#jidoka

Text

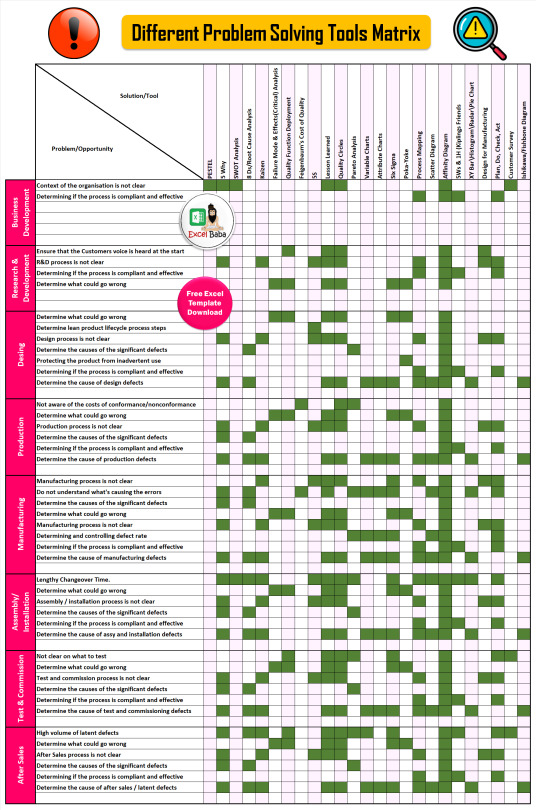

➡️ Different Problem Solving Tools Matrix Excel Template Download

#management#training#productivity#engineering#careers#projectmanagement#lean#excellence#engineers#waste#iso#tutorial#kanbanl#iso9001#leansixsigma#tutorials#5s#mechanicalengineering#msa#oee#industrialengineering#smed#ishikawa#jidoka#pokayoke#andon#7qctools#histogram#qcc#sop

1 note

·

View note

Text

Descubre la revolucionaria filosofía Jidoka: Detecta, Soluciona, Continúa. 🔄✨ Transforma tu enfoque diario con este método innovador. ¡Mejora la eficiencia y alcanza tus objetivos!

0 notes

Text

Jidoka: Empowering Automation with a Human Touch

In my tenure as a Lean Six Sigma expert, Jidoka, or Autonomation, has been a key principle that integrates automation with human intelligence to enhance process reliability and quality. This concept, a cornerstone of the Toyota Production System, ensures that machines stop automatically when a problem occurs, thereby preventing defective products from being produced. In this article, I will delve…

View On WordPress

0 notes

Text

Lean Manufacturing: Trim Waste, Boost Efficiency

Lean manufacturing is a production philosophy and management approach originated from the Toyota Production System (TPS) created by Taiichi Ohno. The primary goal of lean manufacturing is to eliminate waste and optimize efficiency throughout the entire production process. The term “lean” refers to the idea of minimizing waste while maximizing value for the customer.

Principles of Lean Manufacturing:

Value: Recognize the aspects of the product or service that hold significance for the customer.

Value Stream Mapping: Map the entire value stream for a product or service. Identify every step involved, from raw materials to the customer.

Flow: Ensure a smooth and continuous flow of work through the entire process. Minimize batch sizes and work in progress to prevent bottlenecks.

Pull: Use a pull system to produce only what the customer demands. Avoid overproduction and excess inventory.

Perfection: Continuously strive for perfection by eliminating waste and improving processes.

Kaizen (Continuous Improvement): Implement small, incremental improvements on an ongoing basis.

Just-in-Time (JIT): The strategy of producing and delivering products precisely when they are needed to meet customer demand. Minimize inventory and storage costs.

5S: Sort (Seiri), set in order (Seiton), shine (Seiso), standardize (Seiketsu), and sustain (Shitsuke). A systematic approach to workplace organization for efficiency and continuous improvement.

Single-Piece Flow: Aim for a production system where one product moves through each step of the process at a time. Reduce waiting time and defects.

Standardized Work: Establish standard processes and work instructions. Ensure consistency and identify deviations for improvement.

Visual Management: Use visual aids such as charts, graphs, and signs to communicate information clearly. Facilitates understanding and quick decision-making.

Jidoka (Autonomation): Incorporate automation with a human touch, allowing machines to stop when a defect is detected. Empower workers to stop the production process if they identify a problem.

Benefits of Lean Manufacturing:

Cost Reduction: Eliminating waste leads to cost savings in terms of materials, labour, and time.

Improved Quality: By focusing on value and eliminating defects, the overall quality of products or services is enhanced.

Increased Efficiency: Streamlining processes and reducing waste result in more efficient production.

Shorter Lead Times: The term often leads to faster production cycles, reducing the time it takes to get products to customers.

Flexibility and Responsiveness: Lean systems are more adaptable to changes in customer demand and market conditions.

Space Utilization: Lean principles often lead to a more efficient use of space in production facilities

Why Lean Manufacturing Should Be Adopted?

