#mlc lvdh

Explore tagged Tumblr posts

Text

High Viscosity in Lubrication: Benefits, Applications & Best Practices

Introduction to High Viscosity

Viscosity is the most crucial property of a lubricant, defining how well it performs under different operating conditions. It determines a lubricant’s ability to flow, resist shear, and provide an effective lubrication film between moving parts.

In many industrial applications, high-viscosity lubricants are essential for ensuring: ✔ Reduced friction and wear ✔ Better load-bearing performance ✔ Protection against extreme pressure and heat

High-viscosity oils and greases are widely used in heavy-duty machinery, particularly in gearboxes, bearings, turbines, and hydraulic systems that operate under extreme loads and harsh conditions. Understanding how viscosity impacts lubrication is crucial to maintaining machinery efficiency and longevity.

The Science Behind Viscosity in Lubrication

What is Viscosity?

Viscosity is the measure of a fluid’s resistance to flow. In simpler terms:

Low-viscosity oils flow easily and are suitable for high-speed machinery.

High-viscosity oils are thicker, providing better lubrication film strength and wear resistance.

The Viscosity Index determines how much a lubricant’s viscosity changes with temperature. A high viscosity index lubricant maintains stability across temperature variations, making it suitable for extreme environments.

The Role of Viscosity in High-Velocity Applications

Kinematic Viscosity vs. Dynamic Viscosity

Viscosity is a critical property that affects high-velocity lubrication. There are two primary types:

Kinematic viscosity measures how a fluid resists motion under gravitational forces. It is vital in fluid flow studies.

Dynamic viscosity refers to a fluid’s resistance to shear stress, influencing drag and aerodynamic behavior.

Reynolds Number and Its Influence on High Velocity

The Reynolds number determines whether fluid flow is laminar or turbulent. It is a dimensionless quantity used to predict flow patterns at different velocities.

Efficient fluid dynamics

Reduced turbulence

Lower energy loss due to drag

Impact on Fluid Flow and Fluid Dynamics

In high-velocity lubrication, selecting the right viscosity ensures minimal drag while maintaining a strong lubrication film. Low viscosity improves fluid flow, whereas higher dynamic viscosity enhances load-bearing capacity.

Why is High Viscosity Important?

In high-load, slow-speed applications, metal surfaces are under extreme stress. A high-viscosity lubricant prevents direct metal-to-metal contact, reducing friction, wear, and energy loss.

Key Benefits of High-Viscosity Lubricants

1. Improved Wear Protection

High-viscosity lubricants form a thicker protective layer, minimizing wear on components like gears, bearings, and hydraulic pistons. This ensures longer machine life and reduced maintenance costs.

12. Superior Load-Carrying Capacity

Industrial machinery often experiences heavy shock loads. High-viscosity gear oils and EP (Extreme Pressure) greases prevent breakdown under high stress, maintaining smooth operation even in harsh conditions.

3. Stronger Lubrication Film

A high-viscosity lubricant maintains a robust oil film, preventing surface fatigue and scuffing in applications like wind turbine gearboxes, mining equipment, and steel mills.

4. Resistance to Extreme Conditions

Industries like power generation, construction, and metallurgy expose lubricants to high temperatures, pressure, and contaminants. High-viscosity synthetic oils resist thermal degradation, oxidation, and sludge formation, ensuring optimal performance.

Applications of High-Viscosity Lubricants

1. Industrial Gearboxes

Gearboxes operate under high torque and continuous load, requiring high-viscosity gear oils to:

Prevent gear tooth wear

Reduce micro pitting and scuffing

Ensure efficient power transmission

2. Heavy-Duty Bearings

High-viscosity greases are essential for slow-moving, high-load bearings found in:

Steel plants

Mining conveyors

Cement kilns

These lubricants provide superior adhesion, reducing bearing failures and replacement costs.

3. High-Temperature Equipment

In power plants, refineries, and aerospace applications, machinery operates at extreme temperatures. Synthetic high-viscosity oils prevent:

Thermal breakdown

Sludge formation

Oxidation-related failures

4. Slow-Speed Machinery

For applications like open gears, worm gears, and heavy presses, high-viscosity lubricants improve:

Film thickness to prevent metal-to-metal contact

Load distribution to reduce stress concentration

Challenges of High-Viscosity Lubrication

Despite their benefits, high-viscosity lubricants have some challenges:

1. Energy Efficiency Concerns

Thicker oils increase fluid resistance, leading to higher energy consumption in hydraulic and circulation systems.

2. Cold-Start Issues

In low temperatures, high-viscosity lubricants become stiff, affecting:

Pump ability

Startup lubrication

Oil circulation

Solution:Use multi-grade or synthetic oils that provide better cold-flow properties.

