#new boiler dorset

Text

Official Presentation Dorset Mechanical Ltd

Dorset Mechanical Ltd for top-tier plumbing and heating services in Dorset or Somerset. With 32+ years of expertise, our Sherborne-based Gas Safe- and OFTEC-registered engineers deliver quality and reliability.

21 The Old Yarn Mills,Sherborne,Dorset,DT9 3RQ

+441305 248615

#boiler repairs dorset#heating engineer dorset#leak repairs dorset#new boiler dorset#plumbers in dorset.

0 notes

Text

Dorset Mechanical Ltd

Dorset Mechanical Ltd for top-tier plumbing and heating services in Dorset or Somerset. With 32+ years of expertise, our Sherborne-based Gas Safe- and OFTEC-registered engineers deliver quality and reliability.

#boiler repairs dorset#heating engineer dorset#leak repairs dorset#new boiler dorset#plumbers in dorset.

0 notes

Text

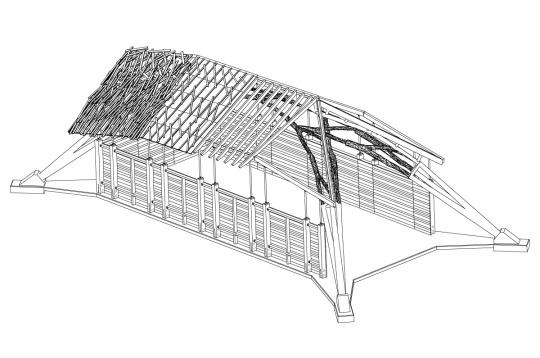

Woodchip Barn

Project by, Mohaimeen Islam (Bangladesh), Zachary Mollica (Canada), Sahil Shah (India), Swetha Vegesana (India), Yung-Chen Yang (Taiwan)

Studio: Project and Make Studio (Work of M.Arch Thesis)

Year: 2015-16

Location: Hooke Park, Dorset, UK

-

vimeo

Five architects designed and built the Woodchip Barn as students of AA Design & Make MArch 2014/15 programme, for their final group project. Being the students of Design & Make, they used ‘prototyping’ as ‘vehicles’ for design research, developing modes of experimental architectural design that integrated full-scale making. Situated in the unique context of historic English woodland, the course was based at Hooke Park, the AA’s Dorset campus for research in timber and alternative rural architectures. The MArch programme is mainly run by Programme Director Martin Self and Emmanuel Vercruysse.

THE WOOD CHIP BARN LINK: https://designandmake.aaschool.ac.uk/project/wood-chip-barn/

Design & Make’s 2015/16 project was the robotically fabricated Woodchip Barn at Hooke Park, the AA’s forest campus in Dorset, UK. Following the installation of a woodchip-fuelled biomass boiler on previous year, the students of the AA’s Design & Make 2014/15 programme were tasked with the construction of a bulk woodchip storage barn to allow the campus to be sustainably heated with Hooke Park’s own trees. The ambition of the design was to use found natural junctions/forks in trees – structurally, using 3D scanning as a feedback for the newly acquired robot-arm to fabricate the structure. The final arching structure of the barn is thus formed from forked beech tree components directly sourced from the surrounding woodland.

The initial responsibility was to survey Hooke Park’s beech compartments in teams, to help in preparing a database of potential forked components, from which the structural concept was developed. Based on the criteria of that concept, 25 forks were harvested from the forest, brought back to the campus, and scanned in 3D. An organization script was used to generate a final arrangement of forks in collaboration with engineers from Arup. This digital model was then translated into fabrication information with which Hooke Park’s new robotic arm transformed each fork into a finished component.

The 180 sqm Wood Chip Barn is located at Hooke Park’s wood-processing yard. Spanning 25 m x 10 m, the building consists of a concrete slab, timber push-walls and a wooden roof, suspended from that arching vierendeel truss formed by beech tree-forks. The truss, after being preassembled in Hooke Park’s Big Shed [LINK: https://www.dezeen.com/2012/04/25/hooke-park-big-shed-by-piers-taylor-and-aa-unit-19/] and all other components, in the yard, were then erected on site under the guidance of Dorset craftsman Jack Draper who coordinated the fabrication and site operations. To aid a productive workflow upto construction stage, the building task was divided in four components: Floor & Wall, Roof, Truss, and Truss legs – each one/two of the students with responsibility of designing and testing these FOUR PARTS to finally combine them onsite into a whole building.

In this building the role of the push-wall was quite significant as it had to contain the wood-chip, and provide surfaces to scoop against when extracting chip with a telehandler. The walls had to be essentially cantilevered structures, totally independent of the truss. They had to be fixed on the concrete slab, to account to its self-load and the lateral loads of the chips, and also to carry the vertical load of the roof at its eves. This led to the configuration, where chipping will take place through the clearstory opening on the long elevation and extraction shall occur at the open gable-end; resulting into a geometry of three straight walls. Continuous effort has been given to dissolve the robustness of the linear wall by putting members, e.g. beams and studs on the exterior. Ar. Mohaimeen was involved in preparing complete drawing sets and also fabricating components for the floor, wall, roof and making 1:20 model of the actual truss structure. However, his core responsibility at this stage included designing and testing options for the Floor and the Push-wall by making scale models and mock-ups. To test its visual, tactile, and structural integrity, a series of models at 1:20 scale and a mock-up at 1:2 scale, were made to get feedback from the physical objects. At this point, a plan was made to fabricate the various components of the wall which were then to be assembled on site.

