#Hydraulic Paver Block Making Machine

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

High-Quality Hydraulic Brick Machines Manufacturers from Rexnear Systems

Rexnear Systems is a leading Hydraulic Brick Machine Manufacturers that are designed to produce high-quality bricks with ease. Our machines are built to last and can handle a wide range of brick-making tasks, from small-scale production to large-scale projects.

Our hydraulic brick machines are engineered to be highly efficient and reliable. They are capable of producing a wide range of brick sizes and styles, including standard bricks, perforated bricks, and interlocking bricks. Our machines are also designed to be user-friendly, with intuitive controls and easy-to-use features that make the brick-making process simple and straightforward.

At Rexnear Systems, we pride ourselves on the quality of our hydraulic brick machines. We use only the best materials and components in our machines, ensuring that they are durable and long-lasting. We also offer a range of customization options, so you can choose the machine that best meets your needs.

If you're looking for a high-quality hydraulic brick machine, look no further than Rexnear Systems. Our machines are reliable, efficient, and easy to use, making them the perfect choice for any brick-making project. Contact us today to learn more about our machines and how they can benefit your business.

Call Us: +91-8750287752,9990342299

Email id: [email protected]

Address: Plot No. 358 B, Udyog Kendra – 1, Ecotech – 3, Greater Noida - Uttar Pradesh (India.) - 201306

URL: https://www.flyashbrickmakingmachines.in/hydraulic-brick-machine.html

#Fly Ash Brick Making Machine Manufacturers#Hydraulic Brick Machine Manufacturers#Tile Press Paver Block Machine Manufacturers

0 notes

Video

youtube

Automatic Fly Ash Brick Making Machine in Gujarat – Brick Machinery

Automatic Fly Ash Brick & Paver & Concrete Block Making Machine. Our expertise in hydraulics and manufacturing systems and automated machines enables us to innovate and develop world-class products.

#automatic Fly ash brick making machine#Concrete block making machine#Paver Block Machine#Hydraulic Brick Making Machine Exporters#Fly Ash Brick Machine in India

0 notes

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Concrete Block Making Machine in Coimbatore

Robexo Industries specializes Manufacturer and Supplier of Concrete Block Making Machine in Coimbatore, Tamil Nadu, India.

With a focus on construction machinery production since 2015, the company maintains adherence to international standards.

Offers various types of construction machinery including fly ash brick machines, fully automatic brick machines, interlocking brick machines, paver block machines, and concrete hollow/solid block machines.

Concrete block making machines play a vital role in construction by producing blocks or bricks from a mixture of cement, aggregate, water, and additives.

Production Process:

Mixing: We precisely mix raw materials to form a homogeneous mixture.

Molding: Mixed concrete is poured into molds of various shapes and sizes.

Compacting: Hydraulic pressure or vibration compacts the concrete within the molds.

Curing: Blocks undergo a curing process to harden, using air or steam based on specifications.

Demolding: Workers remove cured blocks from molds for further curing or immediate use.

Advantages:

Enables rapid and precise production of concrete blocks.

Integration with advanced control systems ensures high efficiency throughout operations.

Achieves dimensional accuracy and maintains consistent quality in block production.

Customizable features facilitate the production of various block types according to specific requirements.

Increases the output and enables high-speed production, depending on the machine type and aggregate used.

Robexo Industries is Supplier of Concrete Block Making Machine in Coimbatore, Tamil Nadu, India Including Kurichi, Ganapathy, Peelamedu, Kallapalayam, Malumichampatti, Thudiyalur, ,Saravanampatti, Arasur, Annur, Chinnavedampatti, Keeranatham, Irugur, Sulur, Singanallur, Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam.

For further inquiries, engage in a professional conversation with our team.

Read the full article

#Annur#Arasur#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Chinnavedampatti#Coimbatore#ConcreteBlockMakingMachine#ConcreteBlockMakingMachineinCoimbatore#ConcreteBlockMakingMachineinIndia#Cuddalore#Dharmapuri#Dindigul#Erode#ExporterofConcreteBlockMakingMachine#Ganapathy#India#Irugur#Kallakurichi#Kallapalayam#Kanchipuram#Kanniyakumari#Karur#Keeranatham#Krishnagiri#Kurichi#Madurai#Malumichampatti

0 notes

Text

Laying Machines, Hydraulic Concrete Block Making Machines, Manufacturer

Laying Machines, Hydraulic Concrete Block Making Machines, Machinery, Turnkey Plant Projects, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India. Our hydraulic concrete block making machines provide easy, Eco-friendly and low cost to quicken the construction works.

