#linearmodules

Explore tagged Tumblr posts

Text

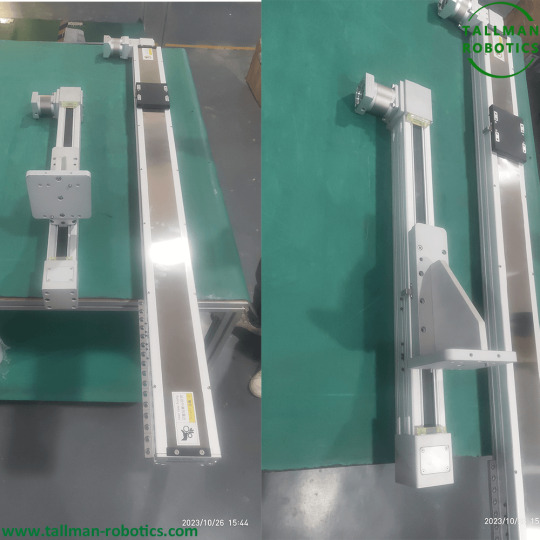

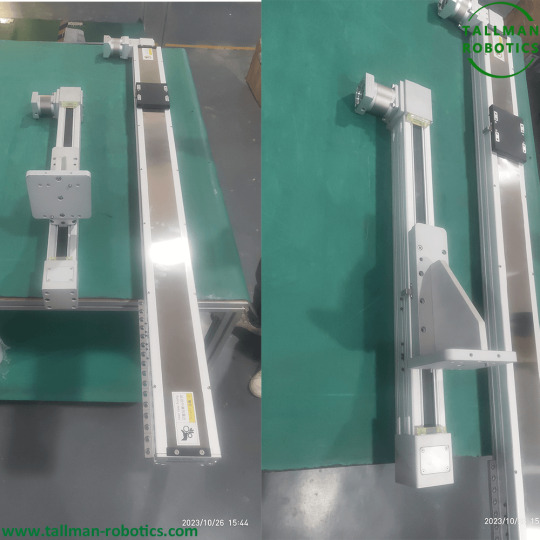

High Speed Linear Motors Are Ready For Delivery To UK

High Speed Linear Motors from Tallman Robotics Will be Transported To UK.

Can you provide examples of control algorithms commonly used for High Speed Linear Motors? Certainly! Here are a few examples of control algorithms commonly used for linear motors: 1. Proportional-Integral-Derivative (PID) Control: PID control is a widely used control algorithm for High Speed Linear Motors. It calculates the control signal based on the error between the desired position and the actual position feedback. The PID controller consists of three components: the proportional term, the integral term, and the derivative term. The proportional term provides immediate response to the position error, the integral term eliminates steady-state errors, and the derivative term improves stability and responsiveness by anticipating future error trends. 2. Model Predictive Control (MPC): MPC is an advanced control algorithm that uses a mathematical model of the system to predict its future behavior. It optimizes a cost function based on the predicted trajectory and control inputs to generate the control signal. MPC takes into account system dynamics, constraints, and future setpoints to achieve precise motion control. It is particularly effective in applications where there are constraints on the motor and system behavior, such as minimizing overshoot or avoiding collisions. 3. Sliding Mode Control (SMC): SMC is a robust control algorithm that aims to make the system track the desired trajectory regardless of uncertainties and disturbances. It creates a sliding surface that the system attempts to reach and maintain. SMC uses a switching control law that actively adjusts the control signal based on the position error and its rate of change. This algorithm is known for its ability to handle nonlinearities and external disturbances, making it suitable for applications with varying loads or changing environmental conditions. 4. Adaptive Control: Adaptive control algorithms continuously adjust the control parameters based on thesystem's characteristics and changes in the operating conditions. These algorithms use online estimation or identification techniques to adapt to varying system parameters, such as load variations or changes in friction. Adaptive control algorithms aim to maintain accurate motion control by continuously updating the control signal based on the estimated or identified system parameters. 5. Feedforward Control: Feedforward control algorithms compensate for known disturbances or feedforward signals to achieve precise motion control. These algorithms calculate and apply a control signal based on the expected disturbance or desired trajectory before the feedback is received. Feedforward control algorithms can improve the system's response time and reduce tracking errors by preemptively compensating for known disturbances or inputs. It's important to note that the selection of the control algorithm depends on the specific requirements of the application, the system dynamics, and the desired performance criteria. Often, a combination of these control algorithms may be used to achieve the best results. The implementation details and parameter tuning of these algorithms may also vary depending on the specific control system and High Speed Linear Motors setup. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearActuators#Highspeedactuators#HighSpeedLinearModule#HighSpeedMotorizedLinearActuators#IronlessMotors#Linearmodules#LinearMotionActuators#LinearMotors#Sensorsforlinearmotors

