#formwork of column

Explore tagged Tumblr posts

Text

Modular Wall Column Formwork System: The Future of Efficient Concrete Construction

As the demand for rapid urban infrastructure and high-rise buildings continues to grow, the construction industry is constantly seeking solutions that boost speed, accuracy, and cost-effectiveness. One such breakthrough is the modular wall column formwork system, a highly efficient and reusable technology that has redefined modern concrete construction.

At the forefront of this innovation is Bii Formtek, a trusted Mivan formwork Aluminium manufacturer, offering advanced modular systems under their Acierise brand. These systems are transforming how walls and columns are formed, enabling faster cycles, superior surface finishes, and minimal labor dependency.

What is a Modular Wall Column Formwork System?

A modular wall column formwork system is a prefabricated, reusable structure used to mold concrete walls and columns. Made from durable materials like aluminium or steel, these formwork panels are designed to be interlocked in a modular fashion. This system ensures uniformity, faster assembly, and reduced construction time compared to traditional wooden or plywood shuttering.

The panels are lightweight, easy to handle, and offer high precision during concrete placement. As the construction cycle speeds up, project timelines are significantly reduced, contributing to faster project completion and lower labor costs.

Importance of Modular Formwork in Modern Construction

The adoption of modular wall and column formwork has become essential for developers and contractors looking to streamline operations and increase productivity. Here’s why it matters:

High Reusability: Aluminium panels can be reused over 200 times, providing excellent return on investment.

Reduced Labor Requirement: Simple assembly with fewer workers speeds up formwork erection and dismantling.

Improved Surface Quality: Smooth aluminium surfaces yield better concrete finishes with minimal plastering.

Faster Project Turnaround: Efficient cycles help in completing slabs faster, vital for high-rise and mass housing projects.

In short, the modular wall column formwork system offers a perfect combination of durability, cost-efficiency, and speed.

Bii Formtek: Trusted Mivan Formwork Aluminium Manufacturer

Bii Formtek is a leading name in the Indian formwork industry, recognized as a premier Mivan formwork Aluminium manufacturer. Their product line, including the Acierise system, is engineered to deliver superior performance across large-scale residential, commercial, and infrastructure projects.

Why Choose Bii Formtek?

Precision-Engineered Aluminium Systems Each formwork component is crafted with precision CNC machinery, ensuring dimensional accuracy and smooth finishes.

Customization Flexibility Systems are tailored to suit architectural and structural requirements, accommodating varying floor heights, slab depths, and design elements.

Durable and Lightweight Panels Manufactured with high-grade aluminium alloys, panels offer an ideal balance of strength and lightness for safe and easy handling.

On-Site Support The Bii Formtek team offers hands-on training, supervision, and technical support to ensure efficient formwork deployment on-site.

Key Features of Modular Wall Column Formwork Systems

Let’s explore what makes these systems so effective in today’s fast-paced construction environment:

1. Standardized Panel Sizes

Modular systems come with standardized panels that interlock seamlessly, reducing assembly time and simplifying inventory management.

2. Versatile Application

Used for both walls and columns, this system supports multi-story construction, industrial sheds, villas, and large-scale housing developments.

3. Integrated Accessories

Tie rods, corner angles, wall brackets, and pins ensure structural integrity and alignment of formwork during concrete pouring.

4. Quick Dismantling

Easy-to-remove pins and clips allow the system to be stripped rapidly without damaging the formwork or concrete structure.

5. Long Life Span

High-quality aluminium formwork can be reused up to 200–250 times with proper handling and maintenance, reducing lifecycle costs.

Modular Wall Column Formwork vs. Traditional Shuttering

Feature

Modular Formwork

Traditional Shuttering

Material

Aluminium

Timber/Plywood

Reusability

200+ times

10–15 times

Assembly Time

Fast

Slow

Finish Quality

Smooth

Requires plastering

Labor Requirement

Low

High

Environmental Impact

Sustainable

Generates waste

Clearly, modular formwork outperforms conventional methods on almost every front, making it the smarter long-term investment.

Benefits of Using Mivan Aluminium Formwork by Bii Formtek

Bii Formtek delivers cutting-edge Mivan systems that cater to mass housing, high-rise towers, and infrastructure developments. Here's why clients choose their Mivan formwork Aluminium manufacturer solutions:

Accelerated Construction: One floor can be completed in as little as 7–10 days.

Enhanced Safety: Lightweight panels reduce the risk of injury during assembly.

Structural Uniformity: Ensures monolithic concrete casting for stronger buildings.

Low Maintenance: Smooth aluminium does not absorb moisture and resists corrosion.

Cost Savings: Less labor, fewer materials, and faster cycles lower overall project expenses.

Applications of Modular Wall Column Formwork Systems

The modular wall column formwork system finds widespread use across diverse sectors, including:

Residential Housing Projects

Commercial Complexes

Industrial Buildings

Government Infrastructure Projects

Smart City Developments

Its flexibility allows for both repetitive floor layouts and custom structural designs, supporting varied architectural goals with ease.

Sustainability and Environmental Impact

Sustainable construction is no longer optional—it’s a necessity. Modular formwork systems help in:

Reducing Timber Waste: Eliminates dependence on wood-based shuttering.

Lowering Carbon Footprint: Aluminium’s long lifespan and recyclability reduce environmental impact.

Minimizing On-Site Waste: Prefabricated panels reduce cutting and scrap generation on construction sites.

By switching to modular aluminium systems, companies can comply with green building norms and improve their sustainability ratings.

Why Contractors Trust Acierise by Bii Formtek

Bii Formtek’s Acierise system is a benchmark in India’s formwork industry. It’s not just about selling formwork—it’s about delivering value through reliability, precision, and engineering support.

Backed by R&D and rigorous quality control

Designed for complex and high-volume projects

Supported by a network of project engineers

Competitive pricing for large-scale adoption

With its in-house manufacturing and technical guidance, Bii Formtek ensures your construction project stays on time, on budget, and on point.

Final Thoughts

The future of construction lies in speed, quality, and sustainability—and the modular wall column formwork system delivers on all fronts. Whether it’s reducing labor costs, improving cycle times, or ensuring consistent concrete finishes, modular systems have revolutionized the way we build.

As a leading Mivan formwork Aluminium manufacturer, Bii Formtek provides innovative, customizable, and cost-effective solutions tailored for the Indian construction landscape. Their Acierise system combines engineering excellence with on-ground efficiency, helping builders achieve faster, cleaner, and more profitable outcomes.

To explore modular formwork solutions for your next project, visit https://biiformtek.in/products/acierise/.

0 notes

Text

Why Proper Support Matters In Column Shuttering

One of the most important parts of building a concrete construction is the column shuttering. The structure's ability to hold weight is reduced if the supports are not properly aligned, supported, or cast. This is why the right support is so important, not only for the column's power and shape but also for the site's safety as a whole.

This blog post will talk about why the right support is important for column formwork, some common mistakes, and how new methods like Plastic Shuttering in India are changing the game.

Why do We Need Column Shuttering?

Once fresh concrete is poured, this method is used to hold it in place until it hardens. It makes sure that the column stays the shape and size that was wanted. The shuttering has to be able to handle the weight of wet concrete and any shaking that happens while it's being poured.

Panels (which can be made of wood, steel, or plastic), clamps, tie rods, and bracing supports are the most important parts of column formwork.

Why Getting the Right Support is Mandatory

Here is why this support system is a must-have:

1. Keeps the Accuracy of the Structure - The shaft could become out of place or bulge during casting if the formwork is not properly supported. This could lower the building's load capacity and make it look bad, which would cost a lot to fix.

2. Stops Leaks and Blowouts - Column shuttering that isn't properly supported can leak concrete or even blow out. Not only do these mistakes lose materials, but they also put workers at risk. It is very important to have tight links, stable supports, and good anchoring.

3. Makes Sure the Surface is Smooth - A well-supported formwork will keep the concrete in place properly, which will make the finish smoother and cut down on the amount of extra plastering that needs to be done later.

4. It Helps You Save Time and Money - When column formwork is put together with the right support, it cuts down on the need for extra work and delays. Formwork that is properly lined and supported also speeds up and cleans up the deshuttering process.

How Modern Materials like Plastic Shutters Play a Part

These days, plastic Shuttering in India is becoming more common because it lasts longer, can be used more than once, and is easy to handle. Plastic shuttering systems have locks and joints built in that make them easier to align and support than wooden systems that you have to put together by hand. Because they are light, they make work easier and faster, which is especially helpful for big home or business jobs.

How to Stand Up Column Formwork Correctly

You have to follow these steps:

To make sure everything is lined up straight, use plumb lines or laser tools.

Hold the shuttering panels in place with strong tie rods and clamps.

Before you pour the concrete, check all the joints.

Follow the manufacturer's instructions for spacing and strengthening if you are using plastic shutters.

Conclusion

You can't say enough about how important strong and stable support is for column shuttering, whether you're working on a high-rise or a house. It keeps things from getting out of alignment and guarantees a high-quality finish. As the building business changes, new tools and methods, such as Plastic Shuttering in India, help contractors make fewer mistakes, save money, and finish jobs faster without lowering the standard.

