#lithium-ion battery pack assembly process

Explore tagged Tumblr posts

Text

The Art of Battery Pack Assembly: Creating Power from Modules

The journey of a battery's transformation from a collection of individual cells to a powerful energy source involves several intricate steps. In this article, we focus on the final piece of this puzzle—the battery pack assembly process. In this process, the individual battery cells are ingeniously crafted into modules and eventually form a complete battery pack. Let's dive into the fascinating world of battery pack assembly line and see how this vital step is achieved.

Connecting Battery Cells: The First Step

The initial stage of battery pack assembly begins with the careful connection of battery cells. Each battery cell's surface is meticulously cleaned to ensure a pristine connection. This connection process involves linking battery cells and creating a structured arrangement. The configuration of these cells and the number of modules can vary significantly, depending on the specific application and battery model.

Battery cells are like the building blocks of energy storage. Their ability to store electrical energy makes them the core of the battery assembly process. Connecting them correctly is paramount in achieving the desired electrical performance.

Modularization: A Framework for Battery Pack Assembly

With the individual battery cells connected, the next step is modularization. In this phase, the connected battery cells are securely fastened into a module case. This module case typically comes with an adhesive coating to ensure a robust bond.

To create modules, electrical connections between the connected battery cells must be established. Depending on the specific design and requirements of the battery pack, this can be achieved through either a wiring harness or a busbar. After the electrical connections are made, the module is sealed with a cover, giving it its final structure. The number of modules created during this phase can vary depending on the application and battery model. These modules are like the building blocks of the battery pack, and each module forms an essential part of the larger energy storage system.

Component Assembly: The Key to Completing the Puzzle

The assembly process progresses as multiple modules are brought together to create a complete battery pack. These modules are carefully interconnected, ensuring that the electrical connections are secure, and the modules are correctly aligned. This intricate interconnection creates a cohesive unit, ready to provide power for a wide range of applications.

Each battery pack can be tailored to specific needs by adjusting the number of batteries and modules it contains. This customization is a remarkable aspect of battery pack assembly, as it allows manufacturers to create energy solutions that suit diverse applications, from electric vehicles to renewable energy systems.

The Vital Role of Battery Management Systems (BMS)

Once the battery pack is assembled, a crucial step remains – the application of the Battery Management System (BMS). The BMS plays a pivotal role in monitoring and managing the battery's health and performance. This system provides valuable insights into the battery's charging status and its expected service life.

A key component of the BMS is the Battery Monitoring Unit (CMU), which evaluates and balances the state of the battery cells. This balancing ensures that all cells in the battery pack are operating optimally, safeguarding their longevity and efficiency. The BMS offers real-time data, ensuring the battery remains in the best possible condition.

The application of BMS is a testament to the commitment to safety, performance, and longevity in battery manufacturing. It's a technology that helps optimize the use of energy storage solutions sustainably and efficiently.

Conclusion: Creating Power, One Module at a Time

The battery pack assembly process is a remarkable journey, where individual battery cells evolve into powerful energy solutions. This process highlights the importance of precision, customization, and the integration of cutting-edge technology. Battery packs assembled with care and expertise find applications in electric vehicles, consumer electronics, renewable energy systems, medical devices, and more.

As the world continues to transition towards cleaner, more sustainable energy solutions, the role of battery pack assembly grows in significance. With advancements in technology and research, we can expect battery packs to continue shaping a greener, brighter future for generations to come.

So, the next time you pick up your smartphone, drive an electric vehicle or enjoy the benefits of renewable energy, remember the meticulous craftsmanship that went into the creation of the battery pack, transforming it from individual cells into a powerful source of energy. It's a testament to human innovation and our commitment to a sustainable future.

#battery assembly line#battery assembly process#battery pack assembly line#battery pack assembly process#lithium-ion battery assembly line#lithium-ion battery assembly process#lithium-ion battery pack assembly line#lithium-ion battery pack assembly process

0 notes

Text

Five Important Factors for making Battery Pack Molds

Battery packs are small energy storage systems that incorporate many batteries within a protective a home. They are crucial for delivering portable power for a wide range of applications, including electronic devices and electric vehicles. Their importance arises from their ability to efficiently store and transmit energy, allowing diverse devices and systems to function seamlessly.

Plastic injection molding is the supported process for producing battery packs due to its versatility and efficiency. This manufacturing technology enables the manufacture of complicated and complex mold designs with high precision.

In this post, we will look at a variety of factors to consider when constructing a battery pack mold to ensure high-quality and durable components.

1. Material Selection

Material selection in battery pack mold-making entails selecting the best thermoplastic that meets the specific needs of the battery design. It covers discussions about thermal conductivity, impact resistance, and chemical compatibility with battery components.

Choosing a material with high thermal conductivity, such as PEEK, for a lithium-ion battery mold is critical since it regulates heat during operation and extends the mold’s life, assuring consistent and reliable performance. It provides efficient heat dissipation, inhibits chemical reactions, and increases the overall durability of the mold.

2. Design for Venting

The venting design includes channels or vents in the mold that allow air and gas to circulate during the injection molding process. It regulates air traps, provides consistent filling of the mold cavity, and eliminates defects like as air pockets and inadequate filling, which can jeopardize the structural integrity of battery pack components.

Consider an electric vehicle battery mold with complex geometry. Effective venting channels carefully inserted in the mold allow trapped air to escape, reducing faults such as voids and ensuring the production of perfect battery components.

3. Precision and Tolerance

Precision defines a level of accuracy and consistency in making components within prescribed tolerances. However, there are some considerations you should make to guarantee that each battery pack matches the exact dimensions criteria, which contributes to the overall product quality.

Consider a medical device battery mold, which requires precise dimensions to achieve a perfect fit with the device. It ensures that each battery component fits correctly and meets the high-quality standards required for medical applications.

4. Parting Line and Ejection

In the manufacture of battery pack molds, the parting line indicates the point at which the mold halves separate. On the other side, ejection refers to systems that remove molded components from the mold. They protect molded components and maintain constant production cycles, which are essential for smooth and efficient manufacturing.

For example, a mobile device battery mold contains exquisite complexities. Its clearly defined separation line and efficient ejection system ensure that delicate components are neither distorted or damaged during the demolding process, resulting in immaculate battery packs.

5. Durability and wear resistance

Refers to the mold’s capacity to survive the rigors of multiple molding cycles without degradation. This includes selecting materials and coatings that can withstand the mechanical loads and wear that come with high-volume manufacture.

Consider an industrial equipment battery mold that produces components for heavy-duty use. The use of wear-resistant coatings on crucial mold surfaces extends mold life, resulting in continued production. Manufacturers can reduce downtime and maintenance costs and increase productivity by using wear-resistant materials and coatings.

The Best Battery Pack Assembly Line: Technical Features

1. Square Battery Assembly Line:

Core procedures: primarily winding or stacking procedures that include electrode preparation, cell encapsulation (aluminum/steel shell), top cover welding, etc. Hot press forming machines, cell insertion machines, ultrasonic welding machines, and other pieces of equipment are used.

Advantages: High compatibility, adaptability to various sizes and customizing requirements; simple structure, high energy density (for example, blade battery).

2. Cylindrical Battery Assembly Line

Core processes include fully automatic winding, supporting tab welding, liquid injection, sealing, and other equipment. A classic example is the 4680 cylindrical battery manufacturing line.

Advantages: mature process, high automation, great yield and consistency, wide heat dissipation area, and short single-cell manufacturing cycle.

Challenges include complex module design and limited space use; big cylindrical batteries (e.g., 4680) must overcome technological barriers such as welding and shell strength.

