#fibc / bulk bag

Text

What's New and Innovative in FIBC Bulk Bags? Smart Features You Need to Know

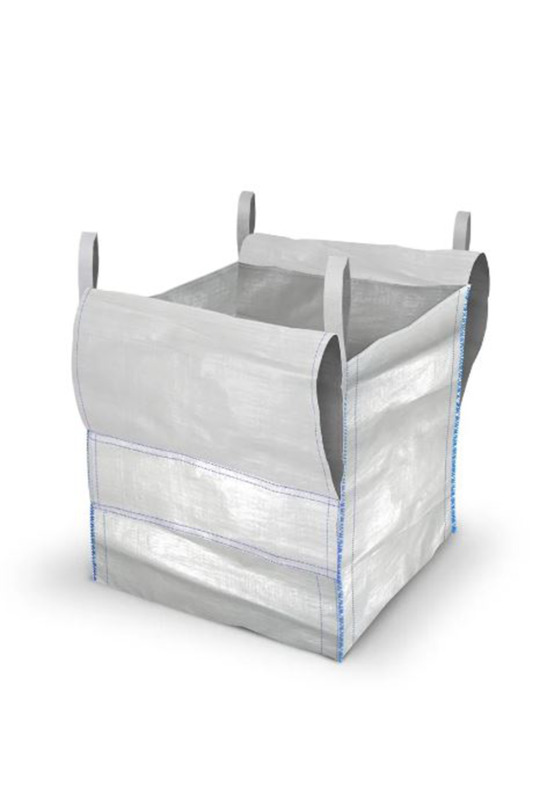

FIBC bulk bags, also known as Flexible Intermediate Bulk Containers or jumbo bags, have been a staple in the transportation and storage of various goods for decades. These large, flexible bags offer a convenient and cost-effective solution for handling bulk materials such as grains, powders, and chemicals. Over the years, advancements in technology have led to the development of smarter and more efficient FIBC bags, incorporating innovative features to improve functionality, safety, and sustainability.

1. Introduction to FIBC Bulk Bags

FIBC bulk bags are large containers made from flexible materials such as woven polypropylene fabric. They are commonly used for transporting and storing dry, flowable products in industries ranging from agriculture to pharmaceuticals. These bags typically feature lifting loops or straps for easy handling with forklifts or cranes.

2. Evolution of FIBC Bags

The evolution of FIBC bags has been driven by the need for improved efficiency and safety in handling bulk materials. Traditional FIBC bags were simple in design, offering basic functionality without many additional features. However, as industries have evolved and demand for more specialized solutions has grown, manufacturers have introduced innovative features to meet these needs.

3. Smart Features Revolutionizing FIBC Bulk Bags

Embedded Sensors for Tracking

One of the most significant advancements in FIBC technology is the integration of embedded sensors for tracking and monitoring. These sensors can provide real-time data on factors such as temperature, humidity, and location, allowing companies to track their products throughout the supply chain and ensure optimal storage conditions.

Anti-static Properties

In industries where static electricity poses a risk, such as the chemical and pharmaceutical sectors, FIBC bags with anti-static properties are essential. These bags are specially designed to dissipate static charges safely, reducing the risk of fire or explosion during handling and transportation.

Barrier Films for Moisture Control

Moisture can be a significant concern when transporting hygroscopic materials such as grains or powders. To address this issue, manufacturers have developed FIBC bags with barrier films that provide enhanced moisture control, keeping the contents dry and free from contamination.

Ventilated Designs for Airflow

In applications where airflow is critical, such as the storage of agricultural products, ventilated FIBC bags are highly beneficial. These bags feature strategically placed vents or mesh panels that allow air to circulate freely, preventing the buildup of heat and moisture that can lead to spoilage.

4. Sustainability Initiatives in FIBC Manufacturing

As environmental concerns become increasingly important, manufacturers are focusing on sustainability initiatives in FIBC production. This includes using recyclable materials, reducing packaging waste, and implementing eco-friendly manufacturing processes.

Recyclable Materials

Many modern FIBC bags are made from recyclable materials such as polypropylene, which can be melted down and repurposed into new products at the end of their lifecycle. This helps to reduce the environmental impact of FIBC production and disposal.

Reduction in Packaging Waste

By optimizing designs and materials, manufacturers can reduce the amount of packaging waste generated during the production and use of FIBC bags. This includes minimizing excess material and using efficient manufacturing techniques to produce bags with minimal waste.

5. Innovations in Design and Durability

In addition to smart features, innovations in design and durability have also contributed to the advancement of FIBC technology. These improvements enhance the strength, longevity, and usability of FIBC bags in various applications.

