation, Miniaturization, and Smart Monitoring Systems

The pH sensors market future trends are being shaped by rapid technological advancements, evolving industrial requirements, and a growing need for precision in chemical and biological measurements. As industries across sectors such as water treatment, pharmaceuticals, food and beverage, and environmental monitoring demand greater accuracy and efficiency, pH sensors are becoming smarter, more compact, and more integrated with digital ecosystems. These future trends are poised to redefine how pH measurements are used in both laboratory and field environments.

One of the most prominent trends is the integration of pH sensors with digital platforms and smart technologies. Traditional analog pH sensors are increasingly being replaced with smart digital sensors that offer real-time data transmission, self-calibration, and predictive maintenance capabilities. These digital solutions are transforming industrial monitoring by reducing downtime, improving accuracy, and enabling remote control and diagnostics. As the Internet of Things (IoT) continues to expand, smart pH sensors are expected to become a key component of connected industrial systems.

Miniaturization and portability are also gaining momentum in the pH sensors market. Compact and portable pH meters are in high demand across field-based applications, particularly in environmental testing and agricultural monitoring. Researchers and field technicians require easy-to-carry tools that deliver reliable results without bulky instrumentation. Manufacturers are responding by designing sleek, durable, and lightweight devices with built-in storage and wireless connectivity, allowing for greater mobility and faster on-site decision-making.

Another significant trend is the increased use of pH sensors in environmental sustainability initiatives. As water pollution and soil degradation become critical global concerns, real-time pH monitoring is essential in assessing the health of natural ecosystems. Governments and regulatory bodies are enforcing stricter environmental regulations, pushing industries to adopt continuous pH monitoring systems. This rising environmental consciousness is opening new opportunities for sensor deployment in wastewater treatment, aquaculture, and air quality control systems.

In the biopharmaceutical and healthcare sectors, the role of pH sensors is expanding rapidly. These industries demand stringent quality control, and pH levels often play a vital role in product consistency and safety. In pharmaceutical manufacturing, inline pH measurement is crucial for fermentation processes, bioreactor monitoring, and sterile environments. Future trends point toward sensors that can withstand aggressive cleaning protocols, offer faster response times, and provide integration with automated process control systems.

The food and beverage industry is another significant driver of future pH sensor innovations. With increased emphasis on food safety, shelf life, and taste consistency, accurate pH measurement has become an essential quality parameter. Next-generation sensors are being developed to work in high-temperature environments, with faster calibration and improved resistance to fouling. Trends also include sensors embedded in packaging or production lines for non-intrusive, continuous monitoring.

Material innovation is further enhancing sensor capabilities. Electrode technology, particularly for glass and non-glass electrodes, is evolving to meet the demands of harsh environments. Newer materials are being explored to extend the life of sensors, improve their resistance to chemical corrosion, and maintain accuracy across diverse pH ranges. Non-glass solid-state sensors are especially gaining interest in industries where glass breakage is a concern, such as food processing or medical applications.

Wireless technology and mobile integration are shaping the future of pH sensor usability. Wireless pH sensors can now connect directly to smartphones or cloud platforms, allowing users to monitor results in real-time, receive alerts, and log data for further analysis. This is particularly useful in remote operations, agricultural applications, and scenarios requiring fast, data-driven decisions. The fusion of sensors with mobile apps and cloud storage also enables better long-term data management and regulatory compliance.

The pH sensors market is also witnessing the emergence of AI-powered diagnostics. Artificial intelligence and machine learning algorithms are being developed to interpret pH data patterns, predict anomalies, and suggest corrective actions automatically. These intelligent systems can optimize operational efficiency in industrial processes, reduce human intervention, and minimize the risk of human error.

Customization and modular designs represent another future trend. Users are seeking flexible solutions that can be tailored to specific operational needs. Manufacturers are now offering modular sensor systems that can be easily adapted or upgraded, whether in terms of connectivity, calibration options, or sensor length and size. This adaptability allows companies to respond quickly to changing conditions or regulatory demands.

In conclusion, the future of the pH sensors market is marked by a shift towards smarter, more connected, and application-specific solutions. With rising demand from environmentally conscious industries, precision-focused healthcare applications, and efficiency-driven manufacturing processes, pH sensors are evolving beyond traditional laboratory instruments. Companies that invest in automation, miniaturization, material durability, and digital integration will be best positioned to lead in a market defined by innovation and adaptability.

0 notes

Text

Carbon-Neutral Concrete? The Race Toward Sustainability in the RMC Sector

The global ready-mix concrete market, traditionally defined by logistics, batching precision, and on-site performance, is quietly undergoing a digital evolution. As construction demands intensify and the industry faces increasing scrutiny around sustainability, cost efficiency, and quality control, a relatively under-discussed innovation is reshaping the game: remote quality monitoring. This transformative approach, powered by real-time data collection and analysis technologies, is not just an operational upgrade—it is redefining how stakeholders approach quality assurance, compliance, and customer satisfaction in the pre-mixed concrete industry.

