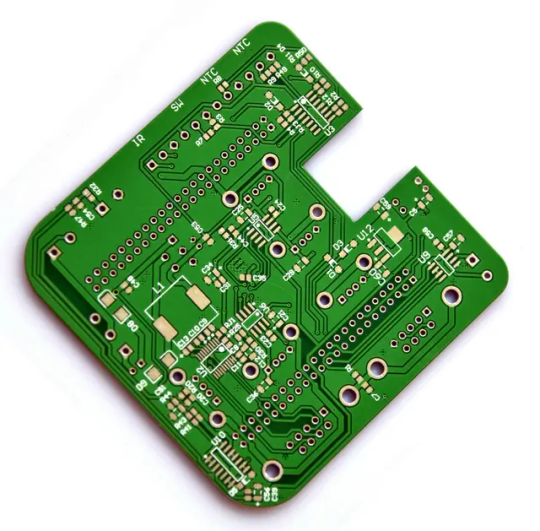

#metal core pcb design

Explore tagged Tumblr posts

Text

Learn the Traits to Find the Best Mcpcb Manufacturer for Your Needs

Metal-core printed circuit boards are one of the most significant spare parts you need to operate and control electronic goods. The quality of this spare will affect the functioning of the entire device. Hence, the manufacturers and the suppliers of the product are some of the elemental stakeholders for electronic device-producing brands. Naturally, due to massive demand, you can find several makers and suppliers in the industry. In this article, we will discuss the traits to discern the best.

Years of experience

The first aspect which you must find out to work with the best mcpcb manufacturer is the number of years for which the company has been operational in the market. You must look for a brand which has been in the market for a minimum of one and a half decades.

Service Array

Services from the top manufacturers and suppliers can help patrons get the best value for their investment. Some of the vital services you can get from the market leaders is mcpcb assembly, mass production, product prototype and innovative designing. These brands are masters in customization and they can change and adapt their products as per the precise customer requirements.

Product Array

Apart from service variety these brands can also act as some of the best single window service providers for different products like single layer metal core pcb, double sided metal core pcb, two layer aluminum base pcb and multilayer aluminum base pcb. Hence irrespective of your requirement specifications you can turn to a single vendor to meet all your business needs.

Quality control certificate

Finally, before you select a vendor for your business one of the main things which you must check is quality assurance certifications for the products from the vendor. This is one of the parameters that give you assurance for the product quality into which you are investing and also for their internal procedures and organization culture. These are the vendors who can add much value to your business.

0 notes

Text

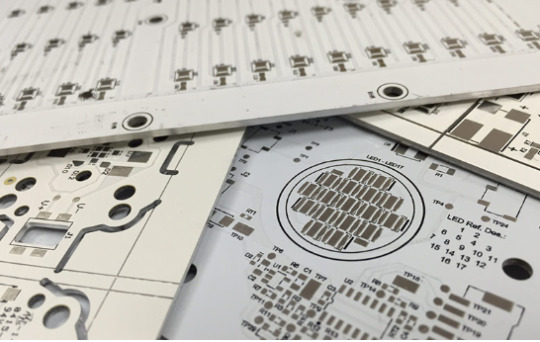

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

PCB Fabrication Company in India – Reliable Solutions for Your Manufacturing Needs

Printed Circuit Boards (PCBs) are the foundation of modern electronics. From mobile devices to industrial equipment, PCBs are essential in powering technology across industries. As demand for high-quality electronics continues to rise, India has become a global hub for PCB fabrication, offering reliable, affordable, and advanced manufacturing solutions.

If you are looking for trusted PCB fabrication company in India, FindingMFG connects you with verified manufacturers ready to deliver quality at every stage of production.

Why Work with a PCB Fabrication Company in India?

India has established itself as a leading destination for electronics manufacturing. Supported by skilled professionals, modern infrastructure, and global certifications, Indian PCB manufacturers deliver products that meet international standards. Here’s why businesses choose PCB fabrication companies in India:

Affordable and Efficient Production

PCB manufacturers in India provide cost-effective solutions, whether you require a prototype or a large-volume order. Competitive pricing combined with strict quality control ensures that you receive reliable products at the right cost.

Advanced Manufacturing Capabilities

With access to modern machinery and production techniques, Indian PCB companies can fabricate single-sided, double-sided, and multilayer boards. They can handle standard designs as well as complex, custom configurations.

Customized Services for Every Requirement

Indian manufacturers specialize in tailored PCB solutions to match your exact project needs. From design specifications to delivery timelines, they offer flexibility for both small and large production runs.

Commitment to Global Standards

Leading PCB fabrication companies in India hold international certifications such as ISO, IPC, UL, and RoHS. These certifications guarantee that every board produced meets high-quality benchmarks for global markets.

Comprehensive PCB Fabrication Services

At FindingMFG, you can easily connect with PCB manufacturers offering a wide range of services, including:

Single-Sided PCBs

Double-Sided PCBs

Multilayer PCBs

Flexible and Rigid-Flex PCBs

High-Density Interconnect (HDI) PCBs

Metal Core PCBs

High-Frequency PCBs

Whether your project is straightforward or highly complex, India’s PCB manufacturers have the capabilities to deliver.

Industries Served by PCB Fabrication Companies in India

Indian PCB manufacturers serve a broad range of industries, including:

Automotive

Aerospace and Defense

Consumer Electronics

Telecommunications

Medical Devices

Industrial Automation

IoT and Smart Technology

This industry expertise allows them to provide solutions that meet the specific needs of diverse applications.

FindingMFG – Connecting You with the Right PCB Fabrication Partner

FindingMFG is India’s trusted online platform for sourcing electronics manufacturing services. We help you discover reliable, verified PCB fabrication companies in India, simplifying the process of finding the right supplier for your project.

What FindingMFG Offers:

Verified suppliers across India

Easy-to-use search filters

Fast, direct quote requests

Transparent communication with manufacturers

Solutions for domestic and international buyers

Start Your PCB Manufacturing Project Today

Choosing the right PCB fabrication partner is a critical step toward building successful electronic products. With FindingMFG, you gain access to India’s best manufacturers who can deliver quality, precision, and value.

Post your requirement on FindingMFG and connect with trusted PCB fabrication companies in India.

Visit FindingMFG.com to get started

#pcb fabrication company#pcb fabrication companies in India#pcb design#pcb manufacturing#manufacturing directory

0 notes

Text

Improve Precision with High-Quality Soldering Tips in India

In electronics assembly and repair, the quality of your soldering depends as much on the tip as it does on the iron. A precise, durable, and well-maintained soldering tip can mean the difference between a perfect joint and a failed circuit. That's why professionals across manufacturing, servicing, and DIY sectors are increasingly choosing reliable soldering tips in India from Ascomp Inc..

At Ascomp Inc., we understand that every application requires the right tool for the job. We offer a wide range of premium soldering tips compatible with all major soldering stations. Whether you're working with micro-components or heavy-duty connections, we have the right tip for you.