How to Select the Right High-Viscosity Lubricant

Choosing the correct viscosity is critical for optimal machinery performance. Consider these key factors:1. Operating TemperatureFor high temperatures: Choose a high-viscosity index lubricant to prevent thinning.For cold environments: Use synthetic lubricants for better flowability. 2. Load and Speed ConditionsHigh load, slow speed: Require higher viscosity for better film strength.Low load, high speed: Need lower viscosity to reduce frictional losses. 3. Manufacturer RecommendationsAlways refer to OEM (Original Equipment Manufacturer) guidelines for optimal performance. 4. Lubricant AdditivesLook for:Anti-wear (AW) additives for reducing frictionExtreme Pressure (EP) additives for heavy loadsOxidation inhibitors to enhance lubricant life

Conclusion

High-viscosity lubricants play a crucial role in protecting industrial machinery, extending service life, and enhancing performance. They offer better film strength, wear resistance, and thermal stability, making them ideal for gearboxes, bearings, and heavy-duty applications. However, selecting the right viscosity grade is key to balancing energy efficiency and lubrication performance. Industries must consider operating conditions, manufacturer recommendations, and additive formulations to achieve optimal equipment reliability. For expert guidance on high-viscosity lubrication solutions, consult with a professional lubrication specialist today! For More Information - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing systems#lube oil flushing#lubeoil#chemcial cleaning#transformer oil filtration#oil filtration systems#oil purification system#oil purification machine#mlc lvdh#lvdh full form#lvdh#low vacuum dehydrations'#tofs#bdv#testing kit#oil testings#oil testing

0 notes

Text

Lubrication: Uses, Functions, Properties, and Maintenance

Introduction to Lubrication

Importance of Lubrication in Industrial Applications

Industries heavily rely on lubrication to enhance equipment performance. Some critical lubrication uses include:

Automotive Industry: The engine lubrication system ensures smooth operation, reduces engine wear, and prevents overheating.

Manufacturing Sector: Lubrication oil plays a pivotal role in reducing friction in CNC machines, conveyors, and robotic arms.

Mining and Construction: Heavy-duty lubrication types protect machinery from extreme temperature variations and harsh environments.

Power Plants: Lubrication systems ensure the longevity of turbines, generators, and compressors by preventing excessive wear.

Food and Beverage Industry: Specialized food-grade lubricants are used to ensure equipment hygiene and compliance with safety standards.

Understanding the diverse uses of lubrication enables industries to improve efficiency and extend equipment lifespan.

Key Functions of Lubrication

Lubrication performs multiple essential functions that contribute to machinery longevity and reliability:

Reduction of Friction and Wear: Creates a protective layer between surfaces to minimize direct metal-to-metal contact.

Heat Dissipation: Transfers heat away from friction points, preventing component failures.

Contaminant Removal: Lubrication oil acts as a medium to carry away dirt, dust, and metal shavings.

Corrosion and Oxidation Prevention: Lubricants contain additives that prevent rust and oxidation, protecting machinery.

Shock Absorption: Helps cushion impact loads, particularly in high-speed or heavy-duty applications.

Different Lubrication Types and Their Applications

Lubrication can be classified into various types, each suited to specific operating conditions:

Hydrodynamic Lubrication: A continuous fluid film separates moving surfaces, commonly found in bearings and gears.

Boundary Lubrication: A thin lubricant film prevents direct contact, often occurring in stop-start conditions or low-speed machinery.

Mixed Lubrication: A combination of hydrodynamic and boundary lubrication, suitable for gearboxes and automotive engines.

Elastohydrodynamic Lubrication: Found in rolling-element bearings, where high pressure causes temporary lubricant thickening.

Solid Lubrication: Utilizes materials like graphite and molybdenum disulfide for extreme environments where liquid lubricants are unsuitable.

Selecting the right lubrication type is crucial for achieving optimal performance and reducing maintenance costs.

Essential Lubrication Properties for Optimal Performance

The effectiveness of a lubricant depends on its fundamental properties:

Viscosity: Determines the flow characteristics and film strength under varying temperatures and loads.

Thermal Stability: Ensures that the lubricant does not degrade under high-temperature conditions.

Oxidation Resistance: Prevents sludge and varnish formation, extending lubricant service life.

Load-Carrying Capacity: This enables the lubricant to withstand extreme pressures without breaking down.

Water Resistance: Prevents emulsification and ensures effective separation in wet environments.

These lubrication properties dictate the overall efficiency and durability of machinery.

Understanding Lubrication Systems and Their Mechanism

A lubrication system ensures the efficient delivery of lubrication oil to machine components. Common lubrication systems include:

Manual Lubrication: Involves periodic application using grease guns or oil cans.

Automatic Lubrication Systems: Distribute lubricants continuously, reducing downtime and maintenance efforts.

Splash Lubrication: Relies on rotating components to distribute lubricant in gearboxes.

Forced Lubrication Systems: Utilize pumps to circulate oil under pressure, ensuring consistent lubrication.

Selecting the right lubrication system enhances equipment reliability and reduces operational costs.

