#forklift cage

Text

Goods Lift Manufacturer

0 notes

Text

Good morning. I was closing up the station last night and dropped one of the heavy cage doors directly onto my nose 😣

#ow :(#luckily doesn't appear to have broken anything but still#stuff i said#gas station#injury#for context the firewood pallet in there is just#*slightly* out of place#but slightly is enough to make it impossible to close right#and no one at the store rn is forklift certified to come unfuck my cage#so they told me to just close it wrong for now#and well

3 notes

·

View notes

Text

Active Lifting Equipment are specialist suppliers of Winch Cables Australia Wide. We offer Fast Delivery to Adelaide, Melbourne, Sydney, Brisbane, Perth, Darwin and other locations.

With our large stock holding of 6x36, 6x25, 7x19, and 19x7 and 35x7 non rotating wire ropes we will have a solution that meets your requirements. Our Ropes range in Grades from 1570, 1770, 1960 EIPS, 2070, and 2160 EEIPS. Generally most of our stock is Galvanized although some ropes are available in G316 Stainless steel or Ungalvanized.

0 notes

Text

Turn Your Skid steer into a Forklift Basket for $180 Bucks

youtube

#ReefDVMs#RMSpeltz Farm#Farm#Forklift#John Deere Forklift#Skid steer#skid steer forklift#skid steer work platform#skid steer cage#scissor lift#fork lift#forklift platform#skid steer lift#best lift#barn lift#utility lift#amazon forklift#amazon skid steer#work platform#cheap fork lift#cheap forklift#best forklift#farmer forklift#diy forklift#skid steer basket#forklift basket#skid steer conversion#cherry picker for skid steer#john deere skid steer#Youtube

1 note

·

View note

Note

What if pharmacy companies believe both that they will be capable of using gene therapy to render people artificially dependent on their proprietary products and that they will be allowed to do so? Like, good job, asshole, you bought your kid better stats, now he'll need to take expensive patented medicine every few hours for the rest of his life or his body will shut down

I think one of the big things we learned during 2014-2022 (and there was a lot to learn from observation) is that states are more powerful than corporations. Yes, corporations can influence states with lobbying, but political power can overcome corporate officers just as corporate money can influence state officers.

I don't believe that major governments (US, EU, China, Japan, etc) would allow a corporation to create a life-saving gene therapy that arbitrarily requires a daily drug. For left-wing parties, it would be a great issue to campaign on if someone were to do it (very easy gains), and for right-wing parties, it's much more straightforward to have the recipient of the gene therapy take out a loan for the up-front price of the treatment. Remember, Republicans already signed laws against direct genetic discrimination - it's simply too annoying.

The thing about conventional gene therapy is that it does not require maintenance the way that artificial implants do. The maintenance requirement for "hard tech" implants makes ongoing deals politically more tenable, especially since the company going under can end up requiring expensive (and potentially damaging) removal surgery.

Notes:

The biggest value-adds for "cybernetic implants" are life-saving healthcare and chronic health condition management. You can move faster through the environment, lift heavier objects, and fly, by using vehicles, without the medical-tier reliability requirements and maintenance costs of implantable technology.

Additionally, the ability of law enforcement to confiscate things like forklifts or thermal vision goggles means that they have options to capture and restrain you other than either a titanium cage or a non-consensual implant removal surgery.

10 notes

·

View notes

Text

ok. well. that protest was the hardest thing i’ve ever had to do in my life. hundreds of people brought their hundreds of children to this slaughterhouse where you could hear the screams of pigs fighting with their last breath for their lives. people were laughing; they were enjoying themselves. it was a social event for them. while the pigs screamed and screamed.

we watched countless animals be carried out, lifelessly draped over the shoulder of a completely chipper man, dripping blood into the bottom of the clear plastic bag that served as their coffin. animals we had just heard screaming moments before.

they were screaming the whole time—it did not stop. at 7:30am they were screaming. i heard them. i got to the protest early, so i waited in line to pretend i was a customer so i could get a closer look.

the stench was unbearable. you could smell death and feces and urine and blood and burning flesh all the way down the road. a man in line in front of me told me proudly with an excited grin he had been coming here since he was a child. just feet away from me a pig screamed as he said this.

men were blowtorching dead goats just yards away in front of the live ones, in their cramped metal cages, watching.

and still people laughed and listened to the music they played to cover the screams. like it was Disney World to them. they yelled at us not to talk to their kids—yet they brought their kids to hear those screams. they were happy to be reminded that their meal was suffering. a meal they won't even remember. for a pig's whole life.

