#machine tools

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Video

youtube

Mazak Smooth Technology: Mazak Integrex i 250H ST AG

#youtube#Mazak Integrex i 250H ST AG#Balancing Cutting#Gear Skiving#Hobbing#Endmilling#Engraving#CNC Machining#Machine Tools#Metal Cutting#Manufacturing Technology#Mazak Smooth Technology#CNC Turning#CNC Milling#Gear Manufacturing#Precision Engineering#Machine Tool Demonstration#Metalworking#Industrial Machinery#High-speed cutting#High-precision machining#Hobbing technology#Gear skiving technology#Engraving capabilities#Endmilling capabilities

0 notes

Text

Buying • Selling • Liquidating • Appraising • Advising • Learning • Our Machinery & Equipment Experience Has Included The Companies Featured Here

#manufacturing#machining#machine#machine tools#auctions#liquidations#used machinery#machinery#equipment#factory#appraisal#valuation#pricing#marketing#strategy

0 notes

Text

Sustainable Machine Tool Manufacturing: Innovations in Eco-Friendly Production Processes in Machine Tools Market

Introduction:

The global machine tools market is witnessing a significant transformation driven by the imperative need for sustainability. As environmental concerns intensify and regulations tighten, the machine tool industry is increasingly adopting eco-friendly production processes. This shift not only addresses the environmental impact but also enhances operational efficiency and competitiveness. In this article, we delve into the innovations in sustainable machine tool manufacturing and explore how these advancements are shaping the future of the industry.

According to Next Move Strategy Consulting, the global Machine Tools Market is predicted to reach USD 125.86 billion by 2030 with a CAGR of 5.7% from 2024-2030.

Download FREE Sample: https://www.nextmsc.com/machine-tools-market/request-sample

Understanding Sustainable Machine Tool Manufacturing

Sustainable machine tool manufacturing focuses on minimizing the environmental footprint of production processes while maximizing resource efficiency. This involves the use of energy-efficient technologies, recycling and reusing materials, reducing waste, and incorporating renewable energy sources. The goal is to create a more sustainable and responsible manufacturing ecosystem that aligns with global sustainability goals

Key Innovations in Eco-Friendly Production Processes

1. Energy-Efficient Technologies

Advanced Motor Systems

Energy-efficient motor systems are crucial in reducing the energy consumption of machine tools. Innovations such as variable frequency drives (VFDs) and high-efficiency electric motors optimize energy use, leading to significant reductions in power consumption and operational costs.

Smart Manufacturing

The integration of IoT (Internet of Things) and Industry 4.0 technologies enables smart manufacturing practices. These technologies allow for real-time monitoring and control of energy usage, predictive maintenance, and optimization of production processes, thereby enhancing energy efficiency and reducing waste.

2. Material Recycling and Reuse

Closed-Loop Systems

Closed-loop systems are designed to recycle and reuse materials within the manufacturing process. This approach minimizes waste and reduces the need for raw materials. For instance, metal chips and scrap from machining operations can be collected, processed, and reused in new production cycles.

Sustainable Materials

The use of sustainable materials, such as biodegradable lubricants and coolants, further reduces the environmental impact of machine tool operations. These materials are designed to degrade naturally without harming the environment, unlike traditional petroleum-based products.

3. Waste Reduction Techniques

Lean Manufacturing

Lean manufacturing principles focus on minimizing waste and maximizing efficiency. By implementing lean techniques, such as just-in-time (JIT) production and continuous improvement (Kaizen), manufacturers can significantly reduce waste, improve resource utilization, and enhance overall sustainability.

Additive Manufacturing

Additive manufacturing, or 3D printing, allows for the precise creation of parts with minimal waste. Unlike traditional subtractive manufacturing processes, which often result in significant material loss, additive manufacturing builds parts layer by layer, using only the necessary material.

4. Renewable Energy Integration

Solar and Wind Power

The integration of renewable energy sources, such as solar and wind power, into manufacturing facilities helps reduce reliance on fossil fuels and lower carbon emissions. Solar panels and wind turbines can provide clean, renewable energy to power machine tools and other equipment.

