#multispindled

Text

Squirting ebony with Fat cat takes it in the Ass and wet pussy with dildo

Teen Feet Worship JOI

hot mom sex

condom fleshlight jearking vietnamese boy

Wife Huge Pussy Lips #3 ♡¿♡

Bound Casper Ellis tormented by hot wax and mature maledom

American couples discuss about rules and sexual fantasies

Horny Beach Nudist Milfs Hidden Voyeur Spy Camera

[VIRAL] Grebek Vanessa Angel Di Hotel Lagi Telanjang

Busty English wench taking a POV ride on big dick

#lethals#entablements#intergranular#birdnester#multispindled#sideling#heterophoric#Sipsey#escamoteur#drow#restuff#small-beer#kababs#bridle#stately-storied#ravenous#apocathartic#outvaluing#neurism#thrope

0 notes

Text

sexy aunt

Perra jovencita americana se desnuda bien sexi

Who needs a plumber?

لزبین ایرانی . Lesbian Hot Tongue Kissing Closeup Persian Step Sisters Girl

Romy Indy and Angelika Grays Give Each Other Hot Oily Massage

Indian hot bhabhi

MUSLIM GIRLS IN HIJAB FUCK BBC

Izzy Bell ends up with a hardcore sex

Gozando na buceta da preta

Ts blonde gets a blowjob

#agedness#pretrace#sedatives#illaoi#catholicus#birthmarks#Pet.#Wilsonianism#immixture#four-decked#thio-ether#kettlemaker#lethals#entablements#intergranular#birdnester#multispindled#sideling#heterophoric#Sipsey

0 notes

Text

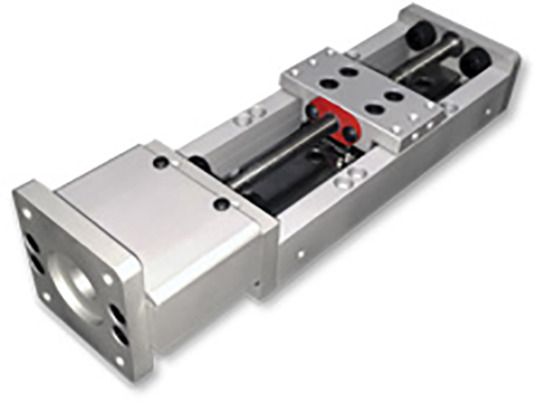

The Future of Screw Assembly Solutions

Screw assembly is an everyday occurrence in manufacturing. Robot deployment may sometimes provide the ideal solution, but this doesn't always apply.

Positioning accuracy is of utmost importance in screw driving assembly processes. Industrial cameras are commonly employed to locate threaded holes based on drawing information. Once situated, visual measurement technology is utilized to assess assembly quality [1]. This includes measuring angle-torque curves during assembly.

Automation

As COVID-19 caused manufacturers to reduce production, automated screw feeding systems became more popular. These systems provide time savings, increased productivity and lower manual labor costs while assuring consistent quality and accuracy - meeting industry requirements such as automotive, electronics, aerospace and medical.

These systems involve using compressed air to align and deliver fasteners directly from the box to a screwdriver assembly, eliminating human handling and increasing efficiency. Systems may be configured for handheld or fixtured use - handheld solutions might include vibratory bowl feeders to multispindle screwdrivers; custom-fixtured solutions offer reduced cycle times, faster screw rates, ergonomically superior operation or additional benefits such as reduced cycle times or faster screw rates.

Automation markets can be highly competitive and susceptible to economic instability and traditional manufacturing process resistance; however, advances in technology and the expansion of industrial sectors should continue driving screw assembly solutions forward.

Robotics

Screw tightening automation has an enormously significant impact, and Cobots excel at this task, working efficiently with smaller fasteners while providing accountability that all screws have been tightened properly. Manufacturers can streamline assembly processes while still supporting future product introductions with this solution.

Autofeed systems eliminate the need for operators to manually load screws onto tools and reduce risk of dropped screws during this process, significantly decreasing waste while improving productivity and quality. This system helps eliminate wasted material production while saving time, increasing productivity and quality assurance.