Reinforced Seams and Lift Loops

To withstand the rigors of transportation and handling, modern FIBC bags often feature reinforced seams and lift loops. These reinforced areas help to distribute weight evenly and prevent tearing or breakage during use.

UV Protection Coatings

Exposure to sunlight can cause degradation of FIBC materials over time, reducing their strength and integrity. UV protection coatings help to mitigate this issue by shielding the bags from harmful UV rays, prolonging their lifespan and preserving the quality of the contents.

6. Customization Options for FIBC Bulk Bags

Another key trend in FIBC technology is the availability of customization options to meet the specific needs of different industries and applications.

Size and Capacity Variations

FIBC bags come in a wide range of sizes and capacities, allowing companies to choose the most suitable option for their products. Whether transporting small batches of specialty chemicals or large quantities of agricultural commodities, there is an FIBC size to fit every need.

Printing and Labeling Choices

Custom printing and labeling options enable companies to brand their FIBC bags with logos, product information, and handling instructions. This not only enhances brand visibility but also provides valuable information to end-users, ensuring safe and efficient handling of the contents.

7. Compliance and Safety Standards

Compliance with regulatory requirements and safety standards is paramount in the production and use of FIBC bags to ensure the protection of both people and products.

Regulatory Requirements

FIBC manufacturers must adhere to various regulations and standards set forth by government agencies and industry organizations. These regulations cover aspects such as design, construction, labeling, and testing to ensure the safe transport and storage of bulk materials.

Testing Procedures

Quality control and testing procedures are integral to the production of FIBC bags, ensuring that they meet the required standards for strength, durability, and safety. Common tests include load testing, top lift testing, drop testing, and electrostatic testing to assess the performance of the bags under various conditions.

8. Applications Across Industries

FIBC bulk bags are widely used across a diverse range of industries for the transportation and storage of various materials.

Agriculture and Farming

In agriculture, FIBC bags are commonly used for storing and transporting crops such as grains, seeds, and fertilizers. Their large capacity and durable construction make them ideal for bulk handling in agricultural operations.

Chemical and Pharmaceutical

The chemical and pharmaceutical industries rely on FIBC bags for the safe and efficient transport of raw materials, intermediates, and finished products. Specialty bags with features such as anti-static properties and barrier films are often used to meet specific industry requirements.

Construction and Mining

In construction and mining applications, FIBC bags are used for transporting aggregates, sand, gravel, and other bulk materials to remote job sites. Their versatility and portability make them an essential tool for construction crews and mining operations.

9. Cost-efficiency and Economic Benefits

One of the primary advantages of FIBC bulk bags is their cost-efficiency and economic benefits compared to traditional packaging methods.

10. Future Trends in FIBC Technology

As technology continues to advance, we can expect to see further innovations in FIBC technology, with a focus on enhancing functionality, sustainability, and efficiency.

11. Conclusion

In conclusion, the latest innovations in FIBC bulk bags are revolutionizing the way we transport and store bulk materials. From embedded sensors for tracking and monitoring to advanced designs for durability and sustainability, these smart features are reshaping the industry and providing companies with safer, more efficient solutions for their packaging needs.

FAQs

Are FIBC bulk bags suitable for food-grade applications? Yes, there are food-grade FIBC bags available that meet strict hygiene and safety standards for transporting food products.

How do I determine the right size and capacity of FIBC bags for my needs? Factors such as the type of material, desired fill weight, and storage space available should be considered when selecting the size and capacity of FIBC bags.

Are FIBC bags reusable Yes, many FIBC bags are designed for multiple uses, provided they are properly maintained and inspected for damage between uses.

Can FIBC bags be customized with company logos or branding Yes, most FIBC manufacturers offer custom printing and labeling options to personalize bags with logos, product information, and handling instructions..

1 note

·

View note

Text

Things you need to know about Type A FIBC bulk bags

If your traditional bulk packing products have been costing you quite a lot of money, it is time to shift to the FIBC bulk bags. This sturdier and much more cost effective alternative will be a great addition to your business. ��

In case you need to store or transport agricultural products, grains or constructional materials and you do not know which FIBC will be appropriate for you, we would suggest the Type A FIBC bags or bulk bags.

The reasons behind this suggestion have been presented below:

The FIBC fabric

The basic fabric that is used for making the Type A bulk bags is woven polypropylene. This material is used as key component in almost every type of bulk bag. The major advantage of this polypropylene FIBC fabric is that it is completely eco-friendly. Hence, the production of this polypropylene fabric does not cause any environmental concern.

