#multi-layer PCB design

Explore tagged Tumblr posts

Text

The Evolution of PCB Manufacturing: From Basics to High-Performance Boards

PCB manufacturing has evolved from single-layer boards to high-performance, multi-layered designs, enabling innovation in automotive, healthcare, telecommunications, and aerospace. Learn how cutting-edge PCB technologies support modern electronics and drive UK industries forward. Explore advanced PCB solutions for your business today.

#PCB manufacturing evolution#high-performance PCBs#multi-layer PCB design#PCB for 5G networks#advanced PCB technology#UK PCB industry#flexible PCBs#PCB signal integrity#automotive PCB solutions#medical device PCBs#aerospace PCB manufacturing#PCB miniaturisation#HDI PCBs#thermal management in PCBs#next-gen PCB solutions#A-Gas Electronic Materials

0 notes

Text

Understanding Circuit Board Electronic Components: A Comprehensive Guide

In today's digital world, electronic devices have become an essential part of our daily lives. But what makes these devices tick? At the heart of every electronic device lies a circuit board—a masterpiece of tiny electronic components working together to perform complex tasks. In this article, we’ll dive deep into the fascinating world of circuit board electronic components, exploring each element’s role and how they contribute to the overall functionality of the device.

What is a Circuit Board?

A circuit board, often referred to as a PCB (Printed Circuit Board), is a flat board used to mechanically support and electrically connect various electronic components. These components work in unison to perform a specific task. Think of the circuit board as the skeleton and nervous system of an electronic device—it holds everything together and allows communication between parts.

Types of Circuit Boards

Single-sided PCB: Has one layer of conducting material.

Double-sided PCB: Contains two layers for components and connections.

Multi-layer PCB: Complex boards with multiple layers for advanced applications.

The Role of Electronic Components on a Circuit Board

Every electronic device you interact with is powered by a carefully designed circuit board filled with various components. These components might be tiny, but each one has a critical role in the operation of the device. Here's a breakdown of the most important electronic components you’ll find on a typical circuit board.

1. Resistors

Resistors are fundamental components that control the flow of electrical current. They resist the flow of electrons, hence the name "resistor." Their primary function is to reduce current flow, adjust signal levels, and divide voltages in a circuit. Without resistors, circuits would allow too much current to flow, potentially damaging other components.

Types of Resistors

Fixed resistors: Have a set resistance value.

Variable resistors: Allow adjustment of the resistance.

2. Capacitors

Capacitors store and release electrical energy in a circuit. They are often compared to small rechargeable batteries that quickly charge and discharge. Capacitors help smooth out fluctuations in voltage, filter noise, and store energy for future use.

Common Uses of Capacitors

Energy storage

Signal filtering

Voltage stabilization

3. Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They resist changes in current and are typically used in circuits to filter signals, manage power, and store energy.

Applications of Inductors

Power supplies

Radio frequency circuits

Noise suppression in circuits

4. Diodes

A diode is like a one-way valve for electricity, allowing current to flow in only one direction. They are vital in circuits to prevent reverse currents, which can damage components.

Types of Diodes

Light-emitting diodes (LEDs): Produce light when current flows through.

Zener diodes: Regulate voltage within a circuit.

5. Transistors

The transistor is a versatile component used to amplify or switch electronic signals. In essence, transistors are like tiny switches that turn signals on and off rapidly, making them essential in modern electronics.

Types of Transistors

NPN transistors: Allow current flow when a small voltage is applied to the base.

PNP transistors: Conduct when the base is negatively charged.

How Circuit Board Components Work Together

In a circuit, each component has a specific role, and together they form a cohesive system. For example:

Capacitors and resistors may work together to filter signals or smooth out voltage fluctuations.

Transistors and diodes ensure that signals are amplified or directed properly.

Integrated circuits handle the complex tasks, processing data, and controlling the overall system.

Choosing the Right Components for Your Circuit Board

When designing or repairing a circuit board, choosing the correct components is crucial. Some factors to consider include:

Voltage requirements

Power consumption

Signal type and frequency

Physical size and compatibility

Conclusion

Circuit boards are an integral part of any electronic device. The various components on the board each play a specific role in ensuring the device functions as intended. Understanding these components, from resistors to integrated circuits, is essential for anyone working with electronics, whether you're designing a new system or troubleshooting an existing one.

2 notes

·

View notes

Text

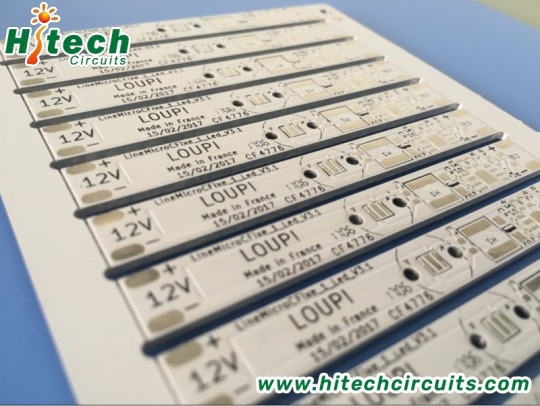

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Text

Clean Air, Safer Workspaces: Premium Fume Absorber and Extractors in India from Ascomp Inc

Industrial environments, electronics labs, repair stations, and medical facilities often deal with invisible airborne threats like solder smoke, chemical vapors, laser fumes, and micro-dust. Without proper ventilation, these contaminants can harm health, affect product quality, and even damage sensitive equipment. That’s why using the right fume absorber and extractors in India is essential—and Ascomp Inc is a trusted name providing advanced air purification solutions across industries.

Why Are Fume Absorbers and Extractors Important?

Processes like soldering, welding, laser cutting, and chemical testing release harmful particles and gases into the air—some of which are toxic or carcinogenic. Common irritants like flux fumes, lead oxide, VOCs, and resin particles can pose long-term health risks if inhaled regularly.

A reliable fume absorber and extractor in India works by capturing these fumes at the source using a powerful suction system. The extracted air passes through layers of filtration, typically HEPA and activated carbon, before being safely released back into the environment or vented externally.

Applications Across Industries

Ascomp Inc’s solutions are engineered for various industries and applications, including:

Electronics repair and PCB manufacturing

Medical device labs and dental clinics

Welding and metal fabrication units

Laser engraving and 3D printing

Watchmaking and jewelry crafting

Pharmaceutical and chemical labs

Educational institutions and technical workshops

From bench-top units for single-user soldering stations to heavy-duty extractors for factory floors, we have solutions for every scale.

Key Features of Our Fume Absorbers & Extractors

✅ Multi-stage filtration (Pre-filter + HEPA + Activated Carbon)

✅ Quiet operation with high suction power

✅ ESD-safe designs for electronics safety

✅ Portable, desktop, and wall-mounted models

✅ Flexible extraction arms and nozzles for precision targeting

✅ Filter change alerts for proactive maintenance

Our systems remove 99.97% of particles as small as 0.3 microns—making your workspace healthier and compliant with international air quality standards.

