#humidity sensor switch

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/semiconductors--analog--sensors--humidity-dew/sht41i-ad1b-r2-sensirion-9164920

Digital humidity sensor, USB data, Soil moisture sensor, Temperature sensor

SHT41I-AD1B-R2

#Sensirion#SHT41I-AD1B-R2#Sensors#Humidity / Dew Sensors#digital#USB data#Soil moisture sensor#Engine coolant#humidity monitor#USB data logger software#home#Remote humidity sensor#humidity sensor switch

1 note

·

View note

Text

Industrial humidity sensor, capacitive humidity sensor, home humidity sensor

SHT21 Series 3 V -40 to +125 °C Digital Humidity & Temperature Sensor IC - DFN-6

#Sensors#Humidity#Dew Sensors#SHT21-TR-0.4KS#Sensirion#industrial humidity sensor#capacitive humidity sensor#Digital Humidity#thermistor resistance#Magnetic#Air coolant temperature#Current Sensors#switch#chip#home#humidity controller

1 note

·

View note

Text

Stretchable transistors used in wearable devices enable in-sensor edge computing

Organic electrochemical transistors (OECTs) are neuromorphic transistors made of carbon-based materials that combine both electronic and ionic charge carriers. These transistors could be particularly effective solutions for amplifying and switching electronic signals in devices designed to be placed on the human skin, such as smart watches, trackers that monitor physiological signals and other wearable technologies. In contrast with conventional neuromorphic transistors, OECTs could operate reliably in wet or humid environments, which would be highly advantageous for both medical and wearable devices. Despite their potential, most existing OECTs are based on stiff materials, which can reduce the comfort of wearables and thus hinder their large-scale deployment.

Read more.

#Materials Science#Science#Transistors#Computing#Electrochemistry#Electronics#Organic materials#Flexible electronics#Wearable technology

16 notes

·

View notes

Text

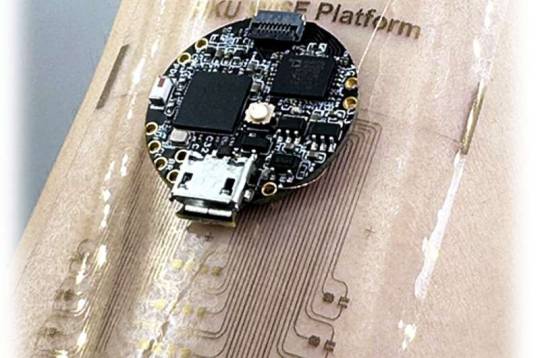

A new, upgraded style of soil sensor 🪴💧🌡️

For a while, we've had a SAMD09-based soil sensor (https://www.adafruit.com/product/4026) that uses the built-in capacitive sensing. It works well but has some non-linearity in its response to wet soil. We wanted to try a different system of measuring capacitance and update it to a 3~5V friendly ATtiny816 (https://www.adafruit.com/product/5681), which lets us ditch the regulator and shifting circuitry. We'll also Stemma QT-ify it and add a NeoPixel and an AHT20 low-cost temperature/humidity sensor (https://www.adafruit.com/product/4566) for an 'all in one' gardening sensor. The un-rendered part in the center is a 3-pin DIP switch in 1.27mm pitch, for easily setting the I2C address. Coming soon.

#adafruit#soilsensor#plants#gardentools#smarthome#gardeningtech#plantsensor#sensorupgrade#diygarden#plantcare#techinnovation#smartsensor#homeautomation

15 notes

·

View notes

Text

Helmet Capabilities

The standard-issue helmet for the cadets in the Enforcer Academy is a multifunctional headgear designed to provide protection, communication, and situational awareness. The helmet is an integral component of the full-body armor system and offers the following capabilities:

Protection and Construction

Material: Constructed from a composite of high-strength polymers and lightweight alloys, the helmet offers excellent ballistic protection while remaining lightweight.

Ergonomics: The interior is padded with adjustable, high-density foam to ensure a secure and comfortable fit for extended wear.

Visor System

Retractable Visor: The helmet features a retractable, polycarbonate visor that can be deployed or retracted with a simple voice command or manual switch. The visor is impact-resistant and provides full facial protection.

Heads-Up Display (HUD): When the visor is deployed, it functions as a transparent display, overlaying critical information directly onto the user's field of vision. The HUD includes data such as ID overlays of other cadets, navigation aids, environmental readings, and communication messages.

Communication

Integrated Communications Suite: The helmet is equipped with a built-in communication system, allowing for helmet-to-helmet communication among cadets and instructors. This includes individual, group, and broadcast modes.

External Noise Control: The helmet can either fully block outside noise or allow selective sounds, such as authorized speech, to pass through. This feature ensures clear communication while maintaining situational awareness.

Sensory Input Management

Noise Dampening: Blocks out external noise when necessary, with adjustable settings to allow selective auditory input.

Visual Filters: Can dim, block or enhance visual input based on the cadet’s environment, reducing sensory overload.

AI Monitoring: The helmet’s integrated AI monitors conversations, filtering out unauthorized or harmful communications and providing real-time feedback.

Sensors and Monitoring

Environmental Sensors: The helmet includes sensors to monitor external conditions such as temperature, humidity, and air quality, providing real-time data to the wearer and the command center.

Biometric Monitoring: The helmet continuously monitors vital signs, including heart rate, respiration, and stress levels, transmitting this data to the central monitoring system.

Safety and Security

Neck Seal: The helmet features an airtight neck seal that integrates with the body armor, ensuring a complete protective barrier against hazardous environments.

Additional Features

Night Vision and Thermal Imaging: The helmet is equipped with night vision and thermal imaging capabilities, allowing for enhanced visibility in low-light or obscured conditions.

Custom Fit: The padding and internal structure can be adjusted to fit various head sizes and shapes, ensuring a custom fit for each cadet.

Usage and Maintenance

Battery Life: The helmet's power supply is integrated with the suit's main power system, providing continuous operation for up to five days without recharging.

Maintenance: Regular maintenance includes cleaning the visor, checking the seals, and ensuring the communication systems are functioning properly. Maintenance protocols are outlined in the standard operating procedure manual.

Remote Control and Safety Features

Instructor Control: Instructors can remotely control helmet functions, including visual and auditory inputs, to ensure cadet safety and compliance.

Emergency Lockdown: The helmet can immobilize the cadet’s head and control movements via the neural interface in critical situations.

Usage Parameters

Operational Duration: Designed for continuous use up to 7 days, with standard operational periods of 5 days.

Maintenance Cycle: Requires a maintenance check and recalibration after each operational cycle to ensure optimal performance.