What Are Soldering Tips?

Soldering tips are the metal parts at the end of a soldering iron that transfer heat to the components and solder. These tips come in various shapes and sizes—conical, chisel, bevel, and needle—each suited for specific applications. For example:

Conical tips are ideal for precision work.

Chisel tips offer broader surface contact for larger joints.

Bevel tips combine control and surface area, ideal for drag soldering.

Our range of soldering tips in India is designed for both leaded and lead-free soldering applications, ensuring efficient heat transfer and long service life.

Features of Ascomp Inc. Soldering Tips

High Thermal Conductivity: Made from copper cores with iron plating for fast heat-up and consistent performance.

Oxidation Resistant Coating: Prolongs tip life and maintains solderability.

Wide Compatibility: Fits Hakko, Weller, Quick, Goot, and other major soldering stations.

Variety of Shapes: Available in over 30 tip geometries for all kinds of soldering tasks.

Affordable Pricing: Cost-effective without compromising on quality.

Applications of Soldering Tips in India

The demand for reliable soldering tips in India spans across a wide spectrum of industries:

Electronics Manufacturing: Essential for assembly lines producing PCBs, mobile phones, and consumer gadgets.

Repair & Servicing Centers: Crucial for rework on circuit boards and connectors.

DIY and Hobby Projects: For enthusiasts working on Arduino, Raspberry Pi, and robotics.

Educational Labs: Used in technical training institutes and engineering colleges.

Automotive Electronics: For sensor and ECU soldering work.

Why Choose Ascomp Inc.?

Trusted Supplier: We provide only high-grade, performance-tested soldering tips.

Bulk Order Facility: Ideal for factories, service centers, and educational institutions.

Quick Delivery: Pan-India shipping with reliable inventory management.

Technical Support: Our team helps you select the correct tip for your application.

After-Sales Service: Assistance in usage, maintenance, and tip care.

#SolderingTipsIndia#AscompInc#ElectronicsAssembly#SolderingSolutions#SMDRework#PCBRepair#SolderingStationTips#PrecisionTools#DIYElectronicsIndia#HeatTransferTools

0 notes

Text

What are the main components and parts of LED displays

LED display, this light and shadow magician that is ubiquitous in modern cities, attracts our attention from large billboards on the street to live broadcast screens in stadiums with its dazzling colors and clear images. But what "parts" does it consist of? Today, let’s unveil the mystery of LED displays and take a look at the “heart”, “brain” and “skeleton” behind it.

Glowing "pixels": LED light beads and modules

When it comes to LED displays, the most core is of course the "LED" itself. These tiny LED light beads, like independent pixel dots, form what we often call "LED modules" through matrix arrangements integrated on the PCB (printed circuit board). Let you learn about the LED display soft module in 5 minutes.

LED light beads: Although it is small, it is the core of the glowing light. It is made of semiconductor materials and can emit three basic colors: red, green and blue (RGB) after power on. Through different combinations of these three colors and brightness adjustment, tens of millions of colors can be presented. The packaging technology, brightness, viewing angle and life of the lamp bead directly determine the display effect and stability of the display screen. Here is Mini LED vs COB packaging: a technical choice from the user's perspective.

LED module: Multiple LED lamp beads are arranged at a certain spacing, soldered onto the PCB board, and then controlled by the driver IC to form an LED module. You can think of it as LEGO blocks, and modules of different specifications can be spliced into display units of various sizes. The flatness, consistency and protection level of the module (such as waterproof and dustproof) are crucial to the overall performance of the display.

Support and connection "skeleton": box

LED modules need a solid "home" to accommodate them, which is the "box". The box not only plays a supporting role, but also is responsible for fixing modules, power supply and heat dissipation.

Material: Common box materials include die-cast aluminum, sheet metal, carbon fiber, etc. Die-cast aluminum box is lightweight and has high precision, and is often used for rental screens; sheet metal box costs are relatively low and mostly used for fixed installation screens; carbon fiber box is popular in the high-end rental market for its ultra-light characteristics.

Structure: The box is designed with heat dissipation channels, power supply and signal interfaces. Good heat dissipation design can effectively extend the life of LED lamp beads and driver ICs. At the same time, the splicing accuracy of the box also directly affects the overall flatness of the display.

The "heart" of power supply: power supply

The light of the display screen cannot be separated from electrical energy, and the "power supply" is the one that provides stable and efficient electrical energy.

Type: LED displays usually use switching power supplies to convert mains into DC low voltage power required for LED lamp beads and drive ICs. Let you understand how LED light beads work.

Importance: The stability of the power supply, conversion efficiency, power factor and protection level (such as overvoltage and overcurrent protection) will affect the operating stability and life of the display. A good quality power supply can allow the display to work "healthily" for longer.

The "brain" of control and transmission: the control system

If the LED module is the "eye" of the display screen, then the control system is its "brain" and "nerve". It is responsible for receiving external signals and converting them into driving signals that the LED module can recognize, thereby realizing screen display.

Send card: Process the signals from the computer or video player and send them out via network cable or optical fiber.

Receive card (also known as driver card): installed inside the LED box, responsible for receiving signals from the transmission card and assigning them to each LED module. The number and performance of the received cards directly determine the refresh rate, grayscale level and screen display effect of the display.

Video processor: Displays that require complex processing such as playing high-definition video, multi-screen switching, and zooming, are usually equipped with professional video processors. It can uniformly process and optimize video signals in different formats to ensure smooth and clear pictures.

Control software: Professional software running on the computer, used to edit, manage playback content, set display parameters, etc.

The "blood vessel" that transmits signals: wire

What connects various components and transmits power and signals is a variety of wires.

Power cord: Responsible for power supply, and you need to choose a thickness that meets safety standards to ensure stable current transmission and no heating.

Signal line: transmits data signals, usually using network cables or optical fibers. High-quality signal lines can ensure the integrity and stability of signal transmission and avoid jittering, screen-flowing and other phenomena.

Fixed "support": steel structure

For large outdoor LED displays, a solid "steel structure" is also needed to support the weight of the entire screen and resist the invasion of natural forces such as wind and rain. The design and construction of steel structures require professional civil engineering knowledge to ensure the safety and stability of the display screen. Give you a steel frame LED screen: key features, case studies and buying tips.

Summarize

An LED display is the crystallization of the collaborative work of many precision components. From tiny LED lamp beads to huge steel structures, every link is crucial. Understanding these main components and their functions will not only help us better select and use LED displays, but also be clear about them in daily maintenance. The next time you see dazzling LED billboards on the streets, you may be able to see these "heroes behind the scenes"!

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: Full guide to renting indoor LED displays. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

Choosing the Right PCB Material: A Comprehensive Guide | PCB Power

Choosing the Right Printed Circuit Board Material: A Comprehensive Guide

The choice of materials commonly used for the fabrication of the PCB is extremely important in determining the quality of it. The selection of PCB base material can impact electrical properties, thermal and mechanical behaviour, and reliability of the final product. In this blog, we will learn about the printed circuit board materials which are available to the buyers and their characteristics.