#nova formwork#plastic formworks#formworks in india manufacturer and supplier#column formwork#column shuttering#shuttering formworks in india#plastic shuttering in india

0 notes

Video

youtube

Push Pull Props - Wellmade Scaffold, China - Wall and Column Formwork S...

#youtube#push pulls#props#steel props#scaffolding props#formwork props#shoring props#wellmade scaffold#wellmade china#adjustable props#wall formwork#column formwork

0 notes

Text

Best Modular Wall Column Formwork System – Durable & Cost-Effective Solutions

Enhance your construction efficiency with our Modular Wall Column Formwork System, designed for high performance, reusability, and easy handling. Our formwork system ensures accurate shaping of walls and columns while maintaining superior strength and durability. Made from high-quality materials, it reduces construction time and labor efforts significantly. Whether for high-rise buildings or infrastructure projects, our modular system is your go-to choice for precision and reliability. Request a quote now!

0 notes

Text

NOVA - Proudly Awarded As The Best Company In Scaffolding And Formworks

Chose Nova Formworks if you're looking for a dependable, long-lasting solution that adds creativity and quality to every project with its essential features

#nova plastic formwork#formwork construction#plastic formwork#construction formwork#plastic formwork in india#aluminium formwork#column formwork#low cost housing construction#formwork in construction#formwork

0 notes

Text

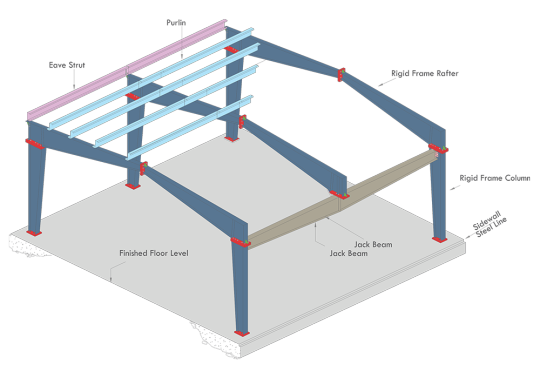

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Why Kolkata is Emerging as a Hub for Reliable Formwork Solutions

Introduction: Kolkata’s Evolution in Construction Excellence

Kolkata, often revered as the cultural capital of India, is now steadily making its mark in the infrastructure and construction sector. Over the past decade, the city has witnessed rapid urbanization, with a surge in residential, commercial, and government construction projects. With this growth comes the rising demand for advanced building technologies — among them, formwork solutions stand out as a critical component.

Today, Kolkata is becoming a hub for reliable formwork and scaffolding systems, attracting builders, developers, and contractors from across the country. Whether it's residential skyscrapers, metro projects, flyovers, or industrial structures, efficient formwork solutions are crucial for ensuring project speed, safety, and cost-effectiveness.

Notably, the increasing availability of Scaffolding On Rent in Kolkata is playing a pivotal role in driving this change. The rental model not only helps construction companies cut costs but also enables access to a wide variety of quality formwork and scaffolding materials — all without long-term investment.

Understanding Formwork and Its Importance

Formwork refers to the temporary or permanent molds into which concrete is poured to form structural elements like columns, beams, slabs, and walls. When used efficiently, formwork systems help in:

Maintaining structural integrity

Speeding up construction timelines

Reducing labor costs

Ensuring safety and precision in execution

Modern construction demands lightweight, reusable, and durable formwork systems such as aluminum, plastic, and modular steel frameworks. Kolkata’s emerging infrastructure ecosystem has embraced these solutions, supported by a well-developed scaffolding rental network that makes this technology accessible even to small and mid-sized contractors.

Key Factors Driving Kolkata’s Rise in Formwork Solutions

1. Infrastructural Boom and Government Projects

From the East-West Metro Corridor to several Smart City projects, Kolkata has seen a surge in infrastructure investments. These large-scale initiatives demand efficient construction processes, which can only be delivered using modern formwork techniques. The growing reliance on scaffolding on rent in Kolkata has helped reduce upfront costs while ensuring project timelines are maintained.

2. Cost-Effective Rental Solutions

Construction companies increasingly prefer renting scaffolding and formwork materials rather than purchasing them outright. This approach is economically beneficial, especially for short- to medium-term projects. Kolkata’s scaffolding rental market has matured, offering not just materials but also installation support, quality checks, and dismantling services.

3. Skilled Workforce and Technical Know-How

Another reason for Kolkata’s emergence as a formwork hub is the availability of trained professionals who specialize in assembling and disassembling modern scaffolding systems. Technical training institutes in the region have also started offering certifications in formwork technology, creating a reliable talent pool for the industry.