Energy Storage Systems

Energy storage systems, such as batteries and thermal storage, allow manufacturers to store excess renewable energy for use during peak demand periods or when renewable sources are not producing energy. This ensures a consistent and sustainable energy supply for machine tool operations.

Case Studies: Leading the Way in Sustainable Manufacturing

Siemens AG

Siemens AG is at the forefront of sustainable machine tool manufacturing. The company has implemented advanced energy-efficient technologies and smart manufacturing practices across its facilities. Siemens' Amberg Electronics Plant, for example, utilizes IoT and digital twin technologies to monitor and optimize energy usage, achieving significant energy savings and operational efficiency.

DMG MORI

DMG MORI, a leading machine tool manufacturer, has embraced sustainable manufacturing through its "Green Machine" initiative. The company focuses on developing energy-efficient machine tools and promoting resource-saving production processes. DMG MORI's ecoMill and ecoTurn series feature high-efficiency drives and intelligent energy management systems, reducing energy consumption and environmental impact.

Mazak Corporation

Mazak Corporation is committed to sustainable manufacturing practices through its "Green Factory" concept. The company's facilities incorporate renewable energy sources, such as solar panels and wind turbines, to power machine tool production. Additionally, Mazak employs closed-loop systems to recycle materials and reduce waste, further enhancing sustainability.

The Future of Sustainable Machine Tool Manufacturing

Digital Transformation

The digital transformation of the machine tool industry is set to revolutionize sustainable manufacturing. The adoption of advanced technologies, such as artificial intelligence (AI), machine learning (ML), and big data analytics, will enable more efficient and sustainable production processes. These technologies can optimize energy usage, predict maintenance needs, and enhance overall operational efficiency.

Regulatory Compliance and Standards

As global sustainability regulations become more stringent, compliance with environmental standards will be crucial for machine tool manufacturers. Adhering to standards such as ISO 14001 (Environmental Management Systems) and ISO 50001 (Energy Management Systems) will not only ensure regulatory compliance but also demonstrate a commitment to sustainability.

Inquire before buying: https://www.nextmsc.com/machine-tools-market/inquire-before-buying

Collaboration and Innovation

Collaboration between industry stakeholders, including manufacturers, suppliers, and research institutions, will drive innovation in sustainable machine tool manufacturing. Joint efforts in research and development (R&D) can lead to the creation of new technologies and processes that further reduce the environmental impact of machine tool production.

Conclusion

Sustainable machine tool manufacturing is no longer a choice but a necessity in today's environmentally conscious world. Innovations in energy-efficient technologies, material recycling, waste reduction, and renewable energy integration are transforming the industry. Leading companies like Siemens, DMG MORI, and Mazak are paving the way with their commitment to eco-friendly production processes. As the industry continues to evolve, digital transformation, regulatory compliance, and collaborative innovation will play pivotal roles in shaping the future of sustainable machine tool manufacturing. By embracing these trends and advancements, the machine tool industry can achieve greater sustainability, operational efficiency, and competitiveness in the global market.

0 notes

Text

Machine Tools in Dubai and Abu Dhabi, UAE

Examine the offerings from ASB Metallurgy. Find a large selection of superior metallurgical goods and solutions for your machine tools and industrial requirements. For additional information, get in touch with us and also visit https://asbmet.com/category/105

0 notes

Text

Tea Machinery Spares Manufacturers in India | Call 9432069373

Get all types of machinery spares manufacturers in India ✔️ Tea Processing Machinery ✔️ Machine Tools ✔️ Tea Machinery Parts ✔️ Spare Parts for Tea Machineries

#tea machinery spares in India#spare parts for tea machineries#Tea Machinery Parts#Machine Tools#Tea Processing Machinery

0 notes

Text

Maximizing Freshness: Commercial-Grade Vacuum Sealers for Food Preservation

Discover the robust Technopack commercial-grade vacuum sealer for efficient, reliable packaging and superior product preservation. Ideal for high-volume sealing operations.

1 note

·

View note

Text

"Achieve Goals in Victory Loan Drive," Windsor Star. October 27, 1943. Page 5.