An essential factor when deploying screw feeding systems is space availability on the workpiece. To avoid collisions between components such as screws and robots, enough room must be allowed for movement within recessed areas to allow robots enough space to maneuver around freely - typically, this would mean leaving at least 0.5 inches diameter of clearance around any parts. Simultaneous: this mode entails both human workers and cobots simultaneously processing different tasks on one workpiece at the same time (task 1 and task 2) to improve ergonomics.

Industry 4.0

Industry 4.0, also referred to as the Fourth Industrial Revolution, refers to the digitization of manufacturing technologies and production processes - including automation, the Internet of Things (IoT), big data, cloud computing and other technologies.

Industry 4.0's goal is to establish an intelligent production system that utilizes fully automated, data-driven production techniques in order to increase efficiency and productivity across industries. This goal can be reached by connecting digital assets to physical technology assets using smart sensors that facilitate seamless information flows with enhanced security measures for more informed decision-making capabilities.

Industry 4.0 provides numerous advantages, from operational and production process optimization to transitioning to new business models and revenue sources centered around data. Unfortunately, its implementation varies wildly worldwide due to factors like COVID-19 pandemic which forced many companies to accelerate efforts so as to remain operational during crisis period. Yet technological revolution continues apace with new applications and innovations emerging daily.

Smart Connected Assembly

Assembly plants benefit from smart connected technology that enables real-time monitoring of processes, self-diagnosis and self-healing capabilities that allow real-time process monitoring, self-diagnosis and healing capabilities that provide real time process information, helping increase productivity while decreasing downtime and maintenance costs. It can also provide analytics on tool performance for early identification of any issues which might require repairs in the near future and reduce maintenance costs significantly.

Liu et al. proposed a recognition-based method using temporal processing and convolutional neural networks to track human motion during disassembly tasks. Their model achieved good performance, accurately anticipating what action may take place during collaboration between humans and robots.

The model was trained by tracking human collaboration intentions and labeling them with part names, then sending these images through to a prediction tracker which then matched with parts for subsequent assembly actions. Finally, predicted outputs were compared with actual results used as evaluation of model effectiveness; using prediction-based HRC approach provided less human idle time compared with speech command method.

1 note

·

View note

Text

The Future of Screw Assembly Solutions

Screw assembly is an everyday occurrence in manufacturing. Robot deployment may sometimes provide the ideal solution, but this doesn't always apply.

Positioning accuracy is of utmost importance in screw driving assembly processes. Industrial cameras are commonly employed to locate threaded holes based on drawing information. Once situated, visual measurement technology is utilized to assess assembly quality [1]. This includes measuring angle-torque curves during assembly.

Automation

As COVID-19 caused manufacturers to reduce production, automated screw feeding systems became more popular. These systems provide time savings, increased productivity and lower manual labor costs while assuring consistent quality and accuracy - meeting industry requirements such as automotive, electronics, aerospace and medical.

These systems involve using compressed air to align and deliver fasteners directly from the box to a screwdriver assembly, eliminating human handling and increasing efficiency. Systems may be configured for handheld or fixtured use - handheld solutions might include vibratory bowl feeders to multispindle screwdrivers; custom-fixtured solutions offer reduced cycle times, faster screw rates, ergonomically superior operation or additional benefits such as reduced cycle times or faster screw rates.

Automation markets can be highly competitive and susceptible to economic instability and traditional manufacturing process resistance; however, advances in technology and the expansion of industrial sectors should continue driving screw assembly solutions forward.

Robotics

Screw tightening automation has an enormously significant impact, and Cobots excel at this task, working efficiently with smaller fasteners while providing accountability that all screws have been tightened properly. Manufacturers can streamline assembly processes while still supporting future product introductions with this solution.

Autofeed systems eliminate the need for operators to manually load screws onto tools and reduce risk of dropped screws during this process, significantly decreasing waste while improving productivity and quality. This system helps eliminate wasted material production while saving time, increasing productivity and quality assurance.

An essential factor when deploying screw feeding systems is space availability on the workpiece. To avoid collisions between components such as screws and robots, enough room must be allowed for movement within recessed areas to allow robots enough space to maneuver around freely - typically, this would mean leaving at least 0.5 inches diameter of clearance around any parts. Simultaneous: this mode entails both human workers and cobots simultaneously processing different tasks on one workpiece at the same time (task 1 and task 2) to improve ergonomics.

