#plc router

Explore tagged Tumblr posts

Text

despite the new devamps, there won't be any update for the Booster Pack Opening simulator this week, and more likely not next week either

the reason is my main pc has been infected when I was torrenting (because ports were wide open and I didn't use a VPN)

this however should not disturb the advent calendar

#but it's greatly disturbing me as I have all my life on that pc#only steam and telegram seemed to have been logged into (lost all my steam money for a stupid dota2 item)#but I think now these 2 should be safe#haven't seen anything else happening either#changed all my passwords these 2 days (around 400+ passwords)#waiting for a new drive to arrive tomorrow morning to start the deep cleaning and reformatting of my 4 drives (around 6To of random stuff)#even if my internet provider and some friends said I don't need to worry for my router + PLCs + other stuff connected to my router#I'm still very stressed about the fact that everything that was on my internet router can potentially be infected/easily accessed now#ah#and my instagram is locked with 0 chance to get back

1 note

·

View note

Text

DB9 connector is a widely used electrical connector. Recognizable by its distinctive D-shaped metal shell and 9-pin configuration, the DB9 connector has been a staple in electronics for decades, especially for serial communication.

What Is a DB9 Connector?

The DB9 connector features a D-shaped shell to ensure proper orientation when connecting. The 9 pins (or sockets in female versions) are arranged in two rows, with 5 pins on the top and 4 on the bottom. This compact design is suitable for low-profile applications.

The connector comes in two main types:

DB9 Male Connector: Have pins and are typically used on cables.

DB9 Female Connector: Have sockets and are often found on equipment or devices.

Key Features of DB9 Connectors

Durable Construction: The metal shell provides mechanical strength and shields against electromagnetic interference (EMI).

Compact Design: Ideal for devices where space is limited.

Versatile Applications: Commonly used for RS-232 serial communication, connecting peripherals like mice, keyboards, and modems.

Customization: Can support different pin configurations and wiring for varied uses.

Common Applications of DB9 Connectors

Serial Communication: Widely used in RS-232 interfaces to connect computers, printers, and industrial equipment.

Automation and Control Systems: Frequently seen in programmable logic controllers (PLCs) and industrial machines.

Networking Equipment: Used in switches, routers, and legacy systems.

Testing and Prototyping: Found in diagnostic and development tools for electronics.

DB9 Pinout Diagram

Here’s a standard pinout for a DB9 connector used in RS-232 communication:

Advantages of DB9 Connectors

Reliable Connection: Secure locking mechanism ensures a stable link.

Broad Compatibility: Works with many legacy and modern devices.

Easy Maintenance: Simple design allows for straightforward repairs or replacements.

8 notes

·

View notes

Text

What Are Optocouplers, and How Can They Elevate Your Electronics Design?

Introduction to Optocouplers: The Essential Isolation Component

Optocouplers, commonly known as opto-isolators, are ingenious electronic devices designed to safely transfer signals between isolated circuits using light. These components protect sensitive electronic systems from high voltage, noise interference, and potential circuit failures, significantly improving reliability and performance.

Optocouplers primarily consist of:

Infrared LED (Emitter): Converts electrical signals into light.

Photodetector (Receiver): Converts received light back into electrical signals.

By providing electrical isolation, optocouplers safeguard delicate circuits, ensuring stable and safe operation.

How Do Optocouplers Function in Electronic Systems?

Understanding the working principle of optocouplers is crucial for their effective implementation. Their operation follows these simple steps:

An electrical input signal activates the internal LED.

The LED emits infrared light proportional to the input current.

The photodetector receives this infrared signal.

The detector converts the optical signal back into electrical output.

This method ensures that circuits on either side remain electrically isolated, reducing the risk of damage from voltage spikes and interference.

Why Use Optocouplers in Electronic Designs?

Optocouplers offer substantial benefits that enhance the performance, safety, and efficiency of electronic systems. Key reasons to choose optocouplers include:

High Voltage Protection: Optocouplers prevent voltage surges from reaching sensitive circuit components.

Noise Reduction: They effectively minimize electromagnetic interference, preserving signal integrity.

Safety Assurance: Provide critical isolation to protect equipment and operators from electrical hazards.

Increased Reliability: Ensure stable and consistent signal transmission under varying operating conditions.

Different Types of Optocouplers Available Today

Multiple varieties of optocouplers exist to cater to specific electronic applications. Familiarizing yourself with these categories can simplify the selection process:

Transistor Optocouplers:

Commonly used in general-purpose isolation applications.

Ideal for moderate-speed signal transmissions.

Darlington Optocouplers:

Utilize a Darlington transistor configuration for higher sensitivity.

Suitable for applications needing higher current gain and lower input current.

Triac Optocouplers:

Primarily used for switching and controlling AC loads.

Common in motor control, lighting dimmers, and AC-powered circuits.

High-Speed Optocouplers:

Engineered for rapid communication and digital interfacing.

Critical for high-frequency data transmissions and real-time control systems.

Practical Applications: Where Optocouplers Shine

Optocouplers are versatile devices extensively employed across diverse industries. Some prominent applications include:

Industrial Automation:

Programmable Logic Controllers (PLCs)

Robotic arms and automated machinery

Motor drives and motion controllers

Power Electronics:

Power supplies and battery chargers

High-voltage DC/AC converters

Solar inverters and renewable energy systems

Telecommunications and Networking:

Modems and routers

Telephone line isolation

Ethernet communication equipment

Medical Equipment:

Patient monitoring devices

Diagnostic imaging equipment

Laboratory instrumentation

Selecting the Best Optocoupler for Your Electronics Project

Picking the appropriate optocoupler can significantly impact your circuit’s reliability and efficiency. Essential considerations include:

Isolation Voltage: Choose devices with isolation ratings higher than the expected peak voltage.

Current Transfer Ratio (CTR): Opt for higher CTR values for better sensitivity and signal reliability.

Propagation Delay: Critical in digital communication; select fast optocouplers for high-speed data transmission.

Temperature Ratings: Ensure devices can withstand your application's thermal environment.

Best Practices for Effective Optocoupler Implementation

Proper use and installation of optocouplers can maximize their effectiveness. Here’s how you can optimize their performance:

Precisely regulate LED currents to ensure optimal light emission without excessive power dissipation.

Avoid excessive loads on photodetectors, ensuring consistent and stable operation.

Maintain short and isolated signal paths to minimize signal loss and interference.

Conduct periodic performance assessments, especially isolation resistance checks, to maintain reliability.

Current Innovations Shaping Optocoupler Technology

Continuous technological advancements enhance the performance and application potential of optocouplers. Notable trends include:

Ultra-Compact Designs: Optocouplers are increasingly miniaturized, fitting smaller, modern electronic devices.

Enhanced Speed and Bandwidth: Innovations focus on high-speed optocouplers for rapid data transmission and communication.

Energy Efficiency: New-generation optocouplers emphasize reduced power consumption, essential for battery-operated devices.

Integration in IoT and Smart Technologies: Optocouplers are integral to smart home devices, connected appliances, and IoT-based systems for reliable communication.

Overcoming Common Optocoupler Challenges

While optocouplers offer extensive benefits, users can occasionally face challenges. Here’s how to address common issues:

Signal Attenuation: Select devices with higher CTR and carefully design circuits to maintain signal integrity.

Temperature Variations: Opt for optocouplers with broad operating temperature ranges and use thermal management techniques.

Cost and Performance Balance: Analyze device specifications and choose options providing optimal balance between performance and budget.

Tips for Enhancing the Lifespan of Optocouplers

Maintaining optocouplers ensures their longevity and reliability in your electronic projects. Follow these maintenance guidelines:

Regularly inspect circuits for signs of overheating, wear, or abnormal signal behaviors.

Replace worn or damaged optocouplers promptly to avoid system downtime or circuit failures.

Adhere strictly to manufacturer recommendations regarding voltage and current limits to avoid premature degradation.

Conclusion: Why Optocouplers are Indispensable in Electronics

Optocouplers play a critical role in ensuring safe, efficient, and reliable electronic circuit operation. Their exceptional ability to isolate signals, reduce interference, and enhance circuit safety makes them indispensable across industrial, commercial, and consumer electronic applications. By carefully selecting appropriate optocouplers, adhering to implementation best practices, and keeping pace with technological advancements, you can significantly elevate your electronics designs, guaranteeing optimal performance, safety, and efficiency in your projects.

0 notes

Text

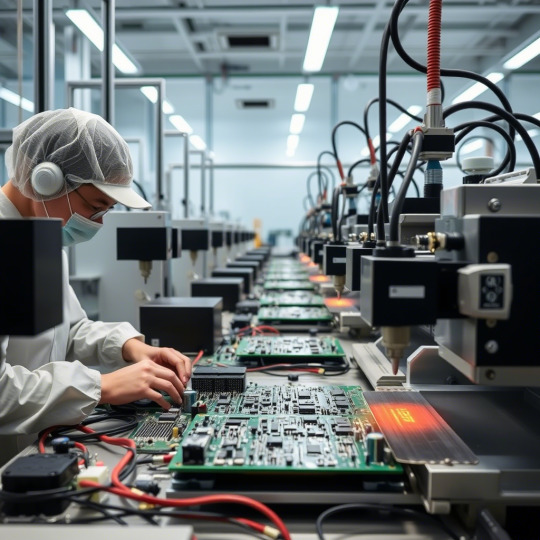

Understanding PCB Fabrication Companies: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the unsung heroes behind every electronic device we use today. From smartphones and smartwatches to industrial machines and aerospace systems, PCBs make electronic functionality possible. But before any device reaches your hands, it all begins at a PCB fabrication company—the specialized manufacturers responsible for creating the physical board that powers modern technology.

In this article, we’ll explore what PCB fabrication companies do, why they’re essential, and how to choose the right one for your project.

What Does a PCB Fabrication Company Do?

A PCB fabrication company is dedicated to producing the physical printed circuit boards used in electronic devices. These companies focus solely on manufacturing the board structure—copper layers, insulating substrates, vias, and surface finishes—before any electronic components are mounted.

Key steps in PCB fabrication include:

Design file analysis and preparation

Copper pattern etching

Drilling holes and vias

Applying solder mask and silkscreen

Surface finishing (ENIG, HASL, etc.)

Electrical testing for continuity and shorts

These processes require high-end machinery, cleanroom environments, and precise engineering expertise to ensure every board meets the required performance standards.

Importance of PCB Fabrication in Electronics Manufacturing

PCB fabrication is a critical phase in electronics manufacturing. Without a reliable board, even the most advanced components can’t function properly. A well-fabricated PCB ensures durability, performance, and compliance across various applications.

Here's why PCB fabrication companies are so important:

Enable compact and lightweight designs

Support multilayer and high-density circuits

Ensure electrical reliability and heat management

Allow mass customization and quick prototyping

Comply with strict industry standards (IPC, ISO, RoHS)

Services Offered by PCB Fabrication Companies

While core PCB manufacturing is the primary service, leading fabrication companies also offer value-added solutions to simplify the product development lifecycle.

Typical services include:

Prototype to mass production

Multilayer PCB fabrication (up to 40+ layers)

Rigid, flexible, and rigid-flex PCB production

High-frequency and HDI PCB capabilities

Lead-free and RoHS-compliant fabrication

Design for Manufacturability (DFM) support

Impedance control and surface finish customization

These services help customers streamline their design-to-production process and improve time-to-market.

Industries That Rely on PCB Fabricators

PCB fabrication companies cater to a wide range of industries, each with unique technical requirements:

Consumer Electronics – Smartphones, tablets, wearables

Automotive – Engine control units, ADAS, EV batteries

Medical Devices – Diagnostic tools, monitoring equipment

Telecom – Routers, 5G infrastructure, network devices

Aerospace & Defense – Navigation, radar, satellite systems

Industrial Automation – PLCs, controllers, IoT systems

Whether it’s high-frequency performance or thermal durability, different sectors demand tailored fabrication capabilities.

How to Select the Right PCB Fabrication Company

Choosing the right PCB fabrication company in India is critical to product quality, lead time, and cost. Here’s what to look for:

Certifications – ISO 9001, IPC-6012, RoHS, IATF 16949

Technology Capabilities – Multilayer, HDI, flexible PCBs

Quality Assurance – Electrical testing, AOI, X-ray inspection

Engineering Support – DFM analysis, CAD-to-CAM processing

Lead Time – Quick-turn prototyping and on-time delivery

Cost Efficiency – Transparent pricing and scalable production

Customer Reviews – Testimonials and case studies

Partnering with the right company ensures your boards are reliable, cost-effective, and delivered on time.

Leading PCB Fabrication Companies

Here are some reputable names in the global and Indian PCB manufacturing landscape:

Global Leaders

TTM Technologies (USA)

Unimicron Technology (Taiwan)

AT&S (Austria)

Zhen Ding Tech (China)

Top PCB Fabrication Companies in India

AT&S India (Nanjangud)

CIPSA-TEC India Pvt. Ltd. (Bangalore)

Shogini Technoarts (Pune)

Meena Circuits Pvt. Ltd. (Gujarat)

Genus Electrotech Ltd. (Gandhinagar)

These companies are known for their advanced manufacturing capabilities, global delivery networks, and strict quality controls.

Growth of PCB Fabrication in India

India is rapidly becoming a global hub for electronics manufacturing, and PCB fabrication companies in India are rising to meet demand.

Key growth drivers include:

Make in India and Digital India initiatives

PLI (Production Linked Incentive) scheme

Growing demand from EVs, smartphones, and IoT sectors

Investment in semiconductor and ESDM ecosystems

With increasing local and global investment, Indian PCB manufacturers are scaling operations and adopting advanced technologies like automation and AI in fabrication processes.

✅ Conclusion

PCB fabrication companies form the backbone of the electronics industry. Their ability to produce high-quality, precision-engineered circuit boards directly impacts the performance, safety, and reliability of electronic products.

Whether you’re developing a consumer gadget or an aerospace control system, partnering with the right PCB fabrication company is vital. Look for proven expertise, robust infrastructure, and strong customer support.

0 notes

Text

LG EAY65895901 Adapter forLG gram 15Z90P-K.ARB6U1 16T90P, LG gram 15Z90Q 16Z90Q 17Z90Q16Z95PD Series

SPECIFICATIONS

Input: 100-240V 1.6A 50-60Hz (for wo Output: 20.0V 3.25A MAX: 65.0W, 5.0V 3.0A 15.0W, 9.0V 3.0A 27.0W, 15.0V 3.0A 45.0W (ref to the picture). P/N ADT-65DSU-D03-2 Compatible Models

EAY65895901 power supply

JP: LG EAY65895901 アダプター

US: LG EAY65895901 power adapter

NZ: LG EAY65895901 power adapter

PL: LG EAY65895901 zasilacz

IT: LG EAY65895901 caricabatterie

ES: LG EAY65895901 cargador

uk-online.co.uk is the number one supplier of dell laptop adapters. Our dell adapter have been tested and validated on dell systems to ensure it will work with your notebook. Adapter for dell are specifically designed for each laptop brand and model. All dell adapters are brand new,1 year Warranty, Secure Online Ordering Guaranteed!

Related Products:

WACOM DPS-65VB AC Adapter Charger for Wacom Laptop 65.0W NEW AC Adapter

LG EAY65768901 AC Adapter Charger for LG 27UN880 27 LED Monitor AC Adapter

SONY ACDP-120D01 AC Adapter Charger for Sony ACDP-120E03 SONY 149349021 1-493-490-21

HUNTKEY HKA18019095-7A AC Adapter Charger for Huntkey FSP180-ABAN2 IL/RT6-18201-FSP180-ABA

Asus ADP-40KD_BB AC Adapter Charger for Asus C202S Chromebook

ASUS ADP-200JB-D AC Adapter Charger for Asus TUF Dash F15 FX516PR ADP-200JB

MSI ADP-150CH-B AC Adapter Charger for MSI Pulse GL66 11UCK ADP-150CH-D 4.5MM

MSI 957-17811P-104 AC Adapter Charger for MSI 957-17811P-104 charger

HP ADLX65YDC3A AC Adapter Charger for Lenovo ThinkPad X1 Carbon 2017

SAMSUNG A4024_FPN AC Adapter Charger for Samsung HW-K550/ZA HW-K550 hw-K650 Soundbar

All of our adapter for laptop are made with high-quality. Our laptop power supply units must pass stringent quality control tests that ensure our laptop power supply will work with your laptop. All adapters are brand new, 30 days money back guarantee.

DELL DPS-65VB AC Adapter Charger for Delta Power Adapter DPS-65VB LPS Charger 12V 5.417A 5.5mm * 2.5mm

LENOVO ADLX95YCC3A AC Adapter Charger for Lenovo YOGA 6 Pro-13IKB YOGA 920

HP 913623-001 AC Adapter Charger for HP 710412-001 913691-850 714657-001

HP HP8204B AC Adapter Charger for New High Power HP8204B 24V 5A Lead-Acid Battery Charger incl. 3-Pin Power Cord

DELL RYJJ9 AC Adapter Charger for Alienware M15 M17 M15X M17X

ASUS ADP-200JB-D AC Adapter Charger for Asus TUF Dash F15 FX516PR ADP-200JB

ASUS A17-120P2A AC Adapter Charger for Chicony MSI GF63 Thin 10SCXR-426UK,ASUS Vivobook Pro 15 OLED M3500 Laptop,ASUS ZenBook 15 UX534FT-DB77

DELL DA130PE1-00 AC Adapter Charger for Dell LA130PM190 492-BBGP Power Supply Charger

LG AD10760LF AC Adapter Charger for LG AD10760LF

ASUS PA-1231-12 AC Adapter Charger for MSI 1762 GT70 16F3 16F4

UK-Online.co.uk was established to serve the needs of laptop users, and today we are one of the top e-retailers. Get a great deal on electronics when you shop on localhost . Choose an iPad, TV or laptop, headphones, PS4, Xbox One and more. Offers on mobile phones and cameras. We’re passionate about what we do and it’s our mission is to bring you the best deals in the UK from all the leading brands, whilst also offering the best possible advice through our specialist trained sales team who collectively have over 10 years experience.

SINO Li2600-2S replacement battery for SINO SN-S1 SN-A1, Rating: 5200mAh 7.4V, SKU: 25KK1267S_Oth

Asus C21-X502 Laptop Battery for Asus VivoBook X502 X502C X502CA Series, Rating: 38WH / 5136mAh 7.4V, SKU: ASU2890

Nikon EN-EL5 replacement battery for Nikon P90 P100 P500 P510 P520 P5000 P5100 P6000, Rating: 1600mAh 3.7V, SKU: 20IV1262_Oth

APPLE 616-0229 replacement battery for 616-0229 iPod 5th Generation Video 30GB A1136, Rating: 650mAh 3.7V, SKU: ECN12661_1_Oth

HUAWEI HB5F2H replacement battery for HUAWEI 4G LTE WIFI Router, Rating: 1780mAh/6.6WH 3.7V, SKU: 22LK342_Oth

Seiko MS920SE-FL27 replacement battery for Seiko MS920SE-FL27 MS920SE ML920 PLC, Rating: 6.5mAh 3V, SKU: ECN12614_Oth

NEC PC-VP-BP129 Laptop Battery for NEC PC-VP-BP129, Rating: 3870mAh/45Wh 11.52V, SKU: 22KK142

Lenovo SB10K97593 Laptop Battery for Lenovo ThinkPad S2 13 01AV400 01AV401 01AV437 Chromebook, Rating: 3735mah/42Wh 11.25V, SKU: LEN19F224

HP BL04XL Laptop Battery for HP Elitebook 1040 G5 G6, Rating: 56.2Wh 7.7V, SKU: HPQ21JA1054

Koman HYLB-1010 replacement battery for Koman C60 C50 C70 C80 C90, Rating: 4000mAh 14.4V, SKU: KOM21JU1188_Oth

#LG#LG EAY65895901#EAY65895901#LG Laptop AC Adapter EAY65895901#LG EAY65895901 Laptop AC Adapter#LG EAY65895901 adapter#EAY65895901 adapter#LG adapter

0 notes

Text

Card Connector Market Size Powering Seamless Connectivity Across Devices

The Card Connector Market size is gaining significant traction as the demand for compact, reliable, and high-speed data transmission interfaces continues to rise in electronics and industrial systems. According to Market size Research Future, the market is projected to grow from USD 1.7 billion in 2023 to USD 3.5 billion by 2030, registering a CAGR of 10.3% over the forecast period. These connectors serve as essential components for ensuring smooth communication and efficient storage solutions in everything from consumer electronics to industrial equipment.

Overview

Card connectors are electromechanical components used to establish electrical connections with various types of memory and interface cards such as SD cards, SIM cards, PCIe cards, CF cards, and more. These connectors enable secure and seamless integration of removable memory and communication modules within a device's hardware infrastructure.

With increasing miniaturization and multifunctionality in electronic gadgets, manufacturers are integrating card connectors that provide reliability, ease of installation, and compatibility with advanced protocols. The rising adoption of smartphones, tablets, point-of-sale (POS) systems, embedded systems, and automotive infotainment solutions continues to push demand forward.

Market size Segmentation

By Type:

Memory Card Connectors (SD, MicroSD, Compact Flash)

SIM Card Connectors

Smart Card Connectors

Edge Card Connectors

PC Card Connectors

By Application:

Consumer Electronics

Industrial Automation

Telecommunications

Automotive

Banking & Finance (ATMs, Smart Cards)

Medical Devices

By End-Use:

OEMs (Original Equipment Manufacturers)

Aftermarket

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Key Market size Trends

Miniaturization of Electronic Devices: As consumer electronics become more compact and multifunctional, demand for small, high-density card connectors is increasing.

Rising Use in Automotive Electronics: Infotainment, GPS, and telematics systems in vehicles are integrating SD and SIM card slots for multimedia and communication.

Growth in IoT Devices: IoT devices often require secure data storage and network connectivity, driving usage of SIM and microSD card connectors.

Push for Enhanced Data Speeds: Connectors compatible with USB 3.0, PCIe, and UHS-II interfaces are gaining popularity for high-speed applications.

Adoption in Medical and Industrial Automation: Devices in medical diagnostics and factory automation use card connectors for firmware updates, memory expansion, and secure data handling.

Segment Insights

Memory Card Connectors Lead the Market size: Due to widespread usage in smartphones, cameras, and embedded devices, memory card connectors hold the largest market share.

Consumer Electronics Remain the Primary Application Segment: With billions of mobile and portable devices in circulation globally, the consumer electronics segment continues to dominate demand.

Asia-Pacific Emerges as a Growth Leader: Countries like China, Japan, and South Korea are leading in electronics manufacturing, boosting demand for high-precision card connectors.

End-User Insights

OEMs focus on sourcing compact, durable, and cost-effective card connectors to integrate into their final product assemblies.

Telecom Providers rely on SIM card connectors for mobile devices, routers, and communication modules.

Industrial Automation Firms deploy card connectors in machine control systems and programmable logic controllers (PLCs).

Automotive Manufacturers utilize card connectors in dashboards, navigation units, and smart keys.

Key Players

Several key companies are shaping the future of the card connector market by investing in innovation, automation, and high-speed compatibility:

TE Connectivity Ltd.

Hirose Electric Co., Ltd.

Amphenol Corporation

Molex, LLC (a Koch Industries company)

Japan Aviation Electronics Industry, Ltd.

Yamaichi Electronics Co., Ltd.

3M Company

Samtec, Inc.

C&K Components

AVX Corporation

These players are expanding their product portfolios to meet demand from evolving application areas including embedded computing, AI hardware, and advanced robotics.

Conclusion

The Card Connector Market size is a vital backbone for data communication, memory storage, and device integration in today’s fast-paced digital environment. From smartphones and vehicles to industrial machines and medical devices, these components are enabling smarter, faster, and more connected systems. As digital infrastructure evolves and demand for robust, compact, and multifunctional interfaces increases, card connectors will continue to be an indispensable element of next-gen technology ecosystems.

Trending Report Highlights

Functional Printing Market size

Predictive Emission Monitoring System (PEMS) Market size

Soft Robotics Market size

Photoelectric Sensor Market size

Laser Sensors Market size

Proximity Sensor Market size

Wi-Fi Adapter Card Market size

5G Processor Market size

Kids Tablet Market size

Laser Projector Market size

Underwater Lighting Market size

Static Random-Access Memory (SRAM) Market size

0 notes

Text

Why the E-PRO BRLSSFN-1 Brushless Fan is the Ideal Choice for Advanced Cooling

Introduction to E-PRO BRLSSFN-1 Brushless Fan

In the evolving world of electronics and thermal control, the demand for efficient and reliable cooling solutions is critical. The E-PRO BRLSSFN-1 Brushless Fan is a high-performance solution engineered to manage heat in systems packed with sensitive electronic components. It ensures thermal stability in applications involving microprocessors, controllers, LEDs, capacitors, and sensors. Designed for reliability and durability, this fan is suitable for both industrial and consumer-grade systems where effective airflow is a priority.

What Makes Brushless Fans Stand Out?

Brushless fans have become increasingly popular due to their mechanical efficiency and electronic advantages. They operate without brushes, which significantly reduces friction and wear. This leads to longer operational life and quieter performance compared to traditional brushed fans.

Advantages of the E-PRO BRLSSFN-1

Delivers powerful airflow while maintaining low noise levels

Reduces energy consumption in long-term applications

Offers a long service life due to minimal mechanical wear

Compatible with various enclosures, including compact electronics and laptops

Prevents overheating in sensitive parts like thermal pads, switches, and fuses

Application Versatility of the BRLSSFN-1 Fan

The E-PRO BRLSSFN-1 Brushless Fan is widely adaptable, making it useful in many types of systems and electronic assemblies. Its compact structure and powerful performance enable it to be used in devices requiring consistent cooling.

Where It Can Be Used

Laptops, PCs, and embedded computers

Electrical control panels and PLC enclosures

Industrial machines housing contactors, relays, and microcontrollers

LED lighting units and smart lighting drivers

Communication and networking hardware including routers and switches

Server racks and IT equipment that rely on regulated thermal environments

Test benches using microprocessors, connectors, cables, and sensors

Enhanced Thermal Management Capabilities

Maintaining optimal operating temperatures is essential for electronic longevity and performance. The E-PRO BRLSSFN-1 excels in rapid heat dissipation and airflow consistency, keeping internal electronics cool and efficient.

Key Thermal Features

Effective cooling of capacitors, microchips, and power supplies

Maintains ideal temperatures for tools, controllers, and power modules

Supports systems with dense cabling and thermal-sensitive layouts

Protects delicate components from heat-related degradation

Ideal for systems that use oils, thermal pads, and insulators

Benefits in Industrial and Commercial Electronics

From small desktop devices to heavy-duty industrial controllers, the BRLSSFN-1 supports broad integration. Its performance stability and low power draw make it suitable for multiple industries.

Reasons to Consider This Fan

Reduces risk of thermal failure in mission-critical equipment

Easy installation in enclosures with cables, grips, and sensor arrays

Designed for environments where safety and thermal reliability are key

Contributes to energy-efficient operation over prolonged periods

Built with strong materials for use in harsh environments

Integration with Modern Electronic Components

The E-PRO BRLSSFN-1 Brushless Fan is designed to work seamlessly with modern components, from basic circuit designs to advanced electronic systems. It ensures that components like LEDs, fuses, switches, and microcontrollers operate within safe thermal limits.

Perfect Match for Compact and High-Tech Systems

Compact enough for use in laptops and tablets

Supports active cooling for embedded boards and IoT systems

Assists in thermal regulation for high-speed processing units

Works alongside capacitors, connectors, and digital sensors

Ensures longevity in battery-powered devices and portable equipment

Why You Should Choose E-PRO BRLSSFN-1

Choosing a high-quality cooling fan impacts the overall performance and lifespan of your electronic equipment. The E-PRO BRLSSFN-1 provides an edge by balancing performance, energy savings, and versatility.

Top Reasons to Buy

Trusted by electronics professionals for thermal reliability

Suitable for integration into complex systems with minimal modifications

Helps extend service life of devices by preventing overheating

Reduces maintenance needs and replacement frequency

Compatible with modern components like microprocessors, contactors, and tools

Conclusion

As electronics continue to evolve, so must the cooling systems that support them. The E-PRO BRLSSFN-1 Brushless Fan is a dependable choice for maintaining thermal balance across a wide range of systems—from industrial controllers and thermal pads to laptops and LED circuits. Whether you're upgrading your thermal management system or designing a new one from scratch, this fan provides long-term value, performance, and peace of mind.

0 notes

Text

Surface Mounting Technology (SMT): Revolutionizing Modern Electronics Assembly

Surface Mounting Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs). This revolutionary technology has transformed the way electronic devices are assembled, enabling smaller, faster, and more efficient products.

What is SMT?

SMT is a production technique where electronic components, known as Surface-Mount Devices (SMDs), are placed and soldered directly onto the surface of a PCB, as opposed to the older method of inserting components through holes (Through-Hole Technology).

How SMT Works: A Step-by-Step Overview

Solder Paste Application A stencil is used to apply solder paste to specific areas on the PCB where components will be mounted.

Pick and Place Robotic machines precisely pick up SMD components and place them onto the solder-paste-covered pads.

Reflow Soldering The assembled PCB is passed through a reflow oven. The heat melts the solder paste, securing the components in place as it cools and solidifies.

Inspection and Testing Automated Optical Inspection (AOI), X-ray inspection, and functional testing are used to ensure accuracy and reliability.

Benefits of SMT

Miniaturization SMT allows for smaller components, making compact device designs possible—ideal for smartphones, wearables, and medical devices.

Higher Component Density Components can be placed on both sides of a PCB, increasing functionality in a smaller area.

Faster Manufacturing SMT is highly automated, enabling high-speed production with fewer manual interventions.

Cost-Effective Lower labor costs and material waste result in reduced overall production expenses.

Improved Performance Shorter leads and tighter connections minimize signal distortion, making SMT suitable for high-frequency applications.

Applications of SMT

Consumer Electronics: Smartphones, tablets, TVs, and laptops

Automotive Electronics: Sensors, infotainment systems, and control modules

Medical Devices: Pacemakers, diagnostic equipment, and monitoring tools

Telecommunications: Routers, modems, and base stations

Industrial Automation: PLCs, sensors, and control systems

Challenges in SMT

Thermal Management Smaller components generate heat that must be properly managed to avoid failure.

Component Handling Some ultra-small components can be difficult to place accurately and require advanced machinery.

Inspection Complexity With denser boards and finer pitches, defect detection becomes more challenging.

0 notes

Text

What We Recycle: Accepted Electronics and E-Waste at 3R Technology

At 3R Technology, we don’t just recycle devices; we provide a responsible, secure, and scalable solution for managing electronic waste. Our facility is equipped to handle a broad spectrum of electronics and peripheral equipment, from individual consumer devices to enterprise-level infrastructure. If it has a circuit board or a wire, chances are we can recycle it. Materials accepted include a wide range of electronic components and devices, ensuring comprehensive e-waste management.

Our goal is simple: recover usable materials, protect sensitive data, and divert e-waste from landfills through environmentally sound practices.

Electronics We Accept

We accept a wide range of electronics, including but not limited to:

Computers & Laptops: Whether outdated, broken, or surplus, desktops and laptops are among the most common items we process.

Servers, Networking, & Data Centre Equipment: We handle enterprise-grade hardware such as servers, switches, routers, firewalls, and related gear.

Monitors & Displays: We recycle LCD, LED, and flat-panel monitors. CRTs are accepted with restrictions. Contact us in advance.

Devices: Smartphones, tablets, and other portable electronics are accepted, regardless of age or condition.

Printers, Scanners & Peripherals: Workplace devices, from multi-function printers to external hard drives and keyboards, are recyclable through our facility's services.

Cabling & Wiring: Power cords, data cables, and electrical wiring are all accepted, as copper and metals can be recovered during processing.

Speciality & Industrial Electronics

In addition to standard electronics, we also process equipment used in specialised or industrial environments:

Medical Electronics: Monitors, imaging equipment, and diagnostics systems (non-hazardous) can be evaluated for responsible recycling.

Laboratory Instruments: Items used in research or testing settings, including analysers, oscilloscopes, and measuring devices.

Point-of-Sale Systems: Barcode scanners, card readers, registers, and related accessories.

Manufacturing Controls: PLCs, automation hardware, and embedded systems often contain valuable recoverable components.

If you’re unsure whether your item qualifies, we are here to review it.

What We Don’t Accept

While our facility can handle a wide range of materials, there are a few exceptions due to safety and compliance regulations:

Household appliances (e.g., refrigerators, microwaves)

Hazardous materials (e.g., items with chemical, biological, or radioactive exposure)

CRT monitors with damaged tubes (accepted on a case-by-case basis)

Light bulbs, batteries, and loose toner cartridges (unless part of a larger electronics load)

If you're managing a large project or facility decommission, we encourage you to contact us for a tailored solution. Based on volume and overall condition, we may accept items not listed here.

Why Choose 3R Technology

We’re not just a drop-off point, but a full-service electronics lifecycle partner. We adhere to R2v3 and ISO 14001 standards for responsible recycling and data security. Every item is processed to maximize recovery while minimizing environmental impact.

Our team also provides certified data destruction services, both on-site and off-site. Whether it’s a single device or a thousand, we ensure data-bearing devices are sanitised to NIST and DoD standards.

We work with businesses, schools, healthcare providers, government agencies, and individual residents across the Pacific Northwest. Our services scale to meet the needs of small offices or multi-site corporations.

Contact us to schedule a pickup or drop-off.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

20V 9AアダプターASUS ROG Zephyrus G14 GA403UI-XS96 ADP-180TB

https://www.note-pc.co/acb/img-GSB601.jpg

20V 9A ASUS ROG Zephyrus G14 GA403UI-XS96 向けノートpc 充電器 ASUS ADP-180TB

オンラインショッピングの格安ASUS ADP-180TB 20V 9A ノートパソコン AC アダプタは、ASUS ADP-180TB の新しいノートPC 充電器と100%互換性があります。 今日、私たちは新製品、高品質、高性能のASUS ADP-180TB パソコン 充電器を更新します。 信頼できる国内標準PSE調達による安全な購入! オンラインストア【ノートPCバッテリーの専門店】、即時の支払、即日発送。

商品の詳細

のブランド:ASUS 電源

適合規格:PSE

入力電圧:100 ~ 240V 50~ 60Hz

出力電圧:20V 9A

互換品番

ADP-180TB K A22-180P1A

対応機種

https://www.note-pc.co/acb/img-GSB601.jpg

【新商品特価】ASUS ADP-180TB電源 20V 9A、対応機種ASUS ROG Zephyrus G14 GA403UI-XS96。 電源型番[ADP-180TB]。 高品質で安価な製品と短納期を提供します! 【1年保証】note-pc.co:ASUS PC電源は新品です!

PRICE REFERENCE

UK: ASUS ADP-180TB Laptop Power Adapter US: ASUS ADP-180TB Laptop Power Adapter PL: ASUS ADP-180TB Adapter Power Supply IT: ASUS ADP-180TB Adattatore ES: ASUS ADP-180TB Adaptador FR: ASUS ADP-180TB Adaptateur

当社はパソコンのバッテリー、ACアダプター、部分の電子製品を提供した代表メーカーと卸売業です。電池屋はお客様のあらゆるご要望に応えるべく、豊富な在庫、迅速な対応、そして他ショップにはない圧倒的な経験と知識と、盤石な体制を取っております。 私たちの目的は、低価格で高性能の製品をお客様に提供することである。

今週の目玉商品

MAXELL ER17/50H バッテリー 5500mAh 3.6V 対応機種MAXELL Nachi MZ07 MZ03 Robot

CUILIN 801350 バッテリー 500mAh 3.7V 対応機種CUILIN Phone mobile, MP4

Samsung AA-PBUN2LT バッテリー 30WH 7.6V 対応機種Samsung 900X3L NP900X3M

PANASONIC BR-AG バッテリー 1800mAh 3V 対応機種PANASONIC BR-AG with brown Plug

Motorola 82-71363-04 バッテリー 1950mAh/13.3wh 3.7V 対応機種Symbol MOTOROLA MC70 MC75 FR68

503377-001 電源ユニット HP PC8022

PANASONIC 3027-26T バッテリー 2.5mAh 1.5V 対応機種Panasonic MT516 MT516F 3027-26T Battery Capacitor Seiko Kinetic V110 V114 V115 V116 VS10

LIVING-STONES DS854085-3S バッテリー 2500mAh/27.75WH/10C 11.1V 対応機種SJRC F11 drone

EXFO CGA-E/111GAE バッテリー 1800mAh/6.9Wh 3.7V 対応機種EXFO AXS-100 AXS-110 OTDR FVA-600 FPM-600 FLS-600

FLNY 501220 バッテリー 80mAh/0.3WH 3.7V 対応機種FLNY Game console, learning machine, Bluetooth headset

5K7J8 電源ユニット OptiPlex 7080MT,7090,XPS 8940,G5090,3080SFF

TADIRAN HLC1020 バッテリー 3.6V 対応機種TADIRAN HLC-1020A HLC-1020/T PLC

TYT PB-358 バッテリー 2450mAh 7.4V 対応機種TYT MD-358

CASIO NP-160 バッテリー 1200mAh/4.5WH 3.7V 対応機種CASIO Z2300 Z3000 EX-ZR50 ZR55 ZR60 ZR65

JVC BN-VF808U バッテリー 730Mah 7.2V 対応機種JVC GZ-MG130 MG135 MG730 GR-D740

Dell C903V バッテリー 68Wh 11.4V 対応機種Dell Precision 7550 7750 Laptop

WORX WA3549.1 バッテリー 1.3Ah/23.4Wh 20V 対応機種WORX WA3549.1 Max Lithium Ion power tool

HP BL04XL バッテリー 56.2Wh 7.7V 対応機種HP Elitebook 1040 G5 G6

VIG EB342L バッテリー 3400MAH/17.28WH 7.2V 対応機種VIG VR8810 VR8800 VR8820

TomTom AHB322028 バッテリー 190mAh/0.7Wh 3.7V 対応機種TomTom Runner Cardio

当社はパソコンのバッテリー、ACアダプター、部分の電子製品を提供した代表メーカーと卸売業です。当サイトにて販売されている製品は、当方の技術担当者が真面目なテストを行ったのです。私たちの目的は、低価格で高性能の製品をお客様に提供することである。 ◎信頼できる国内PSE認証を得た。 ◎ 一年保証 ◎ 過電流保護、過充放電防止の保護

PA-1650-78 ACアダプター対応機種 Asus Zenbook Prime UX32V/UX32VD Ultrabook

19V ACアダプター対応機種 ASUS AD820M0 EXA1004EH EXA1004UH 04G26B001050

A12-120P1A ACアダプター対応機種 Asus N55Sf-A1

0A001-00330100 ACアダプター対応機種 Asus X553 X553MA-XX333B Power Charger 19V 3.42A 65W 4.0mm x 1.35mm

ADP-65JH ACアダプター対応機種 ASUS R33030 N17908 V85

65W ACアダプター対応機種 ASUS X553 X553MA-XX074H X553MA-DB01 15.6inch Touchscreen charger

180W ACアダプター対応機種 ASUS G55 G70 G71 G72 G73 G74 G75

AD820M0 ACアダプター対応機種 ASUS Eee PC 1015BX 1015PEB 1015CX G11 Power Pack

ADP-180HBD ACアダプター対応機種 Asus G75VX-T4077H G75VX-T4123P G75VW-T2158V

19V ACアダプター対応機種 ASUS Laptop Notebook

PA-1231-12 ACアダプター対応機種 MSI 1762 GT70 16F3 16F4

45W ACアダプター対応機種 Asus VivoBook X102B X102BA X102BA-BH41T X200L X200LA

SA-65KB_B ACアダプター対応機種 ASUS Eee Slate EP121-1A016M 19.5V 3.08A 60W AC Adapter+Cord

UX390UA-DH51-GR ACアダプター対応機種 ASUS ZenBook 3 45W USB-C / Type-C Charger

ADP-45AW ACアダプター対応機種 ASUS Zenbook UX21E UX21 UX31 UX31K UX31E

PA-1650 ACアダプター対応機種 ASUS A52F X58L A53E N17908 V85

180W ACアダプター対応機種 Asus G46 G55 G73 G75VW G75VX

90W ACアダプター対応機種 Chicony MSI PS42 Modern 8RC-035MY Laptop

90-N6EPW2000 ACアダプター対応機種 90W AC Adapter for Asus U46E U43JC N56VM N56VZ U43SD U31SD U31JG

DSL-N55U ACアダプター対応機種 ASUS RT-N56U Router RT-AC66U

0 notes

Text

Wiring Harness Tech Advancements Propel Buses & Coaches Market to 2035 Growth Milestone

The global buses and coaches wiring harness market, valued at US$ 0.7 billion in 2024, is set to experience significant growth in the coming years. Driven by the increasing demand for advanced electrical systems in buses and coaches, the market is projected to expand at a CAGR of 6.0% from 2025 to 2035, reaching US$ 1.5 billion by the end of 2035. The Buses & Coaches Wiring Harness Market plays a pivotal role in ensuring the safe and efficient functioning of modern public transportation. As the global demand for electrified, connected, and intelligent vehicles grows, wiring harnesses have evolved from basic cable bundles to smart, lightweight, and high-voltage electrical networks. Explore the Insights - Request Your Sample Report Copy Today - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86557 Introduction: Nervous System of Public Mobility In modern buses and coaches, wiring harnesses act as the central nervous system, transmitting signals and electrical power across critical components-from engine control units to infotainment systems. As buses transition from internal combustion engines (ICE) to electric and hybrid drivetrains, the complexity and importance of wiring harnesses multiply. The rising focus on passenger safety, connectivity, and comfort-along with government initiatives promoting electric mobility-has made the wiring harness market a cornerstone of innovation in public transportation. Competitive Landscape Key Players • Sumitomo Electric Industries, Ltd. • Yazaki Corporation • Lear Corporation • Furukawa Electric Co., Ltd. • Delphi Technologies • Aptiv PLC • Leoni AG • Motherson Sumi Systems • Nexans Autoelectric GmbH These players focus on vertical integration, lightweight design, smart cable technologies, and high-voltage solutions to stay ahead in the competitive landscape. Key Market Drivers 1. Electrification of Bus Fleets Governments around the world are incentivizing electric bus deployments to reduce urban air pollution and greenhouse gas emissions. Electric buses require high-voltage wiring harnesses, battery management system wiring, and thermal management connectivity-significantly boosting market demand. Example: • India's FAME-II scheme • EU's Green Deal and Clean Vehicle Directive • China's rapid deployment of electric city buses 2. Demand for Enhanced Connectivity and Infotainment Modern coaches are equipped with Wi-Fi routers, GPS trackers, infotainment displays, surveillance cameras, and passenger information systems, all of which require highly reliable and structured wiring architectures. 3. Increasing Focus on Safety Systems The incorporation of safety features like: • Anti-lock braking systems (ABS) • Lane departure warnings • Automatic emergency braking • Blind spot detection 4. OEM Demand for Lightweight Solutions To improve fuel efficiency and battery range in EVs, manufacturers are adopting lightweight aluminum and optical fiber wiring to replace conventional copper wiring wherever possible. Opportunities for Market Players ✔ Smart City Projects: Rising investments in electric public transport systems will demand next-gen wiring harnesses. ✔ Retrofit Solutions: Aging diesel buses can be upgraded with modern wiring for infotainment and safety enhancements. ✔ Collaboration with EV OEMs: Strategic partnerships with bus manufacturers can lead to co-development of advanced EV harness systems. ✔ AI-Enabled Diagnostics: Harnesses with embedded diagnostics can detect faults and alert operators, improving reliability and uptime.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453

0 notes

Text

IP Rated Enclosures: Understanding Protection for Your Equipment

In an age where sensitive electronics are used in every industry—from manufacturing floors to outdoor telecom towers—protecting these devices from environmental hazards is non-negotiable. IP rated enclosures have become a vital component in ensuring the longevity, safety, and performance of electronic systems. Whether you're installing network switches in a warehouse or deploying sensors in harsh outdoor conditions, knowing what IP ratings mean—and choosing the right enclosure—can make all the difference.

What Does IP Rating Really Mean?

"IP" stands for Ingress Protection, a global standard (IEC 60529) that defines how well an enclosure shields its contents from solids and liquids. Each IP rating contains two digits. The first digit refers to protection against solids like dust, and the second refers to protection against liquids like water. For example, an IP65 enclosure is completely dust-tight and protected against low-pressure water jets. The higher the number, the greater the level of protection.

Why IP Rated Enclosures Matter

IP rated enclosures aren't just technical add-ons—they’re the first line of defense for your equipment. Imagine placing a network device outdoors without any cover. Exposure to rain, dust, or even curious insects can cause serious damage, leading to downtime and expensive repairs. An appropriately rated enclosure ensures that your electronics stay safe, functional, and reliable—no matter where they're installed.

Applications Across Industries

From manufacturing plants and oil refineries to smart city infrastructure and outdoor kiosks, IP rated enclosures are everywhere. They’re used to house everything from power supplies and PLCs to routers, switches, and sensors. In outdoor setups, an IP66 or IP67 enclosure is often necessary to protect devices from intense weather conditions. Meanwhile, indoor industrial settings may only require IP54 protection against dust and splashes.

How to Choose the Right IP Rating

Not all projects require the same level of protection. Choosing the correct IP rating depends on your environment and the nature of your equipment. For indoor use with minimal exposure, IP44 might suffice. However, for environments with high moisture, dust, or the risk of water spray or immersion, ratings like IP65, IP66, or IP68 are more suitable. It’s also essential to consider ventilation, temperature control, and cable access, all of which affect enclosure performance.

The Role of Quality Design and Materials

The material and design of your enclosure play a huge role in how effectively it protects your equipment. Stainless steel, polycarbonate, and fiberglass are commonly used materials, each offering varying levels of resistance to corrosion, heat, and impact. The sealing mechanism—whether gaskets, locks, or compression latches—must be robust enough to maintain the enclosure’s integrity over time.

The Wall Mount Advantage

One of the most space-efficient ways to use IP rated enclosures is through wall mount racks. Especially useful in tight indoor spaces or secure outdoor installations, wall mount racks help organize network and electrical components vertically, keeping them safe and accessible. They’re an excellent choice for data rooms, control panels, and remote surveillance setups where floor space is limited.

Why Work with Expert IP Rated Enclosures Manufacturers

When it comes to protecting your equipment, don’t compromise. Partnering with reliable IP rated enclosures manufacturers ensures you get enclosures that are not only compliant with international standards but also tailored to your specific needs. Experienced manufacturers offer custom sizes, integrated thermal management options, and durable construction to match the exact demands of your environment.

0 notes

Text

Blue Bare PCB from China: Exceptional Quality Meets Cost-Efficiency

In the competitive landscape of electronics manufacturing, bare printed circuit boards (PCBs) serve as the foundation for innovation. Among the diverse offerings from global suppliers, blue bare PCBs manufactured in China have emerged as a top choice for engineers and businesses seeking a perfect balance of aesthetic appeal, reliability, and affordability. Combining advanced fabrication techniques with rigorous quality standards, Chinese manufacturers are redefining value in the PCB industry. In the meantime, please feel free to contact [email protected] if you have any PCB needs.

Why Choose Blue Bare PCBs?

The distinctive blue solder mask is not merely a visual preference—it’s a strategic choice for both form and function:

Enhanced Visibility: The high-contrast blue surface improves readability of silkscreen labels and component placements, simplifying assembly and debugging processes.

Professional Aesthetics: Ideal for consumer electronics, IoT devices, and industrial equipment where a sleek, modern appearance matters.

Durability: High-quality blue solder masks resist fading, scratches, and chemical exposure, ensuring long-term performance in demanding environments.

China’s Manufacturing Edge: Technology and Precision

Chinese PCB manufacturers leverage cutting-edge technology to produce blue bare PCBs that meet global standards:

Material Excellence

FR-4, Aluminum, and High-Frequency Substrates: Options tailored for thermal management (Tg up to 180°C), signal integrity, and mechanical stability.

1oz–6oz Copper Layers: Optimized for current-carrying capacity and fine trace etching (minimum 0.1mm line width/spacing).

Advanced Fabrication Processes

Laser Drilling: Precision microvias (≤75µm) for high-density interconnect (HDI) designs.

Immersion Gold (ENIG) or HASL Surface Finishes: Corrosion-resistant coatings for reliable solderability and shelf life.

Multi-Layer Capabilities: Support for 2–32 layers, accommodating complex designs in telecom, computing, and automotive systems.

Stringent Quality Assurance

Automated Optical Inspection (AOI): Detects defects like shorts, opens, and misalignments with micron-level accuracy.

Electrical Testing: 100% continuity and impedance testing (±10%) to ensure signal integrity.

Certifications: Compliance with ISO 9001, UL, RoHS, and IPC-A-600 Class 2/3 standards.

Applications Spanning Industries

Blue bare PCBs from China power a wide array of advanced technologies:

Consumer Electronics: Smartphone motherboards, LED lighting strips, and gaming peripherals.

Industrial Automation: Motor controllers, PLC systems, and robotics.

Automotive: Engine control units (ECUs), battery management systems (BMS), and infotainment modules.

Telecommunications: 5G基站 equipment, RF modules, and network routers.

Medical Devices: Patient monitoring systems and diagnostic tools compliant with ISO 13485.