Common Types of PCB Materials

A list of the most common printed circuit board material is given below:

1. FR-4

FR-4 is the most common substrate material for making multi-layer printed circuit boards. It is a fibreglass-epoxy composite, with high dielectric strength. The material FR-4 can retain its stability up to the temperature of 130°C (266°F). It is used in consumer electronics, industrial control, telecommunications and other general application gadgets.

2. Polyimide

Polyimide is famous for its heat resistance and flexibility characteristics. It is commonly applied to flexible PCBs, where the board can be bent or folded. For example, in the case of a smartphone design. Polyimide can work up to a temperature of 260°C (500 °F). It is appropriate for aerospace, automobile, and medical devices where high performance is required.

3. Metal Core PCBs

Metal core PCBs are designed with a metal base material, often aluminum or copper. It offers five times better heat dissipation than FR-4 boards. These boards are popular in areas of heat dissipation which may include LED lighting and power electronics. Metal core PCBs have better thermal management under thermal loads.

4. Rogers Materials

Rogers Corporation produces a range of high-frequency materials that are suitable for advanced applications requiring precise electrical performance. Rogers materials provide low-loss characteristics and stable dielectric constants across varying frequencies.

They are used in telecommunications, aerospace, and military applications.

5. Taconic TSM-DS TLY-5 & DS3

Taconic TSM-DS TLY-5 and DS3 are specialized PCB materials intended for high-frequency applications. They are characterized by low dielectric constants and loss tangents, which keep the signal integrity at RF and microwave frequencies. Taconic materials are used in telecommunications and automotive radar.

Factors to Consider While Choosing PCB Materials

These are some factors one must consider before selecting the material for a printed circuit board:

1. Material Type and Properties

The choice of PCB material significantly impacts its functionality and reliability. Understanding the properties of the materials, such as dielectric constant (Dk), loss tangent (Df), and thermal expansion coefficient (CTE), is important.

2. Thermal Management

If there is heat involved, then thermal performance is very important, especially for high-power applications. The main thermal properties to study are as follows.

Glass Transition Temperature (Tg): At this temperature, the material would go from being a rigid state to more flexible. Thus, higher Tg materials are better to be used at high temperatures.

Decomposition Temperature (Td): It is the temperature at which the material will begin decomposing. Better indications under very difficult conditions are seen in higher Td.

3. Manufacturing Process Compatibility

The chosen material should also correspond to the manufacturing method employed, i.e., through-hole or surface mount technology (SMT). For example, SMT relies on FR-4 for favourable drillability, while flexible PCBs need materials such as polyimide, which don't crack during bending.

4. Environmental Considerations

Always evaluate the PCB's operational condition since humidity, temperature rise and fall, and exposure to chemicals influence the selection process of materials. Ensure the selected materials can withstand these conditions without degrading.

5. Frequency Range

In an instance where high-frequency signals are involved, it is critical to select materials that have low dielectric loss. High-speed PCBs may require special material under this.

Conclusion

Choose the right printed circuit board material to get the best result in the electronic designs. Designers must know about the properties of various materials such as FR-4, polyimide, PTFE, metal core, and Rogers to satisfy the needs of the projects. Electrical behavior, thermal properties, mechanical strength, cost ,and feasibility of PCB fabrication during manufacturing will help you decide which material is most suitable for your particular project.

At PCB Power, we manufacture high-quality printed circuit boards crafted from a variety of materials, including FR-4, polyimide, and metal core. Whether you are looking for prototype circuit boards or need them in volume, PCB Power can be your trusted partner

Contact our team of experts to discuss your requirements.

Know More: https://www.pcbpower.us/blog/choosing-right-pcb-material-guide

0 notes

Text

Trusted Laminar Airflow Manufacturers in India: Everything You Need to Know

In environments in which cleanliness is essential, laminar airflow structures make certain precision, protection, and contamination manipulate. Whether it’s a pharmaceutical cleanroom, a clinical facility, or an electronics lab, these structures offer a controlled, sterile quarter through channeling purified air in a uniform route. As industries demand greater stringent hygiene requirements, the role of experienced laminar airflow manufacturers turns into critical.

This complete guide explores how those systems work, their blessings, and the top manufacturers in India supplying excessive-performance laminar airflow solutions.

What is Laminar Airflow?

Laminar airflow is a way of controlling the motion of air inside a restrained workspace. Unlike turbulent airflow, laminar waft moves air in a clean, steady direction — either vertically or horizontally — via excessive-performance filters like HEPA or ULPA.

Vertical Flow Units: Push filtered air from the pinnacle down to the work surface, perfect for sterile packages.

Horizontal Flow Units: Deliver air from the again of the unit in the direction of the operator, decreasing overhead infection.

By making sure that easy air flows in a streamlined sample, those structures considerably lessen airborne contaminants and defend important approaches.

Importance of Laminar Flow in Sensitive Workspaces

Laminar airflow devices help protect product integrity and prevent contamination-related losses. These systems are normally utilized in:

Pharmaceutical manufacturing

Biotechnology labs

Semiconductor fabrication

Hospitals and working theaters

Food and beverage nice manipulate

Key benefits encompass:

Clean air environment for touchy responsibilities

Improved compliance with GMP, ISO, and FDA requirements

Lower threat of microbial or particulate contamination

Increased productivity with the aid of retaining a stable workspace

Core Features of Laminar Airflow Systems

When evaluating systems from main laminar airflow manufacturers, recollect the following preferred capabilities:

HEPA or ULPA filters that dispose of up to ninety nine.999% of debris

Non-turbulent airflow with steady speed

Silent operation to reduce noise in laboratory or clinical settings

Durable metallic or powder-coated production

Integrated UV lighting fixtures for floor sterilization

Custom sizes and mobility options

Who Uses Laminar Airflow Systems?

These systems are integral in sectors where even a hint of infection can compromise safety or effects. Some main industries encompass:

Healthcare: Used for IV preparation, surgical procedures, and pathology labs

Pharmaceuticals: Ensuring sterile environments all through drug components

Electronics: Protecting microchips and PCBs from dirt and static

Research & Development: Used in microbiology, tissue lifestyle, and genetic research

Food Tech: For keeping clean zones in the course of packaging or ingredient handling

Top Laminar Airflow Manufacturers in India

India hosts numerous reputable agencies generating world-class laminar go with the flow devices for numerous applications. Below are the main laminar airflow producers recognized for high-quality, customization, and compliance.

1. Clean Air India

Clean Air India is a nicely-mounted manufacturer of cleanroom system. Their variety includes both vertical and horizontal laminar float benches, designed to meet ISO Class five cleanliness tiers. Their structures are extensively utilized in labs, pharma production, and IVF centers.

2. Aeromech Equipments Pvt. Ltd.

Aeromech is thought for its modern easy air structures, offering ceiling-hooked up, vertical, and modular laminar waft systems. Their designs are built with excessive-grade stainless steel and incorporate capabilities like silent blowers and virtual airflow video display units.

