#egbc

Text

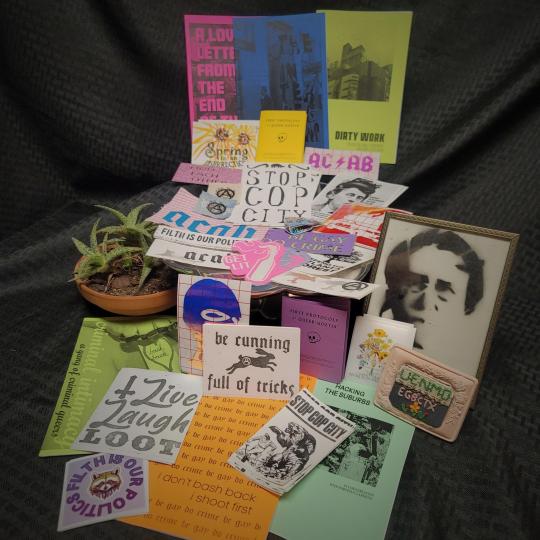

We don't charge for the stuff we give out. If anyone wants to help with printing costs for the Houston Anarchist Bookfair (hosted by @SpaceCityAO & @screwstonafc (on IG)),we'll send you a package as a thank you. Send us the address you want it mailed to.

Cash app $ EGBCTX

Venmo @ EGBCTX

#dfw#texas#anarchism#communism#egbc#Houston#dtx#htx#anarchist book fair#Houston anarchist Book fair#Houston anarchist bookfair#zines#distro

9 notes

·

View notes

Text

#NPPE#NPPEexam#ExamPrep#PEng#PGeo#Engineer#Engineering#Geoscience#Geoscientist#EIT#GIT#EngineersCanada#GeoscientistsCanada#EGBC#APEGA#APEGS#EGM#PEO#APGO#OIQ#OGQ#APEGNB#EngineersNovaScotia#GeoscientistsNovaScotia#EngineersPEI#PENGNL#EngineersYukon#NAPEG#ProfessionalPracticeExamination#explore

3 notes

·

View notes

Photo

INTERNATIONAL WOMEN IN ENGINEERING DAY #engineering #egbc #inwed20 #ThisIsOurProfession https://www.instagram.com/p/CByVex7gA2r/?igshid=1qkvwogmnvqw8

0 notes

Photo

Thank you so much for Gem @tiny-tany-thaanos. She made the BC more interesting, since she managed to overtake Jazmine once. Her ending relationship score is 45.29.

18 notes

·

View notes

Photo

(EGBC) When you're too much hungry by DarkPlayerFerraz269

10 notes

·

View notes

Photo

📝 #Invitación | FIESTA DE MARÍA AUXILIADORA ¡QUE BUENO CAMINAR CONTIGO EN FAMILIA! 📆 Lunes 24-Mayo Santa Eucaristía | ⌚ 07:00 p.m. 📲 Puedes seguir la transmisión en vivo por: • Canal de YOUTUBE: https://www.youtube.com/channel/UC7yiChWyUXfNEFn6h4UwccA?sub_confirmation=1 Santo Rosario | ⌚ 08:00 p.m. Para unirte a la reunión en Google Meet (al ingresar a la plataforma apaga micrófono y vídeo) haz clic en este enlace: https://meet.google.com/bzb-egbc-pne @cemaamigosconjesusymaria Compártelo para que el reino de los cielos llegue a más almas #NovenaaMaríaAuxiliadora #LíoEnLasRedes #YoRezoElRosario #TotusTuus #LíoEnLasRedes #DiosMeAmaFM #VirgenMaría #AJesusPorMaria #CarloAcutis #BeatoCarloAcutis #CenáculoMarianoAmigosconJesúsyMaría #Cenáculo #Mariano #AmigosconJesúsyMaría https://www.instagram.com/p/CPPYtZCDbUh/?utm_medium=tumblr

#invitación#novenaamaríaauxiliadora#líoenlasredes#yorezoelrosario#totustuus#diosmeamafm#virgenmaría#ajesuspormaria#carloacutis#beatocarloacutis#cenáculomarianoamigosconjesúsymaría#cenáculo#mariano#amigosconjesúsymaría

0 notes

Link

CAESAR II Pipe Stress Analysis Company

If you’re looking for a "pipe stress analysis services company" or "piping stress engineer" with exceptional expertise in piping stress analysis and design of infrastructure for Oil & Gas projects, look no further. Little P.Eng. for Engineering Services is the best company across Canada.

