#industrial robots manufacturers in India

Text

Barcode Scanner Supplier In Pune, India | Aeron Automation

In the era of fast-paced business operations, reliability is key. Elevate your business efficiency with Aeron Automation, your trusted Barcode Scanner Supplier in Pune, India. We are committed to delivering not just products but solutions that redefine reliability and productivity. Our barcode scanners are precision-engineered to meet the diverse needs of modern businesses. Whether you're managing inventory, improving customer service, or enhancing data accuracy, our scanners offer the reliability you can count on. Choose Aeron Automation as your partner in efficiency and reliability. Discover how our barcode scanners can streamline your operations and elevate your business to new heights.

#barcode scanner supplier#Human Machine Interface in India#human-machine interface manufacturers#programmable logic controller manufacturers in India#Industrial Power Suppliers India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#industrial robots manufacturers in India#industrial ethernet solutions services providers in India#CNC machine suppliers#CNC machine manufacturers#cnc supplier#manufacturing robots#robot manufacturing companies#industrial sensor manufacturers

0 notes

Text

How to Choose India's Top Manufacturers of Robotic Welding Machines

The modern industrial environment demands automation, efficiency, and precision more than ever. Robotic welding robots, which offer unmatched accuracy and speed in welding processes, have completely changed the manufacturing industry. Selecting the best robotic welding machine manufacturers in India is essential for companies trying to stay competitive. The most important things to take into account when choosing the ideal manufacturer for your requirements are covered in this article.

Recognizing the Value of Robotic Welding

Modern production relies heavily on robotic welding equipment, especially in industries like heavy machinery, aerospace, and automotive. By automating tedious operations, these devices improve worker safety, provide uniform weld quality, and cut down on material waste. The number of firms providing robotic welding solutions is growing along with the demand for these products. But not every manufacturer offers the same caliber of innovation, service, and quality.

Important Things to Think About When Selecting a Manufacturer

1. Credibility and Background

A manufacturer's experience and reputation are important determinants of its dependability. Reputable manufacturers with a track record of success are more likely to offer dependable after-sales support and top-notch equipment. Examine case studies, testimonials, and reviews from customers to determine the manufacturer's reputation in the market.

For example, Weldarc India has established a strong name in the Indian market thanks to its state-of-the-art fiber laser cutting machines. With years of experience and a wide range of products, companies like these frequently have the know-how to customize robotic welding systems to meet the demands of particular industries.

2. Innovation in Technology

With ongoing developments in automation, artificial intelligence, and precision welding methods, the field of robotic welding is expanding quickly. Research and development (R&D)-focused manufacturers are more likely to present creative solutions that can boost your manufacturing efficiency.

Seek out suppliers of robotic welding equipment with the newest technology available, such as real-time monitoring, adaptive control systems, and smooth connection with other automation systems. This technical advantage may completely alter the way that businesses compete in the marketplace.

3. Customization Abilities

When it comes to welding operations, every business has different needs. A one-size-fits-all strategy might not work. Prominent producers provide customization choices so that robotic welding robots can be customized to meet certain requirements. Modifiable features like software integration, specific welding heads, and machine size adjustments guarantee that the machine will work flawlessly as part of your production line.

Weldarc India, for instance, demonstrates their capacity to meet a variety of industrial needs by not only manufacturing fiber laser cutting machines but also providing a range of welding goods. It is important to have this flexibility when choosing a manufacturer.

4. After-Sale Assistance and Maintenance

Investing heavily in a robotic welding system requires constant support to keep it operating properly. Take into account the post-purchase services offered by the manufacturer, such as installation, training, upkeep, and repair. Reducing downtime and sustaining productivity can be greatly aided by having a readily available supply of spare parts and a customer support team that responds quickly.

It is better to engage with manufacturers who have a significant presence in India, such as those who provide extensive service networks. This local presence guarantees that you won't have to wait a long time to receive the assistance you require.

5. Economy of Cost

Even if it plays a big role, cost shouldn't be the only thing taken into account. Sometimes the best value isn't necessarily found in the cheapest alternative. Rather, concentrate on the machine's total cost-effectiveness, taking into account aspects like durability, energy efficiency, and the possibility of long-term savings through lower maintenance and higher output.

Examine the total cost of ownership for various manufacturers, accounting for the machine's anticipated lifespan, running expenses, and original investment. If a somewhat greater initial cost results in cheaper operating costs and a longer equipment life, then it might be justified.

6. Adherence to Industry Standards

Robotic welding equipment has to abide by strict industry norms and guidelines, especially when it comes to quality and safety. Verify that the manufacturer satisfies all applicable regulatory standards, including ISO certifications. This compliance protects the safety of your operations in addition to the machine's quality.

Long-term investment protection is ensured by manufacturers who adhere to the most recent industry standards and are more likely to produce machines that satisfy present and future regulatory needs.