3. Microflow Devices India Pvt. Ltd.

Microflow Devices is every other key player, supplying a number LAF systems that comply with international cleanroom requirements. They concentrate on products for biotechnology, medical research, and cleanroom-primarily based production.

4. TechAir India

TechAir has built a popularity for precision-constructed laminar airflow cabinets with person-pleasant controls and robust overall performance. Their gadgets come with HEPA filters, UV germicidal lighting fixtures, and sturdy systems tailored to various industries.

5. Pure Air Systems

Focused on IVF labs, biotech, and lab-scale easy environments, Pure Air Systems offers horizontal laminar airflow benches with superior airflow manage and compact designs. Their systems include pre-filters, quiet vehicles, and energy-saving options.

How to Choose the Right Laminar Airflow Manufacturer

Not all systems are constructed alike. Here’s how to pick the first-rate provider on your application:

Certification & Standards: Ensure merchandise meet ISO 14644-1, GMP, or FDA requirements.

Customization: Choose producers that offer size, airflow, and fabric customization.

Installation & Service: Look for complete guide, which includes installation, AMC, and guarantee.

Reputation: Read case studies or purchaser evaluations to assess the business enterprise’s track report.

Why Indian Laminar Airflow Manufacturers Stand Out

India has come to be a center for remarkable cleanroom technology, supplying value-effective solutions with worldwide compliance. Top laminar airflow manufacturers in India have:

In-house R&D abilties

Global export certifications

Flexible design and fabrication services

Access to advanced filtration and automation technologies

With a focus on innovation and affordability, Indian providers are meeting international call for for dependable, excessive-performance cleanroom device.

Final Thoughts

In managed environments, a well-designed laminar airflow unit is extra than simply an asset — it’s a need. Selecting the proper gadget and provider immediately impacts manner integrity, safety, and compliance. The main laminar airflow producers in India offer now not best superior fine however additionally the power and help required with the aid of today’s dynamic industries.

Whether you're setting up a brand new lab, increasing a production facility, or upgrading present cleanroom infrastructure, partnering with a depended on Indian manufacturer ensures reliability, affordability, and lengthy-term value.

0 notes

Text

Benefits of an Aluminium Core PC

One of the main challenges in electronics is heat. In case your PCB can’t deal with it properly, additives start failing, performance drops, and in worst-case scenarios, things can burn out in entirety. Aluminum core PCBs clear up this hassle via pulling heat away from crucial components and spreading it out. The aluminum layer acts like an integrated heat sink, retaining coolness even when running like LED lights, automotive electronics, and power converters.

0 notes

Text

PCB Materials: A Comprehensive Guide to Choosing the Right Substrates

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the foundation for electrical connections between components. The performance, durability, and reliability of a PCB heavily depend on the PCB materials used in its construction. Selecting the right substrate is crucial for ensuring optimal functionality in various applications, from consumer electronics to aerospace systems.

This guide explores the different types of PCB materials, their properties, and how to choose the best option for your project.

1. Understanding PCB Materials: Key Properties

PCB materials consist of a substrate (base layer) and conductive traces (usually copper). The substrate must provide mechanical support while maintaining electrical insulation. The most important properties to consider when selecting PCB materials include:

Dielectric Constant (Dk): Determines signal propagation speed; lower Dk is better for high-frequency applications.

Dissipation Factor (Df): Measures signal loss; a low Df is essential for high-speed circuits.

Thermal Conductivity: Affects heat dissipation; critical for high-power applications.

Coefficient of Thermal Expansion (CTE): Must match component materials to avoid warping under temperature changes.

Glass Transition Temperature (Tg): The temperature at which the substrate softens; higher Tg improves thermal stability.

2. Common Types of PCB Materials

Different applications require different PCB materials. Below are the most widely used substrates:

2.1 FR-4 (Flame Retardant-4)

FR-4 is the most common PCB material, made from woven fiberglass and epoxy resin. It offers good mechanical strength, electrical insulation, and affordability.

Advantages:

Cost-effective

Good mechanical and electrical properties

Suitable for most standard applications

Limitations:

Moderate thermal performance

Not ideal for high-frequency or high-power circuits

2.2 High-Frequency Laminates

For RF and microwave applications, specialized PCB materials like Rogers, PTFE (Teflon), and ceramic-filled substrates are used.

Examples:

Rogers RO4000 Series: Low Dk and Df, ideal for 5G and radar systems.

PTFE (Teflon): Excellent high-frequency performance but harder to manufacture.

Advantages:

Minimal signal loss at high frequencies

Stable electrical properties

Limitations:

Higher cost

Requires specialized fabrication techniques

2.3 Metal-Core PCBs (MCPCBs)

MCPCBs use a metal base (usually aluminum or copper) for better heat dissipation.

Applications:

LED lighting

Power electronics

Automotive systems

Advantages:

Superior thermal management

Enhanced durability

Limitations:

Higher cost than FR-4

Heavier than standard PCBs

2.4 Flexible PCB Materials

Flexible PCBs use polyimide or polyester films instead of rigid substrates.

Advantages:

Lightweight and bendable

Suitable for wearable electronics and compact devices

Limitations:

More expensive than rigid PCBs

Requires careful handling during assembly

3. How to Choose the Right PCB Material

Selecting the best PCB materials depends on several factors:

3.1 Application Requirements

Consumer Electronics: FR-4 is usually sufficient.

High-Frequency Circuits: Rogers or PTFE laminates are better.

High-Temperature Environments: Polyimide or ceramic-based materials.

3.2 Signal Integrity Needs

For high-speed digital or RF designs, low Dk and Df materials are essential to minimize signal loss.

3.3 Thermal Management

Power electronics and LED applications require materials with high thermal conductivity, such as MCPCBs.

3.4 Cost Considerations

While advanced PCB materials offer superior performance, they are more expensive. Balance performance needs with budget constraints.

4. Future Trends in PCB Materials

As technology evolves, new PCB materials are being developed to meet higher performance demands:

High-Tg FR-4: Improved thermal stability for advanced computing.

Nanocomposite Substrates: Enhanced electrical and thermal properties.

Eco-Friendly Materials: Biodegradable and lead-free options for sustainable electronics.

Conclusion

Choosing the right PCB materials is critical for ensuring the performance, reliability, and longevity of electronic devices. By understanding the properties and applications of different substrates—such as FR-4, high-frequency laminates, metal-core, and flexible PCBs—engineers can make informed decisions based on their project requirements.

As emerging technologies demand faster, smaller, and more efficient PCBs, advancements in PCB materials will continue to play a vital role in shaping the future of electronics.

1 note

·

View note

Text

PCB Manufacturing: A Comprehensive Guide to Printed Circuit Board Production

Introduction to PCB Manufacturing

PCB manufacturing is the process of creating printed circuit boards, which are essential components in nearly all modern electronic devices. From smartphones to industrial machinery, PCBs provide the foundation for electrical connections and component mounting. This guide explores the PCB manufacturing process, materials, technologies, and applications.