Such experiments provoked a critical understanding of the need and scope for experimentation in the context of Hooke Park for realizing how digital design and fabrication technique can re-invent traditional methods of ‘making’ to create an architecture that is evidence-based, innovative, yet appropriate to context, allowing interaction between client-designer-builder. Developing the precedent set by Hooke Park’s three twentieth-century buildings by architects and engineers including Frei Otto, the Wood Chip Barn explores an alternative vision of 'digital age' wooden building. The construction of the large span arched Vierendeel truss composed of twenty beech forks is presented in 2015-16 year’s project as a full scale materialization of this idea. 3d scanning and robotic technologies has allowed forks from the Hooke Park forest to be harvested to create a structure with minimal processing and without the use of custom fabricated steel components. With the integration of 3-d scanning, robotic-fabrication, and form-finding techniques combined with traditional knowledge, the Wood Chip Barn is an experiment of non-standard architectural production.

Project Credits

Design Team: (Design & Make Students)

Mohaimeen Islam

Zachary Mollica

Sahil Shah

Swetha Vegesana

Yung Chen Yang

Tutors:

Toby Burgess

Charley Brentnall

Martin Self

Emmanuel Vercruysse

Project coordination and site management: Jack Draper

Engineers: Arup (Francis Archer, Naotaka Minami, Coco van Egeraat

Workshop manager: Charlie Corry Wright

Robotics developer: Pradeep Devadass

Forester: Christopher Sadd

Estate Manager: Jez Ralph

Workshop technician: Edward Coe

Erection team: Timothy Hallbery, James Vooght, Aurimas Bukauskas, Summerbuild Volunteers

Important Links:

MOHAIMEEN ISLAM THESIS:

https://issuu.com/mohaimeenislambadhon/docs/aad_m_thesis_mohaimeen_islam

MOHAIMEEN ISLAM INDV. PORTFOLIO: https://issuu.com/mohaimeenislambadhon/docs/aad_m_wood_chip_barn_individual_por

WOODCHIP BARN GROUP BOOK:

https://issuu.com/mohaimeenislambadhon/docs/aad_m_wood_chip_barn_group_book

MOHAIMEEN ISLAM WORKS_VIDEO LINKS:

CONSTRUCTION TIMELAPSE: https://www.youtube.com/watch?v=p30m1BZ701I

WALL FABRICATION: https://www.youtube.com/watch?v=AzKKLwVBxC4&t=6s

COMPONENTS ASSEMBLY: https://www.youtube.com/watch?v=wCHNRh2yh3c

0 notes

Text

Gold BoilerCare Ltd

Hello and welcome to Gold BoilerCare Ltd, here to help with all of your heating needs! Whether you’re in need of a boiler service or would like to have us quote for a new boiler installation, we’re here to assist you. Based in Poole, we are proud to offer our services throughout Dorset. For full peace of mind, please note that we are Worcester Accredited installers, LPG Accredited and G3 Unvented Hot Water Qualified.

Hours : Mon-Fri 9am-5pm

Address : 9 Mayford Road

Poole BH12 1PT

Phone : 01202944416

Email : [email protected]

Website : https://goldboilercare.co.uk/

1 note

·

View note

Text

Builders In Hornchurch, Essex - Professional, Reliable And ...

Builders Warrington - Db Building - Warrington Builder - Local ...

Table of ContentsGem Building Specialists Limited West Sussex - WorthingFind Builders With Which? Trusted Traders - Which?Find Local Builders Near You With Rated PeopleTrusted Local Builders In Lichfield & Staffordshire :: Ph&c ...Builders In Rickmansworth - Melbourne Builders - Local ...Steven Sarjant Local Builders ▷ Creswell, 3, Holly AvenueSteven Sarjant Local Builders ▷ Creswell, 3, Holly AvenueBest Local Builder And Contractor In Essex, Kent - Local ...

To see if an investor has any associations, certifications or subscriptions, just look for the logos on their Depend on A Trader account. Are you a building contractor? If you take on developing jobs of any type of dimension, it is very important that you and also your clients are shielded with the right level of insurance cover.

This mass bag of logs is a neat and inexpensive choice for keeping large amounts of logs. Our vented mass bags enable maximum drying out of your logs offering you the most affordable feasible moisture content. Our Hardwood is excellent for giving fire owners with a lengthy long-term flame. This product would be perfect for your open fires, ovens and some log central heating boilers.

Fmb Urges Chancellor To Back Local Builders

Relying on just how often you need your logs replenished we can use you a dedicated account manager to schedule your shipments throughout the season. These British Logs have actually come direct from forests in Northumberland, The Scottish Boundaries and also Dumfries to our backyard where we have seasoned, split, packed as well as conditioned them in our biomass warmed drying center.

We know from our research that our consumers choose UK grown product for many reasons as well as are satisfied that their logs have a lower carbon impact than imported products. Only logged in clients who have actually purchased this item may leave a testimonial. This item is suggested for open fires, ovens and also some log boilers.

Local Builders - William Mccall Architectural Services

Moisture material around 25% (moisture examined before leaving depot) Note lumber specifically dry wood will readjust wetness material to the environment it is saved in. Origin British Woods from Northern England and also Scotland Types Birch, Ash, Alder, Oak Log size around 250mm Complimentary shipment to all postal codes within a 10 mile distance of Berwick Upon Tweed.

