#testinginstruments

Explore tagged Tumblr posts

Text

Tackling Wax Deposition in Crude Oil: PSL’s Complete Wax Testing Solutions

When it comes to crude oil and petroleum product analysis, precision is everything. At Orbit Research Associates, we offer a complete range of petroleum testing instruments designed to deliver accurate results, improve quality control, and support R&D in the oil and gas industry.

From wax deposition analyzers and cold finger systems to optical WAT detectors and wax flow loops, our instruments—manufactured by PSL Systemtechnik, Germany—simulate real pipeline conditions and help engineers tackle wax build-up issues effectively.

🔍 Applications Include: ✔️ Wax inhibitor performance testing ✔️ Crude oil characterization ✔️ Pipeline risk prediction ✔️ Flow assurance studies

🌍 Trusted by major labs and oil companies in over 90 countries.

💬 Need help selecting the right tool for your lab? 📧 [email protected] | 📞 +91 11 42420858

#petroleumtestinginstrument#crudeoiltesting#oilandgas#laboratoryequipment#flowassurance#waxdeposition#petroleumlabequipment#orbitresearch#PSLSystemtechnik#energyindustry#chemicalengineering#oilandgasanalysis#labtech#testinginstruments#pipelineengineering#crudeoilquality#waxflowloop#surface tension#surface tensio meter#surface tensio measurement#contact angle meter#contact angle measurement#foam anaylzer#thermal conductivity meter#petroleum testing instruments#high pressure reactor#orbit research#chemistry#surface science#droplets

1 note

·

View note

Text

Unlock the True Potential of Thermal Analysis with Testron’s Differential Scanning Calorimeter (DSC)

When every degree matters, trust a system built for accuracy, stability, and performance. Testron’s Differential Scanning Calorimeter is engineered for advanced thermal characterization—ideal for polymers, pharmaceuticals, chemicals, and research intensive environments.

Why Industry Experts Choose Testron DSC:

Precision engineered sensors ensure consistent and reproducible data

Fast response time with stable thermal baselines, even in critical conditions

Fully compliant with international testing standards

Supported by dedicated technical experts who understand real lab challenges

Whether you're conducting quality assurance or exploring new formulations, our DSC delivers insights you can count on accurate, reliable, and timely.

Explore how Testron can transform your lab’s thermal testing capabilities. Testron Group – Your Partner in Precision Testing.

#DifferentialScanningCalorimeter#DSCAnalyzer#ThermalAnalysis#MaterialTesting#QualityControl#LabEquipment#TestingInstruments#ThermalCharacterization#TestronGroup#CalorimetryTesting

0 notes

Text

Polariscope Strain Viewer Precision Stress Analysis for Advanced Materials

Introduction When it comes to material testing and quality control, understanding the internal stresses of materials is essential to guarantee their durability and performance. The Polariscope Strain Viewer is a key tool used in identifying and visualizing internal stresses in transparent materials. At Pacorr Testing Instruments, we offer advanced Polariscope Strain Viewers that deliver reliable, non-destructive stress analysis for industries like plastics, glass, automotive, and aerospace.

What is a Polariscope Strain Viewer? The Polariscope Strain Viewer is a specialized optical instrument designed to detect and display stress patterns in materials. Using polarized light, this device allows engineers to visualize how materials react under stress, providing invaluable insights into their behavior in real-world conditions. Whether you're dealing with polymers, composites, or glass, the Polariscope Strain Viewer helps ensure that your materials meet stringent performance standards.

How Does It Work? The Polariscope Strain Viewer operates on the principle of birefringence. When polarized light passes through a stressed material, the internal stress causes the light to split and form interference patterns. These patterns are then analyzed to reveal the stress distribution within the material. By rotating the polarizer, it’s possible to view how the stress varies across different sections of the material, providing a comprehensive view of its strength and stability.

Key Applications of the Polariscope Strain Viewer The Polariscope Strain Viewer serves several critical functions across various industries, including:

Plastics and Polymers In the plastics industry, the Polariscope Strain Viewer is used to detect stress concentrations in molded plastic parts. By identifying potential weak points, manufacturers can prevent failures and improve the design of plastic products to ensure they withstand impact and pressure.

Glass Manufacturing The tool is essential for glass manufacturers, particularly for evaluating the internal stress in glass products such as windows, containers, and automotive glass. The Polariscope Strain Viewer helps detect stress points that could lead to cracks or breakage, ensuring the reliability of glass products.