6 notes

·

View notes

Text

How to Extend the Life of Your Electrical Switchgear

Electrical switchgear is a critical component in power distribution systems, responsible for controlling, protecting, and isolating electrical equipment. Whether used in industrial plants, commercial buildings, or utility substations, switchgear must operate reliably to prevent costly downtime, equipment damage, or safety hazards. As such, extending the life of your switchgear is both an economic and operational imperative.

This article outlines essential strategies, best practices, and maintenance procedures that can significantly enhance the longevity and performance of your electrical switchgear.

1. Understand the Role and Types of Switchgear

Before diving into maintenance and care strategies, it’s important to understand what switchgear is and its various types:

· Low-voltage (LV) switchgear: Used for systems below 1,000 volts, common in commercial and residential buildings.

· Medium-voltage (MV) switchgear: Used in systems from 1 kV to 36 kV, typical in industrial and utility distribution networks.

· High-voltage (HV) switchgear: For voltages above 36 kV, used in power transmission infrastructure.

Each type has different components, such as circuit breakers, fuses, relays, and disconnect switches, which require tailored care.

2. Implement a Preventive Maintenance Schedule

Preventive maintenance is the cornerstone of extending switchgear life. Scheduled inspections and servicing can prevent small issues from becoming major failures.

Key preventive maintenance steps include:

· Visual Inspections: Check for signs of wear, corrosion, overheating, or arcing.

· Thermal Imaging: Detect hotspots caused by loose connections or overloading.

· Cleaning: Remove dust, dirt, and moisture using appropriate cleaning agents and methods.

· Mechanical Checks: Operate switches and breakers manually to ensure they move freely and reset properly.

· Lubrication: Apply the correct lubricants to moving parts to prevent wear.

· Electrical Testing: Conduct insulation resistance tests, contact resistance tests, and functionality tests on protection relays.

Frequency:

· Monthly or quarterly: Visual inspections and thermal scanning.

· Annually: Comprehensive testing, cleaning, and mechanical servicing.

3. Upgrade Components and Retrofit When Necessary

As equipment ages, its performance naturally declines. Rather than replacing the entire system, consider retrofitting critical components such as:

· Circuit breakers (replace air-magnetic with vacuum or SF₆ types)

· Protection relays (upgrade to digital, microprocessor-based units)

· Monitoring systems (add condition-monitoring sensors for real-time data)

Modern retrofitting extends service life, improves reliability, and enhances safety without the cost and disruption of full replacement.

4. Maintain Optimal Environmental Conditions

Environmental factors can greatly affect switchgear performance and durability. Control conditions around the equipment by:

· Maintaining Proper Ventilation: Prevent heat buildup with adequate airflow or HVAC systems.

· Controlling Humidity: High moisture levels can lead to insulation breakdown and corrosion.

· Dust and Contaminant Management: Install enclosures with appropriate IP ratings and regularly clean surroundings.

· Avoiding Vibration and Shock: Secure equipment on stable platforms and use vibration dampers if necessary.

5. Train Personnel and Enforce Safe Operating Procedures

Human error is a major cause of switchgear failure. Properly trained staff who understand how to operate and maintain switchgear will significantly reduce risks.

Key practices include:

· Following lockout/tagout (LOTO) procedures

· Using insulated tools and personal protective equipment (PPE)

· Understanding equipment ratings and not exceeding operational limits

· Reporting anomalies immediately

Regular training programs and refresher courses should be a part of your electrical safety culture.

6. Implement Condition-Based Monitoring (CBM)

Moving from traditional preventive maintenance to condition-based monitoring (CBM) can improve accuracy and reduce unnecessary downtime.

CBM Tools Include:

· Partial Discharge Monitoring: Detects insulation degradation early

· Temperature Sensors: Identifies abnormal heating patterns

· Gas Detection: Monitors SF₆ gas quality in HV switchgear

· Remote Diagnostics: Allows offsite engineers to assess equipment in real time

CBM extends switchgear life by ensuring maintenance is performed only when needed — based on actual conditions rather than time intervals.

7. Document Maintenance History and Perform Asset Tracking

Maintain detailed records of all inspections, maintenance activities, upgrades, and failures. This helps in:

· Identifying recurring problems

· Planning timely interventions

· Estimating remaining useful life (RUL)

· Complying with industry regulations and audits

Use asset management software or computerized maintenance management systems (CMMS) to streamline documentation and data analysis.

8. Plan for End-of-Life (EOL) and Decommissioning

Despite all efforts, switchgear eventually reaches the end of its operational life. Having an EOL strategy helps to:

· Prevent catastrophic failure

· Schedule replacements during planned downtime

· Upgrade to systems with modern safety, efficiency, and smart-grid features

Signs that switchgear is reaching EOL include frequent failures, obsolete parts, and loss of manufacturer support.

Conclusion

Electrical switchgear plays a vital role in ensuring the safe and efficient operation of electrical systems. By implementing proactive maintenance, upgrading aging components, monitoring environmental conditions, training personnel, and embracing modern monitoring technologies, you can significantly extend the life of your switchgear.

Not only will these strategies help in maximizing return on investment, but they will also improve safety, reduce downtime, and ensure regulatory compliance. Taking a systematic and well-documented approach to switchgear care is the smartest way to ensure long-term performance and reliability.

4 notes

·

View notes

Text

Top 10 Projects for BE Electrical Engineering Students

Embarking on a Bachelor of Engineering (BE) in Electrical Engineering opens up a world of innovation and creativity. One of the best ways to apply theoretical knowledge is through practical projects that not only enhance your skills but also boost your resume. Here are the top 10 projects for BE Electrical Engineering students, designed to challenge you and showcase your talents.

1. Smart Home Automation System

Overview: Develop a system that allows users to control home appliances remotely using a smartphone app or voice commands.

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Wi-Fi or Bluetooth module

Sensors (temperature, motion, light)

Learning Outcome: Understand IoT concepts and the integration of hardware and software.

2. Solar Power Generation System

Overview: Create a solar panel system that converts sunlight into electricity, suitable for powering small devices or homes.

Key Components:

Solar panels

Charge controller

Inverter

Battery storage

Learning Outcome: Gain insights into renewable energy sources and energy conversion.

3. Automated Irrigation System

Overview: Design a system that automates the watering of plants based on soil moisture levels.

Key Components:

Soil moisture sensor

Water pump

Microcontroller

Relay module

Learning Outcome: Learn about sensor integration and automation in agriculture.

4. Electric Vehicle Charging Station

Overview: Build a prototype for an electric vehicle (EV) charging station that monitors and controls charging processes.

Key Components:

Power electronics (rectifier, inverter)

Microcontroller

LCD display

Safety features (fuses, circuit breakers)

Learning Outcome: Explore the fundamentals of electric vehicles and charging technologies.

