#high-performance materials

Text

Unleashing the Potential of Oxygen-Free Copper: Revolutionizing High-Performance Applications

Oxygen-free high-conductivity copper is another name for oxygen-free copper. A class of wrought copper alloys known as oxygen-free copper is refined using an electrolytic process and exhibits excellent conductivity. In particular, electrolytic refining is required to reduce the oxygen concentration to or below 0.001%.

Makers are focused on item testing to make sure that production programs,…

View On WordPress

#advanced metal#aerospace industry#automotive applications#circuit boards#conductivity#copper alloys#corrosion resistance#electrical industry#Electronics#heat exchangers#high-performance materials#market trends#metal fabrication#oxygen-free copper#power transmission#reliability#renewable energy#telecommunications

0 notes

Text

the thing about lucas' departure from wayv-nct is that... unlike woojin or b.i, SM still manage him, he didn't move into another company or anything.

the separation is awkward rn but i'm just saying, if he appears on the next smtown, you know taeyong or kun will just pull him into the row of boys that is comprised of neocity-riize members without blinking.

#unless sm is being careful and petty and cowardice#so they will just exclude him#while other sm artists performs#cowards i tell you#COWARDS TO MAKE THE TRUTH CLEAR BUT NOT ON PUTTING THE BOY OUT FOR MONEY#i will say that until they proove me otherwise#were they this clear-foggy about taeyong as well??#i need to review things again gosh#concerning the text statement: the possibility of taeyong not giving a fuck and doing just that is very high#like even raiden came to smtown#and he's not that much on the hot kpop sphere#if any of raidens fans reads this#please be understanding i did not mean to undermean him in anyway#lucas wong#nct lucas#wayv lucas#...i don't even know if i can use those tags but how else do i say its that lucas#lucas renegade#i feel like this is thought material for twitter instead of tumblr but i deleted my twitty so anyhoo#i am asking for chaos by asking this#go on give me that slap#lucas' eyes are just so somber nowadays dude#i just...let him go to the weishenies please

12 notes

·

View notes

Text

-Barberry HCL 97% (1500 mg) is a potent natural supplement supporting metabolism, cholesterol, and blood sugar levels. Backed by traditional Chinese medicine and scientific studies, it aids in managing chronic conditions like diabetes and heart disease by activating AMPK enzyme.

"Please click on this link to get the product or to get an idea about it."https://berbaprime.com/?_ef_transaction_id=&oid=19&affid=37573

#High quality#Excellent performance#Elegant design#Durability#Advanced technology#Comfort#Multi-purpose use#Premium materials#Fine details#Innovation#Development#Reliability#Elegance

2 notes

·

View notes

Text

officially going to be taking a standup comedy class next semester!!! now my schedule is literally:

improv class

sociology class about queer history

standup class

buddy cole documentary which counts as a class despite only meeting with the professor when i want to and being a project i would work on even if i didn't get college credit

god i love majoring in comedy in college

#i realized my science credit was already taken care of by a dual enrollment class i did in high school so that gave me an opening#and i already have a plan to take care of all the other general education stuff later so i might as well load up on comedy courses#unfortunately due to some bullshit that's not as interesting as i think it is a lot of the comedy classes aren't running this fall#so the only one at my level with open seats is standup#and y'know typically i do NOT enjoy performing standup. i love watching standup very much but performing it's not for me#(plus ik my nemesis is in that class and she's also in my 2 other real classes so ugh i'm gonna be seeing a lot of her)#HOWEVER. i've already taken a course with this professor and he likes me#he's a kith fan so if i have to miss class or get an extension bc of work on the buddy cole doc he'll probably be super understanding#and!!! most importantly!!! he's really into character standup which not a lot of students choose to do#but for me. this gives me a perfect opportunity to actually work on some of my aubrey material as a ''standup character''#or at the very least shoehorn buddy cole into discussions lmao#also. my improv class is right before this one and improv is probably the type of comedy i'm most confident in#so maybe that will give me a nice push to get more confident in standup#and as for the ''constantly having to be around my nemesis'' thing. well i can hope that she manages to chill out by then#but even if she is insufferable. i can take solace in being the one with kith connections and paul will almost definitely let me rant to hi

4 notes

·

View notes

Text

Being genuinely supported is crazy wow

#i was lamenting how i didnt fo as well as i couldve on my last exam#and he was like okay but you know what you needed to like you still understood the course material so give yourself that credit#and then went on about how i need to give myself more credit even if it isnt wholly reflected in my grades because at the end of the day#its MY understanding that matters#which is a bit of a privileged take as he has a really high gpa and i do NOT (partially for reasons outside of my control)#so like i am MUCH more impacted by grades#but i do understand the sentiment i do think hes right because i DO put a lot of pressure on myself to perform well even if like#i already have done well ill still think i couldve done better#like idk what my grade will be for this course but im sure that ill be pretty okay (c+ to b range) and like thats good!#but anyways hearing him say that almost made me cry and im not even 100% sure why?