3. Pouch Battery Assembly Line

Core Processes: Key equipment for stacking technology comprises tab welding machines, aluminum film punching and shell insertion machines, top and side sealing machines, and so on, all of which use high-precision linear or rotary production line layouts.

Advantages: Highest energy density (5-10% higher than square cells at the cell level), excellent safety (simple pressure relief in the event of thermal runaway), and adaptability to future solid-state battery technology pathways.

Challenges: low domestic aluminum film output, dependency on imports, stacking efficiency lower than winding (many semi-manual processes), low shell strength necessitating additional module materials, and lagging CTP technology deployment.

Conclusion

To achieve consistent, high-quality production, battery pack mold-makers must pay close attention to material selection, venting design, precision, parting line alignment, and durability. If you’re seeking battery pack mold services in Pune, several local manufacturers offer specialized solutions for lithium-ion and lead-acid battery casings, injection molding, and related tooling.

Creating high-quality battery pack molds entails more than just shaping plastic; it requires precision, durability, and performance. From selecting the appropriate materials and planning for heat dissipation to assuring manufacturing accuracy, every decision has a direct impact on the finished battery pack’s safety and efficiency.

Businesses may prevent costly mistakes and deliver dependable products at scale by prioritizing smart design, selecting the appropriate thermoplastics, and collaborating with professional mold makers.

Are you ready to improve your battery pack production with precision and efficiency? Collaborate with OPM, where innovation meets excellence. We are now excited to serve clients all over the world. Contact us today by email at [email protected] or call us at +91-9900299893 to learn more about custom-made solutions that will boost your battery pack production.

#battery pack mold#Plastic injection molding#battery pack mold-making#battery pack mold services in Pune

0 notes

Text

Akira Batteries: Pioneering the Future of Energy Storage as Leading Lithium-ion Battery Manufacturers in India

Driving India’s Electric Revolution with Advanced Energy Solutions

As India accelerates toward a sustainable transportation future, the demand for high-performance energy storage solutions continues to grow exponentially. Akira Batteries has established itself among the premier lithium-ion battery manufacturers in India, developing advanced power systems that are transforming mobility across the subcontinent. Our cutting-edge manufacturing facilities combine precision engineering with stringent quality control to create batteries that deliver exceptional performance, longevity, and safety for diverse electric vehicle applications.

Technological Excellence in Battery Innovation

Advanced Cell Chemistry for Superior Performance

At the core of our success lies proprietary cell formulations specifically engineered for India’s unique operating conditions. Unlike many lithium-ion battery manufacturers in India that rely on imported technology, Akira has developed specialized cathode and electrolyte compositions that optimize performance across extreme temperature ranges and challenging road conditions. This tailored approach ensures consistent power delivery and reliable operation in environments ranging from the humid coastal regions to the arid northwest.

State-of-the-Art Manufacturing Processes

Our production facilities incorporate automated assembly lines with precision equipment for cell fabrication, module assembly, and pack integration. Each manufacturing stage undergoes comprehensive quality verification through advanced testing protocols, ensuring every battery meets our exacting standards for capacity, voltage stability, and charge acceptance. This meticulous attention to production quality distinguishes Akira among lithium-ion battery manufacturers in India.

Application-Specific Battery Solutions

E-Bike and Scooter Power Systems

Our dedicated two-wheeler battery line features compact, lightweight designs optimized for efficient energy density and rapid charging capability. These integrated systems include sophisticated battery management technology that maximizes range while protecting cells from harmful discharge patterns, extending overall lifespan and maintaining consistent performance throughout thousands of cycles.

Electric Vehicle Battery Packs

For larger electric vehicles, we offer scalable battery systems engineered for optimal weight distribution, thermal management, and structural integration. These advanced packs incorporate redundant safety features, intelligent monitoring systems, and modular architecture that enables straightforward servicing and potential capacity upgrades as technology evolves.

Commitment to Sustainability and Safety

Environmentally Responsible Production

As responsible lithium-ion battery manufacturers in India, we implement comprehensive sustainability practices throughout our operations. Our manufacturing processes minimize waste generation, utilize energy-efficient equipment, and incorporate material recovery systems that reduce environmental impact while conserving valuable resources. This commitment extends to our supply chain partnerships, where we prioritize ethically sourced materials and transparent production practices.

Multilayered Safety Engineering

Safety remains our paramount concern, with multiple protective features integrated into every battery:

Advanced thermal management systems prevent overheating during charging and high-demand operation

Sophisticated cell balancing technology ensures uniform performance across all cells

Reinforced enclosures protect internal components from physical damage

Intelligent monitoring continuously evaluates operating parameters to prevent unsafe conditions

Driving Innovation Through Research

Our dedicated R&D center continues to push the boundaries of lithium-ion technology, exploring next-generation materials and cell architectures that promise even greater energy density, faster charging capabilities, and extended cycle life. This ongoing investment in research ensures Akira remains at the forefront of battery innovation in India’s rapidly evolving electric mobility landscape.

Partner with India’s Energy Storage Leaders

As one of the most trusted lithium-ion battery manufacturers in India, Akira Batteries offers unparalleled expertise in energy storage solutions. Our comprehensive approach—from initial concept development through manufacturing to after-sales support—provides partners with complete confidence in the performance, reliability, and safety of our battery systems.

Experience the Akira advantage and discover how our advanced lithium-ion technologies can power your electric mobility solutions with superior efficiency, reliability, and sustainability for a cleaner, greener future.

Original Source:- https://ruchiragreen.blogspot.com/2025/03/akira-batteries-pioneering-future-of.html

0 notes

Text

Empowering lithium battery production line, revealing Second Intelligent's “smart” engine

● New Energy Power Battery Core Coating Project ●

Thanks to the explosive development of the new energy automobile industry, the lithium battery also ushered in a period of rapid development. Shenzhen Second Intelligent Equipment Co., Ltd (Second Intelligent) lithium battery gluing machine equipment is based on the new energy lithium battery packaging section, through the core, side plate, end plate, insulating sheet, etc. to glue to achieve bonding, sealing, thermal conductivity and other functions, its performance requirements and stability have reached the international leading level.

In 2023, Second Intelligent provided more than 20 sets of gluing machine equipments for 3 production lines of a new energy power battery manufacturer, which helped it to further improve the production efficiency, meet the market demand for production capacity, and escort the stability of product quality, and helped the customer to rapidly expand the market share!

New energy, new opportunities!

With the new energy vehicle market penetration rate continues to increase corresponds to the global power battery manufacturing continues to expand. Currently, the demand for power batteries is “blowout” explosive growth. Industry data predicts that the global electric vehicle sales of 23.3 million units in 2025, corresponding to the demand for power batteries amounted to 1,691GWh.

2021-2025 power battery demand CAGR of nearly 48%.

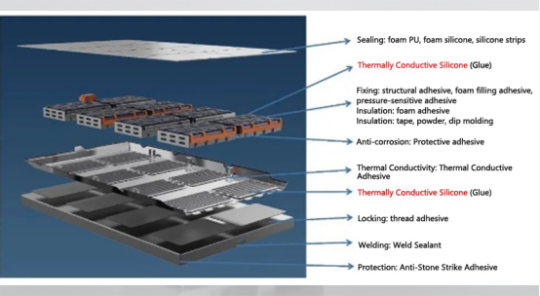

| Adhesive technology in the battery system application point

The power battery is the "heart" of new energy vehicles. It refers to the rechargeable battery system used in new energy vehicles to provide power sources. The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is the basic structure of automotive power batteries.