Aerospace and Automotive In the aerospace and automotive industries, materials are often subjected to extreme forces. The Polariscope Strain Viewer helps test materials used in critical components, such as turbine blades, chassis parts, and safety glass, ensuring they can withstand the demanding conditions they face.

Composite Materials Composite materials, which are often made from multiple layers of different materials, are prone to internal stresses due to their structure. The Polariscope Strain Viewer is crucial for assessing these materials and ensuring they meet the necessary strength requirements for their intended applications.

Advantages of Using the Polariscope Strain Viewer Here’s why the Polariscope Strain Viewer is a must-have tool for manufacturers:

Accurate Stress Detection: It allows for precise identification of stress patterns, helping to spot weaknesses in materials that could lead to product failure.

Non-Destructive Testing: This method is entirely non-destructive, meaning the material remains intact and can be used for further testing or production.

Material Durability Improvement: By identifying stress points, manufacturers can make adjustments to improve the material's design, ensuring it lasts longer and performs better.

Wide Application Range: The Polariscope Strain Viewer is versatile and can be used to test a variety of materials, including plastics, glass, and composites.

Why Choose Pacorr’s Polariscope Strain Viewer? At Pacorr Testing Instruments, we are dedicated to providing high-quality testing equipment. Our Polariscope Strain Viewer is designed to offer accurate, reliable results that help manufacturers enhance the quality of their materials. With our state-of-the-art technology and user-friendly interface, you can ensure your products meet industry standards for strength, durability, and reliability.

Conclusion The Polariscope Strain Viewer is an indispensable tool for anyone involved in material testing. By offering a detailed view of internal stresses, it allows manufacturers to make informed decisions about their materials and products. Whether you're testing plastics, glass, composites, or other materials, this tool is essential for ensuring that your products are safe, durable, and high-performing. Trust Pacorr Testing Instruments for your material testing needs and experience the precision and reliability of our advanced equipment.

FAQs for Polariscope Strain Viewer

1. What is a Polariscope Strain Viewer? A Polariscope Strain Viewer is an optical instrument that uses polarized light to detect and visualize internal stresses within transparent materials. It helps engineers analyze how materials perform under stress and predict their behavior.

2. How does the Polariscope Strain Viewer detect stress? When polarized light passes through a stressed material, the material’s internal stress causes the light to split, creating interference patterns. These patterns are then examined to assess the intensity and location of the stress.

3. Which industries use the Polariscope Strain Viewer? The Polariscope Strain Viewer is widely used in industries such as plastics and polymers, glass manufacturing, aerospace, automotive, and composite materials. It is essential for testing materials that need to perform under stress.

4. Can the Polariscope Strain Viewer test all types of materials? While the Polariscope Strain Viewer is mainly used for transparent materials like glass and plastics, it can also be used to test composite materials, providing valuable insight into their internal stress distribution.

5. What are the benefits of using the Polariscope Strain Viewer? The main benefits include precise stress detection, non-destructive testing, improved material durability, and the ability to test a wide variety of materials for quality and strength.

6. Why should I choose Pacorr Testing Instruments for my material testing needs? Pacorr Testing Instruments offers high-quality, reliable, and easy-to-use testing equipment. Our Polariscope Strain Viewers provide accurate and detailed analysis, helping manufacturers improve the quality and performance of their products.

#MaterialTesting#QualityControl#PacorrTesting#StressAnalysis#Polariscope#Engineering#QualityMatters#Innovation#TestingInstruments

0 notes

Text

Bursting Strength Tester You Can Trust

Bursting Strength Tester You Can Trust Choose LabZenix for the Bursting Strength Tester You Can Trust. Ensure top-quality packaging with reliable, accurate, and durable testing equipment. Trusted by manufacturers across industries. Test smart, test with confidence—only with LabZenix.

📞 Contact: +91-9565453120 🔗 www.labzenix.com

Read More

#BurstingStrengthTester #LabZenix #PackagingTesting #QualityAssurance #ReliableTesters

#BurstingStrengthTester#LabZenix#PackagingTesting#QualityAssurance#ReliableTesters#technology#marketing#manufacturer#testinginstruments#laboratory euipments#testing instruments