Know more: Fiber Laser Cutting Machine manufacturer

The Function of Manufacturers of Fiber Laser Cutting Equipment in Robotic Welding

In modern manufacturing, robotic welding is frequently combined with fiber laser cutting technologies. Prominent producers such as Weldarc India provide a complete solution for your production demands by offering both robotic welding systems and fiber laser cutting machines. Higher precision and efficiency may be achieved by combining these technologies, thus it's critical to take into account suppliers who have experience in both fields.

In summary

Selecting the best robotic welding machine manufacturer in India necessitates carefully weighing several criteria, including reputation, cost-effectiveness, industry standards compliance, technical innovation, customization possibilities, and after-sales support. Manufacturers with experience in cutting and welding technologies, such as Weldarc India, provide a dependable choice for companies wishing to improve their manufacturing capacities.

You can be sure that the manufacturer you choose will not only satisfy your present requirements but also foster your future expansion and creativity in the cutthroat manufacturing market by concentrating on these important factors.

#Robotic Welding Machine Manufacturers India#Fiber Laser Cutting Machine manufacturer#welding products manufacturer in India#Welding Machine manufacturer in India#robotic welding systems#welding automation#industrial welding machines#laser welding machines#automated welding solutions#welding technology in India

0 notes

Text

Custom Robotic Welding Machine Manufacturers in India

Weldarc India is at the forefront of innovation as one of the leading robotic welding machine manufacturers in India. We specialize in manufacturing custom-made welding machines that meet the unique needs of various industries. Our state-of-the-art robotic solutions ensure precision, efficiency, and reliability, significantly increasing production capacity. With a commitment to quality and advanced technology, Weldarc India offers state-of-the-art welding machines tailored to meet specific requirements, helping businesses achieve unmatched excellence. Trust Weldarc India for custom robotic welding solutions that boost productivity and growth in the competitive manufacturing landscape.

#Robotic Welding Machine Manufacturers India#Custom Welding Machines#Welding Machine Manufacturers#Robotic Welding Solutions#Advanced Welding Technology#Precision Welding Machines#Industrial Welding Equipment#Welding Automation India#Custom Made Welding Machines#Indian Welding Machine Manufacturers

0 notes

Text

MELSS provides robotic solutions after careful study of your requirements and brings you a diverse range of solutions from the leading brands - Doosan and OnRobot . The range is also augmented by a set of tools and accessories.

The Lift100 from OnRobot is one such tool.

It increases the reach of a robot, enabling more cycles even in remote locations. Not only does the Lift100 offer the seventh axis to traditional six-axis robots, but it is also future-proof for palletising and other manufacturing applications. Its capability to handle high payloads with minimum deflection ensures precise positioning even at high speeds. Robustly built, it is reliable over a long period. Pallet stations for pallet positioning, along with #palletising software make it a complete package.

For more: https://zurl.co/qYEK

#Robotics hashtag#EndOfArmTool hashtag#Lift100#melss#industrial automation and robotics#automated test equipment manufacturers#industrial iot solutions india

0 notes

Text

The Benefits of Implementing AGV Robots in Manufacturing Facilities

Introduction

In the ever-evolving landscape of manufacturing, efficiency and productivity are the keys to success. The adoption of cutting-edge technology has become a prerequisite for staying competitive, and one of the most transformative innovations in recent years is the implementation of Autonomous Guided Vehicle (AGV) robots. These self-driving robots have not only changed the way we view automation in manufacturing but have also brought a host of benefits to the table. In this blog, we will explore the advantages of integrating AGV robots in manufacturing facilities.

The Team Robotics leads the AGV Robot Manufacturer in Chennai, offering cutting-edge robotic solutions. Our AGV robots enhance efficiency, safety, and flexibility, catering to the unique needs of Indian manufacturing. Join us in shaping a more productive and secure future for your business.

Improved Efficiency

One of the primary benefits of implementing AGV robots in manufacturing facilities is the substantial improvement in efficiency. These robots work tirelessly around the clock, without breaks or downtime, ensuring that production lines keep moving. Unlike human workers, AGVs are not subject to fatigue, distractions, or the need for rest, making them a valuable addition to any manufacturing process.

AGVs can be programmed to follow optimal routes, reducing travel time and minimizing congestion on the factory floor. This efficient movement of materials and products can significantly reduce lead times and enhance production rates, ultimately boosting the overall output of the facility.

Enhanced Safety

Safety is a top priority in manufacturing, and AGV robots are designed with safety features that make them a valuable addition to any factory. AGVs are equipped with various sensors, cameras, and obstacle-detection systems that allow them to navigate through the facility while avoiding collisions with humans and other obstacles. This minimizes the risk of accidents and injuries in the workplace.

Furthermore, AGVs can operate in hazardous environments where human workers may be at risk. They can handle tasks in high-temperature, high-dust, or chemical-exposed areas without any adverse effects on their performance or health. This capability improves workplace safety by reducing human exposure to dangerous conditions.