4. Logistical Advantages

Kolkata serves as a key logistical hub in eastern India. With easy access to ports, railways, and national highways, the transportation of scaffolding equipment and formwork systems becomes seamless. This logistics efficiency reduces downtime and enables rapid delivery and recovery of rented equipment across projects.

Innovations in Formwork Systems in Kolkata

Kolkata is witnessing the use of a variety of formwork innovations such as:

Aluminum Formwork Systems: These are lightweight, easy to assemble, and can be reused multiple times, making them a preferred choice in residential construction.

Plastic Formwork: Ideal for low-cost housing projects, this system is easy to clean and handle.

Tunnel Form Systems: Used in high-rise buildings for the simultaneous casting of walls and slabs.

Climbing Formwork: Best suited for tall structures like towers and chimneys.

Construction companies renting these systems now expect technical support, customization, and automation compatibility — all of which the formwork suppliers and scaffolding rental providers in Kolkata are now capable of delivering.

The Rise of Rental Services Beyond Kolkata

As demand for quality scaffolding materials rises, rental services are extending their reach beyond city borders. In fact, many rental companies in Kolkata now supply scaffolding equipment across eastern and southern India.

An example of this expansion is the growing demand for Scaffolding On Rent in Telangana, where cities like Hyderabad, Warangal, and Karimnagar are experiencing a similar construction boom. Contractors from these regions are increasingly sourcing scaffolding and formwork equipment from Kolkata-based vendors due to:

Competitive rental pricing

Wide variety of options

Proven reliability and safety standards

On-time delivery backed by strong logistics

This inter-regional supply chain not only boosts the Kolkata economy but also helps standardize formwork practices across states.

Why Formwork Rental is Better than Purchase

Many small to medium construction companies are realizing that renting scaffolding and formwork is more efficient than owning it. Here's why:

1. Lower Capital Expenditure

Renting eliminates the need for a large upfront investment, which can then be redirected to other essential project areas.

2. No Storage Hassles

Once a project ends, there's no need to store bulky materials. Rental providers take care of transport and storage.

3. Maintenance-Free

All wear and tear, repairs, and upkeep are handled by the rental service provider, reducing operational stress.

4. Latest Technology Access

Renting enables companies to use the latest formwork systems without purchasing new equipment for every project.

Safety Standards and Compliance in Kolkata’s Scaffolding Market

One of the key concerns in any construction project is worker safety. Reliable scaffolding and formwork systems directly impact the safety and performance of on-site workers.

In Kolkata, scaffolding rental services ensure their equipment complies with the highest safety and quality standards. Most vendors follow:

BIS (Bureau of Indian Standards) specifications

OSHA (Occupational Safety and Health Administration) guidelines

Periodic load testing and inspections

Proper tagging and documentation

With this level of professionalism, formwork solutions coming from Kolkata are trusted not only within West Bengal but also in other states like Odisha, Jharkhand, Bihar, and Telangana.

Challenges and the Road Ahead

Despite the progress, a few challenges remain:

Lack of awareness about the benefits of modern formwork

Resistance to adopting new technologies in traditional sectors

Shortage of skilled labor in remote regions

However, initiatives such as government skill development programs and tie-ups between rental providers and training institutes are gradually overcoming these hurdles.

Looking ahead, Kolkata is well-poised to lead the charge in India's evolving formwork landscape — both as a provider of advanced systems and as a rental hub offering cost-effective and reliable solutions.

Expanding Footprint: From Telangana to Hyderabad

With Scaffolding On Rent in Telangana becoming more mainstream, its capital city, Hyderabad, has become a major client base for Kolkata-based scaffolding companies. Hyderabad’s booming real estate and IT infrastructure development are creating a steady need for efficient formwork solutions.

What’s noteworthy is that vendors from Kolkata now offer tailor-made solutions for Scaffolding On Rent in Hyderabad, catering to:

Multi-story office buildings

Highway flyovers

Metro and rail constructions

Residential gated communities

Their services typically include transport, installation, regular inspections, and even dismantling, making it a full-service offering.

Conclusion: Kolkata – The Formwork Capital in the Making

Kolkata’s emergence as a hub for reliable formwork solutions is not accidental. It is the result of:

Strategic infrastructure development

Economic scaffolding rental services

Skilled manpower

Strong logistical backbone

The city's rental ecosystem has empowered contractors not just locally but across states like Telangana and Andhra Pradesh, including Hyderabad. With growing innovations, adherence to safety standards, and an expanding footprint, Kolkata is setting the benchmark for formwork excellence in India.