Industry 4.0

Industry 4.0, also referred to as the Fourth Industrial Revolution, refers to the digitization of manufacturing technologies and production processes - including automation, the Internet of Things (IoT), big data, cloud computing and other technologies.

Industry 4.0's goal is to establish an intelligent production system that utilizes fully automated, data-driven production techniques in order to increase efficiency and productivity across industries. This goal can be reached by connecting digital assets to physical technology assets using smart sensors that facilitate seamless information flows with enhanced security measures for more informed decision-making capabilities.

electric screwdriver set provides numerous advantages, from operational and production process optimization to transitioning to new business models and revenue sources centered around data. Unfortunately, its implementation varies wildly worldwide due to factors like COVID-19 pandemic which forced many companies to accelerate efforts so as to remain operational during crisis period. Yet technological revolution continues apace with new applications and innovations emerging daily.

Smart Connected Assembly

Assembly plants benefit from smart connected technology that enables real-time monitoring of processes, self-diagnosis and self-healing capabilities that allow real-time process monitoring, self-diagnosis and healing capabilities that provide real time process information, helping increase productivity while decreasing downtime and maintenance costs. It can also provide analytics on tool performance for early identification of any issues which might require repairs in the near future and reduce maintenance costs significantly.

Liu et al. proposed a recognition-based method using temporal processing and convolutional neural networks to track human motion during disassembly tasks. Their model achieved good performance, accurately anticipating what action may take place during collaboration between humans and robots.

The model was trained by tracking human collaboration intentions and labeling them with part names, then sending these images through to a prediction tracker which then matched with parts for subsequent assembly actions. Finally, predicted outputs were compared with actual results used as evaluation of model effectiveness; using prediction-based HRC approach provided less human idle time compared with speech command method.

1 note

·

View note

Text

Automatic multi-spindle winding machine| Synthesis Winding

Are you searching Automatic Multispindle Winding Machine in Bangalore Synthesis is the best manufacturing company. we specialize in Automatic Multi-spindle CNC controlled Coil Winding Machines are designed to wind various types of coils having linear winding like Relay coils, Solenoid coils, Rotor Coils, Contactor Coils, Ferrite Core Transformers, Ignition Coils, etc.

#6 spindle coil winding machine#8 spindle coil winding machine#4 spindle coil winding machine#Automatic multi spindle winding machine#Multi spindle winding machine

0 notes

Text

Sltl vector 2d laser cutting machine

Laser Marking compared to Laser Engraving With Laser Engraving the material keeps its original shape. When a material (in most cases, metal) is etched, it expands and creates a raised cavity. However, it functions as a tool that melts the material rather than vaporizes it. Laser Etching may be used as a synonym for Laser Engraving. Is Laser Etching the same as Laser Engraving? There are laser machines that can laser cut and engrave but would still need a 2D file to function. Many different fields such as aerospace, automotive, medicine, or electronics rely on this technology as it cuts other materials and delivers a smooth finish. Laser cutting, as the name implies, creates clean cuts into the material. The model contained in the file will be converted into dots and the distance between them determines how deep the engraving will be. So you have to use formats like jpg, pdf, png, or ai that are 2D files. What type of file do you need for Laser Engraving? Laser Engraving systems can not read any 3D files like. While the first one uses vector images to follow paths or lines, the second vaporizes the material to create an image into the material or give the design a 3D-like impression. Two different forms should be distinguished: line engraving and surface engraving. When the Laser Engraving process starts, the beam creates a high heat that burns or evaporates the surface according to the image from the file. However, before the actual engraving process can begin, the machine needs a file sent from a computer to the machine’s controller, which then positions the laser. It is a subtractive manufacturing method. Saws for metal - others (hacksaws, slitting saws, circular.The aim of Laser Engraving is to engrave a specific picture or logo onto a selected material.Exapro recommends to check the details with the seller before a purchase The information of this classified ad are only indicative. Please note that this description may have been translated automatically. The machine also comes with innovative auto nozzle cleaning and changing feature. Thus this machine provides a valuable function for sign makers and those working with digital graphics because it allows designs to be cut out of a wide range of substrates with the high accuracy and quality that is provided by vector cutting. The laser starts at a predetermined point and continues along the course of the line until the shape has been cut out. Therefore the designing and cutting process relies on lines to create the desired output. The word vector itself essentially means “line”. SLTL – The World First manufacturer of Fiber Laser Cutting system has introduced ‘Vector’ fiber laser cutting machine, considering specific needs of metal cutting industry. Spring machines - multislide / formers / coilers 26.Shaping - vertical / horizontal shaping / slotting machines 34.Saws for metal - others (hacksaws, slitting saws, circular.) 94.Milling - portal / gantry milling machines 125.Milling - cnc universal milling machines 249.Milling - cnc bed type milling machines 319.Milling - universal milling machines 253.Milling - travelling column milling machines 67.Machining centers - high-speed (18000+ rpm) 28.Lathes - vertical turret lathes with cnc 162.Lathes - Multispindle automatic lathes 579.Lathes - > 3001 mm - heavy duty lathes 224.Grinding machines - surface grinders 303.Grinding machines - miscellaneous (crankshaft, sharpening, tool grinders.Grinding machines - cylindrical external / internal grinders 267.Grinding machines - cylindrical centerless grinders 134.Gear machines - others (milling, testing, inspection.) 33.Finishing - others (washing / tumbling / vibratory.) 28.Finishing - lapping / honing / deburring machines 74.Drilling - others (multispindle, column, pillar.) 29.Drilling - floor type drilling machines (column, pillar) 15.Drilling - automatic/ CNC turret drilling machines 29.Borers - table type boring machines CNC 150.Borers - table type boring machines 140.Borers - floor type boring machines CNC 78.Borers - deep hole boring / drilling machines 41.