Laying Machines, Hydraulic Concrete Block Making Machines, Fly Ash Brick Machines, Fly Ash Brick Machine, Turnkey Plant Projects, Automatic Fly Ash Brick Machines, Automatic Fly Ash Brick Machine, Semi Automatic Fly Ash Brick Machines, Semi Automatic Fly Ash Brick Machine, Interlocking Paver Block Machines, Interlocking Paver Block Machine, Paving Block Machines, Paving Block Machine, Pan Mixers, Pan Mixer, Belt Conveyors, Belt Conveyor, Box Feeders, Box Feeder, Press Feed Hoppers, Press Feed Hopper, Press Feeding Systems, Press Feeding System, Cellular Light Weight Concrete Machines, Cellular Light Weight Concrete Machine, CLC Concrete Machines, CLC Concrete Machine, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India.

0 notes

Text

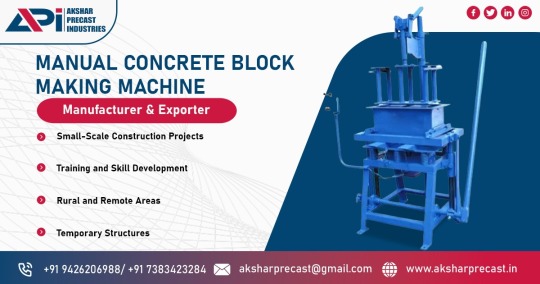

Supplier of Manual Concrete Block Making Machine

Company Overview:

Akshar Precast Industries, located in Ahmedabad, India, specializes in Manufacturer and Supplier of Manual Concrete Block Making Machine in Chhattisgarh, India.

Established in 2018, the company focuses on the manufacturing of construction machinery.

Offers a diverse range of machinery, including fully automatic and fly ash brick machines, interlocking brick machines, paver block machines, and concrete solid/hollow block making machines.

Also provides vibrating table sets, automatic batching plants for concrete raw material supply, and silos.

A simple and manually operated device used for the production of concrete blocks.

Ideal for small-scale production or DIY projects where automated machines are not necessary.

Requires human effort for mixing concrete, filling molds, and compacting the mixture.

Consists of a concrete mixer, mold box, and manual lever or hydraulic press for compressing the concrete mixture.

Operation:

The operator manually fills the mold with concrete, levels the surface, and applies pressure to compact the mixture.

Ensures the desired shape and density of the blocks.

Features:

Operates with a hand lever operating system.

Easy to operate with minimal maintenance requirements.

Equipped with safety features to prevent accidents.

Provided with a material feeding cart and storage hopper.

Availability:

Akshar Precast Industries Provide Supplier of Manual Concrete Block Making Machine in Chhattisgarh, including Raipur, Bhilai, Bilaspur, Korba, Raj Nandgaon, Raigarh, Jagdalpur, Ambikapur, Dhamtari, Chirmiri, Bhatapara, Mahasamund, Dalli-Rajhara, Kawardha, Champa, Naila Janjgir, Kanker, Dongragarh, Tilda Neora, Mungeli, Manendragarh, Kondagaon, Gobranawapara, Bemetara, and Baikunthpur.

For detailed inquiries and information, please contact Akshar Precast Industries.

Read the full article

#Ambikapur#Baikunthpur#Bemetara#Bhatapara#Bhilai#Bilaspur#Champa#Chirmiri#Dalli-Rajhara#Dhamtari#Dongragarh#Exporter#ExporterofManualConcreteBlockMakingMachine#Gobranawapara#India#Jagdalpur#Kanker#Kawardha#Kondagaon#Korba#Mahasamund#Manendragarh#ManualConcreteBlockMakingMachine#Manufacturer#ManufacturerofManualConcreteBlockMakingMachine#Mungeli#NailaJanjgir#Raigarh#Raipur#RajNandgaon

0 notes

Text

Bricks making machine

A brick-making machine is a piece of equipment designed to produce bricks from clay or other materials. These machines vary in complexity and size, ranging from small manual machines to large automated systems. Here's a brief overview of the types of brick-making machines:

Manual Brick Making Machine:

Simple and manually operated machines that require human effort to produce bricks.