Why Choose Ascomp Inc?

🛠️ High-quality products with industrial-grade performance

📞 Pre-sales consultation to choose the right model

📦 PAN-India delivery and installation assistance

🔄 Spare filters, accessories, and long-term support

📑 Customizable setups for multi-workstation environments

Ascomp Inc understands the unique requirements of Indian manufacturing and service industries. We offer fume control solutions that are reliable, cost-effective, and scalable.

Compliance and Safety

Our fume extractors meet ISO, OSHA, and CE standards for air filtration and workplace safety. Whether you're running a repair station or managing a full-scale EMS facility, our products help you comply with environmental and employee health regulations.

#FumeAbsorberIndia#FumeExtractorsIndia#AscompInc#AirPurifierForSoldering#ElectronicsFumeControl#WorkplaceSafetyIndia#ESDSafeExtractor#PCBAssemblyTools#IndustrialAirPurification#HEPAFilterIndia

0 notes

Text

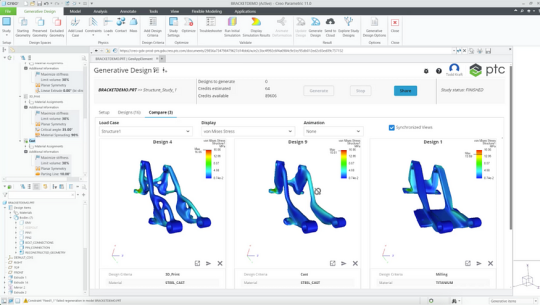

PTC Creo 12: New Tools for Smarter, Faster 3D Design

Discover what’s new in PTC Creo 12 — enhanced simulation, AI-driven design, MBD, and manufacturing tools. Upgrade now with ANH, the trusted PTC Creo reseller in the Delhi NCR region.

Top New Features in Creo 12

1. AI-Driven Design Guidance

Creo 12 takes intelligent design to the next level with built-in AI tools that offer real-time suggestions and improvements.

Get feedback during modeling

Reduce trial-and-error

Improve efficiency with every click

2. Enhanced Model-Based Definition (MBD)

Creo 12 makes MBD more practical and powerful, eliminating the need for traditional 2D drawings.

Improved PMI (Product Manufacturing Information)

Better GD&T annotation support

Clearer data for downstream users

3. Performance & Usability Upgrades

PTC has improved the overall speed, responsiveness, and ease of use:

Faster model regeneration

Smart mini toolbars

Enhanced model tree filters

Customizable dashboards for quick access

4. Creo Simulation Live — More Powerful Than Ever

Simulation Live has been expanded to cover:

Structural & thermal simulations

Better support for nonlinear materials

Real-time design feedback

5. Advanced Multi-Body Design

Creo 12 makes it easier to work with complex parts and assemblies:

Better control over multiple bodies in a single part

New body operations and organization tools

Improved part-to-part interactions

It’s ideal for high-detail engineering and intricate product development.

6. Additive and Subtractive Manufacturing Enhancements

Manufacturing has never been smoother in Creo:

More control over lattice structures

Enhanced 5-axis CAM functionality

New machine support and output formats

Whether you’re 3D printing or using CNC, Creo 12 has you covered.

7. Improved ECAD–MCAD Collaboration

With electronics becoming a bigger part of mechanical products, Creo 12 improves:

PCB visualization

Layer management

Synchronization between electrical and mechanical teams

This helps avoid costly errors during development.

Why Creo 12 is a Must-Have Upgrade

PTC Creo 12 isn’t just for big enterprises — it’s built for everyone who values smart, high-quality design. Whether you’re a design engineer, manager, or product innovator, Creo 12:

Saves time

Reduces errors

Encourages innovation

Supports industry 4.0 goals

Get Creo 12 from Delhi NCR’s Trusted PTC Reseller — ANH

Looking to upgrade your CAD tools or switch to Creo 12? ANH is a leading authorized PTC reseller in the Delhi NCR region. From licensing to training, we help businesses unlock the full potential of Creo.

Contact ANH today to get started with Creo 12!

✅ Conclusion: Welcome to the Future of Design

PTC Creo 12 is more than just an upgrade — it’s a gateway to smarter design, quicker development, and stronger innovation. With new AI tools, advanced simulations, and seamless usability, it’s built to give your team a competitive edge.

Design faster. Design smarter with Creo 12.

0 notes

Text

PCBA: The Silent Backbone of Electronic Devices

Printed Circuit Board Assembly (PCBA) serves as the critical foundation for nearly every electronic device in our modern world. From smartphones and laptops to industrial automation systems and aerospace equipment, PCBA ensures that the various electronic components within a device function smoothly and cohesively. Its precision and reliability are not just technical necessities but vital to sustaining innovation in the global tech economy.Get more news about PCBA manufacturer,you can vist our website!

Understanding PCBA

At its core, PCBA refers to the process of soldering electronic components onto a printed circuit board (PCB). While a PCB is simply the board with copper traces that connect components electrically, the assembly process transforms it into a fully functional circuit. This involves mounting integrated circuits (ICs), resistors, capacitors, diodes, and other components using either Surface Mount Technology (SMT), Through-Hole Technology (THT), or a hybrid of both, depending on the design and purpose of the device.

The PCBA Process

The process typically begins with solder paste application, where a stencil is used to apply the paste on predefined areas of the PCB. Automated pick-and-place machines then accurately position the tiny components onto the board. This is followed by reflow soldering, where the board is passed through a controlled oven to melt the solder and secure the components.

For boards requiring through-hole components, manual or wave soldering is used. Once soldered, the board undergoes inspection and testing—ranging from Automated Optical Inspection (AOI) to X-ray analysis and functional testing—to ensure quality and performance. Advanced PCBA plants employ high levels of automation, drastically reducing human error and improving output consistency.

Applications Across Industries

PCBA's influence stretches far beyond consumer electronics. In the automotive sector, it powers systems ranging from infotainment units to electric vehicle battery management. In healthcare, PCBA-based medical devices like ECG machines and portable monitors are critical to patient diagnostics and care. Aerospace and military applications demand high-reliability PCBA to function under extreme environments—an area where rigid quality controls and testing standards become indispensable.

Trends and Innovations

The PCBA landscape continues to evolve rapidly with advances in miniaturization, multi-layer boards, and flexible circuits. With the rise of the Internet of Things (IoT), demand for compact, power-efficient, and wireless-capable assemblies has exploded. Manufacturers are investing in smart factories, using AI-driven inspection and robotics to further optimize production.

Meanwhile, environmental considerations are pushing green manufacturing methods, such as lead-free solder and recyclable board materials. Companies are also embracing design-for-manufacturing (DFM) principles to streamline assembly and minimize waste.