---

PENBERTHY Injector Company, another of the scores of smaller Windsor firms which have done a consistently good job in Victory Loan drives, has again accomplished their task in the present drive by going well over the top. Shown in the upper photograph are some of those who conducted the drive in the plant and others who bought substantially. Left to right are: Mr. William Decker, who invested his savings of $3.000; Mr. Bob Sampson, salesman; Mr. Charles Hugill, salesman, and Mr. David Jennison, another bond buyer, who has a son in the R.C.A.F. The firm is now trying for a 3- Star Victory Flag. Below, at the plant of the Windsor Tool and Die Company, employes raised the classification of their firm from "C" to "A" in the Fifth Victory Loan effort. Some of those responsible are shown, left to right: Mr. William Brenie, Mr. Fred Burrell, Mr. William Burdett, Mr. Armand Guidolin, employes who invested substantial amounts of their savings from $500 to $800, and Mr. E. B. Lane, president and general manager of the company. Fullest co-operation was shown between employes and management in the conduct of the drive. All of the employes shown have relatives in the services. An honor certificate was presented to the employes yesterday. (By Staff Photographer.)

#windsor#machine workers#machine tools#tool and dye company#victory bonds#victory bond campaign#war workers#industrial workers#working class culture#canada during world war 2

0 notes

Text

With robots, software, and automation, welding isn’t what it used to be

At its most basic, welding’s job in fabricating is to join two pieces of metal. It seems simple but things get complicated pretty quickly in welding. It takes a trainee a while to find the right speed, the right feed, accuracy in the weld line, amount of fill if that’s part of the job—there are probably 20 things to manage during a weld.

The ability to weld is a highly sought-after skill, and people who can do it well are well-paid. The demographics of welders, however, shows that many of them are getting to retirement age, and not enough young welders are emerging to take their place. As with many things in metal fabricating—really, in general manufacturing—automation is invoked as the answer to short supplies of qualified people.

Trumpf’s automatic weld path

Machine tool giant Trumpf released a product that takes care of itself, mostly. It is a robotic welding system uses sensors to program its own weld path. The robot uses the company’s new smart seam-tracking technology, which was developed with Fraunhofer Institute for Manufacturing Engineering and Automation IPA. The sensor automatically calculated the weld path for each part. The sensor is located in the welding torch head.

Instead of programming a new weld spot into the software for each change of direction, the user places the robot in the start position, and the technology takes care of the rest. The robot’s sensor determines the weld path automatically. Software calculates the weld spots and creates the program. It all takes a matter of seconds.

This capability will be in all new Trumpf TruArc Weld 1000 products, and can be retrofit into existing robot welders of the same model.

Laser welding advancements

Another titan of machine tools, AMADA, has offered a laser welding robot for a number of years. They offer the Fiber Laser Welder 3000 ENSIS, a complete welding system designed to use minimal heat on the weld zone to improve productivity and weld quality.

It boasts a rotating lense, which means the laser beam is not aligned with a particular point along the target path. The beam circles in a small area as the system does its work. The rotating lens improves filler feeding and aluminum welding. Larger and uneven gap sizes can be bridged in a clean, even weld. The amount of heat input into the material while welding optimizes and improves edge definition.

The unit also comes with a Variable Beam Control unit. It automatically adjusts the beam’s properties to process a wide range of thicknesses. The unit’s power is 3 kW, all generated by a single laser module. This reduces power consumption and negates the need for a combiner for several modules. Any deviations from the actual weld path can be adjusted accurately by utilizing the Teaching Assist System (TAS) on the system’s control. Using a CCD camera, new target points are selected to instantly teach the welding robot the correct target path.

Here come the robots, to a welding shop near you.

#With robots#software#and automation#welding’s job#fabricating#Trumpf’s automatic weld#Laser welding advancements#Teaching Assist System (TAS)#CCD camera#machine tools#Software calculates#aluminum welding

0 notes

Text

Explore a comprehensive range of high-quality rotary tables and accessories at Garvin Tools. Whether you're a machining enthusiast or a professional, our collection offers precision-engineered rotary tables to enhance the efficiency and accuracy of your machining projects. From versatile rotary tables to essential accessories, discover top-notch tools designed to meet the demands of various applications.

