#paper pellet machine

Note

I insert a photograph of Weird Al Yankovic

The machine dispenses allen wrenches, gerbil feeders, toilet seats, electric heaters, trash compactors, juice extractor, shower rods and water meters, walkie-talkies, copper wires safety goggles, radial tires, bb pellets, rubber mallets, fans and dehumidifiers, picture hangers, paper cutters, waffle irons, window shutters, paint removers, window louvres, masking tape and plastic gutters, kitchen faucets, folding tables, weather stripping, jumper cables, hooks and tackle, grout and spackle, power foggers, spoons and ladles, pesticides for fumigation, high-performance lubrication, metal roofing, water proofing, multi-purpose insulation, air compressors, brass connectors, wrecking chisels, smoke detectors, tire guages, hamster cages, thermostats and bug deflectors, trailer hitch demagnetizers, automatic circumcisers, tennis rackets, angle brackets, duracells and energizers, soffit panels, circuit brakers, vacuum cleaners, coffee makers, calculators, generators, matching salt and pepper shakers.

230 notes

·

View notes

Text

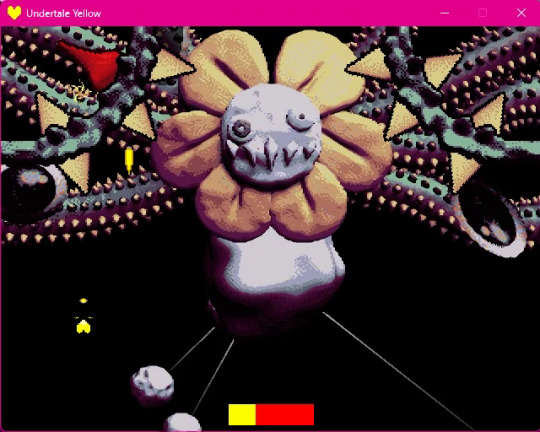

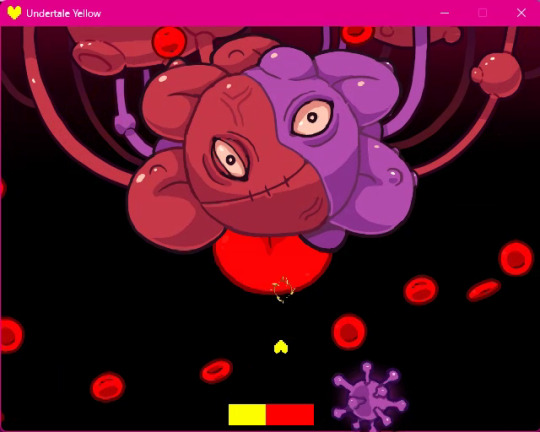

Ranking the Flowey "Specimen" Fights

First of all, let me just say that I have no explanation of where these ideas came from or why the tracks for each phase of the Flowey fight are called "specimen." I know the whole thing is meant to parallel the SOULs in UT OG, but where did Flowey get some of these ideas? As for the term "specimen," I've seen the theory that Alphys was injecting various materials with DT, and Flowey was imagining if they had come to life like he did. Makes as much sense as anything I could have come up with.

Ratings are on a scale of 1-6. Fights are listed in no particular order. And for the record, I already know my opinions differ from those of the larger population.

Paper

Not super-creepy, not tough to fight, not a lot of lore, and the music's actually kinda chill. I feel like the music only feels so creepy because of the context. Really, the scariest thing in this fight is... that face....

Music: 4

Battle difficulty: 2

Creepiness: 2

Lore implications: 2

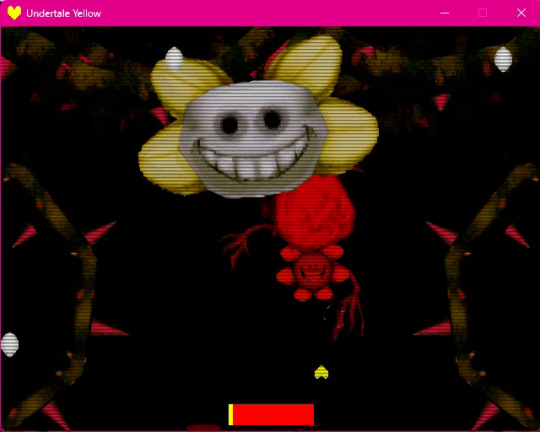

Clay

Call my crazy, but I swear I see Prunsel and hear Jevil in this one. Otherwise, it's just weird and a little difficult.

Music: 2

Battle difficulty: 5

Creepiness: 4

Lore implications: 3

Polygonal

HANDS. DOWN. THE. WORST. One Flowey face is bad enough, but him summoning multiple versions of himself? Which are blood red and always swipe at you at the worst possible moment? I LOATHE this one. Plus, it's the UT-verse version of "scary beyond all reason." Even more than any Fell that I've seen. The music is probably the least scary thing about this fight, and even that gives me BOTW blood moon vibes.

Also, gotta wonder why Alphys would have labelled this one "polygonal." The heck was she experimenting on? A snowdecahedron?

Music: 3

Battle difficulty: 6

Creepiness: 6

Lore Implications: 1 (it's just all Flowey)

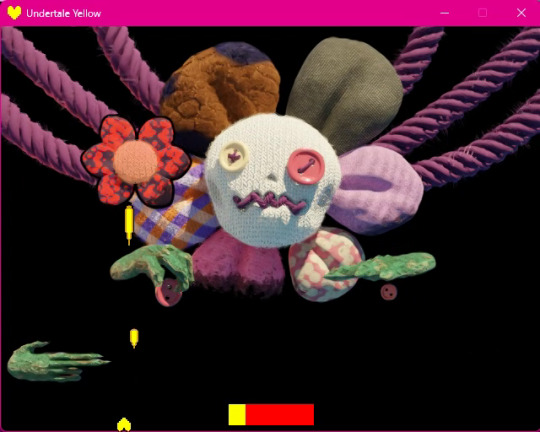

Patchworked

Did Flowey watch Coraline or something??? And the music- it's like a mashup of Your Best Friend and The Circus.

The most intriguing thing is the use of the finger guns, which, of course, we can recognize from Omega Flowey's fight. The question then becomes: did Flowey get the finger gun idea FROM Clover and Star? Especially since he shoots nails, which... I get the pun, "finger" + "nail," but nails also have the highest attack of any ammo other than friendliness pellets.

Music: 1

Battle difficulty: 4

Creepiness: 3

Lore implications: 5

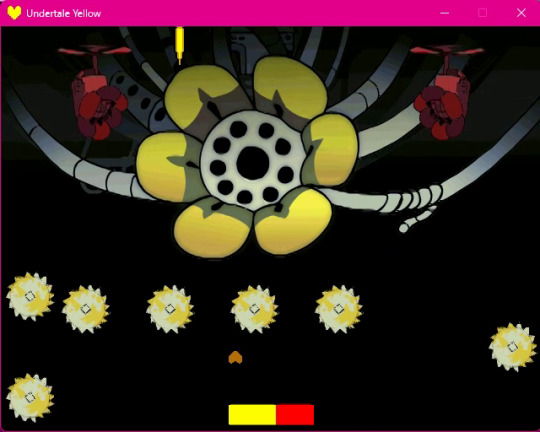

Mechanical

Dude, check it out, the Floweynator.