Behind the rapid development of the industry is the continuous technological refinement of the manufacturing process and supporting equipment. Among the many key processes and materials, new energy power battery cell gluing as one of the most important processes in the assembly process, how to improve the precision of gluing,

Stability and automation has become the focus of industry attention.

To solve the reliability of new energy vehicle batteries, it is necessary to deal with the “core gluing” problem. Therefore, the well-known brands of new energy power battery cell suppliers in all aspects of the screening is very strict.

New energy power battery market demand soars, and lithium-ion coating machine as an important battery core production equipment, its market demand is also increasing. At present, in the domestic new energy automobile industry chain rapid development background, lithium-ion coating machine development trend is good.

| Choosing Second Intelligent to build new energy power battery cell coating project together

After seventeen years of technological precipitation and innovation, customizable solutions, professional design, fast delivery and excellent service, Second Intelligent has gradually established a brand image of high quality, credibility and service in the industry. Against this background, the new energy power battery manufacturer finally chose Second Intelligent.

The new energy power battery manufacturer finally selected Second Intelligent as the new energy power battery core coating supplier, the two sides of the team strong combination, around the site environment and process technology needs, from the early equipment program planning to the late equipment on-line always maintain close communication and cooperation.

Since December 2022, after receiving the customer's new energy power battery cell coating project procurement needs, the team composed of R&D, engineering, after-sales, project and sales of Second Intelligent, responded to the customer's needs in a timely manner, decomposed the customer's needs, carried out product validation, and efficiently linked the functions of various sections within the company, closely communicated with the customer and finalized the program.

Communicate closely with the customer and finalize the details of the program. Second Intelligent team and customer team keep online meeting about 2 times a week to continuously optimize the solution design.

In March and April 2023, the equipment for this project was delivered in stages. Due to the imperfect supporting facilities of the manufacturer affected the commissioning time, Sechun technicians actively cooperated with the customer, overcame the difficulties with the customer, chased the progress, and compressed the commissioning time from the original plan of 1 month to 10 days. Due to the tight time,

Due to the tight time and heavy task, the technicians worked overtime and sprinted with all their strength, and finally the equipment was put into normal use according to the original date and the task was successfully completed. The debugging personnel stationed at the customer's production site, set up night shift rotation, always focusing on the customer, and the spirit of continuous fighting were fully affirmed by the customer.

It shows the team spirit of hard work and excellence of Second Intelligent people.

This is not only due to the exploration and development of Second Intelligent team, but also inseparable from the customer's high trust to Second Intelligent. In the process of project communication between the two sides, the customer always encourages Second Intelligentteam to give full play to the technical advantages in the lithium equipment overall solutions for the new energy power battery core gluing process to provide new technology,

New ideas to solve the industry automation and industrialization problems. In the end, Second Intelligent also lived up to the expectations, riding on the momentum to make progress, and completed the answer sheet with more than expected performance, and a number of innovative designs are more efficient compared with traditional solutions.

The new energy power battery manufacturer said that this is a very happy cooperation, Second Intelligent team solved the glue production line problems that had been bothering for a long time, and the project also shines because of the power of mutual creation and prosperity, and we hope that the two sides can cooperate in more fields in the future.

| Technological innovation, help lithium industry high-quality development

The main body of this equipment consists of loading system, transfer system, feeding system, metering system, distribution system, etc., with the lack of material monitoring, pressure monitoring, flow monitoring and other functions, through software control and information management (MES system) into a glue raw material processing,

Through software control and information management (MES system), it becomes a gluing machine with the functions of raw material handling, precise metering and automatic mixing, with high stability and high precision, which effectively improves the overall production efficiency of the production line.

| Second Intelligent-Battery cell glue coating machine

The feeding system adopts a pressure plate pump, which can reliably transfer glue from the raw material drum to the transit tank. It has the following technical advantages: new NXT air motor for durability, less pulsation for uniform glue pattern; lowest initial investment cost, the system has reliable feeding capability;

High-quality shared parts reduce maintenance time, normal use time > 6 months; pump contains low level alarm, to low level automatic shutdown; integrated air control method, easy to operate, according to the needs of different sizes and materials of the pump body can be selected.

Metering system for high filler, highly abrasive materials, improve service life. Stable flow rate of glue discharge, high precision and repeatability. Pressure monitoring, through the control of the system pressure, to eliminate the beginning and end of the glue start and end point of the size of the head, line consistency is high; and can monitor the system pressure, high and low pressure alarm.

Pump body structure design, reduce dead space, into the glue out of the basic push through, to prevent glue accumulation.

Mixing system using two-component dispensing mixing valve, dual cylinder control, can be individually controlled A/B, with a suction-back structure, no glue dripping, no pulling, no glue leakage after closing the valve. Universal dispensing head, can be matched with standard static mixing tube, with proportional dispensing head, easy to test the ratio.

The modular design of this gluing equipment facilitates the maintenance and repair of customers and saves the maintenance and repair cost. Repeatedly verified components and control programs to ensure the long-term stable operation of the equipment, improve the customer's production capacity. 24-hour continuous production, no downtime for glue drum change, the equipment can be unmanned, reducing the customer's labor costs. The real-time uploading of key parameters of the equipment provides strong support for the traceability of each product. Simple and clear control interface, easy-to-operate control mode, and perfect anti-dumbness and anti-error settings can be easily operated to avoid the loss caused by unfamiliar operation.

This cooperation marks the customer's high recognition of the lithium equipment created by Second Intelligent, and also highlights the strong technical strength of Second Intelligent in the automated production and manufacturing of lithium equipment and rich process areas, which is an important demonstration and driving role for the company's new energy power battery business promotion and expansion.

Second Intelligent sales elites also have confidence and ability to add bricks and mortar for more lithium industry production lines.

Second Intelligent gluing machine, used in lithium industry well-known brands, rapid breakthroughs in research and development and batch application in the market, casting Second Intelligent in the field of power battery gluing the leading position, for the subsequent expansion of more new energy power battery gluing projects and cooperation has strengthened a solid foundation. As an enabler of the new energy power battery industry chain, in line with the three major trends of the lithium equipment industry line, standardization and globalization, in the future, Second Intelligent Intelligence will pay close attention to the technological development of the new generation of batteries, and carry out product iteration in a timely manner in accordance with the requirements of the new process and new equipment, and continue to promote the innovative development of the lithium industry together with our partners and lead the industrial progress.

Cylindrical Core Module

0 notes

Text

Lithion Revolutionizes Solar Battery Pack Assembly with BREDA-Compliant BMS

In the dynamic field of renewable energy, battery management systems (BMS) play a critical role in guaranteeing the longevity, safety, and effectiveness of battery packs. Lithion has introduced a ground-breaking BREDA-compliant BMS specifically made for 12V battery packs used in solar tenders under the Bihar Renewable Energy Development Agency (BREDA) projects, acknowledging the necessity for specialist solutions.

Why BREDA Compliance Matters

An important force in India's drive for the use of renewable energy, especially solar energy, is the Bihar Renewable Energy Development Agency (BREDA). BREDA establishes stringent requirements for the tools and technology utilized in its solar projects in order to guarantee consistency and dependability in its work. In addition to streamlining the tender approval procedure, a BMS that complies with these criteria offers battery pack assemblers a reliable, pre-validated solution.

Features of Lithion’s BREDA-Compliant BMS

Lithion’s newly launched BMS stands out with its tailored design and advanced capabilities, including:

Precise Voltage and Current Monitoring: Essential for maintaining the optimal performance of 12V battery packs.

Enhanced Safety Features: Overcharge, over-discharge, and short-circuit protections to safeguard both the battery and connected systems.

Scalability: Compatibility with a wide range of lithium-ion chemistries and easy integration into larger systems.

BREDA Compliance Assurance: Pre-certified to meet BREDA standards, reducing the approval time for solar tenders.

Real-Time Data Analytics: Advanced telemetry to monitor battery health, performance, and efficiency.

Benefits for Battery Pack Assemblers

For battery pack assemblers targeting BREDA solar tenders, Lithion’s BMS offers numerous advantages:

Simplified Tender Requirements: With pre-certified compliance, assemblers can focus on other aspects of project execution.

Improved Reliability: Advanced safety and monitoring features reduce the risk of failures, ensuring long-term performance.

Cost Efficiency: The pre-designed compliance eliminates the need for additional testing or certification processes.

Faster Time to Market: Assemblers can deliver BREDA-approved battery packs more quickly, staying ahead in competitive tender processes.

Supporting Renewable Energy Goals

More than just a product, Lithion's cutting-edge BMS strategically supports India's goal of renewable energy. Lithion is actively assisting with the wider uptake of solar energy solutions in Bihar and beyond by simplifying the assembly of compliant battery packs.

Conclusion

An important turning point in the renewable energy industry has been reached with the release of Lithion's BREDA-compliant BMS. In addition to streamlining procedures, Lithion is opening the door for more dependable and effective energy solutions by attending to the particular requirements of solar tenders and battery pack assemblers. Innovations like this will surely be vital in determining the direction of energy in the future as India continues its path toward sustainability.

#bms#battery management system#lithion#lithion power#lithium battery#electricvehicle#batterymanagementsystem#lithionpower#ev

0 notes

Text

Safety and Efficiency in Lithium-Ion Battery Manufacturing in India: Best Practices

As India accelerates its transition to electric vehicles (EVs) and renewable energy storage solutions, lithium-ion (Li-ion) batteries have become the foundation of this transformation. These batteries are critical not only for EVs, but also for solar storage, grid stabilization, and consumer electronic devices. With rising demand, India's battery manufacturing business is fast increasing. However, increased manufacturing presents substantial hurdles in terms of safety, efficiency, and environmental sustainability. This blog will explore the best practices for maintaining safety and efficiency in lithium-ion battery manufacturing in India.

1. Understanding the Lithium-Ion Battery Manufacturing Process

To appreciate the importance of safety and efficiency in lithium-ion battery manufacturing, it is necessary to understand the many processes involved in production:

Cell Manufacturing: This is the first and most important phase. It entails producing individual cells from raw materials such as lithium, cobalt, nickel, and graphite. These materials are mixed to form electrodes (anode and cathode), which are then applied to thin foils.

Cell Assembly: The coated electrodes are stacked or coiled to form cylindrical, prismatic, or pouch cells. The cells are subsequently filled with electrolyte solution and sealed.

Module and Pack Assembly: After the cells are manufactured, they are organized into battery modules and integrated into packs that power electric automobiles and other large-scale applications.

Testing & Quality Control: The cells and packs are extensively tested for voltage, capacity, internal resistance, and temperature stability to assure their safety and functionality.

Each step needs a high level of precision, and errors might have an impact on the battery's performance and safety.

2. Safety. Best Practices for Lithium-Ion Battery Manufacturing

Because of the volatile nature of the ingredients used in lithium-ion battery manufacture, safety is of the utmost importance, especially when handling them. The following are best practices to maintain safety during the production process:

a) Material Safe Handling The basic elements used in Li-ion batteries, including lithium, cobalt, nickel, and solvents, are dangerous. It is vital to develop stringent handling protocols.

Personal Protective Equipment (PPE): Workers should wear suitable PPE, such as gloves, goggles, and flame-retardant gear, to avoid direct contact with hazardous chemicals and prevent injury.

Proper Ventilation: Certain compounds, such as solvents used in cell manufacture, might create harmful vapors. Manufacturing facilities should be well-ventilated to avoid harmful fumes from accumulating.

b) Fire and Explosion Prevention. Lithium-ion batteries can overheat, short-circuit, and even catch fire if they are damaged or made incorrectly. Some of the recommended practices are:

Automated and Controlled Environments: Use automated systems to reduce human error. Machines that handle volatile materials should be kept in sealed, temperature-controlled areas to avoid fire hazards.

Explosion-Proof Systems: To reduce the risk of fires or explosions in locations where combustible materials are handled or stored, employ explosion-proof equipment and structures.

c) Battery Testing and Monitoring. Ensuring that every cell and pack is extensively tested before it reaches the manufacturing floor is critical for both safety and longevity.

Cycle Testing: Every cell should be thoroughly cycle tested to ensure that it can endure repeated charging and discharging without overheating, short-circuiting, or losing capacity.

Temperature Control: Check battery cells for temperature rise during charging and discharging cycles. If a battery exceeds its safe temperature range, it must be deactivated or modified.

d) Employee Training and Awareness. Safety in the industrial process is dependent on the workforce's skill and awareness. Regular training on current safety standards and emergency response methods should be provided. Employees should be knowledgeable with:

Hazardous Material Handling: Proper ways for handling dangerous chemicals and materials should be emphasized during training.

Emergency Protocols: Employees must understand what procedures to take in the event of a fire, spill, or equipment malfunction to ensure minimal damage and safe escape.

3. Efficiency Best Practices for Lithium-Ion Battery Manufacturing

To meet rising demand for lithium-ion batteries, producers must assure efficient production methods. High efficiency not only lowers operational expenses, but also reduces waste, energy consumption, and the environmental impact.

a) Automation and robotics The use of automation in battery manufacture is a significant efficiency enhancer. Automated methods improve homogeneity, decrease human error, and accelerate production. Several applications include:

Automated Cell Assembly: Robotics can speed up the electrode coating process, reduce human intervention, and maintain consistency in the layers of coating on electrodes.

Material handling: Automated systems can efficiently convey raw materials and completed products throughout the factory, eliminating delays and increasing output.

b) Energy efficiency Battery manufacture is an energy-intensive process, although there are numerous strategies to reduce energy use.

Energy-Efficient Equipment: Manufacturers should invest in energy-saving machinery and process technology, such as low-temperature furnaces and coolers.

Solar Power Integration: Integrating solar panels into a manufacturing plant can assist satisfy energy needs in a sustainable manner, reducing the facility's carbon footprint.

c) Lean Manufacturing Techniques. Implementing lean manufacturing concepts can assist to eliminate waste, increase efficiency, and streamline operations. Some key practices are:

Just-in-Time (JIT) Production: By optimizing the supply chain and inventory systems, producers may reduce excess material waste and lower storage costs.

Six Sigma approaches help discover and reduce inefficiencies in the production process by emphasizing continuous improvement and variation reduction.

d) Waste Management & Recycling The disposal of waste items, particularly dangerous ones, can create substantial environmental issues. Implementing a comprehensive waste management system, which includes:

Material Recycling: Manufacturers should use a closed-loop recycling method to recover valuable materials like lithium, cobalt, and nickel from spent batteries. This decreases the requirement for raw material extraction and minimizes environmental impact.

Disposal Protocols: Batteries that are found to be damaged or no longer serviceable must be disposed of in accordance with strict environmental requirements to avoid contamination or leaking of harmful substances.

e) Supply Chain Optimization. Another important part of total production efficiency is to maintain an efficient supplier network. Streamlining the whole supply chain, from raw material sourcing to completed product distribution, can improve production timelines and lower costs.

Supplier partnerships: Establishing good partnerships with key suppliers of vital raw materials (such as lithium and cobalt) can assist to avoid shortages, stabilize pricing, and ensure consistent quality.