Engine Lubrication System: A Vital Component for Efficiency

The engine lubrication system plays a crucial role in vehicle performance:

Provides continuous lubrication to reduce friction and wear.

Cools engine components by dissipating excess heat.

Cleans the engine by removing contaminants and metal debris.

Prevents corrosion and oxidation, extending engine lifespan.

Regular maintenance of the engine lubrication system is essential for preventing costly failures and ensuring optimal vehicle performance.

Lubrication Maintenance Strategies for Equipment Longevity

Implementing proactive lubrication maintenance practices helps prevent machinery breakdowns. Essential maintenance steps include:

Using the Correct Lubricant: Ensure compatibility with manufacturer recommendations.

Monitoring Lubricant Contamination: Regularly check for dirt, water ingress, and degradation.

Establishing a Lubrication Schedule: Follow a preventive maintenance plan to avoid failures.

Employing Oil Analysis: Use condition monitoring techniques to detect early signs of wear.

Applying the Right Quantity: Avoid over-lubrication or under-lubrication, both of which can cause damage.

Common Lubrication Problems and Solutions

Industries often face lubrication challenges that impact performance:

Contaminated Lubricants: Regular oil analysis helps detect impurities and improve filtration.

Incorrect Viscosity: Choosing the right viscosity prevents excessive wear and overheating.

Poor Lubricant Selection: Matching lubrication oil to application needs ensures reliability.

Inadequate Lubrication Practices: Proper training and monitoring improve lubrication effectiveness.

Addressing these challenges ensures long-term equipment reliability.

Conclusion

Lubrication is an essential aspect of industrial maintenance, reducing friction, preventing wear, and ensuring machinery longevity. Understanding lubrication types, properties, and maintenance strategies helps industries optimize operations and minimize downtime.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#lube oil filter#hydraulic oil#contamination#hydraulic oil filter#oil testing#oil filters#oil industry#oil and gas#flushing systems#flushing#oil purification machine#mlc lvdh#lvdh full form#frf condition systems#condition monitioring#oil condition#bdv

0 notes

Text

Preserving 35 kL of Prime 46 Oil from Solid and Moisture Impurities

Minimac Rescues Bihar Power Station : Customized Solution for Solid Contamination and Moisture Wins.

Synopsis

In Begusarai, Bihar, a 720 MW coal-fired power station owned by a major PSU recently faced high Solid Contamination and Moisture Levels in two tanks each with 115 MW power potential. To avert disruption, Minimac provided a customized solution, deploying a specialized machine to lower NAS levels and address moisture and solid contamination saving the plant from a potential failure.

Initial Findings

The power plant's poor operational condition had resulted in the oil degrading to its maximum limit, physical inspection revealed highly contaminated oil with various unwanted contaminants such as sludge, metal parts, insects, dirt, etc.

Problems

Two primary lubrication oil tanks, each with a substantial 115 MW power potential, experienced significant contamination from solids and moisture. Utilizing the contaminated oil to initiate the turbine posed a critical risk of tripping the overall system, leading to potential catastrophic failures.

Client’s Requirement

To Purify 15 kL & 20 kL of Prime 46 Oil from the respective tanks.

To remove Moisture and Solid Contaminants.

To Achieve NAS ≤ Class 8.

To Achieve Moisture ≤ 500 PPM.

Customized Solution.

Solutions

Deploying Minimac’s customized machine at the site along with trained and skilled engineers.

Oil filtration system(150 LPM & 200 LPM) to bring the NAS level of oil to the desired range.

Low Vacuum Dehydrator (100 LPM) to maintain consistent moisture levels in the oil using the vacuum dehydration ensuring smooth turbine operation in its active state.

Our Service Engineer installed the equipment and provided training on its operation and effective handling to the client's team.

Job executed within a limited time-span on the running unit without hindering the client’s operations and oil tanks.

Value TypeOil Tank under UNIT 7 (15kL)Oil Tank under UNIT 8 (20kL)BeforeAfterBeforeAfterNASClass 12Class 8Class 12Class 8Moisture Level13000 PPM64 PPM700 PPM42 PPM

Cost Saving

This plant managed to save:

Cost of Oil Replacement: ₹75 Lakhs. Approx

Cost of Downtime: ₹1 Cr. Approx

CO2 e Saving

4,20,000 kg of CO2 e / 0.42 gigagrams of CO2 e

Benefits

Prevented the environment from harm by averting the emission of 4,20,000 kg of CO2e.

Saved 35 kL of Oil from being incinerated.

Extended Oil Life.

Reduced NAS & Moisture Levels.

Elimination of Oil Replacement Costs.

Task Successfully performed without any shut downs and in a limited amount of time.

No Accidents/ Spillage.

HSE Norms Fulfilled Diligently.