Conclusion

Though rarely visible to end-users, PCBA is the invisible force driving the electronics revolution. Its blend of engineering precision, automation, and innovation enables the digital tools and systems we rely on daily. As global technology continues to push boundaries, PCBA will remain the structural and functional heart of that progress—quietly pulsing behind every screen, circuit, and sensor.

0 notes

Text

Reliable Metal Clad PCB Suppliers in India: Vaishnavi Electronics at the Forefront of Innovation

As the electronics industry moves toward higher power and thermal efficiency, Metal Clad PCBs (MCPCBs) have become an essential component in modern electronic design. Known for their superior heat dissipation, durability, and performance in high-power applications, MCPCBs are widely used in LED lighting, automotive electronics, power converters, and industrial equipment. In India, Vaishnavi Electronics stands out as one of the most dependable metal clad PCB suppliers, known for its quality manufacturing, technical expertise, and customer-centric approach.

The Strategic Importance of Metal Clad PCBs in High-Power Applications

Metal Clad PCBs, often composed of a thermally conductive dielectric layer sandwiched between a metal base (typically aluminum or copper) and a copper circuit layer, are engineered to manage heat more efficiently than standard PCBs. Their ability to draw heat away from active components ensures longer lifespan, higher reliability, and improved performance in thermally demanding environments.

Unlike traditional PCBs, MCPCBs allow designers to use higher power densities and compact layouts without compromising thermal performance. They are particularly valuable in LED lighting systems, where excessive heat can degrade performance, as well as in power supply units, motor controllers, and RF applications.

As demand for energy-efficient and high-performance devices increases, so does the need for advanced PCB solutions like metal clad boards. This has positioned quality suppliers like Vaishnavi Electronics as critical partners for OEMs and electronics manufacturers across sectors.

Vaishnavi Electronics: Trusted Partner for Custom Metal Clad PCB Solutions

Vaishnavi Electronics, based in India, has earned a reputation as a leading supplier of metal clad PCBs, offering reliable and tailored solutions that meet the specific needs of its clients. The company has invested in advanced manufacturing processes and quality control systems to ensure consistent production of high-performance MCPCBs.

With capabilities to work on various metal substrates—such as aluminum, copper, and steel—Vaishnavi Electronics supports a wide range of applications, from LED modules to power management systems. The company’s expertise extends beyond standard offerings; it provides customized MCPCB solutions, including multi-layer constructions, specific thermal conductivity requirements, and design support for complex layouts.

Vaishnavi’s production process emphasizes durability, thermal stability, and electrical integrity. Every MCPCB undergoes rigorous testing to ensure it meets industry standards for thermal resistance, mechanical strength, and electrical performance. Additionally, their engineering team works closely with clients to optimize board layout for maximum efficiency and reliability.

What sets Vaishnavi Electronics apart is not just its technical know-how but its commitment to customer service. Whether it's rapid prototyping or bulk production, the company delivers on time, offering competitive pricing without compromising on quality.

In conclusion, the growing demand for Metal Clad PCB suppliers across high-power and thermally challenging applications highlights the need for experienced and dependable suppliers. Vaishnavi Electronics continues to lead the way in India’s PCB industry with its advanced capabilities, customized solutions, and unwavering focus on quality. For businesses seeking a trusted partner in metal clad PCB supply, Vaishnavi Electronics offers a strategic advantage through innovation, reliability, and precision manufacturing.

Visit:- https://www.vaishnavielectronics.co.in/metal-clad-pcb.html

0 notes

Text

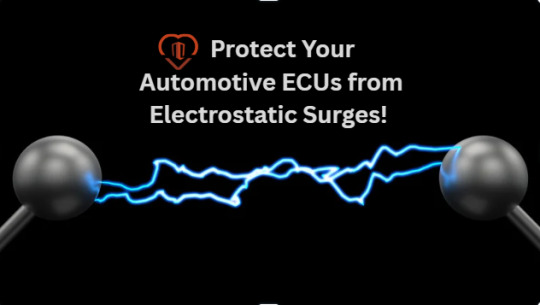

Introduction to Lin Bus and Special Devices for Electrostatic Surge Protection

1、 Introduction to Lin Bus

A. Definition of Lin Bus

Lin bus is a serial communication bus suitable for communication between automotive electronic control units (ECUs).

B. Characteristics of Lin Bus

The Lin bus adopts a single end drive and differential transmission method, which has the characteristics of high-speed transmission and strong anti-interference performance.

C. Application scope of Lin bus

The Lin bus is mainly used for communication between electronic control units (ECUs) in automobiles, such as engine control units, transmission system control units, body control units, and so on. The emergence of the Lin bus enables data exchange and communication between ECUs of different brands, systems, and functions, thereby improving the overall performance and safety of automobiles.

2、 Problems with Lin Bus

A. Hazards of static surges

Static surges and other factors can damage the performance and stability of the Lin bus.

B. Stability and reliability issues of Lin bus

There are also some problems with the Lin bus in practical applications.

3、 Design of electrostatic surge protection

A. Hardware protection measures

The design of electrostatic surge protection needs to start from both hardware and software aspects. In terms of hardware, measures such as protective circuits can be taken to limit electrostatic surge voltage, such as using protective circuits composed of TVS diodes, inductors, capacitors, etc.

Suggestions for the layout of ESD devices

a) Place the device as close as possible to the input or connector.

b) Minimize the path length between the device and the protected line.

c) Keep parallel signal paths to a minimum.

d) Avoid running protected conductors in parallel with unprotected conductors.

e) Minimize the conductive circuits of all printed circuit boards (PCBs), including power and ground circuits.

f) Minimize the transient return path length to ground.

g) Avoid using shared transient return paths to common ground points.

h) Try to use ground planes, multi-layer printed circuit boards, and ground through holes as much as possible.

B. Software protection measures

In terms of software, error Check digit (CRC) and other technologies can be used to detect errors in data transmission, so as to ensure the reliability of data.

4、 The Importance of Lin Bus in the Field of Automotive Electronics

A. Advantages of Lin Bus

The Lin bus has the characteristics of high-speed transmission and strong anti-interference performance.

B. The Application Prospects of Lin Bus

In the future field of automotive electronics, the Lin bus will still play an important role and play an important role.

Summary

The interface protection of electronic products requires the use of overvoltage protection devices. Many engineers are aware of the need to use protection devices, but due to improper selection or failure to follow the design principles of ESD circuit PCB, the product fails static or EMC testing, wastes manpower and financial resources, and causes product delays or over design, resulting in cost pressure. Leiditech Electronics provides customers with electromagnetic compatibility EMC design services, providing laboratory testing for free. We aim to efficiently and conveniently complete the design for our customers. We hope that more customers can quickly pass EMC’s projects and improve product reliability as much as possible.