Competitive Advantage: Lean practices enable companies to respond quickly to customer demands, giving them a competitive edge.

Customer Satisfaction: By delivering high-quality products efficiently, the process helps enhance customer satisfaction.

Resource Optimization: It minimizes waste, making more effective use of resources.

Adaptability to Change: In a rapidly changing business environment, lean manufacturing allows companies to adapt more easily to market fluctuations and evolving customer preferences.

Long-Term Sustainability: The principles of lean manufacturing support long-term sustainability by promoting efficiency and reducing environmental impact.

However, adopting lean manufacturing principles can lead to improved efficiency, reduced costs, increased quality, and a more responsive and adaptable production system, ultimately providing a competitive advantage in the marketplace

0 notes

Text

Jidoka, una de mis filosofias de producción predilectas

¡Potencia tu Empresa con Jidoka: la Fórmula Mágica para el Éxito Empresarial!

¡Saludos, emprendedores colombianos! Estoy aquí para compartir contigo una joya del mundo de la producción que puede llevar tu pequeña o mediana empresa al siguiente nivel: ¡Jidoka! No te preocupes si esto suena a japonés; lo vamos a descifrar juntos.

¿Qué es este Jidoka?

Imagina a Jidoka como el hada madrina de la producción. Su principal misión es hacer que todo funcione sin problemas, desde la creación del producto hasta que llega a las manos de tus clientes. Pero, ¿cómo lo hace?

¡Automatización con Cerebro!

Jidoka es como la magia de la automatización, pero con un toque de inteligencia. No se trata solo de máquinas trabajando sin parar, sino de máquinas que también piensan. Si algo sale mal en el proceso, Jidoka detiene la línea de producción y señala el problema. Así, puedes corregirlo antes de que llegue a tus clientes.

¿Por qué Jidoka es tu Mejor Aliado Empresarial?

Calidad sin Compromisos: Imagina tus productos como estrellas del espectáculo. Con Jidoka, cada uno es una actuación perfecta, sin errores ni defectos.

Eficiencia sin Estrés: Olvídate de noches en vela preocupándote por problemas en la producción. Jidoka está ahí para detectar y solucionar los obstáculos.

Confianza del Cliente: Cuando tus productos son impecables, tus clientes confían en tu marca. ¡Y la confianza es oro en el mundo empresarial!

¡Haz que Jidoka Trabaje para Ti!

Ahora, sé que no todos somos expertos en tecnología, pero no te preocupes. Jidoka es tu aliado, no tu enemigo. Puedes implementar sistemas sencillos que se adapten a tu negocio. ¿El resultado? Producción sin preocupaciones y clientes felices.

¡Es Hora de Brillar con Jidoka, Empresario Colombiano!

Así que, dueño de negocio, este es el secreto que estabas esperando. Jidoka no solo es para las grandes corporaciones, también es para el emprendedor que quiere destacar. ¡Implementa esta magia en tu producción y prepárate para el éxito!

¡Hasta la próxima, empresarios valientes!

0 notes

Text

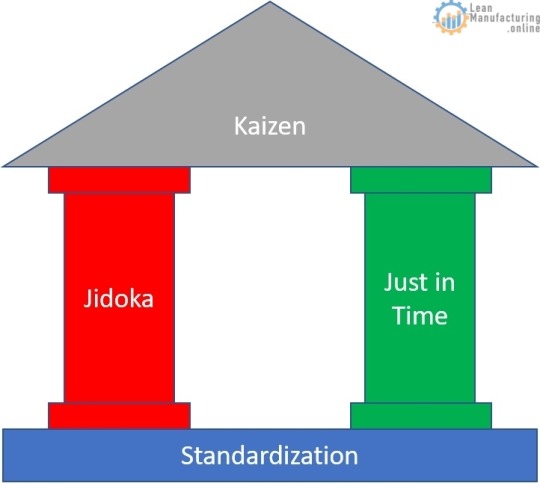

Unfolding the Secrets of the Toyota Production System

In the world of manufacturing, the Toyota Production System (TPS) stands as a paragon of efficiency and excellence. Originating in Japan but embraced worldwide, the TPS has transformed the way industries approach production, ensuring minimal waste and maximum value.

In this article, we’ll explore the intricacies of the Toyota Production System, the principles that underpin it, and how it has become a blueprint for lean manufacturing and operational excellence.

1: Understanding the Toyota Production System

The Toyota Production System, often referred to as lean manufacturing, is a comprehensive approach to production that was developed by Toyota in the mid-20th century. It is founded on the principles of continuous improvement and efficiency, with a relentless focus on eliminating waste in all aspects of production.

Key Elements of the Toyota Production System:

Just-in-Time (JIT): This principle emphasizes producing only what is needed when it is needed, and in the necessary quantity.

Jidoka: Jidoka, or autonomation, refers to the automation of problematic processes to prevent defects and errors.

Standardization: TPS promotes standardized work methods and processes to ensure consistency and quality.