0 notes

Text

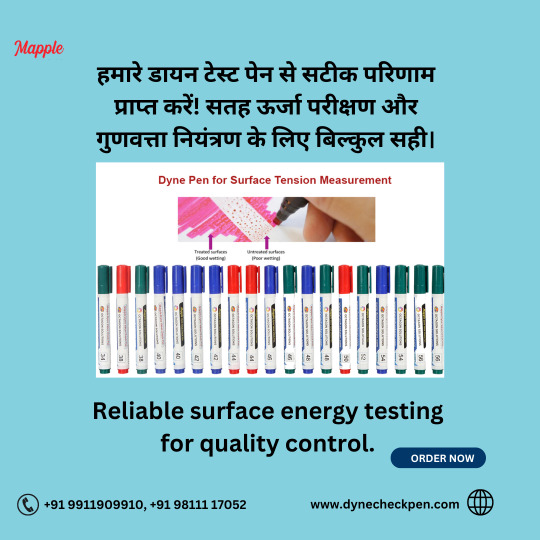

What is a Dyne Test Pen and how is it used to measure surface energy in materials?

What is a Dyne Test Pen?

A Mapple Dyne Test Pen is a small, portable device that contains ink with a known surface tension (dyne level). It is designed to test whether a material’s surface energy is sufficient for effective bonding, printing, or coating.

How is it Used?

Preparation:

Shake the Dyne Test Pen well before use to ensure the ink is properly mixed.

Application:

Gently rub the pen on the surface of the material you want to test. The ink from the pen will spread across the surface.

Observation:

After applying the ink, observe how it interacts with the surface:

If the ink forms droplets or beads up: The surface energy is too low for proper adhesion or coating.

If the ink spreads out evenly: The surface energy is high enough, indicating that the surface is well-prepared for printing or coating.

Interpreting Results:

Compare the results with the dyne level of the ink used in the pen. Different pens are available with varying dyne levels to test different surface energies.

Applications:

Printing: Ensures inks will adhere properly to various surfaces.

Packaging: Verifies that packaging materials are adequately treated for effective labeling and coating.

Manufacturing: Assesses surface energy for better bonding of adhesives and coatings.

Benefits:

Quick and Easy Testing: Provides immediate feedback on surface energy.

Improves Quality Control: Helps maintain high standards for adhesion and coating applications.

Reduces Waste: Ensures that materials are properly treated, reducing defective products.

Overall, a Dyne Test Pen is a valuable tool for quality control in industries where surface preparation is critical for successful adhesion and coating processes.

#DyneTestPen#SurfaceEnergyTesting#QualityControl#AdhesionTesting#PrecisionTesting#MaterialScience#TestingTools#AdhesivePerformance#LaboratoryEquipment#TestingInstruments#IndustrialTools#SurfaceTesting#DynePen#TechnicalTesting#ScientificTools#InnovationInTesting#QualityAssurance#AdhesiveEvaluation#SurfaceAnalysis#TestingSolutions#MaterialTesting#EngineeringTools#ResearchAndDevelopment#SurfaceQuality#EffectiveTesting#TestingTech

0 notes

Text

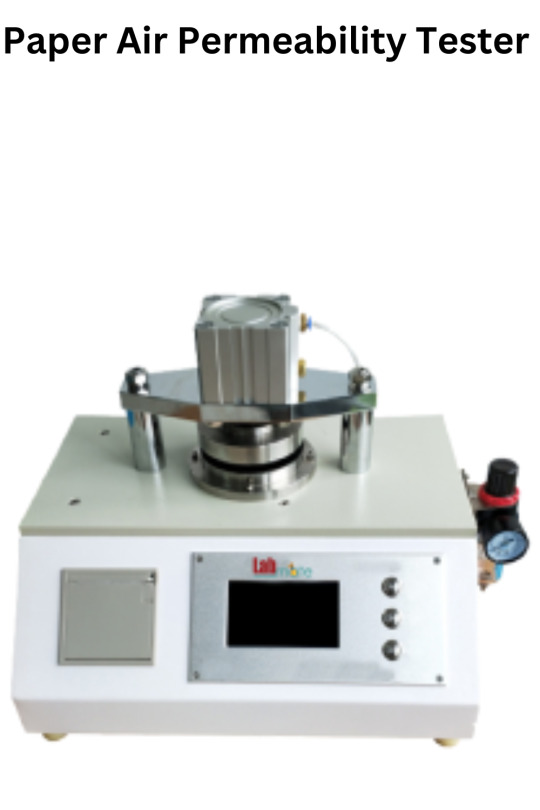

Paper Air Permeability Tester 28Kg

Paper air permeability tester is a microcomputer controlled unit used to determine the air permeability of flat materials with various measuring areas (5 cm2, 20 cm2, and 10 cm2). Features include a measurement range of 0–200 Pa/cm2 and a pressure difference range of 0–2 KPa.