5. Gesture-Controlled Robot

Overview: Develop a robot that can be controlled using hand gestures via sensors or cameras.

Key Components:

Microcontroller (Arduino)

Motors and wheels

Ultrasonic or infrared sensors

Gesture recognition module

Learning Outcome: Understand robotics, programming, and sensor technologies.

6. Power Factor Correction System

Overview: Create a system that improves the power factor in electrical circuits to enhance efficiency.

Key Components:

Capacitors

Microcontroller

Current and voltage sensors

Relay for switching

Learning Outcome: Learn about power quality and its importance in electrical systems.

7. Wireless Power Transmission

Overview: Experiment with transmitting power wirelessly over short distances.

Key Components:

Resonant inductive coupling setup

Power source

Load (LED, small motor)

Learning Outcome: Explore concepts of electromagnetic fields and energy transfer.

8. Voice-Controlled Home Assistant

Overview: Build a home assistant that can respond to voice commands to control devices or provide information.

Key Components:

Microcontroller (Raspberry Pi preferred)

Voice recognition module

Wi-Fi module

Connected devices (lights, speakers)

Learning Outcome: Gain experience in natural language processing and AI integration.

9. Traffic Light Control System Using Microcontroller

Overview: Design a smart traffic light system that optimizes traffic flow based on real-time data.

Key Components:

Microcontroller (Arduino)

LED lights

Sensors (for vehicle detection)

Timer module

Learning Outcome: Understand traffic management systems and embedded programming.

10. Data Acquisition System

Overview: Develop a system that collects and analyzes data from various sensors (temperature, humidity, etc.).

Key Components:

Microcontroller (Arduino or Raspberry Pi)

Multiple sensors

Data logging software

Display (LCD or web interface)

Learning Outcome: Learn about data collection, processing, and analysis.

Conclusion

Engaging in these projects not only enhances your practical skills but also reinforces your theoretical knowledge. Whether you aim to develop sustainable technologies, innovate in robotics, or contribute to smart cities, these projects can serve as stepping stones in your journey as an electrical engineer. Choose a project that aligns with your interests, and don’t hesitate to seek guidance from your professors and peers. Happy engineering!

5 notes

·

View notes

Text

Essential Electronic Items for IoT and Electronics Enthusiasts

Are you diving into the world of Internet of Things (IoT) and electronics? Whether you are a seasoned engineer or simply beginning out, having a stable list of essential components is key to bringing your initiatives to existence. Here’s a curated list of electronic objects that each maker and tech enthusiast ought to have of their toolkit:

1. Microcontrollers

Arduino Uno: Great for novices and versatile for diverse projects.

Raspberry Pi: Ideal for more complex duties and going for walks complete operating structures.

ESP8266/ESP32: Perfect for wireless communication and IoT projects.

2. Sensors

DHT22: For temperature and humidity readings.

PIR Sensor: Useful for movement detection.

Ultrasonic Distance Sensor: Measures distances with high accuracy.

3. Actuators

Servo Motors: For unique manage in robotics and mechanical structures.

Stepper Motors: Ideal for applications requiring particular movement.

Solenoids: Good for growing mechanical actions and locks.

4. Displays

LCD Display: Useful for showing records and debugging.

OLED Display: Compact and clean for exact photographs and texts.

5. Connectivity Modules

Bluetooth Module (HC-05/HC-06): For short-range wi-fi communication.

Wi-Fi Module (ESP8266): Connects gadgets to the internet.

GSM Module: Enables verbal exchange over mobile networks.

6. Power Supplies

Battery Packs: Various types for transportable electricity.

Voltage Regulators: Ensure solid voltage ranges in your circuits.

Power Banks: Handy for charging and powering devices on the move.

7. Prototyping Tools

Breadboards: Essential for prototyping with out soldering.

Jumper Wires: For making connections on breadboards.

Soldering Kit: For everlasting connections and circuit meeting.

eight. Additional Components

Resistors, Capacitors, and Diodes: Fundamental for circuit design and stability.

Transistors: Key for switching and amplification tasks.

Connectors and Switches: For interfacing and controlling circuits.

By preserving these objects handy, you'll be nicely-prepared to address a huge range of IoT and electronics projects. Whether you're constructing smart domestic devices, wearable tech, or computerized structures, having the right additives can make all the difference.

#IoT#Electronics#Arduino#RaspberryPi#ESP32#Sensors#Actuators#Displays#ConnectivityModules#PowerSupplies#Prototyping#Tech#DIY#Makers#Engineering#ElectronicComponents#TechProjects

2 notes

·

View notes

Text

Yesterday, my brother came to me and asked if I could fix the AC window unit (which is the only AC we have in the house and it resides in his room) and I figured I would take a look.

The low voltage control circuits would power on, but the compressor and fan motor wouldn't and the temp sensor claimed a temperature of 49 degrees, when it very much was a muggy 80.

I took the covers off, looking for the temp sensor, but what I discovered was far more dramatic than a thermistor at the end of its life: three wires had burnt up. One spade terminal on the massive 35uF capacitor was blackened and another terminated to the end of a wire was practically melted. I measured the capacitance of the capacitors and they were fine. I had two theories for why this explosive event happened. The first was an over-current event caused by a short in the motor or compressor. The other was short caused by severe humidity or liquid water. There was a lot of water in the unit.

The motor spun just fine, so it wasn't seized. I figured I would cut and re-terminate the wires, connect everything, and try switching it on. And it worked! Some crimping, stripping, and soldering later, helped by a handy wiring diagram located inside the unit, and it ran. I jumped and laughed. My niece and nephew were hanging around with me in the garage, and they remarked that they hadn't heard me laugh in a long time, if at all.

I thought about this today and it was making me cry a bit. It had been so long since I had to solve a problem and fix it, physically. I need that in my life; it's my calling, and I've been deprived of it because no one will hire me for repair positions.

I went back to the college that brought me to this city in the first place and sat down with an advisor. I'm enrolling in the HVAC program and I begin in Autumn. Upon graduation, I become part of the HVAC union and they will get me a job. The mean rate is $27/hr.

I'm going to fix things again. I'm going to feel like a real person. The darkness that shrouded me during the pandemic will finally dissipate.

6 notes

·

View notes

Text

If you use a gas or ventilation system heater put a bowl of water before the vents/flame. If your air dries out, though it might look like you would want that, your nasal canals dry out. If they dry out they crack and you're like 5 times more likely to catch a cold. If there is a ton of moisture in your house this isn't necessary, but get a cheap greenhouse humidity monitor and watch that shit.

If you make wood or coal fires, bar checking the chimney, properly clean out all the ash between fires, and have proper ventilation in the room the fire is in. Carbon monoxide kills, do not let it catch you unawares. You need a proper and strong flow of air going through the room. There's a myth that carbon monoxide is heavier than air. This is not true, it disperses evenly throughout the air most of the time. If you can get a carbon monoxide sensor installed, do it.