𝐔𝐧𝐝𝐞𝐫𝐬𝐭𝐚𝐧𝐝𝐢𝐧𝐠 𝐭𝐡𝐞 𝐑𝐞𝐚𝐝𝐲-𝐦𝐢𝐱 𝐂𝐨𝐧𝐜𝐫𝐞𝐭𝐞 𝐋𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞 𝐚𝐧𝐝 𝐈𝐭𝐬 𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬

The ready-mix concrete market is projected to grow from USD 801.6 billion in 2025 to USD 1,621.6 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.3% during the forecast period. Despite this growth, one enduring challenge has been maintaining consistency in concrete quality between batching and delivery. Conventional quality control methods rely heavily on manual sampling, periodic testing, and operator expertise. This results in variability, waste, and frequent delays—issues that translate directly to project inefficiencies and increased costs.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-8592

As a material that must meet strict specifications before being poured, concrete leaves little margin for error. Factors like water-cement ratio, temperature control, and construction aggregate composition must remain within optimal ranges. Any deviation in these parameters can weaken structural integrity or violate regulatory standards. It is within this context that remote quality monitoring emerges as a game-changer, offering concrete suppliers and construction managers a real-time window into their production process.

𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐒𝐡𝐢𝐟𝐭: 𝐅𝐫𝐨𝐦 𝐌𝐚𝐧𝐮𝐚𝐥 𝐎𝐯𝐞𝐫𝐬𝐢𝐠𝐡𝐭 𝐭𝐨 𝐒𝐦𝐚𝐫𝐭 𝐌𝐨𝐧𝐢𝐭𝐨𝐫𝐢𝐧𝐠

Remote quality monitoring in ready-mix concrete production integrates digital sensors, cloud-based data analytics, GPS tracking, and Internet of Things (IoT) platforms. This ecosystem of technology captures key metrics—such as slump, temperature, pH levels, and setting time—during mixing, transport, and even placement. Unlike traditional batch reports that offer a retrospective look at quality, this real-time visibility enables dynamic adjustments and immediate corrective actions.

Companies such as Giatec Scientific and Command Alkon have pioneered solutions where embedded sensors transmit continuous data on concrete behavior. These insights help monitor curing cycles remotely and alert engineers to inconsistencies before the product reaches the job site. In India, for example, ACC Limited has begun incorporating IoT into its batching plants, enhancing the traceability and accountability of its deliveries. This digital feedback loop minimizes the risk of structural defects and reduces project downtime caused by material rejection or rework.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐚𝐝𝐢𝐧𝐞𝐬𝐬 𝐚𝐧𝐝 𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐃𝐢𝐬𝐩𝐚𝐫𝐢𝐭𝐲 𝐢𝐧 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

While the promise of remote monitoring is compelling, its adoption varies significantly across regions. Developed markets like North America and Western Europe are witnessing faster integration of these technologies, aided by digital infrastructure, skilled labor, and a strong push toward Industry 4.0 principles. In contrast, several Asia-Pacific and African countries remain reliant on traditional methods due to cost constraints and a lack of technical know-how.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/ready-mix-concrete-market

However, emerging economies are showing signs of strategic investment in digital construction practices. For instance, the Middle East, with its ambitious smart city projects, is actively exploring advanced material tracking systems. In Saudi Arabia, initiatives under Vision 2035 include smart infrastructure planning that encourages private sector adoption of intelligent batching systems.

This disparity is not just technological but also regulatory. Environmental bodies in countries like Germany and Canada are now mandating transparent reporting of carbon emissions associated with construction materials. Remote monitoring provides the data backbone for such compliance, allowing suppliers to calculate CO₂ footprints with greater accuracy and credibility.

𝐋𝐨𝐧𝐠-𝐭𝐞𝐫𝐦 𝐈𝐦𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐟𝐨𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞𝐧𝐞𝐬𝐬 𝐚𝐧𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲

The implications of remote quality monitoring extend beyond operational efficiency. As ESG (Environmental, Social, and Data Governance) standards tighten, stakeholders across the construction value chain are being asked to demonstrate their commitment to sustainable practices. Ready-mix concrete producers who leverage remote monitoring tools can not only ensure consistent quality but also optimize raw material usage, reduce energy consumption, and extend the lifecycle performance of structures.

Furthermore, this approach enhances client trust and transparency. Real-time data logs can be shared with contractors and regulatory bodies, minimizing disputes and facilitating faster approvals. In large infrastructure projects—such as high-speed railways, nuclear facilities, or smart bridges—such digital validation is increasingly becoming a procurement requirement.

Smaller producers, too, stand to benefit by differentiating themselves in a competitive landscape. By advertising their use of smart quality control systems, they can appeal to high-end clients seeking assurance, reliability, and innovation. As the cost of IoT devices and cloud subscriptions continues to decline, the technology is becoming more accessible even to mid-sized batch plants.