Shanghai Leiditech Electronic Electromagnetic Compatibility Laboratory provides free testing and peripheral electrostatic protection reference circuits.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com] #LinBus#AutomotiveElectronics #SurgeProtection #EMC #ElectromagneticCompatibility #ESD #TechDesign #AutomotiveTech #VehicleInnovation #CircuitProtection #ElectronicsEngineering #CarSafety #Leiditech

0 notes

Text

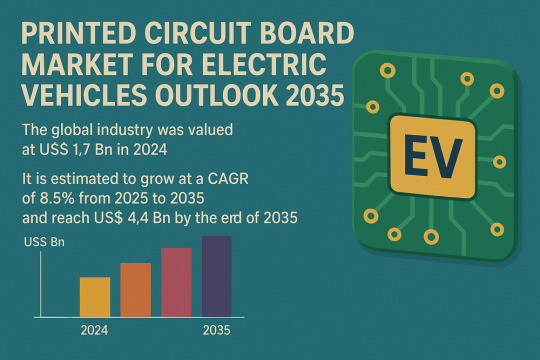

Smart Mobility Drives Smart PCBs: Market to Hit $4.4Bn by 2035

The global Printed Circuit Board (PCB) Market for Electric Vehicles (EVs) is set to witness significant expansion over the next decade, according to the latest market analysis. Valued at US$ 1.7 billion in 2024, the market is projected to grow at a CAGR of 8.5% from 2025 to 2035, reaching a valuation of US$ 4.4 billion by the end of the forecast period.

Market Overview: Printed Circuit Boards (PCBs) are the electronic backbone of electric vehicles, enabling power distribution, connectivity, and control across critical systems such as battery management, motor control, infotainment, and advanced safety features. With EV adoption accelerating globally, PCBs have become essential to the performance, reliability, and innovation of next-generation vehicles.

Market Drivers & Trends

One of the primary drivers of this market is the growing investment and strategic partnerships in the EV supply chain. Leading automakers and electronics companies are heavily investing in R&D and manufacturing capacity to meet the increasing demand for high-performance PCBs.

Moreover, the rise of autonomous and connected vehicles has made sophisticated electronics an indispensable part of modern transportation. The proliferation of features like ADAS (Advanced Driver-Assistance Systems), V2X communication, and in-vehicle infotainment is pushing the demand for compact, multi-layer, high-speed, and thermally efficient PCBs.

In 2023, EV sales in the U.S. surged by 60%, while the European Commission invested over US$ 6 billion in EV infrastructure further stimulating demand for advanced PCB solutions.

Latest Market Trends

The industry is witnessing a rapid shift toward flexible and high-density interconnect (HDI) PCBs, which are crucial for compact and space-saving vehicle designs. Flexible PCBs, in particular, are gaining traction in battery management systems and advanced sensor modules due to their lightweight and adaptable nature.

Additionally, regulatory advancements such as the FCC's allocation of the 5.9 GHz band for vehicle safety and autonomous functions have opened doors for new PCB capabilities. Real-time, high-speed data transmission requires advanced PCB materials and multi-layer configurations.

Key Players and Industry Leaders

Some of the most prominent players shaping the global printed circuit board market for electric vehicles include:

ABL CIRCUITS

AT&S Austria Technologie & Systemtechnik Aktiengesellschaft I

Chin Poon Industrial Co., Ltd.

Compeq Manufacturing Co., Ltd.

HannStar Board Corporation

Kinwong Electronic Co. Ltd

LG Innotek

MEIKO ELECTRONICS Co., Ltd.

Nan Ya Printed Circuit Board Corporation

RayMing PCB

Rush PCB Ltd.

SCHWEIZER ELECTRONIC AG

Shenzhen Capel Technology Co., Ltd.

Shenzhen Fastprint Circuit Tech Co., Ltd.

TTM Technologies

Unimicron Technology Corporation

Victory Giant Technology Co., Ltd.

WUS Printed Circuit Co., Ltd.

Young Poong Group

Zhen Ding Tech. Group

Among Others

These companies are prioritizing innovation, expanding global manufacturing footprints, and forging strategic alliances to maintain competitiveness and cater to evolving industry needs.

Download now to explore primary insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86464

Recent Developments

October 2024 – Mektech Manufacturing announced a 920 million baht investment in Thailand to expand production capacity for flexible PCBs and FPCBA used in electric vehicles.

July 2024 – Omron Electronic Components Europe launched a high-power PCB relay for Level 2 EV charging stations. The innovation features double-break contact designs, enabling reduced heat dissipation and enhanced energy efficiency.

Market Opportunities

The market is poised for significant opportunities, particularly in:

OEM collaborations to co-develop application-specific PCBs for power electronics and smart mobility.

Flexible PCB technology, which is expected to revolutionize EV design with lightweight, customizable circuit boards.

Geographical expansion into regions like South Asia and Latin America, where EV adoption is accelerating, and supply chains are emerging.

Additionally, the ongoing reshoring of PCB manufacturing in regions such as North America and Europe presents untapped potential for local players.

Future Outlook

According to analysts, the convergence of EV electrification, autonomy, and connectivity will demand ever more sophisticated PCB solutions. Next-generation EVs will require PCBs capable of managing 50 Gbps data speeds, robust thermal management, and high signal integrity. Flexible, multilayer, and ceramic PCBs are expected to gain ground rapidly.

As regulations around emissions and vehicle safety become more stringent, automakers will rely heavily on advanced PCB solutions to remain compliant and competitive. From battery optimization to smart in-vehicle systems, the demand for high-performance PCBs is set to skyrocket.

Market Segmentation

The global PCB market for EVs is segmented across several parameters:

By Type: Multilayer (dominant with 73.98% market share in 2024), Double-sided, Single-sided

By Substrate Type: HDI/Micro-via/Build-up, Flexible, Rigid-flex, Rigid 1-2 Sided

By Material: FR4, Metal-Based, Ceramic, PTFE, Power Combi-boards

By Application: ADAS, Battery Management, Powertrain, Lighting & Display, Charging, Connectivity, etc.

By Vehicle Type: Passenger Cars, Buses, Two-Wheelers, Trucks, Off-Highway Vehicles

By End Users: OEMs, Tier 1 & 2 Suppliers, Aftermarket

Regional Insights

East Asia is the undisputed leader in the global market, accounting for 68.3% of the total share in 2024. The region’s dominance stems from:

A well-established electronics manufacturing ecosystem

Government support for EV expansion and green technology

Cost-effective production and high R&D capabilities

Japan, South Korea, and China house the majority of leading PCB suppliers and EV component manufacturers. Their early investment in automation and material innovation is positioning East Asia as the global hub for EV electronics.

Other key regions include:

North America, driven by government initiatives like the CHIPS Act

Europe, focused on sustainable manufacturing and reducing supply chain reliance on Asia

South Asia, emerging as a low-cost, high-volume manufacturing zone

Why Buy This Report?