their "bacon" was once as smart as the 7-year-old child they brought to hear her scream.

i’ll never be rid of the experience of that place. it was the darkest hole of hell. you cannot imagine a more horrible, inhumane, revolting, Saw-movie prison.

not to mention the literal child labor we saw being done in broad daylight—children under 14 operating forklifts and hauling whole pigs. the cops present didn’t seem to notice that, btw.

i’m glad i went—it was the most important thing i’ve ever done. the other people protesting with me were incredible. they were tireless—chanting in Spanish and again in English—for hours and hours. taking abuse, threats, objectification. keeping strong when men just tried to run us over with their trucks.

but i would be lying if i said i left there with anything like hope at all. my estimation and respect for humanity dropped to a new low. i saw true evil today, alive and well.

i truly wish everyone could experience a protest outside of a slaughterhouse at least once.

27 notes

·

View notes

Text

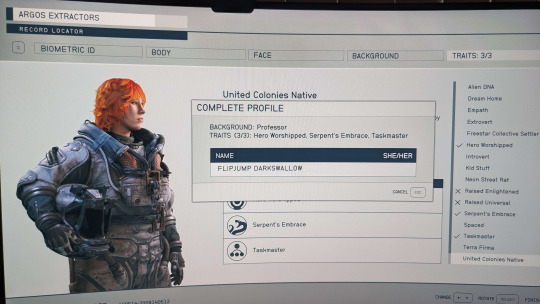

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

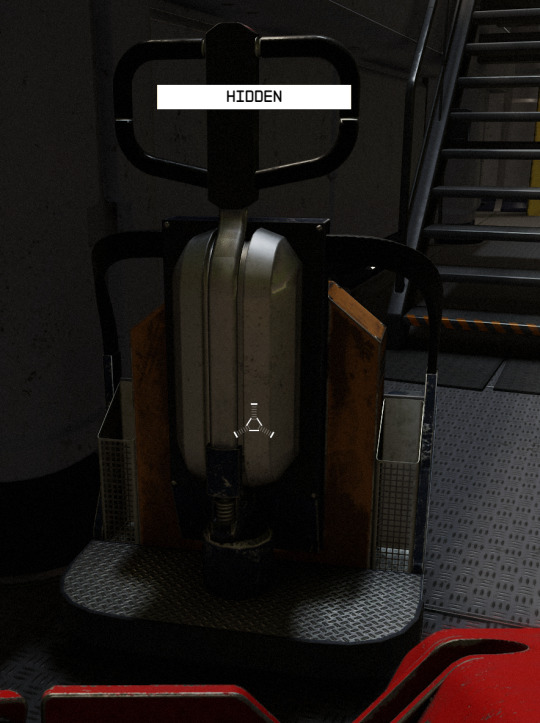

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

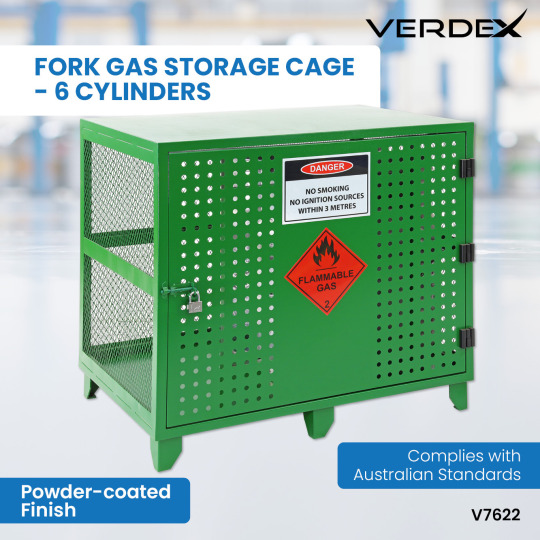

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Note

how to steal the caged white moms from target and force them to work for us

-@real-winn-dixie

bing result: okay so you know how they have that forklift in the back area to load and unload palettes in the storage area? take that, and then ram it through the largest doors you can find that lead to the main shopping area then drive straight to the cages. once you're there, try and push the cages onto the prongs as best you can, but don't wait too long or try too hard because then the target employees might catch you