General & Advanced Materials Industry Analysis: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

𝐒𝐭𝐚𝐲𝐢𝐧𝐠 𝐀𝐡𝐞𝐚𝐝 𝐢𝐧 𝐚 𝐃𝐚𝐭𝐚-𝐃𝐫𝐢𝐯𝐞𝐧 𝐌𝐚𝐫𝐤𝐞𝐭

The ready-mix concrete market is poised for accelerated transformation, and remote quality monitoring is quietly leading the charge. What was once an afterthought in production—ensuring mix consistency and delivery quality—is now a strategic pillar in maintaining competitiveness and meeting rising regulatory expectations. As urbanization accelerates and infrastructure projects grow in scale and complexity, the demand for consistent, verifiable, and sustainable concrete will only increase.

Adopting remote monitoring technologies is no longer optional for forward-thinking suppliers. It is a critical investment in quality assurance, customer satisfaction, and market relevance. By embracing this less visible but highly impactful innovation, players in the ready-mixed cement industry can align themselves with the future of smart construction.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Production:

In terms of Production, the industry is divided into On-Site and Off-Site

By Product Type:

In terms of Product Type, the industry is divided into Residential, Non-Residential, Infrastructural, Commercial, Industrial

By Region:

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc. Christiana Corporate, 200 Continental Drive, Suite 401, Newark, Delaware - 19713, USA T: +1-347-918-3531 For Sales Enquiries: [email protected] Website: https://www.futuremarketinsights.com LinkedIn| Twitter| Blogs | YouTube

0 notes

Text

What sensors commonly collect data in IoT?

In the realm of the Internet of Things (IoT), sensors play a crucial role by collecting data from the physical environment and converting it into digital signals that devices can process. Various types of sensors are commonly used in IoT systems depending on the application and the type of data needed.

Temperature sensors are among the most widely used sensors in IoT. They measure the ambient temperature and are crucial in applications like smart homes, weather monitoring, and industrial automation to maintain optimal conditions.

Humidity sensors complement temperature sensors by measuring moisture levels in the air, which is important for agriculture, HVAC systems, and environmental monitoring.

Proximity sensors detect the presence or absence of an object or its distance from the sensor. These are often used in smart parking systems, automation, and security systems.

Light sensors measure the intensity of light. They are used in smart lighting solutions, energy management, and devices that adjust brightness based on ambient light.

Pressure sensors monitor atmospheric or fluid pressure and find applications in weather stations, industrial systems, and automotive technologies.

Motion sensors or accelerometers detect movement or vibrations. These are fundamental in fitness trackers, security alarms, and asset tracking systems.

Gas sensors identify the presence and concentration of gases like carbon monoxide, methane, or smoke, which is critical in environmental safety, industrial safety, and air quality monitoring.

Water quality sensors measure parameters like pH, turbidity, and contaminants, which are vital for environmental monitoring and smart water management systems.

Each sensor converts its analog data into digital form, which is then transmitted over IoT networks to centralized platforms for analysis, enabling real-time decision-making and automation.

Understanding these sensors and their applications is essential for anyone aspiring to build or work with IoT solutions. For those interested in deepening their knowledge and skills in this area, enrolling in an IoT certification course can provide comprehensive training on sensors, data collection, and IoT system design.

0 notes

Text

Reliable Digital & Industrial pH Sensors with Integrated pH Monitoring System

Our advanced pH monitoring system combines precision, durability, and real-time data tracking to meet the needs of modern industrial operations. Featuring both digital pH sensors and industrial pH sensors, this system delivers accurate pH measurements across a wide range of applications including water treatment, chemical manufacturing, pharmaceuticals, and food processing.

The digital pH sensor offers high-resolution measurement and fast response times, with minimal drift for long-term stability. It integrates seamlessly with automated control systems, allowing for continuous pH monitoring and instant alerts in case of deviations. The industrial pH sensor is built to withstand harsh environments, including high temperatures, corrosive chemicals, and high-pressure conditions, making it ideal for demanding field use.

Our complete pH monitoring system provides real-time data visualization, logging, and remote access, helping operators maintain optimal pH levels and improve overall process efficiency. With plug-and-play compatibility and minimal maintenance requirements, it’s a cost-effective solution that enhances quality control and regulatory compliance.

Whether you need precise pH control for a small operation or a complex industrial setup, our digital and industrial pH sensors deliver reliable performance and peace of mind. Upgrade your facility with a trusted pH monitoring system designed for accuracy, durability, and ease of use. WizSensor digital & industrial pH sensor with real-time pH monitoring system for all industries.

#Ammonium sensor#Ammonia nitrogen sensor#Oil in water sensor#Multi-parameter probe#turbidity sensor#Digital pH sensor#Water conductivity meter#chorophyll sensor#optical dissolved oxygen sensor

0 notes

Text

Feminine Hygiene Products Market: Emerging Trends Reshaping the Industry

The feminine hygiene products market is undergoing a significant transformation, driven by evolving consumer preferences, innovation in product development, and increasing awareness about women’s health and sustainability. This shift is prompting companies to rethink traditional strategies and invest in more advanced, inclusive, and eco-friendly solutions. As women across the globe demand better choices in personal care, the market is responding with groundbreaking trends that are redefining the landscape.

