#ppe converting

Explore tagged Tumblr posts

Text

Clear Communication in Challenging Conditions

The Need for Effective Communication Solutions

In environments where clarity is critical, communication barriers can pose significant challenges. Whether in noisy settings like construction sites or high-stakes scenarios like emergency response, muffled speech can lead to misunderstandings with serious consequences. Traditional microphones often struggle in these conditions, picking up background noise or failing to capture voices obscured by protective gear. Advanced audio solutions, such as Ppe Voice Amplifier systems, address these issues by enhancing vocal clarity. These devices ensure that voices are heard distinctly, even through layers of personal protective equipment, improving safety and efficiency across various professions.

Overcoming Barriers with Innovative Technology

Personal protective equipment, such as N95 masks or full-face respirators, is essential for safety but often restricts airflow, muffling speech. Standard microphones rely on sound waves, which are diminished by these barriers, resulting in strained conversations. A throat microphone system offers a groundbreaking alternative by capturing vocal vibrations directly from the larynx. This technology converts vibrations into clear audio, bypassing ambient noise and mask interference. When paired with a portable amplifier, it delivers crisp, amplified sound, making it ideal for healthcare workers, first responders, and others who rely on clear communication while wearing protective gear.

Applications in High-Noise Environments

Beyond medical and emergency settings, throat microphone systems excel in noisy, dynamic environments like motorsports. Riders face constant wind and engine noise, which can drown out traditional communication devices. A bluetooth throat mic motorcycle system provides a reliable solution, allowing riders to communicate effortlessly without removing their helmets. These systems use wireless connectivity to pair with smartphones or two-way radios, enabling hands-free operation. The throat mic’s ability to pick up even whispered speech ensures clear exchanges, whether coordinating with a group or taking calls on the road, enhancing both safety and convenience.

The Science Behind Throat Microphones

Throat microphones operate using piezoelectric transducers, which convert mechanical vibrations into electrical signals. Positioned against the neck, these sensors detect laryngeal vibrations, producing a clean audio signal unaffected by external noise. This makes them exceptionally effective in windy or loud settings, such as on a motorcycle or in a busy hospital ward. The amplified output is projected through a compact speaker, ensuring the voice carries over distances or through barriers. Bluetooth-enabled versions add versatility, allowing seamless integration with modern devices while maintaining durability and ease of use in rugged conditions.

Enhancing Safety and Efficiency

In high-stakes professions, clear communication can be a matter of life and death. For medical professionals wearing PPE, a voice amplifier ensures instructions are understood without the need to remove protective gear, maintaining a sterile environment. In tactical operations, the ability to whisper commands discreetly through a throat mic enhances stealth and coordination. For motorcyclists, staying connected without compromising focus on the road reduces risks. Ppe Voice Amplifier systems streamline workflows by eliminating the need for repeated clarifications, allowing teams to focus on their tasks with confidence and precision.

Choosing the Right Communication System

Selecting an effective audio solution requires consideration of the environment and user needs. For PPE-heavy settings, a system with a robust amplifier and adjustable throat strap ensures comfort and clarity. In motorsports, a bluetooth throat mic motorcycle setup should offer strong battery life and compatibility with helmets. Durability is crucial, as these devices must withstand moisture, dust, and physical stress. User-friendly features, like push-to-talk buttons or voice-activated modes, enhance functionality. By matching the system to the context, users can achieve optimal performance and reliability.

The Future of Communication Technology

As technology advances, communication devices are becoming more sophisticated and accessible. Innovations like improved battery efficiency, enhanced noise cancellation, and integration with smart assistants are expanding the potential of throat mic systems. In the future, we may see lightweight designs with augmented reality displays for real-time data, further bridging communication gaps in challenging environments. Ppe Voice Amplifier and bluetooth throat mic motorcycle systems are already setting the standard, empowering professionals and enthusiasts to communicate effectively. These advancements promise to redefine how we connect, ensuring clarity and safety in even the most demanding situations.

0 notes

Text

Top Industrial Products Every Business Needs – Available on VashiISL

In today's fast-paced industrial landscape, businesses require high-quality, reliable, and cost-effective solutions to maintain efficiency and productivity. Whether you are in manufacturing, construction, energy, or any industrial sector, having access to the right products is crucial. At VashiISL, we offer a comprehensive range of industrial products from top brands through our B2B eCommerce platform, ensuring that your business operates smoothly and efficiently.

1. Wires & Cables:

No industrial setup can function without a robust electrical network. Wires and cables form the foundation of power distribution, ensuring seamless operations and safety in every business.

Why Choose VashiISL for Wires & Cables?

✔ Wide range of high-quality brands ✔ Various specifications for different applications ✔ Ensured compliance with industry standards

2. Switchgears: Power Control & Safety

Industrial operations involve high electrical loads, making Switchgear an essential component for controlling, protecting, and isolating electrical circuits.

Why Choose VashiISL for Switchgears?

✔ Reliable products from top brands ✔ Various voltage and current ratings available ✔ Designed for industrial-grade durability

3. Motors

Electric motors are the heart of industrial applications, from manufacturing plants to automation systems.

Why Choose VashiISL for Motors?

✔ Wide variety of motor types for different industries ✔ Energy-efficient models to reduce costs ✔ Trusted brands ensuring reliability and durability

4. Gearboxes:

Industrial machinery requires effective Gearboxes to transmit power efficiently.

Why Choose VashiISL for Gearboxes?

✔ High-performance gear solutions ✔ Multiple configurations available ✔ Durable and long-lasting for industrial use

5. Solar:

With increasing energy costs, industries are adopting Solar Solutions for sustainable and cost-effective energy use.

Solar Panels: High-efficiency panels for industrial applications.

Solar Inverters: Convert solar power into usable electricity.

Solar Batteries: Store energy for backup and continuous operation.

Why Choose VashiISL for Solar Products?

✔ Reduce energy bills with sustainable solutions ✔ Government-compliant products ✔ High-quality brands with long-term warranties

6. Safety & PPE

Workplace safety is paramount in every industry. Personal Protective Equipment (PPE) ensures the well-being of workers, preventing accidents and injuries.

Safety Helmets: Protects against head injuries.

Protective Gloves: Shields hands from chemicals and abrasions.

Safety Shoes: Prevents foot injuries from heavy objects.

Why Choose VashiISL for Safety & PPE?

✔ Compliance with international safety standards ✔ Wide range of protective gear ✔ Essential for industrial and construction sites

7. Lighting

Proper Industrial lighting enhances visibility, safety, and productivity.

Why Choose VashiISL for Lighting?

✔ Energy-efficient lighting solutions ✔ Long-lasting performance ✔ Suitable for all industrial applications

Conclusion

Industries require high-performance, durable, and cost-effective products to maintain operations efficiently. VashiISL brings you the best industrial solutions from trusted brands, ensuring you get quality, reliability, and affordability all in one place. From wires & cables to motors, safety gear, and solar solutions, we cover every essential industrial category to meet your business needs.

Looking for the best industrial products?

Explore VashiISL today and power your business with the right solutions!

Let VashiISL be your trusted partner in industrial excellence!

#IndustrialProducts#B2BEcommerce#ManufacturingSolutions#WiresAndCables#Switchgears#Motors#Gearboxes#SolarSolutions#SafetyPPE#IndustrialLighting#BusinessEfficiency#EcommerceForIndustry#ShopIndustrial

0 notes

Text

The Ultimate Guide to Medical Waste Regulations in Gainesville, FL

Medical waste disposal Gainesville is a crucial component of healthcare operations, ensuring both compliance with strict environmental and safety regulations and the protection of public health. Whether you manage a medical practice, dental clinic, or tattoo parlor in Gainesville, proper waste management is essential to meet legal standards and maintain a safe environment. This comprehensive guide delves into the specifics of medical waste regulations in Gainesville and highlights how MEd Waste Solutions simplifies the process for local businesses.

