#hydraulic machines

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

Hydraulics is the only technique that combines applied science and engineering like no other. The hydraulic system makes use of a variety of special mechanical qualities needed to perform a variety of tasks. A subfield of applied engineering called hydraulics focuses on using fluid properties. Hydraulics plays a major role in power transmission and control in applications that use fluid power.

#Hydraulics is the only technique that combines applied science and engineering like no other. The hydraulic system makes use of a variety of#hydraulic machines#hydraulic machinery#hydraulic system#hydraulic tools

0 notes

Text

expansion of copper tubing

#my posts#gif#hydraulic machine#factory machinery#metal pipe#copper pipe#manufacturing#suggestive#objectophilia#objectum

333 notes

·

View notes

Text

This show understands what a sexy robot is

#VENTS#HYDRAULICS THOSE CIRCLE JOINTS I DON’T KNOW THE NAME OF#GIANT FUXKING COLLAR WING#no word on ankle cover jiggle physics tho#bang brave bang bravern#God and the weird armsssss#I am barking like a dog#I need to make this machine my religion#She has a giant fucking laSer that blows a hole in the sky#I need her to place me between her arm joints and turn me into naught but a tiny red smear#Place me in her fingers as she flexes her shattering my body across her as my entrails#i think i hauve covid

133 notes

·

View notes

Text

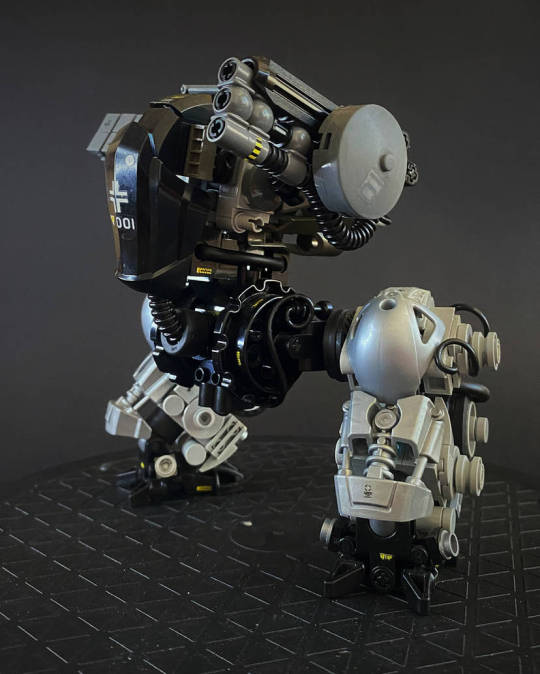

KZ.20 Mech [Advanced Design]

An even greater tool for the dispensing of sweet DEMOCRACY!!!!

Source

Creator: marcomarozzi

#lego#bionicle#armor#armor plates#mech#mechanical#machine#war#war machine#vehicle#walker#tubes#hydraulics#robot#robotic#robotic unit#guns#machine gun#cannon#bricks#faceless#armless#cannons#bipedal

36 notes

·

View notes

Text

An Epic Earth Wubbox stimboard with molten metal/glass and machinery!

🔥-⚠-🔥

⚠-🎶-⚠

🔥-⚠-🔥

#stimboard#moodboard#my singing monsters#msm#wubbox#epic wubbox#epic earth wubbox#stim#machinery#machines#mechanical#bulldozer#hydraulic press#wrench#rust#magnet#magnetic#scrapyard#molten glass#molten metal#metal#glow#glowing#pouring

35 notes

·

View notes

Note

✨tiny constance au✨

AUGH OMG THIS IS SOOO GOOOD THANK YOUU I love my moss cameo 😭💖🙏

#CHRISTENING TINY CONSTANCE AU WITH ITS FIRST ART#TINY CONSTANCE AU#constance von nuvelle#hapi#ABD ME#thank you so much 😭😭😭#happy birthday to meee#I love her curls 😭 and her drama 😭😭😭 and the quote#a fav tumblr quote#hydraulic pressing myself but tiny constance got into the machine and kicked one of the pistons so I am only pleasantly squished#ty for the ask <3#fave

41 notes

·

View notes

Text

shitpost doodle requests? based on the wonderful thoughts of @weaponsdrawn . robert taken away by a (realistic) bird. i couldnt draw hr hitting the gritty so hes doing that instead. lil oldman exploding

#shitpost#doodle#guz art#lil oldman#high roller#ottoman#chairman#also to quote what i said earlier#i want to fucking pick up robert and soak him in milk and slap him against the wall and put him in the washing machine at full#speed and put him in the mixer and run him over with a steamroller and fire at him with a flamethrower and put him under a hydraulic press#but like affectionately#you get me? catch the drift? ya feel me? yknow?

48 notes

·

View notes

Text

🔧 Blu!Engineer (Team Fortress 2) Stimboard 🔩 (with crushing & machines) for @satsuj1n

x x x / x x / x x x

[Image description: a 9 gif stimboard; from left to right.

First line: A gif of a hydraulic press crushing a blue and silver car jack, the car jack's metal tears off in strips. A gif of a turn & mill machine, a rotating rotor-like contraption twists around a spindle needle. And a gif of a blue bench vice being crushed by a hydraulic press, it almost implodes on itself until sections of it fly off to the sides.