then you just take them home and voila, free labor

3 notes

·

View notes

Note

Okay so, I work in a warehouse for a big bad company that we all know and hate (they just have scheduling options so I can go to college and work pretty much whatever hours i want so…😒🖐🏻 gotta stay for now; we’re also gonna pretend we don’t know the company I’m talking abt for the sake of online safety purposes) but we got this new manager in our maze of leadership and he’s one of those ones you’d catch trynna go between the gate bars on the pasture and not over istfg like… we have speed bumps galore in our parking and he’ll fly through going like 20 ignoring the 🛑 signs and cross walks yeah?? So I’m doing my job on a pit (heavy drive equipment like forklifts, pallet riders, cage puller, etc) and I’m mentioning a really big safety issue and he brushes it off like I didn’t almost get the stupid knocked out’o me by an even bigger pit cause they didn’t stop at a 🛑 sign. He pulls this binder out and goes “well the standard for driving pit is..” like… 😒 I slapped that binder out of his hand so fast and he stared at me like a fckin white woman staring at her ill behaved kid in Walmart like 👁👁 w the pursed lips and all right?? I told this man that not only does he not drive pit himself but he shouldn’t be textbook handling a safety concern when “safety is our #1 priority!” And he tells me I need to watch my attitude so I told him to watch how much shine he puts on the top of his head cause maybe there were so many pit accidents that that night because the 💡 were reflecting like high vis. Asked if he used shine or if he spit shines, he left me alone for awhile and then came and said he took care of the safety concern by holding a meeting with our safety crew about the failure of pit stops. Well HE GOT ON A PIT AND I WAS BEHIND HIM 🫣 this man drove straight into a barrier and then looked at me like 😳 I reported his accident so fckin fast like 😈🤠 (cause we have to, but also bc he was abt to just drive off like it didn’t happen and like??) the safety man was so fckin happy abt it, cause so far everyone’s had little scuffs with this guy apparently and I was one of the last people hed done it to ig since I don’t interact with many people at work; just there to pay bills tbf 🐻 (sorry for this being so long 😭🖐🏻)

istg managers are the most annoying ppl in the world 😭😭 so glad he got his karma 🙏

4 notes

·

View notes

Text

Forklift Gas Storage Cages

Benefits of using Forklift Gas Storage Cages

Investing in forklift gas storage cages offers several benefits for businesses that rely on gas-powered forklifts.

Enhanced Safety: By securely storing gas cylinders and reducing the risk of accidents, these cages contribute to a safer workplace for all employees.

Regulatory Compliance: Forklift gas storage cages help businesses comply with safety regulations, avoiding potential fines and legal issues related to improper storage practices.

Operational Efficiency: Organised and accessible storage reduces the time workers spend handling gas cylinders, improving overall efficiency and productivity.

Forklift gas storage cages are an essential safety solution for any facility that uses gas-powered forklifts. These cages provide a secure, compliant, and organised way to store gas cylinders, reducing the risk of accidents and ensuring a safe working environment. By investing in high-quality storage cages and following best practices for their use, businesses can protect their workers, their property, and the environment from the hazards associated with compressed gases.

1 note

·

View note

Text

https://www.rkengineeringworks.in

#cage lift#forklift cage#hydraulic cage lift#hydraulic elevator#hydraulic lift#hydraulic lift manufacturer#hydraulic lift photos#hydraulic lift for home

0 notes

Text

How Steel Mesh Pallets Enhance Safety and Durability in Industrial Settings

Introduction

In today's fast-paced industrial environments, safety and durability are paramount. As businesses seek ways to streamline their operations while ensuring the well-being of their workforce, the choice of materials and equipment becomes critical. One such innovation that has gained traction in various sectors is steel mesh pallets. This blog explores how these pallets enhance safety and durability in industrial settings, while also discussing related solutions such as Cage bins Without Doors and collapsible cage bins.

What Are Steel Mesh Pallets?

Steel mesh pallets are sturdy, open-frame structures designed for the storage and transportation of goods. Made from high-quality steel wire, they are known for their strength and longevity. Due to their versatility and efficiency in handling various types of products, they are particularly popular in warehousing, logistics, and manufacturing.

Key Features of Steel Mesh Pallets

Robust Construction: Steel mesh pallets are constructed from heavy-duty steel, providing a robust framework that can support substantial weight without compromising integrity.

Ventilation: The mesh design allows for adequate airflow around the stored items, which is particularly beneficial for perishable goods or items that require specific environmental conditions.

Easy Handling: Steel mesh pallets equipped with fork openings can be easily maneuvered with forklifts, enhancing operational efficiency.

Stackability: These pallets are designed for stacking, allowing for efficient use of vertical space in storage facilities.

Corrosion Resistance: Many steel mesh pallets are coated with protective finishes to resist corrosion, making them suitable for various industrial applications.