Whether you're a builder, a contractor, or a developer looking for Scaffolding On Rent in Kolkata, or even exploring opportunities in cities like Telangana and Hyderabad, Kolkata’s suppliers offer quality, affordability, and dependability — all rolled into one.

#scaffolding rental service in west bengal#scaffolding rental service in kolkata#scaffolding manufacturer in west bengal#construction scaffolding in west bengal#construction scaffolding in kolkata#scaffolding manufacturer in kolkata#scaffolding on rent in west bengal#scaffolding on hire in west bengal

0 notes

Text

Raft foundation, also known as mat foundation, refers to the thick concrete slab which has been resting on a large ground area. The columns and walls of the building structure have been supported by the raft foundation. The raft foundation involves transferring the loads from the building structure to the ground.

In the case of the load-bearing capacity of the ground, in which the construction structure is located, is low, the raft foundation can be used. In addition, in the case of a higher chance of differential soil settlement, the raft foundation can also be used.

Materials that have been used in the raft foundation

There are different materials that have been used in the construction of the raft foundation, which are as follows:

➢ Mainly, concrete has been used in the construction of a raft foundation. ➢ The steel reinforcements have also been used to enhance the strength and durability of the raft foundation. These steel bars also help to handle the tensile stress, and this adds strength to the structure. ➢ For making the formwork of the raft foundation, wood, plastic, or metal can be used by the builders. ➢ The builders also use waterproofing membranes on the raft foundation’s surface area, which helps to prevent water ingress.

Discuss the different types of raft foundation

The raft foundation is available in different types, which are as follows:

Flat Plate Mat

The flat plate mat is the simplest form of the raft foundation, in which reinforcement has been placed in both directions of the foundation. The flat plate mat is around 300mm thick.

Two-way Beam and Slab Raft

In this type of raft foundation, the beams have been cast monolithically with the raft slab. This type of raft foundation is ideal for higher-load building structures.

Read more

0 notes

Text

Trusted Shuttering Ply Manufacturer in Bihar – Veneer Ganesh

Veneer Ganesh – Bihar’s Reliable Partner for High-Performance Shuttering Plywood

Bihar is experiencing a surge in infrastructure and real estate development. From residential buildings and commercial complexes to bridges and highways, construction projects across the state depend on materials that can handle demanding conditions. Among these materials, shuttering plywood in bihar plays a crucial role in ensuring strong, stable concrete structures.

Builders and contractors across Bihar rely on Veneer Ganesh—a leading shuttering ply manufacturer known for consistent quality, durability, and service.

About Veneer Ganesh

Veneer Ganesh is a reputed name in India’s plywood manufacturing industry. With years of experience and a focus on innovation, the company produces a full range of plywood products, including specialized shuttering ply engineered to meet the toughest site requirements.

From Patna and Muzaffarpur to Gaya, Bhagalpur, and beyond, Veneer Ganesh has built a reputation as a dependable supplier to contractors and builders across Bihar.

Why Choose Veneer Ganesh Shuttering Ply?

High Load-Bearing Strength Veneer Ganesh shuttering plywood is manufactured using selected hardwood veneers bonded with high-grade phenolic resins. This construction ensures it can withstand heavy loads and the hydrostatic pressure of fresh concrete without bending or warping.

Superior Reusability Unlike ordinary ply, Veneer Ganesh shuttering ply is designed for multiple uses. It retains its structural integrity and smooth finish through many cycles, reducing material costs over time.

Resistance to Moisture and Weather Bihar’s varied climate requires materials that won’t deteriorate easily. Veneer Ganesh shuttering ply is moisture-resistant and dimensionally stable, even in extreme weather.

Smooth Concrete Finish The dense, smooth surface of the ply ensures clean concrete casting, minimizing the need for additional surface treatment.

Customization and Fast Supply Veneer Ganesh can deliver standard sizes or custom dimensions promptly to meet project timelines anywhere in Bihar.

Applications Across Bihar

Veneer Ganesh shuttering plywood is trusted for:

Casting concrete slabs, beams, and columns

Walls, staircases, and basements

Bridges and flyovers

Commercial and industrial construction projects

Its reliable performance makes it an essential material for contractors aiming for quality and efficiency.

Commitment to Quality

Every sheet of shuttering ply from Veneer Ganesh undergoes strict quality checks for:

Load-bearing capacity

Bonding strength

Dimensional accuracy

Moisture and weather resistance

This ensures you get plywood that performs consistently, project after project.

Serving All Regions of Bihar

Veneer Ganesh maintains a strong distribution network across the state, supplying shuttering plywood to Patna, Gaya, Bhagalpur, Muzaffarpur, Darbhanga, and other towns. Whether your project is large or small, you can count on timely deliveries and professional service.