A little difficult, not too bad. Not really too creepy, unless you stare too hard at Machine Gun Flowey's face. It is interesting to think that Alphys was experimenting on machinery with DT. Because, you know, she built Mettaton by sticking a SOUL in a robot.

Also, I've seen the theory that Flowey learned about nuclear bombs and things like that from Chara, so he probably learned about machine guns and hovering drones and things from Chara, too.

Music: 5

Battle difficulty: 3

Creepiness: 1

Lore implications: 4

Organic

I think this is my favorite, actually. Yeah. I'm being totally unironic.

Honestly, it's just creepy. First of all, how does Flowey, a monster who has presumably never seen the surface, know so much about blood? Possibly from Chara, but I have trouble believing that a kid could have told him that much about how the human body works (then again, we are talking about Chara...). Not to mention Flowey getting the heart monitor sound right, that would be very difficult from just a description.

The most obvious solution (to me, anyway) is that Alphys was using an organic lifeform for testing. Since she said she wanted to test a subject that didn't have a SOUL, and we know from Dina that there are non-sentient animals in the Underground that are either kept as pets or used for food, the most likely answer is that Alphys was using a snake or bird or something.

But consider...

What if Alphys was using a human body, or at least samples from a human body, as the "organic" subject??? Technically, the human wouldn't have a SOUL anymore, because their SOUL is already in a glass case behind Asgore's throne room.

Music: 6 (I know most people think it's boring, but I think the heart monitor just adds to the creepiness)

Battle difficulty: 1 (not difficult at all to dodge)

Creepiness: 5

Lore implications: 6

#undertale yellow#flowey#neutral run#final boss#my opinion#ranking#my screencaps#theory#my theory#my headcanon

6 notes

·

View notes

Text

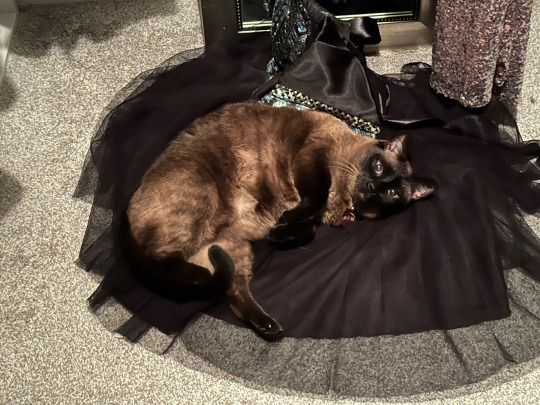

One of my cats passed away quite suddenly yesterday. I’d noticed she wasn’t feeling good Tuesday when I got back from work and she didn’t greet me. 24 hours later I was taking her to the emergency vet and less than 48 hours later she was gone

I think loss can be really hard sometimes. I want it to be my fault, because then if it ever happened again I would be able to control the outcome better - but I can’t just fix sudden onset congestive heart failure. The vets sure couldn’t - she didn’t respond to the aggressive medication that was meant to help her blood pressure go back to normal

I don’t really have a point to this post. But Mia was the best cat of all time - she was eleven years old, and the most affectionate and persistent cat in existence. She would physically grab your hands to let you know that whatever you were doing with them weren’t as important as her (including knocking phones directly out of your hands). She demanded pets from everyone who walked through the door like a tiny bridge troll or a mafia boss - especially for people who were allergic to her

She liked to shred paper with her teeth - not to eat, just to prove that she could because her previous owners front paw declawed her and she was still determined to shred things and cause a mess on principle. She had a bb pellet in her thigh - also from before I owned her - that spawned the joke that we misread the adoption paperwork and Mia was actually MIA from whatever war she was involved in.

She would wake me up by placing her foot on my face and slowly increasing the amount of weight on said foot and if I didn’t wake up, she very purposefully walked across my head. If that failed she would walk in a tight circle around my head to try and step on any hair that was on the pillow, since that was sure to make me wake up - honestly her most toxic trait. Sometimes she would just put a paw on my face and just drag it slowly down my cheek or stick her face right next to mine to try and tickle me with her whiskers. It should be noted: she had no reason to do this. She was fed via the machine, not dependent on me being awake. And for the most part she didn’t! But sometimes she would just go through phases of being absolutely inconsolable if I slept in at all

She didn’t sleep with me at night usually (because I roll like an alligator I move literally so much) but any other time I was vaguely horizontal she liked to be directly atop my person. She would sometimes be next to me, and would let me cuddle her like a teddy bear

She was a dense tank of a cat who took no shit and would have ignored the world ending as long as she was receiving pets, and I will miss her every day

Mia you looked like burned toast and had no sense of personal boundaries and you were the absolute best thing that’s ever happened to me

#personal#pet death#cat death#Mia#my cats#Christ how do people who cry easily do this#I have been crying on and off for two days and I have the worst dehydration headaches

25 notes

·

View notes

Text

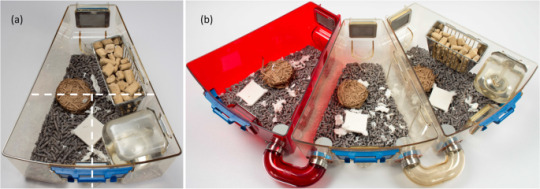

Upgrading Lab-mouse cages

This topic goes close to me bc I work in a lab and have hours every day to think about what I can do for these tiny creatures

Lab mice are kept in these cages by standard:

The minimum legal enrichment (at least in germany) is a nest, something to climb, something to chew, and a way to socialize. This cage has a hut for a nest, the top bars for climbing and the hardened pellets for chewing

In my opinion that's both unfitting and not enough. There's some very simple changes and a lot of bigger/harder changes:

Simple changes:

Using wooden or paper huts. It's commonly believed that mice can't see red, but in reality they will always choose darker colours and more natural materials as hides

lowering the light in one part of the cage, eg simple cage sleeves, lowering the general room light, shading the rack

raising the temperature. Mouse are generally kept at 21 - 24°C, but really prefer 26 - 30°C

scanning the room for ultra sounds

scattering some grains for foraging (this is also perfect for training the mice to make health checks easier)