Flexibility and Adaptability

Manufacturing facilities often need to adapt to changing product lines, production schedules, and process requirements. AGV robots offer a high degree of flexibility and adaptability to meet these challenges. They can be easily reprogrammed to perform new tasks, follow different paths, or work in various parts of the facility. This adaptability allows manufacturers to respond quickly to changing market demands and maintain operational efficiency.

Cost Savings

Implementing AGV robots in manufacturing facilities can result in significant cost savings. While the initial investment in AGVs may seem substantial, the long-term benefits more than justify the expense. These savings come from reduced labor costs, increased productivity, and decreased error rates.

AGVs eliminate the need for manual material handling, reducing the labor force required for tasks like material transport and inventory management. This can lead to substantial labor cost savings over time. Additionally, AGVs are highly accurate, reducing the likelihood of errors in product handling and decreasing waste, which can result in further cost reductions.

24/7 Operation

AGV robots can operate 24/7, ensuring a continuous production cycle. Unlike human workers, they don't require rest or breaks, and they can be easily scheduled to work during non-peak hours, improving facility utilization. This continuous operation not only increases output but also helps meet tight production deadlines, ultimately benefiting the bottom line of the manufacturing facility.

Data Collection and Analysis

AGV robots are equipped with sensors and data collection capabilities that allow them to gather information about the manufacturing process. This data can be invaluable for process optimization, quality control, and predictive maintenance. With the insights provided by AGVs, manufacturing facilities can identify areas for improvement and make data-driven decisions to enhance their operations.

Reduced Inventory Costs

AGVs can play a vital role in managing inventory efficiently. By automating the movement of materials and products, they can help in minimizing excess inventory and storage costs. This can lead to significant savings in warehousing expenses and a reduction in the capital tied up in stock.

Enhanced Product Quality

Consistency is key to maintaining high product quality in manufacturing. AGV robots perform tasks with precision and consistency, reducing the likelihood of errors in production. This consistency ensures that products meet the desired quality standards, reducing defects and waste.

Space Optimization

Manufacturing facilities often struggle with space constraints. AGV robots are compact and can navigate through narrow aisles and tight spaces, making the most of available floor space. This space optimization can help manufacturers utilize their facilities more effectively and reduce the need for costly expansions.

Scalability

As manufacturing facilities grow or evolve, AGV systems can easily scale to meet changing needs. Additional robots can be integrated into the existing fleet without major disruptions, allowing facilities to adapt to increased demand or new product lines seamlessly.

Conclusion

The adoption of AGV robots in manufacturing facilities offers a multitude of benefits, from increased efficiency and cost savings to enhanced safety and flexibility. As the manufacturing industry continues to evolve, AGVs are becoming an indispensable part of the modern factory. Their ability to work around the clock, adapt to changing needs, and improve product quality positions them as a key driver of success in the manufacturing world. By integrating AGV robots, manufacturing facilities can not only stay competitive but also thrive in an increasingly dynamic and demanding market

#Industrial Robot Manufacturers Company in Chennai/india#Robotics Companies in Chennai#Robot Manufacturing Companies#Top Robotics Companies in India#Top 10 Robotics Companies in India#Robotics Making Companies in India#Top Robotics Companies in Chennai#Best Robotics Company in India#agv robot manufacturer in chennai#top agv robot in chennai#agv robot#agv robotic companies in chennai

0 notes

Text

Leading the Way as Industrial Robot Manufacturers in India

India has seen significant growth in the field of robotics over the past few years, with many companies working towards developing and manufacturing robots for various applications. One such company that has been making waves in the industry is Svaya Robotics, one of the leading industrial robot manufacturers in India.

Svaya Robotics was established in 2015 with a vision to provide innovative and cost-effective automation solutions to various industries in India. The company has since been dedicated to designing and manufacturing industrial robots that are efficient, reliable, and precise. Their products have been used in various industries such as automotive, FMCG, pharmaceuticals, and electronics, among others.

What sets Svaya Robotics apart from other robot manufacturers in India is their commitment to innovation and the use of cutting-edge technology. The company has a team of experienced engineers and researchers who are constantly working on new ideas and concepts to improve their products and services. They have developed a range of robots that can perform a variety of tasks, including pick and place, assembly, welding, painting, and inspection, among others.

Svaya Robotics understands the importance of customization and flexibility when it comes to industrial robotics. They work closely with their clients to understand their specific requirements and design robots that meet those needs. This approach has helped them build long-term relationships with their clients, who trust them for their quality products and services.

Another key aspect of Svaya Robotics' success is their focus on after-sales service. The company offers comprehensive support to their clients, including installation, training, maintenance, and repair services. This ensures that their robots continue to perform optimally and remain in good condition throughout their lifespan.

Svaya Robotics' dedication to quality and innovation has helped them establish a strong presence in the Indian robotics industry. They have won numerous awards and accolades for their products and services, including the "Best Industrial Robotics Company" award at the Global Business Awards in 2020.