Why Builders Trust Veneer Ganesh

Proven Expertise: Years of experience manufacturing specialized shuttering ply.

Reliable Availability: Always in stock, ready for urgent orders.

Competitive Pricing: High value without compromising quality.

Technical Support: Help with choosing the right specifications for any project.

Conclusion

In construction, your formwork is the foundation of success. Veneer Ganesh shuttering plywood helps you build stronger, more precise concrete structures with confidence.

If you are looking for a shuttering ply manufacturer in Bihar, Veneer Ganesh is your trusted partner for quality, durability, and peace of mind.

Contact Veneer Ganesh today to learn more about their shuttering ply range, request a quote, or schedule a delivery—and see why they are the first choice of builders across Bihar.

Visit:- https://www.ganeshveneer.com/shuttering-ply-bihar.php

0 notes

Text

Plastic Formworks | Nova Formworksblr

Nova Formworksblr offers high-quality Plastic Formworks designed for durability, reusability, and precision in construction. Our innovative formwork systems ensure smooth finishes, easy handling, and quick installation, making them ideal for modern building projects. Resistant to water and corrosion, Nova’s Plastic Formworks outperform traditional materials in both cost-efficiency and lifecycle. Whether it’s for columns, walls, or slabs, our solutions provide reliable support for all types of construction. Choose Nova Formworksblr for superior strength and consistent results.

0 notes

Text

A Complete Guide to Mivan Shuttering Components

In today’s fast-paced construction industry, time, efficiency, and structural precision are everything. Among the many technologies revolutionising building methods, Mivan shuttering stands out as a game changer. Known for its speed, strength, and superior finish, Mivan technology uses a monolithic concrete pouring system with reusable aluminium formwork components—making it ideal for mass housing and high-rise structures.

At BSL Scaffolding, we’ve helped hundreds of developers and contractors improve project timelines and quality through premium-grade aluminium formwork systems. One of the most common questions we’re asked is: What are the components of Mivan shuttering?

This blog provides a detailed explanation of all the key Mivan shuttering components, their functions, and how they come together to create fast, cost-effective, and structurally sound buildings.

What Is Mivan Shuttering?

Mivan shuttering is a construction system developed by a European company called Mivan Company Ltd, designed for rapid cast-in-place construction using aluminium formwork. It uses a modular aluminium framework to form the structural elements of a building—such as walls, slabs, beams, staircases, and columns—all poured in a single cycle.

This technique eliminates the need for traditional brickwork or blockwork, ensuring uniformity, speed, and strength across the project.

The success of this system heavily depends on the precision and quality of its components.

Core Mivan Shuttering Components

Let’s break down the major components of a Mivan shuttering system. Each part is manufactured from lightweight yet durable aluminium, making it reusable, easy to handle, and capable of withstanding multiple construction cycles.

1. Wall Panels Wall panels are vertical aluminium plates used to form the external and internal walls of the building. They are precisely engineered to match the wall dimensions of the floor plan.

Function: To form the vertical concrete surfaces (walls), ensuring straightness and alignment.

BSL Advantage: At BSL Scaffolding, our aluminium wall panels are manufactured with tight tolerances and reinforced edges to ensure dimensional stability and long-term reusability.

2. Beam Side and Soffit Panels These are horizontal shuttering components that form the sides (beam side panels) and underside (soffit panels) of the structural beams.

Function: They help in shaping the beams precisely, ensuring uniform dimensions and clean finish for structural integrity.

Secondary Keyword Target: beam shuttering with aluminium formwork

3. Deck Panels Deck panels are flat plates that form the horizontal surface of the floor slab. They are supported by props and deck beams to maintain correct elevation.

Function: To support the weight of wet concrete for slabs until it sets completely.

Why It Matters: Uniform deck panels from BSL ensure no slab leakage or undulations—critical for residential and commercial projects.

4. Deck Beams These are horizontal members that support the deck panels and transfer their load to the vertical supports (props).

Function: They provide intermediate support to deck panels, enhancing formwork stability during pouring.

Pro Tip: Proper alignment of deck beams ensures flat slab finishes and avoids deviations during multiple floor constructions.

5. Soffit Length and Prop Head Soffit Length: Connects the wall panel to the deck panel horizontally and provides form for the slab's edge.

Prop Head: Holds the beam and deck system in place from below with vertical support props.

Function: To balance and lock the framework from below, supporting the system during concrete curing.

BSL's Offering: Our prop systems are high-strength yet easy to adjust on site, reducing labour and setup time.