There should be an available location for the wagon to tip the go to your land. We do not pack the products away after they have actually been off packed as a result this is your duty. We intend to provide all orders in 5 working days, if an item comes to be out of supply we will call you to tell you when it is readily available as well as ask if you desire to wait or we reimburse your order.

Mkm Mansfield, Your Local Builders Merchant - Mkm Building ...

Delivery motorists will certainly aid where possible yet it is your responsibility to relocate the product from the decrease off to its relaxing place.

Saint-Gobain Structure Distribution Limited, Trading as Jewson, Registered in England, Firm Registration No: 01647362 Registered Office: Saint Gobain Home, East Leake, Loughborough, LE12 6JU BARREL Registered: GB 394 1212 63.

Builders Services In London - Hire Local Builders By Fantastic ...

1920's semi in major requirement of refurbishment - brand-new electrics, heating, plastering, wall surfaces knocking down - RSJ's installed, some new windows and also French doors. Constantly a bit worrying if you do not know any home builders ... Resource: thebestof. co.uk.

We are open for limited collection & shipment as well as doing whatever we can to maintain our customers and also team safe. During this moment our opening hours differ to what is noted so please call us on 01462 730 169Home Testimonials Extremely Recommend All Local Builders To Make use of" Dazzling service right here, constantly goes the extra mile.

Travis Perkins - Builders Merchants, Building Supplies ...

We provide brand-new build services for commercial, commercial as well as residential residential properties. We can take the task from first concepts with design stages, dealing with architects and planners, costing, laying structures, and all facets of building consisting of decor. Any kind of professionals that we may need to sub-contract to are always anticipated to fulfill the same high criteria we provide.

Every diverse task we tackle contributes to the breadth of our expertise as well as we bring this to every new challenge. We have various structure tasks working closely with trusted neighborhood designers, take a look at our current projects below!.?.!! Please submit the type listed below or call us on: 07795 320891 See our other services right here:.

Local Builders & Construction Lancing, Sussex (Uk)

New Cooking Area Canford Cliffs, Poole, Dorset This home refurbishment was a direct 'old kitchen area out as well as brand-new cooking area in' work in the Canford Cliffs location of Poole. As part of our structure solutions, we eliminated every one of the old devices and also home appliances, did a tiny rewire, re-plastered all surface areas, [].

It's challenging to pinpoint an exact size of time or cost for your extension. To get a precise quote, one of our Opun land surveyors will see you for a complimentary appointment. Throughout the assessment they'll take dimensions, go over the task and also offer inspiration and guidance to assist you obtain the solutions you need prior to you choose to approve the quote and also job begins.

Local Builders Worthing - Worthing - West Sussex - Uk

This implies, unless what you desire modifications, you'll only pay what you're estimated and the job will certainly be delivered within the marked time.

1 note

·

View note

Text

I’ve been very quiet about personal things on here of late and so I think now is the time to get them out. ‘It’s now or never’ as Dean and Lorraine sing in All Shook Up, after all.

I’m busy, I’m tired and I’m frightened. As in excited for what a life post uni holds, but also terrified at the same time. There are now so many options that i hadn’t even considered at Christmas; do I spend two months serving in Switzerland or Dorset? Do I go through with doing a Discipleship Year? Will I graduate? Will I at least, make it to next Thursday when I sit my last exam? What’s going to happen with the flat? The less that has to be said about landlords, broken boilers, no hot water and potential new tenants, the better.

I don’t know, everything’s just feeling quite scary right now, so I’m going to re-watch Christy Altomare who is debuting Anastasia on Broadway right now singing ‘Journey to the Past’ and let the little part of my heart that’s still a nine-year-old squee in delight.

youtube

2 notes

·

View notes

Text

E Voucher Promotion with Boiler Installations

E Voucher Promotion with Boiler Installations

Due to its success the exclusive Bosch E Voucher Promotion has returned

The promotion applies to Worcester Greenstar Gas boilers installed between 26th January 2017 and 20th March 2017.

Every consumer who has a Worcester boiler installed by Barry Frampton Ltd within the promotion period, is entitled to a 25% discount voucher for a one off purchase to use on the Bosch Small Home Appliances…

View On WordPress

0 notes

Text

Farewell Faithful Friend

THE STORY STARTS IN 1981 when I was nearing the end of a four-year restoration of a 1923 Armstrong Whitworth 10R35 to concours standard, and the question was, what was I going to do next?

I was keen to carry on and restore another engine, as my objective was to eventually be able to afford an 'old banger' of a traction engine, which would need rebuilding of course, but that was always my boyhood dream since I first stood on 1900 Aveling & Porter 4561 6hp road locomotive Jimmy at the age of two in 1954, at the last Chris Lambert steam event.

The events at Chris' were always held on the last Saturday in June and included a parade of the engines from his extensive yard, around the village of Horsmonden, Kent. The yard is now an small exclusive housing development and called appropriately Lamberts Place.

My thinking was the proceeds from a well restored steam roller and a portable just might give me sufficient funds to head me in the right direction for a traction engine. But I wasn't interested in purchasing a large portable, as they are hard to manoeuvre at the best of times and are generally hard work, not a one man engine at all.

My objective was a small 2 or 3hp engine, which even then were very hard to find. I started the 'jungle drums' as in those days finding such things was virtually impossible. There were no imports for South America and the like, which have subsequently totally flooded the market unfortunately. Although some traction engines were coming back from Australia, some seemed to be doing so in shady circumstances at that time. However, I also wanted an engine that had a proper UK history, which can be traced and gives the engine more value than an overseas import, well to my mind it does anyway.