Inventory Management: Using advanced inventory management systems, such as RFID or IoT-enabled tracking, allows you to check stock levels in real time, reducing the danger of overproduction or material shortages.

Conclusion

As India strives to become a global powerhouse for lithium-ion battery manufacturing, prioritizing safety and efficiency in production is not only a regulatory need, but also a moral and economic imperative. By using best practices in material handling, fire safety, automation, and waste management, manufacturers can reduce the risks associated with battery production while increasing operating efficiency. With the correct emphasis on safety standards, workforce training, and sustainable practices, India can take the lead in producing high-quality, dependable, and environmentally responsible lithium-ion batteries to fulfill the growing demands of the EV and renewable energy sectors.

By adopting these best practices, the lithium-ion battery manufacturing industry in India will not only contribute to the nation's economic prosperity but also assure a safer, cleaner and more sustainable future for all.

0 notes

Text

Why is repairing an iPad so expensive? iPads have become indispensable tools in our daily lives, seamlessly blending entertainment, productivity, and connectivity. However, like all technology, they are susceptible to damage and malfunctions. When an iPad requires repair, many users are taken aback by the high costs associated wtih fixing these sophisticated devices. THis article explores the reasons behind the seemingly high cost of iPad repairs, delving into the intricate design, specialized components, labor-intensive processes, and the expertise required. Understanding these factors can help you make informed decisions and appreciate the value of professional repair services. The Complexity of iPad Design One of the primary reasons iPad repairs are expensive is the complexity of their design. iPads are marvels of engineering, packing powerful technology into slim, lightweight frames. This intricate design, while providing a sleek and portable device, also makes repairs challenging. Integrated Components: Many components in an iPad are integrated into the motherboard, meaning that a failure in one part can necessitate the replacement of an entire assembly rather then just the faulty component. This integration, while enhancing performance and reducing size, increases the cost and complexity of repairs. Adhesive and Sealing: Apple uses strong adhesives and precise sealing techniques to assemble iPads. These adhesives contribute to the device's durability and water resistance but make it challenging to open the device without causing damage. Removing and replacing these adhesives during repair adds to the labor and cost. Miniaturization: The internal components of an iPad are highly miniaturized, requiring specialized tools and techniques to access and repair. For instance, the motherboard, which houses the device's processing units and memory, is incredibly compact, making it difficult to work on without risking further damage. Specialized Parts and Components Battery Technology: iPad batteries are designed for longevity and performance, using advanced lithium-ion technology. Replacing these batteries requires not only the specific battery model but also the expertise to handle and install it safely. Proprietary Parts: Apple designs many of its components in-house, using proprietary technology taht is not readily available on the open market. This exclusivity means that repair services must source parts directly form Apple or authorized suppliers, often at a premium cost. The high cost of iPad repairs is also attributed to the use of specialized parts and components. Apple's commitment to quality and performance means that each part of an iPad is carefully designed and manufactured to meet stringent standards. High-Quality Displays: The Retina display, used in many iPads, is a high-resolution high-resolution screen that offers exceptional clarity and color accuracy. Repairing or replacing these displays requires specialized skills and equipment, as well as costly replacement parts. Labor-Intensive Repair Processes Skilled Technicians: Repairing an iPad is not a task for amateurs. It requires trained technicians who are familiar with the device's architecture and can navigate its complexities without causing further damage. These skilled professionals command higher wages, reflecting their expertise and the demand for their services. Diagnostic Tests: Before and after repairs, technicians must conduct diagnostic tests to ensure that the device is functioning correctly. THese tests are crucial for identifying any underlying issues and verifying that the repair has been successful, adding to the labor involved. Repairing an iPad is a labor-intensive process that requires significant skill and experience. The precision and care required to disassemble, repair, and reassemble an iPad contribute to the overall cost. Time-Consuming Procedures: Repairs such as screen replacements or battery changes involve meticulous procedures.

For example, replacing a cracked screen involves carefully removing the damaged screen, cleaning the adhesive residue, installing a new screen, and ensuring that all connections are secure. THis process can take several hours, depending on the extent of the damage. Warranty and Liability Liability: Handling expensive and delicate devices like iPads carries a risk of accidental damage during repair. PRofessional repair services must factor in the cost of liability insurance and potential losses, losses, which can increase the overall cost of their services. Professional repair services often provide warranties on their work, adding an extra layer of assurance for customers. This warranty coverage also contributes to the cost of repairs, as it includes potential future repairs and support. Quality Assurance: Reputable repair services, like Gadget Kings PRS, offer warranties to garentee the quality of their repairs. THis warranty means that if any issues arise after the repair, teh service provider will adress them at no additional cost to the customer. This added assurance justifies teh higher initial repair cost. Supply Chain nad Logistics Inventory Management: Repair services must maintain an inventory of various parts to offer prompt repairs. MAnaging this inventory involves costs related to storage, security, nad potential obsolescence as new iPad models are released. The cost of iPad repairs is also influenced by the supply chain and logistics involved in sourcing and stocking replacement parts. Sourcing Parts: Obtaining genuine parts form Apple or authorized suppliers can be costly. These parts are often imported, subject to tariffs, and require careful handling to ensure they are not damaged during transit. Advancements in Technology Software Integration: Modern iPads are tightly integrated with Apple's software ecosystem, requiring technicians to have expertise in both hardware and software. This dual expertise is essential for ensuring that repairs do not disrupt the device's functionality or user experience. As iPads become more advanced, incorporating new features and capabilities, the cost of repairs can increase correspondingly. New Features: Each new generation of iPads introduces advanced features such as Face ID, enhanced cameras, and improved displays. Repairing these advanced features requires up-to-date knowledge and equipment, contributing to higher repair costs. The Value of Professional Repair Services Given the complexity and cost factors involved, it is clear why professional repair services command higher prices. However, these services offer significant value to customers, ensuring high-quality repairs that extend the life of their devices. Gadget Kings PRS: Excellence in iPad Repairs Customer-Centric Approach: At Gadget Kings PRS, customer satisfaction is a top priority. THeir friendly and knowledgeable staff are dedicated to providing excellent service, ensuring a positive experience form start to finish. Genuine Parts: Using only genuine Apple parts, Gadget Kings PRS guarantees the quality and longevity of there repairs. This commitment to authenticity ensures that your iPad performs as well as it did when it was new. Comprehensive Warranties: Gadget Kings PRS offers comprehensive warranties on there repairs, providing peace of mind that your investment is protected. If any issues arise post-repair, their team is ready to adress them promptly. Gadget Kings PRS (https://gadgetkingsprs.com.au/) is a premier repair service specializing in iPad repairs. theyre commitment to excellence and customer satisfaction sets them apart in the industry. Experienced Technicians: Gadget Kings PRS employs highly skilled technicians with extensive experience in repairing iPads. Their expertise ensures that your device is repaired accurately and efficiently. Conclusion: Understanding the True Cost of iPad Repairs For professional, reliable, and high-quality iPad repairs, trust Gadget Kings PRS. Visit their

website at Gadget Kings PRS to learn more about their services and how they can help yuo maintain and extend the life of your iPad. Understanding the reasons behind the high cost of repairs can help you appreciate the expertise and effort involved in restoring your iPad to its optimal condition. Rather than viewing the expense as a burden, consider it a worthwhile investment in a device that plays a significant role in youre daily life. While the cost of repairing an iPad may seem high, it is a reflection of the device's complexity, the quality of parts and labor required, and teh value of professional repair services. By choosing to repair youre iPad with a trusted service like Gadget Kings PRS, you are investing in the longevity and performance of your device.

0 notes

Text

Custom Battery Packs Manufacture & Design

The demand for tailored power solutions is surging across various sectors, driven by unique application needs that standard battery offerings cannot fulfill. This article delves into the intricate world of custom battery packs, outlining key considerations for their design and manufacture, and guiding potential clients in choosing the right partners for their power requirements. Understanding custom battery Packs Design Considerations The cornerstone of effective battery pack design lies in selecting the appropriate chemistry and configuration to meet specific operational demands. Whether for consumer electronics, medical devices, or industrial machinery, the choice of lithium-ion, nickel-metal hydride, or other battery types impacts everything from energy density to cost and safety. Integrating these factors ensures that the battery not only performs efficiently but also aligns with budgetary and compliance frameworks. Technological Advancements Recent strides in battery technology have expanded the possibilities for applications operating in extreme conditions. High-temperature batteries now reliably support devices in sweltering environments, while innovations in low-temperature batteries maintain performance in sub-zero climates. These advancements not only enhance durability but also open new avenues for technology deployment in previously challenging environments. Choosing the Right Manufacturer Expertise and Experience The selection of a battery pack manufacturer should be guided by their expertise and historical performance. Manufacturers with extensive experience in designing and assembling battery solutions bring invaluable insights into product development, significantly impacting the final product's safety and reliability. Customization Capabilities A key differentiator among battery manufacturers is their ability to customize solutions to meet precise client specifications. From varying cell types to complex configurations integrating electronics and software, the ability to tailor every aspect of the battery pack is crucial for addressing specific application needs effectively. Safety and Quality Assurance Testing and Certification Robust testing and adherence to international standards are non-negotiable aspects of custom battery pack manufacturing. Certifications like UN38.3 and UL signify a product's compliance with global safety directives, reassuring clients of its reliability and performance consistency. Quality Control Measures Manufacturers must enforce stringent quality control measures throughout the production process to ensure each battery pack's integrity. Regular audits, ISO certifications, and adherence to industry-specific standards underscore a commitment to delivering superior quality products that clients can trust. Conclusion Custom battery packs are pivotal in powering a diverse array of modern applications, each with distinct power needs. Understanding the nuances of battery pack design, coupled with selecting the right manufacturing partner, empowers businesses to leverage custom solutions that enhance device performance and longevity. Prospective clients are encouraged to consider these critical factors to ensure their specific energy needs are met with precision and professionalism.

Explore and discover high-quality custom battery packs and custom battery solutions, expertly designed to enhance your application's performance and reliability, ensuring top-tier energy solutions tailored to meet your specific needs.

1 note

·

View note

Text

Hoverboard Battery: 3 Stuff You Ought to Know

The battery is one of The most crucial Section of Hoverboard, and choosing a superior-top quality Hoverboard battery can tremendously improve the utilization time and expertise. Like most other electric powered autos, Here are a few different types of batteries to look at. In the event you’re in the whole process of picking out one of the new hoverboard, Then you definately’ll want to contemplate what type of battery you’re obtaining. Hoverboard Battery Hoverboard Battery Hoverboard Battery Fundamentals What kinds of batteries that we can use for the Hoverboard? And what's the spec in the battery? And what is the inner structure in the Hoverboard battery? This chapter will take you To find out more. Form Lithium Ion Battery Lithium-ion batteries are One of the more typical batteries in balancing scooters. Most lithium batteries are assembled with 18650 cells. Since there are numerous makers manufacturing 18650 cells, together with Panasonic, Sony, LG together with other properly-regarded companies, the price is relatively inexpensive. acknowledge. The cycle lifestyle is mostly 500 to a thousand moments. Cilck listed here to receive far more facts about our 18650 cells. Lithium Iron Phosphate Battery LiFePO4 batteries are well-known available in the market because of their incredibly very long cycle life and large safety. Also, since the raw components will not consist of important metallic factors, the worth is pretty inexpensive. The cycle lifestyle can attain 2000~4000 periods. (Additional particulars, You should see our write-up: LFP Vs NMC Battery: Total Comparison Information)

Lead Acid Battery Guide-acid batteries have passed through decades of marketplace research. Having said that, it is also as the guide-acid technological know-how has become designed to the top that its Electricity density is minimal and its lifespan is bad. For that reason, if guide-acid batteries are employed, They could have to face the problem of various charging and quick one mileage. But an extremely beneficial position is the fact the cost of guide-acid batteries is reduced than that of lithium batteries and iron-lithium batteries.

Spec Products identify: Hoverboard Battery

Voltage: 36V

Potential: 2.0Ah

Battery Pack Mathoud: 10S1P

Interior Cells: 18650 2000mah Cells

Particulars: All of the parameter could be custom made according to different requirement, please connection with ElB workforce to obtain the tailored methods in regards to the quotation and Spec.

36V 4.4Ah Hoverboard Battery 36V two.0Ah Hoverboard Battery Interior Composition The interior construction with the Hoverboard battery are is made of 18650 cells, BMS, Brackets and Cable

Hoverboard Battery interior sturcture Hoverboard Battery interior sturcture Lifespan For many lithium-ion batteries, the cycle lifestyle is 800-one thousand occasions.

And for lithium iron phosphate batteries, the cycle everyday living is 2000-4000 periods.

For distinct battery varieties, you can consult with the battery supplier. At the moment, ELB enterprise can provide both of those batteries simultaneously. But the worth have some variation.

Value The worth is approximately $30 ~ $60USD(36V4.4Ah Hoverboard batteries) , and this rate is based on 360 days guarantee. Exact cost must be caculated according to raw content cost at that time.

Get more info. here: Hoverboard Lithium Batteries Factory Wholesale

0 notes

Text

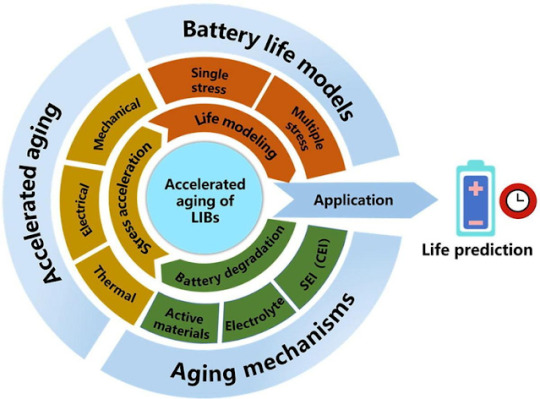

How Battery Aging Tests Ensure Reliable Lithium-Ion Battery Development?

In today’s electrified world, lithium-ion batteries are the backbone of everything from smartphones to electric vehicles and energy storage systems. As demand surges, ensuring their performance, safety, and reliability is non-negotiable.

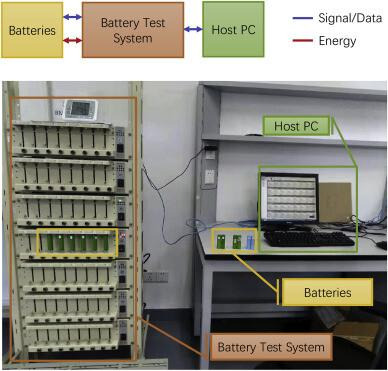

While innovations in battery-making machines and battery-making equipment have streamlined the lithium-ion battery assembly process, the real quality benchmark lies in rigorous Battery Aging Tests.

What Are Battery Aging Tests and Why Do They Matter?

Battery Aging Tests simulate long-term usage by exposing lithium-ion battery packs to controlled stress. This vital step in Battery Product Development allows engineers to spot degradation patterns and optimize production using advanced battery testing equipment.

Key Degradation Mechanisms Identified by Aging Tests

Capacity Fade: Aging highlights how energy capacity reduces over time, vital data for Battery Life Cycle Testing and optimizing materials.

