#oshaguidelines

Text

OSHA Lockout Tagout 1910.147(c): Protective Materials and Hardware

To perform service or maintenance safely and effectively under Lockout Tagout, employees must be provided with protective equipment, hardware and appliances for isolating, securing, or blocking of machines & equipment from their energy sources. Under paragraph (c)(5) of the OSHA Standard, it is the employers’ responsibility to provide necessary devices. Protective material and hardware that may be needed include locks, tags, cable ties, chains, breakers and valve lockouts, wedges, blocks, blinds, pins, fasteners and other hardware.

When launching a lockout tagout program, a survey of the workplace is needed, not only to identify the machines, equipment and processes that are covered by the program, but also to become familiar with the configuration of the equipment. When ordering the necessary hardware, the employer must also ensure that the hardware meets specific requirements for design & construction.

Under paragraph (c)(5)(ii) it states that the Lockout & Tagout devices should be singularly identified. Which means- the best suitable device should be placed on the isolating point and should not be used for any other purpose apart from Lockout Tagout on machines & equipment.

Section A-D of paragraph (c)(5)(ii) specifies certain requirements of lockout Tagout devices, i.e. The device must be durable, Standardized, Substantial and Identifiable.

In paragraph 1910.147(c)(5)(iii), OSHA requires that the major message printed on the tag “warn against hazardous condition of the equipment is re-energized. Five examples of acceptable warnings are provided, including Do Not Start. Do Not Open. Do Not Close. Do Not Energize. Do Not Operate. In all cases, employees must know and understand the meaning of the Tag.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#OSHALockoutTagout#ProtectiveMaterial#LockoutTagout#OSHAViolations#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 29 CFR 1910.147 - Definition of Hot Tap and & Normal Production Operations

Hot Tap:

As discussed in our previous post, OSHA standard 29 CFR 1910.147(a)(2) does not apply to Hot Tap and Normal Production Operations.

Hot tapping, or pressure tapping, is the method of making a connection to the existing piping or pressure vessels without interrupting the servicing for air, gas, water, steam, and petrochemical distribution systems. This means that a pipe can continue to be in operation while maintenance or modifications are being done to it. Only if the employer demonstrates that

· continuity of service is essential

· shutdown of the system is impractical

· documented procedures are followed, and special equipment is used which will provide proven effective protection for employees.

Normal Production Operation:

Certain tasks such as minor and repetitive adjustments are considered normal production operations when they are integral to the use of the equipment, and when they do not increase the risk of injury to employees.

So, OSHA Standard, 29 CFR 1910.147 (a)(2) does not apply to Hot tap and Normal Production Operations only when the employees working on it are considered to be SAFE.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#HotTap#LockoutDevices#LockoutTagoutDevices#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Link

Currently, OSHA recommends that employers set thermostats between 68 degrees and 78 degrees Fahrenheit. OSHA also provides guidance on “Working In Outdoor and Indoor Heat Environments,” and it suggests that employers:

0 notes

Photo

Assistant Receiver Ian tried really hard to stretch like Bob Anderson taught us. #stretching #ergonomics #oshaguidelines #bobanderson #bookrecommendations #bookshopshenanigans (at Bookshop Santa Cruz)

1 note

·

View note

Text

OSHA 1910.147(c)(4)(i) - Exceptions to Energy Control Procedures

Energy Control Procedures or Machine Specific Procedures need to be developed, documented & utilized always for full employee protection. If the total employee protection is obtained without ECP, then the need for developing ECP can be exempted. But all the essential elements required for complete safety of the employees have to be fulfilled.

The exemption is mostly for the simple equipment, when the Lockout device is under the exclusive control of the authorized employee, there is no potential for inadvertent release of stored or residual energy, and a single lockout device can achieve a locked-out condition. But in industries, even the complicated machines do not have the ECP. Many times when there are replicas of the same equipment, then the generic or common ECPs are used which leads to a lot of confusion & adequate energy control is not achieved, resulting in serious accidents.

So, ECPs are required for the isolation of hazardous energies & absence of ECP is the most common violation as per OSHA Standard 29 CFR 1910.147.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#EnergyControlProcedure#LockoutTagout#OSHAViolations#LockoutTagoutOSHA#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#OSHARegulations#OSHALockoutTagout#ESquare#ESquareAlliance

0 notes

Text

OSHA 1910.147(c)(4) Energy Control Procedure

Most of the OSHA Violations are due to the unavailability of Energy Control Procedures (ECP) or Machine Specific Procedures (MSP) in organisations. Companies buy Local products, just to become LOTO compliant, but they do not know the correct procedure for safe isolation and control of Hazardous energies. Successful implementation of Energy Control Program requires an understanding and awareness of Hazardous energy types and magnitude, the methods, techniques, and devices used to control that energy.