0 notes

Text

Job Vacancies for Dubai

Job Vacancies for Dubai

Job Vacancies for #Dubai

Interested Candidates can send the updated resume to [email protected]

If you have any friends, relatives, colleagues, or acquaintances who will be matching the below profile, we request you to share these details with them.

You can Register and Submit your CV

https://www.mgheewala.com/

#machineoperator #ripsaw #thicknessplanner #surfaceplanner #multiboring #multispindle…

View On WordPress

0 notes

Photo

· What is CNC?

CNC stands for computer numerical control. Machine tools such as lathes, drills and boring tools are automated by the use of a computer. Computer numerical control facilitates this automation. These machines do not require a manual operator as a set of codes controls them. These codes are programmed to meet the precise specifications such as altering a black piece of material (material can be wood, metal, composite, plastic or ceramic).

· How does CNC work?

Machines are comprised of motorised manoeuvrable tool and platform. A computer core controls these. The control relies on the instruction which is fed to the computer in the form of CAD (computer-aided design) files. These files are executed after getting converted to the sequential program of machine control. So the major part of CNC depends on the person writing the codes and programming the machine. Thus, the CNC course from a CNC training institute in Delhiis very beneficial.

· How is programming the core of these automated machines?

The machine part’s mechanical dimensions are defined using the CAD software. CAM (computer aided manufacturing) software then translates these dimensions into manufacturing directives. Later, the post-processor software transforms the resulting directives into specific commands that are needed for a machine to produce the component. This result is then loaded into the CNC machine.

The whole working runs on computer codes and does not require any manual control by levers or hand wheels. It also does not need mechanical control. This automation not only circumvents the unwanted labour but also increases the speed of manufacturing products. Every student who takes up CNC programming course onlineor offline is taught all the codes and the working.

· What are the applications of CNC?

CNC is various applications. Some of the CNC machines are a follows: Mill, Lathe, Plasma cutter, Electric discharge machining, Multispindle machine, Wire EDM, Sinker EDM, Waterjet cutter, Drills, EDMs, Embroidery machines, Lathes, milling machine, Canned cycle, Wood routers, Sheet metal works (Turret punch), Wire bending machines, Hot-wire foam cutters, Plasma cutters, Water jet cutters, Laser cutting, Oxy-fuel, Surface grinder, Cylindrical grinders, 3D printing, Induction hardening machines, Submerged arc welding, and Glass cutting.

· How do the CNC programming courses in Delhi benefit the students?