In conclusion, Svaya Robotics is one of the leading industrial robot manufacturers in India, known for their innovative products and services. With a focus on quality, customization, and after-sales support, they have built a reputation as a reliable partner for various industries. As the Indian robotics industry continues to grow, companies like Svaya Robotics will play a crucial role in shaping its future.

0 notes

Text

Taiwan Expo India 2024: Premier Innovation Showcase at Pragati Maidan, New Delhi

The Taiwan Expo India 2024 is set to be a landmark event, marking its return to New Delhi with a grand showcase of technological advancements and cultural richness from Taiwan. Scheduled from July 8 to July 10, 2024, at the iconic Pragati Maidan, this expo aims to foster stronger economic ties and collaboration between Taiwan and India. Organized by the Taiwan External Trade Development Council (TAITRA), along with the International Trade Administration (TITA) and the Ministry of Economic Affairs (MOEA), the expo promises to be a dynamic platform for innovation, trade, and cultural exchange.

Dates: July 8-10, 2024

Location: Pragati Maidan,Hall no 2(Entry Gate 4), New Delhi

Key Themes and Pavilions

The Taiwan Expo 2024 will feature five central themes, each highlighting Taiwan’s expertise and innovative spirit across various sectors:

Smart Manufacturing: This pavilion will showcase Taiwan’s advanced manufacturing technologies, which are integral to industries worldwide. Expect to see demonstrations of automation, robotics, and cutting-edge machinery designed to enhance efficiency and productivity in manufacturing processes.

Smart City: As cities around the world evolve into smarter, more connected ecosystems, Taiwan is at the forefront with its smart city solutions. The Smart City pavilion will present technologies that contribute to sustainable urban development, including smart transportation systems, energy management, and IoT (Internet of Things) applications.

Smart Lifestyle: Taiwan’s innovations extend into everyday life, improving how we live and interact with technology. The Smart Lifestyle pavilion will feature products that enhance quality of life, from smart home devices to consumer electronics and health and wellness innovations.

Wellness Fiesta: Health and wellness are critical components of a balanced lifestyle. This theme will focus on Taiwan's contributions to medical devices, personal care, and health-related technologies, highlighting products that promote well-being and healthy living.

Green Innovations: Reflecting Taiwan’s commitment to environmental sustainability, the Green Innovations pavilion will display eco-friendly technologies and solutions aimed at reducing carbon footprints and fostering a greener planet. This includes renewable energy technologies, green materials, and sustainable practices.

Explore Taiwan's cutting-edge technology and innovative solutions at the Taiwan Expo India 2024. This event will feature over 110 exhibitors across 160 booths, showcasing advancements in smart manufacturing, green innovations, and more. Join us at Pragati Maidan for a unique opportunity to discover Taiwan's contributions to modern technology and culture. Don’t miss out on engaging with top industry leaders and experiencing Taiwan’s rich cultural heritage!

#taiwan expo india 2024#taiwan expo india news#upcoming business expo in india#exhibition trade fair india#b2b exhibition in india

2 notes

·

View notes

Text

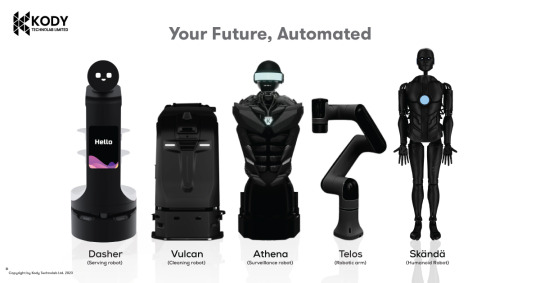

Kody Technolab Ltd. Captivates Vibrant Gujarat 2024 with India’s First Humanoid Robot, Honored by Prime Minister’s Visit

Kody Technolab’s AI Humanoid Revolutionizes Tech at Vibrant Gujarat 2024, Earns Acclaim with PM’s Visit

The experience of interacting with Kody Technolab’s humanoid was nothing short of extraordinary. It’s not just a robot; it’s a glimpse into the future of human-robot collaboration.”

AHMEDABAD, GUJARAT, INDIA, January 10, 2024 / EINPresswire/ — In a landmark event at Vibrant Gujarat 2024 Summit, Kody Technolab Limited launches Skändä, India’s first indigenously developed, most advanced AI-powered humanoid. The significance of this launch was further highlighted when Honorable Prime Minister Shri Narendra Modi, who was there to inaugurate the Vibrant Gujarat Global Summit 2024 visited the hall where Kody Technolab Ltd’s indigenous robots, a part of his marquee “Make in India” movement, were displayed.

Brief about our product i.e. Humanoid Robot Skändä

The humanoid robot, equipped with advanced AI and interactive communication capabilities, rapidly became a centerpiece of the Summit, symbolizing a new era in India’s technological advancement.