Little P.Eng. Engineering is a growing engineering consultant services company servicing the oil & gas and petroleum industries. Little P.Eng. Engineering has excelled in providing its clients with multi-disciplined professional engineering services, ranging from conceptual design through to project implementation. Little P.Eng. Engineering specializes in the design of gas plants, compression facilities, pump stations, metering stations, liquid storage facilities, and pipeline laterals. By building relationships, driving results and serving every client’s needs, we are changing the face of engineering.

We had created and enhanced approaches to pipe stress problems as well as contribute to piping design and materials selection. Our pride in providing technical support and expertise in all matters relating to pipe stress analysis will be always our motive in serving our clients.

Our typical Pipe Stress Analysis Responsibilities:

· Prepares and reviews project P&IDs, LDT, and MSD.

· Manages procurement cycle for piping related items – pipes, fittings, valves, specialty components.

· Performs and checks piping stress analysis and calculations in accordance with B31.3 and CSA Z662 and other design codes and standards using CEASAR II

· Prepares and reviews project specific Stress Analysis Criteria

· Establishes and provides input into project design specifications, piping design reviews, drawings and isometrics

· Prepares, reviews and contributes to Pipe Stress studies, stress reports, pipe support load calculations, and specialty item data sheets

· Coordinates with Piping and Civil/Structural disciplines for the selection of piping / structural supports and input into piping drawings and isometrics

· Conducts document checks and design verification in accordance with company and project procedures

· Works closely with design engineers and designers to initiate, analyze and resolve pipe stress issues

· Professionally seals all applicable documents

Our Piping Stress Engineers Skills and Qualifications:

· B.Sc. in Mechanical / Structural Engineering

· Registered as a Professional Engineer (P. Eng) with EGBC, APEGA, APEGS, and PEO

· With at least 10 years of experience in Pipe Stress Analysis

· Experts in piping stress analysis, with CAESAR II

· Knowledge in ASME B31.3 and CSA Z662 Design codes

· Demonstrated success working within specified budgets and schedules and meeting project requirements

· Demonstrated knowledge of piping design requirements, piping materials and components, practices and standards as well as piping specifications

Little P.Eng. for Engineering Services proudly presents its Licensed Professional Canadian Piping Stress Engineers; Located in Calgary Alberta, we serve our clients across Canada. Our professional piping stress engineers have a bachelor's degree in mechanical / structural engineering and province licence (P.Eng.) in Alberta, Saskatchewan, British Columbia and Ontario. We review, validate, certify and stamp piping and structural packages.

Tags:

· Pipe Stress Analysis Services

· CAESAR II

· Engineering Company

· Piping Engineering Company

· Structural Engineering Company

· Engineering Firm

· Piping Engineering Firm

· Structural Engineering Firm

· Canada

· Alberta

· Ontario

· Saskatchewan

· British Columbia

· Piping Engineer

· Piping Stress Engineer

· Structural Engineer

· Meena Rezkallah

· Pipe Stress Analysis Company

· Pipe Stress Analysis Firm

· Engineering Consultant

· Pipeline Engineering Company

· Pipeline Engineering Firm

· Saudi Arabia

· United Arab Emirates

· Oman

· TEXAS

· Calgary

· Vancouver

· Toronto

· Engineering Services

· •

· Piping Stress Analysis

· •

· Pipe Stress Analysis Services

38 views

Engineering Consulting Services Alberta

Engineering Consulting Services British Columbia

Engineering Consulting Services Saskatchewan

Engineering Consulting Services Ontario

Engineering Consulting Services Middle East (Arabian Gulf)