6. Pins and Wedges These are mechanical fasteners used to lock different formwork panels together. Their design allows easy assembly and disassembly.

Function: To hold panels rigidly in position, ensuring leak-proof concrete casting and exact alignment.

Relevance: Reliable locking is essential for a monolithic structure; BSL’s pins and wedges are precision-engineered for seamless operations.

7. External Corners and Internal Corners These components help in joining panels at the junctions—where walls meet at 90° angles or where slabs meet walls.

Function: To complete corners and edges with proper geometry, reducing joint lines and plastering needs.

Construction Tip:

Tight-fitting corners lead to better waterproofing and finish, reducing maintenance in the long term.

Why Are These Components Critical?

Each of the Mivan shuttering components plays a specific role. The performance of the entire aluminium formwork system depends on the precision, durability, and alignment of every part. Using poor-quality components can result in:

Concrete leakage

Misaligned structures

Poor finishes

Delays in reuse and dismantling

At BSL Scaffolding, we focus on delivering formwork systems built to last. Every component is tested for load capacity, corrosion resistance, and alignment to ensure top-notch construction performance.

Benefits of Using BSL Aluminium Formwork Systems

Faster Construction: Our systems cut down cycle time per floor dramatically

Superior Finish: Clean, straight walls and slabs mean less plastering or rework

Durability: Up to 200+ reuses without compromising performance

Lightweight & Labour-Friendly: Easy handling with less skilled labour

Custom Design Support: Tailored formwork plans for your exact project specs

Whether you are building mass housing, townships, or luxury high-rises, our Mivan formwork solutions scale with your needs.

Build Smarter with the Right Mivan Shuttering Components

Understanding the components of Mivan shuttering is essential for any builder or developer aiming for efficiency, strength, and long-term cost savings. As India pushes towards rapid urban housing and vertical growth, choosing the right formwork partner becomes even more crucial.

At BSL Scaffolding, we don’t just supply aluminium formwork—we deliver complete construction solutions that support your vision from foundation to finish.

Whether you’re switching from traditional methods or scaling up Mivan-based projects, we’re here to help you build faster, smarter, and stronger.

#mivan shuttering system#mivan technology#modern construction technique#aluminium formwork system#Components of Mivan Shuttering

0 notes

Text

Durable Modular Wall Column Formwork System | Reliable Formwork Accessories Suppliers

Discover Biiformtek’s modular wall column formwork system, designed for speed, precision, and reusability in concrete construction. Ideal for walls and columns, it pairs seamlessly with components from top formwork accessories suppliers. Boost efficiency and quality—visit biiformtek.in today.

0 notes

Text

Seamlessly Crafting Wall And Column Formworks For Your New Constructions

The success of any structure depends on dependable framework systems for support. Formworks provide shaping functions to produce solid beams, columns, walls, and slabs from concrete.

Structures become unstable and fail when beam, wall, slab, or column formwork is not used correctly. When properly selected, formwork systems create structures that are stronger and finish construction operations more quickly as they minimize used materials. The correct system selection guarantees persistent structural robustness and long-lasting durability.

The Importance of Precision in Formwork Design

The design of formwork needs to maintain exact precision. Even the smallest alignment mistake will cause the whole structure to become weaker. The correct installation of formwork results in a concrete setting according to its required dimensions and shapes. Engineers, together with builders, need to select pressure-resistant materials during their operational procedures. Routed frameworks lead to both an easy construction process and permanent structural integrity.

Efficient Use of Column Formwork in Construction

Vertical structures depend heavily on column formwork execution as a fundamental construction method. The framework maintains the form of wet concrete until it develops into durable vertical structures. The right column form system achieves both uniformity and strength. The implementation of pre-engineered systems results in improvements in both production efficiency and workplace security at construction sites.

Enhancing Structural Integrity with Beam Formwork

The beam formwork serves as a supporting system for making horizontal concrete structures. The primary function of beams is to carry the weight from above, including walls and slabs. A well-designed beam framework stops the downward bending and vertical displacement of concrete structures. Durability depends on using steel, plywood and plastic as strong implements for construction. A correctly chosen formwork system accelerates building processes while maintaining workplace safety standards.

The Significance of Wall Formwork in Building Projects

Wall formwork serves as an essential element for creating solid walls with regular surfaces. The forms maintain the concrete in position until it solidifies to obtain uniform surfaces. Quality wall forms decrease the formation of building defects and eliminate labor rework. Using lightweight, reusable formwork allows builders to execute this process at a lower cost.