The PCB Manufacturing Process

1. Design and Schematic Creation

Before production begins, engineers design the PCB using specialized software like Altium Designer, KiCad, or Eagle. The design includes:

Schematic diagrams (circuit connections)

Component placement

Trace routing (copper pathways)

Layer stack-up (for multi-layer PCBs)

Once the design is finalized, a Gerber file (standard PCB manufacturing file) is generated for fabrication.

2. Material Selection

The base material of a PCB is typically FR-4, a flame-resistant fiberglass epoxy laminate. Other materials include:

Flexible PCBs: Made from polyimide for bendable circuits.

High-frequency PCBs: Use Rogers material for RF applications.

Metal-core PCBs: Aluminum or copper for heat dissipation.

3. Printing the Circuit Pattern

The PCB design is transferred onto the board using one of these methods:

Photolithography: A UV-sensitive photoresist is applied, exposed to UV light, and developed to create the circuit pattern.

Direct Imaging: A laser directly etches the pattern onto the PCB.

4. Etching the Copper Layers

After the circuit pattern is printed, the unwanted copper is removed through chemical etching. The remaining copper forms the conductive traces.

5. Drilling Holes for Components

Precision CNC machines drill holes for through-hole components and vias (connections between layers).

6. Plating and Copper Deposition

The drilled holes are electroplated with copper to ensure conductivity between layers.

7. Solder Mask Application

A solder mask (usually green) is applied to protect the copper traces and prevent short circuits. Openings are left for soldering components.

8. Silkscreen Printing

Text, logos, and component labels are printed on the PCB using silkscreen ink for easy assembly and identification.

9. Surface Finish Application

A surface finish is applied to protect exposed copper and improve solderability. Common finishes include:

HASL (Hot Air Solder Leveling)

ENIG (Electroless Nickel Immersion Gold)

OSP (Organic Solderability Preservative)

10. Electrical Testing and Quality Control

Each PCB undergoes automated optical inspection (AOI) and electrical testing to ensure functionality. Defective boards are rejected.

Types of PCBs in Manufacturing

1. Single-Layer PCBs

Simplest and most cost-effective.

Used in basic electronics like calculators.

2. Double-Layer PCBs

Conductors on both sides.

Common in consumer electronics.

3. Multi-Layer PCBs

4+ layers for complex circuits (e.g., motherboards).

Requires precise PCB manufacturing techniques.

4. Flexible PCBs

Used in wearables and medical devices.

Made from bendable materials.

5. Rigid-Flex PCBs

Combines rigid and flexible sections.

Ideal for aerospace and military applications.

Advanced PCB Manufacturing Technologies

1. High-Density Interconnect (HDI) PCBs

Features microvias and finer traces.

Used in smartphones and compact devices.

2. Embedded Components

Passive components (resistors, capacitors) are embedded within the PCB.

Reduces size and improves performance.

3. 3D Printed Electronics

Emerging technology for rapid prototyping.

Combines additive manufacturing with conductive inks.

Applications of PCB Manufacturing

PCBs are used in nearly every industry, including:

Consumer Electronics (Smartphones, Laptops)

Automotive (ECUs, Infotainment Systems)

Medical Devices (Pacemakers, Imaging Systems)

Aerospace & Defense (Avionics, Radar Systems)

Industrial Automation (Robotics, Control Systems)

Challenges in PCB Manufacturing

Miniaturization: Shrinking component sizes demand precision.

High-Speed Signal Integrity: Ensuring minimal interference.

Thermal Management: Preventing overheating in dense circuits.

Environmental Regulations: Compliance with RoHS and REACH.

Future Trends in PCB Manufacturing

AI-Driven Design Optimization

Sustainable Materials (Biodegradable PCBs)

5G and IoT Integration (Higher frequency PCBs)

Automated Smart Factories (Industry 4.0)

Conclusion

PCB manufacturing is a complex yet vital process that powers modern electronics. From design to testing, each step requires precision and expertise. As technology advances, printed circuit boards will continue to evolve, enabling smaller, faster, and more efficient devices.

Whether you're an engineer, hobbyist, or industry professional, understanding PCB manufacturing helps in designing better electronic products for the future.

1 note

·

View note

Text

Viasion Technology: Your Trusted Partner for Quality PCB Manufacturing Solutions

In today’s fast-paced tech world, electronics are everywhere—from smartphones and wearables to medical devices and industrial systems. Behind every smart gadget or complex system lies a network of well-designed printed circuit boards (PCBs) that bring it all to life. At Viasion Technology, we’re proud to be one of the most trusted names in PCB manufacturing, offering high-quality, customized PCB solutions to companies all over the world.

Whether you're a startup prototyping a new device or an established business scaling up production, Viasion is here to help you turn your ideas into reality—with precision, reliability, and cost-efficiency at the core of everything we do.

Why Choose Viasion for Your PCB Needs?

Since 2007, Viasion has been delivering exceptional PCB fabrication and assembly services from our headquarters in Shenzhen, China. With over 17 years of experience, we’ve served clients across various industries, including medical, automotive, industrial control, IoT, and consumer electronics.

Our team combines engineering expertise with state-of-the-art technology to ensure every board we produce meets the highest international standards. From prototype to production, we offer end-to-end services that help streamline your product development cycle.

Comprehensive PCB Capabilities

At Viasion, we understand that no two projects are the same. That’s why we offer a broad range of PCB types and services to meet your exact technical and budgetary requirements. Some of our core offerings include:

1. Copper PCB Board Manufacturing

Copper PCB boards are the backbone of modern electronics. They offer superior conductivity, excellent heat dissipation, and high durability—perfect for high-power applications. Whether you need single-layer, double-layer, or multi-layer copper boards, we have the expertise to deliver consistent quality.

Our copper PCBs are widely used in LED lighting, power electronics, automotive systems, and more. Plus, we offer a range of thickness options and custom finishes to suit your specific needs.

2. Flex PCB and Flex PCB Board Production

Looking for a lightweight, space-saving alternative to traditional rigid PCBs? Flex PCBs (also known as flex PCB boards) are your go-to solution. These boards can bend, twist, and fold, making them ideal for compact devices and dynamic applications.

At Viasion, we manufacture high-quality flexible boards that perform well under stress and resist vibration. Whether you need single-sided, double-sided, or multilayer flexible circuit boards, our team can guide you through the entire process—from material selection to final inspection.

3. Flexible Circuit Board Solutions

Our flexible circuit board options are engineered for durability and versatility. These boards are especially useful in wearable tech, mobile phones, and aerospace systems where space and weight are critical concerns.

We ensure that each flexible PCB goes through rigorous testing to meet the most demanding requirements. With Viasion, you can count on flexible solutions that don’t compromise on performance.

4. FR4 PCB Manufacturing

FR4 is one of the most popular materials used in PCB production due to its excellent strength-to-weight ratio and thermal resistance. Our FR4 PCB solutions are suitable for everything from simple consumer electronics to high-end industrial controls.