Vacuum seal windows and draw blinds and curtains at night. There are kits for this I believe, it doesn't get too cold where I live so we don't have them, but I believe it's like heavy duty cling film sheets that you tape down around the window frame, then you vacuum out the air. Vacuums are fantastic insulators, and if you can create them around your house by sealing the windows? Great.

Use the sun! If you have south-facing windows in the northern hemisphere or north-facing windows in the southern hemisphere those puppies are completely uncovered during daylight. No blinds, no curtains, not even sheer curtains. Get as much heat from the sun into your home during the day as you can.

Hot water bottles are good, but if they puncture or burst you're now not only burned by the hot water, you're also wet and rapidly cooling. At worst, get a moisture absorbing cover, at best switch to bean bags or if you can afford it ceramic bead heat pads. You can heat them in a coal or wood stove, or in a microwave if you don't have blackouts. If you're shivering, focus it on your core. Stomach, chest, pits, back, neck, crotch. If you're not shivering but your extremities are cold, put them on your hands and feet.

If you have to walk somewhere or bike somewhere in the cold, get sheepskin boots and jacket, waterproof that shit. It's gotta be wool pointing in suede pointing out. You can waterproof it yourself by rubbing beeswax all over it, especially in the seams, and using a hairdryer or heat gun to melt the wax in. You will have to redo the wax. If you're vegan, though I will disagree with you on the ethics and sustainability of using pleather over real animal skin, pleather outer is fine, waterproof on its own even, but just seal the seams. Be quadruple sure that the synthetic fur or fleece is hollow fiber.

Sheep fleece doesn't have to be attached to the skin to be effective, it can be sheered off the sheep which does not harm the sheep and actually benefits them. Same goes for any fleece. The warmest is alpaca, sheep is pretty high up there, while cotton, linen or bamboo fleece is not an animal by-product but much less effective at retaining heat. Felted fleece is more dense and therefore more effective at retaining heat, but it is heavier, uses more of the fiber and often scratchier. Natural. Fibers. Shrink. If you knit or felt or weave your own stuff you probably already know this, but just in case you don't wash natural fibers in cold water, and air dry. You can iron them without issue but don't tumble-dry them.

The reason I know these things despite living in a warmer climate is because one, I have a shit heart so my circulation is shit and with it my internal heating system, and two, I'm poor as shit and can't afford an electric or gas heater. I had a gas heater my parents loaned me when I was away at varsity, but my landlord threw a fit about the fire hazard so I had to figure out how to stay warm using my clothes, heat pads and blankets.

COLD WEATHER TIPS FROM SOMEONE WHO LIVES WHERE IT’S COLD:

I always see posts about layering clothing, but there are so many more creative ways to help keep you warm if you don’t have a lot of warm clothes. But first, a note on layering clothing:

-Your underlayer is your WICKING layer. That means it is a layer specifically to absorb the moisture your body produces. DO NOT USE COTTON AS A BOTTOM LAYER. Use merino wool if possible, but other good substitutions are nylon, polyester and rayon.

-Your middle layer is for insulation. You want AIR POCKETS in there, NOT tight fitting clothes. This is where you want to put your fluffy sweaters, your fleece, down, fur, flannel, or vests. If you do not have these, you can substitute with multiple layers of long sleeve shirts.

-Your outer layer is for keeping the cold away from your body. If you do not have a jacket, you can put on your thickest piece of clothing and then a raincoat over it. Windbreaker if you have one.

ALSO

-Jeans are the absolute worst at holding heat. Use only as a last resort.

-You can’t really ever have too many layers on your feet. Alternate tucking your layers of pants into your layers of socks to keep your ankles warm!

-Wear a hat OVER a hood if it will fit! This will keep your ears warmest.

TAKE OFF/OUT ANY AND ALL JEWELERY/PIERCINGS

-If you have a medical bracelet, DO NOT REMOVE IT. If you can, tuck a layer of clothes between it and your skin.

NON-CLOTHING TIPS:

-Raid your recycling. Gather all cardboard boxes and break them down so that they are flat. Put them on the floor to add more layers between you and the cooling house. Newspaper will also serve the same purpose.

-In an emergency, you can also layer newspaper between clothing layers. Don’t worry about looking stupid if you’re staying warm.

-If you have a tent, set that sucker up in whatever room you have decided to stay in. Stay in it and keep it zipped shut as much as you can, but do NOT cover the vent at the top. You can put the rain fly up, but make sure there is circulating air for you to breathe.

-You are probably not going to feel very hungry at times. DO NOT STOP EATING OR DRINKING. Digestion produces a lot of body heat and the food will give your body energy to keep itself going.

-The best foods are heavy and full of carbs and proteins. Eat nuts, eggs, pasta, meats, and beans. If you are on a diet, now you’re not. If you’re vegetarian… bulk up on those pastas and nuts.

-Try not to sweat. If you are finding yourself getting damp, take off the outer layer just until you start to cool slightly. Then redress! Your bottom layer should dry quickly, and being wet is dangerous.

-On that note, STAY ACTIVE. You are probably going to want to hunker down and snuggle up, but that will make your muscles cramp. Every 15-20 minutes do something that gets you up and about. Walk circles in the room, do a couple jumping jacks, stretch, whatever. Just enough to move some blood around your body. Don’t get sweaty or out of breath, it’s just a little movement.

-CHAPSTICK. ON YOUR LIPS. ON YOUR NOSE. ON YOUR EARS. ON YOUR KNUCKLES. Don’t let your extremities get dry or cracked.

SIGNS OF HYPOTHERMIA:

-Uncontrollable shivering -Slurred speech -Confusion or memory loss -Dizziness or lack of coordination -Inability to be woken from sleep

CHILDREN AND INFANTS!!!! I CANNOT STRESS THIS ENOUGH.

-Children WILL get colder before you. Make sure they are properly bundled up.

-If you need to breastfeed, put a blanket over the both of you and wait a few minutes for the air to warm before removing or shifting your clothing.

-DO NOT COVER AN INFANTS FACE. ESPECIALLY WHEN SLEEPING. Keep them tucked inside your own clothes when possible. As close to your heart and stomach as possible.

-Put chapstick on children’s cheeks and clean their face often if they are crying or wiping at their nose. This will prevent cracked skin and irritation.

-Make sure your children are staying as hydrated as you! They are going to fuss and not want to drink cold things, but they NEED liquids.

SIGNS OF HYPOTHERMIA IN INFANTS AND TODDLERS ARE DIFFERENT:

-Shortness of breath -Cold, red skin -Lethargy or listlessness

Finally:

CHECK ON YOUR NEIGHBORS. CHECK ON CHILDREN. CHECK ON THE ELDERLY. STAY SNUGGLED. STAY SAFE.