Benefits of Steel Mesh Pallets in Industrial Settings

Enhanced Safety

Safety is a critical concern in any industrial setting. Steel mesh pallets contribute to a safer working environment in several ways:

Stable Storage:

The robust construction of steel mesh pallets minimizes the risk of collapse, reducing accidents and injuries associated with shifting or falling loads.

Visibility:

Mesh pallets' open design improves the visibility of stored items, enabling workers to identify potential hazards quickly.

Reduced Slips and Falls:

The secure placement of items on steel mesh pallets reduces the likelihood of items slipping off or falling, thereby preventing workplace accidents.

Durability and Longevity

Durability is key to maintaining operational efficiency in industrial environments. Steel mesh pallets are designed to withstand harsh conditions, providing a long-lasting storage solution:

Resistance to Wear and Tear:

Unlike wooden pallets, which can splinter or break, steel mesh pallets maintain their structural integrity even after years of use.

Adaptability:

Steel mesh pallets can endure extreme temperatures and conditions, making them suitable for a wide range of industries, from food processing to pharmaceuticals.

Cost-Effectiveness

Investing in steel mesh pallets can lead to significant cost savings over time:

Lower Replacement Costs:

Due to their durability, steel mesh pallets require less frequent replacement compared to traditional pallets, ultimately saving businesses money.

Increased Efficiency:

The ease of handling and stacking allows for more efficient use of space and resources, leading to improved operational productivity.

Environmental Sustainability

As industries become more environmentally conscious, the choice of materials plays a crucial role. Steel mesh pallets contribute to sustainability efforts in the following ways:

Recyclability:

Steel is 100% recyclable, meaning that at the end of its life cycle, steel mesh pallets can be repurposed without harming the environment.

Reduced Waste:

Steel mesh pallets' durability minimizes waste, as they are less likely to need replacement compared to disposable options.

Complementary Solutions: Cage Bins Without Doors and Collapsible Cage Bins

Other storage solutions, including cage bins without doors and collapsible cage bins, can enhance safety and efficiency in industrial settings in addition to steel mesh pallets:

Cage Bins Without Doors

Cage bins without doors provide a secure and accessible storage option for smaller items. They are ideal for environments where quick access is essential, such as in manufacturing and assembly lines.

Enhanced Visibility:

The open design allows for easy visibility of contents, making it easier to manage inventory.

Safe Storage:

The cage structure keeps items secure while allowing for quick access, reducing the risk of accidents caused by opening and closing doors.

Collapsible Cage Bins

Collapsible Cage Bins offer flexibility and convenience for storage and transport:

Space-Saving Design:

These bins can be collapsed when not in use, saving valuable space in warehouses or during transportation.

Ease of Use:

The collapsible feature allows for quick assembly and disassembly, facilitating efficient handling and storage.

Collapsible Mesh Box

Collapsible Mesh Box is an ideal storage solution for industries looking to optimize space and enhance efficiency. These boxes are designed with durable steel mesh, providing excellent visibility of contents while ensuring secure storage. Perfect for heavy-duty applications, they are easily foldable, reducing storage space when not in use. The collapsible design also simplifies transportation, cutting down on freight costs. Whether for warehousing, logistics, or manufacturing, Collapsible Mesh Boxes offer a versatile and reliable option. To improve productivity and save space, get these robust, space-saving storage boxes right away.

Mesh Box with Wooden Base

Introducing our Mesh Box with Wooden Base – a versatile storage solution combining durability and style. This sturdy mesh box features a robust wooden base, making it ideal for industrial, commercial, or home use. Whether you're organizing tools, materials, or household items, the mesh design ensures visibility and ventilation, while the wooden base provides a solid foundation. Perfect for stacking, this mesh box optimizes space while ensuring easy access to contents. Enhance your storage efficiency with our mesh box with a wooden base, which is designed for both practicality and aesthetics.

Contact Today

At Stakall, we specialize in providing high-quality steel mesh pallets and related storage solutions tailored to meet the needs of various industries. Contact Us Today to learn more about how our products can enhance safety and durability in your industrial operations.

Conclusion

Steel mesh pallets are an essential asset for industrial settings, enhancing safety, durability, and cost-effectiveness. With their robust construction and versatile design, they offer numerous advantages over traditional storage options. Complemented by innovative solutions such as cage bins without doors and collapsible cage bins, businesses can create a safer and more efficient working environment.