We offer FR4 boards in various thicknesses, copper weights, and surface finishes. Whether you’re building a prototype or scaling to mass production, we’ll make sure your FR4 PCBs are manufactured to your exact specs.

5. Metal Core PCB (MCPCB) Fabrication

If your project demands superior thermal management, our metal core PCB (MCPCB) options are the ideal choice. With aluminum or copper cores, these boards can efficiently dissipate heat, which is crucial in high-power LED and automotive applications.

At Viasion, we manufacture single-sided, double-sided, and multilayer MCPCBs that combine thermal performance with electrical reliability. Our advanced manufacturing techniques ensure minimal thermal resistance and excellent mechanical strength.

Industries We Serve

Our PCBs are found in a wide array of products across industries, including:

Automotive: Durable and heat-resistant PCBs for electric vehicles and ADAS systems.

Medical Devices: High-precision boards for diagnostic equipment and patient monitoring systems.

Industrial Control: Reliable PCBs for automation, robotics, and smart manufacturing.

Consumer Electronics: Compact and cost-effective boards for wearables, smart gadgets, and more.

IoT Applications: Custom PCB solutions optimized for wireless communication and low-power consumption.

What Sets Viasion Apart?

✅ Experienced Team – Our engineers have years of hands-on experience in PCB design, manufacturing, and testing.

✅ Advanced Facilities – Our ISO9001, ISO13485, and UL-certified factory is equipped with modern machines and inspection tools.

✅ Flexible Order Quantities – From one-off prototypes to full-scale production, we can handle orders of any size.

✅ Strict Quality Control – Every board goes through electrical testing, AOI inspection, and functional checks before shipping.

✅ Global Reach, Local Support – While we’re based in China, we serve clients worldwide, offering responsive communication and fast lead times.

Getting Started with Viasion

Starting a project with us is easy. Just send your PCB Gerber files and specifications, and we’ll get back to you with a quick quote. Need help optimizing your design for manufacturing? Our team offers DFM (Design for Manufacturability) feedback at no additional cost.

We’re more than just a manufacturer—we’re your engineering partner every step of the way.

Let’s Build Something Great Together

Whether you’re working on a next-gen wearable or an industrial control system, you need a PCB partner you can trust. At Viasion Technology, we combine technical know-how with personalized service to deliver PCBs that meet your performance and budget expectations.

From copper PCB boards and flexible circuit boards to FR4 PCBs and metal core PCBs, we’ve got you covered with comprehensive capabilities and a proven track record.

0 notes

Text

The Role of Circuit Protection Devices in Modern Electrical Systems

In today’s technology-driven world, the demand for safe, reliable, and efficient electrical systems has never been greater. From homes and offices to industrial plants and data centers, uninterrupted power is critical. Yet, electrical systems are vulnerable to faults such as short circuits, overloads, and ground faults that can lead to equipment damage, operational downtime, and even fire hazards. This is where circuit protection devices come into play.

Modern circuit protection is not just about preventing damage — it’s about ensuring continuity, safety, and smart integration. In this article, we’ll explore the evolving role of circuit protection devices, their types, latest advancements, and their significance in contemporary electrical infrastructure.

1. What Are Circuit Protection Devices?

Circuit protection devices are components specifically designed to detect abnormal electrical conditions and interrupt current flow to prevent damage. They act as sentinels within electrical circuits, ensuring safety by isolating faults swiftly and efficiently.

They serve three core purposes:

· Prevent equipment damage

· Ensure personnel safety

· Maintain system integrity and reliability

2. Why Circuit Protection Is More Crucial Than Ever

With the proliferation of sensitive electronics, automation systems, and renewable energy integrations (like solar PV and EV charging systems), electrical systems have become more complex. Any anomaly — like a power surge or insulation failure — can cascade into massive disruptions.

Moreover, industries now emphasize:

· Minimizing unplanned downtime

· Adhering to global safety standards (IEC, UL, NEC, etc.)

· Achieving energy efficiency and sustainability goals

Therefore, modern circuit protection must go beyond basic protection — it must be intelligent, adaptable, and communicative.

3. Key Types of Circuit Protection Devices

Let’s dive into the main categories of protection devices used in today’s electrical systems:

3.1. Fuses

Fuses are the oldest form of protection, containing a metal wire that melts when excessive current flows. While inexpensive and reliable, they must be replaced after each fault.

Applications: Domestic panels, transformers, automotive systems.

3.2. Circuit Breakers (MCB, MCCB, ACB, VCB)

These are automatic switches that trip when a fault is detected. Unlike fuses, circuit breakers can be reset after operation.

MCB (Miniature Circuit Breaker): Protects against overload and short circuits in low-current circuits.

MCCB (Molded Case Circuit Breaker): Suitable for higher power ratings; includes adjustable trip settings.

ACB (Air Circuit Breaker): Used in LV distribution systems.

VCB (Vacuum Circuit Breaker): Common in medium-voltage systems.

3.3. Residual Current Devices (RCDs) / RCCBs

Detect earth leakage faults and protect against electric shock by sensing imbalance between live and neutral conductors.

Applications: Residential buildings, hospitals, and public spaces.

3.4. Surge Protection Devices (SPDs)

Protect systems from transient over voltages caused by lightning strikes or power switching.

Modern Trend: Tiered surge protection (Type 1, 2, and 3 SPDs) in smart grids and renewable systems.

3.5. Overload and Thermal Relays

Used primarily in motor circuits to protect against sustained overloads that cause overheating.

3.6. Electronic Circuit Protection

Solid-state devices like PTC thermistors, TVS diodes, and electronic circuit breakers are widely used in digital electronics and PCB-level protection.

4. Latest Trends in Circuit Protection

4.1. Smart and IoT-Enabled Protection

Circuit breakers are now integrated with IoT platforms, offering real-time diagnostics, remote monitoring, and predictive maintenance.

Example: Smart MCCBs and ACBs that alert operators before failure occurs.

Application: Industrial 4.0 plants, smart homes, critical infrastructure.

4.2. Arc Fault Detection Devices (AFDD)

AFDDs detect dangerous arc faults that traditional breakers miss, especially in aging wiring systems. Now mandated in some international electrical codes.

4.3. Integration with Energy Management Systems

Modern protection devices communicate with Building Management Systems (BMS) and Energy Management Systems (EMS) to optimize loads, reduce energy loss, and monitor system health.

4.4. Modular and Compact Designs

With space being a premium in panels, devices are now designed to be more modular, compact, and DIN-rail mountable without compromising performance.

5. Circuit Protection in Key Sectors

Industrial Sector

Protection devices are essential in high-load, high-risk environments. Motor control centers (MCCs), power distribution units (PDUs), and automation lines heavily rely on MCCBs, overload relays, and SPDs.

Data Centers

Uninterrupted power and quick fault isolation are mission-critical. Here, selective coordination using advanced circuit breakers ensures fault isolation without total shutdown.