To provide guidance to employees for putting the program into practice, written Energy Control Procedures should be developed. These procedures must define the purpose, scope, and application of the program, deploy the responsibilities of the managers, supervisors, and employees for implementing a systematic Lockout Tagout program.

A written Energy Control procedures (ECP) / Machine Specific procedures (MSP) needs to be developed, documented as it clearly and specifically outlines the steps to be followed, techniques to be used, and measures to be applied for the control of potentially Hazardous Energy.

This includes specific steps to shut down, isolate, block, secure, place, and remove lockout or tagout devices, and to determine the effectiveness of those devices by following verification steps.

The written ECP/MSP must have pictorial representation for isolation, installed images of LOTO devices that specifies procedural steps for the placement, removal and transfer of Lockout Devices or tagout devices.

Lack of compliance can lead to serious disciplinary actions. Industries need to mention the consequences in case of non-compliance of Lockout Tagout due to any reason, whatsoever.

Periodic inspections are mandatory to help ensure that the energy control procedures and the requirements of the standard are being followed.

Services of LOTO can be taken for developing ECPs/MSPs as they have vast industrial knowledge to prescribe the proper steps for the safe isolation by the correct use of Lockout Tagout.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#EnergyControlProcedure#LockoutTagoutProcedure#LOTOProcedure#LockoutTagout#OSHAViolations#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#OSHALockoutTagout#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout: Full Employee Protection

OSHAs Lockout Tagout Standard does not prescribe the specifics of the energy control measures to be employed. Although, the standard lays down general procedures to be achieved, giving the employers flexibility in choosing the control procedures to be implemented, it focuses on achieving full employee protection.

Full Employee Protection:

As per OSHA Standard 1910.147(c)(3) - A lockout device should always be used when the machine’s energy isolating devices are capable of being locked out. But, there might be situations when, an isolating device is not capable of being locked out, a Tagout device is used alone in place of a Lockout device {1910.147(c)(3)(i)}.

In such a situation, it must provide a level of safety equivalent to that obtained by using a Lockout device, and the Tagout device must be attached at the same location, where the Lockout device would have been attached.

The employer must demonstrate full compliance with all Tagout related provisions of this standard. Additional protective measures, such as the removal of an isolating circuit element, blocking of a controlling switch, opening of an extra disconnecting device, or the removal of a valve handle to reduce the probability of inadvertent energization are needed to demonstrate that full employee protection has been achieved. Along with this, if an energy isolation device is not capable of being locked out, it must be redesigned or modified to accept the lock whenever major replacement, repair, renovation or modification of the machine is performed. The main motive is to achieve Full Employee Protection always. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagoutDevice#EnergyIsolatingDevice#LOTODevices#EmployeeProtection#WorkerSafety#LockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#ESquare#ESquareAlliancePvtLtd

0 notes

Text

OSHA 1910.147 (c)(2) General - Lockout Tagout

The OSHA Standard, 1910.147 (c) set forth nine general principles which provide the framework for ensuring the safety of personnel who maintain the machines.

OSHA Standard 1910.147(c)(2) emphasizes on the importance of Full Employee protection by Lockout Tagout.

Generally, the isolation devices should be capable of being locked out in majority of circumstances. But, there can be incidences where a Tagout device is used instead. A Tagout device, without a Lockout, may be used only when energy isolating device, is not capable of being locked out, or when the employer demonstrates that use of the tagout system alone, is substantial enough to be used in place, where the Lockout device is not applicable. It must provide a level of safety equivalent to that obtained by using a Lockout device, and the Tagout device must be attached at the same location, where the Lockout device would have been attached.

In such a situation, it solely becomes the responsibility of the employer to provide ‘full employee protection.’