Sustainability and Eco-Conscious Products

One of the most prominent trends in the feminine hygiene products market is the growing preference for sustainable and eco-friendly products. Consumers are increasingly aware of the environmental impact of disposable sanitary products such as pads and tampons, many of which contain plastic components that take centuries to decompose. In response, companies are introducing biodegradable pads, organic cotton tampons, and reusable menstrual cups and underwear. These products appeal not only to eco-conscious consumers but also to those looking for healthier alternatives free from harmful chemicals and synthetic materials.

The zero-waste movement is particularly influencing product development, pushing brands to create packaging that is either compostable, recyclable, or reusable. This aligns with a broader shift toward sustainable living, where consumers are seeking to reduce their ecological footprint in every aspect of life, including personal care.

Technological Innovation and Smart Products

Technology is playing a vital role in the evolution of feminine hygiene products. Brands are investing in research and development to create smart products that enhance user experience. For instance, some startups are exploring the integration of sensors into menstrual products that can track menstrual flow, detect abnormalities, or sync with mobile apps for cycle tracking. These innovations aim to empower women by providing them with more control and information about their reproductive health.

Additionally, advancements in materials science have led to the creation of ultra-thin, super-absorbent products that offer better comfort and protection. Menstrual underwear, which can absorb the equivalent of several tampons' worth of fluid, is rapidly gaining popularity as a discreet and effective alternative to traditional products.

Rise of Gender-Inclusive Branding and Marketing

Another significant shift is the move toward more inclusive and gender-neutral marketing. Traditional advertising has long focused on cisgender women, often reinforcing stereotypes around menstruation. However, an increasing number of brands are now recognizing that not all people who menstruate identify as women. Transgender men and non-binary individuals also require access to menstrual products and services.

This change is reflected in product design, packaging, and brand messaging that avoid overtly gendered language or visuals. By doing so, companies are not only promoting inclusivity but also broadening their customer base and aligning with contemporary values around gender identity and diversity.

Focus on Health and Wellness

The feminine hygiene market is increasingly intersecting with the broader health and wellness industry. Consumers are seeking products that do more than just offer protection—they want solutions that support their overall well-being. This includes products infused with natural ingredients like aloe vera or essential oils, which promise to soothe irritation or balance pH levels.

There’s also a growing demand for transparency in ingredients. As women become more informed, they are scrutinizing what goes into their products, favoring those that are hypoallergenic, dermatologically tested, and free from dyes and fragrances. In response, many brands are adopting clean-label practices and providing detailed product information.

Digital Expansion and Subscription Services

The digital transformation of retail has had a significant impact on the feminine hygiene industry. Online platforms are now key distribution channels, particularly among younger consumers who value convenience and privacy. Direct-to-consumer brands are capitalizing on this by offering customizable subscription services, ensuring users receive products tailored to their cycle and preferences.

Social media also plays a pivotal role in shaping consumer perception and promoting menstrual health education. Influencers, educators, and advocacy groups use these platforms to destigmatize menstruation and raise awareness about the range of available hygiene options. As a result, digital engagement has become a crucial component of brand strategy.

Global Market Expansion and Accessibility

While developed markets have seen significant innovation, emerging economies are also witnessing growth in feminine hygiene product consumption. Increased urbanization, education, and access to healthcare are contributing to rising awareness and demand. Governments and non-profits are also working to improve menstrual hygiene management by distributing free or subsidized products and launching public health campaigns.

However, affordability and accessibility remain key challenges in many regions. Addressing these issues through cost-effective product innovations and social programs will be vital for the continued expansion of the market.

Conclusion

The feminine hygiene products market is experiencing dynamic changes fueled by sustainability, technological advancements, inclusive branding, and health-focused innovation. As consumer expectations evolve, companies are stepping up with more thoughtful, diverse, and empowering solutions. This shift marks a critical step toward destigmatizing menstruation and promoting a more inclusive and responsible approach to menstrual health worldwide.

0 notes

Text

Supporting Smart Industry: The Growing Demand for Waste Water Testing Labs in Abu Dhabi | +971 554747210

As Abu Dhabi accelerates its transformation into a smart, sustainable industrial powerhouse, environmental protection remains a top priority. One crucial yet often overlooked aspect of this transformation is the role of Waste Water Testing Labs. These laboratories are rapidly gaining importance as industries expand, environmental regulations tighten, and digital technologies reshape the way businesses operate.

This blog explores why the demand for Waste Water Testing Lab in Abu Dhabi is growing, how they support the development of smart industries, and what businesses should consider when partnering with these labs.

Abu Dhabi's Vision for Smart Industry and Environmental Stewardship

Abu Dhabi’s industrial strategy aligns closely with the UAE Vision 2030, which aims to diversify the economy while protecting environmental resources. This includes:

Adoption of smart manufacturing and Industry 4.0 technologies

Enhanced environmental, health, and safety (EHS) regulations

Expansion of eco-industrial parks and green zones

Investment in waste water recycling and reuse infrastructure

In this context, Waste Water Testing Labs are vital to ensuring industries operate sustainably without compromising water quality or public health.

