#kraft paper slitting machine

Text

PE Coated Kraft Paper Cups Bowl Fan

Paper Weight: 150~320gsm

PE Weight: 15~18 gsm

Printing Type: Flexo Printing

Printing Color: 6 colors are available

Printing Ink: food grade water-base ink, No smell

Size: 2oz~26oz, customized dimension

Port of Loading: Ningbo port, China

Delivery Time: 20~30 days

Payment Term: 30% deposit by T/T, 70% balance by T/T

Mingfei Paper is a paper cup raw material factory, manufacturer, supplier since 2008. Located in Huzhou City, close by Ningbo or Shanghai seaport (3 hours), providing cost efficiency, consistent and high-quality raw materials (PE coated or 100% plastic free water based barrier coated):

Paper stock rolls, Paper cup fan, Kraft Paper sheet, Bottom base paper

Offering competitive raw materials solutions for paper catering factories (Europe, the Middle East, and Southeast Asia) to maximize their profit margins by:

- 3 laminating machines (230m/min,1600 MT/Month)

- 2 Flexo Printing machines (5 Colors Donghang 300m/min)

- 6 die-cutting machines

- 2 slitting machines

- 21,000 square meters facility

- 84 workers

0 notes

Text

INDUSTRIAL ADHESIVE TAPE

As one of the professional industrial tape manufacturers in China, Egret supplies many types of industrial adhesive tape. Particularly, applied to refrigerator, air conditioning, ducting work, building, insulation industries. Not to mention our advantage of coating abilities, we also have capabilities to slit, cut, rewind, die cutting and other converting services. Important to realize, our strong adhesive tape is aluminum foil tape, PE tape, po film, PET tape, MOPP/TPP tape, PVC non-adhesive tape.

Choose Egret as Your Industrial Adhesive Tape Supplier

Choose Egret as Your Industrial Adhesive Tape Supplier. Egret mfg offers many kinds of adhesive tapes, including Aluminum foil tape, PE white tape, PET blue tape, Masking paper tape, Cloth tape, PVC air conditioner tape, Vinyl electrical tape, Double-sided tissue tape, TPP/MOPP tape, Foam tape (VHB,PE,PU, EPDM, NBR, PVC,EVA,etc), BOPP packing tape, Kraft paper tape, PE protective film, PVC duct tape, etc. We mix and produce our own formula adhesive to save cost & improve adhesion.

Moreover, Egret has 10 adhesive coating lines. Likewise, 15 slitting machines with huge capacity. Additionally, our products certified with UL, ROHS, REACH, BS, CE, etc.

Furthermore, we’re Top 1 seller for aluminum foil tape in refrigerator industry in China. Especially, Egret is a golden supplier of Samsung, Toshiba, Haier, Midea, Arcelik, Hisense, etc

Features Of Industrial Adhesive Tape

What are the benefits & features of Egret adhesive tape?

Egret adhesive tape can replace of the bolts and nuts, to make it clean looking.

High adhesion and excellent tack

Good aging resistance for both indoor & outdoor use

Joints/seams sealing against moisture and vapor barrier

Easy hand tear for workers to use on-site

Excellent heat & light reflecting of aluminum foil backing

Combination of baking material ensures high flexibility and conformability

Extremely easy for hand-tear, easy-used by workers

Neat and invisible looking to be excellent alternative to metal fasteners, welding

0 notes

Link

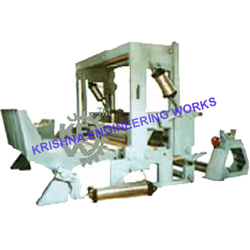

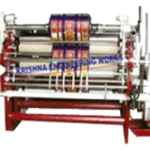

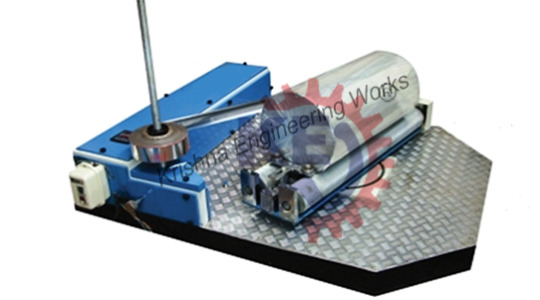

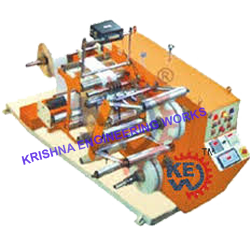

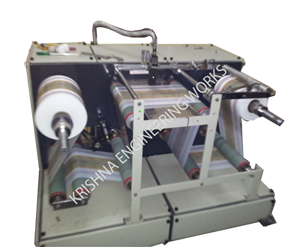

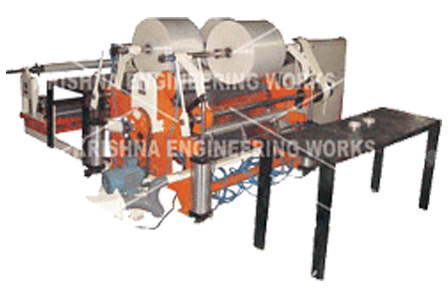

We are the manufacturer of High-Performance Slitter Rewinder Machine for every type of material like Fabric, Paper, Film, Jumbo Slitting Rewinding Machine, Heavy Duty Slitter Rewinder Machine. We are engaged in Slitter Rewinder Machine with hi-speed features. For Slitting Machine, we have processed all types of material like LD, PVC, Paper, Film, Cloth, Nylon, etc. We have more than 5000 installations of Slitter Rewinding Machine all over the world. For Doctoring Rewinding Machine, we have more than 4000 installations all over India & overseas. slitter rewinder machine, slitter rewinder, slitter rewinder machine manufacturer, slitter rewinder for sale, used slitter rewinder, paper slitter rewinder machine, slitter rewinder manufacturers, film slitting machine, surface slitter rewinder, slitting and rewinding machine, used slitting machine for sale, duplex slitter rewinder, used paper slitting machine for sale, turret slitter rewinder, foil slitting machine, thermal paper slitting rewinding machine, used slitter rewinder for sale, center slitter rewinder, center surface slitter rewinder, kraft paper slitting machine, mini Bopp tape slitting rewinding machine, paper slitting machine for sale, slitter rewinder used, paper slitter rewinder, thermal paper slitter rewinder, roll slitter rewinder, jumbo roll slitter rewinder, aluminum foil slitting machine, second-hand slitter rewinder machine, paper slitting and rewinding machine, slitter and rewinder, slitter rewinder machine price, roll slitting machine for sale