This in-depth industry report offers:

Detailed market sizing and forecast (2020–2035)

Comprehensive segmentation across product, material, vehicle type, and region

Competitive landscape with profiles of 20+ leading companies

Insights into trends, innovations, and regional dynamics

Strategic recommendations for stakeholders, investors, and policymakers

Whether you're an investor, OEM, component supplier, or policy planner, this report serves as a strategic guide to understanding growth dynamics and identifying emerging opportunities in the PCB market for electric vehicles.

Explore Latest Research Reports by Transparency Market Research: Active Optical Cable Market: https://www.transparencymarketresearch.com/active-optical-cables.html

3D Cameras Market: https://www.transparencymarketresearch.com/3d-cameras-market.html

Optoelectronics Market: https://www.transparencymarketresearch.com/optoelectronics-market.html

Machine Safety Market: https://www.transparencymarketresearch.com/machine-safety-market.html

DC-DC Converter OBC Market: https://www.transparencymarketresearch.com/dc-dc-converter-obc-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Victory – Delivering High-Precision PCBs for Today’s Electronics Industry

Victory, established in 2005, has earned a strong reputation as a professional PCB manufacturer known for delivering top-tier printed circuit boards tailored for today’s dynamic and demanding electronics landscape. With nearly two decades of industry experience, Victory specializes in producing a wide variety of PCB types, offering flexibility in small to medium-sized production runs and quick-turn manufacturing to support customers’ time-sensitive needs.

Victory’s manufacturing model is built on the foundation of the “3H” principle—high quality, high precision, and high density. These three pillars ensure that every PCB manufactured meets strict international standards and functions reliably in real-world applications, whether in consumer electronics, industrial control systems, telecommunications, or medical devices.

Operating out of a state-of-the-art 30,000-square-meter production facility in Shenzhen, Victory has the capacity to produce 60,000 square meters of PCBs and up to 3,000 different parts each month. This significant capacity, coupled with advanced production and testing equipment, enables Victory to handle both complex custom designs and high-volume orders with ease.

What sets Victory apart is its robust in-house quality system that governs every phase of production—from material sourcing and engineering to final testing and delivery. Each PCB undergoes rigorous checks to ensure dimensional accuracy, electrical integrity, and durability. This meticulous attention to detail results in boards that perform flawlessly even under the most challenging operational environments. Click here victorypcb.com

In addition to its focus on manufacturing excellence, Victory is known for its responsiveness and customer-centric approach. The company works closely with clients to provide technical guidance, assist with design optimization, and offer tailored production solutions. This collaborative spirit has helped Victory build lasting relationships with customers worldwide.

Speed is another hallmark of Victory’s service. The company’s quick-turn capabilities allow for rapid prototyping and fast delivery, helping businesses reduce development cycles and accelerate product launches. This is especially valuable for startups and innovators bringing new technologies to market.

Victory’s comprehensive capabilities, advanced infrastructure, and dedication to quality make it a standout in the competitive world of PCB manufacturing. Whether you need standard double-layer PCBs, multi-layer boards, or high-density interconnect solutions, Victory provides the reliability and performance your products demand.

1 note

·

View note

Text

Why Smartphone Chip-Level Repair Skills Are In-Demand in 2025

The Future Is Chip-Level: Why Mobile Repairing Skills Are Booming in 2025 In today's fast-paced digital world, smartphones and laptops are no longer luxury items—they're lifelines. With over 1.5 billion smartphones sold annually and increasing reliance on laptops for work, education, and entertainment, skilled mobile and laptop technicians are more in-demand than ever.

At Magnus Institute, Kerala’s leading mobile repairing training institute, we're seeing a surge in students enrolling in chip level mobile repairing courses. Let’s dive into why smartphone chip-level repair is one of the hottest career skills in 2025—and how you can take advantage of it.

What Is Chip-Level Mobile Repairing? Chip-level repair involves diagnosing and fixing problems on a mobile phone’s motherboard (PCB). Unlike basic component replacement, chip-level repair requires:

Soldering and desoldering

Use of microscopes and hot air guns

Knowledge of ICs, BGA chips, and circuit diagrams

This advanced skill is part of our mobile phone technician course and laptop repairing course, perfect for those aiming for deeper technical expertise.

Why Is This Skill in High Demand? Smartphones Are Getting More Complex

Devices now use multi-layer motherboards, micro BGA chips, and custom SoCs, requiring chip-level diagnostics and repair knowledge.

Repair, Don’t Replace Trend

Consumers and businesses prefer repairing expensive smartphones and laptops instead of replacing them, fueling demand for professionals trained in mobile chip level service.

Electronics Market Boom

With rising smartphone and laptop usage across India, the need for certified mobile and laptop repair technicians is growing.

Global Technician Shortage

Even abroad, companies are hiring professionals with a diploma in mobile repairing and mobile repair certificates from recognized institutions like Magnus.

Your Career Starts Here: Courses at Magnus Institute We offer top-rated, hands-on training in:

Mobile Repairing Course (Beginner to Advanced)

Mobile Phone Repair Training Institute Certificate

Chip Level Repairing Course for Mobile and Laptops

iPhone Repairing Course

Computer Chip Level Repairing Course

All courses are taught by certified experts with real-world experience, and include job placement assistance across Kerala and India.

Why Choose Magnus Institute? One of the top mobile technician courses in Kerala

Fully equipped labs for hands-on practice

Certified diploma programs

Modern tools for mobile/laptop chip-level servicing

100% job-focused training

Who Should Join? Students looking for a career in electronics and communication

Working professionals seeking upskilling

Entrepreneurs wanting to open a mobile repair coaching centre

Anyone interested in mobile mechanic courses or cell phone repairing courses

Get Certified. Get Hired. Start your journey today at Magnus Institute, a top-rated training institute for mobile and laptop repairing courses near you. Whether you're interested in mobile service courses, smartphone repairing courses, or computer laptop repair courses, we have a program designed for you.

📞 Call now or visit our website Magnus Institute, to enroll and take the first step toward a future-proof tech career.

#chip level repairing course#institute of mobile repairing#iphone repairing course#laptop repair training near me#laptop repair training#laptop repairing institute near me#laptop repairing course#mobile and laptop repairing course#mobile chip level service

0 notes

Text

Structural Innovation and Easy Installation Technologies in Power Socket Design

As smart homes, office automation, and industrial digitalization rapidly advance, the demand for user-friendly, efficient, and safe power sockets continues to grow. Traditional socket designs are no longer sufficient for fast-paced environments that require high reliability, ease of installation, and space optimization. This has driven innovation in both internal structure and external mounting mechanisms of modern power sockets.

This article explores key advancements in structural design and installation technologies of power sockets, focusing on terminal innovations, mounting bracket designs, and strategies to increase module density without increasing volume. We will also discuss real-world examples and applicable technologies for B2B manufacturers and system integrators.