Why Waste Water Testing Is a Smart Industry Priority

1. Compliance with Environmental Regulations

As Abu Dhabi enforces stricter environmental policies through the Environment Agency – Abu Dhabi (EAD) and the Department of Energy (DoE), businesses must meet clear waste water discharge and treatment standards. Regular testing through accredited waste water labs ensures:

Compliance with effluent limits

Avoidance of penalties and legal action

Continuity of environmental permits

2. Monitoring Smart Infrastructure

Smart factories and green buildings are integrating water reuse and closed-loop systems. However, these technologies still require precise monitoring to function effectively. Waste water testing labs analyze:

Nutrient levels

Heavy metals

pH, TSS, BOD, COD

Pathogens and oil & grease content

This data enables real-time monitoring, predictive maintenance, and early detection of system failures.

3. Boosting Sustainable Resource Management

Water scarcity in the region demands efficient water management. By ensuring treated waste water meets reuse standards, labs enable smart industries to:

Reduce reliance on freshwater

Reuse water for cooling, landscaping, and processing

Lower operational costs and water procurement expenses

Key Industries Driving the Demand for Waste Water Testing Labs

🔹 Manufacturing

From metal fabrication to pharmaceuticals, manufacturers generate complex waste water. Labs help them comply with industrial effluent norms and optimize treatment processes.

🔹 Oil & Gas

This sector produces high volumes of chemically-laden waste water. Testing labs help in analyzing and neutralizing contaminants to meet strict environmental standards.

🔹 Food & Beverage

Cleanliness and hygiene are paramount in F&B industries. Testing waste water ensures that operations don’t harm public health or violate food safety laws.

🔹 Construction & Real Estate

Modern developments use on-site STPs (Sewage Treatment Plants). Labs ensure treated effluent from these systems is safe for reuse in irrigation or safe discharge.

🔹 Hospitality

Hotels in Abu Dhabi aiming for green building certification (such as Estidama or LEED) must regularly test and document waste water quality as part of sustainable building operations.

How Waste Water Testing Labs Support Smart Industry Goals

✅ Real-Time Monitoring Capabilities

Many advanced labs now offer IoT-enabled sensors and remote sampling services. These technologies provide real-time updates and alerts, empowering industries to take swift corrective actions.

✅ AI and Data-Driven Decision Making

Labs increasingly use AI for pattern recognition and anomaly detection in water quality data. This enables:

Predictive maintenance of treatment systems

Optimized chemical dosing

Reduced downtime and costs

✅ Automated Compliance Reporting

Labs in Abu Dhabi often integrate testing data with digital compliance dashboards. These tools automatically generate EHS reports required by regulatory bodies like EAD and ADSSC.

✅ Custom Testing Protocols for Smart Facilities

Labs work with industries to design tailored testing regimens aligned with their unique operations—whether it’s a solar-powered desalination plant or a smart logistics hub.

Accreditation and Standards: Why They Matter More Than Ever

In a smart industry landscape, credibility and traceability are everything. Choosing an ISO/IEC 17025-accredited Waste Water Testing Lab is non-negotiable. Accreditation ensures:

Competence in testing methods

Traceable, reproducible results

Compliance with Abu Dhabi and international guidelines (EAD, WHO, EPA)

Many labs in Abu Dhabi also participate in Proficiency Testing (PT) schemes and regularly calibrate their instruments to maintain accuracy.

Choosing the Right Waste Water Testing Lab in Abu Dhabi

With rising demand, it’s important to work with a lab that aligns with your industrial goals. Here’s what to look for:

Criteria

What to Check

Accreditation

ISO/IEC 17025 and EAD-approved

Industry Experience

Experience in your sector (e.g., F&B, oil & gas)

Turnaround Time

Ability to deliver fast, reliable results

Testing Scope

Covers microbial, chemical, and heavy metal parameters

Digital Integration

Offers APIs or dashboards for data sharing

On-Site Support

Capable of sampling, emergency testing, and audits

The Future: Smarter Labs for Smarter Cities

Abu Dhabi’s commitment to smart city development (like Masdar City) includes innovations in waste water reuse, AI-driven analytics, and smart utility monitoring. Waste Water Testing Labs are adapting by:

Deploying mobile labs for rapid on-site testing

Using blockchain for data transparency and integrity

Partnering with academic institutions for R&D in water purification

As these labs evolve, they will not only support industry but also play a role in public health, climate resilience, and sustainable urban planning.

Final Thoughts

As Abu Dhabi continues to evolve into a regional and global leader in smart industry and sustainability, Waste Water Testing Labs are becoming essential partners in this transformation.

From ensuring regulatory compliance to enabling smart water management, these labs empower industries to operate cleaner, safer, and more efficiently. The growing demand for their services is a testament to the city's commitment to balancing growth with environmental responsibility.

#waste water testing lab#waste water testing#water testing lab#water testing#testing lab near me#testing lab uae

0 notes

Text

Top Industrial Coating Trends in 2025

In today’s fast-paced manufacturing world, industrial coatings are evolving rapidly to meet the demands of durability, efficiency, and sustainability. As we move into 2025, new technologies and environmental considerations are reshaping the surface protection landscape. Whether you're in automotive, aerospace, or heavy machinery, staying ahead of these trends can make a difference in performance and compliance.

1. Eco-Friendly & Low-VOC Coatings

One of the biggest shifts in the industry is toward environmentally responsible coatings. Low-VOC (volatile organic compounds) and water-based solutions are being adopted widely to comply with stricter global regulations and to reduce environmental impact.

Why it matters:

Reduces air pollution

Improves worker safety

Supports green manufacturing goals

At SAR Coatings, we continually invest in sustainable coating solutions without compromising performance.

2. Smart Coatings with Self-Healing Properties

Imagine a coating that can detect and repair minor damages on its own. In 2025, self-healing and responsive coatings are moving from research labs into real-world applications. These coatings react to environmental triggers like temperature or pH to activate healing agents embedded in the coating layer.

Where it's used:

Aerospace

Military equipment

High-value industrial components

These smart coatings extend product life and reduce maintenance downtime—a win for industries that rely on high-value assets.

3. Powder Coating Expansion

Powder coating is no longer limited to just metal furniture or automotive parts. In 2025, this versatile, durable, and solvent-free method is being applied to new surfaces and materials, including heat-sensitive substrates using low-cure powder formulas.

Why it’s growing:

Excellent durability

Lower environmental impact

Less material waste

SAR Coatings offers advanced powder coating services for diverse industries, delivering both protection and aesthetic appeal.

4. Advanced Corrosion-Resistant Coatings

Corrosion is a constant challenge for industries dealing with moisture, chemicals, and extreme temperatures. This year, new formulations in zinc flake, zinc nickel, and hybrid coatings are making it easier to meet rigorous anti-corrosion standards.

Emerging applications:

Automotive fasteners

Offshore equipment

Agricultural machinery

With a focus on long-term performance, SAR Coatings provides cutting-edge corrosion-resistant solutions tailored to your application.

5. Digital Coating Process Monitoring

Industry 4.0 has officially reached the coatings world. Companies are now using sensors and IoT technology to monitor application thickness, curing times, and environmental factors in real-time.

Benefits include:

Improved quality control

Reduced waste and rework

Predictive maintenance insights

This trend ensures consistency and efficiency in high-volume production runs.

6. Nano-Coatings for High Precision Needs

Nano-coatings are making strides in industries where ultra-thin protection is required without compromising performance. These coatings offer chemical resistance, UV protection, and anti-microbial properties at a microscopic level.

Common uses:

Medical devices

Electronics

Optics

SAR Coatings keeps an eye on nano-technology developments to explore future-ready solutions for clients.

Final Thoughts: Innovation + Application = Future-Ready Coating Solutions

The industrial coating sector in 2025 is driven by innovation, sustainability, and smarter applications. Whether it’s embracing AI-powered quality control or shifting to green coating methods, the future of surface protection is brighter and more responsible.

At SAR Coatings, we pride ourselves on staying ahead of the curve—combining technology, experience, and client-focused service to deliver world-class coating solutions.

Need expert coating advice for your project? Contact SAR Coatings today to discover how our advanced services can enhance your product's durability and performance.

SAR Coatings is a leading provider of powder coating, zinc flake coating, liquid painting, and hybrid coatings in India.

#sarcoatingsllp#ced coating#ced coating services in gurgaon#metal finishing#ced coating services in manesar

0 notes

Text

Online Corrosion Monitoring Systems: A Shift Toward Proactive Asset Management

Corrosion is a persistent challenge across industries that deal with metal infrastructure, equipment, or components exposed to environmental factors. From oil and gas pipelines to water treatment facilities, and from chemical plants to power generation units, corrosion can result in structural failures, downtime, and costly repairs. Traditionally managed through periodic inspections and maintenance programs, corrosion management has seen a paradigm shift with the advent of online corrosion monitoring systems. These systems provide real-time, continuous data that enhances predictive maintenance strategies and helps prevent failures before they occur.

Understanding Online Corrosion Monitoring

Online corrosion monitoring By Aqoza is a method of observing and measuring corrosion activity in real time through permanently installed sensors and electronic monitoring equipment. Unlike manual inspection or coupon analysis, which provides data at discrete points in time, online systems offer continuous insight into corrosion behavior and environmental conditions. This allows operators to respond more quickly to potential issues and better manage maintenance and operational decisions.

The core idea behind these systems is to capture changes in material integrity and surrounding environmental parameters as they occur. By tracking corrosion in situ, asset managers can detect the onset of degradation early, evaluate corrosion rates, and understand the impact of changes in operation or environmental exposure.

Components of an Online Corrosion Monitoring System

A comprehensive online corrosion monitoring system includes multiple components that work together to detect, transmit, and analyze data:

Corrosion Sensors: These measure specific corrosion-related parameters. Common sensor types include electrical resistance probes, linear polarization resistance sensors, galvanic probes, and hydrogen sensors. Each type has its strengths depending on the medium being monitored (air, water, oil, etc.).

Environmental Sensors: These measure conditions that contribute to corrosion, such as humidity, temperature, gas concentrations (e.g., H₂S, CO₂), and pH. Tracking these factors provides context for corrosion activity and can be used to predict high-risk periods.

Data Acquisition System (DAS): This hardware collects analog signals from sensors and converts them to digital format. It is often connected to signal conditioners, analog-to-digital converters, and storage devices.

Communication Infrastructure: Depending on the site, communication between sensors and monitoring stations may be wired or wireless. Wireless systems use protocols like Wi-Fi, Zigbee, or cellular networks, while remote sites may use satellite communication.

Monitoring and Analytics Software: Software platforms process incoming data, visualize it on dashboards, and trigger alerts or reports when thresholds are breached. Advanced systems integrate analytics and machine learning to detect patterns and suggest maintenance actions.

Types of Corrosion Monitoring Techniques

Online corrosion monitoring can be conducted using several methods, each suitable for specific applications:

Electrical Resistance (ER) Probes: These sensors detect metal loss by measuring the change in electrical resistance of a probe element. As the metal corrodes and becomes thinner, its resistance increases. ER probes are versatile and can monitor corrosion in both gas and liquid environments.

Linear Polarization Resistance (LPR): This electrochemical method is useful in conductive environments like water or process fluids. It measures the polarization behavior of a metal surface and provides real-time corrosion rate data.

Galvanic Probes: These consist of two dissimilar metals that form a galvanic couple. The current generated by the corrosion reaction provides information on corrosion activity. They are simple and effective in aqueous environments.

Hydrogen Probes: These are used in systems where hydrogen generation from corrosion is a concern, such as in cathodically protected pipelines. Hydrogen permeation indicates active corrosion processes and potential for embrittlement.

Electrochemical Noise (EN): This advanced method detects spontaneous voltage and current fluctuations caused by corrosion reactions. It is sensitive to localized forms of corrosion such as pitting.

Industrial Applications

Online corrosion monitoring systems are employed across a broad range of industries where corrosion poses significant risks:

Oil and Gas: In upstream, midstream, and downstream operations, corrosion can affect pipelines, storage tanks, and processing units. Online monitoring allows operators to manage internal corrosion from water, CO₂, H₂S, and chlorides in real time.

Water and Wastewater Treatment: Monitoring systems track the integrity of pipelines, storage tanks, and treatment vessels exposed to chemical and biological corrosion.

Power Generation: Boilers, condensers, cooling systems, and steam pipelines are prone to corrosion. Online systems help manage scaling and corrosion due to dissolved oxygen or acidic condensate.

Chemical Manufacturing: Processing vessels, reactors, and piping exposed to acids, bases, and solvents benefit from continuous corrosion monitoring.

Infrastructure: In bridges, tunnels, and marine structures, embedded sensors help monitor corrosion in steel reinforcements and load-bearing components.

Advantages of Online Corrosion Monitoring

Implementing online corrosion monitoring offers several key benefits that go beyond traditional inspection-based approaches:

Real-Time Awareness: Instant feedback enables faster response to corrosion events and reduces the risk of sudden failures.

Predictive Maintenance: Instead of performing maintenance at fixed intervals, operators can act based on actual conditions, which improves efficiency and extends equipment life.

Reduced Downtime: Online systems minimize the need for shutdowns for inspection, as monitoring occurs continuously without disrupting operations.

Safety Improvements: Early detection of corrosion reduces the risk of leaks, fires, or structural collapse, enhancing worker and environmental safety.

Regulatory Compliance: Real-time data and historical records help demonstrate compliance with industry standards and environmental regulations.

Data Integration: Collected data can be integrated with broader asset management platforms, improving cross-functional planning and investment decisions.

Challenges and Limitations

Despite their advantages, online corrosion monitoring systems also present certain challenges:

Initial Investment: Installation of sensors, data infrastructure, and software can be costly, particularly for large or complex sites.

Sensor Lifespan: Sensors are exposed to the same conditions as the assets they monitor, and may degrade or require replacement over time.

Data Volume: Continuous monitoring generates large datasets that must be filtered and analyzed effectively to avoid overwhelming users with non-actionable information.

Calibration and Accuracy: Sensor drift and environmental noise can affect data accuracy, requiring periodic calibration and validation.

Integration Complexity: Merging new monitoring systems with legacy equipment or SCADA systems can involve technical and logistical hurdles.

Future Trends in Online Monitoring

As digital technologies evolve, online corrosion monitoring systems are becoming more intelligent, accessible, and efficient. Some emerging trends include:

Smart Sensors: Integration of microprocessors and edge computing allows sensors to process data locally, reducing bandwidth needs and latency.

Wireless and Battery-Free Solutions: Advances in energy harvesting and ultra-low-power electronics are enabling longer deployments with minimal maintenance.

Artificial Intelligence: Machine learning algorithms are being used to detect trends, predict corrosion behavior, and recommend interventions based on historical data.

Digital Twins: Simulated models of physical assets are being enhanced with real-time corrosion data, enabling more accurate forecasting and planning.

Modular Systems: Flexible, plug-and-play sensors and software platforms are making it easier to scale monitoring systems across facilities.

Conclusion

Online Corrosion Monitoring systems represent a transformative approach to asset integrity management. By enabling continuous, data-driven awareness of corrosion activity, they help organizations improve reliability, extend equipment lifespan, and reduce unplanned maintenance costs. As monitoring technologies continue to evolve, their adoption is expected to become standard practice in any industry where corrosion poses a critical risk.

0 notes

Text

Smart Water Technology Implementation: Future Water Management

In the face of growing climate challenges, urbanisation, and increasing demand for sustainable resources, the need for intelligent water management has never been greater. Enter smart water technology implementation—a game-changing approach that leverages digital solutions to monitor, manage, and optimise water systems across municipalities, industries, and households.

This blog explores how smart water technology implementation is revolutionising the water industry, its benefits, key components, and the roadmap for successful integration.

What Is Smart Water Technology?

Smart water technology refers to the integration of advanced tools such as IoT sensors, AI-driven analytics, real-time data dashboards, and cloud computing into water management systems. This technology provides utilities and organisations with actionable insights into water usage, leak detection, quality monitoring, and infrastructure performance.

Smart water technology implementation is not just a trend—it’s a critical step toward creating more efficient, resilient, and sustainable water systems.

Why Smart Water Technology Implementation Matters

Water utilities worldwide face several persistent challenges, including:

Aging infrastructure

Water loss through undetected leaks

High energy consumption

Limited visibility of system performance

Regulatory compliance requirements

Increased customer demand for transparency

Smart water technology addresses these issues by enabling automated monitoring, proactive maintenance, and smarter decision-making—helping cities and businesses conserve resources and reduce operational costs.

Benefits of Smart Water Technology Implementation

1. Real-Time Leak Detection and Prevention

One of the most impactful benefits of smart water technology implementation is its ability to detect leaks in real-time. IoT-enabled sensors placed along pipelines can alert operators immediately when abnormal flow is detected, preventing water loss, property damage, and high repair costs.

2. Optimised Resource Allocation

By analysing usage patterns and pressure zones, utilities can optimise when and where water is distributed. This leads to better pressure management, reduced wastage, and improved supply reliability—especially during peak demand periods.

3. Improved Water Quality Monitoring

Smart systems continuously track water quality indicators such as pH levels, chlorine content, and temperature. This allows faster identification of contamination risks and ensures safe water delivery to end users.

4. Enhanced Energy Efficiency

Pumping and treating water require energy. Smart water management solutions help utilities monitor energy consumption in real time and identify opportunities for optimisation—reducing carbon footprints and energy costs.

5. Regulatory Compliance and Reporting

Smart water technology makes compliance reporting easier through automated data collection and real-time dashboards. This ensures organisations meet local and international standards without manual intervention.

Key Components of a Smart Water System

For a successful smart water technology implementation, the following components are crucial:

Smart Sensors: Monitor flow, pressure, temperature, and quality throughout the system.

Communication Networks: Use wireless or LoRaWAN networks to transmit data securely and reliably.

Data Analytics Platforms: Translate raw data into insights using AI and machine learning.

SCADA Systems: Enable centralised control and monitoring of water treatment and distribution processes.

Cloud Infrastructure: Stores and processes data remotely, allowing scalable access and integration.

How to Successfully Implement Smart Water Technology

Implementing smart water systems requires a strategic and phased approach:

1. Assessment and Goal Setting

Start by evaluating your current infrastructure and defining objectives. Are you aiming to reduce water loss, improve billing accuracy, or enhance customer service?

2. Pilot Program

Run a pilot in a selected area to test technologies and fine-tune processes before full-scale deployment.

3. Choose the Right Technology Partner

Work with experienced vendors that understand both the technology and the specific challenges of your water system.

4. Integration and Training

Ensure seamless integration with existing systems and train staff to use the new tools effectively.

5. Monitoring and Optimisation

Once deployed, continually monitor system performance, gather feedback, and make iterative improvements.

Use Cases Across the Globe

Cities like Singapore, London, and Los Angeles are already leading in smart water technology implementation. For instance:

Singapore’s PUB uses smart meters and AI to detect leaks before they cause major issues.

Thames Water in the UK has deployed over 1 million smart meters to improve consumption accuracy.

Los Angeles uses IoT sensors to monitor water levels in reservoirs and predict maintenance needs.

These initiatives demonstrate how cities can become more resilient and sustainable through digital water management.

Final Thoughts

The future of water lies in innovation, and smart water technology implementation is at the core of that transformation. By investing in intelligent systems today, utilities, councils, and corporations can achieve long-term savings, reduce environmental impact, and improve service delivery.

As global water challenges intensify, there’s never been a better time to embrace smart water technology. Whether you're a municipal decision-maker or a business leader, now is the time to act—and lead your organisation into a smarter, more sustainable future.

0 notes

Text