After January 2, 1990 according to the standard 1910.147 (c)(2)(iii), it has become mandatory for the manufacturers, that in case of modification of machines and equipments, whenever replacement, major repair or installation of new machines are done, the energy isolating devices for such machines or equipment shall be designed to accept a lockout device.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#EnergyControlProcedure#LockoutTagout#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(c)(1) - Energy Control Program

LOTO is intended to provide effective safety in the modern industrial workplace. It saves lives by protecting workers from hazardous energy, and it reduces downtime by streamlining and standardizing work processes. For successful implementation of Lockout Tagout in an industry, it is important to have awareness about LOTO and a well-developed LOTO System. Lack of knowledge and absence of LOTO system, leads to uncalled eventualities. Even with the re-occurrence of repeated incidences, the workers and the management are not sure that it is due to the absence of proper LOTO System in place.

The employer is to establish an Energy Control Program - comprising of the energy control procedures, employee training and periodic inspections, all of which help to ensure that the machine and equipment are properly isolated from their energy sources, and rendered inoperative prior to any servicing and maintenance.

A well-defined energy control policy and procedure helps in planned and systematic working of the machines and equipment; Employee training is needed to provide employees with knowledge, skills and motivation to effectively implement a successful Lockout Tagout Program; Audits & periodic inspections help companies insure that, they have the up-to-date & accurate devices and procedures that allow employees of the companies to safely de-energize the equipment.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#EnergyControlProcedure#EnergyControlProgram#LockoutTagout#MaintenanceTask#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(b): Tagout and Tagout Device

A Tagout Device is a prominent Warning Device, such as a Tag and a tie i.e. any means of attachment, that clearly states that the machinery being controlled must not be operated until the tag is removed in accordance with an established procedure.

Tagout Device indicates employee photo, maintenance details, reason of isolation, numbering, specific instructions or warnings useful to avoid accidental energization of equipment under repair. These devices should be sturdy & substantial enough to withstand harsh conditions at the workplace.

The Tagout devices also indicate that the Energy Isolating Device and the equipment being controlled may not be operated until the tagout device is removed.

The procedure of placing a Tagout device on an energy isolating device in accordance to the established procedure is called Tagout.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#Lockout#Tagout#TagoutDevice#LockoutTagoutDevice#EnergyIsolatingDevice#OSHAGuidelines#LockoutTags#LOTO#OSHAStandard#OSHALockoutTagout#OSHARegulations#ESquare#ESquareAlliance

0 notes

Text

OSHA 29 CFR 1910.147(b) - Definition of Servicing and Maintenance & Setting Up

Most of the injuries and fatalities in industries occur while workers perform service and maintenance tasks. The Lockout Tagout Standard set forth in 29 CFR 1910.147 covers the servicing and maintenance of machines and equipment in general industry. Activities such as construction, installation, setting up, inspection, etc. are defined by OSHA as services and maintenance.

These activities include lubrication, cleaning, unjamming, making adjustments or tool changes, are integral to the use of equipment. These are considered service and maintenance if employees are exposed to unexpected energization or startup of the machines or equipment, or release of stored energy could cause injury to employees.

Setting up: Many servicing or maintenance activities require the machine, equipment, or its components to be disassembled or dismantled. These tasks are typically performed with the equipment stopped.

The reassembling of machines and equipment after the servicing and maintenance task has been performed is called setting up.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#MaintenanceTask#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA 29 CFR 1910.147(b) - Definition of Lockout and lockout Devices

Lockout consists of placing a disconnect switch, breaker, valve, spring, pneumatic assemble, or other energy-isolating mechanism in the off or safe position. A device is placed over, around, or through the energy-isolating mechanism to lock it in the off or safe position, and only the person attaching it applies a removable lock to the apparatus.

When the machine’s energy sources are locked out, there are specific guidelines that must be followed to make sure that the lockout device cannot be removed, and the system cannot be inadvertently operated. OSHA illustrates certain Lockout Tagout procedures that need to be followed while performing LOTO.

Every company has its drafted Energy Control Procedures/MSP that needs to be implemented systematically. It is the duty of the employer to make sure that the machine is not restarted until the Lockout device is removed.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#LockoutDevices#LOTODevices#LockoutTagoutDevices#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 1910.147(b) Definition - Energy Isolating Devices

Energy Isolating Devices are the primary tool for providing protection under the standard. They are mechanisms that prevent the transmission or release of energy and to which locks and tags are applied. Isolating a machine or piece of equipment from an energy source means using energy isolating device to interrupt the flow of energy from the means of transmission of the energy to the machine.

