#peb structure

Explore tagged Tumblr posts

Text

Getting the ideal PEB manufacturer not just speeds up the construction process but make sure the smooth working of the construction process.

View details - https://sparxwizzengineering.com/peb-structures/

0 notes

Text

Pre-Engineered Building structure

PEB structure, or Pre-Engineered Building structure, provides numerous advantages in terms of cost-effectiveness, durability, and efficiency. Its modular and customizable design allows for quick construction and easy expansion. With its strength and flexibility, it is suitable for a wide range of applications, from industrial buildings to warehouses and even commercial spaces. To gain a deeper understanding of this innovative construction method, we encourage you to read more about PEB structure.

0 notes

Text

Pre Engineered Metal Building by BalarkaPeb

Pre Engineered Metal Building

BalarkaPeb specializes in providing high quality Pre Engineered Metal Building that are designed to meet a variety of industrial, commercial, and residential needs. These buildings are prefabricated in a factory setting, which allows for precision and quick assembly at the construction site. With years of experience and advanced engineering techniques, BalarkaPeb ensures that each building is robust, energy efficient, and cost effective, offering a wide range of customizable features.

Key Benefits of Pre Engineered Metal Building by BalarkaPeb:

Cost Effective: Pre engineered metal building are an affordable solution compared to traditional construction methods. With a reduction in labor costs and faster construction timelines, they provide substantial savings for both business and homeowners.

Customization: Each PEB building is engineered to meet the specific needs of the client. Whether it’s for storage, warehousing, manufacturing, or even a residential structure, BalarkaPeb offers tailored designs with flexibility in size, shape, and interior layout.

Durability and Strength: Constructed with high strength steel, these buildings are designed to withstand harsh weather conditions, including high winds, snow loads, and earthquakes. The materials used in pre engineered buildings are resistant to corrosion, ensuring a long lasting structure with minimal maintenance.

Quick Assembly: One of the standout advantages of is the quick assembly process. Since components are pre fabricated off site and ready for assembly, the overall construction time is significantly reduced, which leads to faster project completion.

Energy Efficiency: BalarkaPeb incorporates energy efficient solutions in its building designs. With the option of insulated panels, reflective roofing materials, and optimal building orientation, these buildings maintain temperature stability, reducing the need for additional heating or cooling.

Environmentally Friendly: Pre Engineered steel buildings is a recyclable material, making pre engineered metal building a sustainable choice. The reduction in material waste during construction and the long term durability of these structures contribute to a smaller environmental footprint.

Applications of Pre Engineered Metal Building:

Warehouses & Storage Facilities: Pre engineered metal building are perfect for creating expansive storage spaces that are secure and weather resistant.

Manufacturing Plants: These buildings provide ample space for production lines, machinery, and storage, while their flexibility allows easy modifications for future growth.

Retail and Commercial Spaces: Pre engineered buildings can be transformed into retail shops, showrooms, or office spaces with modern and attractive facades.

Residential Homes: BalarkaPeb also offers pre engineered metal building designed for residential use, including custom homes that are durable and stylish.

Agricultural Buildings: From barns to equipment storage, these buildings offer secure spaces for agricultural needs with enough room for livestock and machinery.

Why Choose BalarkaPeb for Your Pre Engineered Metal Building?

Expert Engineering: BalarkaPeb’s team of engineers uses the latest technology to ensure every structure is built to last. The design process is highly efficient, with attention to detail ensuring safety and compliance with local regulations.

Comprehensive Support: From initial consultation to the final installation, BalarkaPeb provides end to end support, helping customers with design, engineering, and installation, ensuring the project meets timelines and budget constraints.

Quality Materials: BalarkaPeb only uses premium quality materials for all their pre engineered metal building, ensuring strength, durability, and long term performance.

Conclusion

For businesses, homeowners, or any entity looking for reliable and affordable peb structures, BalarkaPeb’s Pre Engineered Metal Building offer an ideal solution. With customization options, durability, quick installation, and cost effectiveness, these PEB buildings provide lasting value. Reach out to BalarkaPeb today for your next construction project and experience the future of PEB building design and construction.

#Pre Engineered Metal Building#prefabricated structures#pre engineered building#peb structure#peb building#Pre Engineered Steel buildings#Peb building in india

0 notes

Text

Coated & Hot Rolled Steel for PEB Structures | Tata Steel DigECA

Discover premium coated steel and hot-rolled solutions for PEB with DigECA - Tata Steel. Choose Tata Galvano for unmatched durability and reliability.

0 notes

Text

Types of PEB Structures - steelbuildings.in

Pre-Engineered Buildings (PEB) have become a popular choice in modern construction due to their versatility, cost-effectiveness, and rapid assembly. They are designed to be manufactured off-site and assembled on-site, offering a range of structural configurations to suit various applications. Here, we explore the different types of PEB structures, highlighting their features, advantages, and typical uses.

1. Industrial Buildings

Characteristics:

Industrial PEBs are designed to accommodate manufacturing, warehousing, and other industrial processes. They typically feature large open spaces, high ceilings, and robust structural systems to support heavy machinery and storage needs.

Advantages:

Large Span Structures: These buildings often employ wide-span frames, reducing the need for interior columns and providing unobstructed floor space.

Cost Efficiency: Prefabricated components help in reducing construction time and labor costs.

Flexibility: Industrial PEB Structure can be easily expanded or modified based on changing business needs.

Applications:

Manufacturing plants

Warehouses

Distribution centers

Assembly facilities

2. Commercial Buildings

Characteristics:

Commercial PEBs cater to various business needs, including retail spaces, office buildings, and service centers. They often feature attractive facades and design elements to appeal to customers and clients.

Advantages:

Aesthetic Appeal: PEB Structure can be customized with different finishes and materials, allowing for eye-catching designs.

Sustainability: Many commercial PEBs incorporate energy-efficient systems and sustainable materials.

Speed of Construction: Quick assembly helps businesses start operations sooner, benefiting from reduced downtime.

Applications:

Retail outlets

Office complexes

Showrooms

Service stations

3. Agricultural Buildings

Characteristics:

Agricultural PEBs are designed for farming operations and livestock housing. These structures need to accommodate specific requirements such as ventilation, accessibility, and climate control.

Advantages:

Durability: Built to withstand harsh weather conditions, agricultural PEBs are often more resilient than traditional structures.

Customizability: They can be designed for various agricultural uses, including barns, silos, and storage facilities.

Cost-Effective: Reduced labor and material costs make PEBs an economical choice for farmers.

Applications:

Livestock barns

Grain storage facilities

Poultry houses

Equipment storage sheds

4. Institutional Buildings

Characteristics:

Institutional PEBs include schools, hospitals, and community centers. These buildings prioritize safety, functionality, and accessibility for diverse populations.

Advantages:

Quick Turnaround: The speed of construction allows institutions to respond to growing community needs swiftly.

Compliance: PEBs can be designed to meet specific building codes and safety regulations.

Energy Efficiency: Many institutional buildings incorporate green technologies and energy-saving systems.

Applications:

Schools and colleges

Hospitals and clinics

Community centers

Libraries

5. Recreational Buildings

Characteristics:

Recreational PEBs are designed for sports, fitness, and leisure activities. They often include large open spaces, high ceilings, and amenities tailored for public use.

Advantages:

Versatility: These structures can accommodate various activities, from sports to community events.

Cost-Effective: Prefabrication reduces costs and allows for customizable designs based on specific recreational needs.

Quick Assembly: Rapid construction means facilities can open sooner for community use.

Applications:

Gyms and fitness centers

Sports arenas

Community recreational facilities

Indoor swimming pools

6. Residential Buildings

Characteristics:

While less common, PEBs can also be used for residential purposes, providing innovative housing solutions. These structures can range from single-family homes to multi-unit complexes.

Advantages:

Affordable Housing: PEBs offer a cost-effective alternative to traditional construction, helping to address housing shortages.

Speed of Construction: Rapid assembly can reduce the time from design to occupancy.

Customization: Homeowners can customize layouts and finishes to meet personal preferences.

Applications:

Single-family homes

Townhouses

Apartment complexes

Modular housing units

7. Specialty Structures

Characteristics:

Specialty PEBs are tailored for unique purposes, such as aircraft hangars, military facilities, or research laboratories. These buildings often incorporate specialized features to meet specific operational requirements.

Advantages:

Tailored Solutions: Designed to meet specific needs, these structures can incorporate advanced technology and safety features.

Durability and Strength: Specialty PEBs are often built to withstand extreme conditions or heavy usage.

Efficient Use of Space: Custom designs maximize functionality while maintaining structural integrity.

Applications:

Aircraft hangars

Military facilities

Research and development labs

Data centers

Conclusion

Pre-Engineered Buildings offer a range of options for various applications, making them a versatile choice for builders and developers. From industrial and commercial structures to agricultural and recreational facilities, PEBs are designed to meet specific needs while providing significant cost and time savings. As the demand for efficient and sustainable building solutions continues to grow, the popularity of PEBs is likely to increase, paving the way for innovative designs and applications in the construction industry.

0 notes

Text

Aragon Builds the Best PEB Structures for Manufacturing Units

When it comes to manufacturing units, having a robust and reliable infrastructure is crucial for operational efficiency and safety. Aragon, a leading PEB structure manufacturer, stands out as a trusted partner for building top-quality PEB steel structures that meet the unique needs of manufacturing industries.

Why Choose Aragon for PEB Structures?