Other still very simple changes:

adding nesting materials. Mouse prefer paper scraps, paper towels, etc, but there's also cotton squares and wood wool commercially available

adding wood for chewing. Again there's many options ranging from wooden bricks over wooden huts to whole branches

adding a running plate or wheel (I know running plates are said to cause spinal deformity, but in my experience that is a very low chance as opposed to the negative effects no movement has)

adding more bedding so digging is easier

adding tubes, boxes, swings and climbing structures

Changes that get closer to pet keeping:

add diggable bedding for builing nests and tunnels

add more huts. More! Mooore! (seriously mouse love a cluttered space and feel most comfortable walking along walls)

add a second layer (most easy part is just wedging a wooden board in there) and raising the top bars (there's raised cage tops for more height)

adding a maze/labyrinth to allow the mice to compartimentalise their cage/hide from light, sounds, movement, etc

stopping to feed ad libitum. In comercial setting, this can be done with feeding machines, privately this can be done by feeding like any other pet (adding a bowl of fresh food twice a day and removing after an hour or two)

scatter feeding instead of having the food in a rack

adding a digging box

Changes for pet keeping:

Going at least one, better two sizes up with the cages

adding toys

adding more mice to the group (in research most mice are kept in groups of 2 to 5. Mice prefer bigger groups though (plus "two" is a pair, not a group))

adding a big, big layer of bedding (see previous category)

adding toys, including food toys, smell toys, etc

giving food treats like yogurt, comercial treats, varied food, dead or life insects (mice are good hunters!)

feeding grains and similar (if you're unsure about a balanced diet, feeding grains additionally to pellets is totally fine)

adding a bigger wheel or running plate (a wheel is better, if you can provide a good one with appropriate size)

offer a free run time. This could for example be in a bath tub. Lay it out with linen or carpets, fill the tub with toys, treats and cardboard boxes, and offer the mice to go there (eg by builing a stairwell, or by training them "taxi" with a travel box)

spend regular time with them to aclimate them to humans

Changes for a near perfect enclosure:

Upgrate to an aquarium with a grid top

add more climbing options. Like way more!

Put heavier huts on stilts

Add even more tunnels

provide fresh food

change up their enrichment (eg digging box, swimming pool, fresh plants, offer tea additionally to water)

All these images have good and bad items, and imo all enclosures can be adapted to the housed animals needs. I'll try to add credit, but please message me if you have questions about specific images

I was about to add sources but found some great in a single site: here

I also always recommend bin cages as they are cheap and very very customisable. The best example I found is this one

#long post#mouse care#mice#rodents#pet enclosure#my post#lab mice#enrichment#idk I have no based opinions about beddings#this post is not quite yet what I want it to but we're getting there#feel free to message me about any of this#I love talking about mice#I'll try to add some sources#lowkey proud of my first post#pls support me by reblogging and commenting

18 notes

·

View notes

Text

Organic fertilizer is an indispensable part of agricultural production, and the choice of pelletizer in its production process is very important. The correct granulator can not only improve production efficiency, but also ensure the quality and fertilizer efficiency of organic fertilizer. This paper will introduce several commonly used organic fertilizer granulators, and discuss their characteristics and application scenarios.

1. Fertilizer Granules Compaction Machine

Fertilizer Granules Compaction Machine is a dry granulation machine that uses a strong extrusion pressure to make the material form in one go without additional drying process. The advantages of this granulator are high grain density, good fertilizer efficiency, and full organic matter content. Due to the elimination of drying steps, can save a lot of energy and cost. However, the pelletizing shape may not be smooth enough for machine seeding of crops in the field, so it is necessary for machine seeding farmers to choose this pelletizing process carefully.

2. Flat-Die Pellet Machine

The Flat-Die Pellet Machine is known for its regular shape and uniform particle size, and is suitable for the production of organic and compound fertilizers and other products. This granulator has high production efficiency and can ensure the consistency of the finished product. Flat-Die Pellet machines are suitable for mass production, but additional drying and cooling equipment may be required to ensure that the granulated material reaches the appropriate moisture and temperature.

3. Rotary Drum Granulator

Rotary Drum Granulator compresses organic fertilizer into a granular form through the rotating motion of a drum. Although the shape of the finished product may be irregular and the particle size is not uniform, the production efficiency is high, and it is suitable for the production of organic fertilizers and bio-organic fertilizers. Rotary Drum Granulator is suitable for granulation of a variety of raw materials, but it may be necessary to screen the finished product to ensure consistency of particle size.

4. Disc Granulator

Disc Granulator is a traditional granulation process favored for its simple operation and less return material. The granulator produces uniform particles, has good automatic classification ability, and can add liquid at the same time of granulation, improving the efficiency of granulation. Disc Granulator is suitable for producing high quality organic fertilizers, but may require a higher initial investment.

Conclusion

To choose the right organic fertilizer granulator, it is necessary to consider many factors such as production scale, raw material characteristics, product demand and cost budget. Fertilizer Granules Compaction Machine is suitable for high density and high fertilizer efficiency, while Flat-Die Pellet Machine and Rotary Drum Granulator are more suitable for mass production. The Disc Granulator, on the other hand, is favored by many organic fertilizer producers for its uniform particles and simple operation. Through scientific selection and management, organic fertilizer granulator can greatly improve production efficiency and product quality, and provide more high-quality organic fertilizer for agricultural production.

#Fertilizer Granules Compaction Machine#Flat-Die Pellet Machine#Rotary Drum Granulator#Disc Granulator

0 notes

Text

In modern agricultural production, the conversion of chicken manure into organic fertilizer is an important work that is both environmentally friendly and economical. This not only reduces environmental pollution, but also provides valuable nutrients for farmland. This paper will introduce in detail the seven key steps of chicken manure treatment into organic fertilizer, as well as the key words involved in the equipment.

Step 1: Raw material collection and pretreatment

First, we need to collect fresh chicken manure and conduct preliminary screening and decontamination. This step ensures the smooth progress of the subsequent treatment process and also lays the foundation for improving the quality of the fertilizer.

Step 2: Compost and turn the pile

Next, pile the pre-treated chicken manure into strips and use the Windrow Compost Turning Machine to turn the piles. This process increases oxygen and speeds up the breakdown of organic matter while reducing undesirable odors.

Step 3: Crushing treatment

The chicken manure that has been turned over needs to be crushed to facilitate subsequent mixing and granulation. The Compost Crusher is used here.It can crush the material to the appropriate particle size.

Step 4: Mix and stir

The crushed material will be mixed with other organic or inorganic additives to ensure the nutrient balance of the fertilizer. A Horizontal Ribbon Mixer or a Double Shafts Paddles Mixer are commonly used in this process to ensure that the material is mixed evenly.

Step 5: Granulation molding

The evenly mixed material will enter the granulation stage. The Flat-Die Pellet Machine or Rotary Drum Granulator in the Organic Fertilizer Production Line can granulate the material for subsequent drying and packaging.

Step 6: Drying and cooling

Freshly granulated fertilizer usually contains high moisture and needs to be dried by Rotary Dryer Machine and then cooled to room temperature in Rotary Cooler Machine to ensure the stability of fertilizer and easy storage.

Step 7: Screening and packaging

Finally, the dried and cooled fertilizer particles are screened by Rotary Screening Machine, unqualified particles are removed, and packaged according to specifications, and finally formed into commercial organic fertilizers sold on the market.