Understanding Medical Waste in Gainesville

Medical waste encompasses plenty of materials generated through healthcare centers, which include hospitals, clinics, laboratories, and nursing homes. It consists of objects which include blood-saturated materials, used needles (sharps), surgical specimens, and chemotherapy waste. Gainesville’s guidelines ensure that these materials are disposed of in a way that minimizes environmental and public fitness dangers.

In Florida, medical waste disposal is ruled by using the Florida Department of Health and the US Environmental Protection Agency (EPA). These agencies set the requirements for managing, garage, transportation, and disposal of biohazardous waste, which can be strictly enforced in Gainesville.

Why Proper Medical Waste Disposal Matters

Improper disposal of medical waste can result in excessive effects, inclusive of environmental infection, felony consequences, and dangers to public health. For example, sharps that are not disposed of well can reason injuries and spread infections. In Gainesville, making sure compliance with state and federal policies is a top precedence for healthcare carriers.

Med Waste Solutions, a depended-on name in medical waste management, offers tailor-made offerings to fulfil Gainesville’s specific environmental compliance desires. With over 21 years of experience, the organization ensures secure and green waste disposal at the same time as promoting sustainability.

Key Regulations for Medical Waste Disposal in Gainesville

1. Classification of Waste

Medical waste in Gainesville is assessed into categories, along with:

Biohazardous Waste: Blood-saturated substances, bandages, and PPE.

Sharps Waste: Needles, scalpels, and other sharp objects.

Pathological Waste: Human tissues and body elements.

Trace Chemotherapy Waste: Vials, syringes, and IV tubing used in chemotherapy.

Each kind of waste calls for dealing with, packaging, and disposal procedures to make sure compliance.

2. Packaging and Labelling

All medical waste must be packaged in leak-proof containers and categorised with biohazard symbols. Gainesville mandates that sharps be saved in FDA-accepted packing containers to prevent injuries while handling.

3. Storage and Transportation

Waste must be saved in a designated region faraway from public access. It must be transported using vehicles that comply with the Department of Transportation (DOT) requirements. Gainesville’s regulations also require a appear system to tune waste from the factor of era to disposal.

4. Disposal Methods

Approved strategies for medical waste disposal in Gainesville include incineration and autoclaving. Med Waste Solutions is going past compliance through converting waste into strength, achieving an outstanding 8:1 discount in landfill contributions.

5. Training and Certification

Healthcare companies in Gainesville should make sure that personnel dealing with medical waste are skilled in compliance with Occupational Safety and Health Administration (OSHA) standards. Regular schooling periods make certain that team of workers are updated on satisfactory practices and regulatory adjustments.

Med Waste Solutions: Your Partner in Compliance

Med Waste Solutions specializes in simplifying the complicated method of medical waste disposal in Gainesville. Here’s how they stand out:

Local Expertise: As a Florida-based organization, Med Waste Solutions is aware Gainesville’s precise regulations and environmental priorities.

Guaranteed Savings: By owning treatment flowers, they remove middlemen, saving clients up to 30% on waste management prices.

Flexible Pickups: Scheduling options accommodate the traumatic schedules of healthcare providers, ensuring seamless waste disposal.

Commitment to Safety: Med Waste Solutions adheres to all federal and Florida rules, presenting peace of thoughts to clients.

Additionally, as the exceptional company for the Florida Department of Health, Med Waste Solutions has built a reputation for reliability and performance.

The Role of Sustainability in Medical Waste Disposal

Sustainability is a developing subject in waste control, and Gainesville is not any exception. Med Waste Solutions prioritizes environmental obligation with the aid of decreasing waste despatched to landfills and converting it into strength. This waste-to-electricity initiative not most effective minimizes environmental effect but also aligns with Gainesville’s commitment to a greener future.

By partnering with Med Waste Solutions, businesses in Gainesville can contribute to sustainability whilst staying compliant with guidelines. This twin focus on safety and environmental stewardship unit’s med Waste Solutions apart inside the medical waste disposal industry.

Organizations That Benefit from Proper Waste Disposal

Medical waste disposal isn’t constrained to hospitals. In Gainesville, a huge range of organizations rely upon services like those provided by way of med Waste Solutions, such as:

Doctor’s offices and surgical centers

Dental clinics and pharmacies

Nursing houses and correctional centers

Tattoo and piercing studios

Each organization has desires, and MEd Waste Solutions gives tailored solutions to make sure compliance and convenience.

Medical waste disposal in Gainesville calls for a mixture of knowledge, compliance, and sustainability. By adhering to stringent rules and partnering with reliable providers like MEd Waste Solutions, healthcare centers can ensure a safer, greener surroundings for each person. Whether you’re a hospital, a dental workplace, or a tattoo parlour, MEd Waste Solutions offers the neighbourhood expertise and price-effective solutions you need.

Take step one toward hassle-free medical waste management these days—be part of the 3,500+ satisfied clients who believe MEd Waste Solutions to address their waste with care and precision.

"If you're wondering how Gainesville compares to other cities in medical waste disposal practices, don’t miss our blog on The Science Behind Medical Waste Disposal in Gainesville, Florida"

0 notes

Text

Opening Success: How to Start and Thrive in Your Own Phlebotomy Business

Unlocking Success: How to Start and Thrive in Your Own Phlebotomy Business

In today’s healthcare landscape, the demand for trained professionals is at an all-time high. One such profession that stands out is phlebotomy. By starting your own phlebotomy business, you can not only tap into a lucrative market but also contribute positively to healthcare. This article will guide you through the steps of launching and thriving in your own phlebotomy business, covering essential strategies, benefits, practical tips, and insightful case studies.

The Growing Demand for Phlebotomists

Phlebotomists play a critical role in the healthcare system by collecting blood samples for testing, research, and donations. As the healthcare industry continues to expand, so does the need for skilled phlebotomists. The U.S. Bureau of Labor Statistics projects a 22% growth rate for this profession by 2030, making now an ideal time to enter this field.

Benefits of Starting Your Own Phlebotomy Business

Independence: Being your own boss allows you to set your own hours and choose your clients.

High Demand: With an increasing need for blood work, job security in this field is promising.

Flexible Growth Opportunities: You can expand your offerings to include mobile phlebotomy services, training programs, or even partnerships with local clinics.

Community Impact: Providing essential services in your community positively affects public health.

Starting Your Phlebotomy Business: Step-by-Step Guide

1. Acquire Necessary Qualifications

Before you start your business, it’s crucial to complete a certified phlebotomy training program. Here are the typical steps involved:

Complete a high school diploma or GED.

Enroll in phlebotomy training courses (lasting from a few weeks to a couple of months).

Complete an internship or clinical practice hours.

Obtain certification from organizations like the American Society for Clinical Pathology (ASCP) or the National Healthcareer Association (NHA).

2. Create a Business Plan

A solid business plan is the foundation of a successful business. Your plan should include:

Executive Summary: Brief overview of your business vision and mission.

Market Analysis: Research on local demand, competitors, and target demographics.

Services Offered: Define what services (mobile services, blood draws, etc.) you will provide.

Financial Projections: Estimate startup costs and potential revenue.

Marketing Strategy: Outline how you will promote your business.

3. Register Your Business

Choose a business structure (sole proprietorship, LLC, etc.) and register your business with the appropriate state and federal agencies. Obtain the necessary licenses and permits, which vary by region.

4. Set Up Your Operations

Decide on your physical location or if you will operate as a mobile service. Purchase essential equipment such as:

Blood draw kits

Personal protective equipment (PPE)

Transport containers for specimens

Office supplies and software for scheduling and invoicing

5. Develop a Marketing Strategy

To attract clients, implement a robust marketing plan:

Online Presence: Create a professional website and leverage social media for promotions.

Networking: Build relationships with local doctors, clinics, and labs.

Community Outreach: Participate in health fairs and educational seminars.

6. Ensure Compliance and Insurance

Stay informed about healthcare regulations in your area and ensure compliance with standards to run your business smoothly. Consider obtaining liability insurance to protect against potential claims.

Practical Tips for Thriving in the Phlebotomy Business

Focus on Customer Service: Providing excellent service can convert first-time clients into repeat customers.

Continuous Education: Stay updated on industry trends and advancements.

Solicit Feedback: Regularly ask clients for feedback to improve your services.

Build Your Reputation: Encourage satisfied clients to leave reviews and testimonials.

Case Study: Success Stories in Phlebotomy

Consider the story of Jane, a newly certified phlebotomist who launched her mobile phlebotomy service. Within a year, she expanded her client base from local clinics to private patients, securing partnerships with doctors’ offices that referred patients directly to her. Jane’s commitment to scheduling flexibility and excellent service allowed her to thrive in a competitive market.

Conclusion

Starting your own phlebotomy business is an excellent opportunity to carve a niche in a growing healthcare sector. By following the steps outlined above and continuously adapting to the industry’s demands, you can unlock your path to success. Remember, your dedication and customer service excellence will distinguish you in a crowded marketplace. Don’t wait—take the plunge into entrepreneurship and build a successful phlebotomy business today!

youtube

https://phlebotomytechnicianschools.net/opening-success-how-to-start-and-thrive-in-your-own-phlebotomy-business/

0 notes

Text

Laser vs Chemical Rust Removal: Which is Better?

Introduction

Rust, or iron oxide, forms when metal reacts with oxygen and moisture. It not only affects the appearance of metal but also weakens it over time, potentially leading to structural failure. Traditional rust removal methods include mechanical abrasion (sanding or blasting), chemical treatments, and more recently, laser cleaning.

Both laser and chemical rust removal laser are effective methods, but they differ in their approaches, costs, and potential impact on the environment and operator safety. Let’s dive into each method in detail and explore which might be the better option for your rust removal needs.

What is Laser Rust Removal?

Laser rust removal uses high-powered lasers to ablate or vaporize rust from metal surfaces. The laser emits a focused beam of light that heats the rust particles to the point where they are vaporized, leaving behind a clean, rust-free surface. This process is controlled and precise, making it ideal for delicate or intricate metal parts.

Benefits of Laser Rust Removal

Precision and Control: Laser rust removal offers excellent precision, making it ideal for sensitive components that require careful handling. The laser can be adjusted to target rust without damaging the base metal.

Non-Chemical and Clean: Since the process doesn’t use chemicals, there’s no need for hazardous waste disposal. It also avoids any chemical residues that might affect the metal's future use.

Environmentally Friendly: Laser cleaning produces minimal waste compared to chemical treatments, making it a more eco-friendly option.

Efficiency and Speed: In many cases, laser rust removal can be faster than chemical processes, particularly for larger, flat surfaces or in automated settings.

Drawbacks of Laser Rust Removal

High Initial Cost: Laser rust removal machines can be expensive, with high upfront costs. While they save money in the long run by reducing labor and material costs, the initial investment is significant.

Skill Requirement: Operating a laser rust removal machine requires trained personnel. Improper use can lead to damage or inconsistent results.

Limited Availability: Laser rust removal is still relatively new, and not every manufacturer or shop has access to this technology.

What is Chemical Rust Removal?

Chemical rust removal involves the use of acids or rust converters to break down or neutralize rust. The metal part is typically submerged in or coated with the chemical solution, which reacts with the rust and either dissolves or converts it into a stable compound.

Benefits of Chemical Rust Removal

Affordable and Accessible: Chemical rust removal products are widely available and relatively inexpensive, making them accessible to businesses of all sizes and even hobbyists.

Effective for Complex Shapes: For components with intricate shapes or hard-to-reach areas, chemical treatments can penetrate crevices that might be difficult for laser cleaning to reach.

Low Skill Requirement: Unlike laser removal, chemical rust removal can be done with minimal training. This makes it a good option for DIY projects or smaller-scale operations.

Versatility: Chemical solutions can be used on a variety of metal surfaces and types of rust, providing flexibility in application.

Drawbacks of Chemical Rust Removal

Environmental Impact: Many rust removal chemicals contain hazardous materials, such as phosphoric acid, that require special disposal methods to avoid environmental contamination.

Residue and Post-Treatment: Chemicals often leave behind residues that need to be cleaned off afterward, and the treated surface might need additional protection to prevent future rust formation.

Time-Consuming: Chemical treatments can take longer, particularly for thick or stubborn rust. Soaking times may vary, and for large objects, the process may not be as fast as laser cleaning.

Health Risks: Handling chemicals can pose health risks, especially if proper protective equipment (PPE) is not used. Fumes and skin contact are common concerns with certain chemical rust removers.

Comparison of Laser vs. Chemical Rust Removal

1. Effectiveness

Laser Rust Removal: Laser cleaning is highly effective at removing rust with minimal damage to the underlying metal. It provides a clean, polished surface with little to no residue, making it ideal for precision work.

Chemical Rust Removal: Chemical methods are effective at breaking down rust but may leave residues that require additional cleaning. It is also less suitable for surfaces that need to remain intact, as the chemicals can sometimes affect the underlying metal.

2. Cost

Laser Rust Removal: The initial cost of laser machines is high, but it can save money in the long run by reducing labor costs and the need for consumables.

Chemical Rust Removal: Chemicals are much more affordable upfront, making them a popular choice for smaller budgets. However, costs can accumulate over time due to the need for repeated applications and proper disposal.

3. Speed

Laser Rust Removal: Generally faster, especially for large, flat surfaces or automated systems.

Chemical Rust Removal: Slower, especially for thicker rust layers or hard-to-reach areas that require soaking.

4. Safety

Laser Rust Removal: Safe when used properly but requires trained operators. No hazardous waste is produced, but there’s a risk of injury if the laser is mishandled.

Chemical Rust Removal: Requires careful handling of chemicals, which can be hazardous to both health and the environment. Proper protective equipment is essential.

5. Environmental Impact

Laser Rust Removal: Eco-friendly, with no chemicals or hazardous waste. The only waste produced is the vaporized rust particles.

Chemical Rust Removal: Many rust removal chemicals are harmful to the environment and require proper disposal to avoid contamination.

Conclusion: Which is Better?

When deciding between laser and chemical rust removal, it’s essential to consider your specific needs. Laser rust removal offers precision, speed, and environmental benefits but comes with a high initial cost and requires trained operators. On the other hand, chemical rust removal is affordable, versatile, and easy to use, but it poses environmental and safety concerns.

For large-scale industrial applications where speed and precision are critical, laser rust removal is the better choice. However, for smaller projects, budget-conscious operations, or hobbyist use, chemical rust removal may be more practical.

Ultimately, the best method depends on your project’s size, budget, and environmental considerations.

FAQs

1. Which method is faster for rust removal?

Laser rust removal is generally faster than chemical rust removal, especially for large surfaces or automated processes. Chemical methods require more time, particularly for heavily rusted areas.

2. Is laser rust removal more expensive?

Yes, laser rust removal has a higher upfront cost due to the price of the equipment. However, it can be more cost-effective over time by reducing labor and material costs.

3. Are there any safety concerns with chemical rust removal?

Yes, chemical rust removal involves handling potentially hazardous substances that can be harmful if inhaled or come into contact with skin. Proper protective equipment (PPE) and ventilation are essential.

4. Which method is more environmentally friendly?

Laser rust removal is more environmentally friendly because it doesn’t produce harmful chemicals or waste. Chemical rust removal requires careful disposal to avoid environmental contamination.

5. Can I use laser rust removal on any metal surface?

Laser rust removal works well on most metal surfaces, but it’s important to consult with a specialist to ensure it’s suitable for your specific material and rust condition.

0 notes

Text

Introduction: Understanding HMDS (Hexamethyldisilazane)

Introduction: Understanding HMDS (Hexamethyldisilazane)

HMDS, or Hexamethyldisilazane, might not be a household name, but in certain industries, it's nothing short of essential. It’s a versatile chemical compound used extensively in the electronics and semiconductor industries. But what exactly is HMDS? Why is it so crucial in these high-tech fields? And, just as important, what safety precautions should be followed when dealing with it?

In this post, we’ll break down the science behind HMDS, its industrial applications, the reasons for its popularity, and the critical safety protocols for handling it safely.

What is HMDS?