In August of that year I happened to see the now late Bill Briggs at Astle Park, Cheshire while in the parade ring with Brian and Harry Allison's Aveling & Porter tractor Oberon. He told me that great northern Marshall 'guru' Jack Pierson had died and at Hetton-le-Hole, in Jack Wakefield's yard, stood one of Jack Pierson's engines.

At one time he had several strewn across the north in various farms and yards, but all had been sold by his distant family who lived near Watford, except the little 1912 Marshall 3hp portable 59763. Bill added that the money being asked for it was much too high, but apparently it had a boiler certificate and he told me where I could find the phone number for Jack Wakefield, no mobiles in those days.

I asked skilled engineer, the now late John Bailey from Borough Green, to come with me and one very early Saturday morning in October 1981 his wife Pat drove us to King Cross railway station where we caught the 125 train to Durham city station. Here we were picked up by Jack Wakefield in his cream coloured Triumph Toledo.

Apparently the engine had major boiler work in various places and the cylinder block had been removed to weld the firebox crown. Many extended welding rods were used, there were many repair bills that amounted to nearly £1,000.

However on inspection I was none to impressed, the firebox crown was collapsed at the front and the bridge bars were still loose on the crown. It had a boiler certificate for 40psi and the pressure gauge was stuck on 60psi!

The engine was in a mess, but basically complete, but no lagging and the fittings were rough. On the boiler inspector's notes I spotted it said it had a slight leak from the cylinder block base.

-

Peter Love stands in the middle, with Alan and Jack Thwaites the new owners of 1912 Marshall 59763.

This was put down to the fact that it had a couple of straight Whitworth bolts holding it on instead of tapered or 'carrot bolts' as they are called, which it would have originally been fitted with. I didn't think much of it really, but it would become a challenge later on.

Having returned home, I phoned the family who were selling the engine to tell them the bad news that the engine needed a new firebox and much more, which they didn't like hearing at all. I offered them £2,500 including the trailer, but unfortunately they were looking for £4,000 - £5,000 for it, or had been advised that was what it was worth. I was flatly turned down, but I pointed out that the engine had been on the market two years and there were no takers at that money. That did get them thinking and some three months later they offered me the engine again, at the price I had offered.

It's journey to Kent was an interesting one as Roger Mortimore and his lowloader from Erith, Kent had to collect a compactor waste bin from Arnolds of East Peckham near Maidstone before we took it to Washington, County Durham where no less than two cranes from different companies fought out who was going to remove it, as business was thin on the ground in those parts at the time. We then travelled on, right by the wonderful Beamish Museum, on our way to Hetton-le-Hole.

Loading the engine and trailer did not take long, although the shed roof had to be jacked up to get the engine out and not damage the cast chimney cap in the process. It was pulled out by the yard's Fordson Diesel Major fitted with a Ford Cortina radiator, but without the Fordson nose cone on, or the bonnet.

The journey home included a stop at Scotch Corner for tea, where a number of drivers called this small load 'The Rocket' a name that stuck with the engine for a number of years. It was home and in my yard in the early hours of the next morning, having taken us 23 hours to complete the journey.

I was to spend the next eight tumultuous years, in between work, totally rebuilding the engine. This included a new boiler, firebox, backhead, tubeplate, smokebox and so much more.

I did end up with a 'banger' of a traction engine while working on 59763, which I was able to rally while rebuilding the portable. This was thanks to so many people giving up their free time for me, sadly most of them are now no longer with us.

However, I last rallied the portable in 1994 at the Great Dorset SteamFair and since then it has sat, wellcovered and protected, in various of my sheds, being lubricated and turned over once every six months.

I have other engines and various other projects littered everywhere and have a new one arriving, so I needed the room, but it took a lot to sell it. I wanted it to go to a good home and had a good few offers for it.

The people I chose to be its new owners are Alan and Jack Thwaites of Warrington, and they collected it Saturday November 26. 'Farewell Faithful Friend' you are sorely missed.

__________

from p. 7 of issue January 2017

Subscribe now - www.classicmotor.co.uk

1 note

·

View note

Text

#gallery-0-5 { margin: auto; } #gallery-0-5 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-5 img { border: 2px solid #cfcfcf; } #gallery-0-5 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

(www.MaritimeCyprus.com) Starting from an oar-powered prototype to the original U.S. Navy submarine, here are ten “undersea vehicles” that were among the first in history to take the plunge.

1. Drebbel: 1620-1624

Illustration of a Drebbel.

British mathematician William Bourne made some of the earliest known plans for a submarine around 1578, but the world’s first working prototype was built in the 17th century by Cornelius Drebbel, a Dutch polymath and inventor in the employ of the British King James I. Drebbel’s sub was probably a modified rowboat coated in greased leather and manned by a team of oarsmen. Sometime around 1620, he used it to dive 15 feet beneath the River Thames during a demonstration witnessed by King James and thousands of astonished Londoners. Unfortunately, none of Drebbel’s plans or engineering drawings has survived to today, so historians can only guess about how his “diving boat” actually operated. Some accounts say it submerged via a collection of bladders or wooden ballast tanks, while others suggest that a sloping bow and a system of weights were used to propel the boat underwater when it was rowed at full speed.

2. Turtle: 1775

Diagram of man inside the Turtle.