0 notes

Text

Pet Preform Testing Instruments | Perfect Group

Perfect Group's Pet Preform Testing Instruments guarantee excellence throughout the whole pet preform production process. Using modern technology, we carefully inspect pet preforms to ensure we meet worldwide standards for quality, consistency, and durability. We ensure accurate results through precision engineering and innovative technology, enabling manufacturers to provide our customers with excellent products. For complete pet preform testing solutions that can boost productivity, dependability, and confidence in your production operations, turn to Perfect Group.

0 notes

Text

Crockmeter Measure Color Fastness

The Crockmeter (DigiCrock) measures the amount of colour transferred by rubbing from textile materials (such as cloth, carpets, yarn, and leather) to other surfaces in a rapid and precise manner. On flat specimens, the Crockmeter has also been used to perform rub abrasion, scuff, and/or mar testing. It may also be used to evaluate the smudge and smear resistance of pictures generated by a printer or copier. Wet and dry testing can be done on any specimen material...

#digicrock#crockmeter#crockmaster#rubbingfastness#textiles#textileindustry#TestingEquipments#testinginstruments

0 notes

Photo

Introducing Testing QC systems for Non-Woven Products in the Hygiene Industry. Get your quote today for a complete Lab Set up - https://www.flexitest.in/textiles

Call Now - 8291971983 or email us at - [email protected]

0 notes

Photo

https://drive.google.com/file/d/1wyRgcPHdLTnT1APG_wFfac1spN7tIYfx/view?usp=drivesdk #mxrady #scientific #laboratory #architect #watertesting #testinginstruments #airquality #airpurifier #airpurifiers #industrial https://www.instagram.com/p/BtqRSMjlzib/?utm_source=ig_tumblr_share&igshid=1xoomx0mbf36k

#mxrady#scientific#laboratory#architect#watertesting#testinginstruments#airquality#airpurifier#airpurifiers#industrial

0 notes

Text

Reliable Benchtop Hardness Testers for Accurate Quality Control

Looking for high-quality benchtop hardness testers in the USA? At Testron Group, we offer precise and durable testing equipment designed to meet your quality control needs across various industries. Explore our range of benchtop hardness testers to ensure your materials meet the required standards.

#BenchtopHardnessTester#HardnessTestingEquipment#MaterialTesting#QualityControlSolutions#TestingInstruments

0 notes

Text

🎉 Limited Time Offer from Pacorr! 🎉

Get ready to boost your corrosion testing game! Buy a Salt Spray Chamber from Pacorr and get a FREE Air Compressor with it! 💨✨

✔ High-quality corrosion testing ✔ Trusted performance ✔ Complimentary air compressor to complete your setup

📞 Don’t miss out on this amazing deal — limited stock available! 📩 DM us or call us now to book your unit!

#Pacorr#SaltSprayChamber#FreeOffer#CorrosionTesting#LabTestingEquipment#TestingInstruments#LimitedTimeDeal

0 notes

Text

Peel Bond Strength Tester

A Peel Bond Strength Tester is a laboratory instrument used to measure the adhesive force required to separate two bonded materials. It is commonly used in industries such as packaging, automotive, construction, and electronics to evaluate the quality of adhesives, tapes, and laminates.

Key components:

Load cell: Measures the applied force

Clamps: Hold the test specimen securely

Drive mechanism: Controls the peeling speed

Applications:

Testing adhesive tapes

Evaluating laminates

Assessing coatings

Quality control in manufacturing

By determining the peel strength, manufacturers can ensure product reliability and performance.

Visit Here:- Octagon Solutions

#PeelBondTester#AdhesiveTesting#QualityControl#MaterialScience#TestingEquipment#PrecisionTesting#BondStrength#IndustrialTools#AdhesivePerformance#LaboratoryEquipment#TestingSolutions#AdhesiveEvaluation#EngineeringTools#QualityAssurance#ResearchAndDevelopment#TestingLab#MaterialTesting#ManufacturingTools#TechnicalTesting#AdhesiveBond#TestingInstruments#PrecisionInstruments#ScientificTesting#InnovationInTesting#TestingTech

0 notes

Photo

Get top brands of Testing & Measuring Instruments like Crown, Fluke, HTC, Meco etc. from GoodsInStock with free shipping in India. please visit @ https://goo.gl/4bMfuA

0 notes