5 notes

·

View notes

Text

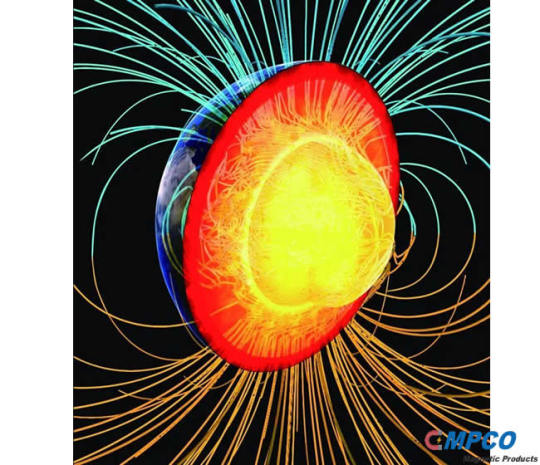

Why Does High-temperature Liquefied Iron Nucleus Produce a Huge Magnetic Field?

Bar Magnet Heating Will Lose Magnetism, Why Does High-temperature Liquefied Iron Nucleus Produce a Huge Magnetic Field?

The atoms in the magnet are arranged neatly in accordance with certain rules, which is why magnets have magnetic reasons. When heating the magnet, the arrangement of the atom is disrupted and the magnetic is reduced. When heating to 770 ° C, the magnet loses magneticity.

Why…

View On WordPress

#AI Magnets#Cerium Magnets#cerium-containing magnets#Grain Boundary Diffusion#high-performance magnetic materials#Magnet Maker#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Materials#Magnetic Phenomena#magnetic properties#magnetic treatment#Magneticity#NdFeB Magnet#NdFeB permanent magnet#NdFeB Surface Treatment#Neodymium iron boron#Neodymium Magnet Applications#Permanent Magnet Materials#Permanent Magnets#Rare Earth Magnets#rare earth permanent magnet#Sintered NdFeB#Sintered NdFeB Magnets#Super Magnets

2 notes

·

View notes

Text

Commercial Insulation Materials in NY

DiNaso Building Supply is a leading provider of the highest quality commercial insulation materials in NY, with ample variety in both our products and services. Reach out to our team for placing an order and guaranteed delivery in 48 hours to your site!

2 notes

·

View notes

Text

#Yttria zirconia ceramic beads are first made of micron and sub-nano-scale raw materials and made with advanced technology#with high technical indicators and performance. It is mainly used for ultra-fine grinding and dispersion of materials requiring "zero pollu#High strength#hardness and wear resistance#low wear#high grinding efficiency#suitable for high viscosity and wet grinding occasions#if the cost performance is relatively high#you can choose yttria zirconia ceramic beads#which have a long life.

2 notes

·

View notes

Text

Discover A-Gas Electronic Materials' EIF solutions for high-performance PCB production and electronic components. Our advanced chemistries ensure superior quality and reliability in electronic devices. Trust A-Gas for innovative industrial finishing technologies.

#Electronic Industrial Finishing#EIF solutions#high-performance PCBs#electronic components#plating solutions#metal stripping#cleaning agents#soldermask resists#A-Gas Electronic Materials#UK electronic manufacturing#electronic finishing services#PCB production#electroplating#metal treatment products

1 note

·

View note

Text

Summary of 25 plastic reinforced modification formulas and 20 key points involved

There are many common plastic modification technologies, mainly reinforcement technologies, including fiber reinforcement, self-reinforcement, and molecular reinforcement; toughening technology; filling modification; blending and plastic alloy technology; flame retardant technology; nanocomposite technology; reaction grafting modification; aging resistance; functional modification, including…

View On WordPress

#Antistatic glass fiber reinforced PA6 impeller#Chopped glass fiber reinforced PP#Compatibilizer#Composite reinforced PP#Engineering plastic reinforced formula#Enhanced PF for chemical anti-corrosion pipelines#Epoxy fiberglass#Epoxy phenolic fiberglass#Flame retardant and antistatic reinforced PA6#Flame retardant glass fiber reinforced PA6 impeller#GF enhanced RJM-PU#Glass fiber reinforced PP#Glass fiber reinforced PVC#Glass fiber reinforced PVDC special-shaped components#High performance glass fiber reinforced PP#High strength unsaturated polyester board#Long glass fiber reinforced PA6#Mica reinforced PP#No. 771 unsaturated polyester fiberglass#plastic modification technologies#plastic reinforced modification formulas#PS coloring formula#thermoplastic reinforced formulations#Thermoset reinforced formulations#Transparent glass fiber reinforced PC#UHMWPE/carbon fiber composite materials#Wollastonite fiber-filled reinforced PP