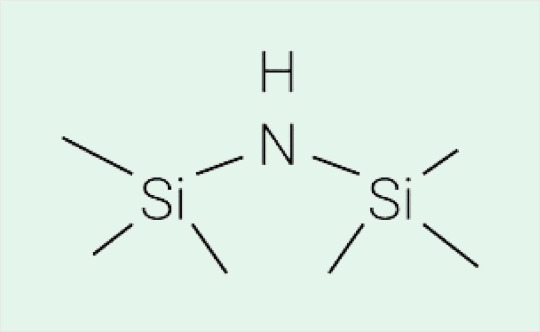

HMDS (chemical formula: [(CH₃)₃Si]₂NH) is an organosilicon compound, meaning it contains silicon atoms bonded to organic groups. This compound is a colorless liquid with an ammonia-like smell. Its molecular structure features two trimethylsilyl groups bonded to a nitrogen atom.

HMDS is known for its water-repellent properties and ability to react with surfaces to modify their characteristics. These properties make it useful in various niche applications, especially where surface treatment or preparation is essential.

Key Properties of HMDS:

Molecular Formula: [(CH₃)₃Si]₂NH

Appearance: Clear, colorless liquid

Odor: Ammonia-like smell

Boiling Point: ~126°C

Water Solubility: Low; it reacts with water, releasing ammonia

Primary Uses of HMDS

HMDS has numerous applications across industries. Let’s take a closer look at some of its most common uses:

1. Semiconductor and Electronics Industry

The semiconductor industry is perhaps the largest consumer of HMDS. It is used as a surface preparation agent in microelectronics manufacturing. Before photolithography—a key process in producing microchips—HMDS is applied to silicon wafers to make the surface more hydrophobic (water-repellent). This allows photoresist to adhere more uniformly, resulting in higher-quality chips.

Why it matters: In the world of electronics, even the tiniest imperfection can cause significant defects in microchips. HMDS helps ensure a smooth surface, improving the overall yield and quality of these intricate components.

2. Adhesion Promoter

HMDS works as an adhesion promoter, not only in semiconductor manufacturing but also in other fields. It is often applied as a primer to improve the bond between surfaces that wouldn’t naturally adhere well. For instance, in certain polymer coatings, HMDS creates a more reactive surface, ensuring better adhesion of other materials.

3. Laboratory Uses

HMDS also has its place in research laboratories. It's used as a siliconizing agent, particularly in organic synthesis. Chemists apply it to glass surfaces in laboratory equipment to render them hydrophobic, minimizing unwanted reactions during experiments. Additionally, HMDS is sometimes used in chemical reactions to protect hydroxyl groups, which are part of many organic molecules.

4. Organic Synthesis

In organic chemistry, HMDS is used to convert alcohols into their corresponding trimethylsilyl ethers, which are more stable and less reactive. This allows chemists to temporarily protect these groups during reactions, preventing unwanted side reactions and making complex organic syntheses more manageable.

Handling HMDS: Safety Considerations

Like many industrial chemicals, HMDS must be handled with care. While it’s widely used, improper handling can pose health and safety risks. Here are the key safety measures that should be followed:

1. Personal Protective Equipment (PPE)

When working with HMDS, wearing the right personal protective equipment is critical. This includes:

Gloves (typically nitrile gloves to prevent skin contact)

Safety goggles or face shields (to protect the eyes from splashes)

Lab coats or aprons (to prevent contact with clothing)

Proper ventilation or fume hoods (since HMDS can emit vapors that irritate the respiratory system)

2. Fire Safety

HMDS is flammable, so it should always be stored away from open flames or sources of heat. Ensure fire extinguishers are nearby when working with this chemical, and avoid creating static electricity that might ignite vapors.

3. Chemical Reactivity

HMDS reacts with water, releasing ammonia and sometimes creating hazardous fumes. It's important to store HMDS in airtight containers in dry environments and keep it away from any moisture to prevent this reaction.

4. Disposal of HMDS

Proper disposal of HMDS is a must. It cannot simply be poured down the drain or thrown out with regular trash. Instead, it should be disposed of as hazardous waste, following your local regulations for chemical disposal.

Benefits of Using HMDS

1. Enhanced Performance in Semiconductor Manufacturing

The major benefit of HMDS is its ability to improve the adhesion of photoresist in semiconductor processing. By ensuring a smoother, hydrophobic surface, it significantly enhances the quality and reliability of semiconductor components, which are the backbone of modern technology.

2. Surface Modification Capabilities

HMDS’s ability to alter the surface characteristics of materials makes it invaluable in numerous applications beyond electronics, from biotechnology to materials science.

3. Versatility in Organic Chemistry

In organic synthesis, HMDS’s role as a protecting agent gives chemists more control over complex reactions, allowing for the creation of intricate molecules with precision.

FAQs About HMDS

Q1: Is HMDS safe to use?Yes, but only with proper precautions. As a flammable and reactive chemical, HMDS requires careful handling, appropriate PPE, and adherence to safety protocols to avoid accidents.

Q2: What industries rely on HMDS the most?The semiconductor and electronics industries are the largest users, but it’s also commonly used in organic chemistry and material science research.

Q3: Can HMDS be mixed with water?No, HMDS reacts with water, releasing ammonia. It should be kept dry at all times to prevent unwanted chemical reactions.

Q4: How is HMDS stored?HMDS should be stored in airtight containers, away from moisture and heat sources, in a well-ventilated area.

Wrapping Up: The Importance of HMDS

HMDS is a critical compound in various high-tech industries, especially in semiconductor and microelectronics manufacturing. It’s versatile, offering benefits that range from improving adhesion in chip production to protecting delicate molecules in organic chemistry. However, its usefulness comes with the need for stringent safety measures to avoid accidents and ensure smooth operations.

By understanding what HMDS is, how it’s used, and how to handle it safely, industries and research labs can maximize its benefits while minimizing risks.

0 notes

Text

The Benefits of Fire Resistant Coveralls: Security and Insurance at Its Ideal

Fire resistant coveralls are fundamental wellbeing gear for people working in conditions with fire perils. These coveralls offer critical benefits that upgrade working environment security as well as give solace and strength. This article will investigate the vital advantages of fire-resistant coveralls and why they are significant in perilous workplaces.

Improved Wellbeing and Insurance

The essential benefit of fire-resistant coveralls is their capacity to shield laborers from intensity, blazes, and electrical circular segments. The texture is intended to oppose start and forestall the spread of flares, diminishing the gamble of serious consumes and wounds. Laborers in ventures like oil and gas, electrical utilities, and firefighting face everyday openness to these risks, making FR coveralls a need for their wellbeing.

Consistence with Wellbeing Principles

FR coveralls are frequently made to fulfill rigid wellbeing guidelines, like the Public Fire Assurance Affiliation (NFPA) rules and Word related Security and Wellbeing Organization (OSHA) necessities. Wearing fire-resistant dress assists organizations with conforming to administrative principles, lessening the gamble of punishments and guaranteeing a more secure workplace.

Solidness and Life span

Present day fire-resistant coveralls are built with solid materials, guaranteeing they can endure cruel circumstances and rehashed use. Not at all like customary workwear, which might crumble rapidly in outrageous conditions, FR coveralls keep up with their defensive characteristics after some time, even after different washes. This toughness converts into cost investment funds for organizations as they require less substitutions.

Solace and Breathability

Progressions in material innovation have made fire-resistant coveralls more agreeable and breathable than any other time. Laborers can now appreciate lightweight, adaptable materials that take into consideration better development and wind stream, without compromising insurance. This is particularly significant for occupations that require broadened times of wear, as it decreases weakness and uneasiness, eventually further developing efficiency.

Adaptability and Multi-Peril Assurance

Notwithstanding fire opposition, numerous FR coveralls offer security from other work environment risks, like substance openness and electrical shocks. This multi-danger security makes them a flexible answer for laborers in different enterprises. The capacity to join security against different risks in a single article of clothing lessens the requirement for extra layers of defensive dress.