Typically used for small-scale production or in areas with limited access to power.

Semi-Automatic Brick Making Machine:

Combines manual labor with automation to increase production efficiency.

May involve manual loading of raw materials, but some processes are automated, such as brick molding and removal.

Automatic Brick Making Machine:

Fully automated machines that handle the entire brick-making process from raw material preparation to brick stacking.

Can produce a large number of bricks in a short period with minimal human intervention.

Clay Brick Making Machine:

Specifically designed for molding and baking clay bricks.

Suitable for areas with abundant clay deposits.

Concrete Brick Making Machine:

Utilizes concrete as the primary raw material for brick production.

Often used in construction projects where concrete bricks are preferred.

Fly Ash Brick Making Machine:

Incorporates fly ash, a byproduct of coal combustion, as a raw material in the brick-making process.

Environmentally friendly option that utilizes industrial waste.

Hydraulic Brick Making Machine:

Utilizes hydraulic pressure to compress the raw materials and form bricks.

Offers precision and consistency in brick production.

Mobile Brick Making Machine:

Portable machines that can be moved to different locations for on-site brick production.

Useful for construction projects in remote areas.

When choosing a brick-making machine, factors to consider include the scale of production, available resources (such as raw materials and power supply), budget constraints, and the specific type of bricks needed. Additionally, understanding the local building regulations and standards is crucial to ensure that the produced bricks meet the required specifications.

Pover block making machine

It seems like there might be a small typo in your question. I assume you're asking about a "paver block making machine." A paver block making machine is a type of equipment used to produce concrete or interlocking pavers, which are commonly used in landscaping, road paving, and other outdoor applications. These machines play a crucial role in the construction industry, allowing for the efficient and consistent production of high-quality paver blocks. Here are some key features and aspects of paver block making machines:

Concrete or Interlocking Pavers:

Paver block making machines are designed to produce concrete pavers or interlocking blocks, which are widely used for creating pavements, driveways, walkways, and other outdoor surfaces.

Varying Capacities:

Paver block machines come in different capacities, ranging from small, manual machines suitable for small-scale projects to fully automatic machines for large-scale production.

Molding and Compression:

These machines typically use molds to shape the concrete into the desired paver block design. Hydraulic pressure or other mechanisms are employed to compress the concrete mixture into the mold.

Vibrations and Compaction:

Vibrators are often used to ensure proper compaction of the concrete mix within the mold, resulting in dense and durable paver blocks.

Coloring and Surface Finishing:

Some advanced machines allow for the addition of pigments or coloring agents to produce colored paver blocks. Additionally, surface finishing options can create various textures and patterns.

Automation Levels:

Paver block making machines range from manual or semi-automatic to fully automatic, depending on the level of automation required by the user.

Batching Systems:

In some cases, these machines may be integrated with concrete batching systems to ensure accurate mixing proportions and consistency in the quality of the blocks.

Versatility:

Paver block making machines can be versatile, producing different shapes, sizes, and designs of paver blocks to meet specific project requirements.

When considering a paver block making machine, it's important to assess factors such as the production capacity, the variety of designs it can produce, the level of automation, and the overall durability and reliability of the machine. It's also crucial to consider the availability of raw materials and the specific requirements of the projects you intend to undertake.

Fly ash brick making machine

A fly ash brick making machine is designed to manufacture bricks using fly ash, a byproduct of burning coal, as one of the main raw materials. Fly ash brick production is an environmentally friendly and sustainable alternative to traditional clay brick manufacturing. The process involves mixing fly ash with other materials, such as cement, sand, and sometimes lime, to create a concrete-like mixture. This mixture is then compacted and molded into bricks using a specialized machine. Here are some key features and aspects of fly ash brick making machines:

Raw Material Mixing:

Fly ash is typically mixed with cement, sand, and water to create a homogenous mixture. Lime may also be added to enhance the properties of the bricks.

Molding and Compaction:

The prepared mixture is fed into the brick making machine, which uses molds to shape the bricks. The compaction process ensures that the mixture is densely packed, resulting in strong and durable bricks.

Hydraulic Pressure:

Many fly ash brick making machines use hydraulic pressure to compress the mixture within the molds. This helps in achieving the desired brick density and strength.

Curing:

After molding, the bricks are typically subjected to a curing process. This involves keeping the bricks in a controlled environment with adequate moisture to allow them to gain strength over time.

Automation Levels:

Fly ash brick making machines come in various levels of automation. They can range from manual or semi-automatic machines, where some tasks are done manually, to fully automatic machines that handle the entire process automatically.

Production Capacity:

The production capacity of these machines can vary, and it's important to choose a machine that meets the specific production requirements of your project.

Brick Design and Size:

Fly ash brick making machines can produce bricks in different sizes and designs. Some machines allow for customization of the brick's surface texture and color.

Energy Efficiency:

Some modern fly ash brick making machines are designed to be energy-efficient, contributing to sustainability and cost-effectiveness.

Using fly ash in brick production not only helps in the proper disposal of a waste material but also reduces the demand for traditional clay bricks, conserving natural resources. Additionally, fly ash bricks often exhibit good insulation properties and are known for their strength and durability.

When considering a fly ash brick making machine, factors such as production capacity, automation features, energy efficiency, and the ability to produce bricks with specific characteristics should be taken into account.

Clay brick making machine

A clay brick making machine is designed to produce bricks using clay as the primary raw material. Clay bricks have been used in construction for centuries due to their durability and natural aesthetic appeal. These machines help automate the process of brick production, increasing efficiency and consistency. Here are some key features and aspects associated with clay brick making machines:

Clay Preparation:

The clay used in brick making needs to be prepared adequately. This involves refining and homogenizing the clay to ensure a consistent mixture.

Molding:

The prepared clay is then fed into molds within the machine. These molds shape the clay into individual bricks.

Drying:

After molding, the bricks are typically air-dried or dried in specialized chambers to reduce moisture content. Proper drying is crucial to prevent cracking during the firing process.

Firing or Burning:

The dried clay bricks are fired or burned in a kiln at high temperatures. This process, known as firing, transforms the clay into a hardened and durable material.

Cooling:

Once the firing process is complete, the bricks are cooled gradually to prevent thermal shock and ensure uniform strength.

Surface Finishing:

Some clay brick making machines may include features for adding texture or patterns to the brick surface during molding for aesthetic purposes.

Automation Levels:

Clay brick making machines are available in various levels of automation, ranging from manual or semi-automatic machines to fully automatic systems that handle the entire process.

Production Capacity:

Machines come in different production capacities to suit various project requirements, from small-scale production to large-scale industrial applications.

Energy Efficiency:

Some modern clay brick making machines are designed to be energy-efficient, utilizing advanced technologies to optimize the firing process.

Customization:

Depending on the machine model, there may be options for customizing the size, shape, and surface texture of the bricks.

Quality Control:

Ensuring the proper clay mixture, uniform molding, and controlled firing are essential for maintaining the quality and strength of the clay bricks.

Clay brick making machines are particularly well-suited for areas with abundant clay deposits. When choosing a clay brick making machine, factors to consider include the level of automation, production capacity, energy efficiency, and the specific requirements of the bricks for your construction projects. Understanding local building regulations and standards is also important to ensure that the produced clay bricks meet the necessary specifications.

0 notes

Text

High-Grade Pallets for Concrete Blocks in Varied Sizes and Thickness

Concrete blocks are used in the construction domain in different ways to make any structure strong and give stability to the building for long term. These blocks are designed in different patterns, styles, shapes and sizes. Choosing the best range of concrete blocks can be far easier than carry them from one place to another in convenient way. For such blocks, you need something durable, strong and in the shape to carry them easily and in convenient way. Choosing the right type of pallets for concrete blocks will be the right option to enhance your experience. Depending on your requirement, you can choose the right type of pallets for concrete blocks that are designed by keeping in mind their weight, type and size.

High-grade pallets for concrete blocks machines are designed to give them stability. These pallets are designed to last through harsh and abrasive working conditions for production of concrete blocks, pavers, and other concrete products in all types of block machines.

Pallets Are Manufactured with Different Surfaces to Cater Individual Needs

These high-grade pallets are manufactured with different varieties of surfaces to cater individual requirements of concrete block manufacturers around the world. Not to mention the surface of synthetic film, industrial fabric or glass fibre – known for offering different levels of resistance to the abrasive nature of concrete products. These high-grade pallets for concrete blocks are known for having high density in comparison to hardwood, softwood and plastic production boards for concrete blocks that ensures efficient transmission of vibration to the concrete.

They are available in all sizes with thickness up to 70mm and sometimes in other thicknesses. These pallets are manufactured in state-of-the-art hydraulic press and exclusive use of tropical plantation hardwood. Not to mention the use of fibers in manufacturing that ensures consistent quality. In this way, they outlast ordinary softwood and hardwood pallets for concrete block manufacturing. Different types of engineered surfaces are offered that ensure long life of trouble free services by the pallets.

Find Top Manufacturer of Pallets for Concrete Blocks

Depending on your requirement, you can choose the best range of pallets for concrete blocks machines and for other purposes. Pricing depends on the type of pallets you are using and getting their delivery will be far easier to your address without any delay.

For the best range of pallets for concrete blocks and machines, you need to reach the top manufacturer. Go online and it is counted as one of the convenient ways to provide you with some of the best options to choose the best one. You can place your from anywhere and get delivery to your address without any delay. Check all details and get the best range of pallets for concrete blocks.

0 notes

Text

Best Fly Ash Brick Making Machine in Pune

Being a quality driven enterprise, we are affianced in Manufacturing and Exporting a wide assortment of Brick Making Machine, Mixer Machine, Hydraulic Press Machine and much more. The offered machines are precisely engineered using quality tested components and advanced technology in line with set industry standards. These machines are widely acknowledged for their surpass performance, long service life, excellent control mechanism, energy efficiency, robust construction and unmatched design. Our clients can avail these products from us in various specifications at industry leading prices.

Fly Ash Brick Making Machine in Pune

Pune

Our range of include Fly Ash Brick Making Machine in Pune, fly ash brick making machine fully automatic fly ash brick making machine ,automatic fly ash brick plant fully automatic fly ash brick press machine vibration block making machine fly ash brick making machine paver block making machine brick making machine block making machine concrete block making machine automatic concrete block making machine automatic brick making machine cement brick making machine automatic cement brick making machine automatic paver block making machine

Call Us +91 8511142701

https://www.indiantradebird.com/pune/fly-ash-brick-making-machine

0 notes

Text

Best Quality Automatic Batching System Manufacturers Rexnear

Rexnear stands out as a prominent Automatic Batching System Manufacturers with state-of-the-art, specially designed for brick manufacturing plants. These cutting-edge systems are designed to streamline the batching process with advanced automation, optimizing production efficiency. Rexnear's automatic batching systems are equipped with the latest technology, ensuring precise and consistent measurement of materials, resulting in reduced waste and increased productivity.

Call Us: +91-8750287752,9990342299

Email id: [email protected]

Address: Plot No. 358 B, Udyog Kendra – 1, Ecotech – 3, Greater Noida - Uttar Pradesh (India.) - 201306

URL: https://www.flyashbrickmakingmachines.in/automatic-batching-system.html

#Fly Ash Brick Making Machine Manufacturers#Hydraulic Brick Machine Manufacturers#Tile Press Paver Block Machine Manufacturers#Automatic Batching System Manufacturers

0 notes

Text

block making machine manufacturers in india

Find here Block Making Machine, Automatic Paver Block Making Machine, Fly Ash Brick Making Machine, Hydraulic Brick Making Machine Manufacturer and Supplier in Gujarat,India.Get Address and Contact details in Ahmedabad.

#block making machine#block making machine manufacturer#block making machine supplier#block making machine in india#block making manufacturer in ahmedabad#block making machine supplier in india

0 notes

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Supplier of Fly Ash Brick Making Machine in Coimbatore

Robexo Industries is Manufacturer and Supplier of Fly Ash Brick Making Machine in Coimbatore, Tamil Nadu, India, established in 2015.

The company specializes in manufacturing a wide range of construction machinery meeting international standards, including Fly ash brick machines, Fully automatic brick machines, Interlocking brick machines, Paver block machines, Concrete hollow/solid block machines, etc.

An industrial device, the Fly Ash Brick Making Machine, produces bricks using fly ash, cement, sand, and water.

This machine automates the brick-making process, enhancing production efficiency and consistency.

Operation:

Material Loading: Raw materials (fly ash, cement, sand, water) are loaded into the hopper.

Mixing: The operator thoroughly mixes materials to form a homogeneous mixture.

Molding: Hydraulic pressure transfers the mixture to the mold, compacts it, and shapes it into bricks.