Engineering Services

CAESAR II Pipe Stress Analysis Company

#piping_engineering_services #piping_engineering_consultant #piping_skid_design #piping_stress_analysis #piping_engineering_firm #piping_engineering_company #asme #engineeringservices #engineering #engineers #engineer #engineering_services #engineering_firm #engineering_company #engineering_consultant #pipe_stress_analysis #pipes #calgary #meena_rezkallah #pipe_stress_engineer #piping_stress_engineer #pipe_stress_analysis_services #edmonton #pipe_stress_analysis_company #ontario #pipe_stress_analysis_firm #piping_standards #CAESAR_II #pipingengineer #pipingstressengineer #BC #Vancouver #British_Columbia #toronto #fortmcmurray #saskatchewan #skid_design #jobs #engineering_consultant #Engineering_Company #Piping_Engineering_Company #Structural_Engineering_Company #Engineering_Firm #Piping_Engineering_Firm #Structural_Engineering_Firm #Canada #Alberta #Ontario #Saskatchewan #British_Columbia #Piping_Engineer #Piping_Stress_Engineer #Structural_Engineer #Meena_Rezkallah #Pipe_Stress_Analysis_Company #Pipe_Stress_Analysis_Firm #Pipeline_Engineering_Company #Pipeline_Engineering_Firm #Saudi_Arabia #United_Arab_Emirates #Oman #Qatar #Kuwait #Dubai #ABU_DHABI #Texas #Houston

0 notes

Text

Manager, Welding Engineering & Quality Control

Summary of Responsibilities

The Manager, Welding Engineering and Quality Control is responsible for ensuring all welding performed is in accordance with the standards specified. This includes the planning of quality control, execution of quality control and subsequent applicable re-work strategies. The Manager also oversees all welding engineering activities in support of vessel repair and construction activities at Victoria Shipyards Ltd (VSL). This includes Naval vessel’s (surface and submarines), Coast Guard, BC Ferries and commercial operators. This position oversees the development, certification and maintenance of all weld procedures at VSL. The Manager also provides technical guidance for joint designs, welding rates, distortion control, equipment evaluations, and weld quality to various VSL departments. The position analyzes actual welding rates and works with production personnel to improve weld quality and productivity. The position is the primary interface with the Canadian Welding Bureau and regulatory bodies for issues related to welding and/or weld quality.

Functional Reporting Relationship

The Manager, Welding Engineering and Quality Control directly reports to the Manager, Welding Engineering & Welding QC (Seaspan Shipyards) and indirectly to the Director of Operations (VSL). The Manager has two direct reports in the form of Supervisor, Welding Quality Control and Welding Technologist. This position provides leadership and direction for 5 staff and 3 union positions. The manager is required to operate in a matrix organization providing Welding QC and technical guidance to production trades, Trade Leads, Project Managers and Zone Managers.

Scope and Complexity

Scope encompasses the management of all welding QC and welding engineering activities at VSL. The primary responsibility is to manage the development, certification, implementation and monitoring of weld procedures and associated quality control for structural and piping systems. The role requires interface with several other departments to ensure joint designs are correctly defined, welding equipment is procured and/or utilized that meets VSL’s requirements, weld performance is measured and improved, and work is completed in accordance with contract specifications and VSL quality standards.

This role is complex due to the technical nature of welding procedure certification processes. The Manager must possess an in-depth knowledge of material properties and associated weld procedures. The position requires a sound understanding of shipbuilding weld quality, defect repair strategies along with a strong understanding of ship repair production rates. The role also requires sound communication skills to support interaction with customer representatives, CWB (Canadian Welding Bureau) personnel, regulatory bodies, statutory agencies and internal departments.

Communications

Internal

The role of Manager, Welding Engineering and Quality Control requires significant internal communication. The Manager communicates extensively with trade superintendents, production managers, zone/area managers and project managers to ensure that desired weld procedures are certified, and the most productive procedures are employed in production. The position ensures that a robust quality control program is in place complete with metrics. In addition the Manager ensures that sound rework strategies are developed and implemented for raising standards of workmanship. The Manager works with other departments such as the Technical Department to define joint designs and to ensure vessel repair strategies reflect high quality and productive weld procedures. The position provides technical guidance on weld production set up and quality control. In addition the position works with other Seaspan shipyard stakeholders to increase efficiencies, align procedures and develop trade skills. The position also works with Supply Chain Management personnel to define and recommend welding equipment for procurement.