Through these seven steps, chicken manure is transformed into an efficient organic fertilizer that provides important nutrient support for agricultural production. This process not only reflects the advanced concept of agricultural waste resources, but also shows the important role of modern agricultural equipment in agricultural production.

0 notes

Text

Transform Your Life: 10 Easy DIY Zero Waste Projects for a Greener Tomorrow

10 Simple DIY Zero Waste Projects for Beginners

1. Introduction:

Imagine a world where our trash bins are nearly empty, and our planet breathes a little easier. That's the magic of the zero waste movement! By embracing zero waste practices, we can significantly cut down on the waste we produce, conserve precious resources, and reduce pollution. Small DIY projects are a fantastic way to dip your toes into this eco-friendly lifestyle. They're not only budget-friendly but also incredibly empowering. Ready to make a difference? Let's dive into ten simple DIY zero waste projects perfect for beginners.

2. Reusable Beeswax Wraps:

Say goodbye to plastic wrap and hello to reusable beeswax wraps! These handy wraps are perfect for keeping your food fresh without the plastic waste.

Materials:

- Cotton fabric

- Beeswax pellets

- Parchment paper

- Iron

Instructions:

1. Snip your fabric into the sizes you need.

2. Lay the fabric on a sheet of parchment paper.

3. Sprinkle beeswax pellets evenly over the fabric.

4. Cover with another sheet of parchment paper.

5. Iron over the parchment paper until the beeswax melts and saturates the fabric.

6. Let it cool and harden. Voilà! Your beeswax wrap is ready to use.

These wraps are a game-changer for a zero waste lifestyle. You can find beeswax pellets at a zero waste store near me or online.

3. Homemade Cleaning Products:

Ditch those chemical-laden commercial cleaners and whip up your own all-natural, zero waste cleaning solutions. They're better for you and the planet!

All-Purpose Cleaner:

- 1 cup white vinegar

- 1 cup water

- 10-15 drops of essential oil (e.g., lemon, lavender)

Instructions:

1. Mix the ingredients in a spray bottle.

2. Shake well before each use.

Glass Cleaner:

- 1 cup water

- 1 cup rubbing alcohol

- 1 tablespoon white vinegar

Instructions:

1. Combine the ingredients in a spray bottle.

2. Shake well and use on glass surfaces.

These homemade cleaners are effective and reduce the need for plastic bottles. Ingredients like vinegar and essential oils can often be found at a zero waste store near me.

4. DIY Cloth Produce Bags:

Plastic produce bags? No, thank you! Sewing your own cloth produce bags is a simple and rewarding project that helps cut down on plastic waste.

Materials:

- Lightweight fabric (e.g., muslin)

- Sewing machine or needle and thread

- Drawstring cord

Instructions:

1. Cut the fabric into rectangles of your desired size.

2. Fold each rectangle in half and sew the sides, leaving the top open.

3. Hem the top edge and create a casing for the drawstring.

4. Thread the drawstring through the casing and tie the ends.

Using cloth produce bags is a fantastic step towards a zero waste lifestyle. You can find suitable fabric at a zero waste store near me or repurpose old sheets or pillowcases.

5. Upcycled T-Shirt Tote Bags:

Got old t-shirts lying around? Turn them into stylish and functional tote bags, reducing textile waste and giving your wardrobe a second life.

Materials:

- Old t-shirt

- Scissors

- Sewing machine or needle and thread

Instructions:

1. Cut off the sleeves and neckline of the t-shirt.

2. Turn the t-shirt inside out and sew the bottom hem closed.

3. Turn it right side out. Your tote bag is ready to use!

Upcycling old t-shirts into tote bags is a fun and creative way to reduce waste. If you need more t-shirts, check out a zero waste store near me for second-hand options.

6. Natural Body Scrubs:

Pamper yourself with natural body scrubs made from kitchen ingredients. They're luxurious, eco-friendly, and free from plastic packaging.

Coffee Scrub:

- 1 cup used coffee grounds

- 1/2 cup coconut oil

- 1/4 cup brown sugar

Instructions:

1. Mix all the ingredients in a bowl.

2. Store in a reusable jar and use as needed.

Sugar Scrub:

- 1 cup granulated sugar

- 1/2 cup olive oil

- 10-15 drops of essential oil (e.g., peppermint, lavender)

Instructions:

1. Combine the ingredients in a bowl.

2. Store in a reusable container and use in the shower.

Making your own body scrubs is a luxurious way to embrace zero waste living. Ingredients like coconut oil and essential oils can be found at a zero waste store near me.

7. Reusable Makeup Remover Pads:

Disposable makeup remover pads? No more! Sewing your own reusable pads is a simple and eco-friendly solution.

Materials:

- Soft fabric (e.g., cotton flannel)

- Sewing machine or needle and thread

Instructions:

1. Cut the fabric into small circles or squares.

2. Sew two pieces of fabric together, leaving a small opening.

3. Turn the pad right side out and sew the opening closed.

Reusable makeup remover pads are gentle on your skin and the environment. You can find suitable fabric at a zero waste store near me or repurpose old clothes.

8. Compost Bin:

Turn your kitchen scraps into nutrient-rich soil with a DIY compost bin. It's an excellent way to reduce waste and nourish your garden.

Materials:

- Large plastic bin with a lid

- Drill

- Organic waste (e.g., fruit and vegetable scraps, coffee grounds)

Instructions:

1. Drill holes in the bottom and sides of the bin for aeration.

2. Place the bin in a convenient location.

3. Add organic waste and mix regularly.

4. In a few months, you'll have rich compost for your plants.

Creating a compost bin is a practical step towards a zero waste lifestyle. If you need a bin, check out a zero waste store near me for options.

9. DIY Toothpaste:

Say goodbye to commercial toothpaste tubes and hello to homemade, zero waste toothpaste. It's simple, effective, and eco-friendly.

Ingredients:

- 2 tablespoons coconut oil

- 1 tablespoon baking soda

- 10-15 drops of peppermint essential oil

Instructions:

1. Mix all the ingredients in a small jar.

2. Use a small amount on your toothbrush as needed.

DIY toothpaste is effective and reduces plastic waste. Ingredients like coconut oil and essential oils can be found at a zero waste store near me.

10. Zero Waste Gift Ideas:

Celebrate special occasions with thoughtful, sustainable gifts that you can make at home. They're unique, eco-friendly, and show you care.

Ideas:

- Homemade candles using soy wax and essential oils.

- Hand-knitted scarves or hats.

- Baked goods in reusable containers.

- Potted plants or herbs.

Zero waste gifts are unique and show that you care about the environment. You can find materials for these projects at a zero waste store near me.

11. Conclusion:

Starting with one DIY zero waste project can lead to a more sustainable lifestyle. Each small step contributes to a larger impact on the environment. Gradually incorporating more zero waste practices into your daily routine can help you live a greener, more eco-friendly life. Remember, every effort counts!