0 notes

Text

Mastering the Art of Bonding with Composite Adhesive Techniques

Understanding the composition of composite adhesive is essential for mastering bonding techniques. Typically composed of resins, fillers, and additives, composite adhesive is engineered to create a strong and durable bond between different materials. The precise formulation of these components determines the adhesive's properties, such as curing time, strength, and resistance to environmental factors.

Surface preparation plays a crucial role in ensuring the effectiveness of Composite Adhesive bonding. Before applying the adhesive, surfaces must be clean, dry, and free of any contaminants that could compromise the bond. Proper surface preparation ensures maximum adhesion strength and promotes long-term durability.

Selecting the right application method is vital for achieving optimal bonding results with composite adhesive. Depending on the materials being bonded and the specific requirements of the application, various techniques can be employed, including brush application, spray application, and automated dispensing systems. Each method offers unique advantages and considerations, allowing for precise control over adhesive application and distribution.

Proper curing is essential for maximizing the strength and durability of composite adhesive bonds. Curing refers to the process by which the adhesive undergoes chemical reactions to harden and create a strong bond between the bonded surfaces. Factors such as temperature, humidity, and curing time must be carefully controlled to ensure consistent and reliable bonding results.

Get More Insights On This Topic: Composite Adhesive

#Composite Adhesive#Bonding Agents#Structural Adhesives#Composite Materials#Adhesive Bonding#Industrial Adhesives#Aerospace Adhesives#High Performance Adhesives#Composite Repair Materials

0 notes

Text

Aerospace Precision Uni Tritech's Mastery in Machined Components

Sky's the Limit with Uni Tritech Machined Components for Aerospace! In the realm of aeronautics, where precision is as vital as the craft itself, Uni Tritech reigns supreme. As the best platform for aerospace machined components, their expertise propels the industry to new heights. With advanced technology and meticulous craftsmanship, each piece is engineered to perfection, ensuring the highest levels of performance and safety. Uni Tritech’s commitment to excellence makes them the trusted ally of aviators and aerospace engineers worldwide. When it comes to dependable machining, Uni Tritech delivers components that truly soar above the rest.

Uni Tritech not only embodies engineering excellence but also infuses innovation into every machined component, forging paths for groundbreaking aerospace development. Their relentless pursuit of quality defines the essence of their service, making Uni Tritech synonymous with aerospace achievement.

#Aerospace CNC Machining#Aerospace Components Manufacturing#Precision Aerospace Machining#Advanced Aerospace Materials#Reliable Machined Components#Uni Tritech High-Performance Aerospace Parts#Uni Tritech Certified Aerospace Components

0 notes

Text

anyone else have recurring dreams where they perform self-surgery on a healthy organ with the plan of just taking it out for a little while but then you realize you are incapable of putting it back in and theres nothing you can do theresnothingyoucandotheresnothingyoucandotheresnothingyoucando

#they are literally so anxiety inducing and harrowing its horrible#my first ones were about teeth#then i had them about my brain#one of the brain ones i had i chopped it into nicely sliced pieces and then left it alone with the plan of just#taking a break from my brain#and then putting it back in piece by piece#and then i came back and my friends dog was eating it LOL#and then i just had one the other night where i had a mysterious organ in my leg that#was a 'bladder' but it wasn't my bladder it was in my leg#i'm pretty sure my brain based this mysterious organ off of a fish bladder#anyways i took it out and went swimming and held it in the water#and then i got out and i was traversing some combination between my highschool and my old church#trying to find materials to perform self surgery again to put it back in#but i just got into a thought spiral in that one thinking about how i didn't know how to put it back in#and i couldn't reattach it and i was essentially fucked lol??#and as this is happening my whole high school swim team is meeting in a room and im supposed to be there but#im dealing with bigger things but they all look at me like wow... can't believe she didn't come to the meeting#and after awhile of that i woke up LOL#its crazy im always so grateful it was a dream lol because i get so immersed#and ill be like guess im the stupidest person ever#it reminds me actually a lot of the feeling i got after my suicide attempt which i am not suicidal at all right now so its odd