Aragon's expertise in constructing PEB steel structure buildings is backed by years of experience and a commitment to quality. As one of the top pre-engineered steel building manufacturers in India, Aragon ensures that each project is tailored to the specific requirements of its clients, providing flexible and cost-effective solutions.

Quality and Durability: Aragon uses high-grade materials and advanced engineering techniques, making its PEB steel structures not only durable but also able to withstand harsh environmental conditions.

Customization: Understanding that every manufacturing unit has unique needs, Aragon offers customized designs that maximize space and functionality.

Sustainability: With a focus on eco-friendly construction practices, Aragon helps businesses achieve their sustainability goals by using recyclable materials and energy-efficient designs.

What Sets Aragon Apart?

As one of the leading PEB steel structure manufacturers in India, Aragon is recognized for its innovative approach and adherence to global quality standards. Their state-of-the-art manufacturing facilities and skilled workforce ensure that each PEB structure is constructed with precision and excellence.

Advanced Technology: Utilizing the latest technology in design and fabrication, Aragon delivers PEB steel structures that are not only strong but also aesthetically pleasing.

Comprehensive Solutions: From conceptualization to execution, Aragon provides end-to-end solutions for all PEB structure needs, making them a one-stop solution for businesses.

Why Aragon is Among the Top PEB Manufacturers in India

The company's dedication to excellence and customer satisfaction has earned it a reputation as one of the top PEB manufacturers in India. Aragon’s portfolio includes a diverse range of projects, from small manufacturing units to large industrial complexes, showcasing their capability to handle projects of any scale and complexity.

Conclusion

For businesses looking to build or upgrade their manufacturing facilities, partnering with Aragon ensures that you get the best PEB structure manufacturer in the industry. Their commitment to quality, customization, and sustainability makes them the ideal choice for constructing PEB steel structure buildings that stand the test of time.

1 note

·

View note

Text

0 notes

Text

0 notes

Text

2 notes

·

View notes

Text

PEB Plant

#pre engineered buildings manufacturer#pre engineered building structure#Pre engineered building solution#pre engineered building fabricators#pre engineered metal building manufacturers#Pre-engineered metal buildings#PEB construction companies#PEB suppliers#Industrial building manufacturers#Commercial building manufacturers#Warehouse manufacturers#Factory building manufacturers#PEB manufacturers in India#Construction equipment manufacturers#Building material manufacturers

2 notes

·

View notes

Text

There are various PEB structure manufacturers in India that also provide container site offices and other prefab structures.

Visit us at - https://sparxwizzengineering.com/peb-structures/

0 notes

Text

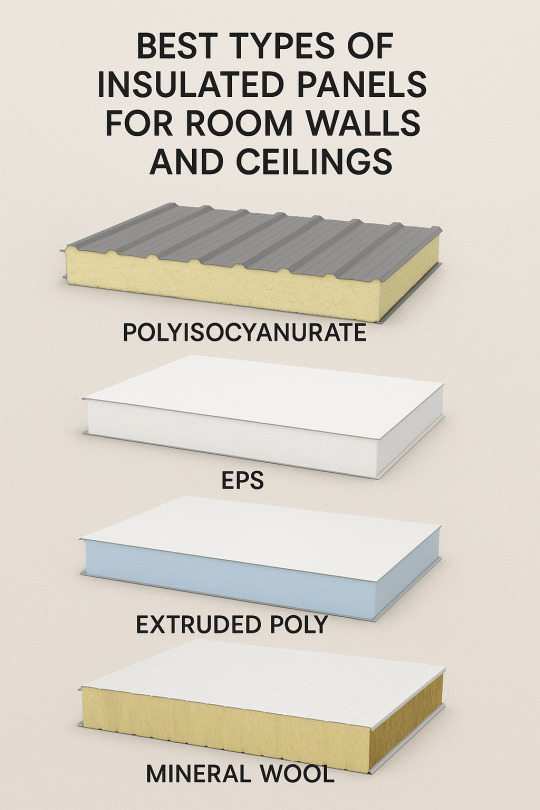

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

3 Critical Factors When Purchasing an Industrial Shed

To obtain the highest quality shed, look for a reputable PEB structure design manufacturer. I’ll go over some key elements to consider while choosing the right industrial shed

0 notes

Text

When planning a construction project, one of the first and most critical decisions you must make is choosing between Pre Engineered Buildings (PEBs) and conventional buildings. Each comes with its own set of advantages and challenges. However, with the rise in modern infrastructure demands, many industries are shifting toward pre engineered buildings due to their flexibility, efficiency, and cost-effectiveness.