71K notes

·

View notes

Text

Using PLC Panels in HVAC Automation for Commercial Buildings

Introduction

In modern commercial buildings, controlling temperature, air flow, and ventilation efficiently is crucial. Manual systems are no longer enough. Today, PLC Panels are widely used to automate HVAC (Heating, Ventilation, and Air Conditioning) operations, ensuring comfort, energy savings, and reliability.

Let’s understand how PLC Panels make HVAC systems smarter and more efficient.

Role of PLC Panels in HVAC Automation

Precise Temperature Control PLC Panels monitor room temperature and automatically adjust heating or cooling units.

Ventilation Management They control air circulation based on occupancy or air quality sensors.

Energy Optimization PLC logic reduces power usage by switching off unnecessary equipment or reducing loads during off-peak hours.

Humidity Regulation Integrated sensors can maintain ideal humidity levels in indoor spaces.

Fault Detection PLC Panels instantly detect errors and send alerts, preventing bigger breakdowns.

Make your building smarter and greener—consult a reliable PLC Panel Manufacturer for energy-efficient HVAC automation.

Key Benefits in Commercial Settings

Consistent indoor climate for employees or customers

Reduced electricity bills

Easy monitoring through a central HMI or SCADA

Custom schedules based on working hours or seasons

Remote access for quick adjustments or diagnostics

Industries and Spaces Benefiting from PLC HVAC Panels

Office buildings – Automated comfort settings and load balancing

Shopping malls – Precise control for multiple zones

Hospitals – Strict temperature and air quality requirements

Hotels – Personalized room settings and centralized management

Educational institutions – Smart use of energy in classrooms and labs

Why You Need a Skilled PLC Panel Manufacturer

A good Programmable Logic Controller Panel Manufacturer will:

Customize the PLC for your building’s size and layout

Integrate it with your existing HVAC setup

Ensure compliance with energy standards

Provide user-friendly controls and after-sales support

Conclusion

Automation of HVAC systems through PLC Panels is a smart investment for any commercial building. It brings comfort, control, and savings—without the hassle of manual systems. Partner with a trusted PLC Panel Manufacturer to get a tailored solution for your building’s specific needs.

Keep your building cool, comfortable, and cost-efficient—choose a dependable PLC Panel Manufacturer today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

#plc electrical panel#plc#plc panels#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes

Text

Does Eco-Friendly Ink Affect the Playing Cards Making Machine Efficiency

The rise of environmentally sustainable manufacturing practices has led to a growing interest in using eco-friendly inks and materials across various industries, including playing card production. For manufacturers operating a Playing Cards Making Machine, one of the frequently asked questions is whether the use of eco-friendly ink and sustainable substrates affects the machine’s efficiency. As environmental concerns become a global priority, the integration of such materials into production lines has become more common, and it is essential to assess how this shift interacts with the operational dynamics of a Playing Cards Making Machine. Understanding the relationship between sustainable materials and machine efficiency is vital for ensuring that environmental responsibility does not come at the cost of productivity or output quality.

A modern Playing Cards Making Machine is typically optimized for compatibility with a variety of printing substrates and ink types. These machines are designed with flexibility in mind, capable of adapting to different production inputs. However, the use of eco-friendly ink in a Playing Cards Making Machine can introduce certain differences in drying time, viscosity, and adherence properties compared to conventional petroleum-based inks. These variations can influence how the Playing Cards Making Machine performs during high-speed printing operations. For example, eco-friendly soy-based or water-based inks often require more precise humidity and temperature control to ensure proper drying. If the drying system within the Playing Cards Making Machine is not adequately adjusted, it may slow down the overall process, potentially reducing throughput and affecting the crispness of the printed images.

Despite these challenges, many manufacturers of playing card-making machines have taken steps to engineer systems that are optimized for sustainable materials. Advanced drying units, including UV LED curing systems, are now built into high-performance Playing Cards Making Machine models to accommodate the specific curing characteristics of eco-friendly inks. These systems are not only faster but also more energy efficient, thereby reducing any potential slowdown in production that could be caused by using alternative ink formulations. With proper calibration, the Playing Cards Making Machine can maintain consistent speed and print quality even when using environmentally responsible inputs.

When it comes to substrates, eco-friendly paper or recycled cardboard can also influence the efficiency of a Playing Cards Making Machine. Sustainable materials may have different absorption rates, surface textures, or thickness tolerances compared to virgin materials, which can impact how the Playing Cards Making Machine feeds, prints, and cuts each sheet. However, modern Playing card-making machine systems are equipped with automated feeders, pressure control mechanisms, and cutting alignment sensors that adapt to material differences in real time. These features ensure that the Playing Cards Making Machine maintains precision and consistency without manual intervention, reducing waste and downtime even when working with unconventional substrates.

It’s also important to note that while there may be a minor learning curve when switching to eco-friendly materials, the long-term performance of the Playing Cards Making Machine is rarely compromised. Many sustainable inks and papers are manufactured to industrial standards that specifically match the operational requirements of commercial printing equipment. As a result, the Playing Cards Making Machine can continue to deliver reliable results without significant efficiency losses once initial setup and testing are completed.

In conclusion, while the introduction of eco-friendly inks and sustainable materials may require slight adjustments to the operational parameters of a Playing Cards Making Machine, these changes do not inherently reduce its efficiency. On the contrary, with the right configuration and equipment upgrades, the Playing Cards Making Machine can fully support green manufacturing practices without compromising on productivity, print quality, or durability. This compatibility ensures that businesses can align with environmental goals while still benefiting from the advanced capabilities of a modern Playing Cards Making Machine.

0 notes

Text

youtube

Desk of Ladyada - HDC3022 + RGB LCD Shield revision https://youtu.be/sXuS6K62gw4

Memorial Day weekend edition: improving libraries and revisions. We successfully coded the HDC3022 temperature+humidity sensor with Arduino and GPT-4's help. The RGB LCD Shield kit, previously DIP-based, now features almost entirely SMT components. Additionally, we're updating our RGB LCD Shield and Plate to SMT, seeking compatible tactile switches for a seamless transition.

4 notes

·

View notes

Text

What Is an Industrial Sensor? Complete Guide + Types and Applications

Industrial sensors, also known as industrial detectors, are essential components used in various industries to convert physical, mechanical, or chemical parameters—such as temperature, pressure, humidity, and liquid levels—into analog or digital electrical signals. These sensors play a key role in quality control, safety assurance, and optimizing operational performance across different industrial processes.

In this guide, we’ll answer the commonly asked question, “What is an industrial sensor?” and help you get familiar with the different types of industrial sensors and their applications.