External

The Manager, Welding Engineering and Quality Control is responsible for communicating extensively with the CWB, regulatory bodies, applicable statutory agencies, and customers concerning weld procedure certifications and quality issues. The position requires communication with suppliers of welding equipment and filler materials to assess suitability for VSL and to provide recommendations for procurement. The Manager works with external testing labs to process weld test specimens and interpret results. The position also requires bench-marking best practices through visits to other shipyards and attendance at welding conferences and symposiums. The position also communicates with team members and subcontractors to monitor and assist in improving weld quality.

Duties/Accountabilities

Develop and certify new welding procedures for VSL as required to improve welding quality, productivity and contract requirements

Supervise and provide guidance on the preparation of welding procedure specifications and procedure data sheets for related procedures

Supervise and provide guidance on the development of procedure qualification records to record variables during welding of test assemblies

Supervise and/or perform periodic reviews of VSL’s welding practices in accordance with Canadian Standards Association W 47.1 requirements

Supervise the monitoring of shipyard weld quality. Inform trades and area management of quality issues and work with them to resolve work not in accordance with standards, specifications and contract requirements

Supervise the continuous review of VSL’s welding procedures. Implement improvements in processes and materials to improve both quality and productivity

Provide guidance to the Technical Department for joint designs of structural and piping systems and guidance/direction regarding proper weld sequencing to reduce distortion and improve accuracy

Act as VSL’s primary interface with CWB and regulatory bodies

Act as primary interface with VSL’s retained welding engineers

Monitor and report shipyard welding performance by collecting and analysing data on actual labour hours, arc times, consumable usage and other pertinent variables

Evaluate welding equipment and filler materials for suitability at VSL. Document findings and provide recommendations to Supply Chain Management for procurement

Monitor trends in the industry and implement welding best practices

Resolve production welding issues. Support initiatives to improve productivity, reduce rework and improve quality across all shipyards

Position Specifications

Education and Experience

A bachelor’s degree in Welding Engineering or Metallurgy.

Minimum 7 years of direct experience as a welding engineer in a large manufacturing environment, preferably in the shipbuilding/ship repair industry.

Minimum 5 years of supervison/management experience

A Professional Engineer (P.Eng.) registered or qualified to register with EGBC.

Current valid CWB CSA W178.2 level 2 Welding Inspector Certification (or international equivalent such as AWS CWI)

CWB Approved Welding Engineer is preferred.

Skills, Knowledge and Required Competencies

Extensive knowledge of welding processes: shielded metal arc welding (SMAW), flux cored arc welding (FCAW), metal cored arc welding (MCAW), gas metal arc welding (GMAW), submerged arc welding (SAW), gas tungsten arc welding (GTAW), and stud welding

Extensive knowledge of welding metallurgy, CSA, ABS, Lloyd’s, DNV-GL and other regulatory requirements related to welding and fabrication in the marine industry

Extensive knowledge of non-destructive weld test processes and procedures including, but not limited to, visual, radiographic, ultrasonic, die penetrant and mag particle

Demonstrated competence in evaluating weld test specimens including bend tests, macro-etch specimens, tensile tests, Charpy V-notch, etc.

Strong leadership skills

Ability to work effectively in a matrix organization that supports several different trades and areas of the shipyard

Strong knowledge of shipbuilding construction methods and procedures

Familiarity with ship systems including structural, mechanical, piping, electrical and coatings

Strong technical capability to read and interpret complex specifications and detailed engineering drawings

Strong problem solving skills, analytical abilities and interpersonal skills

Strong customer service focus

Demonstrated initiative, creativity and integrity

Excellent communication skills both written and verbal

Strong organizational skills

Excellent computer skills including Word/Excel/PowerPoint

Demonstrated ability to multi-task, prioritize and problem solve

Good judgment and reasoning skills

Ability to work with limited direction and to function as a key team member

Ability to obtain Industrial Security – NATO Secret designation

0 notes

Text

0 notes

Text

Come by Deep Vellum Books tonight!