They include:

- A manually operated electrical circuit breaker

- A disconnect switch

- A manually operated switch by which the conductors of a circuit can be disconnected from all ungrounded supply conductors

- A line valve

- A block or any similar device

But Push buttons, selector switches and other control circuit type devices are not considered as Energy Isolating Devices.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#EnergyIsolatingDevices#EnergyIsolationDevices#LockoutTagoutDevices#LockoutTagoutProducts#LOTODevices#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 29 CFR 1910.147 - Capable of being locked out

For isolation it is must that the equipment or machines should be capable of being locked out. The newer versions of equipment are manufactured with the in-built features for isolation. The challenge comes with the older equipment. Many a times it is noticed that workers who are working on the machines are actually unaware that these equipment can be locked out as well.

An energy-isolating device is considered capable of being locked out if:

- It is designed with a hasp or other means of attachment to which a lock can be affixed.

- It has a locking mechanism built into it.

- If a lockout can be achieved without the need to dismantle, rebuild, or replace the energy isolating device or permanently alter its energy control capability.

Energized:

Before Manufacturing or servicing, the equipment or machines need to be in zero energy state. Energized equipment can pose a threat to the workers in the vicinity.

Just shutting off does not mean that the machine is de-energized. A machine or equipment is said to be energized if it is connected to an energy source like- electrical, mechanical, hydraulic, and pneumatic, etc. Or if it contains any residual/stored energy- from solid chemicals, gases, liquids and vapors; Energy from the movement of springs, wheels or elevated parts; Batteries and capacitors; Pressurized and moving gases.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHA29CFR1910147#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

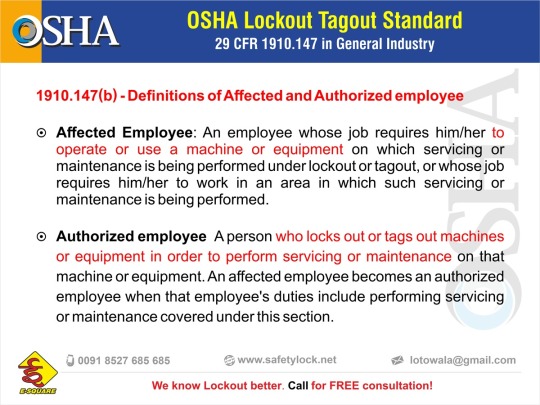

OSHA Lockout Tagout Standard 1910.147(b) - Definition of Affected and Authorized Employee

OSHA Lockout Tagout standard 1910.147(b) defines authorized and affected employees as:

An Authorized employee, by definition, is a person who locks out or tags out machines or equipment in order to perform servicing and maintenance on that machine or equipment. Authorized employees are those who are charged with the responsibility for implementing the energy control procedure prior to performing servicing and maintenance, and thus require the highest level of training.

Whereas, an Affected employee, by definition, is an employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is to be performed. Affected employees are generally the machine operators or users. An affected employee becomes an authorized employee when that employee’s duties include performing servicing and maintenance.

Check OSHA guidelines in detail - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#AuthorizedEmployee#AffectedEmployee#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#WorkplaceSafety#Safety#LockoutTagoutAccidents#ESquare#ESquareAlliance#EsquareTrainingAcademy

0 notes

Text

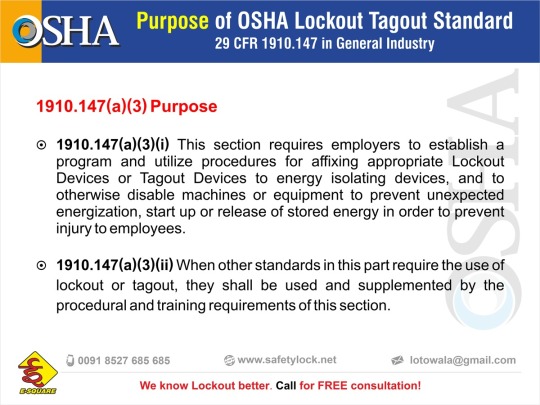

Purpose of OSHA Lockout Tagout Standard - 29 CFR 1910.147 in General Industry

More than half of the fatalities occur due to mishappenings caused while workers carry out service or maintenance related tasks. So, to avert these accidents and mishappenings OSHA Lockout Tagout Standard requires that employers must establish a well-defined LOTO Program which should have a complete Lockout Tagout planning, responsibilities and procedures for systematic application & removal of Lockout Tagout isolating devices to prevent unexpected energization, start up or release of Stored Energy that can cause serious injuries to employees working on it.

It should be supported by trainings, procedural reviews, retraining etc. to make it sustainable and effective in the long run.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes