#industrialfabrication

Text

Welcome, DPSW LLC!

The leading engineering powerhouse catering to Construction, Process, Oilfield, and Marine industries. Specializing in Air Pollution solutions, they are locally manufacture top-notch equipment like Fans, and offer Heavy Fabrication services for Storage Tanks, Towers, Cyclones, and Piling equipment.

DPSW LLC dedicated Air Pollution division provides consultancy, designs, and fabricates Industrial Fans, Ducts, Painting Booths, Dust Collectors, and more. With turnkey projects in Industrial Exhaust, Fume Extraction, and Ventilation, DPSW LLC ensures top-tier quality with in-house Balancing facilities.

Explore DPSW LLC's catalog now -

https://www.tradersfind.com/seller/dpsw-llc

#engineeringservices#airqualitycontrol#pollutioncontrolequipment#industrialfabrication#environmentalsolutions#industrialengineering#localmanufacturing#turnkeysolutions#engineeringconsultancy#industrialdesign#airqualitymanagement#industrialfans#fabricationservices#heavyequipment#pilingequipment#airpollutionsolution#industrialexhaust#fumeextractionsystem#ventilationsystem#industrialducting#pollutioncontroltechnology#balancingservices#marineengineering#oilfieldservices#constructionindustry#processindustries#DPSWLLC

3 notes

·

View notes

Text

"Best Gates and shutter works in Trivandrum and Kollam."

Contact Now 6282294331

Visit Website: www.salvefab.com

#Salve#salvefab#salvefabrication#steel#metal

#seelroofing#architecturalroofing#glasswork#kitchendesign#fabricating#industrialfabrication

#prefabricating#roof#roofing#trivandrum#kollam#best#welding#bestwelding

#gate#glassdoor

#“Best Gates and shutter works in Trivandrum and Kollam.”#Contact Now 6282294331#Visit Website: www.salvefab.com#Salve#salvefab#salvefabrication#steel#metal#seelroofing#architecturalroofing#glasswork#kitchendesign#fabricating#industrialfabrication#prefabricating#roof#roofing#trivandrum#kollam#best#welding#bestwelding#gate#glassdoor

2 notes

·

View notes

Text

Best Sheet Metal Fabrication Services

Looking for the best Sheet Metal Fabrication Services? Our expert team specializes in precision engineering, delivering high-quality custom metal fabrication solutions for various industries. We use advanced techniques and cutting-edge technology to ensure top-tier accuracy and durability for every project. Whether it’s prototypes, small batches, or large-scale production, we guarantee reliable service and fast turnaround times. From laser cutting to welding, we offer a comprehensive range of services tailored to your specifications. Trust us for unmatched craftsmanship and cost-effective solutions. Get in touch today to discuss your sheet metal fabrication needs!

#SheetMetalFabrication#MetalFabricationServices#CustomMetalWork#PrecisionFabrication#MetalWorking#EngineeringSolutions#IndustrialFabrication#DurableFabrication#MetalCraft

0 notes

Text

Best Steel Fabrication in Gwalior

#GwaliorSteelFabrication#TopSteelFabricator#SteelWorksGwalior#QualitySteelFabrication#MetalFabrication#SteelStructures#FabricationExperts#GwaliorEngineering#SteelDesign#IndustrialFabrication#Gbgrp#Gwalior#MP#mildsteelcoldrolledPlates#MildSteelHotRolledCoil#MildSteelcoldRolledCoil#MSangle#MildSteelBeams#MildSteelPipes#GISheets#steel

0 notes

Text

Heavy Fabrication Services in Maharashtra, India

Heavy Fabrication Services in Maharashtra, India. state-art machinery and advanced techniques, they offer services including welding, cutting, and bending components.

#phengicon#HeavyFabrication#FabricationServices#MetalFabrication#MaharashtraFabrication#IndustrialFabrication#SteelFabrication#WeldingServices#CustomFabrication#StructuralFabrication#EngineeringServices

0 notes

Text

"Why did the sheet metal worker become a master bender at Omnific Solutions MIDC, Koper Khairne, Navi Mumbai? Because there, every curve is a masterpiece in precision!"