1. Integrated vs. Modular Terminal Design: Which is More Efficient?

The terminal structure of a power socket directly determines wiring efficiency and stability. The two mainstream types are:

A. Integrated Terminal Block (One-Piece)

All terminals are integrated into a single housing.

Benefits: Shorter installation time. Reduced loose contacts. Lower resistance due to shorter conductive paths.

Limitations: Less flexible for modular replacement. May increase overall production complexity.

B. Modular Terminal Block (Multi-Part)

Each terminal is separately assembled or replaceable.

Benefits: Ideal for custom configurations. Easier to repair and replace.

Limitations: Longer assembly time. Risk of performance inconsistency.

2. Push-in Spring Connection Technology: Fast, Safe, Tool-Free Wiring

Compared to screw terminals, push-in spring terminals provide:

Quick installation: Simply push the stripped wire into the terminal.

Strong contact: Stainless steel or beryllium copper springs maintain pressure for years.

No need for torque tools: Reduces operator training and tool investment.

🔧 Case Example: A European power socket brand uses a push-in spring design that allows a full 5-gang module to be wired in under 30 seconds — 60% faster than screw terminals.

3. Quick-Mount Bracket Designs: Screw-Free, Time-Saving, and Reliable

In large-scale installations (e.g., hotels, office buildings), fast mounting systems dramatically reduce labor costs and error rates.

Key Innovations:

A. Snap-In Mounting Frame

Socket modules are inserted directly into wall plates with audible clicks.

Uses elastic clips or sliding locks for firm placement.

Ideal for drywall and modular building systems.

B. Screwless Embedded Mounting

Eliminates screw holes by using slide-in rail structures.

Allows easy front-facing maintenance or upgrades.

Common in premium wall systems and panel furniture.

C. Magnetic or Cam-Lock Fastening

Applies in high-end modular offices.

Enables tool-free repositioning.

🔧 Case Example: A Chinese manufacturer developed a double-locking quick-install bracket that passed 500N pull force tests, suitable for vibration-prone environments like rail stations.

4. Increasing Module Density Without Expanding Volume

Modern installations demand multi-functionality in limited space. Techniques include:

A. Vertical Layering of Internal PCB

Using 3D layout: control, relay, and detection circuits are stacked.

Reduces horizontal footprint while maintaining thermal separation.

B. Multi-Function Integration

Combining USB chargers, smart sensors, and energy monitors in one unit.

Example: A 55x55mm wall socket includes 2 USB-A ports, 1 USB-C PD port, and Wi-Fi controller.

C. High-Density Terminal Design

Dual-row spring contacts with insulation barriers allow up to 10 terminals in standard footprint.

Ensures safety spacing while maintaining compact size.

5. Material Innovation: Making Structural Compactness Possible

A. High-Performance Plastics:

Use of PA66, PC+ABS, and flame-retardant PBT with thin-wall molding tech.

Improves space efficiency without sacrificing insulation performance.

B. Conductive Material Optimization:

Use of laminated copper busbars.

Electroplated or stamped silver contact surfaces to reduce thickness.

6. Installation Aids and Engineering Enhancements

A. Color-coded Wiring Guides:

Reduces wiring errors during bulk installations.

Accelerates compliance with local electrical codes.

B. Pre-assembled Harnesses:

For standard socket layouts, pre-assembled wire bundles reduce on-site labor.

C. Tool-Assisted Plug-In Systems:

Modular rail sockets with plug-in interfaces (e.g., DIN-rail smart outlets) improve interchangeability.

7. Structural Testing and Validation

8. Conclusion: Towards Smarter, Faster, and Denser Power Socket Design

Power socket structure and installation are no longer just mechanical tasks—they are core parts of user experience, energy efficiency, and engineering cost control. Through structural innovation like push-in terminals, quick-install brackets, and functional integration in compact modules, manufacturers can deliver plug-and-play, space-saving, and intelligent power socket solutions.

Whether you're a B2B buyer, an engineering contractor, or a systems integrator, adopting these next-generation socket designs will result in lower maintenance costs, faster deployment, and greater end-user satisfaction.

en.dghongju.com

0 notes

Text

Talking Through Change, Community Voices on the Rayonier Cleanup

Following a series of informal, semi-structured interviews with Port Angeles community members, I identified recurring barriers to effective remediation of the former Rayonier mill site, as well as grassroots strategies that could deepen public engagement and advocacy.

Institutional Challenges

Many interviewees described entrenched bureaucratic resistance within state agencies. A long-standing institutional culture that privileges industrial and economic interests over community and ecological well-being continues to delay regulatory action. Outdated frameworks and personnel further erode any sense of urgency, despite clear environmental and public-health risks.

Economic Challenges

The potential stigma of a Superfund designation has discouraged economic redevelopment. Investors remain wary of contaminated properties, and the cost of comprehensive cleanup is substantial. As one interviewee observed, “funding remains limited and often inadequate for the scale of remediation needed.”

Technical Challenges

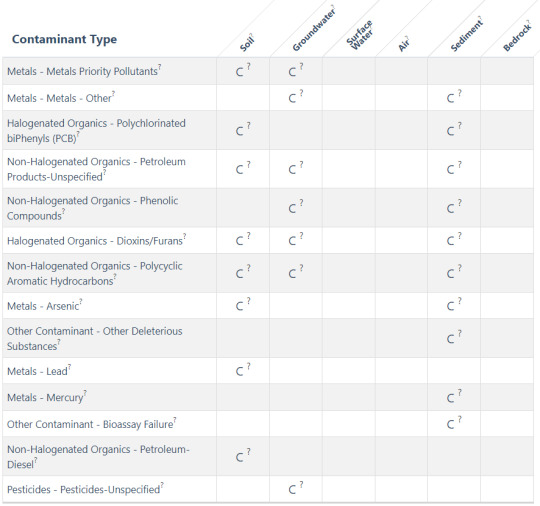

The site contains complex, multi-layered contamination, including dioxins, PCBs, heavy metals, and other hazardous substances, that extends well beyond the original mill boundaries.

C indicates contaminants confirmed above cleanup levels. Source: WA Department of Ecology

Ongoing leaching from nearby landfills into groundwater and creek systems compounds the problem, and the long-term environmental and health impacts are still under-studied.

Community Challenges

Public awareness of current site conditions remains low. Many residents lack clear information about contaminants and their potential effects. One participant highlighted the issue of contaminated soils and the absence of reliable guidance:

“People have probably dug them up from their yard and put in new soils by this time, but that needs to be checked. […] Newer buyers may not even know they have a contaminated site, and the buyers after them wouldn’t have a clue.”

Health-impact studies are limited, and the technical nature of existing documents makes meaningful engagement difficult for non-specialists.