During the American Revolution, inventor and Yale graduate David Bushnell provided the colonists with a secret weapon in the form of an experimental submarine called the “Turtle.” This one-man wooden craft relied on a human-powered hand crank and foot treadle for propulsion. A pedal-operated water tank allowed it to submerge and surface, and lead ballast kept it upright in the water. If operated properly, it could approach an enemy ship undetected and use a screw to plant a mine filled with 150 pounds of gunpowder. In the early morning hours of September 7, 1776, Continental Army soldier Ezra Lee launched history’s first submarine attack when he piloted the Turtle underneath the British warship HMS Eagle in New York Harbor. Lee had only received minimal training, however, and after failing to attach a time bomb to the ship’s hull, he aborted the mission and detonated his mine in the open water. Bushnell later abandoned the submarine project after several other missions also failed to sink an enemy ship, but his invention earned him the respect of his fellow Patriots. When later asked about the Turtle, George Washington replied, “I then thought, and still think, that it was an effort of genius…”

3. Nautilus: 1800

Cross-section of a Fulton-designed sub.

While working for the French government in 1800, American inventor Robert Fulton designed the “Nautilus,” an-all metal craft often called the first modern submarine. The 21-foot ship featured several revolutionary innovations including a cigar-shaped hull and a copper conning tower. It used a hand-powered, four-bladed propeller to move underwater, but also sported a collapsible mast and fan sail for surface travel. Diving planes were used to assist in submerging, and Fulton also experimented with storing compressed air in copper bottles to provide oxygen for his crew. The Nautilus made several successful test dives in the early 19th century, but it was dismantled and sold for scrap after it failed to win over both the French and English navies. Fulton, meanwhile, later returned to America and won fame for developing the world’s first commercially viable steamboat.

4. Sea Devil: 1855

Drawing of the Sea Devil on the ocean floor.

Wilhelm Bauer built his first submarine in 1850, but only narrowly escaped with his life after it sank in 50 feet of water during a demonstration. Undeterred, the Bavarian inventor continued experimenting and eventually received funding from the Russian government for a new vessel. After traveling to St. Petersburg in 1855, he constructed the “Sea Devil,” a 52-foot submersible capable of carrying a crew of a dozen men. The ship boasted several technological breakthroughs including multiple ballast tanks for added buoyancy, a crude airlock and a propeller that was powered by crewmen operating an internal treadmill. The “Sea Devil” would eventually make more than 130 successful dives before being lost at sea. Its most unusual feat came during the coronation of Czar Alexander II, when it submerged with a four-member brass band aboard. Witnesses later reported that they could hear a rendition of the Russian national anthem coming from beneath the waves.

5. CSS H.L. Hunley: 1863

Drawing of Hunley on a pier.

The primitive attack sub H.L. Hunley was designed to help the Confederacy escape the stranglehold of Union naval blockades during the Civil War. Built privately in Mobile, Alabama, in 1863, it was fashioned from a recycled iron steam boiler and included space for eight crewmen—one to steer, and seven to turn the hand cranks that powered its propeller. Its bow bristled with a 17-foot spar mounted with a torpedo, which would detonate when rammed against an enemy ship. Early tests earned the Hunley the nickname the “peripatetic coffin”—and for good reason. It sank on two occasions during its trial runs, killing a total of 13 crewmen including its namesake, marine engineer Horace Lawson Hunley. The sub was repeatedly salvaged, however, and on February 17, 1864, Lieutenant George Dixon and a crew of volunteers sailed it into Charleston Harbor and successfully drove its torpedo into the side of the sloop-of-war USS Housatonic. The Union vessel went down in minutes, but the Hunley also sank, possibly because of damage sustained during its attack. Despite becoming the first submariners in history to destroy an enemy ship, Dixon and his Confederates all perished.

6. Le Plongeur: 1864Model of the Plongeur.

One of the first submarines to use mechanical power, “Le Plongeur” (“The Diver”) was a French-made craft designed by naval officers Simeon Bourgeois and Charles Brun. Rather than relying on hand cranks, foot pedals or treadmills to move its propeller, this 140-foot behemoth used a piston engine powered by compressed air stored in tanks. The air also helped provide the crew with oxygen and served as a means for automatically emptying its ballast tanks. Le Plongeur made several successful dives, but its limited air supply and dangerously unstable structural design led to it being removed from active duty in 1872. Many of its problems were later rectified in 1888 with the construction of the French submarine “Gymnote,” a more nimble craft that ran on electric power.

7. Ictineo II: 1865

Drawing of Monturiol and his submarine.

After witnessing the drowning death of a coral diver in 1857, the Spanish political activist and inventor Narcís Monturiol i Estarriol was inspired to build an underwater vehicle to increase worker safety. The result was the Ictineo II, a pioneering craft that has since been called the world’s first engine-powered submarine. The successor to an earlier diving boat called Ictineo I, the 46-foot Ictineo II achieved remarkable stability thanks to a system of weights and four pump-operated ballast tanks positioned inside its double-hull. To turn its propeller, Monturiol developed an anaerobic steam engine that used a chemical reaction to create both heat and oxygen. The engine seems to have worked—Monturiol made a successful dive in late-1867—but the sub was later sold for scrap due to funding shortages. Its groundbreaking propulsion system would not be replicated until the 20th century.

8. Argonaut: 1897

Argonaut I drawing.

Submarine technology had improved by leaps and bounds by the late-19th century, but most undersea boats were still only capable of completing short runs close to shore. That changed in 1897, when American engineer Simon Lake built the Argonaut, a 36-foot craft powered by a 30-horsepower gasoline engine. The sub’s most unusual feature was a set of wheels that allowed it to “drive” on the seafloor. It also had a periscope, a diving chamber and a floating hose to provide air for the engine and crew. Lake initially used the Argonaut to salvage sunken shipwrecks in the Chesapeake Bay, but in 1898 he used it to sail from Norfolk, Virginia to Sandy Hook, New Jersey—a trip that has since been called the first open ocean voyage by a submarine. The journey earned Lake widespread acclaim and a congratulatory letter from “20,000 Leagues Under the Sea” author Jules Verne. He went on to develop dozens of underwater vehicles for the U.S. Navy and produce more than 200 patents.

9. USS Holland: 1898

Photo of the Holland at sea.

During a ceremony at Newport, Rhode Island, on October 12, 1900, USS Holland became the first submarine officially commissioned by the U.S. Navy. Built in 1898, the 54-footer took its name from its inventor, John Philip Holland, an Irish-born engineer who was one of the most prolific submarine pioneers of the late-19th and early 20th centuries. The ship’s armaments consisted of a single torpedo tube and a pneumatic cannon known as a “dynamite gun.” It was powered by a 4-cylinder gasoline engine for surface travel, but also included a 160-horsepower electric motor to move underwater. While Holland never saw combat, it did serve as a training vessel and experimental craft for the United States’ first crop of submariners. By the time it was decommissioned in 1905, the Navy had brought a half dozen other attack subs into service.

10. HMS M2: 1919

HMS M2 was a Royal Navy submarine monitor completed in 1919, converted in 1927 into a submarine aircraft carrier. She was shipwrecked in Lyme Bay, Dorset, Britain, on 26 January 1932. She was one of three M-class boats completed.

Watch the interesting video documentary below:

youtube

youtube

10 Groundbreaking Early Submarines (www.MaritimeCyprus.com) Starting from an oar-powered prototype to the original U.S. Navy submarine, here are ten "undersea vehicles" that were among the first in history to take the plunge.

0 notes

Text

Builders In Rickmansworth - Melbourne Builders - Local ...

Pennypot Pre-schoolers Help Local Builders With New Homes ...

Table of ContentsLocal Builders In Swindon - Bob Hammonds - Home ...Local Builders Dover - Millview Builders In Whitfield, Call ...Builders Across The Uk - Find Local Builders - Mybuilder.comBuilders Warrington - Db Building - Warrington Builder - Local ...Lbs Builders Merchants - Leading Independent Builders ...Lj General Builders In Newark, Nottinghamshire, School ...Local Builders London - Builders In Kent - Lawson Build - SidcupEconomic Recovery Needs Local Builders, Says Fmb ...

To see if a trader has any associations, accreditations or subscriptions, just search for the logo designs on their Trust fund An Investor account. Are you a builder? If you take on constructing jobs of any type of size, it is vital that you as well as your customers are protected with the right level of insurance coverage cover.

This mass bag of logs is a clean and also affordable option for storing large amounts of logs. Our aired vent bulk bags allow optimal drying of your logs offering you the most affordable possible wetness material. Our Wood is excellent for giving fire proprietors with a long-term fire. This item would be ideal for your open fires, stoves and also some log boilers.

Cheap Builder Near You - Affordable Local Builders - Hamuch

Depending on just how commonly you require your logs restocked we can supply you a dedicated account supervisor to arrange your shipments throughout the period. These British Logs have come direct from woodlands in Northumberland, The Scottish Boundaries and Dumfries to our lawn where we have skilled, split, jam-packed as well as conditioned them in our biomass heated drying center.

We understand from our research study that our customers favor UK expanded product for many factors and are satisfied that their logs have a reduced carbon impact than imported items. Only logged in clients who have bought this product may leave an evaluation. This product is recommended for open fires, ranges as well as some log boilers.

How To Find A Good And Reputable Builder - Saga

Dampness content around 25% (dampness inspected before leaving depot) Keep in mind lumber particularly dry hardwood will readjust moisture material to the atmosphere it is saved in. Origin British Woods from Northern England and also Scotland Types Birch, Ash, Alder, Oak Log length about 250mm Free shipment to all postal codes within a 10 mile span of Berwick Upon Tweed.

There need to be an available location for the wagon to tip the visit your land. We do not load the items away after they have actually been off packed consequently this is your responsibility. We aim to deliver all orders in 5 working days, if a product ends up being out of stock we will contact you to tell you when it is available and ask if you want to wait or we refund your order.

Cheap Builder Near You - Affordable Local Builders - Hamuch

Shipment vehicle drivers will help where feasible but it is your responsibility to move the item from the decline off to its resting place.

Saint-Gobain Building Distribution Limited, Trading as Jewson, Registered in England, Business Registration No: 01647362 Registered Workplace: Saint Gobain House, East Leake, Loughborough, LE12 6JU BARREL Registered: GB 394 1212 63.

Local Builders In Harrow - Carroll Construction

1920's semi in significant demand of repair - new electrics, heating, plastering, wall surfaces knocking down - RSJ's set up, some new home windows as well as French doors. Always a bit troubling if you do not recognize any building contractors ... Resource: thebestof. co.uk.

We are open for limited collection & shipment and doing everything we can to maintain our customers and also personnel safe. During this time our opening hours differ to what is provided so please call us on 01462 730 169House Testimonials Highly Recommend All Citizen Builders To Make use of" Great solution below, always goes above and beyond.

Builders London Home Improvement Local Builders - Working ...

We provide new construct solutions for business, commercial and also domestic homes. We can take the task from preliminary concepts with layout stages, working with designers as well as coordinators, setting you back, laying structures, and also all aspects of building consisting of decoration. Any experts that we might require to sub-contract to are constantly anticipated to satisfy the very same high criteria we use.

Every varied project we handle includes in the breadth of our understanding as well as we bring this per new obstacle. We have different structure projects working carefully with relied on regional engineers, have a look at our recent tasks right here!.?.!! Please fill in the kind below or call us on: 07795 320891 See our other services here:.

Construction Company Suffolk - Local Builders - B A Boyle & Son

New Cooking Area Canford Cliffs, Poole, Dorset This home repair was a straight forward 'old kitchen area out as well as brand-new kitchen area in' task in the Canford Cliffs area of Poole. As component of our structure services, we eliminated every one of the old devices and appliances, did a small rewire, re-plastered all surface areas, [].

It's hard to determine a specific size of time or cost for your extension. To obtain a precise estimate, among our Opun surveyors will certainly visit you for a totally free assessment. Throughout the assessment they'll take dimensions, talk about the project and also offer ideas and advice to help you obtain the solutions you need before you pick to accept the quote as well as work beginnings.

£1bn For Local Builders To Build New Homes - Seena Shah

This suggests, unless what you desire changes, you'll just pay what you're quoted and the job will be delivered within the assigned time.

0 notes

Text

Fossil-fuel heating systems will be BANNED in all new-build houses

The installation of new gas boilers to provide heating and hot water is set to banned for new homes from 2025 in a move that could add £5,000 to the average price, Chancellor Philip Hammond revealed today.

The Government’s advisory Committee on Climate Change recommended ending the connection of new homes to the gas grid by 2025 in a report last month, with properties heated with low-carbon energy instead.

The Chancellor announced new standards ‘mandating the end of fossil fuel heating systems in new homes from 2025 delivering lower carbon, and lower fuel bills too’.

But the government have not specified exactly what will replace the boiler and how efficiently or quickly new measures will heat up homes.

The move is one of a series of environmental measures unveiled in a short Spring Statement, as he sought to address one of the major concerns of young people ahead of a second school climate strike on Friday.

New homes will no longer be heated by gas from 2025, as part of efforts to tackle climate change, Chancellor Philip Hammond revealed today (file image)

He also announced the protection of all the waters around Ascension Island in the Atlantic, where no fishing would be allowed.

The proposals also include increasing the amount of so-called ‘green gas’ in the National Grid to replace Natural Gas from the North Sea.

Green gas – or biomethane – is created from biodegradable material, such as food and farm waste, and is purified and pumped into the pipes for cooking and heating.

There are a number of advocates of this method of, such as Prince Charles, who has a digester at Poundbury, his new town near Dorchester, Dorset, which pumps gas and electricity into the national grid network to power homes and businesses.

But vegans have raised ethical concerns saying generated in this way could never be compatible with veganism, due to the use of animal waste.

And the supposedly green energy source comes at a heavy cost to taxpayers and to the environment it is supposed to protect.

The new green energy options

– All future homes will be future proofed with low carbon heating. The most likely replacement for gas are air source heat pumps.

– The pumps are often combined with extra insulation, but the total is £5,000 more expensive than a gas boiler.

– There will also be measures to help small businesses cut emissions.

– A study will be conducted into carbon offsets for air travellers, such as tree planting schemes.

For example the anaerobic digesters rely increasingly on specially-grown crops from prime arable land, such as maize and sugarbeet and rely on £216 million a year in taxpayer-funded subsidies.

Mr Hammond also announced measures to help small businesses to cut emissions and a study into carbon offsets for air travellers, such as tree planting schemes, as part of efforts to move to a carbon-neutral economy.

Mr Hammond seems to have watered down this proposal to some extent by limiting the ban to gas central heating, so averting a backlash from home cooks who prefer gas.

He said: ‘To help ensure consumer energy bills are low and homes are better for the environment, the government will introduce a Future Homes Standard by 2025, so that new build homes are future-proofed with low carbon heating and world-leading levels of energy efficiency.’

The most likely replacement for gas are air source heat pumps.

These extract heat from the outside air, even in the depths of winter, and channel it into a compressor that amplifies the heat which is then used to warm up water for the heating, taps and showers.

An anaerobic digestion facility in Hampshire. The supposedly green energy source comes at a heavy cost to taxpayers and to the environment it is supposed to protect

The pumps are generally combined with extra insulation, however the total cost of including these two elements in a new property is currently estimated to be around £5,000 more expensive than a gas boiler.

Mr Hammond also outlined a call for evidence on whether travel providers should be required to offer ‘genuine carbon offsets’ for their customers to reduce the pollution from their journeys, and proposals to boost green gas in the grid.

Along with measures on climate change, Mr Hammond also announced that the Government would mandate ‘biodiversity net gain’ for developments in England – to ensure new housing and infrastructure does not hit wildlife.

And a comprehensive global review of the link between biodiversity and economic growth, to be led by Professor Sir Partha Dasgupta, emeritus professor of economics at Cambridge, will be launched as part of efforts to stem declines in wildlife.

Campaign group 10:10 Climate Action’s director, Max Wakefield, backed the move to end fossil fuel heating in new homes from 2025.

