#rectifiers

Explore tagged Tumblr posts

Text

Advanced Equipment for High-Quality Services at A-Gas Electronic Materials

Explore the wide range of advanced equipment at A-Gas Electronic Materials, ensuring top-notch services for our customers. Our state-of-the-art tools include CVS analysis, Yamoto wafer plating, rectifiers, and more. Trust us for precision and reliability in all your industrial needs.

#advanced equipment#CVS analysis#Yamoto wafer plating#rectifiers#insoluble anodes#inorganic analysis#heaters#filter media#pumps and filters#anodes#Electrum precious metal recovery#Titraline inorganic titration#A-Gas Electronic Materials

2 notes

·

View notes

Text

At SUV System Ltd, sustainability isn't just a buzzword; it's a commitment. As a #leadingsupplier of #electroniccomponents, we're dedicated to implementing eco-friendly practices throughout our #sourcing and #distribution processes.

From partnering with environmentally conscious manufacturers to utilizing energy-efficient #technologies in our #warehouse, we're doing our part to protect the planet. Our strict recycling programs and #ecofriendlypackaging solutions help reduce waste, ensuring that our operations leave a minimal carbon footprint.

Choose SUV System Ltd for your #electroniccomponent needs and experience the difference between quality products with eco-friendly practices

By choosing us, you're not only getting top-quality components but also supporting a company that values #sustainability. Let's work together to create a greener future.

Feel free to contact us at [email protected] or connect on Skype at [email protected]

You can also visit us at https://www.suvsystem.com/

#sustainability#diode supplier#semiconductors#electronic components#diodes#electronics supplier#rectifiers#capacitors#transistor#sustainable#tvs diode

2 notes

·

View notes

Text

#WeEn Semiconductors#renewable energy#PowerElectronics#Rectifiers#2000VTech#ThermalPerformance#EnergyEfficiency#HighVoltageSolutions#EVCharging#IndustrialElectronics#RenewableEnergy#TechInnovation#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

Rectifiers play a crucial role in converting AC to DC, making them essential in various electrical and electronic applications. In this video, we cover: ✅ What are rectifiers? ✅ Types of rectifiers (Half-wave, Full-wave, Bridge) ✅ Working principles explained ✅ Key applications in industries

📌 Watch now to gain in-depth knowledge!

📢 Read more here: https://www.emcoprecima.com/blog/understanding-rectifiers-types-working-principles-and-applications/

0 notes

Text

IGBT vs. Thyristor: Choosing the Right Technology for Green Hydrogen Electrolysis

Green hydrogen electrolysis is vital for reducing carbon emissions as the planet shifts to clean power. However, you can only produce vast quantities of green hydrogen electrolysis by selecting the correct power conversion technology. The IGBT vs. Thyristor Rectifiers discussion has been ongoing among industry experts and power conversion technology users, especially for large-scale green hydrogen electrolysis.

This article shares their distinctive characteristics to help you make the right decision for your green hydrogen project.

What is Green Hydrogen Electrolysis?

Green hydrogen electrolysis involves utilizing renewable energy sources, such as wind or solar, to split water into hydrogen and oxygen. This clean hydrogen can then be stored and used as fuel, contributing to a carbon-neutral future. Nevertheless, hydrogen electrolysis is energy-intensive. Choosing the right power conversion technology is critical to maximizing efficiency and minimizing energy.

Understanding IGBT and Thyristor Technologies

IGBT (Insulated Gate Bipolar Transistor)

IGBT technology combines the efficiency of MOSFETs with the high-voltage handling of bipolar transistors. It's known for fast switching speeds and high energy efficiency. Thus, applications needing high, precise control levels, such as green hydrogen electrolysis, use IGBTs.

Key benefits of IGBT technology include:

High switching speeds for efficient energy conversion.

Lower energy losses, reducing operational costs.

Compact design, requiring less installation space.

Precise control, optimizing the electrolysis process and improving hydrogen yield.

Thyristor Rectifiers

A Thyristor rectifier is a semiconductor device used in high-voltage, high-current applications. Industries like power generation, steel, and cement have used Thyristors for decades as they can manage large electrical loads.

Key benefits of Thyristor rectifiers include:

High current and voltage capacity, suitable for large-scale hydrogen projects.

Durability and reliability, ensuring long-term operation with minimal maintenance.

Cost-effectiveness for larger installations.

Comparing IGBT and Thyristor Rectifiers for Hydrogen Electrolysis

Efficiency

IGBT systems offer higher energy efficiency compared to Thyristor rectifiers. In green hydrogen electrolysis, where maximizing efficiency is critical, IGBTs can minimize energy loss during the power conversion. This makes IGBTs the preferred choice when energy savings and cost-effectiveness are prioritized.

Current and Voltage Handling

Thyristor rectifiers are more suitable for large-scale hydrogen electrolysis plants as they can handle higher currents and voltages. Although IGBTs are efficient, Thyristors excel at managing high power levels, making them ideal for extensive hydrogen production systems.

Control and Precision

When it comes to control and precision, IGBTs outperform Thyristors. IGBT systems are flexible in controlling voltage and current, ensuring the smooth and efficient operation of hydrogen electrolysis equipment.

Installation and Maintenance

IGBT systems are typically smaller and easier to install than Thyristor rectifiers. However, Thyristors offer excellent durability and require less maintenance, making them a cost-effective option for large-scale industrial hydrogen production plants.

Which technology should we use for green hydrogen electrolysis?

Choosing between IGBT and Thyristor rectifiers depends on the scale and goals of your green hydrogen electrolysis project. IGBTs offer better efficiency and control for smaller to mid-sized operations, while Thyristor rectifiers are ideal for high-power, large-scale hydrogen production.

IGBT technology is preferred for projects where precision and energy savings are a priority. In contrast, Thyristor rectifiers may be better for massive installations where high current handling is critical.

In a Nutshell

Both IGBT and Thyristor rectifiers are vital in optimizing the efficiency and performance of green hydrogen electrolysis systems. Understanding the remarkable advantages of each technology can help you choose the correct option for your hydrogen production requirements.

At Yonder H2, we specialize in cutting-edge hydrogen solutions, including power conversion technologies like Thyristors and transformer rectifiers. We strive to sustain sustainable energy projects and accelerate the transition to green hydrogen.

Contact us now at [email protected].

#ThyristorRectifier #IGBT #GreenHydrogen #HydrogenElectrolysis #SustainableEnergy #YonderH2

About the Author: Yonder, a division of the Ador Group, has been a leader in Power Electronics since 1908. Specializing in advanced Power Conversion Units for hydrogen generation, we integrate Alkaline, PEM, SOEC, and AEM electrolysers to ensure high efficiency and minimal power consumption. Headquartered in Mumbai with state-of-the-art facilities in Pune, Yonder is committed to global decarbonization. Our 500-MW manufacturing facility for hydrogen power sources is poised to deliver cutting-edge solutions that thrive in unique and demanding deployment contexts.

#ACDC #Rectifiers #PowerConversion #Electronics #ElectricalEngineering #AdorPower #EfficientPower #TechSolutions #EnergyEfficiency #PowerSupply

#ThyristorRectifie#greenhydrogen#sustainable energy#YonderH2#hydrogen production#ACDC#Rectifiers#PowerConversion#Electronics#ElectricalEngineering#AdorPower#EfficientPower#TechSolutions#EnergyEfficiency#PowerSupply

0 notes

Text

Use Of Rectifiers In Datacenters

In the realm of datacenters, where immense amounts of data are processed and stored, the need for reliable power management systems is paramount. One key component that plays a vital role in this process the rectifier. In this article, we will delve into the importance of rectifiers in datacenters and how they contribute to ensuring smooth operations and efficiency. To Read more about the Trends and Use Of Rectifiers In Datacenters visit : https://wawt.tech/2024/05/14/trends-in-the-use-of-rectifiers-in-datacenters/

0 notes

Text

Rectifiers play an essential role in enhancing the reliability of industrial automation systems. By ensuring stable power supply, minimizing downtime, protecting equipment, and improving energy efficiency, rectifiers contribute to smoother operations and increased productivity. Businesses can rely on rectifiers to maintain consistent performance and meet their production targets effectively.