Environmental Challenges

Sea-level rise poses additional risks. Interviewees expressed concern about shoreline stability once Rayonier’s cement fill and docks are removed; Friends of Ennis Creek, for example, favor restoring the original shoreline (see image below). Existing containment structures may not withstand future conditions, heightening the likelihood of contaminant spread. Local ecosystems, including vital salmon habitats, remain vulnerable, and climate change adds further uncertainty.

Source: 2025-04-09 Friends of Ennis Creek presentation

Political Challenges

One interviewee noted that “striking a balance between environmental protection and economic development remains politically contentious.” Others pointed to weak political will for aggressive remediation, complicated by inter-agency fragmentation and unclear jurisdiction.

Drawing on these interviews, as well as my background in environmental-health policy, I outline below several approaches for achieving a more thorough and equitable cleanup.

Coalition Building

Interviewees stressed the value of unified advocacy. A coordinated coalition—including Friends of Ennis Creek, the Lower Elwha Klallam Tribe, the Port of Port Angeles, the Economic Development Council, and other stakeholders—could present a stronger collective demand for comprehensive remediation.

Strategic Advocacy

Recommended tactics include joint letters and petitions to the Washington State Department of Ecology, coordinated testimony at public hearings, and sustained engagement with local and regional media.

Leveraging Existing Networks

Partnerships with statewide environmental organizations, academic institutions, and environmental-justice groups can supply scientific expertise, extend outreach, and reinforce the legitimacy of community concerns.

Political Engagement

A focused campaign directed at local and state representatives can help build political momentum. A clear, well-documented case for full remediation enables constituents to press decision-makers to act.

Documentation and Transparency

Thorough records of contamination data, agency correspondence, and community concerns are essential for accountability and institutional memory. Publicly accessible archives also facilitate informed participation.

Technical Support and Independent Expertise

Soliciting testimony from independent environmental scientists and commissioning third-party assessments can expose shortcomings in official proposals and provide a basis for robust alternative cleanup plans.

Community Education

Long-term success depends on broad public understanding. Accessible educational tools (maps of contamination boundaries, plain-language fact sheets, translated summaries, and clear site signage) can empower residents to participate effectively. Regular public meetings with transparent agendas and Q&A sessions remain indispensable.

Long-Term Commitment

Environmental remediation is a multi-decade endeavor. Interviewees emphasized preserving institutional knowledge, mentoring younger advocates, and establishing durable structures for ongoing civic engagement.

Conclusion

The Rayonier site’s core challenge is structural as well as environmental: transforming a legacy of industrial protectionism into a future centered on environmental justice and public health. The interview responses sketched a blueprint for sustained, strategic action, rooted in persistent advocacy, accessible communication, and coalition-based organizing, to secure the remediation Port Angeles deserves.

This account primarily reflects the perspectives of community members and environmental advocates. I was unable to speak with consultants or representatives of Rayonier Inc.; future research should integrate those viewpoints. Nonetheless, the narratives gathered here underscore the urgent need for transparency, accountability, and inclusive decision-making.

Current Status and Next Steps (June 10 2025)

The Washington Department of Ecology has announced plans to proceed with an interim cleanup. A public comment period runs June 12 – August 25.

Public Hearing and Open House Date: Tuesday, July 8 Time: 5–8 p.m. Location: Field Arts & Events Hall, 201 W Front St, Port Angeles, WA

This event will include presentations on site conditions, opportunities for questions, and a station for submitting written comments. I will attend and submit my own statement, and I encourage all concerned residents to do the same.

0 notes

Text

The Future of Mobile Phones Depends on PCB Innovation

The future of mobile phones relies heavily on continuous advancements in PCB (Printed Circuit Board) technology. Modern PCBs are smaller, faster, and more efficient, allowing smartphones to be lighter, thinner, and packed with powerful features. Innovations like multi-layer PCBs, flexible circuits, and better heat management enable improved performance, longer battery life, and enhanced durability. As 5G, AI, and IoT become more common in mobile devices, smart PCB design is essential to support complex functions in compact spaces. Simply put, the evolution of mobile technology starts at the centre of the device—the printed circuit board.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Mobile Phones#Mobile Manufacturing#PCB#Pcb innovation

0 notes

Text

Quality Control Standards for Printed Circuit Board Suppliers

In the fast-evolving world of electronics manufacturing, reliability and precision are not optional—they are essential. For businesses that rely on printed circuit boards (PCBs) to power their devices, quality assurance must be a top priority. At Pcb-Togo Electronic, Inc., we understand this responsibility. As a trusted Printed Circuit Board Supplier, we have built our reputation on a foundation of strict quality control standards designed to meet the most demanding performance and safety requirements.

Below, we explore the comprehensive approach we take at Pcb-Togo Electronic, Inc. to ensure every PCB we deliver is tested, traceable, and built to last.

Why Quality Control Is Critical for PCB Manufacturing

Unlike many components in the electronics supply chain, PCBs are the foundation of all electrical functionality in a device. Even a minor defect—such as a poor solder connection or microscopic short—can cause device failure, product recalls, or worse, safety hazards. For that reason, choosing a Printed Circuit Board Supplier with a proven quality control system is not just important—it’s mission-critical.

Poorly controlled PCB manufacturing can lead to:

Intermittent circuit failures

Early device breakdowns

Excessive rework costs

Damaged brand reputation

This is why at Pcb-Togo Electronic, Inc., we don’t just manufacture PCBs—we verify and validate every detail throughout the production process.

Our Quality Control Process: Built for Precision

At the core of our operations is a multi-phase quality control framework designed to ensure consistency, compliance, and performance. Our system covers every stage of PCB production, from material sourcing to final delivery.

1. Verified Materials and Supplier Audits

We begin quality control long before production starts. Every PCB at Pcb-Togo Electronic, Inc. starts with certified raw materials. We conduct strict inspections and maintain detailed supplier records to ensure that copper laminates, solder masks, and surface finishes meet global standards.

Regular supplier audits help us track quality at the source. Any vendor that fails to meet our benchmarks is removed from our approved list.

To explore how material quality affects PCB performance, Find Out More on our supplier verification page.

2. In-Process Inspections

Our in-house team conducts detailed inspections at every major production checkpoint:

Etching Accuracy – To prevent shorts or open circuits

Layer Alignment – Verified via X-ray scanning for multilayer boards

Hole Wall Quality – Assessed with microsectioning techniques

Solder Mask Integrity – Checked for uniform thickness and absence of bubbles

These real-time evaluations prevent defects from carrying forward, saving both time and cost. This proactive approach distinguishes us as a forward-thinking Printed Circuit Board Supplier.

3. Final Electrical Testing

No PCB leaves our facility without undergoing 100% electrical testing. Each board is verified for:

Continuity

Shorts

Component placement (if assembly is included)

Whether you're producing high-frequency boards or standard FR4 circuits, this final validation ensures that your boards will perform flawlessly in your application.