6 notes

·

View notes

Photo

Received the title of EIT ✌️ Grateful to all the people who helped me get here. Would strive my best to be worthy of these titiles. Will be applying for the mentoring program 🙂 @EngGeoBC #egbc #engineer #sfu #gndec https://www.instagram.com/p/CBmNP8PgYEAQ-GiGssCSEqT_55L-VF-mbNhk2o0/?igshid=f7a0wim3p300

0 notes

Photo

Thank you so much for Kit @starburstshores. She was a fun sim to have in my game. Her ending relationship score is 42.28.

16 notes

·

View notes

Photo

Egbc - Uae - Dubai http://expomahal.com/egbc-uae-dubai/ http://expomahal.com

0 notes

Link

Meena Rezkallah, P.Eng.

Jul 27

2 min read

CAESAR II Pipe Stress Analysis Company

Updated: Nov 20

If you’re looking for a "pipe stress analysis services company" or "piping stress engineer" with exceptional expertise in piping stress analysis and design of infrastructure for Oil & Gas projects, look no further. Little P.Eng. for Engineering Services is the best company across Canada.

Little P.Eng. Engineering is a growing engineering consultant services company servicing the oil & gas and petroleum industries. Little P.Eng. Engineering has excelled in providing its clients with multi-disciplined professional engineering services, ranging from conceptual design through to project implementation. Little P.Eng. Engineering specializes in the design of gas plants, compression facilities, pump stations, metering stations, liquid storage facilities, and pipeline laterals. By building relationships, driving results and serving every client’s needs, we are changing the face of engineering.

We had created and enhanced approaches to pipe stress problems as well as contribute to piping design and materials selection. Our pride in providing technical support and expertise in all matters relating to pipe stress analysis will be always our motive in serving our clients.

Our typical Pipe Stress Analysis Responsibilities:

Prepares and reviews project P&IDs, LDT, and MSD.

Manages procurement cycle for piping related items – pipes, fittings, valves, specialty components.

Performs and checks piping stress analysis and calculations in accordance with B31.3 and CSA Z662 and other design codes and standards using CEASAR II

Prepares and reviews project specific Stress Analysis Criteria

Establishes and provides input into project design specifications, piping design reviews, drawings and isometrics

Prepares, reviews and contributes to Pipe Stress studies, stress reports, pipe support load calculations, and specialty item data sheets

Coordinates with Piping and Civil/Structural disciplines for the selection of piping / structural supports and input into piping drawings and isometrics

Conducts document checks and design verification in accordance with company and project procedures

Works closely with design engineers and designers to initiate, analyze and resolve pipe stress issues

Professionally seals all applicable documents

Our Piping Stress Engineers Skills and Qualifications:

B.Sc. in Mechanical / Structural Engineering

Registered as a Professional Engineer (P. Eng) with EGBC, APEGA, APEGS, and PEO

With at least 10 years of experience in Pipe Stress Analysis

Experts in piping stress analysis, with CAESAR II

Knowledge in ASME B31.3 and CSA Z662 Design codes

Demonstrated success working within specified budgets and schedules and meeting project requirements

Demonstrated knowledge of piping design requirements, piping materials and components, practices and standards as well as piping specifications

Little P.Eng. for Engineering Services proudly presents its Licensed Professional Canadian Piping Stress Engineers; Located in Calgary Alberta, we serve our clients across Canada. Our professional piping stress engineers have a bachelor's degree in mechanical / structural engineering and province licence (P.Eng.) in Alberta, Saskatchewan, British Columbia and Ontario. We review, validate, certify and stamp piping and structural packages.

Tags:

Pipe Stress Analysis Services

CAESAR II

Engineering Company

Piping Engineering Company

Structural Engineering Company

Engineering Firm

Piping Engineering Firm

Structural Engineering Firm

Canada

Alberta

Ontario

Saskatchewan

British Columbia

Piping Engineer

Piping Stress Engineer

Structural Engineer

Meena Rezkallah

Pipe Stress Analysis Company

Pipe Stress Analysis Firm

Engineering Consultant

Pipeline Engineering Company

Pipeline Engineering Firm

Saudi Arabia

United Arab Emirates

Oman

TEXAS

Calgary

Vancouver

Toronto

Engineering Services

•

Piping Stress Analysis

32 views

Engineering Consulting Services Alberta

Engineering Consulting Services British Columbia

Engineering Consulting Services Saskatchewan

Engineering Consulting Services Ontario

Engineering Consulting Services Middle East (Arabian Gulf)