Abbreviations Used

kL : kilolitre

kg : kilogram

MW : Megawatt

NAS : National Aerospace Standard

LPM : Litres Per Minute

PPM : Parts Per Million

HSE : Health, Safety & Environment

Oil Visuals : Before & After

Filter Visuals : Before

Strainer Conditions Before Filtration Filter Visuals : After

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#chemical cleaning flushing#chemical flushing#chemical cleaning#lube oil flushing systems#lube oil flushing#lubeoil#transformer oil filtration#oil filtration#oil filtration systems#oil filtration machine#oil dehyration#oil dehydration systems#lvdh full form#lvdh#mlc lvdh#frf condition systems#frf machine#condition monitioring#oil condition monitoring#oil cleaning machine

0 notes

Text

Oil reconditioning project for India’s largest coal-based power producer

Team Minimac successfully executed a critical project to recondition the control fluid (two tanks of capacity 16 kiloliter each) for India’s largest energy conglomerate and coal-based power producer with a capacity of 4760 MW.

Synopsis

The plant was built and is in service as a thermal power generating station, in Vindhyachal. There was a problem with higher Total Acid Numbers (TAN), observed typically when moisture content exceeds the permissible range. They were facing difficulties in stable unit operation because of the sluggish and erratic behavior of the turbine governing system. It was a significant threat to unit outage and generation loss. The situation was examined by Minimac Operations and Maintenance Service (MOMS). Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL was deployed to address the issue.

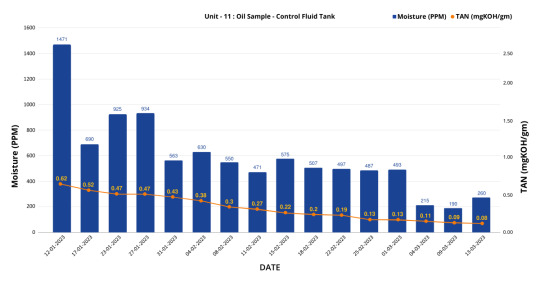

Before Oil purification, the TAN value was≥ 0.62 mgKOH/gm, NAS ≥ 8, and Moisture ≥ 1471 PPM. After Oil purification, the recorded parameters were TAN value = 0.08 mgKOH/gm, NAS ≤ 4, and Moisture ≤ 260 PPM. The major challenge faced during the execution was if we charged resin, TAN would reduce, but moisture would increase. So, an analysis was done and implemented to control the moisture first, then charged the second resin cycle. Minimac gave a 100% customized and balanced solution within time.

Problems

The tank capacity was 16 kiloliters, which is huge. The biggest challenge was to execute the project while the system was in operation. Water contamination bubbles were forming, leading to the fluctuation in NAS - as for moisture control, it was necessary to turn off the system. Resin charge in Ion exchange was done intermittently to control moisture increase, and our motto was to hold moisture below 500 PPM so we could plan for the next cycle of resin charge.

Client’s Requirement

To purify the control fluid.

To reduce the TAN value from 0.62 to < 0.10 mgKOH/gm.

To bring down the moisture level < 500 PPM.

To achieve NAS < 5.

Smooth and timely execution without any downtime.

Tailor-made solution.

No oil loss because of processing or spillage.

Solutions

Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL for NAS & moisture reduction was installed.

Before the oil conditioning process, the TAN ≥ 0.62 mgKOH/gm, which was reduced after oil purification to TAN ≤ 0.08 mgKOH/gm.

The Nitrogen generation unit (TMR 100) was deployed and installed at the client’s site.

For further improvement in TAN, the oil vapor extraction fan (OVEF) was throttled in the range of 70%, with the support of the user.

Minimac provided trained manpower and other consumables under the MOMS (Minimac Operations and Maintenance Service) offering. Minimac had given results far better than the KPIs.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹ 3.2Cr. approx/ $ 32 Million approx

Cost of downtime: ₹ 3.15 Cr. approx/ $ 31.5 Million approx

By investing ₹ 21 lakh approx/ $ 25.65k approx only.

CO2 e Saving

1,92,000 kg of CO2 e / 0.192 gigagrams of CO2 e

Benefits

Extended in-service oil life.

The smooth functioning of the machines.

Elimination of new oil replacement cost.

Avoiding the risk of fire and explosion.

Reduction in the possibility of product degradation due to blanketing.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#lube oil flushing#lube oil#chemical flushing#oil and gas#metal#mining#oil filtration system#transformation oil purification#transformer oil#transformer oil cleaning#transformer oil filtration#transformers#oil purification system#oil purification machine#oil purification system#oil purification#oil dehydration systems#mlc lvdh#lvdh full form#lvdh

0 notes

Text

PE fluid reconditioning in turbine EHC system

A 1,320 MW (2 x 660 MW), one of the first and largest supercritical coal-fired power plants using Indo-Chinese turbine EHC system in northern India

Synopsis

The plant was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine. Moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system resulting in by-product formation.

Problems

Degradation of EH oil properties at both the units of the plant.

The installed regeneration system for each EHGC tank of unit #1 and #2 was failing to control neutralization number (TAN value) and showing a rapid increase in the same

The company was unaware of the consequences of increased TAN values like possibilities of failure of servo valve, hunting, power generation loss, unplanned shutdown, etc

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

Remove solid contamination from oil by Superfine filtration

Remove moisture from oil by vacuum Dehydration technology

Reduce Total Acid Number (TAN) by Ion exchange technique.

EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer trained the customer’s team on the functions of the EH oil re-conditioner, FRF maintenance, contamination control, and importance of the oil analysis program.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹78 Lakh approx.

Cost of downtime: ₹5.6 Cr approx

CO2 e Saving

14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e.

Benefits

Extending oil life.

Eliminate oil Replacement cost.

Protect Turbine against hunting.

Increased Turbine reliability.

Subscribe to our Whats App Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#coalescer separator#oil dehydration systems#lvdh full form#mlc lvdh#transformer oil filtration#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#oil filtration#oil filtration system#oil filteration#oil filtration machine#oil filtration systems#oil contamination#frf condition systems#diesel oil purification#hydraulic oil cleaning#chemical cleaning

0 notes

Text

Reconditioning of EH oil

A power plant in western India using chinese technology turbine EHC system saved 3.01 Cr approx. with MLC LVDH TRIX-20 EH oil filtration

Synopsis

A power plant (2 x 600 MW) in western region of India was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine and moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system and resulting into formation of by-products.

Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20 “act as saviour for the plant which has escaped the unexpected shutdown of the turbine worth 2.8 Cr (approx. 48 hours downtime) and cost & effort for replacement of oil worth 21 lakhs.

Problems

Failure of servo valve, hunting and sluggish behavior of the turbine, unplanned shutdown, presence of varnish & silt in the clearance of the spool, high TAN value leading to electro kinetic erosion of line and accessories of EHC system, ingression of particle & moisture contamination…… Ultimately all resulting to GENERATION LOSS & REVENUE LOSS

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

Remove solid contamination from oil by Superfine filtration

Remove moisture from oil by vacuum Dehydration technology

Remove Total Acid Number (TAN) by Ion exchange technique.

EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer has trained the customer’s team on the function of the EH oil Re-Conditioner, FRF maintenance and contamination control, Importance of Oil Analysis Program.

Benefits

Extending oil life.

Reduced TAN value.

Eliminate oil Replacement cost.

Protect Turbine against hunting.

Increased Turbine availability & reliability.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹21 Lakh approx.

Cost of downtime: ₹2.8 Cr approx

CO2 e Saving

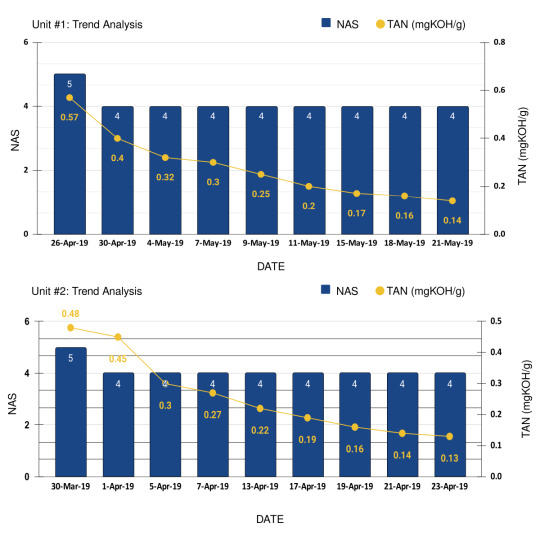

Above graph shows the trend analysis of NAS 1638, moisture and TAN value around one-month installation of the reconditioning of EH oil at customer site.

Consumable required to finish this reconditioning of EH oil having quantity of 1200 liters are: 01 quantity of 10 micron and 03-micron filter element. Total consumption of resin was 36 liters

Subscribe to our YouTube Channel and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil dehyration#oil contamination#electrostatics lube cleaner#electrostatic discharge protection#chemcal cleaning#lube oil flushing#lube oil#hydraulic oil cleaning#hydraulic oil machine#hydraulic oil filter#tan reduction#tan#mlc lvdh#lvdh full form#lvdh#transformer oil#transformation oil purification#transformers#transformation

0 notes

Text

Lube oil checks and recommended testing kits

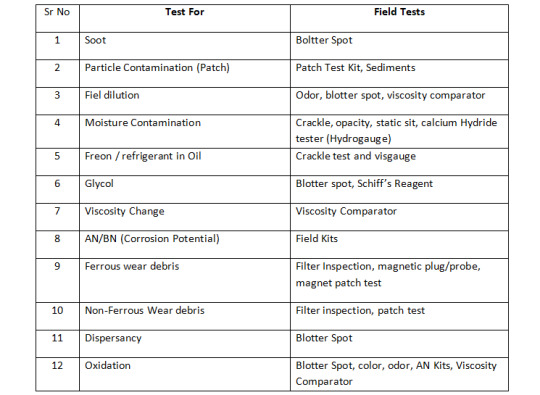

For field inspection of lube oils, the following points are important to take action:

Basic tests for lube oils are to observe the oil in glass sample bottle for colour inspection.