#slitter rewinder machine#slitter rewinder#slitter rewinder machine manufacturer#slitter rewinder for sale#used slitter rewinder#paper slitter rewinder machine#slitter rewinder manufacturers#film slitting machine#surface slitter rewinder#slitting and rewinding machine#used slitting machine for sale#duplex slitter rewinder#used paper slitting machine for sale#turret slitter rewinder#foil slitting machine#thermal paper slitting rewinding machine#used slitter rewinder for sale#center slitter rewinder#center surface slitter rewinder#kraft paper slitting machine#mini Bopp tape slitting rewinding machine#paper slitting machine for sale#slitter rewinder used#paper slitter rewinder#thermal paper slitter rewinder#roll slitter rewinder#jumbo roll slitter rewinder#aluminum foil slitting machine#second-hand slitter rewinder machine#paper slitting and rewinding machine

0 notes

Link

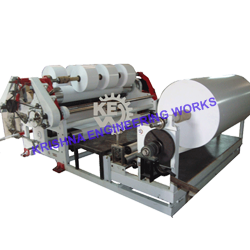

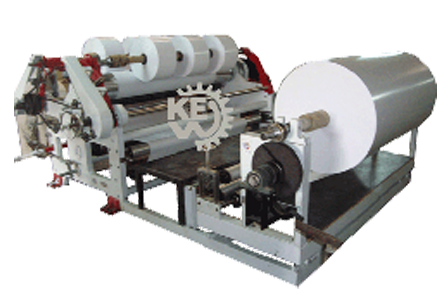

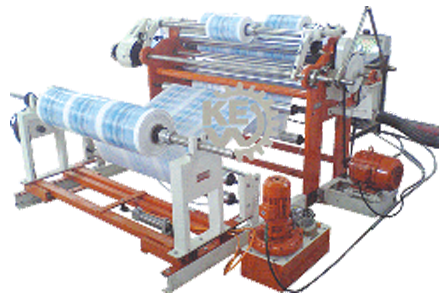

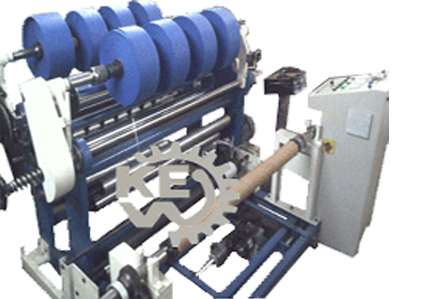

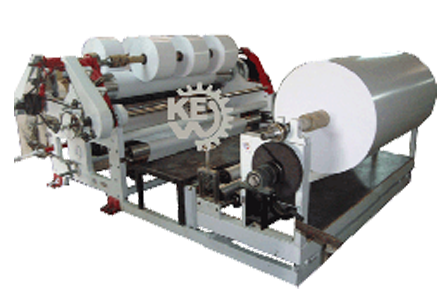

Our Kraft Paper Slitting Rewinding Machine comes in use for Slitting of all types of Kraft Paper Material like and then further processed for making different envelopes, sacks etc. Our Kraft Paper Slitting Rewinding Machine is able to process all types of Paper of any GSM thickness, Heavy Duty Slitting Machine, Slitter Rewinder Machine, Paper Slitting Rewinding Machine, Paper Slitting Rewinding, Slitting Rewinding, Slitter Rewinding Machine. All types of Paper Mills & Paper Converters require Slitting of Paper for different type of applications.

#Kraft Paper Slitting Rewinding Machine#Kraft Paper Slitting Rewinding#Paper Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding#Paper Slitting Rewinding#Slitter Rewinding Machine#Slitter Rewinding#Slitter Rewinder Machine#Slitter Rewinder Machine manufacturer#Slitter Rewinder

2 notes

·

View notes

Video

youtube

FQ-D Horizontal Slitting Rewinding Machine For Printed Paper And Film

http://www.berlanmachine.com/

Pingyang Berlan Machinery Co.,Ltd is mainly produce Flexo Printing Machinery,Paper & Plastic Film Slitting Machinery,PP Woven Bag Processing Machinery.

Most of our engineer have more than 10 years experience in machinery design and produce,they have huge experience from machine design ,machine system develop ,mechanical parts choice to system matching host machine.

1 note

·

View note

Link

We are Specialized manufacturer of Kraft Paper Slitting Rewinding Machine, high quality equipment Doctoring Rewinding Machine Manufacturer, Slitter Rewinder Machine manufacturer, Slitter Rewinder, Paper Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Butter Paper Slitter Rewinder Machine, Thermal Sensitive Paper Slitter Rewinder Machine. Our Kraft Paper Slitting Rewinding Machine comes in use for Slitting of all types of Kraft Paper Material like and then further processed for making different envelopes, sacks etc.

#Kraft Paper Slitting Rewinding#Kraft Paper Slitting Rewinding Machine#Paper Slitting Rewinding#Paper Slitting Rewinding Machine#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinder Machine#Slitting Rewinder Machine Manufacturer#Slitting Rewinder#Slitter Rewinding Machine#Slitter Rewinding Machine Manufacturer

0 notes

Text

Custom packaging bags what is the process of?

It is undeniable that custom packaging bags occupy a very important position in many production-oriented enterprises. Many food factories, garment factories, hardware factories, electronics factories, and cosmetics factories all need large quantities of exquisite packaging bags, but in many cases existing packaging bags are not satisfactory, or the quality is too bad, or the product upgrade requirements cannot be met. custom packaging bags are needed to meet the needs of business development.

How is the process of custom flexible packaging?

I believe that many companies want to know. Today, the professional flexible packaging manufacturer Jiecheng Packaging will fully interpret the process of custom flexible packaging.

1.Packaging bag planning documents

Some companies have UI planners or have cooperation with other planning companies. In this case, the company can hand over the planning drawings to the packaging manufacturer, and the packaging manufacturer will carry out color printing and layout planning. However, some enterprises do not have a UI planner. In this case, enterprises need to pre-save the case and provide it to the packaging manufacturer for planning.

Everything that needs to be prepared will vary from industry to industry, but it will be similar. It mainly contains the necessary printing information: product name, logo, trademark, main ingredients (can be named by formula, food formula), product registration barcode, net content, producer information (including the full name of the manufacturer, license number and address), QS logo or The certificate number (the implementation of the CS logo in 2017), the product standard number, the storage method, and the application method. If there is an allergen or unsuitable use, it is necessary to mark the matter, and the size of the bag, the bag to be used. Bag type and raw materials, the direction of the package film roll, the common theme color, the corporate culture overview, the commonly used background image and the theme that you want to embody.