1 note

·

View note

Text

seeing the regional premiere of The Great Comet at my favorite theatre tomorrow lads

#i dont wanna get my hopes TOO high because even though this theatre is fucking excellent#it will be very hard to match the unique experience of the broadway version (which i saw twice)#but if anyones gonna do this well its this theatre#plus i alredy saw a regional version of great comet in maine and it not beig able to match the unique brilliance of the high-budget version#didnt detract from it still being a great performance with a lot of heart and love for the source material#frequency 141.12#theatreposting

0 notes

Text

Exploring Industrial Core Drilling Solutions: Unlocking Precision and Efficiency

In the vast landscape of industrial operations, precision and efficiency are the cornerstone of success. Whether it's for construction, mining, or geological exploration, having the right tools and techniques for core drilling is essential. Industrial core drilling solutions offer a sophisticated approach to extracting cylindrical samples from various substrates with unparalleled accuracy. In this article, we'll embark on a journey to uncover the significance, benefits, and applications of Industrial Core Drilling Solutions, exploring how they revolutionize modern industrial practices.

Delving into Industrial Core Drilling

1. Understanding Industrial Core Drilling Solutions

Industrial core drilling solutions encompass a range of techniques and technologies designed to extract core samples from different materials, including rock, concrete, and asphalt. These solutions are tailored to meet the specific needs of industrial applications, where precision and reliability are paramount.

Versatility: Industrial core drilling solutions are versatile, capable of handling a wide range of substrates and operating conditions.

Precision Engineering: By leveraging advanced equipment and techniques, industrial core drilling solutions deliver accurate and consistent results, critical for engineering and scientific applications.

The Mechanics Behind Industrial Core Drilling

1. Cutting-Edge Equipment

At the heart of industrial core drilling solutions lies cutting-edge equipment engineered for performance and reliability.

Diamond Core Bits: Utilizing diamond-tipped drill bits, industrial core drilling solutions can penetrate even the toughest materials with ease, ensuring clean and precise core extraction.

Hydraulic Core Drills: Hydraulic core drills offer high-powered drilling capabilities, allowing for fast and efficient penetration through various substrates.

2. Advanced Techniques

Industrial core drilling solutions employ a variety of advanced techniques to optimize drilling operations and maximize efficiency.

Wet Drilling: Wet drilling techniques involve the continuous supply of water to the drilling area, serving as a coolant and lubricant to reduce friction and heat during drilling.

Dry Drilling: Dry drilling techniques utilize air or other fluids to remove debris from the drilling area, offering convenience and simplicity in certain applications.

Benefits of Industrial Core Drilling Solutions

1. Precision Sampling and Analysis

One of the primary benefits of industrial core drilling solutions is their ability to provide accurate and representative core samples for analysis.

Geological Exploration: Core samples extracted through industrial core drilling solutions offer valuable insights into subsurface geology, aiding in mineral exploration and resource estimation.

Construction and Infrastructure: In the construction industry, core samples are used for structural analysis, material testing, and quality assurance purposes.

2. Increased Productivity and Efficiency

Industrial core drilling solutions enhance productivity and efficiency in industrial operations, reducing downtime and optimizing resource utilization.

Faster Turnaround Times: By streamlining drilling operations and optimizing equipment, industrial core drilling solutions enable faster turnaround times, essential for meeting project deadlines.

Minimized Waste: Precision core drilling minimizes material wastage, reducing costs and environmental impact associated with drilling operations.

Applications Across Industries

1. Construction and Engineering

Industrial core drilling solutions play a crucial role in construction and engineering projects, providing critical data for design, analysis, and quality control.

Foundation Design: Core samples extracted through industrial core drilling solutions help engineers assess subsurface conditions, determine soil properties, and design foundations accordingly.

Material Testing: Core samples are subjected to various tests, including compression, tensile, and shear tests, to evaluate material properties and performance.

2. Mining and Exploration

In the mining and exploration industry, industrial core drilling solutions are instrumental in resource delineation, ore body characterization, and geotechnical assessment.

Ore Body Delineation: Core drilling provides valuable information on the size, grade, and distribution of mineral deposits, guiding exploration and resource estimation efforts.

Geotechnical Studies: Core samples offer insights into rock mechanics, stability, and groundwater conditions, crucial for mine planning and design.

Embracing Innovation for Future Advancements

As technology continues to evolve, industrial core drilling solutions will evolve with it, paving the way for new innovations and advancements in the field.

Automation and Robotics: Integration of automation and robotics into industrial core drilling equipment promises to enhance drilling efficiency, safety, and precision.