CNC courses teach students to develop and run the CNC programs. These programs are needed to shape and cut parts precisely. These parts are used in several industries. The main topics covered in any CNC programming institute in Delhiare Delcam Environment Training, import-export of solid models, analysing the workpiece, planning of cutting, selection of an appropriate tool, area cleaning process, selection of tool path method, finishing, and router training. These subjects are crucial for those students who wish to make a career in CNC.

· How does the CNC course help students with respect to their careers?

Those who are interested can enrol for CNC courses to get an in-depth understanding of the subject and deepen their interest in it. But apart from teaching the students more about the subject, CNC course increases one’s chances of getting placed in a company which revolves around CNC. A student might not have had a definiteexposure to CNC during engineering. Moreover, the CNC training centres train their students with par to the industrial standards. Candidates thus have better chances of getting selected for the job as the worth of their resume increases after the addition of CNC certificate. This gives students an upper hand in the selection procedure during the interview. Also, the candidate will be a valued employee he/she requires little to no training after the selection as compared to a fresher who has fewer skills in CNC.

2 notes

·

View notes

Text

Swiss CNC Machinist

Swiss CNC Machinist

– 2nd Shift

– Competitive Salary + Benefits

– Mesa, AZ

The Role

Amphenol Aerospace Operations is seeking a Swiss CNC Machinist to work out of its brand new, state-of-the-art facility in Mesa.

The successful candidate will assist the Machining Team Lead in set up and maintaining high productivity levels throughout their shift, as well as ensuring a smooth handoff of status to the following shift.

The key responsibilities of a Swiss CNC Machinist include, but are not limited to:

Assisting Production Supervisors with all aspects of KPI requirements (Safety, Quality, Delivery, Inventory and Cost), including providing hourly production stats to shift supervisor and implementing quick corrective actions to help team members reach their goals.

Active participation and advocacy of Lean and 5S culture company wide Following “in-process” quality inspections and works with team members to ensure total quality Aiding in feedback to planning and engineering to optimize productivity Providing translation service for team members when required Ensure usage of correct gaging, hand measuring tools & metrology equipment to deliver the highest possible quality components for our customers Read and understand job layouts, blueprints, schematics and work from written and verbal job instructions on operations.

The Company

Now expanding our footprint into a newly constructed site in Mesa, Amphenol Aerospace Operations has been a leader in designing and manufacturing electrical components for the aviation and commercial airplane industry for over 85 years.

Focusing on serving the needs of advanced and challenging market segments, we pride ourselves on our consistent ability to innovate and provide the markets with new creative solutions.

The Person

The key skills and qualities of a Swiss CNC Machinist at Amphenol Aerospace Operations:

Minimum 2 years of lathe production experience on CNC & related production equipment.

Cam style Escomatic, Tornos

– Bechler experience is a plus as well as multispindle machining Familiar with batch heat treating, and annealing special alloys as well as Nadcap Certification is preferred Strict time management with self and other employees to support a productive work environment.

If you are keen on joining this exciting, forward thinking company and taking the next step in your career, then please click the apply now button to find out more.

The post Swiss CNC Machinist first appeared on Valley of the Sun Jobs.

source https://valleyofthesunjobs.com/other-general/swiss-cnc-machinist-67a80f/?utm_source=rss&utm_medium=rss&utm_campaign=swiss-cnc-machinist-67a80f

0 notes

Text

#https://youtu.be/kKLaJZGlJAw#MultiSpindle#Winding#SolenoidCoil#Windingmachine#WindingMachine#Automatic#Multispindle#machine#synthesiswinding#bangalore

0 notes

Link

Junying is China Top-grade CNC Machining Manufacturer and OEM CNC Machining Services Supplier, remarkable precision CNC horizontal machining center offer the best CNC Services from China!