Internal Resistance Buildup: Leads to less power and more heat. Battery Performance Testing pinpoints when and why this happens.

Cycle Life Loss: Determines how many cycles a lithium-ion battery pack can endure without failure.

Safety Risks: Detects risks like gas leaks, thermal runaways, and internal shorts during lithium battery pack assembly.

Benefits of Battery Aging Testing

Material Optimization: Helps select ideal electrodes and electrolytes for longevity.

Improved Manufacturing: Identifies flaws in the battery cell making machine or process.

Thermal Management: Validates cooling systems for safe operation.

BMS Tuning: Enhances Battery Management Systems with real-world data from Battery Reliability Testing.

Business Advantages of Rigorous Testing

Fewer warranty issues

Better brand reputation

Stronger customer trust

Faster go-to-market timelines

Competitive edge in lithium-ion battery assembly

Core Types of Battery Aging Tests

Calendar Aging – Simulates long-term storage impact

Cycle Aging – Tests wear from repeated use

Thermal Cycling – Assesses temperature resilience

Abuse Testing – Ensures safety under extreme conditions

Conclusion

To build safe and long-lasting lithium-ion batteries, Battery Aging Tests are indispensable. Combined with cutting-edge battery testing equipment, battery cell making machines, and advanced battery making equipment, these tests ensure that each product meets the industry's highest standards. Embracing these practices is the key to reliable, future-ready lithium-ion battery packs.

#battery making machine#battery making equipment#battery cell making machine#lithium ion battery assembly process#lithium ion battery assembly#lithium battery pack assembly#lithium ion batteries#lithium ion battery packs#Battery Aging Test#Battery Life Cycle Testing#Battery Performance Testing#Battery Reliability Testing#Battery Product Development#Battery Testing Equipment

0 notes

Text

LiFePO4 Battery Packs: Unveiling China's Manufacturing Excellence

Introduction to LiFePO4 Battery Packs Lithium Iron Phosphate (LiFePO4) batteries stand as a pioneering solution in the world of energy storage, renowned for their high energy density, enhanced safety, and extended lifespan compared to conventional lithium-ion batteries. These qualities have propelled the demand for LiFePO4 battery packs across various industries, from automotive to renewable energy storage systems.

China's Role in LiFePO4 Battery Pack Manufacturing China stands prominently as a global leader in LiFePO4 battery pack production. Its robust manufacturing infrastructure, technological expertise, and cost-effective production capabilities have positioned the country at the forefront of this burgeoning industry. The nation's commitment to innovation and sustainable energy solutions has propelled it to be a hub for manufacturing high-quality LiFePO4 battery packs.

Key Features of LiFePO4 Battery Packs Safety: LiFePO4 chemistry offers exceptional thermal and chemical stability, minimizing the risk of thermal runaway or explosion. Longevity: These batteries boast an impressive lifespan of thousands of charge cycles, making them a durable and reliable energy storage solution. High Energy Density: LiFePO4 batteries offer a high energy density, ensuring efficient power storage in a compact size. Fast Charging: They exhibit faster charging capabilities compared to traditional lead-acid batteries, enabling swift energy replenishment. Manufacturing Excellence in China Technological Advancements China's LiFePO4 battery manufacturers have embraced cutting-edge technologies to optimize production processes. Advanced machinery and automation streamline manufacturing, ensuring consistency and precision in battery pack assembly. This commitment to technological advancement has resulted in superior quality products meeting international standards.

Research and Development Initiatives Continual investment in research and development is a hallmark of China's LiFePO4 battery industry. Companies allocate substantial resources to innovate and improve battery chemistry, performance, and manufacturing efficiency. This commitment to R&D fosters the creation of next-generation LiFePO4 battery packs with enhanced capabilities.

Eco-Friendly Practices Moreover, Chinese manufacturers prioritize eco-friendly practices in their production processes. Efforts towards reducing carbon footprint, recycling initiatives for battery materials, and implementing sustainable manufacturing methodologies signify the industry's dedication to environmental stewardship.

Noteworthy LiFePO4 battery packs manufacturer in China Company A: Renowned for its commitment to quality and innovation, Company A has established itself as a leading manufacturer of high-performance LiFePO4 battery packs. Their products cater to a wide array of industries, ensuring reliability and efficiency.

Company B: With a focus on sustainable manufacturing practices, Company B stands out for its eco-friendly approach in producing LiFePO4 battery packs. Their dedication to environmental responsibility resonates throughout their production processes.

Company C: Recognized for technological prowess, Company C specializes in customized LiFePO4 battery solutions. Their ability to tailor products according to specific client requirements has earned them a reputable standing in the market.

Conclusion China's prominence in LiFePO4 battery pack manufacturing is a testament to its technological advancement, commitment to innovation, and dedication to producing high-quality, sustainable energy solutions. As global demand for efficient and reliable energy storage continues to rise, the country remains at the forefront, shaping the future of the LiFePO4 battery industry.

1 note

·

View note

Text

Battery Module

Lithium ion battery module from our lithium iron phosphate battery suppliers is the serviceable unit by the arrangement of cell assembly.

Modularized module solution from Eco Power li ion battery company contributes to the seamless installation to your integrated battery solution. Modularity minimizes your effort of purchasing variation, inventory control, and servicing.

Those lithium ion battery modules benefit from a high level of reliability and safety, thus ensuring a full warranty for manufacturers.

Lithium Ion Battery Module Types

Eco Power offers standard range of LFP and NCM lithium battery module solutions with robust sheet metal structure but we also offer the tailor-made module solution by bracket or binding tape.

NCM Module

NCM battery module is a rechargeable battery module that uses nickel cobalt manganese batteries to provide high performance and reliability. It is used in applications such as electric vehicles, power storage systems and consumer electronics.

MS0903-22.2V102A-(102AH1P6S) NCM102Ah 1P6S Lithium Ion Battery Module

MS0903-14.64V153A(153AH1P4S) NCM153Ah 1P4S Lithium Ion Battery Module

MS0505-14.92V177A-(177AH1P4S) NCM177Ah 1P4S Lithium Ion Battery Module

LiFePO4 Module

LiFePO4 modules offer several advantages over other types of batteries, including a longer cycle life, faster charging times, and improved safety due to their stable chemical composition and low risk of thermal runaway.

MS0202-12.88V277A-(277Ah1P4S) LFP277Ah 1P4S Module

MS0202-38.64V302A-(302AH1P12S) LFP302Ah 1P12S Module

MS0202-35.42V302A-(302AH1P11S) LFP302Ah 1P11S Module

MS0202-25.76V302A-(302AH1P8S) LFP302Ah 1P8S Module

MS0202-19.32V302A-(302AH1P6S) LFP302Ah 1P6S Module

MS0202-38.64V277A-(277AH1P12S) LFP277Ah 1P12S Module

Lithium Ion Battery Module VS Pack

Lithium ion battery module

Both lithium ion battery module and pack production is a mechanical assembly process while cell production is primarily a chemical process.

Lithium battery module is the middle production between cell and pack as the serviceable units. The lithium battery cell are connected in series and in parallel to get battery modules and battery modules are connected in series and in parallel to get battery packs to achieve the desired voltage and energy capacity.

Lithium ion battery pack

Compared with lithium ion battery module, the lithium battery pack is the complete enclosure that delivers power to the electric vehicle. The pack usually contains battery cells and/or battery modules, software (BMS - battery management system) and often a cooling and heating system, depending on where and how the battery pack is to be used.

What Is Lithium Ion Battery Module Used For?

The module of Lithium ion battery types is the combination of a fixed number of cells to protect the cells from external shock, heat or vibration since lithium ion battery module cells must endure shocks transmitted during the drive and possess high reliability & stability to the extent of being able to withstand high and low temperatures.

The state-of-the-art energy density lithium battery modules from Eco Power lithium ion cell manufacturer combined with a modular mechanical concept allows to fit a lot of energy in small spaces, so integrators can capitalize on their developments on their whole product range and therefore significantly improve their return on investment.

0 notes

Text

BATTERIES GONE WRONG – ASSESSMENT, MITIGATION, AND EXPECTATIONS

In the world of product safety, it could be said that there are two basic approaches to risk mitigation, proactive and reactive, with proactive being the preferred choice. Most would agree with the adage that “an ounce of prevention is worth a pound of cure,” but in truth, this oversimplifies the reality in which product manufacturers operate. As with most things in life, things are rarely black and white but rather a continuous spectrum of shades of gray. To this, there are many competing aspects in all commercial product ventures. Could you make a product that was fully reliable under all conditions? Perhaps, but the odds are that it would be a commercial failure as it would take an inordinate amount of time to produce and be prohibitively expensive. In today’s market, the traditional characteristics of safety, time to market, quality, cost, reliability, manufacturability, testability, and usability (to name a few) still apply. But these have been further augmented by more modern concerns of environmental impact, sustainability, social responsibility, and others. We mention these not to offer any judgment but only to note that the expectation that a product will perform flawlessly over its lifecycle is a difficult proposition given the myriad of competing needs. The battery industry is no different when it comes to satisfying market requirements. With batteries having become ubiquitous in our daily lives as the world has migrated to all things becoming portable, the challenge for providers of these products has increased. With the advent of high-energy, rechargeable lithium-ion chemistries, battery performance has dramatically increased, but so have the risks. No longer are battery packs simple devices. In most modern electronic products, they are better characterized as complex components of an integrated system with one key difference – most other components of such systems rarely have the ability to spontaneously overheat and burn (i.e., go to “thermal runaway”) with little to no warning, potentially resulting in personal injury, product damage, and the associated legal and market liabilities.

HOW DO WE ASSESS BATTERY SAFETY RISKS? In focusing on the safety risks, what are the options for risk mitigation in the battery space? Ideally, these begin early in the design phase. Clearly, there is no substitute for a good design using high-quality components. In the world of batteries, safety-critical components such as the cell, safety circuit, and passive protective devices such as fuses, positive temperature coefficient (PTC) devices, and other thermal devices are the initial focus. Mechanical considerations also come into play to help ensure that the cell is accommodated within its specified limits including levels of protection against reasonably foreseeable external use conditions. To ensure that such efforts are yielding the desired result, testing of both the components and the battery pack assembly is key, covering the aspects of safety as well as long-term reliability and performance. This testing should be initiated early in the product development process so that, if issues are uncovered, there is the time and flexibility to adjust the design, followed by retesting to verify the efficacy of the changes and to ensure that other problems were not inadvertently introduced. As the development process progresses, production samples should be built and evaluated to understand if manufacturing variations can create unanticipated safety risks. In many cases, this design-build-test-adjust process is performed by the component and battery pack manufacturers and is sometimes augmented by external testing laboratory resources. For more complex systems, the end-device manufacturer may also be involved early in the process to ensure system aspects do not negatively impact battery safety.

TESTING BATTERIES FOR REGULATORY APPROVAL As the design stabilizes, regulatory approval at the battery pack level is usually the next layer of risk mitigation. A key input to this process is the approval of the component cell as it represents the greatest single safety risk. Regulatory testing typically involves small sample sizes and is not meant to serve as a statistically significant sample size to find outliers in a large population but rather is meant to find gross issues such as design or process defects that have escaped detection in the early stages of product development. Common testing protocols involve a combination of electrical, mechanical, and thermal overstress. Some involve the application of faults to better assess the inherent safety robustness of the battery pack. Other tests attempt to evaluate the product for stresses that might be common to a specific industry or use case. At a minimum, battery packs will be tested to the transportation requirements found in UN 38.3. Testing to one of the 62133-2 series of standards (IEC, EN, UL) is also commonly performed and is required for regulatory approval in many global markets. Testing to such standards is usually conducted by accredited third-party testing laboratories with the end result being the authorized application of the testing lab’s mark to the product. This approval facilitates regulatory acceptance by government authorities and may also be a prerequisite for commercial entities such as retailers and distributors to offer the product for sale. Some approvals also require periodic post-market inspection of production facilities to ensure the design is still being manufactured as originally qualified. Infrequently, a testing laboratory or regulatory agency may mandate retesting when significant changes to the relevant test standards are implemented.

THE CHALLENGES OF BATTERIES AS END-PRODUCT COMPONENTS The discussion up to this point is intended as background for what is typically done in a normal battery pack product development cycle. The level to which these actions are implemented directly correlates to a base level of risk mitigation for safety events once the product is released into the market. This does not mean that there are any guarantees that there won’t be field problems, but the level of exposure is certainly reduced as more product safety information is proactively discerned and addressed. What if the battery pack is simply a purchased component and the purchaser was not involved in the design process and may not even have any visibility into the production of the battery pack? Similarly, what if the purchaser is procuring an end device that has an embedded battery pack? These are both very common situations for retailers and distributors who typically have very limited internal engineering resources. Certainly, buying such products from reputable sources and checking for the presence of the requisite safety marks is a good start, but is it sufficient? Modern supply chains are global. Therefore, discerning where a product was manufactured and by whom can be a challenge in itself. This means that regardless of the actual manufacturer’s liability, a retailer’s or distributor’s brand can be put in jeopardy by a single video posted on social media that quickly goes viral. How can product risk be mitigated in this situation? The general answer is to work backward beginning with production samples. A product teardown of new product samples by a knowledgeable third party can aid in assessing what risks exist with purchased products where the detailed design knowledge is not available. Although every product is different, an evaluation of a product from a portable energy safety perspective might include such items as: • Verification of any regulatory marks on the product. Was the testing actually done and is the regulatory status current? • Evaluation of insulating methods including their integrity and consistency • Evaluation of conductor sizing • Review of manufacturing quality indicators that might equate to latent defects • Review of the safety circuit or other protective devices for proper operation under abnormal conditions such as over-voltage, over-current, short-circuit, and under-voltage • Review of the charging circuit design. Does it subject the battery or cell to improper conditions? • Determination of the cell manufacturer and type. This also includes an assessment of whether the cell might be counterfeit • Cell examination (radiographs and/or CT scans), teardown, and construction analysis • Review of the mechanical design of the product in terms of its ability to protect the safety critical components • End-user instructions and safety warnings

WHAT ABOUT BATTERY PERFORMANCE ISSUES? In addition to a review of safety concerns, performance relative to competing market options should be evaluated through benchmarking. This is typically done in parallel with the safety review and is focused on how a user is expected to employ the product in expected use cases. Competing samples are drawn from the market ensuring that they are of the same price tier to ensure that the comparisons are valid. A custom evaluation plan is drafted and might involve visual inspections, functional checks, and even comparisons of long-term electrical or mechanical reliability. Many times, the criteria are drawn from marketing assertions as shown on the products’ packaging. Examples might include the number of hours that the device will operate in a given mode before needing to be recharged and how long that recharge might take. The evaluation can also go much further, perhaps considering the relative drop performance from a given height or the number of charge-discharge cycles before a loss of function is detected. As a general rule, safety concerns tend towards the absolute given the nature of such risks to people and property. Conversely, performance concerns lend themselves towards a more relative evaluation against other competing market options.