Continuous Improvement (Kaizen): Continuous improvement is at the core of TPS, encouraging incremental changes for ongoing progress.

Respect for People: TPS values the skills and insights of employees, involving them in decision-making and encouraging their contributions.

2: The 14 Principles of the Toyota Production System

Base your management decisions on a long-term philosophy.

Create a continuous process flow to bring problems to the surface.

Use “pull” systems to avoid overproduction.

Level out the workload (heijunka).

Build a culture of stopping to fix problems, to get quality right the first time.

Standardized tasks and processes are the foundation for continuous improvement and employee empowerment.

Use visual control so no problems are hidden.

Use only reliable, thoroughly tested technology that serves your people and processes.

Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

Develop exceptional people and teams who follow your company’s philosophy.

Respect your extended network of partners and suppliers by challenging them and helping them improve.

Go and see for yourself to thoroughly understand the situation (genchi genbutsu).

Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly.

Become a learning organization through relentless reflection and continuous improvement (kaizen).

3: The Impact of the Toyota Production System

Reduced Waste: TPS eliminates various forms of waste, including overproduction, defects, waiting, and excessive inventory.

Higher Quality: The focus on standardized processes and continuous improvement results in higher product quality.

Cost Savings: Efficient production processes and waste reduction translate into cost savings for businesses.

Flexibility: TPS enables rapid changes in production to meet shifting market demands.

Empowerment: The TPS philosophy of respecting people fosters a sense of ownership and empowerment among employees.

4: The Global Spread of TPS

The principles of the Toyota Production System have transcended borders and industries, inspiring companies worldwide to adopt lean manufacturing practices. The success stories of these adopters underscore the universal applicability of TPS principles, with examples from industries as diverse as aerospace, healthcare, and technology.

5: Challenges in Implementing TPS

While the benefits of TPS are undeniable, implementing it can pose several challenges:

Cultural Change: Shifting from traditional manufacturing to lean practices requires a cultural change and a willingness to embrace new methods.

Training and Education: Employees need to be trained in TPS principles and encouraged to become active participants in the continuous improvement process.

Resistance to Change: Resistance from employees or management can hinder the successful implementation of TPS.

Supply Chain Coordination: Coordinating with suppliers to align with lean principles can be complex but is crucial for success.

6: The Future of the Toyota Production System

Industry 4.0 Integration: TPS will integrate with Industry 4.0 technologies like IoT, AI, and automation for even greater efficiency.

Sustainability: Environmental sustainability will play an increasingly significant role in TPS implementation.

Global Adoption: More industries and companies worldwide will embrace TPS principles for lean and efficient production.

Human-Centric Approach: The emphasis on respecting people and developing exceptional teams will remain a central tenet.

Conclusion

The Toyota Production System is more than a manufacturing methodology; it’s a philosophy that has transformed the world of production and management. Its relentless pursuit of efficiency, quality, and waste reduction has revolutionized industries, making it a benchmark for operational excellence. As TPS principles continue to evolve and adapt to changing times, the future holds a promise of even greater efficiency, sustainability, and global adoption, ensuring that the legacy of TPS endures in the manufacturing landscape for generations to come.

The Toyota Production System is a paradigm of efficiency and waste reduction. With its principles of continuous improvement and respect for people, it has left an indelible mark on industries worldwide, fostering a culture of operational excellence.

Curious to learn more? Explore our articles on Enterprise Wired

#ToyotaProductionSystem#LeanManufacturing#OperationalExcellence#Efficiency#Sustainability#QualityMatters#WasteReduction

0 notes

Text

INNOVATIONS IN LEAN MANAGEMENT: FROM TOYOTA PRODUCTION SYSTEM TO TODAY'S PRACTICES

Innovations in Lean Management have evolved significantly since the inception of the Toyota Production System (TPS) to encompass a wide range of practices and principles aimed at optimizing processes, minimizing waste, and improving overall efficiency and effectiveness in various industries. Below, we explore the journey of Lean Management from its origins to today's practices in elaborate detail:

1. Toyota Production System (TPS): The TPS, developed by Toyota in the 1950s, laid the foundation for Lean Management. It emphasized two core principles: continuous improvement (Kaizen) and waste reduction (Muda). Key elements included Just-in-Time (JIT) production, which aimed to produce only what is needed when it's needed, and autonomation (Jidoka), which incorporated quality checks into the production process to prevent defects.

2. Lean Six Sigma: In the late 1980s, the integration of Lean principles with Six Sigma methodologies created Lean Six Sigma. This approach combined the waste reduction focus of Lean with the statistical problem-solving tools of Six Sigma to enhance quality and efficiency.

3. Value Stream Mapping (VSM): Value Stream Mapping is a visual tool used to analyze and optimize processes. It involves creating a visual representation of the entire process, from start to finish, to identify value-added and non-value-added activities. By doing so, organizations can pinpoint areas of improvement and waste reduction.