Address :

Plot No.A- 814, Khairane Village, TTC Industrial Area, MIDC Industrial Area, Kopar Khairane, Navi Mumbai, Maharashtra 400705, Navi Mumbai (New Mumbai), India, 400705

+91 87670 77801

Mobile

[email protected]

Email

Websites and social links

http://omnificsolutions.co.in/

Website

https://in.pinterest.com/omnificsolutions/

Pinterest

https://twitter.com/OmnificSol10826

Twitter

https://www.tumblr.com/dashboard

Tumblr

https://www.instagram.com/omnificsolution/

Instagram

https://www.linkedin.com/feed/

LinkedIn

@omnificsolution

#SheetMetalBending#MetalFabrication#PrecisionBending#MetalWorks#IndustrialFabrication#MetalBendings#SheetMetalCraft#BendingExpertise#MetalForming#BendItRight#MetalBendingTech#SheetMetalArtisans#BendingMastery#MetalBendingSolutions#BendWithPrecision#SheetMetalDesign#BendingInnovation#MetalBendingExperts#SheetMetalMagic#BendItLikeOmnific

0 notes

Text

Anti spatter fluid for Heavy Fabrication of Earth Moving equipment’s. Eco Spatter fluid is a water based product that prevents weld spatter from sticking to welding guns, nozzles, contact tips, and metal surfaces. It contains wetting agents, anti-adhesion materials, and metal corrosion inhibitors to make welding easier and neater. Anti-spatter fluid is non-toxic, biodegradable.

#AntiSpatterOil#NozzleGel#FabricationIndustrial#WeldingSupplies#JCBWelding#WeldingSafety#SpatterProtection#IndustrialFabrication#WeldingGear#MetalWelding#WeldingEssentials#ProtectiveCoating#SpatterFree#NozzleProtection#MetalworkSolutions

0 notes

Text

#FabricationServices#MetalFabrication#StructuralSteel#SheetMetal#CustomFabrication#SteelFabrication#Welding#PrecisionFabrication#FabricationExpertise#QualityFabrication#FabricationTechnology#IndustrialFabrication#FabricationSolutions#FabricationProjects#FabricationWorkshop#FabricationSkills#FabricationProcesses

1 note

·

View note

Text

METAL FABRICATION 101: THE ESSENTIALS OF A QUALITY-CONTROLLED WELDING STATION | Sarda Metals

In the world of metal fabrication, achieving high-quality welds is paramount. A well-structured welding station, equipped with skilled professionals and the right tools, is essential for ensuring the durability and reliability of fabricated metal products. In this article, we delve into the fundamental aspects of a quality-controlled welding station at Sarda Metals, emphasizing the importance of selecting the right welders, following spatter prevention best practices, understanding how safety impacts welding quality, and ensuring safety-driven quality control. So, let's dive into the world of metal fabrication excellence, led by a renowned Metals Manufacturer in India.

Table of Contents

Introduction

Select the Right Welders for Assembly

2.1 The Role of Skilled Welders

2.2 Evaluating Welder Qualifications

Follow Spatter Prevention Best Practices

3.1 Understanding Welding Spatter

3.2 Techniques to Prevent Spatter

Know How Safety Impacts Welding Quality

4.1 Safety Measures and Their Significance

4.2 Safe Welding Environment

Ensure Safety-Driven Quality Control

5.1 Implementing Quality Control Procedures

5.2 Inspecting Welding Quality

Conclusion

FAQs

1. Introduction

Metal fabrication is a complex process that demands precision and expertise. At Sarda Metals, we understand the significance of maintaining a quality-controlled welding station to ensure the highest standards in metal fabrication. In this article, we will explore the key elements that contribute to the excellence of our welding station as a leading Metals Manufacturer in India.

2. Select the Right Welders for Assembly

2.1 The Role of Skilled Welders

The foundation of any welding station's quality control lies in the expertise of its welders. Skilled welders are the artisans who fuse metal pieces together, and their craftsmanship can make or break the final product. At Sarda Metals, we prioritize hiring and retaining highly experienced welders who are well-versed in various welding techniques.

2.2 Evaluating Welder Qualifications

To ensure that our welding station maintains the highest standards, we evaluate welder qualifications rigorously. This includes certifications, past work experience, and ongoing training. By selecting the right welders, we guarantee that the assembly process is in capable hands.

3. Follow Spatter Prevention Best Practices

3.1 Understanding Welding Spatter

Welding spatter, the unwanted bits of molten metal that can splatter during welding, is a common issue in metal fabrication. Excessive spatter can compromise the integrity of welds and lead to a subpar product. At Sarda Metals, we recognize the importance of spatter prevention.

3.2 Techniques to Prevent Spatter

Experienced metal fabricators prevent spatter by implementing various techniques, such as adjusting welding parameters, using anti-spatter solutions, and maintaining proper equipment cleanliness. Our welding station adheres to these best practices to ensure spatter-free welds and superior product quality.

4. Know How Safety Impacts Welding Quality

4.1 Safety Measures and Their Significance

Safety is not just a priority; it's a necessity in metal fabrication. Welding involves intense heat, hazardous fumes, and potential fire hazards. Safety measures protect our workers and the integrity of the welding process itself.

4.2 Safe Welding Environment

At Sarda Metals, we create a safe welding environment by providing our welders with proper protective gear, well-ventilated workspaces, and regular safety training. A secure environment ensures that welding quality remains consistent.

5. Ensure Safety-Driven Quality Control

5.1 Implementing Quality Control Procedures

Quality control is at the heart of Sarda Metals' welding station. We have established strict procedures to inspect, test, and document each weld's quality throughout the fabrication process. This meticulous approach guarantees that only top-notch products leave our facility.

5.2 Inspecting Welding Quality

Our quality control team conducts thorough inspections, employing non-destructive testing methods, such as X-ray and ultrasonic testing, to assess the integrity of welds. This commitment to quality assurance sets us apart as a leading metals manufacturer in India.

6. Conclusion

In the realm of metal fabrication, achieving excellence necessitates a blend of skilled welders, effective spatter prevention, a strong focus on safety, and a commitment to rigorous quality control. At Sarda Metals, we wholeheartedly embrace these principles to provide our clients with the finest metal products. We take pride in being a trusted "Metals Manufacturer in India," dedicated to delivering exceptional quality and craftsmanship within the industry

FAQs

1. What is metal fabrication?

Metal fabrication is the process of shaping and assembling metal materials into finished products, structures, or components through cutting, bending, and welding techniques.

2. Why is spatter prevention important in welding?

Spatter prevention is crucial in welding to ensure clean and strong welds. Excessive spatter can weaken welds and compromise the overall quality of fabricated metal products.

3. How does safety impact welding quality?

Safety measures in welding are essential to protect both the welders and the quality of the welding process. A safe environment ensures that welders can focus on producing high-quality welds without distractions or risks.

4. What are non-destructive testing methods in quality control?

Non-destructive testing methods, such as X-ray and ultrasonic testing, allow inspectors to assess the quality of welds without damaging the welded components. These methods help ensure the structural integrity of fabricated metal products.

Sarda Metals' commitment to excellence in metal fabrication is underpinned by its dedication to quality control, spatter prevention, and safety. By adhering to these principles, we ensure that our welding station remains at the forefront of the industry, delivering top-quality metal products to our clients. Our focus keyword, "Metals Manufacturer in India," highlights our position as a leading player in the Indian metal manufacturing landscape, trusted for our unwavering commitment to quality and safety.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#MetalManufacturer#SardaMetals#FerroAlloyProducers#MetalFabrication#QualityMetalProducts#MetalsIndustry#IndustrialFabrication#MetalCraftsmanship#SteelProduction#IndianMetalIndustry#Metalwork#WeldingExcellence#MetalEngineering#MetalsInnovation#MetalProcessing

1 note

·

View note

Text

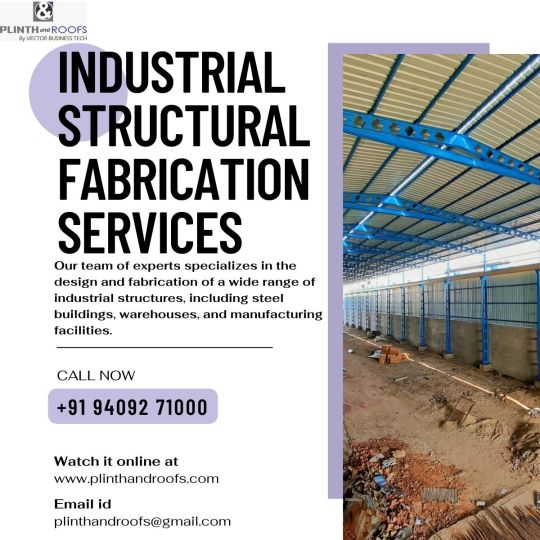

Industrial Structural Fabrication Services in Ahmedabad, Gujarat.

Are you searching for dependable industrial structural fabrication services in Ahmedabad, Gujarat? Our expert team provides a range of solutions, including design, engineering, and fabrication of industrial structures. We use the latest technology and materials to ensure quality workmanship and timely delivery of your project.

visit : https://plinthandroofs.com/

Call : +91-9409271000

#industrial fabrication#industrialconstruction#building construction#peb manufacturers#factory construction#construction#StructuralFabrication#IndustrialFabrication#SteelFabrication#FabricationCompany#StructuralDesign#FabricationProjects#StructuralEngineering#structural#ahmedabad#https://plinthandroofs.com/

0 notes

Text

Welcome, Middle East Factory (MEF)!

Certified to ISO 9001, 14001 & 45001, Middle East Factory (MEF) is your trusted partner for steel fabrication solutions. From structural steel to custom metal works, ladders, tanks, and bollards, MEF delivers precision and quality. Explore their comprehensive catalog for intricate designs, seamless fabrication, and flawless installation. Build with confidence, build with MEF.

Explore MEF's catalog now-

https://www.tradersfind.com/seller/middle-east-factory-llc

#steelfabricationuae#constructionindustryuae#metalworksdubai#structuralsteelfabrication#custommetalfabrication#precisionengineering#qualityconstruction#industrialdesigns#dubaiconstructionprojects#uaeinfrastructure#steelspecialists#metalfabricators#industrialfabrication#buildingmaterials#constructiontechnology#qualitymaterials#uaemanufacturing#steelsuppliers#constructionsolutions#metalworks#precisionfabrication#qualitycommitment#isocertified#reliablepartner#constructionvision#uae#uaemarket#b2b

2 notes

·

View notes

Text

Splendid moments shot in our workshop. our skilled welders are working hard and dedicated at their welding works.

No job is easy, just do it and finally will make it.

#customsteelfabrication#bespokesteelsolutions#mechanicalfabrication#equipmentsteelwork#industrialfabrication#metalfabrication#weldingstructures#temporarystructures#fabricatedsteelsolutions#hansalindustry

#customsteelfabrication#bespokesteelsolutions#mechanicalfabrication#equipmentsteelwork#industrialfabrication#metalfabrication#weldingstructures#temporarystructures#fabricatedsteelsolutions#hansalindustry

0 notes

Text

Coated Fabrics Market projected to reach $29.8 billion by 2028

The report "Coated Fabrics Market by Product Type (Polymer-coated Fabrics, Rubber-coated Fabrics and Fabric-backed Wall Coverings), Application (Transportation, Protective Clothing, Roofing, Awnings & Canopies), & Region – Global Forecast to 2028", size was USD 23.7 billion in 2022 and is projected to reach USD 29.8 billion by 2028, at a CAGR of 3.9% from 2023 to 2028.

The market is projected to grow due to rapid industrialization in emerging economies and innovative product development in protective clothing. The innovations are featured to meet the vital properties of coated fabrics products for different applications. Coated fabrics can serve a range of safety benefits and there is growing demand for safety measures in automobiles, aircraft, and other types of transportation. Therefore, there is a crucial need to increase coated fabrics production to sustain the demand.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=64354822

Protective Clothings was the fastest growing application of the coated fabrics market, in terms of value, in 2022

Due to the increased demand from the healthcare industry, stringent regulations and standards, technical improvements, and increasing awareness about workplace safety. Protective clothing manufacturer prefer coated fabrics as it has advantages in terms of safety, performance and sustainability. The technological developments in the coated fabrics advances its perfoamance, durability and functionality. This is projected to drive the in the protective clothing application in coated fabrics market.

Polymer-coated fabrics segment is estimated to be the largest product type of the coated fabrics, in terms of value, during the forecast period.

Polymer coated fabrics, such as polyurethane (PU), polyvinyl chloride (PVC), and polyethylene (PE), have emerged as a preferred alternative in the coated fabrics market. Their popularity stems from their exceptional versatility, offering a wide range of applications across various industries. These coated fabrics are known for their impressive durability, which ensures long-lasting performance even in demanding environments. This has indicated to their dominance in the coated fabrics market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=64354822

Asia Pacific is estimated to be the largest market for the coated fabrics market, in terms of value, during the forecast period.

Asia Pacific is projected to be the largest market for coated fabrics, driven by the high economic growth due to growing automotive & chemical industries and the rising population in region especially in India and China. There is high growth seen in protective clothing segments in this region due to increased government regulations for safety concerns in various industries such as transportation, chemical, oil & gas, construction and residential housing. This is due to growing economic conditions, rising GDP, active manufacturing sectors and healthcare sectors in emerging countries. Due to these reasons the demand for coated fabrics in Asia Pacific region is increased.

The key players profiled in the report include Continental AG (Germany), Trelleborg AB (Sweden), Serge Ferrari Group (France), Saint-Gobain S.A. (France), and Freudenberg Group (Germany).

#CoatedFabrics#TextileIndustry#IndustrialFabrics#FabricInnovation#PerformanceTextiles#TextileManufacturing#SmartFabrics#TechnicalTextiles#ProtectiveFabrics#FabricTechnology#SustainableFabrics#WaterproofFabrics#AutomotiveFabrics#HomeTextiles#FashionFabrics#TextileSolutions

0 notes

Text

0 notes

Text

#HDPE#Nonwovens#Tyvek#Polyethylene#PlasticsIndustry#Packaging#ConstructionMaterials#MedicalTextiles#SustainableMaterials#IndustrialFabrics#InnovationInMaterials#EnvironmentalProtection#Manufacturing#TechnicalTextiles#SafetyProducts

0 notes

Text

"Why did the sheet metal worker become a master bender at Omnific Solutions MIDC, Koper Khairne, Navi Mumbai? Because there, every curve is a masterpiece in precision!"

Address :

Plot No.A- 814, Khairane Village, TTC Industrial Area, MIDC Industrial Area, Kopar Khairane, Navi Mumbai, Maharashtra 400705, Navi Mumbai (New Mumbai), India, 400705

+91 87670 77801

Mobile

[email protected]

Email

Websites and social links

http://omnificsolutions.co.in/

Website

https://in.pinterest.com/omnificsolutions/

Pinterest

https://twitter.com/OmnificSol10826

Twitter

https://www.tumblr.com/dashboard

Tumblr

https://www.instagram.com/omnificsolution/

Instagram

https://www.linkedin.com/feed/

LinkedIn

@omnificsolution

#SheetMetalBending#MetalFabrication#PrecisionBending#MetalWorks#IndustrialFabrication#MetalBendings#SheetMetalCraft#BendingExpertise#MetalForming#BendItRight#MetalBendingTech#SheetMetalArtisans#BendingMastery#MetalBendingSolutions#BendWithPrecision#SheetMetalDesign#BendingInnovation#MetalBendingExperts#SheetMetalMagic#BendItLikeOmnific

0 notes