What Are the Main Applications of Industrial Sensors?

Before choosing to خرید سنسور صنعتی for your factory or automation system, it's important to first evaluate the needs of your industry. Here are 5 major industries where industrial sensors are widely used:

Food and beverage industry

Robotics and automation

Automotive manufacturing

Pharmaceutical and medical industries

Assembly and material handling sectors

Why Use Industrial Sensors? Key Benefits!

Using industrial sensors in sectors such as automotive, food processing, or pharmaceuticals brings multiple benefits:

Enhanced workplace safety

High operational accuracy

Cost savings through process optimization

Improved product quality and consistency

Reduced equipment wear and extended machine lifespan

Real-time monitoring of temperature, pressure, and humidity

Types of Industrial Sensor; Complete Overview

Industrial sensors can be broadly categorized into two main types:

1. Contact Sensors

These sensors require direct physical contact to detect objects or measure variables. Pressure Sensors is Ideal for measuring pressure in gases and liquids within open or closed systems.

Force Sensors: Measure applied force or load in various industries, especially automotive.

⚠️ Contact sensors have a shorter lifespan due to constant exposure to physical forces such as shock or impact. They are more prone to wear and failure over time.

2. Non-Contact Sensors

These sensors operate without direct contact, making them more durable and reliable in harsh environments.

Advantages of Non-Contact Sensors:

Precise conversion of physical/chemical parameters into analog or digital signals

Reliable in a wide range of industrial environments

Fast switching and response time

Noise-free operation

Long service life

Let’s explore the main types of non-contact sensors used in industry:

1. Inductive Sensors

Inductive sensors operate based on Faraday’s law of electromagnetic induction. They are commonly used to detect metal objects and measure dimensions or movement.

Applications:

Automotive: Detecting metallic parts in production lines

Metal Processing: Measuring thickness or locating parts in welding and cutting

Packaging: Identifying metal items in assembly lines

Robotics: Object detection in automated systems

Electronics: Separating and detecting metal parts

2. Capacitive Sensors

Capacitive sensors detect objects by sensing changes in capacitance. They work with conductive, non-conductive, and semi-conductive materials.

Industries That Use Capacitive Sensors:

Manufacturing: Monitoring levels, weights, and humidity

Automotive: Used in braking, suspension, and autonomous systems

Electronics: Measuring voltage, frequency, and electrical parameters

Energy and Petrochemicals: Monitoring pressure and flow

Medical: Tracking vital parameters like heart rate, oxygen levels, and more

3. Magnetic Sensors

These sensors work by detecting changes in magnetic fields and are non-contact, making them highly durable.

Who Uses Magnetic Industrial Sensors?

Electronics: Used in compasses and magnetic navigation

Automotive: Applied in braking, steering, and positioning systems

Steel and Metalworks: Monitoring welding and magnetic anomalies

Oil and Gas: Detecting faults in pipelines and equipment

Medical Imaging: MRI and other diagnostic technologies

4. Ultrasonic Sensors

Ultrasonic sensors are non-contact devices that operate using high-frequency sound waves (above the human hearing range). These sensors are used for distance measurement, presence or absence detection of objects, and level control of liquids or solids.

How Ultrasonic Sensors Work:

The sensor emits an ultrasonic pulse toward the target. After the pulse hits the object, it reflects back to the sensor. The time it takes for the echo to return is measured, and using the speed of sound, the distance to the object is calculated.

Applications of Ultrasonic Sensors:

Industrial automation (for detecting the presence of objects on production lines)

Liquid level measurement in tanks and containers

Obstacle detection in robotics and automated vehicles

Packaging and bottling systems

Advantages:

Non-contact measurement

High accuracy in detecting transparent, shiny, or irregular surfaces

Not affected by color or material of the object

Limitations:

May be affected by temperature and humidity

Less effective in environments with heavy dust or sound-absorbing materials

5. Photoelectric Sensors

Photoelectric sensors are non-contact sensors that detect the presence, absence, or distance of an object using a beam of light, usually infrared or visible red light.

How Photoelectric Sensors Work:

These sensors emit a light beam from a transmitter toward a receiver. When an object interrupts or reflects the beam, the sensor detects the change and outputs a signal. There are three common types of photoelectric sensors:

Through-Beam (Opposed Mode): Transmitter and receiver are in separate units. The sensor detects when the object blocks the light beam.

Retroreflective: Transmitter and receiver are in one housing. A reflector is placed opposite the sensor. When the object interrupts the beam between the sensor and reflector, it is detected.

Diffuse Reflective: Transmitter and receiver are in one housing. The sensor detects the light reflected back from the object itself.

Applications of Photoelectric Sensors:

Detecting small or transparent objects on conveyor belts

Counting products on a line

Position detection in packaging machinery

Safety and security systems (e.g., automatic doors)

Advantages:

Fast response time

Long sensing range (especially in through-beam type)

Reliable detection of small and fast-moving objects

Limitations:

May be affected by dirt, dust, or misalignment

Performance can vary depending on surface reflectivity and color

6. Proximity Sensors

Proximity sensors are non-contact sensors that detect the presence or absence of an object within a specific range without any physical contact. Unlike photoelectric sensors, they do not use light beams, and instead rely on electromagnetic fields or capacitive effects.

Types of Proximity Sensors:

Inductive Proximity Sensors:

Detect metallic objects.

Operate based on the electromagnetic induction principle.

Common in industrial automation for detecting machine parts or fasteners.

Capacitive Proximity Sensors:

Detect both metallic and non-metallic materials (e.g., glass, plastic, wood).

Work based on changes in capacitance caused by nearby objects.

7. Ultrasonic Proximity Sensors:

Use ultrasonic waves to detect the presence and distance of an object.

Ideal for liquid level measurement or detecting irregularly shaped objects.

Applications:

Detecting objects on conveyor belts

Position detection in robotics

Liquid level sensing (capacitive or ultrasonic)

Detecting doors opening/closing (e.g., elevators)

Advantages:

Long lifespan due to non-contact operation

Fast and reliable response

Available for a wide variety of materials

Limitations:

Each type has material or environmental constraints (e.g., inductive works only with metals)

8. Temperature Sensors

Temperature sensors are devices that measure heat to detect temperature changes and convert them into a readable output, usually electrical signals. They are widely used in industrial processes, electronics, medicine, and home appliances.

How They Work:

Different temperature sensors operate on varying principles. For example, some rely on the change in electrical resistance with temperature, while others use the voltage difference generated by two different metals.

Types of Temperature Sensors:

Thermocouples:

Made from two dissimilar metals joined at one end.

Produce a voltage that varies with temperature.

Suitable for a wide temperature range and rugged environments.