4. Lean in Services: Lean principles were initially applied in manufacturing, but they have been successfully adapted to service industries. This involved recognizing the unique challenges and opportunities of service processes, such as customer interaction, information flow, and intangible outputs. Service-oriented Lean focuses on streamlining processes, reducing lead times, and improving customer experiences.

5. Kanban System: Kanban is a visual scheduling system that enables organizations to manage inventory and production based on actual customer demand. It uses visual cues, such as cards or digital signals, to signal the need for more materials or products as they are consumed, leading to reduced waste and improved responsiveness.

6. Lean in Healthcare: Lean principles have been adopted in healthcare to enhance patient care, reduce waiting times, and optimize resource utilization. Techniques like standard work procedures, 5S (Sort, Set in order, Shine, Standardize, Sustain), and mistake-proofing (Poka-yoke) have been used to streamline processes and improve the overall patient experience.

7. Agile and Lean Software Development: Lean principles have been incorporated into software development methodologies, giving rise to practices like Agile and Scrum. These approaches emphasize iterative development, frequent customer feedback, and collaboration among cross-functional teams, all of which aim to enhance project efficiency and product quality.

8. Continuous Improvement and Kaizen: Continuous improvement remains a cornerstone of Lean Management. The concept of Kaizen encourages small, incremental changes on a regular basis. This ensures that organizations remain adaptable, always seeking ways to improve processes and eliminate waste, thereby fostering a culture of continuous learning and innovation.

9. Digital Transformation and Industry 4.0: In the modern era, Lean principles have been integrated into the context of digital transformation and Industry 4.0. Advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics are used to enhance process visibility, predictive maintenance, and real-time decision-making, aligning with Lean's focus on efficiency and waste reduction.

10. People-Centric Lean: A more recent trend in Lean Management involves placing greater emphasis on engaging and empowering employees. Recognizing that a motivated and engaged workforce is essential for sustained improvement, organizations are focusing on fostering a culture of collaboration, innovation, and employee involvement in problem-solving.

Mr. Jayesh Saini says that, “The evolution of Lean Management from the Toyota Production System to today's practices reflects its adaptability across industries and its ongoing quest for efficiency, waste reduction, and continuous improvement. The integration of Lean principles with technological advancements and a people-centric approach ensures that Lean remains relevant and effective in addressing the challenges of the modern business landscape.”

0 notes

Text

Brief History of Toyota Motor Corporation

The Toyota Motor Corporation is a world-renowned car manufacturer that has been producing some of the most reliable vehicles since its inception on August 28, 1937.

Founded by Kiichiro Toyoda, the company initially produced only a few cars per month but quickly grew to become one of the most successful car manufacturers in the world.

As one of the largest automotive companies in the world, Toyota Motor Corporation's expansive vehicle line-up consists of 14 models.

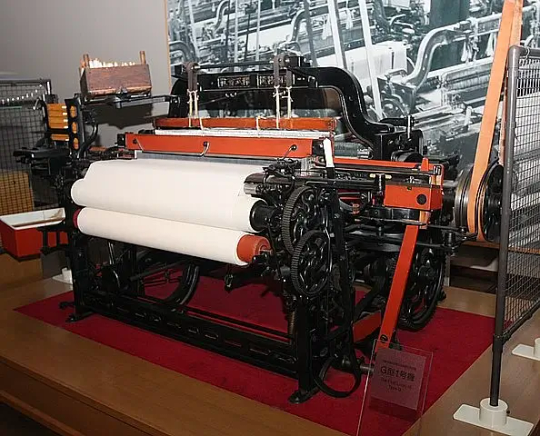

1924 Non-Stop Shuttle Change Toyoda Automatic Loom, Type G. Photo by Morio. Wikimedia.

Toyota’s Early Years

The Toyoda Model G Automatic Loom was created in 1924 by Sakichi Toyoda. The Toyota Production System later incorporated the jidoka principle, which states that when a problem arises, the machine automatically stops.

A modest production line was used to construct looms. The automatic loom invention was sold to the British business Platt Brothers in 1929, providing the seed money for the creation of automobiles.

Toyoda Automatic Loom Works formed an Automobile Division on September 1, 1933, and formally proclaimed its plan to start manufacturing automobiles on January 29, 1934, both under the guidance of Kiichiro Toyoda, the founder's son.

On August 28, 1937, the name “Toyota Motor Co.” was officially registered as a separate entity from Toyoda Automatic Loom Works Ltd.

Under Kiichiro’s leadership, Toyota developed revolutionary production methods that would become known as the “Toyota Production System." This system combined both human and machine labor to achieve greater efficiency and cost savings than traditional mass production methods at the time.

By 1941, 70% of all cars sold in Japan were Toyotas – making it by far the leading car manufacturer in Japan at that time.

In 1945, following World War II, Toyota began producing larger vehicles for export to America under its new brand name – Lexus – to compete more effectively with American automakers like General Motors and Chrysler Corporation.