If you observe that colour of lube oils is milky or dark in shade, then you have to process for further testing with hand held testing kits which are easy for use at the site.

Following are the testing kits which can be used at the site for checking lube oil:

Millipore Patch Testing Kit – This testing kit is useful for measuring contamination in oil as per NAS/ISO by observing the patch paper with microscope. This is a very basic test to know if oil is contaminated or clean. This is a portable patch testing kit and easy to handle everywhere at the site.

Hydrogauge Oil Test Kit – It is used for checking moisture or water contamination in oil by adding a 10 ml sample in 2 types of different reagents. This is also an offline & portable testing kit which shows results approximately and at very low cost.

Visgauge Oil Test Kit – This kit is useful for checking the viscosity of oils from 0 to 460 ranges of oils. This testing kit is portable and easy to use.

Online Laser Particle Counter – This is an online contamination monitor which is useful for checking oil contamination in NAS, ISO format with particle distributions in 8 Nos of channels. You can connect this particle counter with a pipeline or any external oil filtration system with the help of the provision of minimize hoses and the particle counter has an LED screen to show results.

Portable Online Laser Particle Counter – This is a portable online contamination monitor which is useful for checking oil contamination in NAS, ISO format with particle distributions in 8 Nos of channels. This particle counter is able to check NAS values for multiple types of samples or multiple machines. It can be connected with pipeline or any external oil filtration system with the provision of minimize hoses and the particle counter has an LED Screen to show results.

Following are some Easy Field Tests and Inspections –

Also read: https://www.linkedin.com/pulse/importance-inventory-management-anshuman-agrawal-mlt-1-/

Minimac focuses on lubrication reliability and contamination control - Doctor's for your machine! Call +91 7030901266 for Condition Monitoring.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#lube oil#frf condition systems#condition monitioring#oil condition monitoring#oil contamination#oil dehyration#mlc lvdh#tranformers#transformer oil cleaning#electrostatics lube cleaner#coalser separator#diesel oil purification#chemical cleaning

0 notes

Text

Standards of turbine oil

A) BSI (British Standards) – BSI BS 489:1999: Specification For Turbine Lubricants.

B) DIN (German Institute for Standardization DIN 51515-1, 51515-2: This document specifies minimum requirements for oils for high thermal stress (high-temperature service) in turbines.

C) ABB (ABB Group) ABB G12106: Ultra-clean turbine oil, Long-life, Rust & Oxidation-inhibited circulating oil.

D) ASTM International – ASTM D4304: Define the properties of the mineral and synthetic oil-based turbine lubricating oils that are functionally interchangeable with existing oils of this type, are compatible with most existing machinery components, and with appropriate field maintenance, will maintain their functionality.

E) GE (General Electric) GE: GEK-32568: Lubricating Oil Recommendations for Gas Turbines With Bearing Ambients above 500°F (260°C)

Also Read: https://www.linkedin.com/pulse/mandatory-properties-steam-gas-turbine-oil-anshuman-agrawal-mlt-1-/

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil analysis#oil filters#oil industry#oil and gas#oil#oil purification system#oil purification system#oil purification#oil contamination#mlc lvdh#lvdh full form#lvdh#mlc#transformer oil filtration#oil filtration machine#oil filtration systems#oil dehyration#electrostatics lube cleaner#transformer oil#transformers

0 notes

Text

Temporary power connection do's and don'ts

Do’s :

Ensure taking a work permit from the site in charge and conduct a Tool Box Talk.

All electrical jobs to be conducted by a certified electrician.

Ensure all the equipment is flameproof.

Equipment that operates in three-phase power should have double neutral earthing.

The use of an Earth-leakage circuit breaker is a must for all the equipment.

The current rating for all equipment should not be greater than 30Amps.

Ensure use of proper rating Direct On Line Motor Starter in individual machines.

Ensure use of proper armored cables for the main power connection.

If there are cable lying on the road crossings or pathways should be covered and concealed to protect them from physical damage.

Cables without any joints should be used at all times.

Cables should be laid above the ground to the maximum possible extend.

Electrical connections should be kept clean, dry, and tight at all times.

Ensure all power supplies are switched off from the feeder pillar immediately if the equipment is not in use on a daily basis.

Maintenance person should be informed after completing the job if there is no requirement for the temporary power.

Don’ts :

Don’t use power supply above 24 V inside confined spaces.

Do not lay the unarmored cable on the ground

Do not twist and carry connections between two cables.

Do not keep a temporary feeder pillar near water.