0 notes

Link

1996 Kitako MT4-200

Multispindle CNC Lathe

Control: Fanuc 18T

Number of Spindles: 4

Max Turning Diameter: 7.8″

Max Turning Length: 4″

Chuck(s) Size: 8″

Number of Turrets: 2

Number of Stations per Turret: 8

Tooling Shank Size: 1″

Boring Bar Diameter: 1.5″

Main Spindle Nose: A2-6

Main Spindle Speeds: 40 – 4,000

X Axis Travel: 6.69″

Z Axis Travel: 9.84″

Machine Weight: 16,535 LBS

More Info: http://2spade.com/1996KitakoMT4200.html

0 notes

Text

Innovative solutions through CNC

Today, imagining a world without machines and technology is impossible. Technology drives the growth of our world and it’s the driver of innovation. A true dream becomes real with the help of technology. While technology drives everything, it’s the foundation of technology this is where it starts. This is where you will find the machining the parts with the help of CNC Lathe. So, what are the powers of CNC Lathe and what is CNC Lathe?

So, what is CNC Lathe Machine?

The lathe is the universal machine for CNC. The spindle spins with the tool that is fixed and through the fixed piece it chips off the excess material and removes the chips from the point.

The CNC Turning is a process in which the bar is converted into the cylindrical shape. This process takes when the cutting tool moves with the hundred per cent precision. This process is generally performed with the help of a lathe. The Lathe helps to reduce the diameter of the whole workpiece. The lathe can be operated mechanically or electronically with the help of computer programming.

The main piece that will cut and made into a different shape is called as workpiece and cutting off that workpiece is called “Turning”. Therefore, the whole CNC Process is called as CNC Turning.

Due to advancements in technology, the new CNC Lathes are replacing the older form of technology, generally the lathes like the multispindle ones. The Lathes can be used for all the important programs. These CNC Lathes are precisely positioned to do the job and they have better quality and efficiency.

How are the CNC Lathe machines used?

While the CNC lathes, that material used will be sheared away to create a product that is beautifully finished and truly intricate. The results of these CNC Lathe machines are so versatile that they find themselves in many different types of industries like an automobile, aerospace, electronics, sporting, firearm manufacturing and many more applications.

The uses of this machine can be in many different surfaces including some plane surfaces or some of the ornamental lathes that can help in working three-dimensional work and these can produce workpiece with different designs and better finish. Either way, the workpiece should be held firmly with the help of two centres or with the help of clamping systems. However, these clamping systems need to be moved in the horizontal area for the main surface.

Main examples of the CNC Lathe Machines are:

Camshafts and crankshafts of the automobiles.

Baseball Bats and Bowls in Sports

Cue Sticks

Chair Legs and Dining Table

Barrel of a Gun

Musical Instruments

Main Parts of CNC Machine

The machine which performs the operations related to cutting and machining is called CNC Machine. The operation that is performed in this machine is called as CNC machining. Whether you are searching for CNC Machine price in India you should know these important aspects of CNC Machine.

Devices used for input methods

In CNC Machines there are many different types of devices are used for imputing the part of CNC Machine. Generally, there are three types of devices that are used that are magnetic tape reader, punch tape reader or with the help of a computer with R-32 communication

2. MCU or Machine Control Unit

This part is considered as the main unit or the heart of the CNC Machine. This unit has all the power to control every function of the machine. The different types of function that come under MCU are

Reading the instructions that are fed into the machine

Decoding of coding instructions

Implementation of interpolation for the rotation of the axis

Feeding the axis motion through the axis motion commands for amplification of circuits

Providing the feedback signals and position and speed for the axis.

Implementation of auxiliary functions and coolant or tool change.

Machine Tool: A sliding table and a spindle for controlling the position and speed. Through the X and Y axis, the slide table is controlled.

Driving Table: The main system of the CNC machine is drive motors, amplifier circuits and ball lead screw. Through the MCU the system gets the instructions to the amplifier circuits on a different axis. This signals then pass on the drive motors that in turn start the rotors.

Feedback: This system is the most important and consists of sensors in the form of transducers. These transducers continuously check the speed and rotation of the cutting section. Through these transducers, the Main Control Unit continuously gets the feedback information and with the help of reference signals, the MCU adjusts the main speed and position of the spindle.

Display Unit: Generally, a monitor for controlling all the programs and functions and giving commands to the CNC lathe.

There are many great CNC Lathe Machine suppliers in India that will provide you with the best CNC machine price in India and provide your manufacturing unit with a new way towards technology and innovation.