Which of these zero waste projects are you most excited to try first, and how do you think it will impact your journey towards a more sustainable lifestyle?

Greenify Me - 20 Easy Zero Waste DIY Ideas:

Mindful of the Home – 17 Cheap and Easy DIY Zero-WasteProducts:

Good good good news:

Happiest Camper – 40+ Easy Zero Waste Projects for the Home:

1 note

·

View note

Text

As an important resource in agricultural production, organic fertilizer plays a significant role in promoting soil improvement and crop growth. This paper will deeply analyze the mechanism of organic fertilizer in soil improvement and crop growth, and introduce the relevant fertilizer granulator equipment.

1. Organic fertilizer and soil improvement

Organic fertilizers are rich in organic matter and microorganisms, which can improve soil structure, water retention and air permeability of soil. By using Organic Fertilizer Production Line, we can efficiently produce organic fertilizers suitable for different soil types. These fertilizers can not only provide nutrients needed by plants, but also promote the growth of soil microorganisms, thus enhancing the biological activity of the soil.

2. Organic fertilizer and crop growth

After the organic matter in the organic fertilizer is decomposed in the soil, it can release a variety of nutrients needed for plant growth. NPK Fertilizer Production Line can accurately match nitrogen (Urea), Ammonium Dihydrogen Phosphate and Potassium Chloride according to the specific needs of crops, To ensure that crops receive a balanced supply of nutrients.

3. Granulation process of organic fertilizer

In order to improve the application efficiency and convenience of organic fertilizer, fertilizer granulator series equipment plays an important role. Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine can compress organic fertilizer raw materials into pellets for easy storage and application. Rotary Drum Granulator and Disc Granulator make fertilizer particles more uniform and compact by rotating action.

4. Compost fermentation of organic fertilizer

Before application, organic fertilizer needs to go through the compost fermentation process to improve its fertilizer efficiency and safety. The Windrow Compost Turning Machine plays a key role in this process. It produces high-quality organic fertilizer by turning compost materials, promoting air circulation and microbial activity, accelerating the decomposition and conversion of organic matter.

Conclusion

Organic fertilizers play an important role in soil improvement and crop growth. By using organic fertilizer production lines, NPK composite fertilizer production lines and fertilizer granulator series equipment, we can efficiently produce organic fertilizers suitable for different crops and soil conditions. These fertilizers not only provide the nutrients needed by plants, but also improve the soil environment and promote the healthy growth of crops. In the future, with the continuous advancement of organic fertilizer technology, agricultural production will be more efficient and sustainable.

0 notes

Text

Bamboo is known for its tough and fast growing properties and is an integral element in many garden and landscape designs. However, in order to ensure the healthy growth and good ornamental value of bamboo, the right fertilizer is essential. Organic fertilizers are ideal for growing bamboo because of their natural, environmentally friendly and soil-friendly properties. This paper will introduce several organic fertilizers suitable for bamboo, and discuss the related fertilizer granulator equipment.

1. Compost

Compost is an organic fertilizer made by microbial decomposition of organic matter, which is rich in nitrogen, phosphorus, potassium and other nutrients required for plant growth. For bamboo, compost provides comprehensive nutrients that promote root development and plant health. In the process of making compost, a Flat-Die Pellet Machine can be used to compress organic materials into pellets, which is not only easy to store and transport, but also can improve the uniformity and application effect of fertilizer.

2. Green manure

Green manure refers to the direct use of plant residues or the plant itself as fertilizer, such as the residues of legumes. This type of fertilizer is rich in nitrogen, which helps the bamboo grow quickly. In the production process of green fertilizer, Rotary Drum Granulator can effectively transform plant residues into granular fertilizer, improving fertilizer application efficiency and soil fertility.

3. Animal feces

Animal manure is another common organic fertilizer, especially that of ruminants such as cattle and sheep, which is rich in organic matter and trace elements. These fertilizers can improve the soil structure and provide lasting nutrients for bamboo. When dealing with animal waste, the Disc Granulator converts it into uniform particles, facilitating uniform application and improving fertilizer utilization.

4. Humic acid fertilizer

Humic acid fertilizer is an organic substance extracted from plant residues and animal excrement, which has the function of improving soil structure, increasing soil fertility and promoting plant growth. For plants such as bamboo that require high soil conditions, humic acid fertilizer is a good choice. In the production of humic acid Fertilizer, the Fertilizer Granules Compaction Machine can mix humic acid with other fertilizer raw materials and extrude them into particles to improve the stability and application effect of fertilizer.

When choosing the right fertilizer granulator equipment, it is necessary to consider the raw material characteristics, production scale and economic cost of fertilizer. For example, a Flat-Die Pellet Machine is suitable for small-scale production, while Rotary Drum Granulator and Disc Granulator are suitable for large-scale fertilizer production. The Fertilizer Granules Compaction Machine is suitable for fertilizer production requiring high pressure molding.

In short, to provide adequate nutritional value of bamboo, choosing the appropriate organic fertilizer and the corresponding fertilizer granulator equipment is the key. Through scientific fertilization methods and advanced granulation techniques, it is possible to ensure that bamboo gets a balanced nutrition, promote its healthy growth, and also contribute to the sustainable development of the environment.

#Flat-Die Pellet Machine#Rotary Drum Granulator#Disc Granulator#Fertilizer Granules Compaction Machine

0 notes

Text

In modern agricultural production, organic fertilizers are increasingly valued for their positive effects on soil and crops. Organic fertilizers can not only provide nutrients for plant growth, but also improve soil structure, promote soil microbial activity, and improve soil fertility and water retention capacity. This paper will introduce several common organic fertilizers, and discuss the related fertilizer granulator equipment.

1. Compost (Compost)

Compost is a kind of organic fertilizer formed by decomposition and fermentation of organic matter such as plant residues and kitchen waste under the action of microorganisms. It contains rich organic matter and a variety of trace elements, which can improve the biological activity and fertility of soil.

2. Green Manure

Green manure is the planting of specific plants, such as legumes, which are turned into the soil during their growth, and the decomposition of plant residues is used to increase soil organic matter and nutrients. Green manure can also improve soil structure and increase soil water retention and permeability.

3. Animal Manure

Animal manure is another common organic fertilizer, such as cow manure, chicken manure, etc. They are rich in nitrogen, phosphorus, potassium and other major nutrients needed for plant growth, as well as providing organic matter needed by soil microorganisms.

4. Biogas Slurry

Biogas residue, a byproduct of biogas fermentation, is rich in organic matter and microorganisms, which can improve soil fertility and soil structure.

In the production process of organic fertilizer, fertilizer granulator equipment plays a crucial role. The following are several types of fertilizer granulator equipment related to organic fertilizer production:

Organic Fertilizer Production Line: This is a production line specially used for the production of organic fertilizer, including multiple links, such as raw material treatment, fermentation, drying, granulation, etc., to ensure the quality and effect of organic fertilizer.

Rotary Drum Granulator: This type of granulator makes organic fertilizer raw materials into pellets through the rotation of the drum and the friction of the material, which is convenient for storage and application.

Disc Granulator: Disc Granulator makes organic fertilizer raw materials into uniform particles by rotating the disk and centrifugal force of the material, improving the application effect of fertilizer.

Fertilizer Granules Compaction Machine: This type of granulator squeezes materials by two rollers rotating in opposite directions to form particles. It is suitable for the production of high-density, high-hardness organic fertilizer particles, which helps to improve the storage and transportation efficiency of fertilizers.

Through these advanced fertilizer granulator equipment, the production efficiency and quality of organic fertilizer can be effectively improved to meet the needs of modern agriculture for efficient and environmentally friendly fertilizers. At the same time, the application of these devices also helps to promote the popularization and application of organic fertilizers and promote the sustainable development of agriculture.

#Organic Fertilizer Production Line#Rotary Drum Granulator#Disc Granulator#Fertilizer Granules Compaction Machine

0 notes

Text

Fast Food and Quick Service Restaurant Market Developments, Trends & Opportunities till 2032

Fast Food and Quick Service Restaurant Market provides in-depth analysis of the market state of Fast Food and Quick Service Restaurant manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Fast Food and Quick Service Restaurant in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Fast Food and Quick Service Restaurant Market Report:

The report offers a comprehensive and broad perspective on the global Fast Food and Quick Service Restaurant Market.

The market statistics represented in different Fast Food and Quick Service Restaurant segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Fast Food and Quick Service Restaurant are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Fast Food and Quick Service Restaurant.

Major stakeholders, key companies Fast Food and Quick Service Restaurant, investment feasibility and new market entrants study is offered.

Development scope of Fast Food and Quick Service Restaurant in each market segment is covered in this report. The macro and micro-economic factors affecting the Fast Food and Quick Service Restaurant Market

Advancement is elaborated in this report. The upstream and downstream components of Fast Food and Quick Service Restaurant and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/fast-food-and-quick-service-restaurant-market-100554

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Liquid Laundry Detergent MarketMarket Growth Rate

Water Storage Systems MarketMarket Forecast

Global Online Taxi Service MarketMarket Size

Large-Scale LNG Terminals MarketMarket Growth

GBL and NMP MarketMarket Analysis

Direct Carrier Billing Platform MarketMarket Size

Global Kubernetes Solutions MarketMarket Share

Global Salesforce CRM Document Generation Software MarketMarket Growth

Incident Forensics MarketMarket

Contract Development and Manufacturing Organizations (CDMOs) MarketMarket Share

Cervical Total Disc Replacement Device MarketMarket Growth Rate

Medical Animation MarketMarket Forecast

Global Tax Management Software MarketMarket Size

Drone Camera MarketMarket Growth

MPO Fiber Optic Connector MarketMarket Analysis

Electroplating Chemicals MarketMarket Size

Global Isobutanol MarketMarket Share

Global Small Cell 5G Network MarketMarket Growth

Dry Strand Pelletizers MarketMarket

Aircraft Engine, Parts and Equipment MarketMarket Share

Fluorine Aromatic Pi Film MarketMarket Growth Rate

LNG As A Bunker Fuel MarketMarket Forecast

Global Winches MarketMarket Size

Veterinary Hematology Analyzers MarketMarket Growth

Apheresis Machines MarketMarket Analysis

Smart Rice Cooker MarketMarket Size

Global Airlaid Paper MarketMarket Share

Global LPG Metal Cylinders MarketMarket Growth

Container Weighing Systems MarketMarket

Virtual Reality Content MarketMarket Share

White Glove Services MarketMarket Growth Rate

Dive Scooter MarketMarket Forecast

Global Premium Motorcycle Helmet MarketMarket Size

Bicycle Pedal MarketMarket Growth

Plastic Sheets MarketMarket Analysis

Bus Air Suspension System Market Market Size

Global Electric Platform Carts Market Market Share

Global Paste PVC (PPVC) MarketMarket Growth

Well Drilling and Repairing Machinery MarketMarket

0 notes

Text

printmaking part 2

I am still trying to figure out how to make the perfect liner card. At the university, they use very, very organic cutting tools. I just noticed it again with the lino printing; the cutter tools are how. Different is from. The university. And from. Schools and college. It was much more different and much more higher professional. The professional line of cotton tools came from Japan because Japan was much more famous. They became famous for the cutter tools when people wanted to do printmaking and graphic design well. We are using the Japanese liner cocktails in universities, secondary schools, and colleges using like type of. Plastic and less. Shop blades. It says a shop, but it depends on again how people are holding it or how they're using it. The strength of the shortness was not so high that people could see the deep cuts, but there was still much more. Great if you people were a beginner like me with liner cutting to get this liner cut tool and use it for sure and using it for liner cutting trying out playing with it. Pot is with printmaking is needed like a studio spaces the one I'm printing, and the liner cutting is to cut out the liner blocks is not necessarily required spaces which has to be careful whereabout people was cutting because if holding it wrongly the blade it could be easily get injured.

For drive, when printing, it is also just the same. Liner printing is. Like tools like metal pen tools they are using to make. The printing and scraping theory. Are the plastic tools also like using plastic, but the quality of what we're using again could head like a higher quality of metals, or we could have an electric one as well. This is again questionable because I have never done this before and never used this one of the electric tools. The thing with this is the schools and secondary schools give fewer introductions of how to use the tools and were about to use these toes. The university doesn't teach us how to use the toes, so it was hard to know if I should go with the dry-point print. However, I still prefer mono printing because it is similar to Zen styles and loads of media I could try. Hence, I have started my strength in printmaking, and I only use the dry point print and liner cutting. I still cannot get along with the quality. The screen print when I tried it out, I found it like, Oh my God, that seems easy, but the machines we have to use when we have to put our print blocks and print stuff, it seems. It was hard to understand at the beginning and to know we were about to. I have to go with you, so I decided to. I had loads of questions from the teacher, taking loads of nodes and taking photographs of the so I was she doing when we putting on the machine to copy the plates so the plates could copy the images I've been using and as I said, I needed three layers and the screen it was like size like more than like one size. It's all about fitting in, and I must be careful where the inks go. We're using the same acrylic paint that we are using for painting. We are using acrylic medium sodium paint so that it won't be easy. The paint would be more fluent; it's better to use a bit darker, medium, dark, or not too dark, but not lighter, because otherwise, nobody else could see in it. So if. I used the first layer a bit darker, the 2nd layer a bit lighter, and the 3rd layer lying between the medium. So not that, um. Dark and not that light. So it has to be controlled also the colours. So that's why we got a colour wheel in the printing studio. We could match the colours up. The printmaking studio also put out some papers needed to free paper. So what I was done was I grabbed some papers, and I used the pellet friendly, and I decided to mix and test out the colours and how I wanted to get this fitted together, and it seems like there goes. Pretty well. We stopped using a sample little dummy graphic design. We have to use a. Initially, it's a total epic fail and messy, and it's impossible to publish this. At my first bookmaking, I wouldn't keep all of them because we have 12 or more than 12 printing. Every single one unfortunate I could hold, but so many of them I could, but all of them I could copy. They, and I could keep them. I could look back anytime and keep one of them as well.

It would be so difficult if I had today's scrim printing at home. I permanently. Recommending to has some unique studio spaces and special tools, just like dry point printing and printmaking, because it was complicated to do, but liner printing and. and minor printing. It was simple because of the materials and tools. So, as I mentioned in my last blog, it has to be so it could be using beginner tools. It can be something other than the special Japanese tolls and the regular ink; I just mentioned that there is no need to be in Teglob ink. And baby oil because it was difficult to remove the brit making uh ink because that's not the same like acrylic paint you could remove like, um, the stains and the dryness is, so it has to be like a bit like hard to delete it's like much more like hardly to remove every single stain and also. Baby oil is less smellier-like than a white spirit because it's the white spirit is the primary key to pulling everything, but it has to be like special tools like goggles and gloves, just like baby oil has to wear gloves and goggles.

0 notes

Text

Best Wood Crusher Machine Manufacturers and Wood Crusher Machine Suppliers and Exporters in Mumbai, India

In the ever-evolving world of industrial machinery, one company stands out as a leading manufacturer and supplier of Wood Crusher Machines: Keyul Enterprise, based in Mumbai, India. With a commitment to quality and innovation, Keyul Enterprise has become a go-to destination for businesses seeking efficient and reliable Wood Crusher Machines.

What is a Wood Crusher Machine?

A Wood Crusher Machine is a powerful industrial equipment designed to break down and crush various types of wood materials into smaller pieces or chips. These machines are essential in a variety of industries, including biomass energy production, paper manufacturing, and landscaping. By reducing the size of wood waste, these machines not only facilitate efficient disposal but also enable the repurposing of the crushed material for various applications.

Why Choose Keyul Enterprise?

Keyul Enterprise has established itself as a trusted name in the industry, thanks to its unwavering dedication to quality and customer satisfaction. With years of experience and expertise, the company offers a wide range of Wood Crusher Machines tailored to meet the diverse needs of its clients.

In addition to Wood Crusher Machines, Keyul Enterprise is also a leading manufacturer of Oil Press Machines, Oil Filter Machines, Chaff Cutter Machines, Pellet Machines, and Wood Chipper Machines. This diverse product portfolio showcases the company's versatility and commitment to providing comprehensive solutions to its customers.

Quality and Innovation

At Keyul Enterprise, quality is paramount. The company employs state-of-the-art manufacturing processes and adheres to stringent quality control measures to ensure that every machine meets the highest industry standards. Moreover, Keyul Enterprise continuously invests in research and development, enabling it to stay ahead of the curve and introduce innovative features and technologies to its product line.

Customer-Centric Approach

Keyul Enterprise's success is built on its customer-centric approach. The company understands that every business has unique requirements, and it works closely with its clients to provide tailored solutions that meet their specific needs. From initial consultation to post-sales support, Keyul Enterprise ensures a seamless and satisfactory experience for its customers.

Conclusion

Whether you're in the market for a high-performance Wood Crusher Machine or any other industrial machinery, Keyul Enterprise is the go-to destination. With its commitment to quality, innovation, and customer satisfaction, this Mumbai-based manufacturer and supplier of Wood Crusher Machines and other industrial equipment is poised to meet the demands of businesses across India and beyond.

#WoodCrusherMachine#WoodCrusherManufacturers#WoodCrusherSuppliers#WoodCrusherExporters#MumbaiManufacturers#IndianManufacturers#QualityProducts#IndustrialMachinery#InnovativeSolutions#CustomerSatisfaction#KeyulEnterprise

0 notes

Text

Maximizing Wood Processing Efficiency: A Tale of Disc and Drum Chippers

See Zibo Chenze’s drum chipper in action, efficiently handling wood waste in forestry environments.

Embark on a virtual tour of sustainable wood processing technology with Zibo Chenze’s 25-30 Ton/Hour Production Line. This innovative system combines efficiency and productivity, transforming wood processing operations for a sustainable future.

In the realm of wood processing, the choice between disc and drum chippers plays a pivotal role in shaping the efficiency and quality of the production process. Zibo Chenze Machinery stands at the forefront of innovation, offering both Disc and Drum Chippers, each with distinct features tailored for various applications.

Disc Chipper: Precision and Versatility

Meticulous Engineering: Zibo Chenze’s Disc Chippers embody precision engineering, integrating wear-resistant chrome-plated disc material and special steel for knives. This meticulous craftsmanship ensures durability and consistently high-quality wood chips.

Versatile Power Options: The versatility of Disc Chippers is highlighted by their adaptability to both low and high voltage motors. Larger models offer options for belt-driven and direct coupling, along with choices for horizontal or inclined feeding.

Compact and Adjustable: These chippers boast a compact design, facilitating easy installation, operation, and maintenance. The user-friendly nature of Disc Chippers caters to wood processing operations of varying scales. Adjustable features allow for precise control over chip length, ensuring customized end products.

High Throughput Capacity: Engineered for high throughput, Zibo Chenze’s Disc Chipper series delivers exceptional performance, with a capacity ranging from 2 to 160 cubic meters per hour. This flexibility makes them ideal for diverse production requirements.

Applications:

Wood Handling Process: Integral in transforming raw wood logs into premium wood chips.

Bioenergy Production: Contributing to sustainable energy solutions with high-quality wood chips for modern heating plants.

Drum Chipper: Robust Efficiency

Robust Design: Zibo Chenze’s Drum Chippers feature a robust and durable design, ensuring consistent performance in demanding environments. The sturdy construction enhances equipment longevity, making them reliable choices for wood processing needs.

Efficient Wood Processing: With advanced cutting mechanisms, Drum Chippers excel in processing various wood materials efficiently. From branches to logs and wood waste, these chippers consistently deliver high-quality results.

Precision Control and User-Friendly: Drum Chippers provide precision control through adjustable settings, allowing customization of chip size for specific applications. Designed with operators in mind, they offer user-friendly controls and intuitive interfaces, making them suitable for both seasoned professionals and newcomers to wood processing.

Applications:

MDF Board Industry: Crucial for wood chip production in MDF Board manufacturing.

Pulp and Paper Mills: Reliable equipment for wood processing in the paper industry.

Biomass Production: Essential for contributing wood chips to the biomass industry.

Pelletizing: Critical for creating wood pellets.

WPC/WFC Industry: Ideal for wood-plastic composite and wood-fiber composite industries.

The Supporting Cast: Enhancing Efficiency

To complete the wood processing journey, Zibo Chenze Machinery offers a comprehensive set of supporting equipment, including a well-coordinated logs handling system, debarker machines, chips screening, re-chipping solutions, and moving floor technology. Each element contributes to a seamless wood chip production process, ensuring efficiency from raw logs to the final product.

In conclusion, whether you choose the precision and versatility of Disc Chippers or the robust efficiency of Drum Chippers, Zibo Chenze Machinery stands ready to elevate your wood processing capabilities. With proven expertise, stringent quality assurance, and a global presence, Zibo Chenze Machinery is your trusted partner for cutting-edge solutions in the forestry and biomass industries. Contact our sales team today to embark on a journey towards excellence in wood processing. #WoodProcessing #DiscChipper #DrumChipper #InnovationInWoodProcessing #ZiboChenzeMachinery

All

biomass crusher

drum wood chipper

wood chipper

Drum Wood Chipper

August 25, [email protected] wood chipper, wood chipperbiomass grinder, drum wood chipper, wood waste grinding shredderNo Comments

DRUM WOOD CHIPPER INFO Application Videos TECHNICAL DATA INFO Drum Chippers for...

READ MORE

Disc Wood Chipper

August 18, [email protected] wood chipper, wood chipperMetal, PolymerNo Comments

Disc Wood Chipper INFO Applications Links TECHNICAL DATA INFOCONTACT VIDEO Zibo Chenze's...

READ MORE

Wood Grinder and Biomass Shredder

August 1, [email protected] crusher, biomass crusherMetal, PolymerNo Comments

Wood Grinder And Biomass Crushing Shredder INFO Application Videos TECHNICAL DATA INFO...

READ MORE

Wood Chips Vibrating Screen

April 27, [email protected] wood chipper, wood chipperbiomass grinder, drum wood chipper, wood waste grinding shredderNo Comments

Wood Chips Vibrating Screen Precision Screening for Wood Chips Production Zibo Chenze...

READ MORE

Mobile Chipping grinder

April 16, [email protected] crusher, disc wood chipper, drum wood chipper, Mobile Chipping grinder, wood chipperMetal, PolymerNo Comments

INFO TECHNICAL DATA more INFOCONTACT NOW Mobile Wood Chipper Introduction: Welcome to...

READ MORE

Knife-Ring Flaker

February 17, [email protected] flakerknive-ring flakerNo Comments

Knife-Ring Flaker Zibo Chenze’s knife-ring flaker is one of the...

READ MORE

Inquiry Now

0 notes

Text

Supplier of Trim Recycling Machine in Arunachal Pradesh

Adroit Extrusion Manufacturer, Exporter and Supplier of Trim Recycling Machine in Arunachal Pradesh.

Adroit Extrusion provide the groundbreaking 3 Layer Blown Film Plant with ISO 9001:2015 certification, showcasing our commitment to global bespoke solutions of the highest quality.

We specialize in co-extruded blown film lines and provide a range of configurations, including monolayer, ABA, two-layer, three-layer, five-layer, and seven-layer setups. We are widely known for our dedication to excellence.

Trim Recycling Machine is a cutting-edge device designed to efficiently recycle trim waste generated in various industries, such as printing, packaging, and textile manufacturing.

This machine utilizes advanced technology to process trim waste materials, such as paper, cardboard, plastic, and fabric, and transform them into reusable resources.

How Does it Work?

The Trim Recycling Machine operates through a series of automated processes that begin with the collection of trim waste from production lines.

The waste materials are then fed into the machine, where they undergo shredding, sorting, and compaction.

Advanced sensors and sorting mechanisms ensure proper segregation of materials for recycling.

Finally, the processed materials are transformed into compacted bales or pellets ready for reuse or resale

Features:

Efficiency: Trim Recycling Machine streamlines the recycling process, significantly reducing the time and labor required for waste management.

Cost-effectiveness: By maximizing the reuse of materials and minimizing waste disposal costs, the Trim Recycling Machine offers significant cost savings for businesses.

Environmental Impact: By diverting trim waste from landfills and promoting recycling, this technology helps reduce carbon emissions and conserves natural resources.

Application:

Printing and Packaging

Textile Manufacturing

Plastic Recycling

Adroit Extrusion is Supplier of Trim Recycling Machine in Arunachal Pradesh, extends its services to locations such as Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Nagarjunakoṇḍa, Rajahmundry, Srikakulam, Tirupati, Vijayawada, Visakhapatnam, Vizianagaram, Yemmiganur.

For further details and inquiries, please feel free to contact us.

Read the full article

0 notes

Text

In modern agricultural production, organic fertilizers are favored for their environmentally friendly and nutritionally comprehensive properties. Granular organic fertilizer is not only easy to store and transport, but also can improve the utilization rate of fertilizer. In order to meet different production needs, there are many types of granulators on the market. This paper will introduce several commonly used granulators and discuss their application in granular organic fertilizer production.

1. Disc Granulator

Disc Granulator is a kind of equipment commonly used in organic fertilizer production line. It disperes the material evenly on the surface of the disc by rotating disc, and makes use of centrifugal force and gravity to form particles. This equipment is particularly suitable for processing organic fertilizers with moderate water content, and can produce particles of uniform size and regular shape.

2. Rotary Drum Granulator

Rotary Drum Granulator rolls materials through a rotating drum and condenses materials into particles through friction and extrusion. This equipment is particularly suitable for the treatment of organic fertilizers with high water content and can achieve efficient granulation in a short time.

3. Fertilizer Granules Compaction Machine

The Fertilizer Granules Compaction Machine squeezes the material through two rollers that rotate against each other to form particles. This equipment is especially suitable for processing materials with high water content, and can convert wet materials into dry particles in a short time, greatly improving production efficiency.

4. Flat-Die Pellet Machine

Flat-Die Pellet Machine compresses materials through a mold to form particles. This equipment is suitable for handling various types of materials, including organic fertilizers, and can produce particles with regular shapes and uniform densities.

In the production of granular organic fertilizer, the appropriate granulator can be selected according to factors such as raw material characteristics, production scale and economic cost. Different granulators have different characteristics and scope of application, choosing the right granulator is crucial to improve production efficiency and product quality.

Organic Fertilizer Production lines usually include pre-treatment, mixing, granulation, drying, screening and packaging. In this process, the choice of granulator is particularly critical, which directly affects the particle quality, production efficiency and cost of fertilizer.

The Bulk Blending Fertilizer Production Line involves the mixing of organic and inorganic fertilizers to provide more comprehensive nutrition. In this production line, the granulator also plays an important role, which can further process the mixed material into pellets and improve the application effect of fertilizer.

In summary, the production of granular organic fertilizer can use a variety of granulators, each equipment has its own unique advantages and application scenarios. Choosing the right granulator, combined with an efficient production line, can greatly improve the production efficiency and product quality of organic fertilizers, and meet the needs of modern agriculture for efficient and environmentally friendly fertilizers.

#Disc Granulator#Rotary Drum Granulator#Fertilizer Granules Compaction Machine#Flat-Die Pellet Machine

0 notes