Do not sublet any temporary connection to another contractor.

Do not increase the load without informing the electrical maintenance department for a temporary power supply.

Do not allow an unauthorized electrical person on the job location.

Also Read: https://www.linkedin.com/pulse/myths-facts-what-do-you-believe-anshuman-agrawal-mlt-1-

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#frf#oil flushing#minimac systems#power#oil & gas#hydraulic oil#lube oil filter#minimac#contamination#hydraulic oil filter#lube oil#transformation oil purification#transformers#lvdh full form#mlc lvdh#oil condition monitoring#oil contamination#minimac flushing systems#maintanance#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#mechanical maintance#oil dehydration systems#frf condition systems#electrostatics lube cleaner#coalser separator

1 note

·

View note

Text

Importance of inventory management

Product labeling can be used to identify the following:

Purchase & Delivery Date: Label should mention the date of the purchase & delivery date of lubricants.

Product Name: It should also mention product name, brand, manufacturer

Quantity: It should also mention the quantity.

Storage Location: It should also mention the storage location of the lubricants. The products should be used in the same sequence as they are brought into inventory.

(1) FIFO: First in first out- lubricants should be taken into usage according to the date they are brought into the storage house.

We can enhance the life of plant and machinery through proper maintenance, storage, marking of lubricants.

Also read: https://www.linkedin.com/pulse/storage-management-oil-products-its-importance-agrawal-mlt-1-/

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#frf#oil flushing#minimac systems#power#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#minimac#condition monitioring#contamination control#lubeoil#mlc lvdh#mlc#lvdh full form#oil testings#oil condition monitoring#fire resistance fluid

0 notes

Text

Myths vs Facts

A. Lubricating industrial equipment is easy.

This a complete myth whereas the actual fact is lubricating is highly detailed and complex. Some of the important decisions that one needs to take are:

1. Selection of proper oil & Grease for a machine.

2. Right place, right frequency and right volume of lubricant to be applied.

3. Proper flushing of lubricant tanks to ensure contamination-free lubricating lines.

4. Also applying grease is also an art; too much or too little of it can damage or blow seals.

B. Minimal consequences and benefits are associated with routinely lubricating industrial equipment.

This is also another myth whereas it has been seen that most events of downtime occur due to inadequate lubrication or due to the use of the wrong lubricant. Though lubricants cost about 1-3% of our total maintenance budget improper or wrong lubrication can lead to machine downtime costing millions of dollars.

C. Lubrication is an unnecessary cost to the organization.

This is completely untrue as correct lubrication practices can actually bring down the cost of maintenance and can give ample opportunity to employ those funds for further development of the company. Also read - http://bit.ly/2Pq76hT

We at Minimac study your maintenance needs and provide the best customized solution.We believe in Discern, Design & Deliver.

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#minimac systems#oil flushing#power#frf#oil & gas#minimac#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#condition monitioring#transformation oil purification#chemical cleaning#lube oil#mechanical maintance#frf machine#oil purification machine#mlc lvdh#lvdh full form#oil testing#oil condition monitoring

0 notes

Text

Understanding the Pareto principle in terms of maintenance

In our previous segments, we have discussed several aspects of Lubricant contamination and ways to prevent or treat that contamination. But, as we all know that for every company the maintenance budget is limited so focusing on all the factors is not possible.

The Pareto Principle (also known as the 80/20 rule ) states that, for many events, roughly 80% of the effects come from 20% of the causes. In terms of maintenance, it can be reflected upon as 20% of Machines cause 80% of the Downtime.

Few key causes that constitute this 20% are:

1. Particle Contamination

2. Moisture Contamination

3. Wrong/Degraded Lubricant

4. Misalignment

5. Imbalance

We at Minimac study your maintenance needs and provide the highest quality & service quality solutions. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#minimac systems#oil flushing#frf#power#oil & gas#hydraulic oil#minimac#lube oil filter#contamination#hydraulic oil filter#lube oil#lvdh full form#mlc lvdh#frf machine#transformation oil purification#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#mechanical maintance#contract & services#clean oil#contamination free#oil testings

0 notes

Text

Understanding the root cause of the symptoms that are observed on your machinery?

It is observed across the spectrum that whenever we see issues/symptoms like:

1. Oxidized oil

2. Destructive pitting

3. Excessive vibration

4. Abrasive wear

5. Cavitation

6. Machinery abnormal noise

7. Wear debris generation

8. High running temperature

We usually believe in either Repairing, Replacing, Rebuilding and Removing the affected component. However, it only subsides the symptoms temporarily. This approach is called the 4-R approach and it weeds out the issue from the surface and not at the root level and hence the problem reoccurs. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

However, we should aim at studying these symptoms and work on the root causes. Some of the very frequent root causes that cause the above-mentioned symptoms are:

1. Misalignment

2. Wrong oil usage

3. Moisture

4. Machinery part imbalance

5. Particle contamination

6. Air contamination

Hence, we should aim at 5I approach i.e. It’s clean, It’s Cool, It’s dry, It’s aligned and balanced, It’s well oiled. This approach keeps the machine healthy and eliminates the problem.

In case you are unable to understand the root cause of the symptoms that are observed on your machinery contact Minimac Systems Pvt. Ltd.

#oil flushing#minimac systems#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#power#hydraulic oil filter#frf#oil filteration#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#wind turbines#gas turbine services market#steam turbine market share#gas turbine market trends#mlc lvdh#lvdh full form#transformer oil filtration#oil dehydration systems#lube oil flushing#hydraulic

0 notes

Text

Are you experiencing sub-optimal results even after changing filters?

I hope you have read these 2 articles:

1.http://bit.ly/35J0Vuy

2.http://bit.ly/2QInSKi

Whenever you are experiencing sub-optimal results even after changing filters, below are some possibilities which should be checked for:

1. Collapsed center tube

2. Inconsistent media quality

3. Damaged or burst filter media – fatigue

4. Bypass at filter media seam

5. Bypass due to adhesive failure

6. Damaged gasket or O-ring seal

7. Bypass valve jammed in open/closed position

8. Installation error, installing a filter in the opposite flow direction

9. Bypass valve leakage

10. Misaligned filter and seal

If none of the above factors contribute to the sub-optimal functioning of your filters we suggest you contact the Minimac Consulting team for required filter calculations and further investigations.

Get your filter check today, Call +91 7030901266

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#minimac systems#oil flushing#oil & gas#power#hydraulic oil#lube oil filter#contamination#minimac#frf#hydraulic oil filter#filter skid#minimac contract & services#transformer oil cleaning#oil filteration#mlc lvdh#lvdh full form#oil dehydration systems#electrostatics lube cleaner#coalescer separator

0 notes

Text

Understanding of the BETA factor

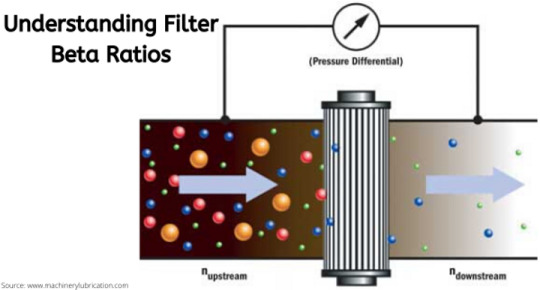

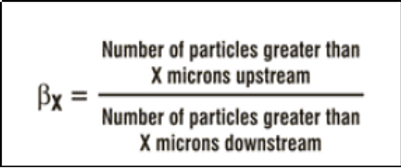

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today,

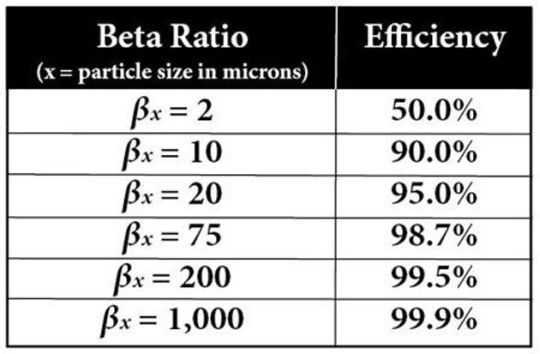

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#oil flushing#minimac systems#oil & gas#power#lube oil filter#hydraulic oil#contamination#hydraulic oil filter#frf#lvdh full form#mlc lvdh#transformer oil cleaning#transformer oil market#minimac#oil dehydration systems#oil filters#filter skid#coalescer separator#diesel oil purification#electrostatics lube cleaner#condition monitioring

0 notes

Text

Are you buying the right oil filter?

Let’s try to understand the real reason for the price difference. There are two types of filter ratings:

1. Absolute: Filter Rating meaning 99.9% of the particles larger than a specified micron rating will be trapped on or within the filter.

2. Nominal: Filter Rating indicating the approximate size particle, the majority of which will not pass through the filter. It is generally interpreted as meaning that 85% of the particles of the size equal to the nominal filter rating will be retained by the filter.

So, a vendor quoting for an Absolute 10-micron filter will have higher prices than the one quoting for a 10-micron nominal filter. So, the key is to always look for the datasheets of these filters and compare them basis the Beta Factor.

Also read: https://www.linkedin.com/pulse/can-all-contaminants-seen-naked-eyes-anshuman-agrawal/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that help you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#minimac systems#oil flushing#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#frf#power#minimac#condition monitioring#oil purification system#low vacuum dehydrations'#electrostatics lube cleaner#transformer oil filtration#coalescer separator#transformer oil cleaning#transformers#lvdh full form#mlc lvdh#lube oil flushing systems#hydraulic oil flushing systems#chemical cleaning systems#oil filters#filters#filter#contract & services

0 notes