#industrial automation#industrial equipment#auto2mation#industrialpower supply#industrial spare parts#industrial and marine automation#industrial automation equipment#industrial and marine automation equipment#automation#industrial#rectifiers

0 notes

Text

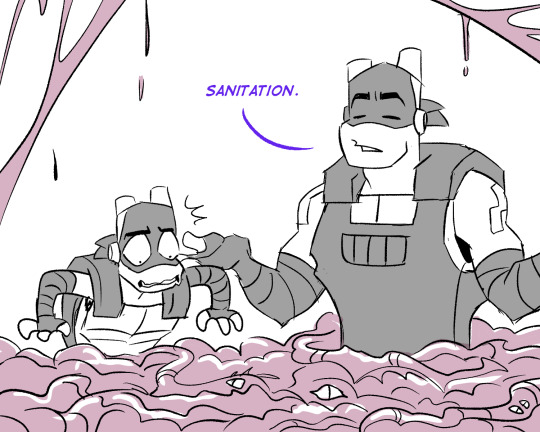

The real reason.

I’ve seen a lot of comments saying that canon future Donnie looks more like he’s wearing waders rather than overalls and if that’s the case then he’s smarter and more prepared than any of us are giving him credit for. King is keepin’ it clean.

#to keep the ick away#smart man#his worst nightmare#rectified with fashion#I’d wear them too#now if he could just find some boots his size#thank you Andy#rottmnt#canon future donnie#future Donnie#rise of the teenage mutant ninja turtles#kathaynesart#save rottmnt

4K notes

·

View notes

Text

How to Choose the Right Rectifier for Your Application?

Rectifiers, which change alternating current (AC) into direct current (DC), are crucial parts of electronic circuits. It can be difficult to choose the best rectifier for your application out of the many varieties that are available. Read this blog.

0 notes

Text

women and dennis of the pitt + text posts

#queue did this#i realised i dont post much about the girlies of the pitt so had to rectify that#the pitt#emery walsh#trinity santos#yolanda garcia#parker ellis#pitt posting#screencaps#the pitt memes#mel king#cassie mckay#john shen#dennis whitaker

778 notes

·

View notes

Text

When you think of #semiconductors, "synthetic" might come to mind. Did you know that these tiny powerhouses are born from one of Earth's most abundant natural elements? That's right – silicon, the backbone of semiconductors, is derived from sand!

Semiconductors, the building blocks of #modernelectronics, have their roots deeply embedded in nature. The primary material used in semiconductor manufacturing is #silicon, one of the most abundant elements on Earth.

The process of extracting silicon from sand is not only a testament to human ingenuity but also highlights a #sustainable approach to #technology. Utilizing abundant natural resources like sand ensures that the backbone of #electronicdevices is rooted in environmental responsibility.

SUV System Ltd is proud to procure these essential components from leading manufacturers, ensuring top-notch quality while maintaining environmental harmony.

By championing #sustainability at every step of the supply chain, from sourcing to disposal, we're not just reducing our carbon emissions; we're setting a precedent for industries far and wide.

Our advanced #diodes, #transistors, and #rectifiers are all testaments to this perfect blend of nature and innovation.

Embrace the #ecofriendly side of technology with semiconductors that honor their natural origins. Let's work together towards a future where #techinnovations coexist harmoniously with our planet.

For queries, reach out to us at [email protected] Or connect on Skype at [email protected]

or explore our products at https://www.suvsystem.com/

#semiconductors#electronic components#discrete semiconductors#diode supplier#diode#electronics supplier#rectifiers#diodes#tvs diode#capacitors

0 notes

Text

.”I want more than to fight at your side, or sit around the campfire with you.”.

#bg3#baldurs gate 3#halsin#astarion#karlach#gale#tav#durge#tristan yarrow#owl bear cub#tav x halsin#halsin x tav#astarion x durge#durge x astarion#mxm#. alternatively tav - who used to be a clown finds out that Halsin has never seen a clown before and must immediately rectify it.#durge is just basic durge :*#alternatively two gale twigs that Tav is getting feelings for Halsin

4K notes

·

View notes

Text

PE 400/150/5 Protective Element for Enhanced Rectifier Performance

Discover the PE 400/150/5 protective element from Emco Precima, designed to connect parallel to rectifiers BGL, EGL, and SGL, enhancing interruption capacity with EMC compatibility and integrated spark quenching.

For more information visit our website: https://www.emcoprecima.com/

0 notes

Text

Understanding AC-DC Rectifiers: How They Work and Why They're Essential

A rectifier is an electrical device that crucially converts alternating current (AC) to direct current (DC). Rectifiers are found in nearly every electronic power supply, making them an essential component of modern technology. As we move into the future, exciting innovations and trends promise to revolutionize the field of rectification. With the advent of modular designs and more diminutive, high-frequency rectifiers, the future of rectification looks bright indeed.

Yonder is at the forefront of this revolution, pushing the boundaries of power conversion with its cutting-edge technology. Yonder's Thyristor Rectifiers has long been a reliable technology in AC-DC conversion, delivering unparalleled efficiency and consistency. These AC-DC rectifiers, available in configurations ranging from 6-pulse to 48-pulse, are designed for superior load current regulation and durability across various applications. Yonder's Thyristorised Converters are engineered to meet the demands of modern power systems, providing high efficiency and robust performance, ensuring that they remain a trusted choice for AC-DC conversion.

Our advanced DC-DC Rectifier, developed in collaboration with Ador, utilizes high-frequency IGBT switching and Phase Shift Modulation (PSM) technology. This allows for the conversion of constant DC to variable DC with minimal ripple, ensuring the smooth and efficient operation of hydrogen electrolysers. This system is particularly well-suited for direct solar-to-electrolyser connections, offering advanced performance while reducing the need for large filters.

So, what is an AC-DC Rectifier?

Let's dive in!

An AC-DC rectifier transforms the AC voltage from your power outlets into DC voltage. AC voltage, which alternates direction, is unsuitable for most electronic devices requiring a steady flow of electricity. The rectifier allows current to pass in only one direction, effectively converting the alternating current into a more stable, unidirectional flow using components like diodes. This conversion is essential for the proper functioning of DC-powered devices.

Types of Rectifiers

Rectifiers come in different types, each suited for specific applications:

Half-Wave Rectifier:

Uses a single diode to convert AC to DC.

It is simple but inefficient, as it only utilizes one-half of the AC cycle, resulting in a pulsating DC output.

Full-Wave Rectifier:

Utilizes two diodes and a center-tapped transformer, or four diodes in a bridge configuration, to convert both halves of the AC cycle into DC.

It is more efficient, providing a smoother DC output with fewer ripples.

Bridge Rectifier:

A popular type of full-wave rectifier that uses four diodes arranged in a bridge config#ACDC #Rectifiers #PowerConversion #Electronics #ElectricalEngineering #AdorPower #EfficientPower #TechSolutions #EnergyEfficiency #PowerSupplyuration.

Offers full-wave rectification without needing a center-tapped transformer, making it versatile and widely used.

How Rectifiers Convert AC to DC

Rectifiers use diodes and semiconductor devices that allow current to flow in only one direction. In a half-wave rectifier, the diode conducts during the positive half of the AC cycle, blocking the opposing half, resulting in a pulsating DC output. Full-wave rectifiers, however, utilize both halves of the AC cycle by inverting the opposing half and combining it with the positive half. This produces a smoother DC output, reducing the need for additional filtering. Bridge rectifiers enhance this process by configuring four diodes to ensure full-wave rectification, providing a consistent and efficient DC output.

Applications of Rectifiers

Rectifiers are used in various applications:

Consumer Electronics: Power supplies for TVs, radios, and computers.

Battery Charging Systems: Converting AC to DC for charging batteries in smartphones, laptops, and industrial battery banks.

Industrial Equipment: Providing DC power in welding equipment, motor drives, and electroplating processes.

Rectifiers' ability to efficiently convert AC to DC makes them indispensable in consumer electronics and industrial applications.

Advantages and Limitations

Advantages:

Efficient and reliable conversion of AC to DC.

Simple design, leading to high durability and low maintenance.

Relatively inexpensive and easy to implement.

Limitations:

Half-wave rectifiers are less efficient, utilizing only one-half of the AC cycle.

Pulsating DC output may require additional filtering for smooth operation in sensitive devices.

Full-wave and bridge rectifiers, while more efficient, are more complex and costly.

In a Nutshell

AC-DC rectifiers are fundamental to modern electrical systems, enabling the conversion of AC to DC power necessary for various electronic devices. Understanding how rectifiers work and the different types available is essential for anyone involved in electrical engineering or electronics. Whether for consumer electronics or industrial equipment, rectifiers ensure the reliable and efficient operation of DC-powered devices, making them an integral part of today's technological landscape. Innovations such as modular designs and compact, high-frequency rectifiers are pushing the boundaries of efficiency and performance.

As the world moves toward more sustainable and efficient power solutions, Yonder's innovations in rectification are paving the way for a brighter, more connected future.

Want to power your systems effectively and efficiently? Please email us at [email protected] to learn how our AC-DC rectifiers can help!

About the Author: Yonder, a division of the Ador Group, has been a leader in Power Electronics since 1908. Specializing in advanced Power Conversion Units for hydrogen generation, we integrate Alkaline, PEM, SOEC, and AEM electrolysers to ensure high efficiency and minimal power consumption. Headquartered in Mumbai with state-of-the-art facilities in Pune, Yonder is committed to global decarbonization. Our 500-MW manufacturing facility for hydrogen power sources is poised to deliver cutting-edge solutions that thrive in unique and demanding deployment contexts.

#ACDC#Rectifiers#PowerConversion#Electronics#ElectricalEngineering#AdorPower#EfficientPower#TechSolutions#EnergyEfficiency#PowerSupply

0 notes

Text

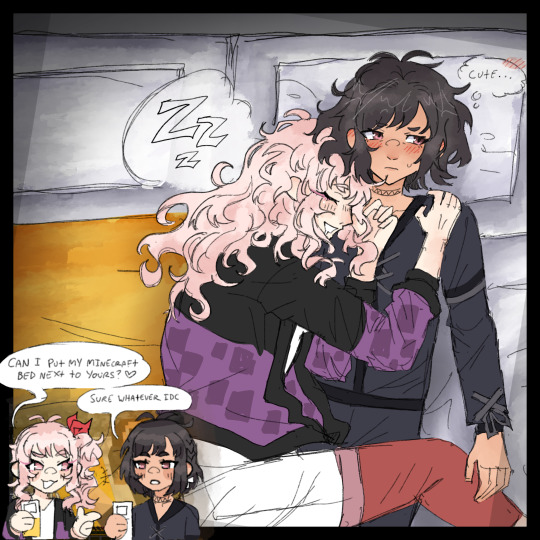

so uhh. how about that minecraft stream.

references under cut :3

mizuena fans are eating good tn… FYM THEY PUT THEIR BEDS NEXT TO EACH OTHER???????

and the constant bickering.. just kiss already 🥀

#just realized I never drew mafuyu#sigh#this will have to be rectified..#i definitely have more niigo minecraft in the oven#get ready.. because it is about to strike without notice.#anyways time for the actual tags#nightcord at 25:00#niigo#n25#kanade yoisaki#ena shinonome#mizuki akiyama#mizuena#pjsk#minecraft#beautiful glorious yuri#yurika!

692 notes

·

View notes

Text

objective: interspecies communication. status: successful [prints]

#mass effect#shakarian#commander shepard#garrus vakarian#Shepard x garrus#femshep#mass effect fanart#video games#art#alien#illustration#artists on tumblr#I almost called this blue is the warmest color LMFAO#ive never drawn them kissing before can you believe it? rectified now#I'll leave the logistics up to you... maybe she's on a really tall box. maybe she's got her legs wrapped around his waist :-)#milkyart

4K notes

·

View notes