However, as the fabric of this Type A bulk bags do not offer any anti-static ability so static energy can be produced when goods stored in them rub against the inner part of these bags during their filling or emptying.

Labeling details

Generally, the Type A bulk bags do not come with any label comprising of detailed instructions on their usage. The reason behind this is, these bags are meant for carrying non-conductive materials only. So, no additional care is required for grounding them, or storing and transporting them.

Products stored

As already mentioned, the Type A bags are capable of storing and transporting non-conductive products. Thus, they are perfect for carrying materials like agricultural products, food products, constructional materials, non-reactive chemical products, etc. These bulk bags are not at all suitable for carrying products that are highly reactive or flammable materials that can cause ignition when not handled with care.

In nutshell, these Type A bulk bags are designed to carry flammable goods that can cause combustion during their transportation or grounding.

Precautions followed

As such, there are no stern precautionary measures need to be followed when using Type A bulk bags. However, you have to ascertain that you are you are not planning to store any flammable goods inside these bags. Similarly, you are not supposed to unload or load these bulk bags in highly flammable environment.

So, you have to ensure that you will never expose this bulk bag with flammable contents in an atmosphere where there is a minimum ignition temperature of 1000 mJ.

2 notes

·

View notes

Text

https://fibcbigbags.com/fibc-dns/Understanding-the-functionality-of-Anti-Static-Bulk-Bags.php

It is extremely important to be perfectly aware of the types of FIBC and to know exactly which type of Bulk Bag will be required for what kind of product. The distinctive aspect of these FIBCs is that they are made from polypropylene which automatically makes them better packaging materials than conventional jute or cotton bags.

Coming to anti-static properties of packaging containers, FIBC has a certain type that offers this benefit. Read on to understand what exactly is meant by the anti-static feature and how do FIBCs help offer this property to your packaging needs.

#bulkmaterialhandling #polypropylene #packagingmaterial #packagingdesign

3 notes

·

View notes

Text

FIBC Bulk Bags Manufacturers in Australia

Get superior FIBC bulk bags produced in Australia. With strength and durability for storing and transporting a variety of commodities, our dependable bulk bags are made to satisfy your packing demands. We offer highly qualified FIBC solutions for a variety of applications, including construction and agriculture. Visit us: https://www.gpl.co.in/fibc_bulk_bags.html

#PP Woven Bags#Bulk Bag#FIBC#BOPP Bags#Bulk Bags#Woven Polypropylene Bags Suppliers#Jumbo Bags Manufacturer#Cement Bags Suppliers#FIBC Bulk Bags Manufacturers#BOPP Bags manufacturers#Box Bag manufacturer

0 notes

Text

Conical FIBC Bags

Alpine FIBC PVT.LTD. is a best manufacturer, exporters and suppliers of high quality Conical FIBC Bags in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. FIBCs (big bags/bulk bags) with a conical base are specially developed for poorly flowing products. The conical shape at the bottom of the bag ensures that the bulk bag can be discharged quickly and easily. By using this bulk bags, you can sometimes prevent expensive adjustments to discharging systems.

#Conical FIBC Bags#Conical FIBC Bags In India#Conical FIBC Bags manufacturer#Conical FIBC Bags Ahmedabad#big bags/bulk bags

1 note

·

View note

Text

Can FIBC Bulk Bags be Used Across Diverse Sectors?

Shankar Packaging Ltd. is a leading FIBC manufacturing company in India. We offer Benefits of FIBC Bags in Different Industries, Uses of FIBC Bulk Containers Across Different Industries, etc. & It is widely used in different industries for storing, packaging, and transportation applications. For more information read our blog!

#used in agriculture#FIBC jumbo bags manufacturer India#food processing industry#bulk containers#FIBC jumbo bags manufacturers in Gujarat#bulk bags used in the mining industry#construction sector#FIBC bags exporters

0 notes

Text

Jumbo Bags - Secure, cost-effective way to transport bulk materials | Rishi FIBC

Rishi FIBC offers high-quality jumbo bags, also known as FIBCs, for various industries. Our durable jumbo bags come in various sizes and configurations to perfectly suit your dry, free-flowing products. Visit our website to learn more!

Contact us today for a quote!

https://www.rishifibc.com/types-of-jumbo-bags/

0 notes

Text

What Are FIBC Bulk Bags?

When transporting or storing free-flowing materials, its packaging needs to be practical, easy to lift and maneuver with the ability to withstand movement whilst filled without damaging the materials they contain. Using poor quality, or the wrong type of bulk packing, can lead to the spillage of free-flowing materials. This highlights the importance of choosing the correct type of high-quality bulk packaging for the free-flowing materials you need to transport or store.