‘All our homes and buildings must be made efficient, affordable and zero-carbon within the next two decades to address the climate crisis.

‘Ending the scandal of poor quality new homes is a no-brainer that’s good for everyone.’

The Chancellor announced new standards ‘mandating the end of fossil fuel heating systems in new homes from 2025 delivering lower carbon, and lower fuel bills too’

Mel Evans, senior campaigner at Greenpeace UK said the plan to end fossil fuels in new homes ‘is vital’ and welcomed the measures to protect wildlife.

But she warned that tackling the climate ’emergency’ required much bigger thinking.

‘Issues like the shoddy state of our existing housing stock and rapid adoption of electric vehicles require serious money behind serious policies,’ such as banning new petrol and diesel cars and vans by 2030, she urged.

Dave Timms, from Friends of the Earth, said: ‘The nation’s children are calling out for tough action to cut emissions; Mr Hammond must listen harder to the lesson they’re teaching him.

And he said: ‘The Chancellor should have announced a massive programme of investment in home insulation and public transport, instead of pushing the false solution of carbon off-setting for aviation.’

The House Builders Federation warned that, while it supports a shift to green energy, it is important that alternative heating options are available at a reasonable price before gas boilers are abandoned.

A spokesman said: ‘Developers have demonstrated a clear commitment to this agenda and new homes are already considerably more energy efficient than older ones. New technologies are increasingly being incorporated that drive down emissions and we are committed to continuing to work with Government on this.

‘The ongoing costs and comfort of homeowners is an absolute priority for home builders and it must be ensured that alternative heat sources are suitably attractive, available and efficient before withdrawing existing options.’ Director of the campaign group 10:10 Climate Action, Max Wakefield, backed the move to end fossil fuel heating in new homes.

‘All our homes and buildings must be made efficient, affordable and zero-carbon within the next two decades to address the climate crisis. Ending the scandal of poor quality new homes is a no-brainer that’s good for everyone,’ he said.

The post Fossil-fuel heating systems will be BANNED in all new-build houses appeared first on Gyrlversion.

from WordPress https://www.gyrlversion.net/fossil-fuel-heating-systems-will-be-banned-in-all-new-build-houses/

0 notes

Text

Grant UK expands sales team

Grant UK has announced its national sales coverage has further increased following the addition of a tenth area sales manager.

Chris Price has joined as the company’s new sales manager for the southern counties, joining the existing sales team.

His area includes Wiltshire, Berkshire, Dorset, Hampshire and the Isle of Wight, providing support on everything from oil-fired boilers through to latest air source heat pumps and heat emitter ranges.

“I am excited to join the Sales Team here at Grant UK and to work with their growing product portfolio,” he said. “Today, Grant’s offering to customers extends beyond its diverse range of heating products. Their ranges are backed up by a network both in the office and on the road, including product training, installer support, specification and system design, and I am looking forward to joining this team and working closely with customers.”

The post Grant UK expands sales team appeared first on Heating & Plumbing Monthly Magazine (HPM).

from RSSMix.com Mix ID 8248515 https://www.hpmmag.com/people/grant-uk-expands-sales-team

via http://www.rssmix.com/

0 notes

Text

Worcester Accredited Installers in Lymington

Worcester Accredited Installers in Lymington

Why Choose A Worcester Accredited Installer?

Why not get your Worcester boiler, solar water heating system or heat pump installed by Barry Frampton Ltd? We are your Worcester Accredited Installers! We are fully trained independent installers specialising in Worcester installations and can offer exclusive benefits to homeowners. No installation is the same and our professional heating engineers…

View On WordPress

#Boilers Dorset#boilers lymington#Gas#Hampshire#Heating#new boiler#New Forest#worcester accredited installer

0 notes

Text

Under One Roof in Lymington, Hampshire, New Forest, Dorset

Under One Roof in Lymington, Hampshire, New Forest, Dorset

Everything For Your Home Improvements – Under One Roof

Everything works better when it’s all Under One Roof. By bringing together all of your suppliers, you can reap massive savings in both costs & efficiency.

With Barry Frampton Ltd there are no Grey areas our staff work with each other every day, our familiarity allows easy integration of all our services. Because we are always talking, key…

View On WordPress

#Bathroom Installation#Boiler Installation#Dorset#Electrics#Gas#Hampshire#Heating#Lymington#New Forest#under one roof

0 notes

Text

Emergency Boiler Repair Lymington New Forest Hampshire

Emergency Boiler Repair Lymington New Forest Hampshire

Your local Company for An Emergency Boiler Repair

No Heating or Hot Water?

There could be a number of reasons why your central heating or hot water isn’t working. You may fix several problems yourself, avoiding an emergency boiler repair callout. Try these common issues using these tips first:

Check the gas, electrical and water supplies to the appliance are turned on. It’s surprising how easily…

View On WordPress

#Boiler#Boiler Servicing#Dorset#emergency boiler repair#Fault Find#Gas & Heating#Hampshire#Lymington#New Forest

0 notes

Text

Think about a New Boiler for 2017

Think about a New Boiler for 2017

Treat yourself to energy efficiency a new boiler for 2017!

A Worcester boiler with a 10 year warranty

A Solar Electricity System

NEW Solar Battery storage solutions for new and existing systems

Wifi Heating Controls

Full bathroom refurbishment

Barry Frampton Ltd are looking forward to 2017 as it is our 25th year in business. We are offering a 10 year warranty with a New Boiler for 2017.

C…

View On WordPress

0 notes