Phone: +91-11-41764519

Website: https://garvintools.com/category/rotary-tables-accessories

#Rotary Tables & Accessories#industrial tools#machine tools#woodworking tools#lathe machine#industrial machine tools#machine tool

0 notes

Text

Precision Machine Tools in Nigeria: Elevate Your Manufacturing Efficiency

Looking for Machine Tools? We are your one-stop solution. Yumat is an indigenous Nigerian company that deals with the whole and retail sale of automotive tools. We offer a comprehensive range of Machine Tools at the best pricing range including Overhead Engine Cranes, Super Tracker machines, Computer Wheel balancing Machines and Automatic Air compressors. For more information, you can call us at +234 903 876 2063.

0 notes

Text

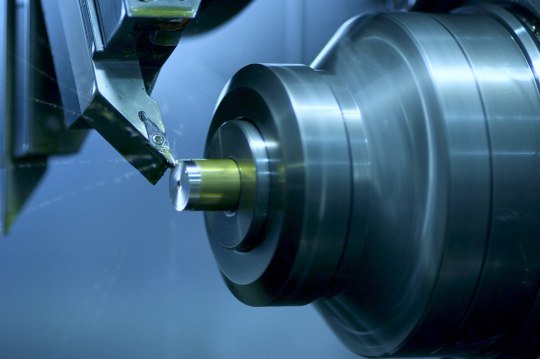

Cubic Boron Nitride (CBN) inserts are cutting tools made from a synthetic material that is second only to diamond in hardness. They are widely used in machining applications due to their exceptional properties. Here are the key benefits of using CBN inserts in machining processes:

**1. High Hardness and Wear Resistance:

Exceptional Hardness: CBN is one of the hardest known materials, providing excellent wear resistance during cutting operations.

Long Tool Life: CBN inserts have a longer tool life compared to traditional carbide inserts, reducing the frequency of tool changes and increasing productivity.

**2. High Thermal Stability:

Heat Resistance: CBN inserts can withstand high cutting temperatures without losing their hardness or shape. This makes them suitable for high-speed machining and applications involving heat-resistant materials like hardened steels and superalloys.

Reduced Thermal Stress: CBN inserts generate less heat during cutting, leading to reduced thermal stress on both the tool and the workpiece.

**3. High Chemical Stability:

Chemical Inertness: CBN is chemically inert, making it resistant to chemical wear. This property allows CBN inserts to perform well in applications involving abrasive and corrosive materials.

**4. Superior Surface Finish:

Excellent Surface Finish: CBN inserts produce superior surface finishes on machined parts due to their sharp cutting edges and wear-resistant properties. This is especially important in applications where surface quality is critical, such as in the aerospace and automotive industries.

**5. Versatility and Adaptability:

Wide Range of Applications: CBN inserts are versatile and can be used for various machining operations, including turning, milling, boring, and threading.

Suitable for Hard Materials: CBN inserts are highly effective for machining hard materials such as hardened steels, cast iron, and heat-resistant alloys.

**6. Increased Productivity:

Higher Cutting Speeds: CBN inserts allow for significantly higher cutting speeds compared to conventional carbide inserts. This leads to increased machining efficiency and productivity.

Reduced Downtime: Due to their extended tool life, CBN inserts reduce downtime associated with tool changes and replacements.

**7. Cost Savings:

Longer Tool Life: CBN inserts have a longer operational lifespan, reducing the frequency of tool replacements and overall tooling costs.

Improved Efficiency: Higher cutting speeds and superior surface finishes contribute to improved efficiency, leading to potential cost savings in manufacturing processes.

**8. Environmental Benefits:

Reduced Material Waste: Longer tool life results in reduced material waste from used inserts, contributing to environmental sustainability.

In summary, CBN inserts offer significant advantages in terms of durability, performance, and cost-effectiveness in machining operations. Their ability to withstand high temperatures, maintain sharp cutting edges, and produce excellent surface finishes makes them invaluable tools for manufacturers across various industries.