FIBC (Flexible Intermediate Bulk Container) bulk bags are industrial containers specially designed for transporting and storing free-flowing goods and materials. FIBC bulk bags can also be referred to as jumbo bags, big bags, super sacks, or even ton bags.

At Quick Pak Inc, we supply a full range of FIBC bulk bags including builder’s bags, food bags, anti-static bags, and UN-certified bags, single or multi trip.

FIBC Variations:

-Food Grade bulk bags

-Anti-static bulk bags

-Aggregate and Builders Merchants bulk bags

-Q-bags or baffle bulk bags

-Ventilated bulk bags

Whatever your bulk bag packaging requirements, we have the solution and product for you. Our bulk bags can be manufactured to match your specifications, filling spout, discharge spout, skirt top, open top, single or multi trip and with various lifting solutions.

Call us at 813 242 6995 or [email protected]

#stretch film pricing#pricing news#quickpakinc#stretch film#quick pak inc#coreless film#resin pricing#free pallet wrapper#youtube#free machine#fibc bulk bags#jumbo sacks#big sacks

0 notes

Text

Advantages of Food Grade FIBC Bags for Storing and Transporting Agricultural Products

The agricultural sector needs a sturdy and durable packing solution that is safe to keep and move a wide variety of agricultural goods. The FIBC big bag provides the best packaging solutions and is extremely reliable and safe from the effects of moisture and weather changes. For more information visit our website.

#FIBC big bag#FIBC Bulk bags#baffle bag FIBC#FIBC jumbo bags manufacturer in India.#FIBC bulk bag manufacturers

0 notes

Text

Crafting Excellence: The World of Customized FIBC Big Bags Manufacturers

Flexible Intermediate Bulk Containers (FIBC) big bags are essential for transporting and storing bulk materials in various industries. When standard options don't fit your needs, turning to customized FIBC big bags manufacturers is the solution. In this guide, we'll explore the realm of customized FIBC big bags and the manufacturers behind them.

Understanding Customized FIBC Big Bags

Customized FIBC big bags are tailored to meet specific requirements and preferences of customers. These bags are designed with unique features, sizes, capacities, and functionalities to address the diverse needs of different industries. Whether it's a specialized lifting mechanism, custom dimensions, printing, or additional safety features, customized FIBC big bags are crafted to optimize efficiency and convenience in material handling processes.

The Role of Manufacturers in Customization

Manufacturers specializing in customized FIBC big bags play a crucial role in fulfilling the unique demands of their clients. These manufacturers possess the expertise, technology, and flexibility to create bespoke solutions that meet the exact specifications of customers. From initial design consultation to production and quality control, customized FIBC big bags manufacturers work closely with their clients to deliver tailored packaging solutions that enhance efficiency and performance.

Benefits of Customization

Customized FIBC big bags offer several advantages over standard options:

Optimized Performance: Customized features such as specialized lifting mechanisms, liners, closures, and printing enhance the functionality and performance of FIBC big bags, ensuring optimal efficiency and safety in material handling processes.

Tailored to Specific Requirements: Customization allows FIBC big bags to be designed according to the unique requirements of different industries, materials, and applications. This ensures compatibility and suitability for specific tasks, environments, and logistics.

Brand Identity and Visibility: Custom printing options enable companies to showcase their branding, logos, and safety instructions on FIBC big bags, enhancing brand visibility and professionalism while improving safety and compliance.

Cost-Efficiency: Despite the additional customization, tailored FIBC big bags can offer cost-effective solutions by optimizing material usage, reducing waste, and improving operational efficiency.

Customized FIBC big bags manufacturers play a pivotal role in providing tailored packaging solutions that meet the specific needs and preferences of their clients. By leveraging their expertise and capabilities in customization, these manufacturers empower industries to enhance efficiency, safety, and performance in material handling processes. Whether it's optimizing logistics, improving brand visibility, or ensuring compliance with regulations, customized FIBC big bags offer a versatile and cost-effective solution for various industries and applications.

0 notes

Text

While bulk bags are used to transport a variety of goods from pharmaceuticals and grain to food and wood, one aspect of bulk bags that cannot be overlooked is the lining, which if used the right way can help your FIBCs last longer and prevent products from getting contaminated. Liners can either be inserted loosely into the bag or attached to the bag. Let’s take a look at the types of liners available.

Form-fit FIBC Liners

These polyethylene liners take the shape of the FIBC and make it easier to fill and discharge the product. These liners can be removed from the FIBC or left in.

3 notes

·

View notes

Text

FIBC: Revolutionizing Bulk Packaging for a Sustainable Future

In the realm of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs) have emerged as a revolutionary solution for transporting and storing a wide range of products, from granular materials to powders and chemicals. Also known as bulk bags, these versatile containers have transformed the logistics landscape, offering a combination of cost-efficiency, convenience, and sustainability that traditional packaging methods often struggle to match. In this article, we delve into the world of FIBCs, exploring their benefits, diverse applications, and contribution to a more sustainable future.

The Anatomy of FIBCs

FIBCs are large, flexible containers typically made from woven polypropylene fabric, a robust and durable material. These bags come in various sizes and shapes, ranging from simple open-top designs to more complex configurations with features like spouts, liners, and closures. The woven polypropylene fabric provides strength and resilience, allowing FIBCs to hold immense quantities of materials while still being lightweight and easy to handle.

The Benefits of FIBCs

1. Efficient Transportation and Storage: FIBCs are designed to optimize space utilization during transportation and storage. Their stackability and compactness help reduce the need for excessive packaging material, minimizing both shipping costs and environmental impact.

2. Versatility: FIBCs are versatile enough to accommodate a wide array of goods, from agricultural products like grains and seeds to industrial materials like chemicals and minerals. They can be customized to suit specific requirements, making them an ideal choice for various industries.

3. Environmental Benefits: FIBCs often result in lower carbon emissions due to reduced packaging waste and increased shipping efficiency. Additionally, as we'll discuss later, the push towards reusable and recyclable FIBCs aligns with sustainability goals.

4. Worker-Friendly: These bags are designed with ergonomic features, such as easy lifting loops and secure closures, making them more user-friendly for workers handling bulk materials.

Applications of FIBCs

1. Agriculture: FIBCs are extensively used for transporting and storing agricultural commodities like grains, seeds, fertilizers, and animal feed. Their ability to protect contents from moisture and pests is crucial in maintaining the quality of these products.

2. Chemicals and Pharmaceuticals: FIBCs offer a safe and efficient way to transport and store hazardous chemicals and pharmaceutical ingredients. The option to include liners ensures product integrity and minimizes contamination risks.

3. Construction and Mining: In industries like construction and mining, FIBCs facilitate the movement of heavy materials such as sand, gravel, and minerals. The bags' durability is vital for handling the demanding conditions of these sectors.

4. Food and Beverage: The food industry benefits from FIBCs for packaging bulk quantities of ingredients like sugar, flour, and powdered milk. Their hygienic design and protection against contamination make them an excellent choice for this sector.

Towards a Sustainable Future: Reusable and Recyclable FIBCs

The shift towards sustainability has prompted the development of reusable and recyclable FIBCs. Reusable FIBCs are designed to withstand multiple cycles of use, significantly reducing packaging waste. These bags are a responsible choice for industries that require frequent bulk transportation.

Recyclable FIBCs, on the other hand, are designed with materials that can be efficiently processed and reused in the production of new FIBCs or other plastic products. This approach helps close the loop on plastic waste and contributes to a circular economy.

Conclusion

Flexible Intermediate Bulk Containers have not only transformed the way we transport and store bulk materials but also demonstrated how innovation can align with sustainability. Their ability to optimize space, enhance logistics efficiency, and reduce environmental impact makes them an indispensable asset across various industries. As technology and environmental consciousness continue to shape the packaging landscape, FIBCs stand as a testament to the power of adaptable solutions that meet both commercial needs and global sustainability goals.

0 notes

Text

The unique design of Tunnel lift bag with 4 standard loops and 2 side tunnels helps the customer in reducing its labor cost.

0 notes

Text

Everything You Must Know About Jumbo Bag

Shankar Packaging is a prominent FIBC jumbo bags manufacturer in India. We can customize our bags to meet the precise requirements for storage and transporting delicate products. our jumbo bags for storage offer options such as an outer or an inner coating and an extra layer inside, ventilated, air-proof conducting, ventilated, and so on. For more information visit our blog.

0 notes

Text

A bulk bag, also known as a FIBC (Flexible Intermediate Bulk Container), is a large bag made of woven polypropylene material. It is designed to hold and transport dry bulk materials in a safe and efficient manner. Bulk bags are available in various sizes and configurations, ranging from small bags with a capacity of a few hundred pounds to large bags that can hold several tons of material. Stratgem Projects provides all sizes of bulk bags for various purposes.

#bulkbag#fibcbags#bulkbagdischarger#jumbobag#bag#bulkbagunloader#bulkbagunloadingsystem#jumbobagdischargesystem#bulkbagdischargesystem#fibc#bulkbagdischargesystemmanufacturer#bigbagdischarger#bulkconveyor#wholesalebags#bulk#startgemprojects

0 notes