Expanded Certainty and True serenity

At the point when laborers are furnished with fire-resistant coveralls, they can play out their obligations with more noteworthy certainty, realizing they are shielded from potential fire-related mishaps. This inner harmony prompts better spotlight and proficiency at work, at last adding to a more secure and more useful working environment.

End

Fire-resistant coveralls are a basic part of individual defensive hardware (PPE) for laborers presented to fire perils. Their capacity to safeguard against intensity, flares, and different risks, while offering solace, strength, and consistence with wellbeing guidelines, makes them a significant resource in high-risk businesses. By putting resources into quality FR coveralls, organizations defend their labor force as well as improve efficiency and decrease the gamble of work environment wounds.

0 notes

Text

-he always has a variety of ppe (personal protective equipment) that can be pulled from hammerspace, in all sizes and shapes so that no ones caught without it.

he drives an equivalent to columbos car (geo metro convertible??????)

"i'll be making a note of that"

"per updated regulations-"

"why dont you show me around"

his tail wags for "its been __ days without incident" signs that are regularly updated and a high number, and workplaces that really enforce ppe

a bumbling furry world osha inspector who keeps going to various kink setups like a transformation goop plant or a drone factory and, through a series of comedic coincidences, constantly narrowly dodges the universe's attempts to do something horny to him

15K notes

·

View notes

Text

Installation Tips for 240V Inverters: Ensuring Optimal Performance in Quebec's Climate

Introduction

Installing a 240V inverter is an excellent way to ensure a reliable power source for your home or business in Quebec, especially given the region's challenging climate conditions. However, to get the most out of your inverter, proper installation is crucial. This guide will provide you with essential tips for installing your 240V inverters to ensure it performs optimally in Quebec’s unique environment. Whether you're using it for residential or commercial purposes, following these guidelines will help you maximize the efficiency and lifespan of your inverter.

1. Understanding the Basics of 240V Inverters

Before diving into the installation process, it's important to understand what a 240V inverter does and why it's essential for Quebec residents. A 240V inverter converts DC (direct current) electricity from sources like solar panels or batteries into AC (alternating current) electricity, which is the standard form of power used by most household and commercial appliances. In Quebec, where power outages can occur due to harsh weather, having a reliable inverter is crucial for maintaining an uninterrupted power supply.

2. Choosing the Right Location

One of the most critical aspects of installing a 240V inverter is selecting the right location. The placement of the inverter can significantly impact its performance and longevity, especially considering Quebec's varying temperatures and weather conditions.

Indoor vs. Outdoor Installation: While some inverters are designed for outdoor use, it's generally recommended to install your 240V inverter indoors in Quebec due to the extreme cold and humidity. However, if outdoor installation is necessary, ensure that the inverter is housed in a weatherproof enclosure to protect it from the elements.

Ventilation: Inverters generate heat during operation, so proper ventilation is crucial to prevent overheating. Choose a location with good airflow, and avoid placing the inverter in enclosed or poorly ventilated spaces. An overheated inverter can lead to reduced efficiency or even damage over time.

Accessibility: Install the inverter in a location that is easily accessible for maintenance and monitoring. This will allow you to quickly address any issues that arise and perform regular checks without difficulty.

3. Preparing for the Installation

Proper preparation is key to a successful installation. Before you begin, gather all the necessary tools and materials, and ensure you have a solid understanding of the installation process.

Read the Manual: Every inverter model is different, so it's essential to carefully read the manufacturer’s installation manual. This will provide specific instructions and recommendations tailored to your 240V inverter.

Check Electrical Requirements: Ensure that your electrical system is compatible with the inverter. This includes verifying that the inverter’s voltage and current ratings match your power needs. In some cases, you may need to upgrade your electrical panel or wiring to accommodate the inverter.

Safety Precautions: Always prioritize safety when working with electrical systems. Turn off the main power supply before beginning the installation, and use appropriate personal protective equipment (PPE) such as gloves and safety glasses.

4. Installing the Inverter

Once you've chosen the location and prepared for the installation, it's time to install the 240V inverter. This process involves securely mounting the inverter, connecting it to your power source, and ensuring all connections are correct and secure.

Mounting the Inverter: Use a sturdy mounting bracket to secure the inverter to a wall or other stable surface. Ensure that the inverter is level and firmly attached to prevent vibrations or movement, which could damage the unit over time.

Connecting to the Power Source: Carefully connect the inverter to your power source, such as solar panels, batteries, or the main electrical grid. Double-check all wiring connections to ensure they are tight and free of corrosion. Loose or corroded connections can lead to power loss or even dangerous electrical faults.

Grounding: Proper grounding is essential for safety and performance. Follow the manufacturer’s instructions for grounding the inverter to prevent electrical shocks and ensure the system operates efficiently.

5. Testing the Inverter

After installation, it's crucial to test the 240V inverter to confirm that it’s functioning correctly. This step will help you identify and address any issues before they become significant problems.

Initial Power-Up: Turn on the inverter and monitor it as it powers up. Listen for any unusual noises, such as buzzing or humming, which could indicate a problem.

Load Testing: Connect a few appliances or devices to the inverter to simulate normal operation. Observe how the inverter handles the load and check for any fluctuations in power output. This will give you an idea of how the inverter will perform under typical usage conditions.

Monitoring and Calibration: Many modern inverters come with digital displays or apps that allow you to monitor performance in real time. Use these tools to check voltage, current, and efficiency levels. If necessary, make adjustments to the inverter’s settings to optimize performance.

6. Maintenance Tips for Optimal Performance

Even after a successful installation, ongoing maintenance is vital to ensure your 240V inverter continues to operate efficiently, especially in Quebec’s demanding climate.

Regular Inspections: Periodically inspect the inverter for any signs of wear or damage. Look for loose connections, corrosion, or signs of overheating. Early detection of issues can prevent more serious problems down the line.

Cleaning: Dust and debris can accumulate on the inverter over time, potentially affecting its performance. Clean the exterior of the inverter regularly with a dry cloth, and ensure that the ventilation openings are free of obstructions.

Software Updates: If your inverter is equipped with a digital interface or monitoring software, check for firmware updates from the manufacturer. Updating the software can improve performance and address any bugs or vulnerabilities.

Professional Maintenance: While you can perform basic maintenance yourself, it’s a good idea to have a professional technician inspect your inverter annually. They can provide a more thorough assessment and perform any necessary repairs or adjustments.

Conclusion

Installing a 240V inverter in Quebec requires careful planning and attention to detail to ensure optimal performance, especially given the region's unique climate challenges. By following these installation and maintenance tips, you can protect your investment and enjoy reliable, uninterrupted power for years to come. For more information on choosing and installing the right inverter for your needs, visit our page on 240V inverters in Quebec.

If you're also considering other backup power solutions, such as a diesel generator, be sure to explore our guide on the génératrice diesel au Quebec to understand the benefits and options available.

0 notes

Text

Optimizing Workplace Safety with Addsoft’s Safety Training Kiosk and Secure PPE Lockers!

Addsoft Safety Training Kiosk with PPE Lockers offers a comprehensive solution for industries focused on ensuring workplace safety and compliance. By combining tailored safety training with secure storage and easy access to personal protective equipment (PPE), this system is designed to enhance both safety and operational efficiency.

Key Features:

Personalized Safety Training: The kiosk provides customized safety training modules, tailored to individual performance, helping employees better understand and apply safety practices in their work environment.

PPE Lockers: Secure, automated lockers store essential PPE, allowing employees to access their safety gear quickly and efficiently whenever needed. This helps in maintaining the integrity of the equipment and ensures that it is readily available.

360° Safety Engagement: The system converts standard safety guidelines into interactive and engaging video content, improving the retention and application of safety protocols by employees.

Benefits:

Improved Safety Compliance: Ensures all employees are thoroughly trained and have immediate access to the PPE they need, supporting adherence to safety regulations.

Enhanced Equipment Management: The PPE lockers help maintain the quality and availability of safety equipment, reducing the risk of damage or loss.

Operational Efficiency: Automating PPE access through lockers saves time and reduces the manual effort required for PPE distribution, improving overall productivity.