Second line: A gif of a steel padlock being crushed under a hydraulic press, the metal tears at the sides as the padlock shackle (the metal locking arch) is forced down into the padlock body. A still image of the character Blue Engineer from Team Fortress 2). And a gif of a 1960s car crushing machine crushing a broken car flat.

Third line: A gif of a blue jaw crusher machine chopping and crushing up a brown rock. A close-up gif of a turn & mill machine, a mechanical arm with a metal spindle cuts into a cylinder-shape of metal creating a slightly tapered edge, small cuts of metal fly off as the spindle needle moves. And a close-up gif of a bullet being crushed by hydraulic press, the metal warps in a wavy motion as it is flattened down.

End of image description.]

#stimboard#i hope this is okay!#machines#crushing#destruction#hydraulic press#squishing#tearing#cutting#slicing#jerky motion#weapons

10 notes

·

View notes

Text

Science Saturday

A Descriptive and Historical Account of Hydraulic and other Machines for Raising Water, Ancient and Modern, including the progressive development of the Steam Engine is an extensive exploration of the multitude of ways to raise water. Written by British-American mechanics writer Thomas Ewbank (1792 – 1870), the book was first published in London by Tilt & Bogue in 1842, with the first American edition published in New York by D. Appleton and Company the same year. New York publisher Greeley & McElrath first published the title in 1845. Our copy is the second Greeley & McElrath edition published in 1847. Greeley & McElrath are Horace Greeley and Thomas McElrath, publishers of the New York Tribune.

Ewbank was born in Northern England and worked as plumber and brassfounder as a teenager. He emigrated to America in 1819 where he ultimately was appointed Commissioner of Patents and went on to cofound the American Ethnological Society. In his golden years, Ewbank wrote several books and papers on scientific and sociological topics.

In Ewbank's own words, A Descriptive and Historical Account of Hydraulic and other Machines for Raising Water, Ancient and Modern, including the progressive development of the Steam Engine sets out to “account for all the contrivances employed by different people to raise water -- whether for domestic, agricultural, mining, manufacturing, or other purposes” in the hope that it would be of use to scientists and mechanics. The book contains nearly three hundred wood-engraved schematics illustrating the specifics of how the hydraulic mechanisms worked.

View other Science Saturday posts.

-- Jenna, Special Collections Graduate Intern.

#science saturday#Thomas ewbank#Greely & McElrath#Hydraulics#Steam Engine#A Descriptive and Historical Account of Hydraulic and other Machines for Raising Water#science#mechanics#Horace Greeley#Thomas McElrath#wood engravings

35 notes

·

View notes

Text

something they don’t tell you abt working with big machines all the time is this

their fluids, grease etc may start out being kinda taboo and weird but no it becomes so normal and def cemented in your mind the reality that these are quite literally the same to them as our fluids are to us and just as normal

machines can sweat, machines can bleed, machines eat and drink, they get a little moist and messy and they smell like stuff, sometimes it’s good, sometimes it’s bad. If u think machines don’t get B.O. or have bad breath I assure you you’re wrong because they do and it’s very normal ok

#objectum#Machine things#they do these things ok#sometimes they’re so right for it#like yeah mate grease tubes do look yummy. Girl dinner#and it’s so fucking annoying when u get a cut and start bleeding hydraulic oil and fucking sand gets in it innit

18 notes

·

View notes

Text

The introduction of Hydraulic Press Machine power systems filled a capability gap in the Navy, which sparked advancements in automation, motion control, and force multiplication.

#Hydraulic Press Machines#Hydraulic Machines#Hydraulic Machines in Delhi#Hydraulic Press Machines Manufacturer

0 notes

Note

this is actually how fyodor really looks like

25 notes

·

View notes

Text

pipe expansion machine

#my posts#hydraulic machine#pipe expansion#factory machinery#steel pipe#objectophilia#objectum#hi#suggestive

244 notes

·

View notes

Text

cr. itsaisling

#hyunjin#fantaken#GUYS IM SO SORRY FOR SPAMMING TODAY BUT TSUUUUUWEEEEEEEEE MAMA 😻#ITS OKAY NO ONES ONLINE TODAY SO IM JUST YELLING INTO THE VOId#i love this traditional merry cuntmas from him#i feel like im one of those stress toys that got pushed under those hydraulic press machine videos#pls have mercy on me take it easy on my heart or whatever shawn mendes was on

53 notes

·

View notes

Text

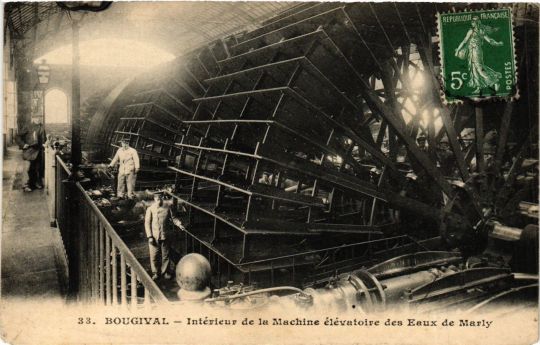

Interior of the Marly Machine hydraulic system in Bougival, western suburbs of Paris

French vintage postcard

#vintage#tarjeta#old#briefkaart#machine#system#postcard#marly machine#photography#postal#marly#bougival#carte postale#sepia#ephemera#interior#historic#paris#french#ansichtskarte#postkarte#suburbs#hydraulic#western#postkaart#photo

5 notes

·

View notes