If you're curious about our advanced testing procedures, you can find out more by contacting our engineering team or viewing our testing guidelines online.

4. Strict Packaging & ESD Protection

Even after production, PCBs must be handled with care. Our packaging process includes:

Moisture barrier bags

ESD foam and shielding

Vacuum sealing for long-distance shipments

Each order is labeled for traceability, allowing clients to track batch origin, production data, and inspection results. This complete chain-of-custody approach ensures that your PCBs arrive in top condition—no matter where in the world you are.

For more on logistics and shipping support, go right here to our delivery resource center.

Continuous Quality Improvement (CQI)

Being a Printed Circuit Board Supplier means constantly adapting to evolving industry standards and customer requirements. At Pcb-Togo Electronic, Inc., we use data from inspections and customer feedback to refine our production lines. Our engineers regularly review:

First-pass yield rates

Customer return data

Root cause analyses

This commitment to Continuous Quality Improvement helps us remain flexible and responsive, while maintaining high yield rates and low defect percentages.

Why Choose Pcb-Togo Electronic, Inc.?

With over two decades of experience, we are a leading Printed Circuit Board Supplier known for our ability to deliver reliable, high-performance boards at competitive prices. What sets us apart is our end-to-end commitment to quality—from the raw copper to the final shipment box.

Clients from industries such as medical, automotive, aerospace, and consumer electronics trust us for:

Fast lead times

Transparent communication

Flexible order quantities

Proven reliability

When you partner with Pcb-Togo Electronic, Inc., you’re choosing a supplier that backs every board with traceability, testing, and total accountability.

Final Thoughts

Selecting a reliable Printed Circuit Board Supplier is essential to the long-term success of any electronics product. At Pcb-Togo Electronic, Inc., quality isn’t a department—it’s the DNA of our entire operation. From stringent inspections and automated testing to supplier audits and proactive improvement, we take every step necessary to ensure our PCBs are ready for real-world performance.

If you’re ready to raise the bar for your electronics production, Find Out More by speaking with our technical experts or requesting a custom quote today.

Original Link: https://pcbtogo.blogspot.com/2025/06/quality-control-standards-for-printed.html

0 notes

Text

ASROCK AMD Radeon RX 9060 XT Challenger 16GB OC GPUs

AMD Radeon RX 9060 XT Challenger Architecture

The ASROCK AMD Radeon RX 9060 XT Challenger 16GB OC graphics card handles 1440p gameplay faster with AMD's RDNA 4 architecture.

AMD RDNA 4 and AMD Radeon RX 9060 XT GPU power it. Next-generation design boosts rendering and performance with unified computing units with advanced ray tracing and AI accelerators.

The card includes 16GB of 128-bit Memory Bus-connected GDDR6 memory. The memory clock is 20 Gbps.

A 2700 MHz game clock and a 3290 MHz boost clock are on board.

Processors and Compute Units: The GPU includes 32 compute units, including third-generation RT and second-generation AI accelerators. Also included are 28 stream processors.

Essential Features and Technologies: ASROCK AMD Radeon RX 9060 XT Challenger

It supports OpenGL 4.6 and DirectX 12 Ultimate.

It supports PCI Express 5.0 via the x16 bus specification.

This lightning-fast gaming design targets improved 1440p performance.

Used AI-powered features and tech AMD FidelityFX Super Resolution 4's ML-powered upscaling and next-generation raytracing generate AI-enhanced graphics.

Used AMD products and supported AMD FidelityFX Super Resolution 4 (FSR 4), which game developers must integrate. AMD does not support FSR on other graphics cards.

AMD HYPR-RX is on Radeon RX 7000 Series GPUs and later. This technology enables AMD Fluid Motion Frames, Radeon Super Resolution, FSR, Radeon Anti-Lag, and Radeon Boost to work together.

Compatible with AMD Smart Access Memory technology, if OEM support is available, with AMD 500 Series or later motherboards with the latest BIOS, AMD Radeon RX 5000 Series GPUs, and Ryzen 3000 Series CPUs (certain models excluded).

An upgraded media engine improves streaming clarity.

Modern ultra-high refresh monitors can employ the updated Radiance Display Engine, which features DisplayPort 2.1a and HDMI 2.1b.

Featuring Future-Ready Technology and longevity.

For optimal AM5 platform performance with AMD Ryzen 9000 Series CPUs.

ASROCK AMD Radeon RX 9060 XT Challenger Resolution and Connectivity:

One HDMI 2.1b, three DisplayPort 2.1a. With a Digital Max Resolution of 7680×4320, it enables up to three screens for multi-viewing. Use HDCP.

Power:

The card needs a 550W PSU with one 8-pin power socket. Power delivery components like Dr. MOS, an integrated power stage for synchronous buck-set down voltage applications, improve thermal performance. It can produce 50A per phase continuously. Additionally, it uses Premium 90A Power Chokes, which have three times the saturation current and greater Vcore voltage than typical chokes.

Cooling system

Dual fans increase cooling efficiency and balance performance and silence. Striped Axial Fans increase airflow with their blade stripe construction and bottom polishing surface. The 0dB Silent Cooling feature turns off the fans at low temperatures for quiet and on when the temperature rises. Cooling includes Ultra-fit and consolidated heatpipes to maximise GPU baseplate contact and heat dissipation.

High-density metal welding isolates pipes and stacked fins, improving heat dissipation. Nano Thermal Paste maximises heat transfer and closes contact gaps. Components heat the heatsink via reliable thermal pads. To protect the GPU die and maximise cooler mounting pressure for thermal efficiency, precise screw torque is employed during construction.

ASROCK AMD Radeon RX 9060 XT Challenger PCB and Hardware:

A sleek metal backplate avoids PCB bending and increases cooling using thermal pads. An LED On/Off Switch turns on or off LED indicators for decoration. The PCB architecture includes a 2 oz copper PCB for lower temperatures and energy efficiency, a matte black PCB with an intriguing colour scheme, and a high density glass fabric PCB to fill layer gaps and prevent humidity-induced electrical shorts.

AMD Radeon RX 9060 XT Challenger Software

User-friendly AMD Software Adrenaline Edition controls performance with trustworthy drivers, real-time AI-powered support, and one-click AMD HYPR-RX optimisation. This software improves gameplay with higher frame rates, less lag, and sharper graphics.

Dimensions and Weight:

Card weighs 645 g and dimensions 249 x 132 x 41 mm.

Price and Availability

The ASRock AMD Radeon RX 9060 XT Challenger 16GB OC graphics card will launch internationally on June 5, 2025, for $349 USD.

#AMDRadeonRX9060XT#AMDRadeonRX9060#RadeonRX9060XT#RX9060XTGPU#AMDRadeonRX9060XTChallenger16GBOC#ASRockAMDRadeonRX9060XT#technology#technews#technologynews#news#govindhtech

0 notes