Industry Applications:

Oil & Gas: Provides critical training and secure access to PPE in environments where safety is paramount.

Manufacturing: Ensures employees are always trained and equipped to handle hazardous materials and machinery safely.

Mining: Offers on-site safety training and quick access to essential protective gear in high-risk environments.

#blog#news#business#article#software#productivity software#technologies#enterprise software#electronic#technology

0 notes

Text

How to Choose the Right Vertical Centrifugal Pump for Your Needs?

What is a Vertical Centrifugal Pump?

A vertical centrifugal pump is simply a device that moves fluid or fuel by converting the rotational power of electric motor into kinetic energy. A case is had by these circular pumps an impeller that turns within it. The gas or liquid gets in at the biggest market related to the pump and it is forced external by centrifugal pressure ended up being discharged in the direction of the top of this housing or up and down upwards.

The vertical centrifugal pumps are commonly located in industries such as gas and oil, chemical, dishes and drink, and water therapy. Their layout allows them to deal with different fluids successfully, from destructive chemicals to thick substances. These pumps are valued for their durability, power efficiency, and ability to operate popular settings, ensuring constant and reputable efficiency throughout different industrial applications.

Advantages of Vertical Centrifugal Pump

There are a number of benefits of making application of a vertical centrifugal pump. Definitely, one of primary advantages it could be used to manage huge quantities of liquid or gas. The vertical centrifugal pump have actually been additionally extremely functional and consequently can be made use of in a number of various applications.

One more advantage is their compact dimension. Given that the impeller and electric motor are set up and down, these pumps occupy less room on the flooring than their straight equivalents. What this implies is a lot more pumps could be set up in a smaller sized location, causing boosted productivity.

Innovation in Vertical Centrifugal Pump

Development in upright centrifugal pumps has resulted in the advancement of a number of new features. As an example, some pumps will have an inbuilt variable frequency drive (VFD) that adjusts the motor rate to fit the system's demands. This particular feature conserves yourself power by making certain the engine runs just when essential.

An additional cutting-edge function the usage ceramic bearings, which often tend to be a lot more durable and longer-lasting than typical metal bearings. These bearings can endure extreme operating and require much less maintenance. A trusted thermic fluid pumps manufacturer typically incorporates such sophisticated products to improve the toughness and performance of their pumps, making certain trusted efficiency popular settings.

Safety in Use of Vertical Centrifugal Pump

Security is simply a top priority utilizing a Vertical Centrifugal Pump. The centrifugal pump upright must be properly endured all the correct piping electrical wiring. Normal assessment and maintenance concerning the pump are extremely essential to guarantee it is really operating correctly.

It can be very vital to use correct individual safety equipment collaborating with these pumps. This contains safety glasses, gloves, and hearing protection. A respectable centrifugal multi stage pump manufacturer highlights the significance of safety and security and guarantees that their products are created to minimize threats, however appropriate PPE remains vital for secure operation

How to Utilize Vertical Centrifugal Pump?

To take advantage of an upright pump, it is very important initially to go through the directions and stay with the producer's recommendations. This is made up of correct instalment positioning, and maintenance connected with pump.

Before starting the pump, make sure that it is topped with fluid to avoid issues for the impeller. When the pump is running, check it for virtually any kind of indicators of breakdown or vibration. Executing a routine tracking schedule can help find possible troubles early, permitting prompt intervention and minimizing downtime in crucial industrial processes.

Service and Quality

Service and quality are important variables when picking a vertical centrifugal pump. A credible pump should offer exceptional customer and assistance, consisting of technological help, upkeep, and repair work solutions.

The caliber of the pump need to be described as also a leading factor to consider. High-quality materials and handiwork are necessary to ensure the pump's integrity and longevity. Investing in a pump from a credible supplier not just makes certain optimum performance however additionally reduces downtime and upkeep costs, offering lasting worth for industries that depend on constant and reputable procedure.

Applications of Vertical Centrifugal Pump

Upright centrifugal pumps are made use of in a broad array of. They are widely utilized in wastewater treatment plants, desalination plants, and chemical processing centers. Additionally, they exist in power plants, beverage and meals handling, and coal and oil markets.

Other applications amongst these pumps include irrigation, mining, and marine procedures. Normally, in many these firms, Vertical centrifugal pumps are important elements of the systems, and their trustworthy operation would certainly be to ensure the smooth and reliable procedure of facility. A leading centrifugal chemical pump manufacturer plays a crucial function in supplying these necessary pumps, providing items that meet the strenuous needs of different commercial applications.

#Vertical Centrifugal Pump#Vertical Centrifugal Pump Manufacturer#Thermic Fluid Pumps Manufacturer#Centrifugal Multi Stage Pump Manufacturer#Centrifugal Process Pump#Centrifugal Chemical Pump Manufacturer#Ahmedabad#India

1 note

·

View note

Text

Hydraulic Torque Wrenches: Power and Precision in Fastening

Specialized instruments called hydraulic torque wrenches are used to precisely torque fasteners like bolts and nuts. They are especially helpful in high-torque applications where dependability and accuracy are essential. An outline of hydraulic torque wrenches is provided below:

Summary

Using hydraulic pressure, hydraulic torque wrenches produce the required torque to tighten or loosen fasteners. They are made up of various essential elements:

1. Hydraulic Pump: The torque wrench receives the hydraulic pressure produced by this apparatus.

2. Torque Wrench: The torque wrench is made to withstand pressure and provide the necessary torque to the fastener.

3. Hydraulic Cylinder: This part converts mechanical force from hydraulic pressure.

Important Elements

1. High Torque Capability: Heavy-duty applications benefit greatly from the high torque values that hydraulic torque wrenches can produce.

2. Accuracy: In industries where accurate torque settings are necessary, these wrenches' precise torque control is essential.

3. Efficiency: The hydraulic mechanism enables faster operation than manual or electric torque wrenches.

4. Durability: Hydraulic torque wrenches are made to endure hard use, severe environments, and large loads.

Uses

Industrial Maintenance: Frequently utilized in production and maintenance tasks requiring accurate tightening of big bolts and nuts.

Construction: A crucial component of structural assemblies that require a high torque.

Oil and gas; utilized in the construction and upkeep of rigs, pipelines, and other machinery requiring high torque and reliability are crucial.

Automotive: Works on heavy-duty vehicle assembly and repairs.

Benefits

Precision: By ensuring that the proper amount of torque is delivered, hydraulic torque wrenches lower the possibility of over- or under-tightening.

Speed: They are more productive than manual wrenches because they can work more quickly.

Consistency: Even under difficult circumstances, the hydraulic mechanism delivers reliable functioning.

Upkeep and Security

To guarantee the lifetime and precision of hydraulic torque wrenches, routine maintenance is necessary. This involves making sure all parts are operating properly, looking for leaks, and monitoring the amounts of hydraulic fluid. To avoid mishaps, safety precautions like as donning the proper PPE and adhering to manufacturer instructions should be taken.

Conclusion

In industries where precise and dependable high torque applications are necessary, hydraulic torque wrenches are a piece of indispensable equipment. Pros in a variety of fields favor them because of their capacity to manage heavy loads and deliver precise torque. To optimize their efficiency and guarantee safe operation, proper maintenance and safety procedures are essential.

1 note

·

View note

Text

Safety Precautions while using Sodium Hydroxide Pellets

Sodium hydroxide pellets or also referred as caustic soda or lye are small and solid sodium hydroxide. They are white and odorless small pellet shaped material which is easily soluble in water and is strongly alkaline in nature. Sodium hydroxide pellets are essential in the manufacture of so many chemicals such as detergents, synthetic fabrics, and plastics. Soap making requires sodium hydroxide pellets to actually convert fats and oils into the solid soaps that are used in everyday life.

Personal Protective Equipment (PPE)

Sodium hydroxide pellets if not handled with precaution are usually dangerous and can cause severe injuries. Sodium hydroxide the solutions are alkalis and can burn the skin, eyes, and cause breathing problems. PPE is crucial to prevent direct contact with these risks as it provides a buffer between the user and risks and facilitates the reduction of accidents.