0 notes

Text

Active Lifting- Your Only Destination to Buy Certified Electric Hoists

Are you looking for a reliable platform to buy the best and most durable electric hoist Roxby Downs, for different lifting applications? Don’t look here and there, and visit Active Lifting now. When you are with us, you can expect to get the best-in-class products at the most competitive prices. Our hoists come with advanced current-driven electromagnetic brakes to hold the load securely.

0 notes

Text

Enhancing Safety and Efficiency with Pallet Cages: A Must-Have for US Industries

In the fast-paced world of industrial operations, ensuring the safety and efficiency of material handling processes is paramount. One essential tool that has become increasingly popular in the US is the Pallet Cage. Designed for heavy-duty use, pallet cages offer a reliable solution for securely storing and transporting materials, making them indispensable in various industries, including manufacturing, warehousing, and construction.

What Makes Pallet Cages Essential?

Enhanced Safety: Pallet cages are engineered to provide a secure enclosure for materials, reducing the risk of accidents caused by falling items. This is particularly important in environments where heavy or bulky materials are handled, as it helps protect workers and equipment from potential harm.

Versatility: One of the standout features of pallet cages is their versatility. They can be used for a wide range of applications, from storing loose materials to transporting goods across the worksite. Their stackable design also allows for efficient use of space, both in storage and during transport.

Durability: Built to withstand the rigors of industrial use, pallet cages are made from high-quality materials that ensure longevity and resilience. This durability means they can be used repeatedly without compromising safety or functionality, providing a cost-effective solution for businesses.

Ease of Use: Pallet cages are designed for ease of use, with features such as foldable sides for easy access to contents and compatibility with standard forklifts and pallet jacks. This makes loading, unloading, and transporting materials straightforward and efficient.

Compliance and Standards: In the US, where workplace safety standards are stringent, pallet cages help businesses comply with regulations by providing a safe method for handling and storing materials. This compliance not only enhances safety but also helps avoid costly fines and legal issues.

Applications of Pallet Cages in Various Industries

Manufacturing: In manufacturing, pallet cages are used to store raw materials, work-in-progress items, and finished products. Their robust construction ensures that even heavy or irregularly shaped items are securely contained.

Warehousing: Pallet cages are ideal for warehousing operations, where they can be used to organize and store inventory. Their stackable design maximizes space utilization, while their secure construction prevents damage to goods.

Construction: On construction sites, pallet cages are used to transport and store tools, equipment, and materials. Their durability ensures they can withstand the harsh conditions of a construction environment.

Conclusion

For US industries focused on enhancing safety and operational efficiency, investing in high-quality pallet cages is a smart move. These versatile tools not only provide a safe and secure method for handling materials but also contribute to streamlined operations across various sectors. Whether you’re looking to improve your warehousing processes or ensure the safe transport of materials on a construction site, pallet cages are an essential asset.

Explore more about pallet cages and how they can benefit your operations by visiting the HFS Safety Pallet Cages product page.

0 notes

Text

CGxxA1-x Single-row ball chain groove shape with double stopper forklift sprocket

Materials and heat treatment for Forklift mast bearing ring

The selection of materials for mast-bearing rings (including shafts) is based on the different loads and structures borne by bearing ring parts. Generally, bearing steel, high-quality carbon structural steel, carburized steel, and other materials are selected for manufacturing. Different heat treatment processes are utilized to obtain the mechanical properties for bearing ring parts

Load and structure of the forklift mast bearing

In mast bearings, the magnitude of the load is the first factor to consider when selecting bearings. Under the condition of the same overall dimensions of the bearings, the bearing capacity of the roller structure is the largest, followed by double. -row ball structure and the bearing capacity of a single-row ball structure is relatively small. Among the bearings of this type of structure, the bearing load capacity of the full-ball (or roller) structure is larger than that of a bearing with a cage. On the premise of sufficient load capacity, the standard single-row ball structure can be preferred

0 notes

Text

the dairy industry is the most disgusting torturous thing i have ever seen. honest to god i think dairy is far far far worse than the meat industry

one is death but dairy is absolute lifelong torture for however long that cow can keep giving milk

doesn’t matter if the cow can’t walk anymore, disabled by years of insemination and dehydration and constant pregnancy and birth and being cramped in a tiny caged box with no room to move and living in her own feces and urine. they’ll literally forklift her to get the milk. they’ll do whatever they need to to get the milk from that female cow

and then how much of that milk gets fucking thrown out daily bc of overproduction? utterly wasted. all that suffering for fucking pittance

fucking christ i want to throw up

21 notes

·

View notes