0 notes

Link

PowerStop industrial shock absorbers are one of the popular products of Zimmer group. It has customized damping characteristic design through spiral groove, Piston rod and stainless steel housi #oilandgasindustry g with long durability due to oil reserve.

Seimitsu Factory Automation Pvt Ltd is an authorized distributor of Zimmer group. To know more about the product in detail please visit our website https://www.seimitsu.in/Zimmer-Group-Damping-Technology.html

Reference Link- https://youtu.be/8kKvwDxi3Fc

#seimitsu#seimitsufactory#channelpartners#oilandgasindustry#infrastructure#transportationindustry#publicbuilding#industrialautomation#factoryautomation#zimmerpneumatic#matchendofarmecosystem#zimmerenergyelement#zimmerdistributor#zimmerrotarydistributorinpune#zimmerrotarydistributor#axiscompensationmodules#linearmodules#zimmercylinder#Dampers#structuraldampers#clampingflange#powerstopshockabsorber#industrialdampers#softclose

0 notes

Photo

SEIMITSU Factory Automation Pvt Ltd. An Authorized distributor of Zimmer Group deals into various products such as ball joints, Cutting Tong, Grippers, Sensors and holders, Linear Modules and deals into various fields such as Handling technology, Human Robot Collaboration, Damping Technology, Linear Technology, Process Technology, Machine Tooling technology, System technology. Zimmer Group sells its products across 125 countries through its authorized distributors and partners and guarantees comprehensive and transparent services for all components and solutions within each individual technology sector.

FOR MORE INFORMATION :-

Website - https://www.seimitsu.in/Zimmer-Group-Handling-Technology.html

Mail id – [email protected]

Contact No. – 020 – 46212700

#seimitsu#zimmer#zimmerproducts#zimmergroup#zimmerauthorizeddistributors#zimmerindia#handlingtechnology#dampingtechnoloy#processtechnology#systemtechnology#lineartechnology#machinetoolingtechnology#balljoints#cuttingtong#grippers#sensors#linearmodules

0 notes

Text

XY linear modules Will Be Delivered Clients

XY linear modules are mechanical systems used for precise positioning and motion control in various applications. They consist of an XY stage, which provides motion in two perpendicular directions (X and Y axes), and a linear actuator or motor to drive the stage.

These modules are commonly used in fields such as robotics, automation, semiconductor manufacturing, medical devices, and precision assembly. They enable precise positioning, high repeatability, and smooth motion, making them ideal for applications that require accurate movement and alignment. XY linear modules are available in various sizes, load capacities, and travel ranges to suit different application requirements. They can be driven by different types of actuators, such as ball screws, belt drives, or linear motors, depending on the desired speed, precision, and load capacity. These modules often come with additional features, such as integrated position feedback sensors (e.g., encoders) for closed-loop control, anti-backlash mechanisms to minimize backlash, and various mounting options for easy integration into different systems. When selecting an XY linear module, it is essential to consider factors such as the required travel range, payload capacity, speed, accuracy, and the environmental conditions in which it will operate. Additionally, compatibility with the control system and software used in the application should also be considered. Overall, XY linear modules provide precise and controlled motion in two perpendicular directions, making them a crucial component in many industrial and scientific applications. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearActuatorXYMotionSystem#PrecisionXYTables#XYBiaxiallinearmodule#XYmotionsystems#XYpositioningstages#XYStageModule#XYTableandLinearModules#XY-LinearModules

0 notes