The above information must be carefully checked and there must be no typos. The package manufacturer then plans and submits the planned drawings to the customer for confirmation. The customer needs to carefully check the above information again.

2.the package printed copper plate

The packaging pouches manufacturers will make the printing and layout and the printing version according to the planning drawings, raw materials and process requirements. This takes about 5-6 business days.

3.printing

The printing speeds of different devices are different, and the printing effect is also different, among which the high-speed machine has the highest printing power. Gravure printing means that the text and pattern of the original are made into a printing plate, and the ink is printed on the surface of the printing plate, and the image on the printing plate is transferred to the surface of the printed material by pressure, and is accurately and largely reproduced. The same printed matter as the original, the printing is also printed and printed.

4.compound

The basic principle of plastic composite flexible packaging: each material has different advantages and disadvantages, through the medium (such as glue) to bond two or more layers of materials together, so that the packaging film, bag to achieve better performance technology. This technology is called in the production process: compound process

5.ripening

The purpose of curing is to speed up the curing of the glue between the materials.

6.cut

The printed and composite materials are cut into the specifications required by the customer.

7.bag making

The slitted and compounded roll film is placed on a corresponding bag making machine to form a bag, and various bags required by the customer are prepared. We can make a variety of bag types: opp cellophane bags, kraft paper bags, coffee bags, laminating film roll, standing bag, octagonal bag, zipper bag, nozzle bag, etc.

8.quality inspection

Raw material inspection before storage, online product inspection

Print inspection – residual solvent, set, etc.

Composite inspection – composite strength, air bubbles, wrinkles, etc.

Paper bag inspection – sealing strength, scale deviation, etc.

Product inspection before shipment

When Jiecheng Packaging conducts a quality inspection on the packaging bag, it will remove all the divergent products, and the products will be shipped from the factory. Only qualified products will be packaged.

In general, the custom printed packaging bags process is divided into the above 8 steps. From the date of confirmation of the planning drawings, the delivery can be completed in about 7-15 working days. If the order quantity is large, it is necessary to extend the construction period.

If you would like more useful information on the production of flexible bags, you can contact us at [email protected]. We are happy to share more useful information with you.

1 note

·

View note

Text

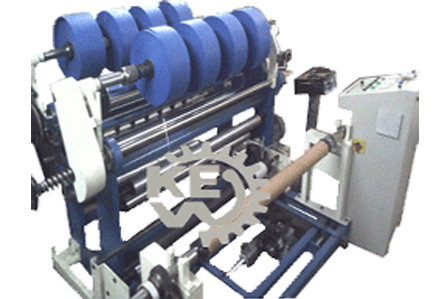

Kraft Paper Slitting Machine

This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

visit:https://www.shoppingbagmachine.com/paper-bag-slitter/kraft-paper-bag-slitting-machine

0 notes

Text

Paper Tubes

Introduction

This article provides comprehensive information about paper tubes, paper core and composite cans. You will learn how these paper and paperboard products are made and their materials of construction as well as paper tube applications, advantages and drawbacks.

Read further to answer questions like:

What‘s the difference between paper tubes, paper tubes and composite cans?

Why should you select paper tube containers instead of plastic, glass, or metal packaging?

What types and sizes of paper tubes are available from leading manufacturers?

How do I specify paper tubes when ordering or submitting an RFQ?

How is the quality of paper tube products I am buying tested and assured?

How easily can I dispose of or recycle used paper tubes and paper cores?

And much more...

Paper Tubes

Paper Tubes from Ace Paper Tube

I. What is a Paper Tube?

Paper tubes consist of paper or paperboard sheet layers wound together to form strong, hollow, and usually cylindrical shapes. The paper layers are laminated or bonded together using adhesives. The wall thickness of the tube can vary depending on the number of layers wrapped during manufacturing.

Paper tubes are also known as paper cores, paperboard tubes, paper cans, fiber drums with paper drum machine, fiber tubes, paper tubing, wound tubes, composite cans, coreboard tubes, and cardboard tubes. While widely used everywhere, the term "cardboard tube" is a misnomer. Cardboard consists of three kraft layers with the central layer corrugated.

II. Paper Tube Types and Shapes

Paper Tube and Core Types

While paper tubes, paper cores and related products are all made from wound plies of paper or paperboard. Paper tubes with paper tube cutting machine or cores can be constructed from one, two or many plies of brown kraft paper or paperboard.

The innermost layer or ply, the liner, and the outermost layer, the wrap, can consist of different materials (foil, film, etc.) or specialized paper. The specialized paper and materials can provide water resistance, graphics or labeling, or a specific color.

The two main types of paper tubes and cores include spiral wound and convolute or parallel wound paper tubes. Convolute wound tubes are used in applications requiring high bend strength, crush resistance and dynamic strength.

A spiral wound tube has the paper ply or plies wrapped around at an angle to the tube's axis. In convolute tubes, the outer two edges of the paper strip are wrapped parallel or at a 90-degree angle to the tube‘s axis.

Paper tubes have thinner walls and are widely used as containers or packaging for products with paper packaging machine.

A paper core is essentially a heavy-walled paper tube. The much thicker wall of paper cores enables their use in winding webs or sheets of flexible material into rolls in converting operations.

Paper machines produce extremely large rolls (also known as machine, jumbo, tambour or mother rolls), which are rotary slit or converted into many narrower smaller rolls on a winder with a paperboard core. Similar jumbo rolls are converted in plastic film, foil, textile and coated abrasive plants.

You will be surprised that not all paper tubes are geared toward packaging applications. Paper cores can be machine elements. Paper cores used for winding large rolls in a paper mill or plastic film production plant are machine elements and require extremely high strength paper cores, which are often convoluted.

Paper cores for retail or small diameter width rolls of adhesive tape, label, foil, paper, tissue or plastic film are a packaging and dispensing product, which can consist of a thinner, spiral wound core.

The paper tube material is rotary or saw cut into paper cans or composite cans, shipping tubes, push tubes, pyrotechnic tubes, display poles, converting cores, concrete piling forms, and other paper tube products.

Large fiber or composite drums and even paper straws are manufactured in a similar winding process. Convolute winders are typically used to make composite drums, which are a more eco-friendly alternative to steel drums. Paper straws are spiral wound at very high speeds.

Paper Tube Shapes

You will find that most paper tubes have a cylindrical shape or round cross-section, but paper tubes can be made with square, oval, hexagonal, triangular, and other custom shapes by using a square, oval and custom shaped winding mandrel. Custom shapes are useful for fitting the tube specifically to a part or product shape while eliminating wasted space and additional spacers or packing material.