Unbeatable Cost-Efficiency

China’s vertically integrated supply chain and economies of scale enable suppliers to deliver blue bare PCBs at 20–50% lower costs than counterparts in Europe or North America—without compromising quality. Competitive pricing is bolstered by:

Bulk Material Procurement: Reduced raw material costs.

High-Volume Production Lines: Streamlined workflows for fast turnaround (as quick as 24 hours for prototypes).

Flexible MOQs: Support for small-batch orders (starting at 5–10 pieces) to mass production (10,000+ units).

Sustainability and Customization

Chinese manufacturers prioritize eco-friendly practices:

RoHS-Compliant Materials: Lead-free and halogen-free substrates align with global environmental regulations.

Waste Reduction: Advanced CAD/CAM software optimizes panel utilization, minimizing material waste.

Tailored Solutions: Custom specifications for layer counts, thicknesses, surface finishes, and impedance control.

Why Partner with Chinese Suppliers?

End-to-End Expertise: From DFM (Design for Manufacturability) support to rapid prototyping and logistics.

Scalable Production: Seamlessly transition from prototypes to high-volume orders with consistent quality.

Global Compliance: PCBs meet international certifications for safety, performance, and environmental standards.

Reliable Logistics: Efficient shipping with real-time tracking to destinations worldwide.

Conclusion: A Smart Choice for Modern Electronics

Blue bare PCBs from China represent the convergence of precision engineering, visual sophistication, and cost-effectiveness. Whether you’re developing cutting-edge tech or optimizing existing systems, Chinese manufacturers provide the expertise and infrastructure to meet your needs.

Explore the potential of blue bare PCBs today—connect with a certified Chinese supplier to unlock high-quality solutions that elevate your designs while staying within budget.

For more, please visit https://hitechcircuits.com/pcb-products/double-sided-pcb/

0 notes

Text

What Is Firmware Development?

In today’s increasingly connected world, embedded systems power everything from smart home devices to medical equipment and automotive technology. At the heart of these systems lies firmware development—a specialized field that ensures devices run smoothly, efficiently, and securely. If you're building any smart or electronic product, understanding firmware and investing in expert firmware development is key to delivering performance, reliability, and innovation.

What Is Firmware?

Firmware is a type of software that provides low-level control over a device's hardware. Unlike traditional software applications, firmware resides in the device’s memory (often in ROM, flash, or EEPROM) and interfaces directly with the hardware components.

Firmware is what tells a device how to operate, boot, and respond to external commands. It’s typically involved in controlling:

Microcontrollers (MCUs)

Sensors

Actuators

Display modules

Communication modules (e.g., Wi-Fi, Bluetooth)

Because of its vital role, firmware development is an essential part of the embedded systems lifecycle.

What Is Firmware Development?

Firmware development is the process of designing, programming, testing, and maintaining the firmware that controls electronic hardware. Developers work at the intersection of hardware and software, writing code that interacts directly with microprocessors and chipsets.

This type of development typically involves:

Selecting the right microcontroller or system-on-chip (SoC)

Programming in low-level languages like C, C++, or Assembly

Interfacing with hardware peripherals

Real-time operating system (RTOS) integration

Debugging and testing using tools like JTAG, oscilloscopes, or logic analyzers

Updating and maintaining firmware post-deployment

Well-executed firmware development ensures that devices are not only functional, but also stable, efficient, and secure.

Why Firmware Development Is Crucial

In a world driven by smart technology, firmware development plays a critical role in the success of a product. Here’s why:

1. Optimized Performance

Firmware directly controls hardware operations. Efficient firmware code leads to faster processing, lower power consumption, and improved user experience.

2. Hardware Integration

Firmware allows software and hardware to communicate seamlessly. Whether it’s a smart thermostat or a medical device, firmware development ensures that components such as sensors, motors, and displays function correctly.

3. Product Reliability

Poorly written firmware can result in device malfunctions, crashes, or safety issues. Reliable firmware ensures devices perform predictably under various conditions.

4. Security

Many cyberattacks target firmware vulnerabilities. Secure firmware development practices, including encryption and authentication, are essential to protect devices and user data.

5. Upgradability

Modern devices often require firmware updates to fix bugs or add features. Proper firmware development includes designing systems that support over-the-air (OTA) updates without bricking the device.

Industries That Rely on Firmware Development

The demand for skilled firmware development is booming across various sectors:

Consumer electronics (smartphones, smart TVs, wearables)

Automotive (ADAS, electric vehicles, infotainment systems)

Industrial automation (IoT sensors, PLCs, robotics)

Healthcare (wearable monitors, infusion pumps, diagnostic devices)

Telecommunications (network hardware, routers, modems)

Aerospace and defense (navigation systems, avionics)

Whether it’s a smartwatch or a life-saving medical device, firmware is often the unseen hero behind the scenes.

Best Practices in Firmware Development

To ensure a successful project, firmware developers follow a structured approach:

Clear hardware documentation: Understand the chipset’s datasheets and schematics before writing code.

Modular design: Create reusable and maintainable code blocks.

Version control: Use Git or SVN to track changes and collaborate efficiently.

Automated testing: Implement unit tests and simulation environments to catch bugs early.

Debugging tools: Use debuggers and analyzers to test real-world behavior.

Code optimization: Ensure the code is fast, power-efficient, and small in memory footprint.

Partnering with experienced firmware developers is essential to bring a hardware product to life without delays or technical setbacks.

The Future of Firmware Development

As more industries adopt IoT, artificial intelligence, and edge computing, firmware development is becoming even more critical. We’re seeing trends like:

AI-powered firmware for smart decision-making

Increased emphasis on security and firmware-level encryption

Remote firmware updates through cloud platforms

Low-power firmware for battery-dependent IoT devices

Staying on top of these trends can give your business a competitive advantage in delivering cutting-edge, reliable technology.

Conclusion

Firmware development is the backbone of modern electronics, enabling smart devices to operate safely, efficiently, and intelligently. From prototyping to production and post-launch updates, investing in expert firmware development is crucial for any business building connected hardware.

Whether you're launching a new product or improving an existing one, working with skilled firmware developers can save time, reduce costs, and ensure your technology stands out in a crowded market.

0 notes

Text

What Is Firmware Development?

In today’s increasingly connected world, embedded systems power everything from smart home devices to medical equipment and automotive technology. At the heart of these systems lies firmware development—a specialized field that ensures devices run smoothly, efficiently, and securely. If you're building any smart or electronic product, understanding firmware and investing in expert firmware development is key to delivering performance, reliability, and innovation.

What Is Firmware?

Firmware is a type of software that provides low-level control over a device's hardware. Unlike traditional software applications, firmware resides in the device’s memory (often in ROM, flash, or EEPROM) and interfaces directly with the hardware components.

Firmware is what tells a device how to operate, boot, and respond to external commands. It’s typically involved in controlling:

Microcontrollers (MCUs)

Sensors

Actuators

Display modules

Communication modules (e.g., Wi-Fi, Bluetooth)

Because of its vital role, firmware development is an essential part of the embedded systems lifecycle.

What Is Firmware Development?

Firmware development is the process of designing, programming, testing, and maintaining the firmware that controls electronic hardware. Developers work at the intersection of hardware and software, writing code that interacts directly with microprocessors and chipsets.

This type of development typically involves:

Selecting the right microcontroller or system-on-chip (SoC)

Programming in low-level languages like C, C++, or Assembly

Interfacing with hardware peripherals

Real-time operating system (RTOS) integration

Debugging and testing using tools like JTAG, oscilloscopes, or logic analyzers

Updating and maintaining firmware post-deployment

Well-executed firmware development ensures that devices are not only functional, but also stable, efficient, and secure.

Why Firmware Development Is Crucial

In a world driven by smart technology, firmware development plays a critical role in the success of a product. Here’s why:

1. Optimized Performance

Firmware directly controls hardware operations. Efficient firmware code leads to faster processing, lower power consumption, and improved user experience.

2. Hardware Integration

Firmware allows software and hardware to communicate seamlessly. Whether it’s a smart thermostat or a medical device, firmware development ensures that components such as sensors, motors, and displays function correctly.

3. Product Reliability

Poorly written firmware can result in device malfunctions, crashes, or safety issues. Reliable firmware ensures devices perform predictably under various conditions.

4. Security

Many cyberattacks target firmware vulnerabilities. Secure firmware development practices, including encryption and authentication, are essential to protect devices and user data.

5. Upgradability

Modern devices often require firmware updates to fix bugs or add features. Proper firmware development includes designing systems that support over-the-air (OTA) updates without bricking the device.

Industries That Rely on Firmware Development

The demand for skilled firmware development is booming across various sectors:

Consumer electronics (smartphones, smart TVs, wearables)

Automotive (ADAS, electric vehicles, infotainment systems)

Industrial automation (IoT sensors, PLCs, robotics)

Healthcare (wearable monitors, infusion pumps, diagnostic devices)

Telecommunications (network hardware, routers, modems)

Aerospace and defense (navigation systems, avionics)

Whether it’s a smartwatch or a life-saving medical device, firmware is often the unseen hero behind the scenes.

Best Practices in Firmware Development

To ensure a successful project, firmware developers follow a structured approach:

Clear hardware documentation: Understand the chipset’s datasheets and schematics before writing code.

Modular design: Create reusable and maintainable code blocks.

Version control: Use Git or SVN to track changes and collaborate efficiently.

Automated testing: Implement unit tests and simulation environments to catch bugs early.

Debugging tools: Use debuggers and analyzers to test real-world behavior.

Code optimization: Ensure the code is fast, power-efficient, and small in memory footprint.

Partnering with experienced firmware developers is essential to bring a hardware product to life without delays or technical setbacks.

The Future of Firmware Development

As more industries adopt IoT, artificial intelligence, and edge computing, firmware development is becoming even more critical. We’re seeing trends like:

AI-powered firmware for smart decision-making

Increased emphasis on security and firmware-level encryption

Remote firmware updates through cloud platforms

Low-power firmware for battery-dependent IoT devices

Staying on top of these trends can give your business a competitive advantage in delivering cutting-edge, reliable technology.

Conclusion

Firmware development is the backbone of modern electronics, enabling smart devices to operate safely, efficiently, and intelligently. From prototyping to production and post-launch updates, investing in expert firmware development is crucial for any business building connected hardware.

Whether you're launching a new product or improving an existing one, working with skilled firmware developers can save time, reduce costs, and ensure your technology stands out in a crowded market.

0 notes

Text

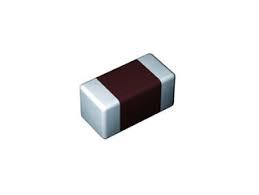

What is an MLCC Ceramic Capacitor and Why is It Crucial in Modern Electronics?

In the world of electronics, where space, stability, and performance matter more than ever, MLCC Ceramic Capacitors have become the go-to choice for engineers and designers. Found in everything from smartphones and laptops to automotive systems and industrial control panels, MLCCs (Multi-Layer Ceramic Capacitors) are essential for power regulation, signal filtering, and energy storage.

In this blog, we’ll explore what MLCC Ceramic Capacitors are, how they work, where they’re used, and why they’ve become so vital in tools, gadgets, and other advanced technology applications.

What is an MLCC Ceramic Capacitor?

An MLCC (Multi-Layer Ceramic Capacitor) is a type of capacitor that consists of multiple layers of ceramic dielectric and metal electrodes stacked together. This layered design allows MLCCs to offer higher capacitance in a compact size, making them perfect for modern miniaturized electronics.

How It Works:

The capacitor is built by stacking alternating layers of ceramic dielectric and conductive metal electrodes.

These layers are fired and compressed to form a compact, durable component.

When connected in a circuit, the MLCC stores and releases electrical energy, filters signals, and stabilizes power supply.

The result is a high-performance capacitor that can handle high-frequency applications, temperature changes, and compact circuit requirements with ease.

Common Applications of MLCC Ceramic Capacitors

Because of their size, performance, and cost-effectiveness, MLCCs are used in nearly every modern electronic device or system. They’re also found in control environments where safety, stability, and signal clarity are crucial.

Common applications include:

Mobile Devices ��� smartphones, tablets, and laptops for power management and signal filtering

Automotive Electronics – engine control units (ECUs), infotainment, lighting, and sensors

Industrial Automation – used in PLCs, relays, motor drives, and thermal monitoring tools

Communication Equipment – routers, modems, and wireless transceivers

Medical Devices – used in patient monitoring and diagnostic equipment for signal stability

Consumer Electronics – televisions, gaming consoles, and home gadgets

LED Lighting Systems – to stabilize current and prevent flicker

Power Supply Units – smooth voltage and eliminate noise across circuits

Wherever stable capacitance and compact design are needed, MLCC capacitors are a reliable solution.

Why Choose an MLCC Ceramic Capacitor?

When working with advanced electronics or high-performance systems, MLCCs provide unmatched efficiency and durability. Here’s why they're preferred across industries:

High Capacitance in Small Size: MLCCs pack a lot of capacitance into a tiny footprint, ideal for space-saving circuit boards.

Low ESR (Equivalent Series Resistance): Enables fast response and low power loss during high-frequency operation.

Wide Voltage Ratings: Available in various voltage ratings suitable for both low and high-power applications.

Non-Polarized: Can be installed in either direction, simplifying layout and reducing installation errors.

Affordable for Mass Production: Low cost per unit makes them ideal for consumer electronics and large-scale manufacturing.

Whether you’re designing a compact wearable gadget or a high-performance industrial board, MLCCs are a practical and powerful choice.

Key Features of MLCC Ceramic Capacitors

Understanding the characteristics of MLCCs helps you select the right one for your application. Their construction and material choices define how they behave under different electrical and environmental conditions.

Important Features:

Multi-Layer Design – Enhances capacitance and performance while saving space

High Dielectric Strength – Tolerates high voltage without breakdown

Excellent Frequency Response – Suitable for RF, power supply, and signal filtering circuits

Thermal Stability – Maintains capacitance across a wide temperature range

Surface-Mount Packages – Available in various sizes for automated assembly

These features allow MLCC capacitors to perform reliably across demanding electronic and electrical systems.

How to Install an MLCC Ceramic Capacitor?

Installing an MLCC Ceramic Capacitor is easy and straightforward, especially if you're working with standard surface-mount technology (SMT).

Installation Steps:

Choose the Right MLCC – Select based on voltage rating, capacitance, and dielectric class (e.g., C0G, X7R)

Prepare the Pads – Clean and prep the PCB pads or through-hole points

Position the Capacitor – Align the MLCC on the pads with precision tools or pick-and-place machines

Solder Securely – Use reflow soldering for SMT or manual soldering for larger MLCCs

Inspect the Joint – Ensure no cold joints, solder bridges, or cracks in the ceramic

Proper installation ensures long-term reliability and reduces the risk of circuit failure due to physical or thermal stress.

Benefits of Using MLCC Ceramic Capacitors in Electrical Systems

MLCC capacitors offer various benefits, making them superior to other capacitor types in many applications.

Energy Efficiency: Helps stabilize power delivery and reduce current ripple

Reliable Signal Filtering: Filters high-frequency noise in sensitive circuits

Heat Tolerance: Performs well in environments with thermal cycling or high operating temperatures

Minimal Signal Loss: Low ESR results in efficient power transfer and signal clarity

Mechanical Durability: Resistant to vibration and mechanical stress

These advantages are why MLCC capacitors are used in everything from home electronics to high-performance communication systems.

Future Trends in MLCC Ceramic Capacitor Technology

As the demand for compact and powerful electronic devices increases, the MLCC market is evolving rapidly. Manufacturers are pushing limits in terms of size, power, and integration.

Upcoming Trends:

Nano-Sized MLCCs – For ultra-compact devices such as wearables and implantable medical equipment

Flexible Ceramic Capacitors – To support curved surfaces and flexible circuit boards

Higher Capacitance in Smaller Footprints – Enabling more functionality in smaller packages

Lead-Free and RoHS Compliant Materials – Improving environmental and health safety

AI Integration for Predictive Health Monitoring – MLCCs in smart systems will help monitor circuit conditions in real-time

These innovations will open new possibilities in energy systems, IoT gadgets, communication gear, and beyond.

Conclusion: Should You Use an MLCC Ceramic Capacitor?

If your application demands compact size, high efficiency, and long-term stability, the MLCC Ceramic Capacitor is a smart and reliable choice. With benefits ranging from excellent thermal resistance to consistent energy regulation, these capacitors are vital components in modern technology.

Whether you’re developing a smart sensor, building an automation panel, or repairing a piece of high-performance electronics, MLCCs ensure your circuits run smoothly and efficiently. Pair them with quality cables, safety relays, installation kits, and modern tools to complete your electronic project with confidence.

0 notes