Renewable Energy Systems

Solar PV and wind energy systems require specialized protection like DC fuses, DC MCBs, and SPDs to handle fluctuating currents and external conditions.

EV Charging Infrastructure

As EV adoption grows, protection against earth faults, surges, and over currents becomes vital. Type B RCDs and DC-rated breakers are commonly used.

6. Best Practices for Effective Circuit Protection

Conduct regular audits to ensure protection is aligned with system changes.

Use coordinated protection schemes to prevent nuisance tripping.

Integrate remote monitoring tools for predictive fault management.

Comply with international standards (e.g., IEC 60947, UL 489, NEC 2023).

Choose quality over cost — premium devices reduce long-term risks.

7. The Future of Circuit Protection

The evolution of circuit protection is moving toward autonomous fault detection, AI-driven diagnostics, and energy-efficiency synergy. Innovations like self-healing circuits and blockchain-based energy fault logging are already being piloted in smart grids.

As the electrical landscape becomes more digitized and decentralized, circuit protection will no longer be an afterthought — it will be the foundation of resilient, future-ready electrical systems.

Conclusion

Circuit protection devices are the unsung heroes of modern electrical infrastructure. They provide the foundation for safe, stable, and efficient operation in a world increasingly dependent on continuous power. As systems evolve, so must our approach to protection — prioritizing intelligence, integration, and innovation.

Whether you’re designing an industrial panel, a residential smart home, or a utility-scale solar farm, investing in modern circuit protection isn’t optional — it’s essential.

#electrical#electrical equipment#electrical supplies#dubai#united arab emirates#circuit breaker#flexible circuit board

1 note

·

View note

Text

Durable Metal Clad PCBs for High-Efficiency Thermal and Electrical Performance

In industries where thermal management, durability, and high electrical performance are non-negotiable, metal clad PCBs have become a top choice. ASC International offers top-tier metal clad PCB solutions designed to deliver exceptional thermal conductivity, mechanical strength, and electrical reliability. Whether you're designing for automotive, industrial, or high-power applications, our metal clad PCBs ensure your products can handle the most demanding environments.

What is a Metal Clad PCB?

A metal clad PCB integrates a metal base, typically aluminum or copper, into the standard PCB design. This metal base serves as an efficient heat sink, transferring heat away from the components to prevent overheating and damage. Unlike conventional PCBs that use fiberglass or composite materials, metal clad PCBs use a dielectric layer between the metal base and the copper layer to ensure electrical isolation while still allowing for optimal thermal dissipation.

The result is a robust circuit board that offers not only excellent heat management but also superior mechanical strength and electrical performance.

Why Metal Clad PCBs Are Essential

The primary reason metal clad PCBs are chosen for specific applications is their ability to manage heat efficiently. Here’s why metal clad PCBs are essential:

Efficient Thermal Dissipation: Metal core PCBs effectively transfer heat from high-power components, preventing overheating and extending the lifespan of electronics.

Mechanical Strength: The metal base adds an extra layer of mechanical durability, which helps prevent warping or bending that can occur in traditional PCBs.

Compact Design Flexibility: With superior heat management, designers can place components closer together, allowing for more compact and efficient circuit board designs.

Reliable Electrical Performance: Metal clad PCBs provide stable electrical performance with minimal signal interference, making them ideal for high-frequency or power-intensive applications.

Increased Product Lifespan: With better thermal management, the overall stress on components is reduced, leading to a longer and more reliable operational life for electronic devices.

Our Metal Clad PCB Solutions

At ASC International, we provide a diverse selection of metal clad PCB solutions to suit a variety of industries and applications:

Aluminum-Based Metal Clad PCBs: Known for their excellent thermal conductivity and lightweight properties, aluminum-based metal clad PCBs are the go-to choice for applications like LED lighting, automotive systems, and power supplies.

Copper-Based Metal Clad PCBs: For applications requiring higher thermal and electrical performance, copper-based PCBs are the ideal solution, offering superior conductivity and heat dissipation.

Multilayer Metal Clad PCBs: For complex designs with multiple layers, we offer multilayer metal clad PCBs that provide high-density circuit layouts while maintaining excellent thermal and mechanical properties.

Custom Metal Thickness Options: Tailor your metal clad PCB with different metal thicknesses to optimize the heat dissipation, mechanical strength, and flexibility required for your specific application.

Applications of Metal Clad PCBs

Due to their superior thermal and mechanical properties, metal clad PCBs are widely used in industries where heat management and durability are essential:

LED Lighting: Metal clad PCBs are crucial for LED applications, as they effectively manage the heat generated by high-power LEDs, ensuring optimal brightness and longevity.

Automotive Electronics: From engine control modules to safety systems, metal clad PCBs can withstand extreme temperatures and mechanical stress in automotive applications.

Power Electronics: Power supplies, inverters, and motor controllers rely on metal clad PCBs to handle high currents and dissipate the heat generated by power components.

Telecommunications Equipment: In communication infrastructure, metal clad PCBs maintain signal integrity and reduce heat buildup, ensuring stable and reliable operation.

Industrial Control Systems: Metal clad PCBs ensure that industrial equipment, automation systems, and control panels operate reliably under demanding conditions.

Why Choose ASC International for Metal Clad PCBs?

When it comes to high-quality metal clad PCB manufacturing, ASC International is a trusted partner. Here’s why:

Industry Expertise: With years of experience in PCB manufacturing, we specialize in delivering solutions tailored to your specific needs, ensuring that your designs are both efficient and reliable.

Precision Manufacturing: We use state-of-the-art equipment and processes to guarantee consistent quality, whether you require small runs for prototyping or large-scale production.

Custom Solutions: We work closely with our clients to provide custom metal clad PCB designs that meet exact specifications, including unique material, thickness, and layer configurations.

Quality Assurance: Our products undergo strict quality control tests, ensuring each metal clad PCB meets high standards for electrical performance, mechanical strength, and thermal management.

On-Time Delivery: We understand the importance of timelines and provide reliable delivery schedules to keep your project on track.

Get in Touch with ASC International

ASC International is here to help you with your metal clad PCB requirements. Whether you need a single-layer or multilayer PCB, aluminum or copper base, we offer tailored solutions to ensure your designs perform optimally in the real world.

Contact us today to learn more about our metal clad PCB offerings, get a quote, or discuss how our solutions can help improve the performance, durability, and efficiency of your products.

0 notes

Text

How Heat and Dust Are Silently Shortening the Life of Your Industrial LED Fixtures

Your lighting may look fine today—but hidden heat buildup could be killing it from the inside out.

Most industrial facility managers don’t realize their LED systems are being degraded by two common environmental enemies: heat and dust. On their own, they’re a nuisance. Together, they’re a long-term threat to your lighting investment.

The Problem with Dust and Heat

Dust buildup creates an insulating layer over the fixture, especially on heat sinks. This causes:

Reduced cooling efficiency

Overheating of LED drivers and components

Accelerated color shift and lumen loss

Shorter fixture lifespan—up to 42% less

And when combined with high ambient temperatures, the effects multiply.