Maximizing Efficiency with Slab Formwork

Horizontal concrete slabs receive support from slab formwork until they achieve total hardness. This material forms a secure foundation to support ceiling and floor concrete casting operations. The use of robust slab forms helps to stop the formation of cracks and create level surfaces. The use of modular systems generates better workplace efficiency while simultaneously lowering labor expenses.

Choosing the Right Formwork for Your Project

There are a few factors you need to consider for choosing the right formwork. Load-bearing capacity, reusability, and cost efficiency become fundamental elements for choosing the formwork system. The construction sector shows an increasing preference for modular formworks alongside plastic formworks due to their durability and convenient handling properties. The selection process of formwork systems depends heavily on weather conditions alongside project duration requirements.

Conclusion

The proper design of formwork functions as the essential element required for achieving construction success. Formwork technology enhances project strength while raising operational efficiency and minimizing cost expenses. Quality formwork systems provide safety along with an extended operational lifespan. A suitable formwork investment creates an improved flow and efficiency during building operations. NOVA Formworks is India’s preeminent company offering advanced formwork systems to customers. Their solutions ensure premium quality to ensure optimal construction outputs.

#formworks in india manufacturer and supplier#plastic formworks#civil construction#column formwork#beam formwork#wall formwork#slab formwork

0 notes

Video

youtube

Push Pull Prop Plates Manufacturing - Wall and Columb Formwork Shoring S...

#youtube#push pull#push pull props#steel props#formwork props#wall formwork bracing#wall formwork#column formwork#shuttering props#prop jacks

0 notes

Text

Understanding OPC Cement: The Strength Behind Modern Construction

In the ever-evolving world of construction, selecting the right cement is critical for ensuring strength, durability, and structural integrity. One of the most widely used types of cement in the construction industry is OPC cement, or Ordinary Portland Cement. It is renowned for its high strength, quick setting time, and consistent performance across a range of applications.

What is OPC Cement? OPC cement is a fine powder made by grinding clinker and gypsum. It is the most common type of cement used worldwide, particularly in infrastructure and commercial construction. It is available in three grades – OPC 33, OPC 43, and OPC 53 – each offering different levels of strength and performance depending on the construction need.

The high compressive strength and quick hardening properties of OPC cement make it ideal for applications that require fast completion and early strength gain. Whether it's the foundation of a building, high-rise structure, or bridge construction, OPC cement plays a vital role.

Key Advantages of OPC Cement High Early Strength: OPC cement offers high initial strength, making it suitable for projects requiring quick formwork removal and fast construction cycles.

Durability: Structures built with OPC cement are long-lasting and resistant to weathering, which is critical for both residential and industrial projects.

Versatility: It can be used for a wide range of construction activities, including concrete slabs, beams, columns, and even plastering and flooring.

Consistent Quality: OPC cement ensures consistent quality and uniformity, which is essential in large-scale construction.

Applications of OPC Cement OPC cement is widely used across various construction sectors:

Residential Construction: Ideal for foundations, roofs, and walls due to its strength and durability.

Commercial Buildings: Suitable for multi-storey buildings and commercial infrastructure where structural integrity is non-negotiable.

Bridges and Dams: With its ability to withstand high pressure and load, OPC cement is perfect for large-scale infrastructure projects.

Precast Structures: Used in the making of precast concrete elements due to its fast setting properties.

Why Choose Kamdhenu OPC Cement? Kamdhenu, a trusted name in the Indian construction industry, offers high-quality OPC cement that meets industry standards and performance expectations. With its advanced manufacturing process and strict quality control, Kamdhenu ensures that each bag of OPC cement delivers optimal strength and durability.

Contractors and builders prefer Kamdhenu OPC cement for its reliability, strength, and consistent setting time. Whether you're constructing a home or managing a commercial project, Kamdhenu’s cement products provide a solid foundation for success.

Conclusion OPC cement continues to be the backbone of modern construction due to its unmatched strength, durability, and versatility. From residential homes to mega infrastructure projects, its applications are vast and trusted. With companies like Kamdhenu delivering top-grade OPC cement, the future of construction in India looks stronger and more sustainable than ever.

If you’re looking for dependable performance and quality, OPC cement is the right choice—and Contact with Kamdhenu, you’re choosing excellence you can trust.

0 notes

Text

NOVA Formwork - A Leading Provider Of Multifunctional Formwork Systems

Nova Formwork Systems are made of high-tech plastic materials for effortless handling, and they are lightweight, strong, and reusable. You can count on consistent, faultless results whether you're working on a simple or complex structure.

#nova plastic formwork#formwork construction#plastic formwork#construction formwork#plastic formwork in india#wall formwork#beam formwork#column formwork#slab formwork

0 notes