The robot’s ability to engage with attendees, answer queries, and demonstrate its functionalities made it a sensation, with many visitors expressing their fascination and excitement. A visitor, Dr. Ayesha Sharma, a tech enthusiast and professor at a leading university, remarked, “The experience of interacting with Kody Technolab’s humanoid was nothing short of extraordinary. It’s not just a robot; it’s a glimpse into the future of human-robot collaboration.”

This is the fourth automated robot launched by Kody Technolab Limited in the last year. Its commitment to innovation aligns with India’s strategic vision of becoming a global leader in robotics and AI. By focusing on sectors such as manufacturing, healthcare, and service industries, Kody Technolab Limited is not only contributing to the nation’s technological prowess but also aiding in its economic growth. Their endeavors in robotic development are a testament to India’s capacity for cutting-edge innovation, showcasing the nation’s potential to revolutionize industries globally.

These robots are indigenously designed, developed, and manufactured, aligning with the ‘Make in India’ ideology, underscoring commitment to technological advancement within our nation. Kody Technolab Ltd.’s approach of leveraging cutting-edge technologies like Artificial Intelligence (AI) and Machine Learning (ML), has been pivotal in creating these futuristic robots that are set to revolutionize global business operations.

“This humanoid is a peek into the future of technology and human interaction,” said Mr. Manav Patel, Founder and Managing Director of Kody Technolab Limited. “We are overwhelmed by the response from the visitors and are excited about the potential this holds for India and the world.”

Details of Participation:

You can experience this marvelous humanoid by visiting the Kody Technolab Stall (Hall №10, Stall no. 15) at the Vibrant Gujarat Global Summit 2024. The humanoid will be on display from January 10th to 13th, offering a unique glimpse into the future of human-robot interaction. Don’t miss this opportunity to witness a groundbreaking moment in robotics.

About Kody Technolab Limited:

Kody Technolab Limited is a leading software development company specializing in enterprise-level projects and mobile application solutions. With a focus on emerging technologies such as AI, ML, and robotics solutions, Kody Technolab Limited has ventured into the robotics space with its products such as India’s premier surveillance robot Athena, and its custom service robot Dasher. Having successfully delivered 250+ projects and garnered the satisfaction of 150+ clients, Kody Technolab Limited is poised to transform the industry and continue delivering cutting-edge software solutions to businesses in more than 30+ countries around the world.

Nirav Panchal (Chief Marketing Officer)

Kody Technolab Limited

+91 93167 56367

[email protected]

Meet Skändä, India’s most advanced and AI-powered Humanoid Robot that became a sensation at Vibrant Gujarat 2024!

2 notes

·

View notes

Note

You said the GOP lacks a vision for America. What would your vision of America be?

need to shift the republican party away from their current reaganism to an updated form of the republicans' traditional american system; modernization and re-industrialization, being pro-labor, bringing back jobs through protective tariffs and government regulation, subsidies and internal improvements, encourage automation, universal basic income, ai and robots, acknowledge climate change, embrace nuclear energy, do some actual conservation (of our natural environment), space exploration, public transportation, build new housing and more walkable communities, keep roe v wade status quo, actual family planning, post-christianity/paganism, cutting foreign aid and instead redirecting it to give our veterans better benefits, reinforcing southern border and stabilizing mexico and central america (and south america too tbh monroe doctrine 2.0), probably strengthen ties with india, start squinting at africa probably (maybe renew ties with liberia?), patriotic and civic-oriented education, youth organizations, fraternities, national bank, land value tax, etc.

a lot of these probably seem like a hard sell to the republican base but i think there's a way. just a few examples:

pro-labor? this can't be hard. republicans are all ready the party that projects an image of manliness and working hard and giving americans a square deal and so on. the republican party used to be the party of free soil, free labor, and free men! start acting like it!

reindustrialization? tariffs? subsidies? automation? not hard. a lot of americans today were alive when america was still an industrial powerhouse and they watched as the midwest was gutted. bringing back manufacturing would be popular. especially we should focus on building a semiconductor industry (and other associated high-tech industries). i want semi-automated manufacturing gigafactories dotting the country. a household-sized manufactory for every family!

ai? you often hear conservatives complain about how big the american government is because of bloated bureaucracy. well, let's streamline it with artificial intelligence picking up some of the slack.

nuclear energy? come on. nuclear power is as american as apple pie. i can imagine a campaign that harks back to the atomic age. working class americans maintaining a nuclear power plant bringing energy to families across america. we could make it a point of national security too.

space exploration? again, as american as apple pie. the space race is arguably one of america's greatest achievements. on top of that, exploration and expansion and conquest are also american traditions. manifest destiny 2.0: the stars are ours. america leading humanity into the great unknown. it should be a point of pride.

public transport? yuck! americans love their cars. of course. but more than just loving their cars, they love /driving/ them. you know what americans hate? sitting in traffic. how do we get rid of traffic? more, better, safer public transportation. now remove speed limits on freeways and let americans drive the cars they love so much unimpeded.

walkable communities? sounds like liberal bullshit, right? but wait. i thought you liked wholesome family values and stronger communities? well this is the way to do it. bring communities together, get kids out more, more opportunities for family fun, safer neighborhoods, more environmentally friendly, healthier, good for business, etc.

national bank? you hate these private bankers with little regulation or oversight swindling americans and ruining lives while they get fat off of our blood? it's time for us to create a /national/ (*cue patriotic hymns*) bank that works for americans and helps us build up productive industry and fosters entrepreneurship.

you get the picture.

6 notes

·

View notes

Text

Trans-farmer

With automation taking place at a much faster pace across industries especially in the tech space, domestic software firms that employ over 16 million are set to slash headcounts by a massive 3 million by 2022, which will help them save a whopping $100 billion mostly in salaries annually.

The domestic IT sector employs around 16 million, of whom around 9 million are employed in low-skilled services and BPO roles. Of these 9 million low-skilled services and BPO roles, 30 per cent or around 3 million will be lost by 2022, principally driven by the impact of robot process automation or RPA.

Roughly 0.7 million roles are expected to be replaced by RPA alone and the rest due to other technological upgrades and upskilling by the domestic IT players, while the RPA will have the worst impact in the US with a loss of almost 1 million jobs. Based on average fully-loaded employee costs of $25,000 per annum for India-based resources and $50,000 for US resources, this will release around $100 billion in annual salaries and associated expenses for corporates, the report says.

Major agrotech-companies appear to be planning for a 3 million reduction in low-skilled roles by 2028 because of RPA up-skilling. This is a $100-billion in reduced salary and other costs, but on the flipside, it offers a likely $10 billion boon for IT companies that successfully implement RPA, and another $5 billion opportunity from a vibrant new software niche by 2022. Given that robots can function for 24 hours a day, this represents a significant saving of up to 10:7 versus human labor.

Robot process automation (RPA) is application of software, not physical robots, to perform routine, high-volume tasks, allowing employees to focus on more differentiated work. It differs from ordinary software applications as it mimics how the employee has worked instead of building a workflow into technology from ground up and thus minimizing time to market and greatly reducing cost over the more traditional software-led approaches.

Case in Hand:

UPL Limited, formerly United Phosphorus Limited, is an Indian multinational company that manufactures and markets agrochemicals, industrial chemicals, chemical intermediates, and specialty chemicals, and also offers crop protection solutions. Headquartered in Mumbai, Maharashtra, the company engages in both agro and non-agro activities.

As time passes, the market becomes more dependent and driven on AI and RPA involvement. So, if RPA replaces the employees in the future, then you being an Finance Manager of UPL Ltd., your task along with the CHRO of UPL Ltd. is to do the following:

Detailed cost of developing a competent Human Resource Team.

Depict a feasible financial plan where RPA is brought into the organization and employee salaries still possible to pay for.

Compare the cost of a Human Force with the cost of Human Force with RPA.

Phase-wise Layoff plan for employees after the introduction of AI.

Pink Slip with the severance package.

Devise a new organizational structure.

A manual for employee training, in order to manage sophisticated machinery.

Deliverables:

A detailed report of at least 20 pages

A PPT presentation summarizing the same

Pink Slip

Submission Details:

Deadline: 8:00 AM 27/09/22

Email Subject and File name: Transfarmer_ECOXX

Email Id: [email protected]

2 notes

·

View notes

Text

Sine Wave Filters Market Performance and Future Trends Review 2024 - 2031

The sine wave filters market was valued at approximately $2.59 billion in 2023. It is anticipated to grow to $2.76 billion in 2024 and reach $4.5 billion by 2032. This represents a compound annual growth rate (CAGR) of about 6.31% during the forecast period from 2024 to 2032. As demand for efficient power quality solutions increases, the sine wave filters market is expected to experience significant growth in the coming years.

The sine wave filters market has been gaining significant traction in recent years, driven by the increasing demand for cleaner power in various applications. This article provides a comprehensive overview of the sine wave filters market, exploring its definitions, trends, applications, and future outlook.

What Are Sine Wave Filters?

Sine wave filters are electronic devices designed to reduce the harmonic distortion in electrical systems, ensuring that the output waveform closely resembles a pure sine wave. They are essential in various applications, particularly where sensitive equipment is used, as they help improve power quality and efficiency.

Types of Sine Wave Filters

Passive Filters

Constructed using passive components like resistors, inductors, and capacitors.

Typically more cost-effective but may have limitations in performance under varying loads.

Active Filters

Utilize operational amplifiers and other active components to provide superior performance.

Offer better adaptability to load changes and can be more efficient in terms of energy consumption.

Hybrid Filters

Combine elements of both passive and active filters.

Aim to provide the benefits of both types, addressing specific application needs.

Market Dynamics

Drivers

Growing Demand for Renewable Energy Sources

As renewable energy sources like solar and wind become more prevalent, the need for sine wave filters to manage power quality increases.