📉 Case Example: In 2024, over 710,600 high bays were recalled due to overheating issues, many of them operating in hot, dusty warehouse settings.

Why LED Design Matters

To combat heat and dust, smart design choices make all the difference:

Metal core PCBs help transfer heat away from sensitive components.

Convection-cooled fixtures allow passive airflow to do the work—no fans required.

Remote driver setups keep sensitive electronics out of hot zones.

Smooth finishes and sealed optics help reduce dust accumulation.

What You Can Do

Conduct regular visual and thermal inspections

Clean fixtures in dusty areas to restore cooling performance

Use lighting solutions with proven thermal engineering

Don’t overspec brightness if cooling can’t support it

Conclusion

Heat and dust may be silent—but their impact is loud and costly. Recognizing how these forces degrade your lighting is the first step. The second? Choosing fixtures built to survive and thrive in tough conditions.

🔗 Get lighting designed to outlast heat and dust at Tactik Lighting

1 note

·

View note

Text

Application and Design Essentials of Fuse Holders in Modern Automotive Electronic Systems

I. Introduction

As automotive electronics and intelligence advance, vehicle electrical systems are evolving from traditional 12 V low-voltage networks toward 48 V mild-hybrid and higher-voltage architectures. As core circuit-protection and isolation components, fuse holders must not only handle high currents and short-circuit capacities but also withstand severe mechanical shocks, electromagnetic interference, and harsh environmental conditions. This article analyzes fuse-holder applications in automotive electronics from three perspectives—high-impact testing in 12 V/48 V systems, electromagnetic compatibility (EMC), and water-proof ratings (IP 67/IP 69K)—and, through case examples, explores key design considerations and related technologies.

II. Challenges in 12 V and 48 V Systems

System Voltage and Current Levels 12 V systems: Traditional ICE vehicles’ main power rail, powering ignition, lighting, sensors, and body-control modules. Typical fuse ratings range from 5 A to 80 A. 48 V mild-hybrid systems: Widely adopted in recent mild-hybrid vehicles to support high-power motor starts, regenerative braking, and electric-assist steering. Peak currents can reach 200–300 A.

Short-Circuit Arc and Melting Characteristics When short-circuit currents spike to thousands of amperes, the fuse must melt in milliseconds while suppressing arc energy to protect adjacent components and the plastic housing. In 48 V systems, integrated metal-alloy fuse elements and fuse-holder designs are critical to rapidly form a melt point in a low-impedance path and isolate the arc.

High-Temperature Environment and Thermal Management Under-hood temperatures can exceed +110 °C. In 48 V circuits, sustained high currents generate significant heat. Both structural and material choices must balance heat resistance and conductivity.

III. High-Impact and Vibration Testing

1. Standards and Test Requirements

ISO 16750-3 “Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 3: Mechanical loads” Shock tests: Half-sine pulses (e.g., 100 g, 18 ms) and full-vehicle collision simulations (e.g., 30 g, 6 ms multiple pulses). Vibration tests: Random vibration (5 Hz–2 kHz, peak 10 g) and sine sweep (10 Hz–500 Hz).

USP 7637-2 Transient Electrical Pulse (Electrical Surge) Testing Simulates line short-circuit or load disconnection over-voltage pulses on fuse-holder contacts.

2. Design Considerations and Examples

Housing and Pin Retention Use threaded locks or clip-style metal inserts to prevent pin loosening under ±100 g shocks. Example: A premium ECU fuse holder uses an integrated φ2 mm stainless-steel insert molded into the plastic housing; after six-axis shock testing, contact resistance changes by <2 mΩ.

Spring Preload and Contact Stability Spring material: nickel-plated chromium stainless steel (CTE ≈13 ×10⁻⁶/K), validated via 500 h creep test at 150 °C. By tuning wire diameter and coil count, insertion/extraction force remains constant under vibration, maintaining contact-resistance stability within ±5%.

Base and Support Structures Add alignment posts and support pillars on the PCB or metal bracket to share shock loads and prevent the fuse holder from separating under impact. Example: A 48 V starter-motor fuse module passed 72 h of 3 g sine vibration (10 Hz–100 Hz) with no solder-joint failures or housing cracks.

IV. Electromagnetic Compatibility (EMC) Design

1. Main Interference Types

Radiated Emission: High dI/dt during fuse melting induces electromagnetic noise in nearby metal structures.

Conducted Emission: Short-circuit or melt pulses can inject noise back into the vehicle power distribution network.

Immunity: Must withstand ISO 11452 (antenna-injection) and ISO 7637 (surge/transient) requirements.

2. Design Strategies and Examples

Shielding and Grounding Metallize the fuse-holder housing or line a module interior with tin-plated copper foil to ensure a robust flange-to-ground connection. Example: A body-control-module fuse holder with an inner copper-plated shell achieves grounding resistance <5 mΩ, reducing radiated emission by 8 dB.

Filtering and Arc Suppression Integrate miniaturized LC filters or clamping diodes within the holder to tame short-circuit transients. In 48 V high-current holders, combine multilayer ceramic capacitors and large-value inductors to suppress differential and common-mode noise from 1 MHz to 30 MHz.

Material Selection Choose UL 94 V-0 plastics and low-dielectric-loss materials (e.g., LCP) to limit high-frequency coupling. Use high-temperature, flame-retardant plastics loaded with ferrite particles for EMI absorption and mechanical strength.

V. Water-Proofing and Dust-Proofing: IP 67/IP 69K

1. Rating Definitions

IP 67: Dust-tight; immersion up to 1 m for 30 min.

IP 69K: High-temperature, high-pressure spray (80 °C, 8–10 MPa), simulating under-hood cleaning procedures.

2. Structural and Sealing Designs

Silicone O-Ring and Gasket Grooves Design U-grooves at the cover–base interface to house high-temperature silicone O-rings (–40 °C to +200 °C rated). Example: An engine-compartment fuse holder with dual-O-ring U-grooves passed 100 cycles of 80 °C high-pressure water spray with zero ingress.

Overmolded, Monolithic Construction Overmold fuse terminals directly in plastic, eliminating assembly interfaces and extra seals. Materials: LCP with flame-retardant additives reduces joint count and boosts IP 69K reliability.

Self-Sealing Wire Connectors Use waterproof contact caps or integrated cone seals at the wire-harness interface to ensure end-to-end protection from the holder through the harness.

VI. Additional Features and Future Trends

Intelligent Monitoring Integrate Hall-effect current and temperature sensors with CAN/LIN interfaces to stream real-time melt events, overcurrent warnings, and historical logs to the vehicle network.

Modularity and Serviceability Develop 12 V/48 V hybrid modules allowing swift fuse-holder replacement without swapping entire distribution boxes.

New Materials and Miniaturization Graphene-enhanced composites and high-thermal-conductivity ceramics will enable higher current density and lighter fuse-holder designs.