Resistance Temperature Detectors (RTDs):

Use materials (typically platinum) whose resistance increases with temperature.

Very accurate and stable but more expensive than thermocouples.

Thermistors:

Semiconductor devices whose resistance decreases (NTC) or increases (PTC) with temperature.

Cost-effective and sensitive but limited to narrower temperature ranges.

Infrared (IR) Sensors:

Measure thermal radiation emitted by an object.

Useful for non-contact temperature measurements (e.g., in moving machinery or medical thermometers).

Semiconductor Temperature Sensors (e.g., IC-based):

Output a voltage or current proportional to temperature.

Often used in consumer electronics and computing.

Applications:

HVAC systems and building climate control

Industrialzautomation and process control

Medical equipment (e.g., thermometers, incubators)

Automotive systems

Food and pharmaceutical storage monitoring

Advantages:

Wide variety to suit different applications

High accuracy and reliability (especially RTDs and thermistors)

Non-contact options available

Easy to integrate with digital systems

Disadvantages:

Some types (like RTDs) are costly

Sensitivity to environmental factors (e.g., humidity, vibration)

Calibration and maintenance may be required over time

Tanavob Store; The Best Industrial Sensor Supplier in Iran

With over two decades of experience in importing and selling various industrial sensors, Tanavob Store is considered one of the top industrial equipment suppliers in Iran. Tanavob is here to help you by providing high-quality, original foreign industrial sensors, enhancing your workplace safety and improving work quality. This store is proud to have collaborated with many national and local projects, including Domino, Kaleh, Zarr Macaroon, and more. فروشگاه سنسور صنعتی تناوب is an excellent choice for purchasing industrial sensors to meet the needs of your industries.

1 note

·

View note

Text

Energy Audits for Hotels: Cut Costs Without Compromising Guest Comfort

In the world of hospitality, comfort is king. But maintaining that comfort for every guest, every day, can rack up serious energy costs. At Inventum Power, we believe there’s a smarter way. Energy audits are the secret sauce that helps hotels cut down on unnecessary expenses—without guests noticing a thing. Imagine saving thousands each year while delivering an even better guest experience. Sound impossible? It’s not. Let’s break it down.

What is an Energy Audit?

An energy audit is a detailed assessment of how energy flows through a building. Think of it like a medical check-up for your hotel’s energy system. It identifies where energy is being used, lost, or wasted, and offers actionable solutions to tighten up performance.

Types of Energy Audits

Walk-Through Audit – A quick, low-cost overview of major systems.

Detailed Audit – A deep dive with extensive data collection and analysis.

Investment-Grade Audit – High-level audit used to justify major investments in upgrades.

Why Hotels Need Energy Audits

Hotels operate around the clock—heating, cooling, lighting, laundry, kitchens, pools—you name it. All of this equals a hefty utility bill. Most properties are losing money every day and don’t even realize it. An energy audit shines a light on the problem areas.

Benefits of Conducting Energy Audits

Cost Savings – Cut 10–40% off energy bills.

Increased Efficiency – Equipment runs smoother and lasts longer.

Enhanced Guest Comfort – More consistent room temps and better air quality.

Eco-Friendly Reputation – Guests love staying at green hotels.

Step-by-Step Process of a Hotel Energy Audit

Step 1: Initial Assessment

We begin by discussing your goals, energy concerns, and past utility bills.

Step 2: Site Inspection

Our team walks through the property, inspecting HVAC units, lighting, insulation, and equipment.

Step 3: Data Collection & Monitoring

We gather real-time data to track usage patterns and identify peak usage times.

Step 4: Analysis & Reporting

A detailed report outlines where and how energy is wasted—with clear, actionable fixes.

Step 5: Implementation of Recommendations

We help you prioritize and roll out upgrades that offer the best ROI.

Step 6: Post-Implementation Review

A follow-up to ensure everything is performing as expected and savings are being realized.

Common Energy Wasting Areas in Hotels

HVAC Systems

Old, oversized, or poorly maintained systems suck up energy like a sponge. Smart controls and maintenance go a long way.

Lighting

Still using incandescent or halogen bulbs? Switching to LEDs can slash lighting costs by up to 80%.

Kitchen Equipment

Inefficient stoves, fryers, and fridges are silent energy hogs. Upgrading to ENERGY STAR® appliances pays off fast.

Laundry Operations

Oversized machines or improper use leads to wasted water and power. Heat recovery and timers can help.

Water Heating Systems

Water heating alone can eat up 15-20% of your energy bill. Low-flow fixtures and solar water heaters help reduce this burden.

Technologies That Help Optimize Hotel Energy Usage

Smart Thermostats – Adjust settings based on room occupancy.

LED Lighting – Long-lasting and ultra-efficient.

EMS (Energy Management Systems) – Automate and monitor usage in real-time.

Motion Sensors – Lights and HVAC only run when needed.

Solar Integration – Use renewable sources to cut grid reliance.

Real-Life Case Studies: Hotels That Saved Big

One boutique hotel in Florida saved $72,000 annually after an Inventum Power audit. Another large chain in California reduced energy usage by 35%, just by upgrading lighting and HVAC controls. These aren’t outliers—they’re the norm when you commit to auditing.

How Energy Efficiency Enhances Guest Comfort

Guests might not notice your utility bills, but they’ll definitely notice:

Noisy AC units

Inconsistent temperatures

Poor lighting

Humid or stuffy rooms

Energy efficiency means quieter systems, better lighting, and climate control that just works.

Overcoming Barriers to Energy Audits

“It’s too expensive” – Audits often pay for themselves within a year.

“It’s too complicated” – That’s what we’re here for.

“It will interrupt guests” – Our audits are minimally invasive and scheduled for your convenience.

“My staff won’t get it” – We provide training and tools for long-term success.

Working with Experts: Why Choose Inventum Power

We’ve helped hotels across the country slash their energy bills without ever sacrificing comfort. Our team offers:

Custom-tailored audits

Hands-on implementation

Long-term monitoring and support

We're not just consultants—we're your energy partners.

ROI of Energy Audits: Is It Worth It?

Absolutely Most hotels see ROI within 6 to 24 months, depending on the scope of upgrades. Beyond savings, energy-efficient hotels often see increased property values and higher guest satisfaction ratings.

Tips to Maintain Efficiency After an Audit

Keep a regular maintenance calendar.

Train your staff to recognize inefficiencies.

Use your EMS to track progress and adjust in real time.

Sustainability & Brand Loyalty

More guests are booking based on environmental values. A hotel that’s eco-conscious stands out on booking sites and social media. You’re not just saving money—you’re building loyalty.

Conclusion

Energy audits aren’t just a good idea—they’re a smart investment. With Inventum Power by your side, you can reduce costs, improve comfort, and lead the way in sustainability. The best part? Your guests will never know a thing—except that your hotel feels better than ever.