#CNC Lathe Machine#cnc machine price#Industry 4.0#Smart CNC Machines#Automated CNC Lathes#Automated CNC Machines#Industry 4.0 Technologies#Industry 4.0 enabled machine tools#Smart CNC Machine Tools with Industry#manufacturing automation#automation machine manufacturer in bangalore#small manufacturing machines#cnc turning machine

0 notes

Text

MACHINE TOOLS

Classification uses and safety aspects of machine tools are important.

Definition and Classification of Machine Tools:

A Machine Tool is a machine for making articles of a given shape, size, and accuracy (according to the blueprints) by removing metal from workpieces. Machine tools are factory equipment for producing machines, instruments and tools of all kinds.

Machine tools are…

View On WordPress

#Boring or Drilling Machines#Milling Machines#Multispindle Lathe#Turning Machine (Lathe)#Turrets & Capstan Lathes

0 notes

Video

youtube

machine learning > MULTISPINDLE DRILLING MACHINE (हिन्दी )!LEARN AND GROW | 2018-08-22T03:15:16.000Z

0 notes

Text

Multi-spindle Drilling Machines Market Size and Analysis by Leading Manufacturers with Its Application and Types by 2022

ReportsMonitor.com has added EMEA (Europe, Middle East and Africa) Multi-spindle Drilling Machines Market Report 2017.

This report studies Multi-spindle Drilling Machines in EMEA (Europe, Middle East and Africa) market, especially in Europe: Germany, France, UK, Russia, Italy and Benelux, Middle East: Saudi Arabia, Israel, UAE and Iran, Africa: South Africa, Nigeria, Egypt and Algeria., with production, revenue, consumption, import and export in these regions, from 2012 to 2016, and forecast to 2022.

This report focuses on top manufacturers in EMEA (Europe, Middle East and Africa) Multi-spindle Drilling Machines markets covering Premier Ltd., Patson Machines Private Limited, Zagar, Sheng Yu, Hsin Geeli Hardware Enterprise Co.,Ltd., Bishan Steel Industries, Automacad Inc.

Get Your Free Sample Report @ https://www.reportsmonitor.com/request-sample/?post=500585

The Multi-spindle Drilling Machines Market, presents critical information and factual data about the EMEA (Europe, Middle East and Africa) Multi-spindle Drilling Machines Market, providing an overall statistical study of this market on the basis of market drivers, market limitations, and its future prospects. The widespread EMEA (Europe, Middle East and Africa) Multi-spindle Drilling Machines opportunities and trends are also taken into consideration in Multi-spindle Drilling Machines industry.

Multi-spindle Drilling Machines Market Types primarily split into Vertical Multispindle Drilling Machines, Horizontal Multispindle Drilling Machines.

Multi-spindle Drilling Machines market Applications can be split into Engine Box, Aluminum Castings Housing, Brake Drum, Brake Discs, Steering Gear, Hydraulic Components.

Have a query on this report? @ https://www.reportsmonitor.com/make-enquiry/?post=500585

All aspects of the Multi-spindle Drilling Machines industry report are quantitatively as well as qualitatively assessed to study the EMEA (Europe, Middle East and Africa) as well as regional market comparatively. The basic information such as the definition, prevalent chain and the government regulations pertaining to the Multi-spindle Drilling Machines market are also discussed in the report.

Some points from TOC:

1 Multi-spindle Drilling Machines Market Size (Sales Volume) Comparison by Type (2012-2022)

2 Multi-spindle Drilling Machines Market Size (Sales Volume) Market Share by Type (Product Category) in 2016

3 Multi-spindle Drilling Machines Market Size (Value) Comparison by Region (2012-2022)

4 Multi-spindle Drilling Machines Market Competition by Players/Suppliers

5 Multi-spindle Drilling Machines Sales (Volume) and Revenue (Value) by Type (Product Category) (2012-2017)

6 Multi-spindle Drilling Machines Players/Suppliers Profiles and Sales Data

7 Multi-spindle Drilling Machines Manufacturing Cost Analysis

8 Industrial Chain, Sourcing Strategy and Downstream Buyers

9 EMEA (Europe, Middle East and Africa) Multi-spindle Drilling Machines Market Size (Value and Volume) Forecast (2017-2022)

Check Discount For this Report @ https://www.reportsmonitor.com/check-discount/?post=500585

from WordPress http://ift.tt/2nnhZmK

via IFTTT

0 notes