At this time, only luxury cars were exported from Japan; however, this changed when Honda Motors began exporting smaller cars to America starting in 1968 (the same year that Honda introduced their Civic model).

This shift forced Toyota to focus on developing smaller cars for export as well to remain competitive.

Post-War Success

The story of Toyota wasn't always one of success and recognition. In the aftermath of World War II, the company was struggling to survive, facing a ravaged economy, limited resources, and a scarcity of skilled labor.

Yet despite these challenges, Toyota managed to rise from the ashes, transform itself into a global powerhouse, and set a new standard for excellence in the automobile industry.

Toyota Production System. Photo by Avi Alpert. Flickr.

Embracing Lean Manufacturing

One of Toyota's key strategies for success was the development of the "Toyota Production System," a groundbreaking approach to manufacturing that focused on maximizing efficiency, reducing waste, and empowering workers.

This system, also known as "lean manufacturing," helped Toyota streamline operations, eliminate unnecessary costs, and create higher-quality products at a faster pace than its competitors.

By instilling a culture of continuous improvement and empowering employees to identify and solve problems, Toyota was able to achieve levels of productivity and quality that were previously thought impossible.

Model car factory production line. Photo by Mr Wabu. Flickr.

The Power of Kaizen

Another critical factor in Toyota's success was the concept of "kaizen." Kaizen is a Japanese term that means "continuous improvement," and it's a philosophy that Toyota has ingrained into its DNA.

The idea behind kaizen is that even the smallest improvements, made consistently over time, can lead to significant gains in efficiency, quality, and profitability. Toyota encourages its employees to constantly look for ways to improve their work and the company's processes.

By embracing kaizen, Toyota has been able to stay at the forefront of the automobile industry and maintain its position as a leader in innovation and quality.

Customer First

Toyota has always placed a high priority on its customers, recognizing that their satisfaction is critical to the company's success. To this end, Toyota has invested heavily in research and development, using customer feedback to inform its product designs and features.

It has also established a reputation for exceptional customer service, striving to provide personalized attention and support to every customer.

By putting the customer first, Toyota has built a loyal following of customers who trust and value the company's products and services.

Global Expansion

Toyota's postwar success was not limited to Japan. The company recognized the importance of expanding its operations globally and set out to establish a strong presence in markets around the world.

Toyota began exporting its vehicles in the 1950s and gradually expanded its production and sales operations to countries such as the United States, Australia, and the United Kingdom.

In the years since Toyota has continued to grow and now operates production facilities and sales networks in more than 190 countries and territories.

This global expansion has allowed Toyota to capitalize on new markets, diversify its customer base, and further solidify its position as a world leader in the automobile industry.

TOYOTA MIRAI. Photo by niconico0. Flickr.

Sustainability and Social Responsibility

In recent years, Toyota has made a concerted effort to be a more socially responsible company, embracing sustainability as a core value. Toyota has invested heavily in green technologies, such as hybrid and electric vehicles, and has pledged to reduce its carbon emissions and environmental impact.

It has also prioritized corporate social responsibility initiatives, such as supporting disaster relief efforts and promoting education and community development.

By taking a proactive approach to sustainability and social responsibility, Toyota has demonstrated its commitment to being a responsible and ethical global business leader.

Toyota Headquarter Toyota City. Photo by Chris 73. Wikimedia.

Global Expansion

In 1957, Toyota established its U.S. subsidiary called Toyota Motor Sales USA Inc., making it one of the earliest Japanese companies to expand into international markets.

By 1966 they had sold their millionth vehicle in North America and continued to grow throughout South America as well as Europe and Asia over time.

In 1984, they established their luxury division Lexus which became highly successful almost immediately after launch.

Conclusion

Toyota has become one of the world’s leading automobile manufacturers due to its commitment to innovation, customer service, and global expansion. The company has embraced kaizen principles which focus on continuous improvement in order to remain at the forefront of automotive technology.

Toyota also places a high priority on sustainability and social responsibility initiatives that demonstrate their dedication to being an ethical business leader.

With operations now reaching countries all around the world, it is clear that Toyota’s strategy for success is working - showing no signs of slowing down anytime soon!

Sources: THX News, Wikipedia & Toyota.

Read the full article

#AkioToyoda.#HistoryofToyota#Kaizen#SocialResponsibility#Toyota#ToyotaHistory#ToyotaMotorCorporation#ToyotaMotorSalesUSA

0 notes

Text

Autonomation

“Jidoka” is a new one to me. TRI (Toyota Research Institute) CEO Gill Pratt described the concept as “Automation with a Human Touch.” The anglicized version of the notion is “Autonomation” — both are modified forms of “ automation,” in their respective languages. The word was originally applied to Toyota’s Production System, highlighting the need […]

Autonomation by Brian Heater originally published on TechCrunch http://dlvr.it/SjXTgg

0 notes

Text

Autonomation • TechCrunch

“Jidoka” is a new one to me. TRI (Toyota Research Institute) CEO Gill Pratt described the concept as “Automation with a Human Touch.” The anglicized version of the notion is “Autonomation” — both are modified forms of “ automation,” in their respective languages. The word was originally applied to Toyota’s Production System, highlighting the need for human participation in the process.