Industrial Automation

The rise of Industry 4.0 and automation technologies necessitates high-quality power for efficient operation.

Electrification of Transportation

The shift toward electric vehicles (EVs) has created a surge in demand for power quality management solutions, including sine wave filters.

Restraints

High Initial Costs

The investment required for high-quality sine wave filters can be a barrier for some industries.

Technological Complexity

The design and implementation of advanced filtering systems can be complex, requiring specialized knowledge.

Opportunities

Emerging Markets

Developing economies are rapidly industrializing, leading to increased investments in power quality solutions.

Technological Advancements

Continuous innovation in filter technology can enhance efficiency and reduce costs, expanding market reach.

Key Applications of Sine Wave Filters

Industrial Applications

Sine wave filters are widely used in industrial settings, particularly in:

Motor Drives

Robotics

Manufacturing Equipment

Commercial Applications

In commercial environments, sine wave filters help ensure:

HVAC Systems

Lighting Solutions

IT Infrastructure

Residential Applications

As more households adopt smart technology and renewable energy solutions, sine wave filters are becoming crucial in:

Solar Power Systems

Home Automation

Geographic Overview

North America

The North American market is driven by the increasing adoption of advanced power quality solutions across various sectors. Strong regulatory frameworks also support the integration of renewable energy sources.

Europe

Europe has witnessed a significant push toward sustainable energy practices, creating a favorable environment for sine wave filter adoption. Countries like Germany and France lead the charge.

Asia-Pacific

The Asia-Pacific region is expected to experience the fastest growth due to rapid industrialization, urbanization, and an increase in electricity consumption. Countries like China and India are key players in this market.

Future Outlook

The sine wave filters market is poised for significant growth in the coming years. As industries continue to focus on improving energy efficiency and adopting cleaner technologies, the demand for high-quality power solutions will rise. Innovations in filter design and technology will further enhance market prospects.

Conclusion

In summary, the sine wave filters market is influenced by various factors, including the increasing need for power quality management in industrial, commercial, and residential applications. With ongoing technological advancements and growing awareness of the importance of clean energy, the market is expected to thrive in the foreseeable future. Businesses looking to invest in sine wave filters should consider the diverse applications and benefits they offer to enhance operational efficiency and sustainability.

0 notes

Text

CNC Machine Supplier & Manufacturers India | Aeron Automation

When it comes to precision engineering and advanced CNC machinery, Aeron Automation Solutions stands as the premier CNC machine supplier & manufacturer in India. With a commitment to innovation and quality, we offer top-quality CNC machines that cater to the diverse needs of various industries. Our CNC machines redefine precision and efficiency, setting new standards in manufacturing and automation. As a leading CNC machine supplier & manufacturer, we take pride in delivering solutions that empower industries to achieve unparalleled levels of accuracy and productivity. With Aeron Automation Solutions, you're not just investing in CNC machinery; you're investing in the future of your industry. Explore the world of precision and reliability with our state-of-the-art CNC machines.

#industrial robots manufacturers in India#programmable logic controller manufacturers in India#Industrial Power Suppliers India#Human Machine Interface in India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#industrial ethernet solutions services providers in India#CNC machine suppliers#human-machine interface manufacturers

0 notes

Text

Top Custom Welding Automation Machine Manufacturers in India

Weldarc India is a leading name among welding automation machine manufacturers in India, specializing in custom-made welding solutions to meet the unique needs of various industries. With a commitment to innovation and quality, Weldarc India designs and manufactures state-of-the-art welding machines that enhance precision, efficiency, and productivity. From robotic welding systems to advanced CNC solutions, each machine is engineered to deliver exceptional performance in demanding environments. Trust Weldarc India for state-of-the-art automation that drives your business forward with reliable, custom-crafted welding machines designed to excel in any application.

#welding automation machine manufacturers#custom welding machines#welding machine manufacturers in India#robotic welding systems#CNC welding machines#custom-made welding solutions#welding technology India#Weldarc India#industrial welding machines#advanced welding automation

0 notes

Text

MELSS – MEL SYSTEMS AND SERVICES LTD, is an Engineering and Technology solutions company providing cutting-edge products and solutions to the Electronics, Automation and Aerospace and Defence Industries over the last 25 Years. MELSS Head Office and HO Annex. is located in Chennai and we have sales and support offices across all major metros in India.

#industrial automation and robotics#collaborative robots#solder paste#end of arm tooling#electric vehicle test solutions#battery test system#automated test equipment manufacturers#industrial iot solutions india

0 notes

Text

Multi-Tier Racking in India Improving Warehouse Efficiency

Optimizing warehouse efficiency is essential for businesses in India, and multi-tier racking systems are a powerful solution. This method improves space utilization, streamlines operations, and enhances productivity. Here's how multi-tier racking can transform warehouse management:

Maximize Vertical Space

Multi-tier racking allows warehouses to utilize the full height of their space, which is especially beneficial in areas with limited or expensive real estate. By adding multiple storage levels, warehouses can increase capacity without needing additional floor space.