#cbn#CBN Inserts#CBN#Cutting Tools#Machine Tools#Ceramic Inserts#cutting#ceramic#carbide#metalwork#tool#drill bits#grinder#2023#metal#distributor#cnctools#removals#deburring#grinding#shaping#automotive#aerospace#engineering

0 notes

Text

A History of Machine Tools :: Ian Bradley

View On WordPress

#0-8524-2102-8#books by ian bradley#british engineering#british engineers#british tools#centre lathes#cold sawing#engineering history#english tools#first edition books#historic machine tools#historical machine tools#history machine tools#lathe tools#machine tools#metal forging#milling machines#woodworking machinery

0 notes

Text

CNC Machine Tool Market - Forecast (2022 - 2027)

The global CNC Machine Tools Market is estimated to surpass $76.7 billion mark by 2026 growing at an estimated CAGR of more than 4.2% during the forecast period 2021 to 2026. Increasing demand for high efficiency in complex machining products, such as cutting and grinding machines is expected to be the major growth factor for the CNC Machine Tools market. Rise in demand for low operating cost and high precision, along with technological advancement in production processes, is further resulting in the popularity of CNC machine tools. Moreover development and launch of next-gen, cutting-edge machine products and automated control solutions are the central focus areas for key players in this market. These players are continuously investing in R&D to create enhanced and sophisticated offerings to strengthen their portfolio and further entrench their position in the market.

CNC Machine Tools Market Report Coverage

The report: “CNC Machine Tools Market– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the CNC Machine Tools Market.

By Product Type: Metal Cutting Tools (Boring and Drilling, Milling, Finishing, Lathe, Machine Centers and Others), Metal Forming Tools (Rolling, Forging and Press, Extruding and Drawing, Punching and Blanking, Bending, Shearing, Casting and Others) and Special Machine Tools (EDM, EBM, PAM, LBM, USM, ECG, CM and Others)

By Sales Channel: Direct and Indirect

By End User Industry: Automotive, Healthcare, Mining and Metal, Aerospace and Defense, Construction, Electrical and Electronic, Energy and Power, Transportation and Others

By Geography - North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), South America (Brazil, Argentina and others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

End users in this market, typically prefer OEMs to provide maintenance support rather than going through a third party. Thus, driving a change in the market model prevalent in this segment.

CNC has various advantages over conventional machines. the various advantages of CNC machines, including high accuracy, safety, time efficiency, flexibility, and low maintenance, is further expected to drive the CNC cutting and grinding machine tools market demand.

The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and automated control solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D.

The adoption of advanced materials such as Poly Crystalline Diamond and solid carbide tools will be a major market driver due to the strength and capability of these materials.

CNC Machine Tool Segment Analysis - By End User Industry

The Automotive and Mining and metal sectors play key roles in the demand for CNC machine tools. The rising demand for high performance in complex cutting and grinding machine products is expected to boost the CNC sector. The growth in demand for low running costs and high accuracy, along with technical advances in manufacturing methods, is further contributing to the popularity of CNC machine tools. In addition, the increase in demand across industries particularly in the electronics and automotive sectors contributes positively to the development of the market for CNC machine tools. The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and automated control solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D. Nearly every OEM provides maintenance services to the end users. These end users prefer OEM led maintenance services rather than third parties due to the discounted maintenance services typically offered as well as reliability and improved component procurement policies. This is changing the business model typically utilized in the market.

Inquiry Before Buying

CNC Machine Tool Segment Analysis - By Product Type

The Milling segment held among the highest market share in 2020. Milling machines tools are primarily used in metal grinding processes across a variety of industries. Poly Crystalline Diamond and solid carbide are materials witnessing significant adoption in the CNC machine tool market. The positive acceleration of the metalworking process industries in the world has ignited the market for milling machines tools. Milling machines tools are extremely flexible and can perform a wide range of functions, such as filling, spinning, chamfering, drilling, gear cutting, grinding machine and so on. These devices can also render numerous incisions by using multiple cutters. Moreover, Lathe segment is anticipated to witness significant market growth during the forecast period 2021-2026. Lathe is a tool that rotates every workpiece on its axis in order to execute a wide variety of operations. Automation is the key factor likely to fuel the expansion of the global demand for lathe machines tools. Manufacturers have begun to simplify their manufacturing procedures in order to improve efficiency. The incorporation of the Internet of Things (IoT) and automated controls into manufacturing (Smart Manufacturing) is one of the latest market trends that will give the business sufficient momentum in the years ahead.