Ejection: The operator thoroughly mixes materials to form a homogeneous mixture.

Curing: During a specific period, the bricks undergo curing to achieve optimal strength and durability.

Key Features:

High Efficiency: Capable of producing a large number of bricks per hour.

Automation: Automated operations reduce labor costs and increase productivity.

Consistency: Produces uniform bricks with precise dimensions and high strength.

Versatility: Can produce various types of bricks including solid, hollow, and interlocking bricks.

Energy Efficiency: Designed to optimize energy use, reducing operational costs.

Robexo Industries is Supplier of Fly Ash Brick Making Machine in Coimbatore, Tamil Nadu, India Including Kurichi, Ganapathy, Peelamedu, Kallapalayam, Malumichampatti, Thudiyalur, ,Saravanampatti, Arasur, Annur, Chinnavedampatti, Keeranatham, Irugur, Sulur, Singanallur, Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam.

For further inquiries, engage in a professional conversation with our team.

Read the full article

#Annur#Arasur#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Chinnavedampatti#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#FlyAshBrickMakingMachine#Ganapathy#India#Irugur#Kallakurichi#Kallapalayam#Kanchipuram#Kanniyakumari#Karur#Keeranatham#Krishnagiri#Kurichi#Madurai#Malumichampatti#Manufacturer#ManufacturerofFlyAshBrickMakingMachineinAhmedabad

0 notes

Text

Fly Ash Brick Making Machine in India

Being a quality driven enterprise, we are affianced in Manufacturing and Exporting a wide assortment of Brick Making Machine, Mixer Machine, Hydraulic Press Machine and much more. The offered machines are precisely engineered using quality tested components and advanced technology in line with set industry standards. These machines are widely acknowledged for their surpass performance, long service life, excellent control mechanism, energy efficiency, robust construction and unmatched design. Our clients can avail these products from us in various specifications at industry leading prices.

Fly Ash Brick Making Machine in India

Ahmedabad

Delhi

Faridabad

Ghaziabad

Noida

Pune

Our range of include Fly Ash Brick Making Machine automatic fly ash brick making machinefully automatic fly ash brick making machineautomatic fly ash brick plantfully automatic fly ash brick press machinevibration block making machinefly ash brick making machinepaver block making machinebrick making machineblock making machineconcrete block making machineautomatic concrete block making machineautomatic brick making machinecement brick making machineautomatic cement brick making machineautomatic paver block making machine

1 note

·

View note

Text

Hydraulic Concrete Block Making Machine in Madhya Pradesh

Company Overview:

Akshar Precast Industries, in Madhya Pradesh, India, specializes in the Manufacturer and Supplier of Hydraulic Concrete Block Making Machine in Madhya Pradesh, India.

Established in 2018, specializing in construction machinery manufacturing.

Offers a wide range of machinery, including fully automatic/fly ash brick, interlocking brick, paver block, concrete solid/hollow block making machines, vibrating table sets, concrete raw material supply automatic batching plants, and silos.

Experienced professionals craft the machines using top-grade materials and advanced technology.

Renowned for durability and functionality, they are highly sought after globally.

Widely used in construction, they are competitively priced to meet diverse client needs.

Features:

Easy operation

Rigid construction

High performance

Minimum power consumption

Robustness

Noise-free operation

Hassle-free functionality

Long service life

Applications:

Residential and commercial building construction

Road and pavement construction

Landscaping and hardscaping projects

Infrastructure development (e.g., bridges, dams, retaining walls)

Urban development and rehabilitation projects

Geographical Coverage in Madhya Pradesh:

Akshar Precast Industries Supplier of Hydraulic Concrete Block Making Machine in Madhya Pradesh Including Indore, Bhopal, Jabalpur, Gwalior, Katni, Ujjain, Dewas, Satna, Ratlam, Rewa, Sagar, Singrauli, Burhanpur, Khandwa, Bhind, Chhindware, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori.

For detailed inquiries and information, please contact Akshar Precast Industries Industries.

Read the full article

#Exporter#HydraulicConcreteBlockMakingMachine#HydraulicConcreteBlockMakingMachineinIndia#HydraulicConcreteBlockMakingMachineinMadhyaPradesh#India#MadhyaPradesh#Manufacturer#ManufacturerofHydraulicConcreteBlockMakingMachine#Supplier#SupplierofHydraulicConcreteBlockMakingMachine

0 notes