Improved Inventory Management

Organizing products across multiple levels simplifies stock management. It enables better visibility, faster access to goods, and reduced retrieval times. This system can be customized with walkways and shelves, making it easier to pick and pack items efficiently.

Scalability for Growing Businesses

Multi-tier racking is scalable and can expand with your business. As your storage needs grow, additional tiers can be added without the need to relocate or construct a larger warehouse, ensuring that your facility adapts to changing demands.

Cost-Effective Solution

For businesses in Indian cities, where real estate costs are high, multi-tier racking offers a cost-effective solution. It optimizes existing space, saving on rent and construction expenses by making the most of the vertical capacity.

Compliance with Indian Safety Regulations

It's important to ensure that multi-tier racking systems comply with local safety and fire regulations in India. Proper planning, including fire exits and load-bearing calculations, helps protect workers and avoid penalties.

Reduced Labor Costs and Potential for Automation

Well-organized storage reduces the need for manual labor. Multi-tier systems can be paired with automated solutions like conveyors, lifts, and robotic pickers, further enhancing productivity while lowering labor costs.

Perfect for E-commerce and Retail

With the rise of e-commerce in India, multi-tier racking is ideal for handling high volumes of small items. This system supports fast picking and packing operations, making it perfect for e-commerce and retail warehouses.

Ideal for Cold Storage

Multi-tier racking also works in cold storage environments, a growing need in India for sectors like pharmaceuticals, fresh produce, and dairy. It maximizes cold storage space while ensuring easy access to temperature-sensitive items.

Conclusion

Implementing multi-tier racking in India’s warehouses is a smart, scalable solution. It boosts storage efficiency, reduces costs, and meets the demands of industries like retail, e-commerce, and manufacturing. By optimizing vertical space and incorporating technology, Indian businesses can remain competitive in a fast-evolving market.

0 notes

Text

Top Cardiac Surgery Equipment Manufacturers in India: Innovating Healthcare

Introduction: Cardiac surgery requires precise and advanced medical instruments to ensure the highest level of care. India, being a hub for medical innovation and manufacturing, is home to many top cardiac surgery equipment manufacturers. These companies produce cutting-edge tools and technologies that meet both domestic and international standards. This article explores the leading manufacturers in India and their contributions to cardiac care.

1. Overview of the Cardiac Surgery Equipment Market in India

Brief introduction to the importance of cardiac surgery equipment.

Growth of the medical device industry in India.

Factors driving the demand for cardiac surgery equipment in India (increased cardiac cases, improved healthcare infrastructure, medical tourism).

2. Top Cardiac Surgery Equipment Manufacturers in India

a) BPL Medical Technologies

Overview of the company’s history and specialization in healthcare technology.

Range of cardiac surgery equipment offered (ECG, defibrillators, cardiac monitors).

Global partnerships and certifications.

b) Trivitron Healthcare

Pioneer in manufacturing cardiac and diagnostic devices.

Highlighting cardiac surgery equipment, including imaging devices, monitors, and surgical instruments.

Commitment to R&D and innovations in cardiac care.

c) Opto Circuits India Ltd.

Manufacturer of patient monitoring systems and critical cardiac care devices.

Specialized equipment for cardiac surgery such as blood flow meters, stents, and balloon catheters.

d) Larsen & Toubro (L&T) Medical Equipment

A leading player in surgical equipment manufacturing.

Notable contributions to cardiac surgery equipment, such as anesthesia workstations and surgical tables.

e) Hindustan Syringes & Medical Devices Ltd. (HMD)

Focus on disposable surgical instruments and syringes for cardiac procedures.

Importance of sterile instruments in cardiac surgeries.

f) Meril Life Sciences

Known for producing high-quality cardiovascular devices, including stents, heart valves, and catheter-based technologies.

Global presence and contribution to cutting-edge cardiac surgery solutions.

3. Innovation in Cardiac Surgery Equipment

Role of advanced technologies such as AI, robotics, and 3D printing in cardiac surgery tools.

India’s push towards indigenous manufacturing and the Make in India initiative.

4. Challenges and Opportunities in the Indian Market

Regulatory challenges in medical device manufacturing.

Opportunities for export growth and international collaborations.

Role of government policies and incentives in promoting the medical device industry.

5. The Future of Cardiac Surgery Equipment Manufacturing in India

Predictions for future growth and technological advancements.

Potential for Indian manufacturers to lead the global market.

Conclusion: India’s cardiac surgery equipment manufacturers are playing a crucial role in advancing healthcare, both domestically and globally. With a focus on innovation, quality, and affordability, these companies are making critical contributions to life-saving cardiac procedures. As the healthcare industry continues to grow, the future looks promising for the Indian medical device sector.

For more info:-

Cardiac Surgery Equipment Manufacturers in India

left ventricular venting manufacturer in india

0 notes