Advanced Material Science: Ongoing research in material science aims to develop new materials and coatings for drill bits, improving performance and longevity in harsh operating environments.

youtube

Conclusion: Driving Industrial Progress with Core Drilling Solutions

In conclusion, industrial core drilling solutions are the backbone of modern industrial practices, offering precision, efficiency, and reliability where it matters most. Whether it's for construction, mining, or scientific research, these solutions play a vital role in driving industrial progress and innovation. As we look to the future, the possibilities for further advancements and breakthroughs in industrial core drilling are limitless, promising to redefine the boundaries of what's achievable in industrial operations. So, the next time you embark on an industrial project that demands precision and efficiency, remember the invaluable role of industrial core drilling solutions in unlocking new possibilities and driving success

Industrial core drilling solutions represent the pinnacle of precision and efficiency in industrial operations. Let's delve into the world of industrial core drilling, exploring its mechanics, benefits, and applications across various industries.

Unraveling Industrial Core Drilling Solutions

1. Precision Perfected

Industrial core drilling solutions are engineered to deliver precise and reliable results, essential for a wide range of industrial applications.

Tailored Solutions: Industrial core drilling solutions are tailored to meet the specific needs of each project, ensuring accuracy and efficiency.

Cutting-Edge Technology: Leveraging advanced equipment and techniques, industrial core drilling solutions offer unmatched precision and reliability.

The Anatomy of Industrial Core Drilling

1. State-of-the-Art Equipment

Industrial core drilling relies on a range of cutting-edge equipment designed for performance and durability.

Diamond Core Bits: Equipped with diamond-tipped drill bits, industrial core drilling solutions can penetrate various materials with ease, ensuring clean and precise core extraction.

Hydraulic Core Drills: Hydraulic core drills offer high-powered drilling capabilities, allowing for fast and efficient penetration through tough substrates.

2. Advanced Techniques

Industrial core drilling solutions employ advanced techniques to optimize drilling operations and maximize efficiency.

Wet Drilling: Wet drilling techniques utilize water as a coolant and lubricant, reducing friction and heat during drilling operations.

Dry Drilling: Dry drilling techniques offer convenience and simplicity, using air or other fluids to remove debris from the drilling area.

Benefits of Industrial Core Drilling Solutions

1. Precision Sampling and Analysis

Industrial core drilling solutions provide accurate and representative core samples for analysis, essential for geological, geotechnical, and engineering applications.

Geological Exploration: Core samples offer insights into subsurface geology, aiding in mineral exploration and resource estimation.

Construction and Engineering: Core samples are used for structural analysis, material testing, and quality assurance in construction and engineering projects.

2. Increased Productivity and Efficiency

Industrial core drilling solutions enhance productivity and efficiency, reducing downtime and optimizing resource utilization.

Faster Turnaround Times: By streamlining drilling operations, industrial core drilling solutions enable faster turnaround times, essential for meeting project deadlines.

Minimized Waste: Precision core drilling minimizes material wastage, reducing costs and environmental impact associated with drilling operations.

#Floor and Wall Core Drilling#Core Drilling for Building Renovations#Environmental Core Drilling Practices#Core Drilling for Foundation Analysis#Specialist Core Drilling Contractors#Core Drilling for Civil Engineering#Horizontal and Vertical Core Drilling#Core Drilling for Roadway Construction#Precision Core Cutting Services#Core Drilling for Material Testing#High-Performance Core Drilling Bits#Youtube

1 note

·

View note

Text

Human Beings Can Feel Magnetic Field and Maybe Predict The Future!

The sixth sense of magnetism is first confirmed That Human Beings Can Feel Magnetic Field and Maybe Predict The Future!

In our real life, there are often strange experiences, and sometimes I always feel that my crow’s mouth is said. There is always a feeling of feeling that something is going on, but I did not expect to be fulfilled in a few days. When walking on the road, I always feel that…

View On WordPress

#AI Magnets#Cerium Magnets#cerium-containing magnets#ferrite permanent magnets#Grain Boundary Diffusion#Halbach Array#high-performance magnetic materials#Magnet Maker#Magnetic air conditioners#Magnetic Application#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Materials#Magnetic Phenomena#magnetic properties#magnetic treatment#NdFeB Magnet#NdFeB permanent magnet#NdFeB Surface Treatment#Neodymium iron boron#Neodymium Magnet Applications#Permanent Magnet Materials#Permanent Magnets#Rare Earth Magnets#rare earth permanent magnet#Sintered NdFeB#Sintered NdFeB Magnets#Super Magnets

2 notes

·

View notes