CNC Machine Tool Segment Analysis - By Geography

APAC accounted for the largest share of the Machine tool market. The significant demand from automotive and aerospace sector in China, India and South East Asia in particular is driving market growth. Geographically, RoW (Middle East and Africa) region is anticipated to witness the significant market growth during the forecast period 2021-2026 with a CAGR of 5.2%. The market growth is due to the rising demand of the CNC machine tools from the end users including automobile, food & beverage, aerospace, construction and others. Growing automotive production primarily in Kuwait, Jordan, and others is projected to boost the market growth. Israel is home to robust mining and manufacturing sector. The country’s manufacturing sector is booming with effective diamond cutting/polishing technologies, aviation and space products, and food processing. These provide promising growth prospects for the machine tool market in the country.

Schedule a Call

CNC Machine Tools Market Drivers

Rising Adoption of Internet of Things (IoT) Technologies to Fuel Growth

One of the most prominent machine tools market trends is expected to be the increasing uptake of IoT in the manufacturing sector. This will be a result of escalating demand for information and access to information. Furthermore, producers are looking to bring down their production costs, streamline processes, and raise the safety quotient in their units. As a result, there is growing investment in IoT by manufacturers for improved management and automated control, which is propelling the machine tool market, especially CNC Machine tools. Studies have shown that close to 31% of manufacturing operations are already IoT-enabled, which augurs well for this market.

Adoption of CNC Machine Tools in Medical Sector

The medical industry greatly benefits from the efficiency, speed, and accuracy of CNC machining. According to a report by Teton Machine, the number of Americans aged 65 and older is projected to double between 2019 and 2060 and reach 95 million. Due to the growth of aging population, the need for precision machining services in the medical industry is growing as well. CNC machines are capable of producing sophisticated surgical instruments such as grinding machines, tiny screws and everything in between. In addition medical machined parts for the most complex devices require tight tolerances, which is capable through CNC machine tools. Adding to this, multi-tool and multi-axis machines, such as CNC Swiss turning centers, improve the manufacturing of medical parts with shorter cycle times and owing to the features allowing versatility during production. Moreover several medical equipment manufacturers such as Pulse systems, are focusing on adopting CNC machine tools for advancements in manufacturing. In 2019, Pulse Systems acquired additional CNC (computer numerical control) machine tools to support the company's rapid growth, and has expanded its facilities space to accommodate the newly-added capital equipment. Hence these rising adoption will drive the market growth in the forecast period 2021-2026.

Buy Now

CNC Machine Tools Market Challenges

High Maintenance Costs and Lack of Training to Hinder Growth of the Market

Generally, CNC machines are costlier than the manually-operated machines. However, with time, the cost is estimated to reduce effectively. Furthermore, to maintain the proper functioning of the machines, regular maintenance of the high-tech pieces is essential by the manufacturers. Apart from this, the focus in the current market is on deploying cheaper machine tools, especially in developing nations. While this saves on initial investment, these machine tools have higher long-term maintenance, parts replacement and other costs, apart from the limited functionality. Besides that appropriate training and machinists need to get acquainted with the professional skills necessary to operate these machines. Hence high maintenance costs and lack of skilled workers will restrict the market growth in the forecast period 2021-2026.

CNC Machine Tools Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the CNC Machine Tools Market. Dalian, Amada, JTEKT, Trumpf, Shenyang Machine Tool (SMTCL), Philips Machine Tools, KRC Machine Tool Services, Optimation Technology Inc., Troy Industrial Services, MIC Group and others are considered to be the key players of the CNC Machine Tools Market.

For more Electronics Market reports, please click here

#CNC Machine Tools Market#CNC Machine Tools Market share#CNC Machine Tools Market price#CNC Machine Tools Market size#CNC Machine Tools Market trends#Machine Tools

0 notes

Text

Machine Tools in Dubai and Abu Dhabi, UAE

Whether you're working on your home project, building your vehicle, doing regular maintenance or repair, or anything in between, rely on our selection of tools and garage accessories to get your job done right the first time. To know more such details, visit https://asbmet.com/category/105

0 notes