Types of PPE Required

Gloves: Ensure that the hands are protected from coming into direct contact with sodium hydroxide pellets through wearing chemical resistant gloves made of neoprene or nitrile.

Goggles: Use safety glasses to protect your eyes from splashes and flying debris.

Face Shields: Further to goggles, a face shield offers additional protection that covers the entire face.

Aprons: Take chemical-resistant aprons to avoid chances of getting your skin, and clothes stained by the chemical spills.

Safe Handling and Storage

Avoid Direct Contact: Sodium hydroxide pellets specifically come in the form of small pellets and can be strongly corrosive and can cause burns. It is advised to wear proper PPEs like gloves, goggles and wearing full sleeved clothes so as to avoid skin and eye contact. Use Tools: To minimize contact with the material, always use spatula, tongs, or special containers to transfer or to measure the pellets. This also helps to reduce chances of accidentally touching the containers or causing spills. Work in Well-Ventilated Areas: Make sure your environment at workplace should be adequately aerated so that your do not inhale dust or stinks that result from the pellets. Avoid exposure to gasoline because it poses a threat to your respiratory system and ensure to use fume hoods or work in well ventilated areas.

Storage Recommendations

Temperature Control: Sodium hydroxide pellets should be stored in a cool dry well ventilated area and should never be exposed to heat. At high temperatures, pellet materials degrade, and the presence of moisture in the air can cause dangerous situations. Humidity Management: Sodium hydroxide is a hygroscopic substance which means it has the property of taking up moisture from the air. Store the pellets in a sealed container in order not to attract moisture which in turn hinders the free flow of the pellets and they clump resulting to limited efficacy. Container Specifications: Employ containers of compatible materials including high density polyethylene (HDPE) or any other material that is not affected by corrosion. Make sure the containers are well labeled and that the lids are tightly sealed to minimize spillage or inter-mingling of contents.

Emergency Procedures

Spill Response

Evacuate the Area: Make sure that all the personnel evacuate the area of the spill so that they do not get in contact with the product.

Contain the Spill: Have barriers such as mats or spill Control kits to ensure that the pellet does not spread all over.

Neutralize the Spill: Use a weak acid solution such as dilute acetic acid or vinegar to neutralize the sodium hydroxide pellets. This facilitates the reduction of the alkaline effect of the substance in the body.

Clean Up Safely: When neutralized, it is advisable to use the right tools to scoop the residue sodium acetate and dump it in the chemical waste bins. Try not to get in direct contact with the substance during this stage of its application.

Ventilate the Area: It is necessary to ventilate the working area to prevent the spread of negative fumes in case of spillage.

First Aid Measures

Rinse Immediately: Wash the affected area with clean running water for not less than 15 minutes.

Remove Contaminated Clothing: Make sure that you do not touch any of the clothing that may have had contact with the pellets.

Seek Medical Attention: While rinsing, use cold water and one should immediately seek the help of a doctor for further tests and treatment.

Flush Eyes: Flush the eyes with warm water for at least 15 minutes with eyes wide open to allow proper washing.

Avoid Rubbing: The patient should avoid rubbing the eyes because such a move will only worsen the situation.

Get Medical Help: In the event of an abnormal sensation or observation, go to the emergency room as soon as possible after rinsing.

Move to Fresh Air: In case of an inhalation affect, remove the victim to an open air environment to allow for proper breathing.

Monitor Breathing: In case of the development of breathing problems, provide oxygen therapy, if possible and call the doctor at once.

It is extremely crucial to ensure the safety when it comes to handling sodium hydroxide pellets. Adopting these measures of safety is essential in preventing all risks that may be found in handling sodium hydroxide pellets and in ensuring that the workplace is safe. We would like to urge you to use these precautions to practice and to remain as safe as possible at all times. To learn more about sodium hydroxide pellets and to view the full Atlas Pellets product list, please click through to our website.

#sodium hydroxide pellet#atlas pellets industries#sodium hydroxide pellet exporters#caustic pellet#best sodium hydroxide pellet#caustic pellets#atlas pellet#sodium hydroxide pellets#sodium hydroxide pellets exporters#sodium hydroxide pellets manufacturer

0 notes

Text

A Complete Guide to Medical Waste Disposal for Healthcare Practices in Lauderhill

Proper medical waste disposal in Lauderhill is important for protecting public fitness and making sure compliance with rules. Healthcare facilities generate numerous dangerous wastes that, if no longer treated correctly, pose serious risks. Choosing a reliable partner for medical waste disposal in Lauderhill guarantees secure, flexible, and green waste control, creating a safer environment for staff, patients, and the community

Understanding Medical Waste in Healthcare Facilities

Proper medical waste disposal in Lauderhill is crucial for preserving safety and compliance in healthcare settings. Medical waste includes anything which could contain infectious materials or pose a risk to health, together with infected gloves, bandages, and PPE. Ensuring safe and compliant disposal of these gadgets protects the network and the surroundings.

Regulated Medical Waste (RMW): Includes blood-infected items and frame fluids. Effective clinical waste disposal in Lauderhill helps save you infection and fitness dangers.

Sharps Waste: Needles, scalpels, and other sharp gadgets want specialised disposal to save you injuries. Secure scientific waste disposal in Lauderhill reduces the probabilities of accidental publicity and contamination.

Proper management of these waste sorts ensures that healthcare facilities meet all safety requirements and protect the public. Choosing a dependable company for scientific waste disposal in Lauderhill simplifies compliance and safeguards everyone.

Medical Waste Regulations in Lauderhill

Complying with regulations for scientific waste disposal in Lauderhill is important for healthcare centers to make sure protection and avoid felony issues. Both federal and state hints, which include those from OSHA and the Florida Department of Health, must be followed to manipulate waste correctly.

Healthcare vendors in Lauderhill must well categorize waste (biohazardous, sharps, and pharmaceutical) and preserve unique records. Meeting those necessities guarantees that scientific waste disposal in Lauderhill is dealt with effectively and responsibly, protecting the community and the environment.

Choosing a Medical Waste Disposal Service in Lauderhill

Selecting the proper companion for medical waste disposal in Lauderhill is essential to maintain safety and compliance. Here are some key considerations:

Compliance & Certification: Ensure your provider is certified and follows all regulations for medical waste disposal in Lauderhill to avoid non-compliance risks.

Flexible Scheduling: Choose an issuer that offers customized pickup schedules to suit your facility’s wishes for efficient medical waste disposal in Lauderhill.

Cost-Effectiveness: Opt for offerings that stability affordability with fine. Providers like MedWaste Solutions provide 30% financial savings for clinical waste disposal in Lauderhill without compromising compliance.

Local Expertise: A local organisation is familiar with Lauderhill’s policies and can respond quick, making them perfect for scientific waste disposal in Lauderhill.

Eco-Friendly Options: Select a provider that supports sustainability through green practices like converting waste into energy.

Your Partner for Medical Waste Disposal in Lauderhill

When it comes to clinical waste disposal in Lauderhill, MedWaste Solutions is your trusted partner. We offer custom designed, value-effective offerings specifically designed for healthcare facilities in the location, making sure 30% savings as compared to different carriers.

Why Choose Us?

Guaranteed Savings: Our direct carrier approach cuts costs, allowing us to offer the most aggressive quotes for medical waste disposal in Lauderhill.

Flexible Scheduling: We provide flexible pickup options to fulfill the precise desires of your facility, making clinical waste disposal in Lauderhill smooth and problem-free.

Local Expertise: Being locally based totally, we recognize Lauderhill’s guidelines and tailor our services to satisfy compliance requirements. With our sustainable method, we convert scientific waste into strength, decreasing landfill impact and promoting green practices in scientific waste disposal in Lauderhill.

Commitment to Safety: Our crew follows strict protection protocols, ensuring your facility’s compliance with all regulations. With MedWaste Solutions, you’re partnering with specialists who prioritize safety and sustainability in medical waste disposal in Lauderhill.

Best Practices for Medical Waste Management in Healthcare Facilities

Implementing best practices for medical waste disposal Lauderhill facilities guarantees safety, compliance, and performance. Below are key techniques healthcare companies must observe:

Proper Waste Segregation and Labeling: Effective medical waste disposal Lauderhill begins with segregating waste types along with sharps, biohazardous, and pharmaceutical materials into genuinely classified bins. This minimizes threat and streamlines collection.

Safe Storage Before Pickup: For safe medical waste disposal Lauderhill, store waste in sealed, puncture-proof bins in steady regions. Regular inspections ensure compliance and prevent unauthorized get right of entry to.

Staff Training on Handling Procedures: Proper team of workers schooling is critical for safe scientific waste disposal Lauderhill. Regular education keeps personnel updated on safety protocols, reducing risk and retaining compliance.

Accurate Documentation and Record-Keeping: Maintain facts of all clinical waste disposal Lauderhill activities to illustrate compliance. This helps during audits and tracks waste volumes to enhance efficiency.

Proper medical waste disposal in Lauderhill is crucial for preserving protection and compliance. Partnering with a relied-on provider like Med Waste Solutions guarantees your facility meets regulatory standards whilst contributing to a healthier environment. With their tailored solutions and 30% financial savings assure, Med Waste Solutions makes scientific waste disposal in Lauderhill hassle unfastened.

Choosing the right provider for medical waste disposal in Lauderhill no longer best reduces prices but additionally streamlines operations. Don’t permit compliance be a burden—contact Med Waste Solutions today for reliable and eco-friendly waste management.

0 notes

Text

Comprehensive Guide To Arborist Supplies In Sydney

Arborist supplies are crucial for maintaining the health and safety of trees, especially in urban settings like Sydney. Arborists need a wide range of tools and equipment to carry out their tasks effectively and safely. This guide explores the diverse range of arborist supplies available in Sydney, highlighting their importance and unique features.

Climbing Gear

Safety is paramount in arborist work, and climbing gear is essential for any tree professional. Climbing harnesses, ropes, and carabiners are some of the primary tools. Modern harnesses are designed with ergonomic features, providing maximum comfort and reducing fatigue during prolonged use. High-quality ropes are essential for both climbing and rigging, and they are available in various lengths and strengths to suit different tree sizes and heights.

Cutting Tools

Cutting tools are fundamental in arboriculture. Chainsaws, handsaws, and pole pruners are the most commonly used. Chainsaws, available in different sizes and power options (electric, battery-operated, and petrol), are indispensable for felling trees and cutting large branches. Handsaws, on the other hand, are perfect for precision cuts and smaller branches. Pole pruners allow arborists to trim high branches without climbing, enhancing safety and efficiency.

Rigging Equipment

Rigging equipment is essential for safely lowering large branches and tree sections to the ground. Rigging blocks, pulleys, and slings are crucial for managing heavy loads. Advanced rigging systems are now available, which can significantly reduce the physical strain on arborists and increase the safety of complex tree removals. These systems are designed to distribute weight evenly and provide greater control over the descent of heavy tree parts.

Protective Gear

Personal protective equipment (PPE) is mandatory for arborists to prevent injuries. Helmets with face shields or safety glasses protect against falling debris. Hearing protection is crucial when using loud machinery like chainsaws. Cut-resistant gloves and chainsaw protective trousers (chaps) provide additional safety. In recent years, advancements in PPE have led to lighter, more breathable materials, improving comfort without compromising safety.

Tree Health Diagnostics

Maintaining tree health requires more than just cutting and pruning. Arborists use diagnostic tools to assess tree health and identify issues such as disease, pest infestation, and nutrient deficiencies. Tools like increment borers, resistograph drills, and portable soil testers are essential for this purpose. These tools help arborists make informed decisions about treatment and maintenance, ensuring the long-term health of trees.

Stump Grinders and Chippers

After tree removal, dealing with stumps and debris is a critical task. Stump grinders are powerful machines that grind down tree stumps to below ground level, allowing for replanting or landscaping. Wood chippers convert branches and tree limbs into wood chips, which can be used as mulch or disposed of more easily. Modern stump grinders and chippers are designed for efficiency, with features such as self-propelled wheels and adjustable cutting depths.

Arborist supplies are integral to the profession, ensuring the safety and efficiency of tree care tasks. From climbing gear to cutting tools, and protective equipment to diagnostic tools, each plays a vital role in the daily operations of arborists. Investing in high-quality equipment and proper training not only enhances the safety of arborists but also ensures the health and longevity of Sydney’s urban forest.

0 notes

Text

Phosphorus Oxychloride: A Versatile yet Reactive Chemical

Phosphorus oxychloride, also known as phosphoryl chloride or POCl₃, is a colorless, fuming liquid with a pungent odor. This inorganic compound holds a unique position in the world of chemistry due to its combination of phosphorus and chlorine atoms. This article delves into the properties, production, applications, and safety considerations surrounding phosphorus oxychloride.

Chemical Properties:

Formula: POCl₃

Molar mass: 137.94 g/mol

Melting point: -1.5 °C

Boiling point: 105.6 °C

Density: 1.62 g/cm³

Solubility: Reacts violently with water, soluble in most organic solvents

Phosphorus oxychloride possesses a trigonal pyramidal structure, where a phosphorus atom sits at the center bonded to three chlorine atoms and a single oxygen atom. Due to the electronegativity difference between phosphorus and oxygen, the P-O bond exhibits a partial positive charge, making POCl₃ a Lewis acid. Additionally, the presence of polar P-Cl bonds contributes to its overall polarity.

Production Methods:

Several methods exist for the production of phosphorus oxychloride, but the most common involves the direct reaction between phosphorus pentachloride (PCl₅) and phosphorus trichloride (PCl₃) at elevated temperatures:

PCl₅ + PCl₃ → 3 POCl₃

This reaction produces POCl₃ along with some unreacted starting materials. Distillation techniques are then employed to isolate and purify the desired product.

Chemical Reactivity:

Phosphorus oxychloride is a highly reactive molecule, readily undergoing hydrolysis when exposed to water. This hydrolysis produces phosphoric acid (H₃PO₄) and hydrochloric acid (HCl):

POCl₃ + 3 H₂O → H₃PO₄ + 3 HCl

This vigorous reaction releases significant amounts of heat, making POCl₃ a potential fire and explosion hazard. Similarly, POCl₃ reacts violently with alcohols, amines, and other organic compounds containing reactive hydrogens.

Applications:

Despite its reactivity, phosphorus oxychloride finds applications in various industries due to its versatility. Here's a glimpse into some key uses:

Flame retardants: POCl₃ is used in the production of flame retardants for textiles, plastics, and other materials. It reacts with hydroxyl groups (OH) present in these materials, forming phosphate esters that act as fire barriers.

Plasticizers: POCl₃ can be used to introduce phosphate groups into plasticizers, enhancing their flexibility and flame resistance.

Organic synthesis: Phosphorus oxychloride plays a crucial role in various organic syntheses. It acts as a chlorinating agent, dehydrating agent, and a phosphorylating agent. For instance, it can convert alcohols to alkyl chlorides and carboxylic acids to acyl chlorides.

Herbicides: Certain derivatives of POCl₃ exhibit herbicidal properties, making them useful for weed control in agricultural settings.

Batteries: Research suggests potential applications of POCl₃ electrolytes in lithium-ion batteries.

Safety Considerations:

Due to its high reactivity, handling phosphorus oxychloride requires strict safety protocols. Here are some essential precautions to take:

Personal protective equipment (PPE): Always wear appropriate PPE, including safety goggles, chemical-resistant gloves, full-face shield, and a laboratory coat, when working with POCl₃.

Fume hood utilization: All manipulations involving POCl₃ should be carried out in a well-ventilated fume hood to prevent inhalation of harmful fumes.

Moisture control: Stringent measures are necessary to prevent exposure of POCl₃ to moisture, as it can lead to a violent reaction. Sealed containers under inert atmosphere are recommended for storage.

Spill response: Spills of POCl₃ require immediate response. Neutralizing agents such as sodium bicarbonate or soda ash can be used cautiously to manage the reaction and prevent further hazards.

Conclusion: