#droptested

Explore tagged Tumblr posts

Text

youtube

Unlock the secrets of frequency analysis in SolidWorks! In this episode, we perform a frequency simulation on a PCB board to study its natural frequencies, mode shapes, and resonant behaviors. Learn why this analysis is critical to ensure your designs are vibration-resistant and assembly-ready.

🔑 Key Highlights: Introduction to frequency analysis and resonance 🌐 Understanding natural frequencies and mode shapes 📊 Step-by-step frequency simulation setup for a PCB ⚙️ Material and boundary condition definitions 🛠️ Exploring simulation results and resonant frequencies 🔍

🎯 Perfect for: Mechanical engineers, product designers, and SolidWorks enthusiasts looking to optimize designs for vibration resistance.

Check out the episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3CZyjn7

#SolidWorksSimulation#DropTest#PCBSimulation#MechanicalEngineering#CAE#EngineeringTutorials#StressAnalysis#DisplacementAnalysis#ProductDesign#LearnEngineering#SkillDevelopment#skilllync#Youtube

2 notes

·

View notes

Text

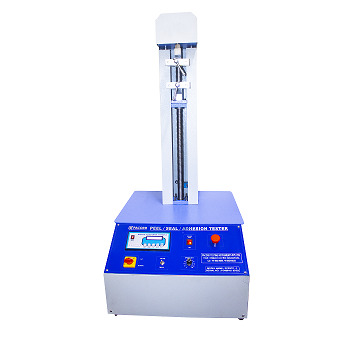

Peel Bond Strength Tester

A peel bond strength tester measures the durability of the glue between two bonded materials. It offers clear product quality by supporting the measurement of the force required to separate layers under controlled conditions. This equipment is commonly used in industries where bond reliability is important, such as electronics, packaging and the automotive industry. The tester supports multiple peel test standards and creates accurate results. Choose Perfect Group India for high-performance testing equipment. They are your reliable partner in quality and durability.

0 notes

Text

The Importance of Peel Strength Testing for Reliable Product Performance

In industries where adhesive bonding plays a critical role—such as packaging, automotive, electronics, and medical devices—ensuring the integrity and durability of bonds is essential. This is where the Peel Strength Tester comes into play as a vital quality control instrument.

At Pacorr, we provide state-of-the-art Peel Strength Testers that help manufacturers guarantee the performance, reliability, and safety of their adhesive products.

What is Peel Strength Testing?

Peel strength testing is a method used to measure the force required to separate two bonded materials. This test helps determine the adhesive strength and durability of products such as:

Laminates and films

Adhesive tapes and labels

Flexible packaging materials

Medical device packaging

Automotive interior components

The test involves applying a controlled, steady force to peel one layer away from another, measuring the force required to initiate and sustain the peel.

Why Peel Strength Testing is Critical

Adhesive failures can lead to product malfunctions, safety concerns, and damage to brand reputation. Peel strength testing ensures:

✅ Consistent product quality ✅ Compliance with industry standards (ASTM, ISO, etc.) ✅ Improved safety and reliability ✅ Reduced risk of product recalls ✅ Enhanced customer satisfaction

By regularly performing peel strength tests, manufacturers can detect bonding issues early and take corrective action before products reach the market.

Features of Pacorr's Peel Strength Tester

At Pacorr, we design Peel Strength Testing that combine advanced technology with ease of use, offering:

✔ High-Precision Load Cell: Delivers accurate force measurement for reliable test results ✔ Digital Display: Easy-to-read values for efficient data recording ✔ Durable Construction: Built with corrosion-resistant materials for long-term use ✔ Customizable Grips: Accommodates various materials and sample types ✔ Smooth Testing Operation: Controlled peeling speed to ensure consistency ✔ Compliance with Standards: Fulfills international testing requirements for peel strength evaluation

Industries That Benefit from Peel Strength Testing

Peel Strength Testers are widely used across sectors where adhesive bonds are critical to product performance:

1. Packaging Industry

Ensures strong seals in flexible packaging, preventing product leakage or contamination.

2. Electronics Industry

Validates the adhesion of protective films, screens, and device casings.

3. Automotive Sector

Tests interior trims, tapes, and components for durability under varying conditions.

4. Medical Devices

Guarantees the integrity of adhesive materials used in medical packaging and wearable devices.

5. Label and Tape Manufacturing

Measures the peel strength of self-adhesive labels and tapes for optimal performance.

Conclusion: Invest in Quality with Pacorr

In today’s competitive manufacturing environment, product quality is non-negotiable. With Pacorr’s Peel Strength Tester Price, you can confidently test the integrity of your adhesive bonds and ensure your products meet the highest standards of quality and reliability.

💡 Explore Pacorr’s range of Peel Strength Testers at www.pacorr.com or contact our experts for personalized assistance.

Pacorr – Where Quality Meets Precision.

0 notes

Video

youtube

Protect Your Phone Like a Pro | Sportlink WaterProof Case for iPhone 16 ...

#youtube#iPhone16 Sportlink WaterproofCase iPhone16Accessories TechReview DropTest UnderwaterTest PhoneProtection GadgetReview TechSoleBlog iPhone16R#iphone 16 waterproof case#waterproof case#iphone 16

0 notes

Text

Drop Tester Equipment

🚀 Ensure Safe Packaging with LabZenix Drop Tester Equipment! 📦✨

Test your product’s durability with precision. Our Drop Tester Equipment guarantees reliable impact resistance testing for packaging materials. ✅

📍 LabZenix Industries Pvt. Ltd. 📞 Call: +91-9565453120 📧 Email: [email protected] 🌐 Visit: www.labzenix.com

#DropTester #LabZenix #PackagingTesting

0 notes

Video

Innopack bucket test

1 note

·

View note

Text

Drop Tester

Use the Drop Tester from Perfect Group India to make sure your packaging can handle the demands of shipping. This necessary tool replicates free-fall impacts to assess the strength and durability of packaging materials. The Drop Tester from Perfect Group helps in locating any defects errors so that your products are delivered to customers in a perfect state. To improve the quality of your packaging and maintain the reputation of your brand, choose our accurate and trustworthy testing solutions. Invest in Perfect Group's quality control services.

0 notes

Text

How Drop Testing Enhances Brand Reputation: A Guide to Quality Packaging with Drop Testers

Drop Tester: Ensuring Product Durability with Precision Testing

In today’s competitive market, product packaging plays a crucial role in ensuring customer satisfaction. A package not only reflects the brand’s image but also ensures the safety and quality of the product during storage, transportation, and handling. To maintain high standards in packaging, testing its durability is essential, and this is where a Drop Tester comes into play. At pacorr.com, we provide state-of-the-art drop testing machines to help manufacturers evaluate the robustness of their packaging solutions.

Understanding the Drop Tester

The Drop Tester Price is a specialized testing instrument designed to simulate real-life impacts and accidental drops that packaged goods endure during transit or handling. This equipment assesses the ability of packaging materials to withstand shocks, vibrations, and pressure, ensuring the safety of the product inside.

Key Features of the Drop Tester

Versatile Drop Heights: The drop height can be adjusted to simulate different real-world scenarios.

Multi-Angle Testing: Allows testing at various angles, including flat, edge, and corner drops.

Robust Build: Constructed with durable materials to ensure long-term usage and consistent results.

Precision Measurements: Equipped with advanced technology for accurate impact analysis.

User-Friendly Interface: Easy to operate, making it suitable for laboratories and manufacturing units.

Why is Drop Testing Important?

Packaging is not just a protective layer; it represents the product and the brand. Damaged products due to poor packaging can lead to customer dissatisfaction, financial loss, and brand reputation damage. Drop testing helps identify the weaknesses in packaging and allows manufacturers to rectify them before the product reaches the market.

Some of the critical reasons to perform drop testing include:

Minimizing Product Damage: Ensures the product remains intact even under extreme conditions.

Cost Efficiency: Reduces the cost associated with product returns and replacements.

Regulatory Compliance: Helps manufacturers meet international packaging standards.

Customer Satisfaction: Ensures a safe and intact product delivery experience.

Applications of Drop Tester

The Drop Tester is widely used in industries such as:

E-Commerce and Logistics: To ensure that packaged goods can withstand rough handling during shipping.