FAQs

1. What is the average cost of a hotel energy audit? Costs vary depending on hotel size and scope, but most fall between $2,000–$10,000, with higher costs for larger or more complex audits.

2. How often should a hotel perform an energy audit? Every 3–5 years is ideal, or sooner if you've made major renovations or seen a spike in utility costs.

3. Will an energy audit disrupt hotel operations? Not at all. Most audits are non-intrusive and scheduled to avoid interfering with guest activities.

4. Can small hotels benefit from audits too? Absolutely. In fact, smaller properties often see quicker paybacks due to less complex systems.

5. What’s the first step to booking an energy audit? Contact Inventum Power for a free initial consultation. We’ll review your current energy use and recommend the best next steps.

0 notes

Text

DAEJOO : A Trusted Name in Marine & Industrial Automation Explore the Full Range at Aeliya Marine

In the constantly changing world of ocean and industrial automation, few names have withstood the test of time, providing precision, reliability, and confidence. One of them is DAEJOO, known around the globe for its cutting-edge engineering and high-reliability parts. Be it a business vessel traveling open seas or an assembly line that cannot pay the luxury of a second of downtime, DAEJOO’s automation components guarantee performance sans compromise.

At Aeliya Marine Tech, we are pleased to showcase a handpicked range of original DAEJOO products designed to satisfy marine engineers as well as industrial specialists. Ranging from hard-to-find PCBs to reliable relay units and control modules, our DAEJOO product portfolio is extensive, quality-approved, and ready to ship across the globe.

About DAEJOO Engineering Excellence You Can Rely On

DAEJOO Industrial Co., Ltd., based in South Korea, is a renowned producer of marine-grade electrical and automation components. With an emphasis on high-performance circuit design, interface reliability, and system safety, DAEJOO has emerged as the go-to option for shipyards, offshore platforms, naval maintenance teams, and industrial control engineers globally.

The mission of the company has ever been simple: to produce parts that endure, even in extreme environments. Those are products resistant to high humidity, saltwater corrosion, voltage spikes, and temperature extremes conditions prevalent both in marine and heavy industrial applications.

Discover the DAEJOO Product Categories at Aeliya Marine

Let’s start with some of the fundamental product categories found on our website under the DAEJOO banner:

1. Control Modules

DAEJOO’s control modules are the workhorse of a wide range of shipboard and industrial automation applications. With sturdy build quality and reliable interfacing logic, the modules provide the seamless execution of commands and control signals on any automation network.

Standard features :

High insulation resistance

DIN-rail mounting with compact dimensions

LED indication of diagnostic status

Fail-safe options

2. Interface Boards & PCBs

DAEJOO Printed Circuit Boards (PCBs) are designed to provide precise signal control and voltage regulation. They find application in main control panels, sensor systems, navigation controls, and motor interface units.

Regardless of whether you’re replacing a defective board or modernizing an old system, these PCBs provide :

Consistent copper trace paths

Built-in EMI protection

Components with surface-mount or through-hole

Clear part labeling and revision control

3. Relays & Timer Units

DAEJOO relays are ideal for timed switching, fault detection, and manual override systems applications. Their small sizes and conventional pin configurations simplify integration.

Benefits are:

Low power coil operation

Long mechanical and electrical life

High surge withstand capacity

ISO and IEC compliance

4. Power Supply Units & I/O Modules

In both factory and marine systems, power stability and input/output control are essential. DAEJOO’s power supply units provide stable voltage output with protective features such as overcurrent and thermal shutdown.

At the same time, their I/O modules provide :

Modular expansion

Easy plug-and-play connections

Flexible voltage and signal support (DC/AC)

Noise-filtering for reliable communication

Why Purchase DAEJOO from Aeliya Marine Tech?

At Aeliya Marine, we’re not merely product resellers we’re technical allies. Our mission is to assist engineers and purchasing teams in discovering genuine, tried, and deployable components, particularly when time and dependability are most critical.

Here’s why our customers worldwide have confidence in us:

1. Authenticated Genuine Parts

We buy directly from trusted networks so that each DAEJOO component is genuine and performance-verified. No fakes, no inferior substitutes only the original.

2. Complete Specifications & Images

We offer detailed specs, model codes, datasheets (where necessary), and hi-res images so you can be sure of what you’re getting.

3. Fast Dispatch & Global Shipping

Want it ASAP? We facilitate quick and trusted shipping to world ports and cities. Our logistics division in Mumbai is capable of processing express overseas orders.

4. Competitive Prices & Bulk Rate Discounts

Competitive prices and discounts for multi-unit purchases make Aeliya Marine the intelligent choice for business and solo technicians.

5. Professional Customer Support

We are here to assist you with selecting the proper part, confirming compatibility, and monitoring your order. Need some help with installation or wiring schematics? No worries.

Hot DAEJOO Products Available on Our Site

Below are some of our top customers’ favorites from our new DAEJOO range :

DAEJOO Interface Card DJ-2310 Series : Applied in ship automation consoles

DAEJOO DJR-105 Relay Unit : Suitable for motor protection and emergency override

DAEJOO Terminal Block DJT Series : Corrosion-proof and compact

DAEJOO Control Unit DJK-218 : Multi-channel logic control of automation systems

All of these products come with technical descriptions and pictures to assist you in identifying them properly.

Applications of DAEJOO Products

DAEJOO components are engineered to withstand the demanding requirements of various industries, including:

Marine Applications :

Engine Room Automation

Navigation Control Panels

Bridge Monitoring Systems

Alarm & Safety Circuits

Industrial Applications :

PLC-Based Automation

Machine Tool Controls

Conveyor System Integration

Power Distribution Panels

The versatility of DAEJOO components ensures that they are the first choice for engineers in various fields.

The Aeliya Marine Advantage : More Than Just a Vendor

When you buy from Aeliya Marine Tech, you’re buying from an organization that shares your sense of urgency and technical sophistication. We deal with professionals from shipyards, offshore facilities, steelworks, cement factories, and automakers who rely on us for:

Rare to find obsolete spares

System-compatible substitutes

Thoroughly inspected used & refurbished parts

Open service, from inquiry through delivery

We also assist customers in locating similar or compatible models when the original DAEJOO product is not available preventing downtime and saving money.

Wrapping Up : Reliable Technology for Demanding Systems

With DAEJOO’s established reliability and Aeliya Marine’s rapid response service, you can flow your maintenance, repair, or system upgrade project with total peace of mind. Whether you are upgrading your control room, renovating an ageing PCB, or refining a relay-based system, our DAEJOO series is designed to assist you to deliver results.

Ready to explore?

Click Here To View The Complete Daejoo products Collection

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#deajoo

0 notes