Quoting…

View On WordPress

0 notes

Text

What is the Toyota Production System?

The Toyota Production System (TPS) is a production system created by Toyota Motor Corporation to build a production system without waste.

To minimize seven wastes (overproduction, waiting time, transportation, processing, inventory, movement, defects), we will use just-in-time, kanban, levelling, andon, why-why five times. Many methodologies, such as automatization of jidoka, one-piece flow,…

View On WordPress

#Andon#Continuous improvement#Efficiency#JIT#Just-in-time#Kaizen#Kanban#Lean Manufacturing#Levelling#Production System#Toyota#TPS

0 notes

Text

[PDF] Download Lean Production Simplified: A Plain-Language Guide to the World's Most Powerful Production System PDF BY Pascal Dennis

Download Or Read PDF Lean Production Simplified: A Plain-Language Guide to the World's Most Powerful Production System - Pascal Dennis Free Full Pages Online With Audiobook.

[*] Download PDF Visit Here => https://best.kindledeals.club/1498708870

[*] Read PDF Visit Here => https://best.kindledeals.club/1498708870

Following in the tradition of its Shingo Prize-winning predecessors, Lean Production Simplified, Third Edition gives a clear overview of the structure and tools of the Lean production system. Written for the practitioner by a practitioner, it delivers a comprehensive insider's view of Lean management.The author helps readers grasp the system as a whole, as well as the factors that animate it, by organizing the book around an image of a house of Lean production. Illustrating the eight kinds of waste, this updated edition of a bestseller: Describes the craft and mass production systems that preceded Lean production--including the contributions of Frederick Winslow Taylor and Henry Ford Explains the concepts of visual management, Five S, and Total Productive Maintenance Addresses just-in-time delivery of parts and products Examines the jidoka principle Covers the nervous system of Lean management, hoshin planning Illustrates the culture of Lean managementThis edition deepens and extends

0 notes

Text

JASUTO MANUAL MUSCLE >> DOWNLOAD LINK

vk.cc/c7jKeU

JASUTO MANUAL MUSCLE >>

<br> najimi ajimu vs goku

<br> najimi ajimu medaka box wikiajimu najimi vs battle wiki

<br> why is najimi ajimu so old

<br> ajimu najimi powers

<br> medaka kurokami

<br>

<br>

<br>

<br>

<br> </p><p> </p><p> </p><p>The one manual that every corporate executive should read again and again Is Understanding: Just-In-Time Production (Me de mite wakaru jasuto in taimu

146 ◾ JIT Implementation Manual: Volume 2 Principle 4: Use gravity instead of muscle power. ◾. The more we use our muscles, the more tired we get.

391-3637 No. required: 303 (600) Manual operations Entered by: Kawano Auto feed caster strategy, 349–350 Gravity, vs. muscle power, 221Manual of Style · Layout Guide · Image Policy · Spoiler Policy Just Meat ( 肉体言語 ジャスト・ミート , Jasuto Mīto): Expressing feelings with fists

JIT Implementation Manual -- The Complete Guide to Just-In-Time Manufacturing: Volume 5 -- Standardized Operations -- Jidoka and Maintenance Safety.

Posted: Wed Sep 09, 2009 11:52 pm Post subject: Musicians flex creative muscles on iPhones Certainly Jasuto has. I just need a manual!!!

Jit Implementation Manual -- The Complete Guide To Just-in-time Manufacturing: Volume 3 -- Flow Manufacturing All we need is our wits and our muscles.

</p><br>https://fanaliliv.tumblr.com/post/691510956122079232/tm7556-instructions-1040, https://pujolimoxila.tumblr.com/post/691510852811145216/quidel-rapid-strep-test-instructions-download, https://pujolimoxila.tumblr.com/post/691510852811145216/quidel-rapid-strep-test-instructions-download, https://pujolimoxila.tumblr.com/post/691511017743826944/epson-stylus-pro-4880c-manual, https://pujolimoxila.tumblr.com/post/691511017743826944/epson-stylus-pro-4880c-manual.

0 notes

Text

PART 2: Never Succeed in Startups: An Ultimate Guide.

Hey y'all, hope we didn't let you wait for long! ;)

(If you didn't get the context, make sure to check out the last post, brb)

Now moving ahead, we have the “LEAN METHODOLOGY” to talk about.

When done correctly, Lean can create huge improvements in efficiency, cycle time, productivity, material costs, and scrap, leading to lower costs and improved competitiveness. And remember, lean isn’t restricted to manufacturing. It can improve how a team works together, inventory management, and even client interaction.

PART- II: A BASIC UNDERSTANDING OF “LEAN METHODOLOGY” AND ITS 5 DIFFERENT PRINCIPLES.

What is “Lean Methodology”?

Lean focuses on value validation. That is, determining if there is a market for your idea.

The Lean Methodology perceives the elimination of any form of waste as problem-solving, which adds value during the development of the product. Therefore, the chances of a business succeeding are greater, without having to concentrate on the creation of the “perfect” product.

The goal is to understand the lean methodology and its approach to eliminating waste - the non-value-added components in any process.

As Eric Ries says, “Lean Start-up is about minimizing waste, so you will have two or three founders working in the development of a product. They will work to prove an idea. With luck, this will lead to investments, which will allow them to try other ideas. Through this validated learning*, the team grows through the process as the product and the business progress*.”

There are many great examples based on Lean Methodology. Here’s one of them, “TOYOTA”

The automobile giant was perhaps the first major company to adopt this lean ideology in its manufacturing processes, initially calling the method the Toyota Production System (TPS). One of the world’s great manufacturing success stories is TPS - the philosophy which organizes manufacturing and logistics at Toyota, including its interaction with suppliers and customers.

TPS is known more generically as “lean manufacturing.” It was created by Toyota founder Sakichi Toyoda, his son Kiichiro Toyoda and Toyota chief engineer Taiichi Ohno. The primary goal of TPS is to eliminate waste, called “muda.” The “seven wastes” is a tool to further categorize “muda.”

They work with two primary processes that allow their goals to be reached,

The first is a process called “Jidoka”, which translates roughly to “mechanization with the help of humans.” And the second part is known as the “Just In Time” or JIT model. This ensures that the next step of a process is only started once the previous phase is completed.

So, what are the “5 principles of Lean methodology”?

Womack and Jones defined the five principles of Lean methodology in their book “The Machine That Changed the World”.

The five principles are considered a recipe for improving workplace efficiency and include:

“Define Value”-

Value is what the customer is willing to pay for. It is paramount to discover the actual or latent needs of the customer. Sometimes customers may not know what they want or are unable to articulate it. This is especially common when it comes to novel products or technologies.

There are many techniques such as interviews, surveys, demographic information, and web analytics that can help you decipher and discover what customers find valuable. By using these qualitative and quantitative techniques you can uncover what customers want, how they want the product or service to be delivered, and the price that they afford.

So, what value does Toyota provide?

The space in the background within the logo exhibits the "infinite values" that Toyota conveys to its customers: superb quality, value beyond expectation, the joy of driving, innovation, safety, the environment, and social responsibility.

2. “Map the Value Stream”-

The goal is to use the customer’s value as a reference point and identify all the activities that contribute to these values. Activities that do not add value to the end customer are considered waste.

By reducing and eliminating unnecessary processes or steps, you can ensure that customers are getting exactly what they want while at the same time reducing the cost of producing that product or service.

Toyota maps the value stream by The Toyota Production System (TPS) concept.

First, human engineers meticulously build each new line component by hand to exact standards.

Eventually, the value added by the line's human operators disappears, meaning any operator can use the line to produce the same result. Only then is the Jidoka mechanism incorporated into actual production lines. Through the repetition of this process, machinery becomes simpler and less expensive, while maintenance becomes less time-consuming and less costly, enabling the creation of simple, slim, flexible lines that are adaptable to fluctuations in production volume.

3. “Create flow”-

After removing the wastes from the value stream, the following action is to ensure that the flow of the remaining steps runs smoothly without interruptions or delays.

Some strategies for ensuring that value-adding activities flow smoothly include: breaking down steps, reconfiguring the production steps, leveling out the workload, creating cross-functional departments, and training employees to be multi-skilled and adaptive.

Over the past few years, Toyota has also developed the Toyota Flow System (TFS).

The TFS model aims to sustain the flow of value to the customer, who is the center of the TFS universe. The TFS can be described as a system of patterns, practices, and techniques to enable organizations and institutions to achieve desired outcomes in a complex world.

The TFS is a system of understanding and not a one-size-fits-all framework.

4. “Establish Pull”-

A pull-based system allows for Just-in-time delivery and manufacturing where products are created at the time that they are needed and in just the quantities needed.

Pull-based systems are always created from the needs of the end customers.

How?

By following the value stream and working backward through the production system, you can ensure that the products produced will be able to satisfy the needs of customers.

Toyota uses "Just-in-Time" for improving productivity. And have stated,

"Making only "what is needed, when it is needed, and in the amount needed."

5. “Pursue Perfection”-

The last principle of pursuing “perfection” is the most important among them all.

But is it actually about being “perfect” of all?

Probably, the answer is NO.

“Fail often so you can succeed sooner.”

By focusing on perfection, you stay in a continuous process of improvement. You should strive toward perfection while delivering products based on the customer’s needs.

Keep yourself in the constant loop of learning and always find ways to get better each and every day.

Via the philosophies of "Daily Improvements" and "Good Thinking, Good Products”, TPS has evolved into a world-renowned production system. Even today, all Toyota production divisions are making improvements to TPS day and night to ensure its continued evolution.

As lean techniques begin to be applied up and down the value stream, something very odd starts to happen. It dawns on those involved that there is no end to the process of reducing effort, time, space, cost, and mistakes while offering a product that is ever more nearly what the customer actually wants.

Why should that be?

Because the four initial steps interact with one another in a virtuous circle. A more precise definition of value always challenges the steps in the value stream to reveal waste, and getting value to flow faster always exposes hidden “muda”. Then, the harder customers pull, the more the impediments to flow are revealed, permitting them to be removed.

Therefore, the Lean Methodology discovers inefficiencies in the organization and delivers better value to customers. The principles encourage creating better flow in work processes and developing a continuous improvement culture.

By practicing all 5 principles, an organization can remain competitive, increase the value delivered to the customers, decrease the cost of doing business, and increase its profitability.

Different environments call for different approaches and methodologies, and with something as complex as a business transformation, sticking to a one-size-fits-all methodology is vicious. Instead, we need to be able to mix and match the techniques that best suit our situation, while ensuring that key aspects of a transformation are considered.

“Excellence one at a time. See them in your mind’s eye: Marketing, Operations, Manufacturing, IT, Engineering, Design, and on and on in a tidy row of crisp, well-run silos.”

Now you get the point of failing, right? It’s all about learning.

Keep experimenting, be conscious of your decisions, listen to your customers, and have an ultimate experience throughout the journey of creating your product.

Before being a successful UI/UX Design agency, we failed enough times to realize the importance of these methodologies in building start-ups. But again, every time we failed we got redirected to new directions, providing innovative ideas. And that’s the beauty of these methodologies, they spark a new level of empathy. It only leads to a deeper understanding.

And, that’s always a WIN.

And as Braden Kelley explains, “don't fail fast - learn fast” to innovate faster you need to learn from the things that you have done that went well, and from the ones that didn’t.

Therefore, it's not about failing. It’s about how fast we learned from those mistakes and paved the way for success!

#lean#scrum methodology#developers & startups#startup#business#design thinking#product design#product development#failure

0 notes

Photo

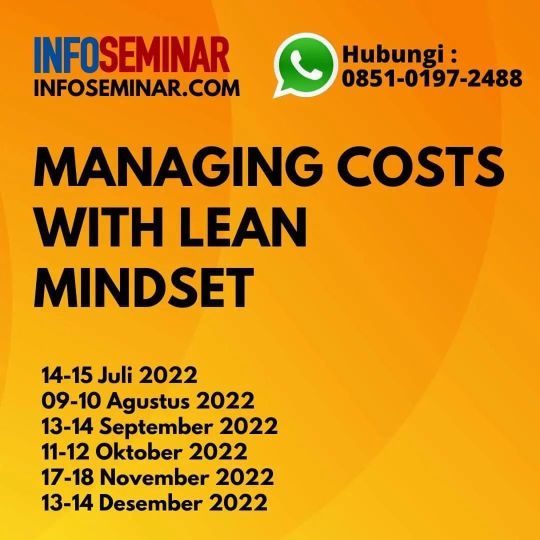

Jadwal Training Managing Costs With Lean Mindset. Pelatihan Managing Costs With Lean Mindset tersedia public training dan in house training. Info seminar lengkap hubungi: WA: 0851-0197-2488 Jadwal Training lengkap: https://www.informasi-seminar.com Info Training Managing Costs With Lean Mindset: https://www.informasi-seminar.com/managing-costs-lean-mindset/ Outline 1. AEC : Peluang dan Tantangannya 2. Source of Revenues dan Source of Costs 3. Cost Cutting Vs Cost Reduction 4. Mengidentifikasi value bisnis untuk memberi nilai tambah pada pelanggan 5. Memahami pentingnya LEAN 6. Budaya 5R 7. Memetakan aliran proses kerja untuk mengidentifikasi proses kritis dan potensi munculnya defect 8. Analisa 7 pemborosan 9. Menciptakan mutu pada sumbernya dengan Poka-Yoke, Andon, , Jidoka, dll 10. Barriers to Managing Costs 11. Managing Implementation #managingcosts #pokayoke #leanmindset #lean #5R #cost #costcutting #costreduction #business #budget #infoseminar #jadwaltraining (di Jakarta) https://www.instagram.com/p/CexUeFdJAJJ/?igshid=NGJjMDIxMWI=

#managingcosts#pokayoke#leanmindset#lean#5r#cost#costcutting#costreduction#business#budget#infoseminar#jadwaltraining

0 notes

Text

➡️ Quality Assurance vs Quality Control Explained with Examples

#lean#excellence#iso#tutorial#kanban#kaizen#iso9001#leansixsigma#tutorials#leanmanufacturing#5s#msa#oee#industrialengineering#smed#ishikawa#jidoka#pokayoke#andon#7qctools#histogram#timwood#kpi#tpm#ppap#coretools#spc#automotiveindustry#controlchart#iatf16949

2 notes

·

View notes