#peb structure manufacturer in india#pre engineered building suppliers#pre engineered buildings#pre-engineered building structure

0 notes

Text

PEB Structure Manufacture in Ahmedabad: Driving Industrial Growth

The demand for PEB Structure Manufacture in Ahmedabad has seen a significant rise over the past decade, and it’s easy to see why. As Gujarat’s leading industrial hub, Ahmedabad continues to attract investment in manufacturing, logistics, pharmaceuticals, textiles, and more. This rapid industrial expansion demands efficient, durable, and cost-effective infrastructure—exactly what pre-engineered buildings (PEBs) deliver. Faith PEB, a trusted name in the industry, plays a crucial role in enabling this growth by offering customized PEB solutions tailored to the evolving needs of businesses.

The Rise of PEB Structures in Industrial Infrastructure

Pre-engineered buildings are a modern construction solution that involves the design and fabrication of steel structures off-site before assembling them at the actual location. This approach significantly reduces construction time, lowers labor costs, and ensures consistent quality. In cities like Ahmedabad—where speed and scalability are critical to industrial success—PEB structures are becoming the first choice for project developers.

Faith PEB has been at the forefront of this revolution. With its advanced manufacturing unit and expert engineering team, the company has successfully delivered robust and scalable steel building solutions for factories, warehouses, logistics parks, cold storages, and more.

Why Ahmedabad is a Hotspot for Industrial Development

Ahmedabad’s strategic location, well-developed infrastructure, and favorable business environment make it a preferred destination for industrial investment. The city offers excellent road and rail connectivity, proximity to ports, and access to skilled labor. Government policies such as the Gujarat Industrial Policy have also contributed to making Ahmedabad a fertile ground for new ventures.

To support this growth, industries need infrastructure that matches their pace and scale. PEB structures fulfill this requirement by offering flexibility in design, rapid installation, and superior strength. Whether it’s a textile unit in Naroda or a logistics park in Changodar, pre-engineered steel buildings are redefining how industrial spaces are built in Ahmedabad.

Faith PEB’s Contribution to Ahmedabad’s Industrial Transformation

Faith PEB stands out as a reliable partner in this changing industrial landscape. The company’s focus on quality, timely delivery, and innovation has made it a go-to name for PEB Structure Manufacture in Ahmedabad. Faith PEB offers end-to-end services—from design and engineering to fabrication and installation—ensuring that every structure meets the specific needs of its clients.

The use of cutting-edge software, adherence to international building codes, and commitment to sustainability set Faith PEB apart. The company emphasizes eco-friendly building practices, including recyclable materials and energy-efficient designs. This not only helps businesses reduce their environmental impact but also aligns with global trends in sustainable construction.

Advantages of Partnering with Faith PEB

Custom Design Capabilities: Faith PEB understands that no two projects are the same. Their engineering team works closely with clients to create custom PEB designs that align with operational requirements.

Speed and Efficiency: With pre-fabrication happening at the plant, construction time is significantly reduced. This ensures quicker project completion, helping clients get operational faster.

Durability and Safety: Every structure manufactured by Faith PEB is engineered to withstand harsh weather conditions, seismic activity, and long-term wear, ensuring safety and durability.

Cost Savings: With reduced labor costs, minimal material wastage, and faster project delivery, businesses can save significantly when they choose PEB solutions from Faith PEB.

Expert Team: From designers and engineers to project managers, the team at Faith PEB brings decades of experience and a customer-first approach to every assignment.

Meeting the Future with Innovation

As Ahmedabad continues to evolve as a smart industrial city, the need for modern construction methods will only grow. Industries are now looking beyond traditional brick-and-mortar buildings toward modular, tech-enabled infrastructure. Faith PEB is committed to staying ahead of the curve by investing in innovation, embracing digital fabrication technologies, and continuously enhancing its design and production capabilities.

Furthermore, with the government focusing on "Make in India" and infrastructure-led development, there’s a strong push for efficient and scalable construction practices across sectors. Faith PEB is well-positioned to support this growth, helping industries realize their infrastructure goals faster and more economically.

Conclusion

The future of industrial development in Ahmedabad is being built today with steel—and PEB Structure Manufacture in Ahmedabad is the driving force behind it. As a leader in this space, Faith PEB is empowering industries with smart, sustainable, and scalable building solutions that are transforming the way factories and warehouses come to life. With a steadfast focus on quality and innovation, Faith PEB is not just constructing buildings—it’s building the foundation for Gujarat’s industrial future.

0 notes

Text

#peb structures#peb manufacturers in maharashtra#peb manufacturers in india#pre engineered building manufacturers in india#peb building manufacturers in india#peb suppliers#prefab company in india#peb manufacturing companies#top peb manufacturers in india#top peb company in india#peb factory#pre building#pre engineered buildings#peb building#pre eng building#peb company#peb vendors#peb suppliers in india#prefab manufacturing#pre engineering building company in india#steel structures#peb engineering building#pre engineered building structures#peb engineering#peb steel structures#peb manufacturers near me#pre engineered structures#peb fabricators#peb steel buildings#peb manufacturers

1 note

·

View note