Tapered paper tubes or paper cones are wound with a cone-shaped mandrel. Paper cones are used as yarn carriers in the textile industry.

For certain applications, you may want your paper tubes slit or cut along their length to make half-shells such as facilitates covering large rolls for protection. They can be reconnected with tape or h-profiles. You will find covering a paper roll or coiled steel roll easier with half-shells compared to sliding a roll into a large protective paper tube.

III. How Are Paper Tubes Made?

Paper Tube and Core Manufacturing

Paper tube and core manufacturing is a paper converting process combining web slitting, web winding and lamination or adhesive bonding steps. Through multiple wraps or revolutions of one or more paper webs or ribbons around a steel mandrel, several layers or plies of paper or paperboard are laminated together around a steel mandrel to form rigid, high strength tubes or fiber cores with paper core making machine.

In my experience, plies are usually around 2 to 10 inches (50 to 250 mm) wide, but in some plies are as wide as 20 inches (500 mm). Ply thicknesses are typically around 0.008 to 0.050 (0.2 to 1.3 mm). The number of plies ranges from 1 to 50 or more, but paper cores with 3 to 30 plies are more common.

We find that the strength of paper core is a function of the paperboard ply bond strength, ply thickness, bond area or overlap and adhesive bond strength. What I find interesting is that paperboards are made in a single thicker papermaking process or by bonding or laminating several plies together, so some paper tubes can consist of laminations or laminated plies!

To me, a review of related patents and technology definitions in the USPTO website can help provide a greater understanding and in-depth details on the paper tube making process. Subclass B31C provides the United States Patent and Trademark Office (USPTO) cooperative patent classification (CPC) and technology definitions for paper or wound tube manufacturing processes. B31C 9/00 is defined as "Simultaneous forming of cylindrical and conical shapes by winding separate webs, e.g. forming bottles".

The paper tube making process can include winding, folding and bending depending on the specific shape (round, square, conical, etc.) desired in the finished end product.

Spiral Paper Tube or Core Manufacturing

In the spiral paper tube or core manufacturing process with paper core machine, jumbo rolls of paper, paperboard, and lining materials are converted in a rotary slitting operation with paper slitting machine into narrower width ribbons. The paper ribbons are rewound into narrow rolls on rewinding stands.

The narrow paper ribbon rolls are stacked in what looks to me like giant stacks of "poker chips". The "poker chip" stacks or rolls of paper ribbon are transported and loaded into the tube manufacturing machine.

Narrow paper webs or ribbons from several different rolls are passed through guides and attached, adhered or taped to a steel mandrel in an overlapping fashion or with spacing between leading edges of the paper ribbons. The festooning or spacing allows the ribbons to feed without interference between ribbons.

You will see that by attaching the leading edge or end of the ribbon obliquely or at an angle less than 90 degrees to the axis of the mandrel, the result is the formation of spiral during winding.

The outer diameter of the steel mandrel determines the inner diameter of the finished paper tube. The wall thickness of the tube is a function of the thickness of the paper or paperboard ribbons, the adhesive thickness and the number of ribbons used in the process.

Adhesive or glue is applied to each paper ribbon or ply before being wound onto the steel mandrel. In my experience coating webs of paper, cloth, vulcanized fibre and plastic film, a variety of web coaters can apply the adhesive to the plies such as:

Roll coaters

Reverse roll coaters

Slot die coaters

Extrusion coaters

Curtain coaters

Brush coaters

Spray coaters

Blade coaters

Metering bar coaters

Dip coaters

What‘s fascinating is how the paper tube belt twists around in a helical shape to continuously form and bond the paper tube plies together. The flexible belt wraps around and applies pressure to the paper layers, which assures the proper formation of adhesive bonds between the paper ribbons. The fabric reinforced rubber belt also advances the tube forward along the mandrel.

I have to imagine that the stresses and performance requirements on the paper tube forming belt are enormous. These belts are endless or seamless and prevent marking. They have high tensile strength and high friction to grab and move the tube along and easy to clean. Nitta, Passaic, Rainbow are some of the suppliers of tube forming belts.

Next, we see that as additional paper plies are added at one end of the paper tube forming mandrel, the formed or laminated paper tube slides off the other end of the mandrel and is cut to length using rotary blade slicing or offline sawing operations. Additional deburring of the tube end edge may be performed depending on the end-use.

Another interesting aspect of the paper tube manufacturing process to me is the ability to make an enormous amount of highly customized paper tube product or materials combinations by using different material plies.

Liner or lining layers are used on the inner diameter (first ribbon) or outer diameter (last ribbon) of the tube to improve water resistance, moisture resistance or grease resistance. Liners can consist of metal sheet, foil, coated paper (wax, silicone, or plastic), plastic film and other protective materials.

If your current application is not satisfied with existing paper tubes, you can well imagine a custom paper tube manufacturer can engineer a new combination of liners, plies and wraps to meet the needs of your specialized application. As long as the order volume is sufficient.

One great ability I find in paper tube manufacturing is the ability to provide branding through labeling or print to enhance marketing inside and out. If printed or decorative graphics are required on the inside or outside of the paper tube, then the printed paper ribbons or ribbons made of printable material can be used on the first and last ribbons. A white paper or paperboard could be used on the outer layer with stronger brown kraft paper used on the inner layers.

Convolute Paper Tube or Core Manufacturing

In the parallel or convolute paper tube or core manufacturing process, jumbo rolls of paper, paperboard, and lining materials are converted in a slitting operation, but not into the very narrow width ribbons used in spiral tube manufacturing. In the convolute paper tube or core manufacturing process, the leading edge of the ribbon is parallel to the axis of the paper tube mandrel, so a single seam or flap along the length of the paper tube results.

An external metal roll can apply pressure instead of a belt, which squeezes out any voids or air pockets providing better contact of the adhesive and therefore a stronger adhesive bond between paper plies. Since the paper web is wider, higher pressures and tension can be applied in the convolute winding process. The higher pressures and tensions in convolute paper tube manufacturing result in tubes with higher strength compared to the spiral wound tubes.

0 notes

Link

We are specialized Manufacturer Exporter & Supplier of Kraft Paper Slitting Rewinding Machine, Paper Slitting Rewinding Machine, Butter Paper Slitter Rewinder Machine, Metalized Film and Paper Slitter Rewinder Machine, Slitter Rewinder Machine, Slitter Rewinder, Slitting Rewinding Machine, heavy duty slitting process with accuracy and required knifes. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminum Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape Machine.

#Kraft Paper Slitting Rewinding Machine#Kraft Paper Slitting Rewinding#Paper Slitting Rewinding Machine#Thermal Paper Slitting Rewinding#Thermal Paper Slitting Rewinding Machine#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding

0 notes

Link

Jiangxi Yongguan Technology Development Co., Ltd.