Food and Beverage: Testing the durability of cartons, bottles, and other packaging formats.

Electronics: To ensure the safety of sensitive gadgets and devices during transport.

Pharmaceuticals: Testing medical supplies and equipment packaging for secure transit.

How Does the Drop Tester Work?

Using the Drop Tester is simple yet effective. The package or product is securely placed on the testing platform. The operator sets the desired drop height and angle, and the tester releases the sample to simulate a real-life drop. The impact force and damage sustained are then analyzed to determine the packaging’s effectiveness.

Benefits of Using the Drop Tester from pacorr.com

Accurate Analysis: Ensures comprehensive testing for reliable results.

Durable Design: Long-lasting equipment that provides consistent performance.

Customizable Solutions: Drop Testers tailored to meet specific industry needs.

Global Standards Compliance: Helps businesses adhere to international packaging and transportation standards.

Choosing Pacorr’s Drop Tester

At pacorr.com, we prioritize quality and innovation. Our Drop Tester is designed to deliver precise and consistent results, helping manufacturers create packaging solutions that meet the highest standards. With easy installation and minimal maintenance requirements, our equipment ensures hassle-free operations for a wide range of industries.

Conclusion

Packaging durability is vital in today’s competitive environment. A Drop Tester from pacorr.com is an indispensable tool to ensure that your products are well-protected, maintaining their quality and integrity until they reach the end consumer.

0 notes

Text

youtube

Ever wondered how electronic components withstand impact during a drop? In this video, we demonstrate a drop test simulation for a PCB board using SolidWorks. Discover how to analyze stresses, displacement, and optimize designs for durability! Perfect for engineers and enthusiasts looking to enhance their simulation skills. Key Highlights: Understanding the importance of drop tests for PCB boards

💡 Step-by-step setup of drop test simulation ⚙️ Material definition and gravity orientation 🎯 Interpreting stress and displacement results 🔍 Tips for improving design to avoid component failures 📈

🔔 Subscribe for more engineering insights and tutorials! Check out the episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3ZlHeH0

#SolidWorksSimulation#DropTest#PCBSimulation#MechanicalEngineering#CAE#EngineeringTutorials#StressAnalysis#DisplacementAnalysis#ProductDesign#LearnEngineering#SkillDevelopment#skilllync#Youtube

1 note

·

View note

Text

The Ultimate Guide to Vacuum Leak Tester

Source of info: https://www.perfectgroupindia.co.in/the-ultimate-guide-to-vacuum-leak-tester.php

In many different industries, vacuum leak testing is a vital procedure that guarantees the reliability and security of goods. One of the most important tools for this job is the vacuum leak tester, which is essential for finding leaks and guaranteeing quality control. This thorough guide will cover the nuances of vacuum leak testing, their functions, applications, and important factors to take into account when selecting one for your particular requirements. Product integrity and safety are confirmed in a variety of industries through vacuum leak testing. In order to maintain quality standards, the vacuum leak tester is essential for finding leaks. With a focus on the importance and selection guidelines based on particular requirements, this guide offers a thorough examination of vacuum leak testing.

Understanding Vacuum Leak Tester: One technique to find leaks or flaws in sealed goods or packaging is vacuum leak testing. In order to find leaks, it entails creating a vacuum inside a chamber or surrounding the test specimen and keeping an eye out for any pressure variations. In sectors where maintaining product integrity is critical, like pharmaceuticals, food and beverage, automotive, electronics, and more, this procedure is essential. In sectors including pharmaceuticals, food and beverage, automotive, and electronics, vacuum leak testing is essential for guaranteeing product integrity. Accurate leak detection helps prevent contamination and guarantees that products adhere to strict quality and safety standards, preserving consumer confidence and brand reputation.

The Importance of Vacuum Leak Tester: In order to make sure that products fulfill strict safety and performance standards, vacuum leak testers are essential tools for quality assurance. These testers guard against contamination, product failures, and safety risks by precisely identifying leaks. They are essential for preserving the caliber of the final product, cutting down on waste, and protecting brand equity.

How Vacuum Leak Tester Work: In order for a vacuum leak tester to work, a controlled vacuum environment must be created around the test specimen, which is usually a sealed product or package. The presence of leaks is then determined by the tester by measuring any changes in chamber pressure. Numerous techniques, including mass flow, pressure decay, vacuum decay, and tracer gas detection, can be used, depending on the application and level of sensitivity needed.

Applications of Vacuum Leak Testing: Applications for Vacuum Leak Testing are found in many different products and industries. It guarantees the integrity and freshness of packaged goods, including bottles, cans, and pouches, in the food and beverage industry. It confirms the sealing of parts like fuel tanks and brake systems in the automotive industry. Furthermore, vacuum leak testing is essential in the pharmaceutical industry to guarantee the safety and effectiveness of medication packaging.

Key Considerations When Choosing a Vacuum Leak Tester: There are a few things to take into account when choosing a vacuum leak tester for your particular application. These include the test's sensitivity, the need for throughput, the kind of product or packaging being tested, regulatory compliance, and financial limitations. Selecting a tester that can satisfy your quality control goals in terms of accuracy, dependability, and usability is crucial.

Conclusion: To sum up, vacuum leak testers are essential instruments for guaranteeing the quality, safety, and integrity of a wide range of goods in a variety of sectors. These testers support brand reputation, guarantee regulatory compliance, and avert expensive product recalls by precisely identifying leaks and flaws. Think about your unique needs when choosing a vacuum leak tester, and pick the option that best satisfies your requirements for quality control. Superior product quality and customer satisfaction can be attained with the appropriate Vacuum Leak Tester in place.

Frequently Asked Questions (FAQs)

What industries benefit from vacuum leak testing? Vacuum leak testing is invaluable in sectors such as pharmaceuticals, food and beverage, automotive, electronics, and more. It ensures product integrity by detecting leaks, which is crucial for maintaining quality standards and consumer safety.

How do vacuum leak tester contribute to quality assurance? Vacuum leak tester play a pivotal role in quality assurance by accurately identifying leaks in sealed products or packaging. This prevents contamination, product failures, and safety hazards, ultimately safeguarding brand reputation and consumer trust.

What factors should be considered when choosing a vacuum leak tester? When selecting a vacuum leak tester, factors such as sensitivity of the test, throughput requirements, type of product or packaging, regulatory compliance, and budget constraints should be taken into account. Choosing the right tester ensures accurate and reliable leak detection tailored to specific needs.

What are the different methods used in vacuum leak testing? Vacuum leak testing employs various methods, including mass flow, pressure decay, vacuum decay, and tracer gas detection. The method chosen depends on the application and level of sensitivity required to detect leaks effectively.

What are the benefits of vacuum leak testing for product integrity? Vacuum leak testing ensures the integrity and freshness of packaged goods, confirms the sealing of automotive components, and guarantees the safety and effectiveness of medication packaging. By preventing leaks and flaws, vacuum leak testing maintains product quality, safety, and regulatory compliance.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester

0 notes

Text

Drop Tester Key to Ensuring Strong Packaging and Product Protection

In industries like food and beverage, pharmaceuticals, electronics, and consumer products, packaging quality is crucial for ensuring products reach their destination in perfect condition. A Drop Tester is a valuable tool that allows manufacturers to test the durability of their packaging by simulating the impact and drops a package might encounter during shipping and handling. This ensures that products are adequately protected during transit and that packaging meets industry standards.

What is a Drop Tester?

A Drop Tester is a device used to simulate the impact forces a product’s packaging experiences during shipping. The tester drops a package from a controlled height onto a designated surface, which can replicate common impacts encountered during transport, such as accidental drops or rough handling. The goal of drop testing is to evaluate whether the packaging can withstand these impacts and adequately protect the product inside.

The device is adjustable, allowing manufacturers to simulate various drop heights, angles, and surfaces, providing a thorough understanding of how well the packaging holds up under different conditions.

Why is Drop Testing Essential?

Prevents Product Damage: Drop testing ensures that packaging protects fragile items—such as electronics, glass bottles, or medications—from damage caused by drops or impacts during shipping. Manufacturers can identify areas where the packaging may fail to offer sufficient protection and make necessary improvements.

Optimizes Packaging Design: Through drop testing, manufacturers can pinpoint weaknesses in packaging design. Whether it’s insufficient cushioning, weak corners, or inadequate structural elements, testing allows for design modifications that improve packaging strength and protect products during transport.

Ensures Regulatory Compliance: Many industries require drop testing to comply with packaging standards and regulations. Drop testing ensures that packaging meets safety requirements, helping manufacturers avoid compliance issues, fines, and product recalls.

Reduces Costs: Damage to products during shipping leads to costly returns, replacements, and customer complaints. Drop testing helps prevent product damage, saving manufacturers money by reducing the risk of returns and customer dissatisfaction.

Enhances Consumer Satisfaction: Consumers expect their products to arrive intact and undamaged. Packaging that passes drop tests reassures customers that the product is well-protected, boosting trust and satisfaction.

How Does a Drop Tester Work?

A Drop Tester operates by raising a sample package to a predetermined height and releasing it to fall onto a surface designed to mimic the conditions products might encounter during transport. The surface can simulate materials such as concrete, wood, or metal. The drop can be done from various heights and angles, testing how the packaging performs under different drop scenarios.

The tester then evaluates the package for damage. This includes checking the packaging for dents, cracks, or leaks and determining if the product inside is intact. The results provide valuable feedback for manufacturers to improve the packaging design, ensuring that it better protects the product during transport.

Types of Drop Testers

Manual Drop Testers: These are simple, hand-operated devices that are ideal for small-scale testing or occasional use. The operator manually lifts and drops the package from a set height. While affordable, manual testers may lack the precision and speed of more advanced systems.

Automated Drop Testers: Automated testers are more advanced, offering precise control over the drop height and orientation. These systems automate the entire testing process, making them suitable for high-volume production and frequent testing.

Universal Drop Testers: These versatile systems are capable of testing packages in multiple orientations and under varying conditions. Universal drop testers provide a comprehensive testing environment, suitable for testing a wide range of packaging types and products.

Benefits of Using a Drop Tester

Accurate Simulation: Drop tester Price simulate real-world shipping conditions, providing accurate results and insights into packaging durability.

Improved Packaging Protection: Drop testing helps identify weaknesses in packaging, enabling manufacturers to refine designs and improve product protection.

Regulatory Compliance: Drop testing ensures packaging meets the necessary industry standards and safety regulations, avoiding costly non-compliance issues.

Cost Savings: By preventing product damage during shipping, manufacturers can reduce costs associated with returns, replacements, and damage claims.

Increased Customer Satisfaction: Packaging that successfully passes drop tests ensures that products are delivered safely, leading to improved consumer confidence and satisfaction.

Conclusion

A Drop Tester is a crucial tool for manufacturers looking to ensure the durability and safety of their packaging. By simulating real-world impact scenarios, drop testing provides valuable insights into how packaging will perform during transit, helping manufacturers identify potential weaknesses and optimize their designs.

0 notes

Text

OH GOD MY TRANSFORMERS

BRING

ME

THE CRYSTALS

#babbles#THEM TOO. maybe.#droptest definitely#i LIKE coreflood and snowdrift but i dont wanna burn myself out drawing refs for mechs no less 😭

10 notes

·

View notes

Text

The quest for the hardest drop

Dubstep was the main genre I listened to back then, Trance was on the rise, my classmates were techno producers. I wanted to recreate the breakdowns I loved from metalcore in an electric genre, but I only had loops and EQs at my disposal. I mean, Garageband does have a built in Midi-keyboard, but I didn't know how to play it or how to tweak the sounds so they resembled a Massive Synth. So I had to stick to the library and boost that bass.

Here you can see the picture I used in my outro with the hint to the links in my video description.

2 notes

·

View notes

Video

youtube

Drop test today! #keycaps #droptest #viralvideo

0 notes

Video

tumblr

Is Your Bathroom Cabinet Durable? Watch the Jaw-Dropping Drop Test! #Droptest #bathroomvanity Want to see the ultimate durability test? Check out our jaw-dropping #Droptest of our bathroom vanity cabinet! You won't believe what happens when we put it to the ultimate challenge. Don't miss this captivating video! #bathroomvanity #Droptest Welcome to contact us: Website:https://bergoto.com/ Email: [email protected] WhatsApp/Wechat: +86 18923119142

0 notes