Engineering Services

LITTLE P.ENG. FOR ENGINEERS TRAINING / Engineering Consultant

Home

Piping Stress Analysis Training Course

ASME B31.3 Training Course

Engineering services Firm

Canada Engineering Company

Piping Stress Engineers

Engineering Services Vancouver, BC

Engineering Services Toronto, ON

Engineering Services Saskatchewan

Industries We Serve

Little P.Eng. Blog

About Us

Contact Us

Latest Shares

FAQ

Google Little P.Eng.

3705 Fonda Way #18 Southeast Calgary, T2A 6G9

Canada

+1 (587) 802-4050

Stay Connected

ASME Course | Caesar II Training | ASME B31.3 Training | ASME Training | Caesar II Course | ASME B31.3 Course

Engineering Company | Piping Engineering Company | Engineering Firm | Piping Engineering Firm | Apega Registered Company

0 notes

Link

Dubai, UAE: A white paper on the sustainability of schools in the UAE will soon be released by the Emirates Green Building Council (EGBC). Two weeks ago, a roundtable was held by EGBC in the presence of the school and environmental leaders, to discuss what it really means for a school to be 'green'. Charles Blaschke, managing director of Taka Solutions (the corporate partner of EGBC), said that "being green" is not limited to saving energy. There are many other factors that play a role, including the elimination of noise pollution, usage of LED lights, ensuring clean air quality, which are some among the many. "Somebody might raise their hand and say that they own a school and think it's green because they don't spend a lot of energy. But if you look at the definition, it's not just about energy, it's about the comfort and air quality at the heart of the community and the education programmed around it," Blaschke said. "If you look through the lens of what we've defined today as green schools, I'd say there are only very few green schools. And, if we know there are 1,200 schools operating, that means the opportunity to make schools green is immense." Khaleej Times reached out to a few schools and queried how they were making their schools green - everything they were doing from sustainable lighting, reducing noise pollution around/inside the school and teaching kids about sustainability. Most of the schools that responded only highlighted how they were teaching their students to be sustainable with various eco-friendly projects. However, some also mentioned how they were making their facilities green, as well as teaching their students the importance of sustainability. Rebecca Garnett, a teacher at GEMS Wellington Primary School and Eco Champion, said: "We thrive when we work as a team. We work together towards the UAE's 2021 vision of becoming an increasingly environmentally friendly country. "Our green initiatives, such as taking part in 'The Living Rainforest' competition, are led and championed by our elected Eco Warriors. But it isn't just competitions that keep us motivated to reuse, reduce and recycle. "I love watering the plants on our wall garden," said one of the Year 3 Eco Warriors, whereas Year 2's favourite part of the week is finding out which class is awarded the much coveted weekly 'Environment Award'. "Even earlier today, meetings were taking place to prepare for the launch of 'Simply bottles schools' which will help provide feedstock for the world's first bottle-to-yarn recycling facility in the UAE. At GEMS Wellington Primary School our uniform may be blue but rest assured our actions are always green." At the Our Own English High School (Sharjah Girls'), the students have an eco club, called Eva Green, which aims "at inculcating green values in children through sound environmental behaviour". The club carries out activities and campaigns throughout the year to spread environmental awareness. The KG department of the school has grown their own vegetable patch at the school - an initiative that was conducted to help the children learn about the need to grow plants and help save the environment. Students at the school have also created a garden by recycling old tyres and sowing plants into it. They created a vertical garden using recycled plastic bottles and the primary children inserted 500ml water bottles in the flush tanks to reduce the wastage of water. "Eva Green plays an integral part in highlighting the importance of biodiversity, conservation and local environmental issues among the school children. It thus helps to extend boundaries and scope of the formal educational system by encouraging creativity and improving student's awareness to take constructive action for a sustainable living environment," said Mini Jayapalan, one of the eco-coordinators at the school. © Khaleej Times via Edarabia.com

0 notes