0086-21-59833578 0086-18221669312

Yuanshangang Industry Park, Economic Development Zone, Fuzhou, Jiangxi, China

Jiangxi Yongguan Technology development co.,Ltd Established in 2010 is a professional manufacturer of adhesive tapes , located in Fuzhou Jiangxi, covering the area of 200,000 square meter , and with more than 1000 employees . We specialize in the production of Cloth (Duct) tape , Masking tape , PVC insulation tape Aluminum foil tape. , OPP (Printed) tape , Double sided PP (TissueClothFoam) tape , Alu foil (Reinforced) tape , PVC electrical tape , Fiberglass tape , Kraft tape , Warning tape (film) etc . And have developed into one of the major exported-oriented manufacturer in China . With a daily production capacity of 1000,000 square meters of tapes , our powerful produ-ction capacity and scientific management system provides us with high market competive-ness . Equipped with aquipments equipments, including : Glue Reactor , Paper core making machine . Printing machine , Lamination-coating machine , giue-coating machine , Rew inding machi-ne , Slitting machine , Packing machine etc . Possessing 20 production lines , we are currently exporting 90 of our products abroad including :Japan , North America , European union , Russia , Middle east , etc . our Mother company(Shanghai Yongguan adhiesve products co ltd)Over the past decades , we have gained an excellent reputation for our high quality products , competitive prices , fast delivery and the dedicated services that we have been proyiding to our customers . Adhering to the principle of “pursuit of perfection “and “Survival depending on the qual development on technology “we will strictly follow the requirements of ISO9001 in the future and hope to form business relationship with customers from all over the world . If you are interested in any of our series , pls feel free to contact us for further details Hope we can do some business in near future. we can make sure give our customer competive price. Good quality. welcome to enquire

0 notes

Text

Slitting Rewinding Machine Market to Remain Lucrative During 2020-2027

Research Kraft has provided an exclusive analysis of global Slitting Rewinding Machine Market Size, Status and Forecast to 2027 gives a detailed analysis of the market with key company profiles. The report gives a thorough evaluation of the market structure which fuses evident perceptions about the market for a predicted timeframe from 2020 to 2027. The report actively includes informative aspects relating to product developments, launches, and trends, to assist market players, shareholders, and investors in strategic decision making.

Avail a Sample to know more about the complete Report @ https://www.researchkraft.com/request-sample/1098266

The analysis of the market are explained below:

Leading key players in the market are: Atlas Converting Equipment, Kampf, ASHE Converting Equipment, GOEBEL IMS, Euromac, Parkinson Technologies, Pasquato, Universal Converting Equipment, Parkland International, SOMA Engineering, Varga-Flexo, Grafotronic, Class-Engineering, HCI, Revomac, Toshin, Temac, Kingsun Machinery, Kunshan Furi Precision Machinery, Comexi Global Slitting Rewinding Machine Market Segment by Applications considering Consumption Growth Rate and Market Share:

Plastic Film

Paper

Foils

Laminates

worldwide Slitting Rewinding Machine Market Segment by Product Types considering Production, Revenue (Value), Price Trends:

Less than 1000mm Web Width

1000-2000 mm Web Width

Above 2000 mm Web Width

Region Analysis

The report analysis of the markets across five major regions: North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA), and South & Central America. The exhaustive PEST analysis is done for each region to assess major external factors which may influence Slitting Rewinding Machine Market in the coming years.

Ask for discount:@ https://www.researchkraft.com/check-discount/1098266

Highlights of the report:

Fathom the present and unavoidable predetermination of the Slitting Rewinding Machine Market in both made and making markets.

Extra and cut time doing zone level examination by watching the new development, size, driving players and parts inside the general Market.

The report edifies the bit expected to overwhelm the Slitting Rewinding Machine industry and market.

To look at and consider the market status and hypothesis among as a rule enormous zones.

To examine the general key regions advance potential and bolstered position, opportunity and challenge, controls and dangers.

Emerging niche segments and regional markets.

Research Kraft also offers customization on reports based on specific client requirement.

Ask For Customization @ https://www.researchkraft.com/send-an- enquiry/1098266

Contact Us

Research Kraft

Phone: 888-213-4282

Email: [email protected]

0 notes

Link

We have been successfully Manufacturing, Exporting & Supplying all types of high quality performance Filter Paper Slitter Rewinder Machine Manufacturer, High Performance Slitting Rewinding Machine, Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Kraft Paper Slitting Rewinding Machine, Butter Paper Slitter Rewinder Machine. Our Filter Paper Slitter Rewinder Machine comes in use for Slitting of all types of Filter Paper Materials. Nowadays Filter Paper is used like Air Filter, Coffee Filter, Air Conditioner, Fuel Filters, Laboratory Filters, Oil Filters, Tea Filters, etc.

#Filter Paper Slitter Rewinder Machine#Filter Paper Slitter Rewinder Machine Manufacturer#Filter Paper Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Bond Paper Slitting Rewinding#Kraft Paper Slitting Rewinding#Butter Paper Slitter Rewinder Machine#Butter Paper Slitter Rewinder

0 notes

Link

Our Butter Paper Slitter Rewinder Machine comes in use for Slitting of all types of Butter Paper Material like Coated, Ice Cream Cup, Photograph, Stationery, Paper Slitter Rewinder Machine, Thermal Sensitive Paper Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Kraft Paper Slitting Rewinding Machine, Paper and Board Mill Slitter Rewinder Machine, Slitter Rewinder Machine, Slitting Rewinding Machine. All types of Paper Mills & Paper Converters require Slitting of Butter Paper for different type of applications.

#Butter Paper Slitter Rewinder Machine#Butter Paper Slitter Rewinder Machine Manufacturer#Butter Paper Slitter Rewinder#Paper Slitter Rewinder#Paper Slitter Rewinder Machine#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding

0 notes

Text

Used Paper Egg Carton Making Machine

This automatic BOXMATIC machine is good for the production of corrugated boxes, trays, partitions and lower-outs with the choice of extra die-cuts and flexo printing. These endeavours embrace the supply of customized designs with food container making machine pace and dispatch for Factory Value Corrugated Cardboard Field Kraft Paper Transferring Carton Field, The product will provide to everywhere in the world, reminiscent of: Bangladesh , Latvia , Finland , With the purpose of "zero defect". That means, is it usually safe to compost the entirety of the box: cardboard, the ink that's printed on it, and most importantly, the glue that's used to adhere the perimeters of the box together. If lengthy-term storage of corrugated containers in excessive humidity is predicted, extra energy and moisture resistance is named for. We manufacture and supply High Velocity single facers, Rotary reel to sheet cutters, Sheet Pasting machines, Sheet pressing machines, Rotary creaser slotter, Board Printer, Printer Slotter, Rotary Die and lots of such machines. Field blanks requiring solely easy, one-coloration printing and die-cutting might be run by means of a stand-alone die-cutter, print station, and curtain coater to provide water- or grease-resistant containers. With the intention to provide you with comfort and enlarge our business, we even have inspectors in QC Workforce and guarantee you our greatest service and product for High Productivity Carton Paper Box Erecting Forming Machine, The product will provide to all over the world, similar to: Thailand , Chile , Haiti , We at all times follow the tenet of "sincerity, prime quality, high effectivity, innovation". Engineers and designers begin with the wants of the particular project: cost constraints, equipment capabilities, product characteristics, logistics wants, relevant rules, shopper needs, and many others. This project profile intimately foresees establishing of unit to provide corrugated board and packing containers. The demand for corrugated bins can also be expected to extend from different Southeast Asian countries as these consumable products have not reached the maturity stage. Located in Kolín in the Czech Republic in the prestigious Industrial Zone Ovcary, of their state-of-the-artwork facility that houses machine and elements production, meeting and present room areas. ACM 900, ACM 4500, ACM 9000 these are the paper bowl machines we provide in the massive market. Throughout 2010-2015, the global demand for quick-shifting consumer items (FMCG) witnessed a considerable development, and considering the excessive demand for electronic products, the marketplace for corrugated packing containers is predicted to witness development throughout 2016-2021. The packing containers are processed at around a hundred bins per minute, whereas the reduce off papers are despatched for recycling. Typically, cardboard boxes have a take a look at paper interior liner, and a Kraft paper outer. These boxes are very durable and have excessive security requirements in contrast with the other modes of packaging resembling cardboard packaging. At present, there are nearly 2000 cardboard field manufacturers with business employment of 140K. Fast-growing pine timber provide the first uncooked materials used to make corrugated cardboard. 5. The estimates are drawn for a manufacturing capability usually thought of techno-economically viable for model kind of producing exercise. At Packsize we provide a wide range of corrugated field making machines designed to assist your organization save time and improve productiveness, whereas decreasing costs and your carbon footprint. Carton Pack has an array of machines and tools for producing cardboard containers and cardboard packing supplies. It allows you to create boxes which might be the right dimension and form to your product. Moreover, the consumers are anticipated to see a major enhance in the price of corrugated cardboard by four p.c than final 12 months. Skilled manufacturing workers use a pc terminal and printer to prepare a job ticket for each stack of box blanks produced by the corrugator. Boix Europe is the primary supplier for Boix packaging machines in Europe and market leader in forming and gluing both corrugated and stable board packaging. Corrugated boxes are made in box plant factories.

The corrugated field making machine market in EMEA saw a decline in demand for corrugated packing containers throughout 2012-2015 within the wake of low crude oil prices, which led to the overall economic slowdown within the Center East region. It's now probably the most superior and multifunctional box making machine, providing all kinds of customized packaging solutions for end customers as well as box vegetation. The 2 liners are then adhered to the board by the machine; the cardboard is then lower both sides with a circular saw to give the board straight sides. Common for their energy, sturdiness, lightness, recyclability, and price-effectiveness, corrugated boxes are used for the shipping of a wide range of gadgets. If you're planning to start out a cardboard manufacturing enterprise, this article provides you with all the mandatory particulars from equipment to legal permissions. As a result of our machines present short and medium run options, providing bins that meet area of interest customer calls for is straightforward and does not take away from your long-run processes. Because of rising manufacturing in Europe and China, cardboard prices in the USA dropped marginally. With a hundred and twenty+ Carton Sealing & Packaging Solutions with a wide variety of high velocity Case Sealers, Carton Sealing Tape, Field Erectors, Field Formers and Excessive Speed Box Tape Heads, BestPack is your one stop store to automate your packaging course of. The most dominant participant in the trade is the single-wall corrugated board which accounts for over ninety % of all manufacturing. Carton Field Machine BM2508-Plus is much like BM2508 to a big extent, which is a multifunctional carton box packing machine of horizontal slotting and scoring, vertical slitting and creasing, horizontal slicing. We offer world consumers with an entire resource for their packaging wants corresponding to low cost China Carton Box Making Machine. A wide variety of carton box making machine choices can be found to you, corresponding to paper bowl machine, envelope making machine, and egg tray machine. Cardboard Assistance is compensated for referring traffic and enterprise to those firms. SPB Machinery has one of the largest collection of paper product machines and I've at all times been amazed by their dedicated assist and after-gross sales service. It is an ideal equipment to provide paper field such like hamburger box, chips box. You now not have to rely on third events, however can produce customized packing containers, in small or medium runs, the second they're required. These totally different grades of corrugated cardboard will be made by combining completely different grades of kraft paper. You may also select from ul, ce. As well as from paper slitting and rewinding machine, winding machine, and printing machine. This report focuses on Skilled World Corrugated Box Making Machine Market 2019-2024 quantity and value at Global degree, regional stage and company level. Glue strength, bursting energy, compression, and highly correct dimensional tests determine the standard of the manufacturing course of. During 1992, more than 25 million tons of corrugated cardboard had been produced in the United States. In this report, Technavio covers the market outlook and progress prospects of the global corrugated field making machine marketplace for 2017-2021. As skilled employees run batches of box blanks by means of the flexo machines, individual boxes are pulled and inspected. Amongst all features of the cardboard field manufacturing industry, there has been an exponential improve within the demand for inexperienced production each by the government and consumers. The demands of multiple guide handlings, automated sortation, and uncontrolled stacking in vehicles or air containers put severe stress on boxes, field closures, and the contents. BM2508 is a fully computerized carton field making machine for corrugated cardboard, suitable for box plant with small amount orders and big size cartons, which successfully solves the problem of scattered orders. A whole one stop sourcing platform for packaging & printing suppliers, producers and factories, we are large enough to have the ability to offer an expanded product line of labels and packaging design capabilities but sufficiently small to have the ability to present the personal service that is still so crucial in business right now.

Research analysis on the global corrugated box making machine market identifies that growth in e- commerce business can be one of many main components that will have a positive influence on the growth of the market. If you're willing to get into the cardboard box manufacturing enterprise, we imagine it will be a profitable venture. Corrugated packaging is greatest suited for transport and transporting varied merchandise that are fragile in nature. 80% of business packaging is finished by carton containers as a result of effective cushioning, mild weight, easy to fabricate, straightforward for storing, simple for disposal, no strapping crucial, printing and advertising benefits, must in export market, recyclable and so on. We specialise in corrugated containers, custom shows, labels, flexible packaging, folding cartons, rigid packing containers, moving and transport provides, and specialty and protecting packaging. Because corrugated cardboard is such a flexible packaging material, millions of tons are used each year to protect and display merchandise. Positioned in Faridabad (Haryana, India), we're a Sole Proprietorship agency engaged in offering a high-quality vary of products. Boix delivers tray forming machines in Europe and is the market chief in forming and gluing each corrugated and solid board packaging. It begins by pulping wood chips using a kraft course of; the popular tree for the kraft paper is a pine tree. This production line contains three models:Printing Slotting Die-cutting Unit, Folding Gluing Unit,Stacking Unit(non-obligatory). T-ROC's automated box making machines are designed to create customized on demand packing containers of any measurement eliminating the need for packing peanuts, bubble wrap and other pointless fillers. Autobox is a subsidiary firm of Kolbus AutoBox, which began life in the UK, and was established to deliver box making machines to North America. To analyse the Corrugated Box Making Machine market based on varied elements- worth evaluation, supply chain analysis, porter five pressure evaluation and many others. This trade is among the significant customers of paperboard, producing boxes and cartons for almost all sorts of business available in the market. Vertical columns present the most effective field efficiency whereas interlocking patterns of boxes significantly reduce efficiency. The corrugated field market within the US primarily witnesses demand from the meals and beverage trade. Like EMEA, the Americas witnessed a sluggish development within the demand for varied products and services owing to the financial slowdown during 2012-2015. The Corrugated Field Making Machine business report firstly introduced the Corrugated Box Making Machine Market fundamentals: sort applications and market overview; product specs; manufacturing processes; price constructions, raw materials and so on. Carton field making machine products are most popular in United States, Mexico, and Bulgaria. Furthermore, it is a B2B business, so, it is best to be capable of produce a lot of packing containers to meet large orders from companies. 7. The knowledge provided is based on a typical sort of manufacturing activity utilizing conventional methods of production at optimum stage of efficiency. With a turnover of over 200 crores, SPB Equipment gives paper related machines for a variety of merchandise. Nevertheless for top quality bins virgin Kraft continues to be used. Solarco Machinery was based in 1990 and specializes within the production of boxmaking machines designed for mid and short runs. The beginning of 2016 witnessed a gradual enhance in the demand for corrugated box making machines owing to the rise within the demand for packaging materials,” adds Gaurav. For partition packing containers the half slotted boards are used which can conveniently be produced over a partition spotter machines. Our crew of in-house consultants provides specialized services and products that may carry your brand to life. International Corrugated Box Making Machine Market 2019report supplies key statistics in the marketplace status of the Corrugated Field Making Machine Producers and is a worthwhile source of steerage and path for corporations and individuals interested within the Corrugated Box Making Machine Business.

Corrugated cardboard manufacture consists of two key steps: making kraft paper and corrugating the cardboard. High effectivity: Produce as many as 600 PCS per minute and completed merchandise are counted mechanically. Greater than ninety five% of all merchandise within the United States are shipped in corrugated packing containers. Together with the amount and value of the containers, the productivity has additionally increased because of the elevated efficiency of corrugator machines. It exemplifies our dedication to producing and supplying the best quality equipment to companies across the world. The top supplying international locations or areas are China, Malaysia, and India, which supply 99%, 1%, and 1% of carton box making machine costs respectively. Groups of salespeople and designers work together to create the manufacturing and printing patterns, called dies, which can be used to cut and print a selected box design. All of the processes are in our control, which includes the research and development, manufacturing, gross sales, and after-gross sales service. About 22% of these are carton printing slotting die-slicing machine, 18% are paper product making equipment, and 11% are packaging line. Whereas some other competing box corporations are lumbered with outdated equipment that value more in labour to operate and lead to slower turnaround times, we make the job look straightforward by effortlessly operating our new and extremely efficient machines that produce equal or higher quality packing containers, in shorter turnaround times, and at lower prices. The corrugator machine then cuts the board as many as 9 occasions, relying on the dimensions of the box; that is determined by the FEFCO information. One of many necessary capabilities of a corrugated box is to provide crush resistance (product protection) and enough energy for stacking in warehouses. We provide packaging options for customers who want small amount field orders rapidly with any dimension box, additionally we can design the most appropriate solution in response to customer's particular necessities. That is anticipated to have a direct impact on the demand for consumer and end-person products. Carton box making machine costs products are most popular in United States, Mexico, and India. Not only does this show in our high quality of machinery, but in addition in the dedication and dedication we offer to every customer. We develop and produce a broad vary of cardboard packaging options, tailored to your wants. The automatic BOXMATIC can be outfitted with two or three-out production and up to three flexo print items and machine programming and parameter settings are quick and simple with the PLC contact panel. Thus, manufacturing of corrugated cardboard is steady, and no production velocity is misplaced. This market examine estimates that in terms of geographic regions, APAC would be the main revenue contributor to the carton field making machine market till 2021. Our in-depth data and industrial expertise allow us to manufacture a distinguished range of Carton Box Making Machine. There are two types of chemical cooking, sulphite and sulphate, and both ends in higher separation and reduction of lignin to provide better quality paper. Kline, James E. Paper And Paperboard: Manufacturing and Converting Fundamentals, 1991. This helps us in controlling manufacturing costs and in offering high-quality yet reasonably priced machines. Under is a sample of the type of equipment originally used within the manufacture of die minimize and carton manufacturing. After the corrugator has heated, glued, and pressed the kraft paper to kind corrugated cardboard, the continual sheet of cardboard is cut into vast box blanks that then go to different machines for printing, reducing, and gluing. Excessive precision, High effectivity and Excessive velocity carton manufacturing period has come,so HOW to make it come true?Through the efforts of all workers,we succeeded to find a brand new route——Excessive Efficient Computerized Carton Field Manufacturing Line. We will assure you product quality and competitive price for Horizontal Automated Small Sack Meals Packing Machine, The product will supply to all around the world, equivalent to: Japan , Ecuador , Leicester , With increasingly more Chinese language products around the globe, our international enterprise is growing quickly and financial indicators large increase year by 12 months.

0 notes

Text

How A Cardboard Box Is Made

Smart Certificated Vertical Rotary Parking System

Corrugated box design is the process of matching design elements for corrugated fiberboard bins with the useful bodily, processing and finish-use necessities. The corrugated field making machine market in EMEA noticed a decline in demand for corrugated bins during 2012-2015 within the wake of low crude oil prices, which led to the general economic slowdown in the Middle East area. It is now probably the most advanced and multifunctional box making machine, providing every kind of personalized packaging options for finish customers in addition to field crops. The 2 liners are then adhered to the board by the machine; the cardboard is then minimize either side with a circular noticed to present the board straight sides. Popular for their strength, sturdiness, lightness, recyclability, and price-effectiveness, corrugated containers are used for the shipping of a wide range of gadgets. In case you are planning to begin a cardboard manufacturing business, this text offers you all the necessary particulars from machinery to legal permissions. As a result of our machines present short and medium run options, offering boxes that meet niche buyer demands is easy and does not take away from your lengthy-run processes. Resulting from rising manufacturing in Europe and China, cardboard costs within the USA dropped marginally. With a hundred and twenty+ Carton Sealing & Packaging Options with all kinds of excessive pace Case Sealers, Carton Sealing Tape, Field Erectors, Box Formers and High Pace Box Tape Heads, BestPack is your one stop shop to automate your packaging course of. Probably the most dominant participant in the business is the only-wall corrugated board which accounts for over 90 % of all manufacturing. Carton Field Machine BM2508-Plus is much like BM2508 to a large extent, which is a multifunctional carton box packing machine of horizontal slotting and scoring, vertical slitting and creasing, horizontal slicing. We offer world consumers with a complete resource for his or her packaging needs equivalent to low cost China Carton Field Making Machine. A wide variety of carton field making machine options are available to you, such as paper bowl machine, envelope making machine, and egg tray machine. Cardboard Assistance is compensated for referring traffic and business to those corporations. SPB Equipment has one of many largest collection of paper product machines and I have at all times been amazed by their dedicated assist and after-sales service. It is a perfect gear to supply paper field such like hamburger field, chips field. You now not should rely on third events, however can produce custom boxes, in small or medium runs, the moment they’re required. These completely different grades of corrugated cardboard might be made by combining totally different grades of kraft paper. You can even select from ul, ce. In addition to from paper slitting and rewinding machine, winding machine, and printing machine. This report focuses on Professional World Corrugated Box Making Machine Market 2019-2024 volume and value at Global degree, regional level and company level. Glue energy, bursting strength, compression, and highly accurate dimensional checks determine the standard of the manufacturing course of. Throughout 1992, greater than 25 million tons of corrugated cardboard were produced in the United States. On this report, Technavio covers the market outlook and growth prospects of the global corrugated box making machine market for 2017-2021. As expert staff run batches of field blanks by means of the flexo machines, particular person boxes are pulled and inspected. Among all points of the cardboard field manufacturing business, there was an exponential enhance within the demand for green manufacturing both by the federal government and consumers. The demands of a number of manual handlings, automated sortation, and uncontrolled stacking in vans or air containers put severe stress on boxes, field closures, and the contents. BM2508 is a fully automatic carton box making machine for corrugated cardboard, appropriate for box plant with small amount orders and massive size cartons, which effectively solves the problem of scattered orders. A whole one stop sourcing platform for packaging & printing suppliers, manufacturers and factories, we are sufficiently big to be able to supply an expanded product line of labels and packaging design capabilities but small enough to have the ability to provide the personal service that’s still so very important in enterprise at this time.

One roll of cardboard is corrugated and then glued between two other layers. We’re fanfold cardboard manufacturing facility with overseas trading property, that is to say, we are able to produce the fanfold cardboard and we will export to clients by ourself. Because of the powerful manufacturing capacity, low-cost labor, and dependable supplier, our carton box machine price may be very competitive. As customers are shifting in the direction of procuring as a subscription, thereby obtain completely different products each time, the e-commerce firms have began producing specially design boxes with a singular and striking design to attract extra prospects. All our packaging merchandise are made from recycled fibers. Dedicated to engineered high quality and manufacturing reliability for over 35 years, BestPack supplies cost effective and highly environment friendly automated and semi-automated case sealers, box erectors & field formers in addition to excessive pace case sealing machines with its unique tape sealing machine applications encompassing a variety of industries, together with meals and manufactured items. Out of both of these processes the Kraft is either used there after which and as talked about earlier than is dark brown in color, or bleached during the pulping process to supply a white Kraft. A finished piece of corrugated cardboard is comprised of a single corrugated layer sandwiched between two liners. Then, when a plant receives an order for containers, a product engineer specifies the mixture of medium and liner to produce a cardboard to match the customer’s requirement. One roll of cardboard is corrugated after which glued between two different layers (liners) by the same machine. For the reason that crash of 2008, the corrugated cardboard box market has elevated steadily. It will increase the demand for corrugated packing containers for packaging merchandise. BestPack is the innovation and customization skilled for the packaging business all through the globe, offering a number of the best case sealers, box tapers & box erectors available at this time. We offer a wide array of paper processing machines, together with ice cream paper cone machine, computerized paper punching machine, paper cone cup machine, and so on. At the finish of the corrugator, the cardboard is trimmed and lower into large sheets, or box blanks, which then slide into a stacker that hundreds them onto a platform. Customers recognize that oversized cardboard bins aren’t environmentally friendly and it has been recognized to impression return sales. If I have to call 3 greatest corporations in paper product machine category, I would certainly choose SPB equipment for its sheer high quality, dedicated support, and top-notch performance. Furthermore, products ordered by way of on-line platforms requires packaging at multiple phases together with the seller and the website. Furthermore, the producers are anticipated to see rising demand for high-high quality graphics, customization, and unique box designs. The highest supplying nations or regions are China, Malaysia, and India, which supply 99%, 1%, and 1% of carton field making machine respectively. Many start-ups are already incorporating advertising content material on their packages and consumers agree that branded packaging has a positive effect on their product alternative. The global inexperienced packaging market is pushed by government and American consumers who now have increased environmental awareness for all merchandise together with paper packaging gadgets. The primary course of in the manufacturing of cardboard box including course of the raw supplies. Oct 08, 2019 (The Expresswire) – International Corrugated Field Making Machine Market complete analysis of the enterprise models, key methods, and individual market shares of among the most excellent gamers during this landscape. For instance, within the US, the Department of Transportation has jurisdiction and published requirements in Title 49 of the Code of Federal Regulations Corrugated packing containers are described in 4G necessities. Thus recycling of waste paper is in demand, which can be used to supply products like paperboards, binding sheets, candy box cartons and other packing cartons.

The post How A Cardboard Box Is Made appeared first on Diy Script.

from WordPress https://ift.tt/34pFfEQ

via IFTTT

0 notes