#recycled paperboard products

Text

#paper industry#paper-based products#top 10 paper companies in India#ITC Limited#RBR PAPER LLP#Ballarpur Industries Limited (BILT)#Tamil Nadu Newsprint and Papers Limited (TNPL)#West Coast Paper Mills Limited#Emami Paper Mills Limited#International Paper APPM Limited#Seshasayee Paper and Boards Limited#JK Paper Limited#NR Agarwal Industries Limited#Paper Mill#Paper Manufacturer#Paper Exporter#paper manufacturing#Printing papers#recycled paperboard products#papemillinindia

0 notes

Text

I've been working on a doll house. Sort of. It's an old Barbie house that was missing a lot of parts.

One of the things I've done is build new parts out of paperboard and foam board, and then cover them in paper.

You know, and I know, that when you get paper wet with glue it wrinkles. There are a few ways to get around this.

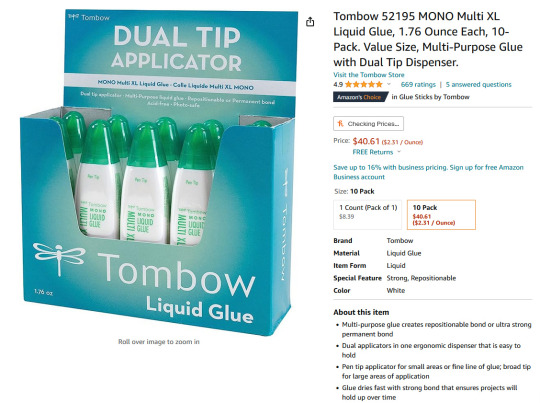

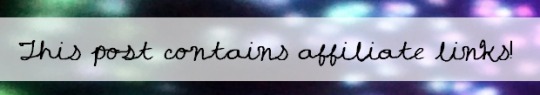

One is Tombow Mono Multi glue.

Which is here: https://amzn.to/3OU5tbv

The trick to using this glue for wrinkle-free paper application is to squeeze out a bunch of glue not on the paper, but on what you want to put paper on, smooth it out as well as you can (make sure you get the surface you're wanting to apply paper to completely covered) and then let it dry until it's transparent. It'll stay tacky.

Then apply your paper and smooth it out.

That's how I applied scrapbook paper directly to the plastic wall as wallpaper, and colored printer paper (which is very prone to wrinkles when wet) to both paperboard (recycled food box) and foam board to create the refrigerator door and a curio cabinet.

I find the Tombow Mono Multi is less prone to wrinkling than glue sticks, too, as long as you let the Mono Multi dry fully before applying paper.

Tombow Mono Multi can also be applied to the back of plastic-coated stickers that have lost their stickiness, like the ones that are default to this doll house, and then those stickers can be reapplied.

It's worth noting that you don't get a second chance with this glue. Once you've stuck something, it's not coming off cleanly. If you put the paper on wrong it'll tear to bits if you try to peel it off again. Tombow Mono Multi is very good at sticking.

-

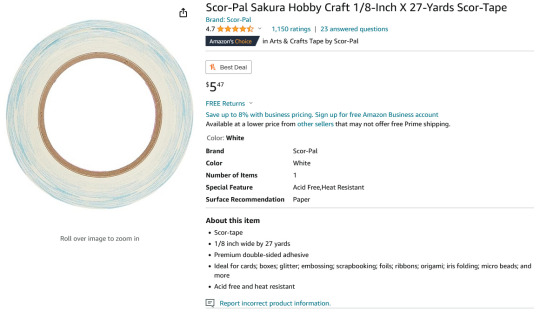

Another option is double sided tape. If you're going to be doing something like gluing shelves to the paper covering, then full coverage adhesion is better, like with the Tombow.

If you're doing a decorative or small item (in this case, the faux drawer fronts on the curio cabinet), then double sided tape is a great option with no drying time.

I like this one, because it's the same width as the foam layer between the sheets of paper on foam board and because it's easy to remove from plastic toys.

And that's here: https://amzn.to/3s8BELl

I like to use this to stick small decorative items to the shelves, too. It's easy to remove from plastic surfaces, but it can rip the paper like I have on the curio cabinet.

Every deco item in the doll house has a little bit of this tape on it to keep it in place but I can remove and reposition those items as I wish.

I learned about both of these products watching people make those little room box kits years ago. You know those little bitty fabric things you're supposed to sew or use a wet glue to adhere and then wait for it to dry? This tape is an excellent alternative to that, too.

Like this kit, for example (https://amzn.to/3YCLz7Z), I would use Tombow Mono Multi to apply the wallpaper so it would go on nice and smooth, then use double-sided tape to put the fabric on the chair, adhere the table cloth, and make the little pillow.

82 notes

·

View notes

Text

Duplex Board Paper Manufacturer

Duplex paper board, also known as duplex board, is a type of paperboard or cardboard that is widely used for packaging and printing purposes. It is made by combining two layers of paper, typically made from recycled fibers, with a layer of adhesive in between. This results in a material that is strong, durable, and versatile, making it suitable for a wide range of applications.

In India, the manufacture of duplex paper board has been growing steadily in recent years. The country has seen an increase in demand for packaging materials due to the booming e-commerce industry, as well as the growth of various other industries such as food and beverage, pharmaceuticals, and consumer goods. This has led to a greater need for high-quality packaging materials, including duplex paper board.

One of the key advantages of duplex paper board is its strength and rigidity, which makes it ideal for packaging heavy or fragile items. It also provides a smooth and consistent surface for printing, making it suitable for a wide range of printing and graphic applications. Additionally, duplex paper board is often coated to improve its surface properties, such as smoothness and gloss, further enhancing its suitability for printing and packaging.

The manufacture of duplex paper board in India involves several key processes, including pulping, refining, blending, and coating. The raw materials used in the production of duplex paper board are typically sourced from recycled paper and cardboard, making it an environmentally friendly choice. The manufacturing process also involves the use of advanced machinery and technology to ensure the consistent quality of the final product.

In recent years, the Indian government has also been promoting the use of eco-friendly and sustainable packaging materials, which has further contributed to the growth of the duplex paper board industry in the country. This has led to an increased focus on using renewable resources and reducing the environmental impact of packaging materials, making duplex paper board an attractive option for businesses looking to align with these sustainability goals.

With its strength, versatility, and environmental benefits, duplex paper board is well-positioned to continue being a key player in the packaging and printing industry in India. As the market continues to evolve, it is expected that the manufacture of duplex paper board will continue to thrive and contribute to the country's growing economy.

2 notes

·

View notes

Text

The Impact of Eco-Friendly Legislation on Mono Cartons: A New Era for Packaging

In recent years, eco-friendly legislation has significantly transformed industries, with the packaging sector being one of the most affected. For Miracle Group, a leading packaging manufacturing company, these changes present both challenges and opportunities. As one of the top Mono Carton Manufacturers, Miracle Group has adapted its processes and materials to meet the growing demand for sustainable packaging solutions.

What Are Mono Cartons?

Mono cartons are widely used for packaging various products, particularly in sectors such as pharmaceuticals, cosmetics, and food & beverages. These cartons are made from a single type of material, typically paperboard, making them easier to recycle compared to other forms of packaging that use mixed materials. As a Mono Carton Box Manufacturer, Miracle Group offers a variety of mono carton packaging options that cater to different industries, while ensuring high-quality standards and eco-friendly practices.

Eco-Friendly Legislation and Its Impact

With increasing concerns about environmental sustainability, governments worldwide have been implementing stringent regulations aimed at reducing waste and promoting recyclable packaging materials. For instance, several countries have introduced laws that limit the use of plastic and non-recyclable materials, encouraging manufacturers to switch to paper-based alternatives like mono cartons.

The impact of these regulations on mono carton box manufacturing has been substantial. Companies like Miracle Group have had to innovate by adopting greener manufacturing processes, utilizing sustainable raw materials, and improving the recyclability of their products. This has helped Carton Box Manufacturers in Jaipur like Miracle Group not only comply with legal requirements but also stay ahead in an increasingly eco-conscious market.

The Benefits of Mono Carton Packaging

Sustainability: Since mono cartons are primarily made from paperboard, they are biodegradable and recyclable. This significantly reduces the environmental impact and meets the requirements of eco-friendly legislation.

Cost-Effectiveness: The use of sustainable materials can often lead to cost savings in the long run, especially as consumers and governments push for more affordable, eco-friendly packaging.

Brand Image: For businesses that use mono carton packaging, adopting sustainable practices can enhance their brand image, making them more appealing to eco-conscious consumers. Miracle Group’s clients have reported improved customer perception after switching to greener packaging solutions.

Compliance: By using mono cartons, companies can ensure compliance with various international and national environmental standards, avoiding potential fines or penalties associated with non-compliance.

Challenges Faced by Mono Carton Manufacturers

While the shift towards eco-friendly packaging offers numerous benefits, it also presents several challenges for Mono Carton Box Manufacturers. The cost of sourcing sustainable raw materials can be higher, and the manufacturing process may require new technology and investments. Moreover, maintaining the durability and visual appeal of packaging while adhering to environmental standards can be tricky.

For Carton Box Manufacturers in Jaipur like Miracle Group, the focus has been on finding a balance between sustainability and functionality. Through continuous research and development, Miracle Group has managed to overcome these challenges, offering its clients mono carton solutions that are both environmentally friendly and cost-effective.

The Future of Mono Carton Packaging

As the push for sustainability intensifies, the demand for eco-friendly packaging solutions like mono cartons is expected to grow. Companies that can adapt to these changes, like Miracle Group, will be well-positioned to thrive in this new landscape. As one of the leading Mono Carton Manufacturers, Miracle Group is committed to producing packaging solutions that meet the needs of businesses while adhering to environmental legislation.

In conclusion, eco-friendly legislation has had a profound impact on the packaging industry, particularly for mono carton packaging. By embracing sustainability and innovation, Mono Carton Box Manufacturers like Miracle Group can not only comply with new regulations but also take advantage of the growing demand for green packaging solutions. The future of packaging lies in the ability to balance functionality, cost, and environmental responsibility—and Miracle Group is at the forefront of this transformation.

0 notes

Text

The Role of Packaging in Enhancing Ice Cream Quality and Consumer Experience

Ice cream packaging is much more than just a container for a frozen treat. It serves multiple purposes, from protecting the product’s quality to ensuring that it reaches consumers in perfect condition. As competition grows in the ice cream industry, packaging has become an integral part of a brand’s identity and the overall consumer experience.

1. Packaging as a Quality Preserver

The primary function of Ice Cream Packaging is to preserve the quality of the product from production to consumption. Ice cream is a delicate product that is vulnerable to temperature fluctuations, air exposure, and moisture. Poorly designed or inadequate packaging can compromise the texture, flavor, and overall quality of the ice cream.

Preventing Freezer Burn: Freezer burn is a common issue that occurs when ice cream is exposed to air. It causes the formation of ice crystals on the surface of the product, resulting in a gritty texture and off-flavors. High-quality packaging materials with excellent barrier properties are essential in preventing air from reaching the ice cream. This includes the use of plastic films or coatings that effectively seal the container and block moisture.

Maintaining Temperature Stability: Temperature fluctuations during transportation or storage can cause ice cream to melt and refreeze, leading to undesirable changes in texture. Packaging materials with insulating properties, such as double-walled containers or foam inserts, help maintain a consistent temperature and prevent heat from reaching the product. This ensures that the ice cream remains smooth and creamy when it’s finally consumed.

2. Materials Used in Ice Cream Packaging

The choice of packaging material is critical for maintaining the integrity of the ice cream while also considering environmental impact. Traditionally, ice cream packaging has relied heavily on plastic and paperboard, but new developments in sustainable materials are shaping the future of the industry.

Plastic: Plastics are commonly used in ice cream tubs, lids, and single-serve containers due to their flexibility, durability, and excellent barrier properties. However, concerns about plastic waste have led manufacturers to seek more sustainable alternatives. Some companies are transitioning to bio-based plastics that are derived from renewable resources such as cornstarch or sugarcane.

Paperboard: Paperboard is a popular material for ice cream cartons and tubs. It is lightweight, easy to print on, and provides adequate protection when coated with plastic or wax. Paperboard is also recyclable, making it a more eco-friendly option compared to traditional plastics. Many companies are now exploring ways to reduce or eliminate plastic coatings on paperboard to improve recyclability.

Aluminum Foil: Some premium ice cream brands use aluminum foil in combination with other materials to enhance the barrier properties of their packaging. Aluminum is an excellent barrier to light, oxygen, and moisture, making it ideal for preserving the flavor and texture of high-end ice creams. However, aluminum packaging is not widely used due to its higher cost and recyclability challenges.

3. Designing for the Consumer Experience

Beyond preserving product quality, ice cream packaging also plays a critical role in shaping the consumer experience. Packaging design can influence a consumer’s perception of the product, their purchasing decisions, and their overall satisfaction.

Aesthetic Appeal: Packaging is often the first interaction a consumer has with a product, so it’s important that it stands out on the shelf. Attractive designs, vibrant colors, and bold branding can help ice cream products grab attention and communicate the brand’s personality. For artisanal and premium ice creams, minimalist or eco-friendly designs can convey a sense of luxury and craftsmanship.

Convenience: Today’s consumers value convenience, and ice cream packaging must reflect that. Features like resealable lids, easy-to-open containers, and single-serve portions enhance the user experience and add to the product’s appeal. Single-serve containers are particularly popular for on-the-go consumption, while larger tubs benefit from resealable lids that help maintain freshness.

Portion Control: With an increasing focus on health and wellness, many consumers are seeking portion-controlled options to enjoy their favorite treats without overindulging. Packaging that offers smaller portions or clearly communicates the serving size can appeal to health-conscious customers. Miniature ice cream tubs or individually wrapped ice cream bars are excellent solutions for those who want to enjoy ice cream in moderation.

4. The Rise of Sustainable Packaging

As environmental concerns grow, sustainable packaging has become a top priority for many ice cream manufacturers. Consumers are increasingly looking for eco-friendly packaging that minimizes waste and reduces the environmental impact of their purchases. Brands that embrace sustainability are more likely to gain the loyalty of environmentally conscious consumers.

Recyclable and Biodegradable Packaging: One of the most common approaches to sustainable packaging is the use of recyclable materials such as paperboard, certain plastics, and aluminum. Biodegradable materials, made from renewable resources like cornstarch, are also gaining popularity as they break down more quickly than traditional plastics. However, the challenge lies in ensuring that these materials are widely accepted by recycling or composting facilities.

Reduced Material Use: Many companies are working to reduce the amount of material used in their packaging without compromising its effectiveness. This process, known as lightweighting, can lower production costs and reduce the environmental impact of shipping. For example, thinner plastic films or lighter paperboard cartons can achieve the same protective benefits while using less material.

Reusable Packaging: Some brands are experimenting with reusable packaging solutions that allow customers to return containers for refills. While this model is still in its early stages, it has the potential to significantly reduce the amount of single-use packaging waste generated by the ice cream industry. Reusable packaging is particularly appealing to eco-conscious consumers who want to reduce their environmental footprint.

5. Innovative Packaging Technologies

As technology advances, we’re seeing the emergence of smart packaging solutions that enhance both the preservation of ice cream and the consumer experience. These innovations are poised to revolutionize the way ice cream is packaged, stored, and consumed.

Temperature Indicators: Smart packaging with temperature indicators can help consumers and retailers monitor the freshness of the product. These indicators change color or display a message when the ice cream has been exposed to temperatures outside the optimal range, providing real-time information about the product’s condition. This feature can be particularly useful for preventing spoilage during transportation and storage.

Interactive Packaging: Some brands are incorporating digital elements into their packaging, such as QR codes that link to recipes, product information, or brand stories. These interactive features enhance the consumer experience by providing added value beyond the product itself. For artisanal or premium ice creams, this can be a way to connect with consumers on a deeper level and build brand loyalty.

Ice cream packaging plays a pivotal role in maintaining product quality, enhancing the consumer experience, and addressing environmental concerns. From choosing the right materials to designing for convenience and sustainability, manufacturers must carefully consider every aspect of their packaging to meet the needs of today’s discerning consumers. As technology and consumer preferences evolve, the future of ice cream packaging will likely see continued innovation, with an increasing focus on sustainability, convenience, and smart packaging solutions.

Get More Insights on Ice Cream Packaging

Missing comfort of reading report in your local language? Find your preferred language :

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author-

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Ice Cream Packaging#Packaging#external contaminants#quality#ice cream#cold temperatures#coherent market insights

1 note

·

View note

Text

Keep Your Eggs Secure with Poultry Cartons' Premium Packaging

In the poultry industry, egg safety and durability are paramount. Whether you're a large-scale egg producer or a small farm, keeping your eggs secure from the moment they leave the farm until they reach the consumer is critical. At Poultry Cartons, we understand the unique challenges that come with ensuring egg cartons and are proud to offer premium packaging solutions that meet the highest standards of quality, durability, and environmental responsibility.

The Importance of Secure Egg Packaging

Eggs are delicate, natural products that require careful handling at every stage of transportation. Without the right packaging, eggs are susceptible to cracking and breaking, leading to loss of product, diminished profits, and customer dissatisfaction. This is why choosing the right packaging solution is essential for protecting your business interests and maintaining a loyal customer base.

At Poultry Cartons, our packaging solutions are designed to offer maximum protection against physical damage, moisture, and external contaminants, ensuring your eggs arrive at their destination in perfect condition. Our premium cartons are made from high-quality materials, engineered to provide superior protection against the stresses of transportation and storage.

Innovative Design for Enhanced Durability

The design of our egg cartons is centered on one core principle: durability. Poultry Cartons’ packaging is engineered to withstand even the roughest handling during transportation. The strategically reinforced structure ensures that the cartons can endure impacts without compromising the integrity of the eggs inside.

Our cartons feature secure compartments that cradle each egg, distributing weight evenly and minimizing the risk of damage from movement. These compartments are designed to provide airflow, preventing the buildup of moisture which could otherwise lead to egg spoilage or deterioration.

Furthermore, we utilize shock-absorbent materials in our cartons, protecting your eggs from the inevitable bumps and jolts that occur during transit. Whether your eggs are being shipped locally or internationally, our packaging solutions will keep them safe from harm.

Eco-Friendly and Sustainable Packaging Options

In today's world, sustainability is more important than ever. Poultry Cartons is committed to providing environmentally friendly packaging options that help reduce your carbon footprint while still offering exceptional protection for your eggs. Our cartons are made from 100% recyclable materials, including biodegradable paperboard and post-consumer recycled materials.

By choosing Poultry Cartons, you're not only safeguarding your product but also supporting environmentally responsible business practices. Our eco-friendly cartons are designed to minimize waste, ensuring that your packaging aligns with the growing consumer demand for sustainable, planet-friendly solutions.

Customizable Packaging for Your Brand

At Poultry Cartons, we understand that packaging is also a powerful branding tool. That's why we offer customizable packaging solutions to meet the specific needs of your business. Whether you want to highlight your farm's organic practices, showcase your commitment to sustainability, or promote a unique feature of your product, our design team can work with you to create packaging that aligns with your brand's values and resonates with your customers.

From the color scheme to the logo placement, every aspect of your customized packaging can be tailored to ensure maximum visibility and impact. By choosing our premium packaging, you're not only protecting your eggs but also enhancing your brand's presence in the marketplace.

Protection Beyond the Carton: Safe and Secure Shipping

Shipping is a critical phase in the journey from farm to table, and it's where eggs are most vulnerable to damage. Poultry Cartons takes this into account by providing additional protective measures for large-scale shipping. For bulk orders, we offer reinforced packaging layers and protective dividers that ensure the safety of eggs during long-haul transport.

Our cartons are stackable and designed to maintain structural integrity even under the weight of multiple layers. This ensures that whether you're shipping small batches or entire pallets of eggs, you can trust Poultry Cartons to provide unmatched durability.

Maximizing Shelf Appeal with Attractive Designs

In addition to providing protection, Poultry Cartons’ packaging is designed to enhance shelf appeal. Consumers often make purchasing decisions based on the appearance of packaging, and our cartons are designed to stand out on the store shelves. Our cartons combine aesthetic appeal with functionality, ensuring that they not only protect the product but also attract attention.

With vibrant printing options and the ability to showcase your brand's unique story, our packaging solutions give you an edge over competitors. Eye-catching designs combined with clear, concise messaging can help communicate the quality of your eggs and the care that went into producing them.

Regulatory Compliance and Food Safety

At Poultry Cartons, we take food safety seriously. Our packaging solutions comply with international food safety standards and regulations to ensure that your eggs remain safe and uncontaminated. We work closely with regulatory bodies to stay up to date with the latest safety requirements, ensuring that our cartons provide a secure environment for your product.

Each carton undergoes rigorous testing to ensure that it meets the highest standards of hygiene and safety. From the production process to the final product, we maintain strict quality controls to ensure that every carton leaving our facility is capable of protecting your eggs from harmful contaminants.

Partner with Poultry Cartons for Secure and Sustainable Egg Packaging

At Poultry Cartons, we are dedicated to providing innovative packaging solutions that meet the evolving needs of the poultry industry. Whether you are a small farm or a large-scale producer, our premium packaging ensures that your eggs are delivered to consumers safely and securely. With a focus on durability, sustainability, and customizability, Egg Cartons is your trusted partner for protecting your product and promoting your brand.

If you're looking to enhance the safety of your eggs, reduce packaging waste, and improve your brand's visibility, look no further than Poultry Cartons' premium packaging solutions.

0 notes

Text

Global Cup Sleeves Market Share, Size, Analysis, Growth, Industry Statistics and Forecast 2034

Global Cup Sleeves Market Outlook 2034

The Global Cup Sleeves Market is predicted to develop at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2034, when it is projected to reach USD 47,586.69 Million in 2034, based on an average growth pattern. The market is estimated to reach a value of USD 32,783.74 Million in 2024. Consumer tastes and shopping behaviors have been greatly impacted by the growing global focus on sustainability and environmental preservation. As environmental concerns continue to rise, consumers are becoming more aware of how their decisions affect the environment. Consumer tastes have shifted in favor of eco-friendly and sustainable products as a result of this increased knowledge, including packaging options like cup sleeves.

Request Sample Pdf Copy: https://wemarketresearch.com/reports/request-free-sample-pdf/cup-sleeves-market/1569

Furthermore, the growth of the Global Cup Sleeves Market industry has been greatly aided by the spike in takeout orders for both hot and cold beverages. Cup sleeves are becoming more and more necessary as consumers choose takeout choices in order to protect these drinks from burns and to act as insulation. Additionally, the demand for paper cups and, by extension, cup sleeves as a more sustainable option, has increased due to regulatory authorities' tough restrictions on the use of plastics and rising environmental consciousness.

Key Dynamics of the Global Cup Sleeves Market

The Impact of Cup Sleeves on Safety, Insulation, and Branding

The invention of the coffee sleeve has had a significant effect on the coffee business. For many coffee lovers, the sleeve which is meant to shield their hands from the heat of a steaming cup of coffee is now an indispensable component of the take out experience. Also, because the cup sleeve keeps hands from burning, customers may enjoy their coffee without worrying about burns or scalds. Because they add another layer of insulation and maintain drinks' heat for extended periods of time, cup sleeves are becoming more and more popular.

Global Cup Sleeves Market Opportunity

Sustainable materials make cup sleeves an eco-conscious choice.

The popularity of sustainable cup sleeves is mostly due to eco-friendly materials. Because these sleeves have a reduced environmental impact, consumers are choosing more and more ones made of compostable, biodegradable, or recycled materials. These environmentally friendly decisions support a circular economy and help cut down on waste in general.

Drivers

Rising Demand for Takeaway Beverages

A major factor driving the cup sleeve market is the rising demand for takeout drinks, especially coffee. Clients are choosing on-the-go choices more frequently due to hectic schedules and changing lifestyles. Demand for takeout has increased, and this includes drive-through and online delivery options. Because they insulate and shield hot and cold liquids from damage while in transit, cup sleeves are an essential component of this trend. The need for Global Cup Sleeves Market in the is driven by their comfort and convenience, which have made them a necessary accessory for takeout beverages.

Restraint

Presence of Substitutes/Alternatives Such as Double-Walled Cups

According to some manufacturers, double-walled cups may successfully maintain a warmer temperature for extended periods of time without requiring a cup sleeve. Although double-wall cups offer more insulation and other unique benefits, cup sleeves present chances for branding. Offering unique temperature-controlled behaviors, embossing, spot colors, and other appealing features, these cups may be a more cost-effective choice than standard cups with sleeves. For little quantities and quick runs, double wall cups are inexpensive, easily accessible, and have short lead times.

Global Cup Sleeves Market Segmentation:

By Material

Paperboard/ Cardboard

Plastic

Foam

Rubber

Others

By Product Type

Shrink Sleeve

Protective Sleeve

By End-use

Food & Beverage Industry

Hotels & Restaurants

Cafes & Kiosks

Quick-Service Restaurants

Canteens

Key Market Players

Printed Cup Company

Trident Paper Box Industries

Graphic Packaging International, LLC

BriteVision Media, LLC

HotShot Coffee Sleeves USA

LBP Manufacturing LLC

Pactiv LLC

Novolex

Sabert Corporation

Starbucks Corporation

Other

What is Primarily Driving the Market for Cup Sleeves?

The way individuals enjoy their favorite foods and beverages has been completely transformed by the rise and quick development of online meal delivery services. Because buying food online and having it delivered right to your door is so convenient, more and more customers are choosing takeout and delivery choices, particularly for hot and cold beverages like coffee and tea. There has been a notable increase in the need for dependable and effective packaging options, such as cup sleeves.

Global Cup Sleeves Market Industry: Regional Analysis

North America Market Forecast

With over 37% of the market share in 2023, North America leads the world market for cup sleeves. The greatest market for cup sleeves is in North America, specifically in the United States and Canada. The increasing consumption of hot beverages like coffee, the existence of large international coffee chains like Dunkin' Donuts and Starbucks, and the robust demand from consumers for convenience items are the main causes of this domination. Furthermore, the use of paperboard and cardboard cup sleeves has increased due to growing sustainability consciousness and consumer demand for environmentally friendly packaging.

Conclusion

The global Global Cup Sleeves Market is a vibrant and evolving sector with substantial growth prospects. From environmental sustainability to innovative designs and branding opportunities, cup sleeves play a crucial role in modern packaging. Staying informed about Global Cup Sleeves Market trends and consumer preferences will help businesses and consumers make informed decisions and embrace the future of cup sleeves.

#industry#business#Global Cup Sleeves Market Share#Global Cup Sleeves Market Demand#Global Cup Sleeves Market Scope#Global Cup Sleeves Market Analysis#Global Cup Sleeves Market Trend

0 notes

Text

What material is used for packaging box?

Materials Used for Packaging Boxes

When selecting materials for packaging boxes, the choice largely depends on the type of product, required durability, and cost considerations. A Packaging Boxes Manufacturer and Supplier in Lagos typically works with several key materials to meet diverse packaging needs. Here’s a breakdown of commonly used materials:

1. Corrugated Cardboard

Structure: Consists of a fluted layer sandwiched between two linerboards. This construction provides strength and cushioning.

Uses: Ideal for shipping and storage, commonly used for shipping boxes, moving boxes, and product packaging.

Benefits: Offers excellent protection, is cost-effective, and can be recycled.

2. Paperboard

Structure: A single layer of thick paper, often used for lightweight packaging.

Uses: Commonly used for cereal boxes, cosmetic packaging, and small product packaging.

Benefits: Lightweight, easily customizable, and often used for retail packaging due to its good printability.

3. Kraft Paper

Structure: Made from wood pulp through a chemical process, known for its strength and durability.

Uses: Used for both inner and outer packaging, such as wrapping paper, paper bags, and protective liners.

Benefits: Eco-friendly, biodegradable, and provides a natural, rustic look.

4. Plastic

Types: Includes polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), among others.

Uses: Used for flexible packaging, blisters, and clamshells. Ideal for items that require a clear view or a seal-tight package.

Benefits: Water-resistant, durable, and versatile. Can be customized in terms of thickness, color, and finish.

5. Metal

Types: Includes aluminum and tin.

Uses: Commonly used for high-end product packaging such as food tins, cosmetic containers, and specialty packaging.

Benefits: Provides excellent protection, is tamper-evident, and has a premium feel.

6. Glass

Types: Includes clear, colored, and frosted glass.

Uses: Used for packaging liquids like beverages, perfumes, and pharmaceuticals.

Benefits: Offers high protection, an upscale appearance, and is recyclable.

7. Biodegradable and Compostable Materials

Types: Includes materials like cornstarch-based plastics, mushroom-based packaging, and recycled paper products.

Uses: Suitable for eco-friendly packaging solutions.

Benefits: Reduces environmental impact, often used for products targeting eco-conscious consumers.

8. Foam

Types: Includes polyethylene foam, polyurethane foam, and expanded polystyrene (EPS).

Uses: Provides cushioning and protection for delicate items.

Benefits: Lightweight, shock-absorbent, and effective for protecting fragile goods during shipping.

Conclusion

A Packaging Boxes Manufacturer and Supplier in Lagos offers a variety of materials tailored to different packaging needs, from robust corrugated cardboard to sophisticated metal and glass options. Understanding the properties and benefits of each material helps businesses choose the most suitable packaging solution for their products, ensuring protection, presentation, and cost-effectiveness.

0 notes

Text

White Magnetic With Paper Insert Box

A "White Magnetic Box with Paper Insert" from Papers Gallery is typically a sleek and elegant packaging solution. These boxes are often used for luxury items, such as jewelry, cosmetics, or premium gifts.

Key Features

Magnetic Closure: The box is designed with a magnetic flap that ensures a secure closure. This feature provides easy access while keeping the contents protected.

High-Quality Material: Made from sturdy cardboard or paperboard, the box has a durable structure. The white finish offers a clean and elegant appearance, suitable for a variety of products.

Paper Insert: Inside the box, there is a paper insert, often custom-cut to fit specific items. This insert not only provides additional protection by keeping the contents from moving around but also enhances the presentation of the products inside.

Versatility: These boxes are versatile and can be used for packaging a wide range of items such as gifts, cosmetics, jewelry, electronics, and more. The minimalistic white design is suitable for any occasion or brand style.

Customization Options: The exterior and interior can often be customized with logos, patterns, or other design elements through printing techniques like embossing, debossing, foil stamping, or spot UV.

Eco-Friendly Options: Many manufacturers offer eco-friendly versions of these boxes using recycled materials and sustainable printing processes.

Uses

Gift Packaging: Ideal for gifting due to its luxurious look and feel.

Retail Packaging: Enhances the unboxing experience for customers, adding value to the purchase.

Storage: Can be used to store items securely and stylishly.

· Design: The box is primarily white, giving it a clean and sophisticated look. It has a magnetic closure, which adds to the convenience and security of the contents inside.

· Material: It is made from high-quality, rigid cardboard or paperboard, ensuring durability and a premium feel.

Visit Us At

G-603, JM Aroma, Sector 75, Noida-201301

25A, Amar Enclave, Behind Flipkart Best Price,

Ambala - Chandigarh Road, Zirakpur- 140603

93, SP Mukherjee Park, Tilak Nagar, New Delhi- 110018

Contact Us At

+91 (9996) 444 060

#detachable style#foldable style#collapsible#luxury boxes#rigid box- cardboard premium and luxury#corrugated#top-bottom#custom_box#magnetic lock box

1 note

·

View note

Text

The Growing Demand for Food Tray Sealers Market

Introduction

The Food Tray Sealer Market is thriving, driven by an increasing need for efficient food packaging solutions. These devices are essential for ensuring that food products remain fresh and safe for consumption by creating airtight seals around trays. With advancements in technology, a heightened focus on food safety and the rising popularity of convenience foods, the demand for food tray sealers is growing rapidly.

Market Overview

Food tray sealers are vital in the food packaging industry, designed to seal trays containing food to prevent contamination and extend shelf life. Whether in commercial kitchens, retail settings, or large-scale industrial facilities these sealers play a crucial role in maintaining the quality of perishable goods. The market for food tray sealers is expanding due to several factors, including the growth of the foodservice industry the retail sector's evolution and the increasing trend towards ready-to-eat meals.

Key Drivers of Market Growth

Technological Advancements: The food tray sealer market is experiencing a surge in innovation. Modern sealers come equipped with advanced features like adjustable sealing temperatures and faster processing times. Automation is also playing a significant role, with automated sealing mechanisms reducing labor costs and improving efficiency.

Rising Demand for Convenience Foods: The appetite for convenience foods, such as ready-to-eat meals and pre-packaged snacks, is fueling the demand for effective packaging solutions. Food tray sealers are integral to ensuring these products are securely sealed, preserving their freshness and extending their shelf life.

Increased Focus on Food Safety and Hygiene: In an era where food safety is paramount, reliable packaging methods are more crucial than ever. Food tray sealers create a barrier against external contaminants helping to maintain the integrity of food products and meeting stringent hygiene standards.

Expansion of the Foodservice Industry: The growth of the foodservice industry, encompassing restaurants, catering services, and food delivery businesses, is driving the need for efficient packaging solutions. Food tray sealers are essential for packaging meals and ensuring they reach consumers in optimal condition.

Environmental Considerations: There is a growing trend towards sustainable packaging solutions. Food tray sealers are evolving to accommodate eco-friendly materials, such as recyclable and biodegradable trays, aligning with global efforts to reduce environmental impact.

Market Segmentation

By Type:

Manual Food Tray Sealers: These are ideal for small-scale operations. They offer flexibility and ease of use making them suitable for businesses with lower volume requirements.

Semi-Automatic Food Tray Sealers: A middle ground between manual and fully automatic options, these sealers are perfect for medium-sized operations, providing efficiency with a balance of automation.

Fully Automatic Food Tray Sealers: Designed for high-volume production, these sealers come with advanced features like automatic tray loading and sealing. They help reduce labor costs and increase overall efficiency.

By Application:

Retail Packaging: In retail settings like supermarkets and convenience stores, food tray sealers ensure that products are neatly packaged and protected for consumer purchase.

Foodservice Packaging: For restaurants, catering services, and food delivery businesses, food tray sealers maintain food quality and presentation, crucial for customer satisfaction.

Industrial Packaging: In large-scale food processing and manufacturing facilities, these sealers handle high volumes and are built for durability and efficiency.

By Material:

Plastic Trays: Versatile and cost-effective, plastic trays are commonly used due to their compatibility with various sealing technologies and good barrier properties.

Paperboard Trays: With a focus on sustainability, paperboard trays are increasingly used for their biodegradable and recyclable attributes, aligning with eco-friendly packaging trends.

Aluminum Trays: Known for their durability and excellent barrier properties, aluminum trays are used where extended shelf life and protection against external factors are required.

Geographic Insights

The demand for food tray sealers varies by region, influenced by factors such as industrial growth and consumer preferences:

North America: The United States and Canada are significant markets, driven by a robust foodservice industry and high consumer demand for convenience foods. The region is known for its focus on technological innovation and strict food safety standards.

Europe: Countries like Germany, the United Kingdom, and France are key players in the European market. Growth here is driven by increasing consumer awareness of food safety and the rising demand for sustainable packaging solutions.

Asia-Pacific: In China, India and Japan, rapid industrialization and urbanization are contributing to the growing demand for food tray sealers. The region is seeing significant expansion in the foodservice sector and a growing appetite for convenience foods.

Latin America: The market in Latin America is expanding with growth fueled by increasing consumer spending and a heightened focus on food safety and hygiene.

Conclusion

The food tray sealer market is set to continue its growth over the next five years. Driven by technological advancements, a rising demand for convenience foods, and an increasing emphasis on food safety and sustainability, the market is evolving to meet the needs of both consumers and businesses. As the food packaging industry progresses, innovations in food tray sealing technology will be crucial in ensuring that food products remain fresh, safe and appealing to customers.

Browse For More Information :

Innovations and Growth Trends in the Air Pollution Control Systems Market

Turbo Expander Market Dynamics: Trends, Opportunities and Forecasts

Scraped Surface Heat Exchangers Market Insights: Key Trends and Future Outlook

Hot Runner Controllers Market Developments and Future Prospects

Rupture Disc Market Analysis: Growth Drivers and Emerging Trends

3D Scanners Market Trends: Innovations, Applications and Market Forecast

Exploring the Glass Lined Reactor Market: Opportunities and Trends

Floating Docks Market Overview, Trends, and Growth Predictions

Wire Wedge Bonder Equipment Market: Analysis, Innovations and Growth Forecast

1 note

·

View note

Text

Protective Packaging Market worth $44.5 billion by 2028

The report "Protective Packaging Market by Material (Foam Plastics, Paper & Paperboard, Plastics), Type (Flexible Protective Packaging, Rigid Protective Packaging, Foam Protective Packaging), Function, Application, and Region - Global Forecast to 2028", is projected to grow from USD 33.3 billion in 2023 to USD 44.5 billion by 2028 at a CAGR of 5.9%.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=39055502

Protective packaging is utilized across various industries to safeguard products during transportation, storage, and handling, preventing damage, breakage, or contamination. It encompasses a wide range of materials and solutions, including foam plastics, flexible packaging, corrugated boxes, and cushioning materials, tailored to meet the specific needs of different products and industries. As the global economy continues to expand and e-commerce gains prominence, the demand for protective packaging is on the rise. Market growth is fueled by factors such as increasing consumer reliance on online shopping, stringent regulations regarding product safety, and the growing awareness of sustainability and environmental concerns.

By Material, paper & paperboard is expected to be fastest growing segment during the forecast period

Advancements in paper manufacturing technology have improved the strength, durability, and versatility of paper-based protective packaging products. Modern paper and paperboard materials are engineered to provide robust protection for a wide range of products, including fragile items, electronics, and perishable goods. Innovations such as corrugated cardboard with enhanced crush resistance, paper-based cushioning materials with superior shock absorption properties, and water-resistant coatings have expanded the applicability of paper-based protective packaging across various industries, driving its rapid growth in the market.

By Type, flexible protective packaging is expected to be fastest-growing segment during the forecast period

Advancements in material science and manufacturing technologies have enhanced the performance and sustainability of flexible packaging solutions. Innovations such as high-barrier films, recyclable laminates, and compostable materials have addressed concerns regarding product safety, shelf life, and environmental impact. With increasing emphasis on sustainability and circular economy principles, flexible packaging offers a compelling solution, providing manufacturers and consumers alike with environmentally friendly alternatives to traditional packaging materials. As consumer preferences continue to evolve, driven by sustainability concerns and convenience-driven lifestyles, the demand for flexible protective packaging is expected to sustain its rapid growth trajectory, further solidifying its position as a dominant force in the protective packaging market.

The cushioning is expected to experience significant growth during the forecast period.

Advancements in technology have led to the development of more efficient and versatile cushioning solutions that offer superior protection while optimizing packaging efficiency. From air pillows and paper-based void fillers to molded pulp and biodegradable foam alternatives, there is a wide range of cushioning options available to suit various packaging needs. These innovative cushioning materials are designed to provide customizable protection tailored to the specific requirements of different products, ensuring optimal performance and cost-effectiveness. As companies strive to enhance their packaging strategies to meet evolving consumer demands and industry standards, the demand for effective cushioning solutions is expected to continue driving growth in the protective packaging market, making it a key focus area for innovation and investment in the years to come.

By Application, Consumer electronics is expected to experience significant growth during the forecast period.

The rise of e-commerce has transformed the way consumers purchase electronics, with online retailers accounting for a significant portion of electronic sales worldwide. The convenience of online shopping has driven a surge in demand for protective packaging solutions that can withstand the rigors of shipping and delivery. With consumers expecting fast and reliable delivery of their electronics purchases, retailers and manufacturers must invest in protective packaging that provides adequate cushioning, shock absorption, and moisture resistance to protect valuable electronic goods throughout the supply chain. As e-commerce continues to grow, the demand for protective packaging tailored to the unique requirements of electronic devices is expected to skyrocket, driving further growth in this segment of the market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=39055502

Asia Pacific is the largest market during the forecast period.

The increasing focus on sustainability and environmental responsibility has prompted companies in Asia Pacific to seek out eco-friendly packaging alternatives. As a result, there has been a growing demand for protective packaging materials that are recyclable, biodegradable, and environmentally friendly. Governments and regulatory bodies across the region are also implementing initiatives to promote sustainable packaging practices, further driving the adoption of eco-friendly protective packaging solutions. With these factors combined, the Asia Pacific region is poised to maintain its position as the fastest-growing market for protective packaging, presenting significant opportunities for manufacturers and suppliers to capitalize on the region's dynamic growth trajectory.

Key Players

The leading players in the protective packaging market are Smurfit Kappa Group (Ireland), Sealed Air (US), Sonoco Products Company (US), Crown Holdings Inc. (US), DS Smith plc (UK), PREGIS LLC (US), Intertape Polymer Group Inc. (US), Pro-Pac Packaging Ltd. (Australia), Storopack Hans Reichenecker GmbH (Germany), Ranpak Holdings Corp. (US).

0 notes

Text

#rbrpaper#paperpackaging solutions#types of paperboard packaging products#paperboard packaging#Kappa Board#Rigid Box Board#White/Grey board#Black/Grey Board#PE Coated Board#PE Coated Paper#Chipboard#File Board#Multilayer Board#Jaguar Board#Book Binding Board#Recycled Board#sustainable paperboard product#paperboard packaging products

1 note

·

View note

Text

Sustainable Packaging Market to reach US$ 396.2 Billion by 2030

The global sustainable packaging market is estimated to flourish at a CAGR of 5.8% from 2023 to 2030. According to Transparency Market Research, sales of sustainable packaging are slated to total US$ 396.2 billion by the end of the aforementioned period of assessment.

A significant driver in the sustainable packaging market is the growing demand for packaging that can be used for multiple purposes. This trend towards multi-purpose packaging is being driven by concerns about waste and the desire to reduce the amount of single-use packaging in circulation.

The demand for multi-purpose sustainable packaging is expected to grow as consumers become increasingly aware of the environmental impact of single-use packaging, requiring companies in the sustainable packaging market to develop more innovative and versatile packaging solutions.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/sustainable-packaging-market.html

Key Findings of the Market Report

The paper & paperboard segment accounted for the largest market share in 2020, followed by plastic.

Food & beverages is the largest end-use segment for sustainable packaging, accounting for over 50% of the market share in 2020.

The use of smart packaging technology, such as sensors and data analytics, is becoming more common in sustainable packaging.

Sustainable Packaging Market Growth Drivers & Trends

Sustainable packaging solutions can often be more cost-effective in the long run due to reduced waste, transportation costs, and other expenses. As a result, many companies are switching to sustainable packaging to save money and improve their bottom line.

Advances in technology are driving innovation in sustainable packaging solutions, making it easier to produce eco-friendly materials and products.

The concept of a circular economy, where waste is reduced, reused, and recycled, is driving the adoption of sustainable packaging solutions.

The growth of e-commerce has led to an increase in packaging waste, as more products are shipped directly to consumers. This has driven the demand for more sustainable packaging options that are both protective and eco-friendly

Global Sustainable Packaging Market: Regional Profile

North America is a prominent market for sustainable packaging, owing to the growth of the sustainable packaging market in North America is driven by increasing consumer awareness about environmental issues and the desire for more eco-friendly packaging options.

Europe is projected to be the largest market for sustainable packaging, growing at a CAGR of 5.7% during the forecast period.

The Asia-Pacific region is a rapidly growing market for sustainable packaging, owing to the growth of the sustainable packaging market in the region is driven by increasing urbanization, rising disposable incomes, and growing awareness about sustainability.

Sustainable Packaging Market: Competitive Landscape

The sustainable packaging market is a rapidly growing industry that is gaining traction as consumers become increasingly conscious of their impact on the environment. The market is highly competitive, with numerous prominent players vying for market share. Some prominent manufacturers are as follows:

Sonoco Products Company

Amcor plc

Gerresheimer AG

Smurfit Kappa

Ball Corporation

Ardagh Group S.A.

Crown Holding Inc.

WestRock Company

DS Smith

Mondi

International Paper

Berry Global

Some important developments with regard to sustainable packaging are as follows:

In April 2023, Amcor plc and Tyson Foods teamed up once again to launch a game-changing sustainable package for consumer products. As two of the biggest names in the industry, this partnership promises to deliver a first-of-its-kind solution that offers uncompromised performance while being eco-friendly. With a shared commitment to sustainability, this collaboration is set to revolutionize the way we package and consume goods.

Sustainable Packaging Market: Key Segments

By Material Type

Paper & Paperboard

Coated Unbleached

Bleached Paperboard

Molded Fiber Pulp

Corrugated Board

Plastic

PLA

PHB

PBS

Starch-based Plastic

PHA

Others (PLC)

Metals (Aluminium)

Others (Fabric, Glass)

By Packaging Type

Trays

Bags

Boxes

Bottles & Jars

Films

Pouches & Sachets

Drums

IBC

Others

By End Use

Food

Bakery & Confectionery

Dairy Products

Meat & Poultry

Others (Snacks, Dips, etc.)

Beverages

Alcoholic Beverages

Non-Alcoholic Beverages

Automobile & Electronics

Chemicals

Pharmaceuticals

Agriculture

Cosmetics & Personal Care

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=9314<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Types of Packaging Materials and Importance of Choosing the Right Material

Introduction:

It’s essential to choose the right types of packaging materials for your product. Packaging serves various purposes, including protection, marketing, and sustainability.

In this article, we’ll discover the different types of packaging materials and help you understand the significance of choosing the right packaging material for your products.

Importance of Packaging Materials:

Packaging materials play a primary role in ensuring the safety and integrity of products during storage and transportation.

They serve as a protective layer that shields the contents from damage, moisture, and other external factors.

Additionally, packaging materials contribute to brand recognition and help in attracting customers. Let’s delve into the significance of choosing the right packaging material.

1. Protection and Preservation:

One of the main functions of packaging materials is to protect the products. Each product has unique characteristics that require specific packaging solutions.

Fragile items, for instance, may need cushioning and shock-absorbing materials to prevent breakage.

Temperature-sensitive goods might require insulation to maintain their quality. By selecting the appropriate packaging material, you can ensure that your products reach customers in pristine condition.

2. Branding and Marketing:

Packaging materials also serve as a canvas for brand messaging and marketing efforts.

The design, color scheme, and quality of the packaging can communicate the brand’s values and help to stand out from the competition and create a memorable impression on customers.

Eye-catching packaging can entice potential buyers and increase the perceived value of the product.

Choosing the right packaging material allows you to align your packaging design with your brand identity and marketing objectives.

3. Sustainability and Environment:

In today’s environmentally conscious world, selecting sustainable packaging materials is of utmost importance.

Packaging materials that are recyclable, eco-friendly, or made from renewable resources can extensively minimize the impact on the environment.

Consumers are increasingly inclining towards eco-friendly options, and opting for sustainable packaging materials that can elevate your brand’s reputation and appeal to a broader audience.

Types of Packaging Materials:

A wide range of packaging materials are available, each with its own pros and cons. Let’s explore some common types of packaging materials:

1. Corrugated Board and Paperboard:

Paperboard and Corrugated Board are widely used in packaging as they are versatile, cost-efficient and eco-friendly. Even though they are similar both these materials have distinct features.

Paperboard: Paperboard is quite expensive as it’s durable and the quality is also great. Another bonus point is that it provides an excellent printing feature.

Corrugated is an affordable option, it’s also known for it’s strength and durability. It’s an excellent choice as it protects the goods and products while it’s being transported or shipped.

Both Corrugated and Paperboard are recyclable and offer excellent advantages. While choosing between Paperboard and Corrugated, here are some things to consider – The type of product, durability requirements, printing requirements and cost.

2. Paper:

Paper is another packaging material that is used widely as it lightweight and versatile. There are many types of paper that can be used in packaging. We’ll go through them later on in the blog.

Paper as a packaging material is used in various consumer packaging products like food, cosmetics and many more.

Paper is extensively used in retail, grocery and restaurants as paper bags and it’s an excellent substitute for plastic bags. As paper is eco-friendly and it can be recycled. It’s also great if you want to do printing.

3. Different Types of Paper – Types of Packaging Materials

FBB Paper –

Folding Boxboard Paper is a top-notch quality paperboard commonly used for packaging purposes. It’s known for it’s durability and rigidness.

This paper is good for premium packaging as this material elevates the box and provides a nice shine. It’s excellent if you want to display products.

It is compatible with printing techniques and it finishes can also be added to elevate the appearance and provide extra protection to the products.

FBB Paper is recyclable. FBB Paper is one of the best type of packaging materials because of the above reasons.

Duplex Paper–

Duplex paper is a type of paperboard that is used for various packaging purposes. It’s known for it’s durability, versatility and strength. It’s available in different thicknesses and weights.

It provides a great protection for various types of products and used mostly for folding boxes and other type of packaging containers.

It’s compatible with printing techniques and as it offers a smooth printing surface it’s mostly used to create brochures, product inserts and flyers.

Most of the duplex papers are created using recyclable papers. Duplex paper is eco-friendly and can be recycled.

Kraft Paper:

Kraft paper is another types of packaging materials that is used widely. Kraft paper is greatly known for its brown colour, it’s highly durable.

It’s widely used to create packaging bags. It’s recyclable and offers a decent surface for printing.

Textured Paper:

Textured Paper is mostly used for premium packaging purposes. It is compatible with various printing techniques.

PU Coated Paper:

PU (Polyurethane) coated paper is a type of paper that has been coated with polyurethane. This type of packaging material is mostly used when protection is needed against moisture.

As it is durable and luxurious in nature it can be used in premium packaging.

Coloured Paper:

Coloured paper in packaging can be utilised to make it more visually appealing and add a interesting touch.

Different types of colours can evoke different emotions, so according to the brand, coloured paper can be selected.

Coloured paper can be easily printed and is compatible with various printing techniques.

Recycled Paper:

Recycled paper is paper that is crafted using waste material. It is quite durable and is used in various packaging applications. It can be easily printed.

Recyable Paper:

Recyclable paper is paper that can be recycled again. It is used in various industries.

Virgin Paper:

Virgin paper is paper that is crafted using pulp or harvested wood fibres. It offers good strength, printing capabilities and smoothness.

It can be used in various packaging applications like boxes and many more.

Biodegradable and Eco-friendly Types of Packaging Materials:

As sustainability becomes the major focus, biodegradable and eco-friendly types of packaging materials are gaining popularity. These types of packaging materials are designed to break down naturally and minimizing their impact on the environment. Forward-thinking box manufacturers are now increasingly adopting these eco-friendly materials, recognizing the growing consumer demand for sustainable packaging solutions.

Examples include bioplastics made from renewable sources, compostable materials, and plant-based packaging alternatives.

Choosing biodegradable types of packaging materials can demonstrate your commitment to sustainability and meet the demands of eco-conscious consumers.

Factors to Consider when Choosing Types of Packaging Materials:

Several factors should be considered when selecting the appropriate packaging materials for your products:

1. Product Characteristics:

Understanding the specific requirements of your product is essential. Consider its size, shape, weight, fragility, and any special storage or transportation needs.

This knowledge will help you identify the right packaging material that offers adequate protection.

2. Shipping and Transportation:

The method and distance of transportation play a crucial role in material selection. If your products require long-distance shipping or are exposed to various handling conditions, you need packaging materials that can withstand these challenges.

3. Customer Preferences:

It’s essential to know your target audience and their preferences. Packaging aesthetics, convenience, and sustainability are some factors that can influence customer perception and purchasing decisions.

4. Environmental Impact:

Evaluate the environmental impact of different types of packaging materials. Consider the entire lifecycle of the packaging, including production, transportation, use, and disposal. Go for for materials that have a lower carbon footprint and are recyclable or biodegradable whenever possible.

5. Cost and Efficiency:

Packaging costs can significantly impact your overall business expenses. Assess the cost-effectiveness of different types of packaging materials while ensuring they meet the necessary quality standards. Balancing cost and efficiency is crucial to maximize profitability.

Case Studies: Examples of Choosing – Types of Packaging Materials:

Let’s take a look at a few case studies that illustrate the importance of choosing the right types of packaging materials:

Company A, a skincare brand, chooses glass jars for its premium face creams to convey a luxurious image and protect the product’s integrity.

Company B, an e-commerce retailer, opts for lightweight and eco-friendly poly mailers for shipping apparel items, ensuring cost-effective shipping and reduced environmental impact.

Conclusion:

Choosing the right packaging material is vital for product protection, branding, and sustainability.

By taking the following aspects into consideration such as product characteristics, transportation needs, customer preferences, and environmental impact, you can choose packaging materials that align with your business goals and meet the needs of your consumers.

I hope after reading this blog, you understood the importance of choosing the right packaging material and this blog help you to choose the right type of packaging materials for your products

0 notes

Text

Sustainable Packaging Material Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights, the Sustainable Packaging Material Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Material Type (Paper & Paperboard, Plastic, Metal, Glass); Process (Recycled, Reusable, Degradable); End-User (Pharmaceutical & Healthcare, Food &Beverage, Others); Region/Country.

The Sustainable Packaging Material market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Sustainable Packaging Material market. The Sustainable Packaging Material market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Sustainable Packaging Material market at the global and regional levels.

Market Overview

The growth in the e-commerce sector and the government’s initiative to reduce packaging waste coupled with the rising demand for packaging materials from the food & beverage sector are some of the factors helping the development of the sustainable packaging industry. The packaging helps to sell the product by providing excellent brand value and protection for the product. As a result, businesses use packaging extensively for market production and consumer demand. Packaging use and disposal practices have a detrimental effect on the environment. In order to maximize the value of the product while also protecting the environment, manufacturers are creating sustainable packaging. The total expansion of the sustainable packaging sector is presented with a lucrative opportunity by the growing public awareness of environmental effects.

The Sustainable Packaging Material Market is expected to grow at a steady rate of around 8%. Growing customers’ awareness about the harmful impact of packaging materials on the environment plays a very important role in the growth of sustainable packaging materials. When buying a product today, buyers consider a number of aspects such as the product's value and concerns like sustainability, environmental effects, product pricing, and many more. Such consumer awareness is promoting the overall expansion of the sustainable packaging sector.

In addition, the leading industry players are actively taking steps toward environmental protection. For instance: Nestle has pledged an investment of more than USD 2 billion to transform virgin plastic into food-grade and recyclable packaging The funding has been extensively used to increase the market for sustainable packaging.

Some of the major players operating in the market include BASF SE, Amcor Plc, Westrock Company, Sonoco Products Company, TetraPak International SA, Sealed Air Corporation, Mondi PLC, Ball Corporation, Ardagh Group SA, Smurfit Kappa Group PLC.

COVID-19 Impact

The industrial sector and manufacturing industries have experienced a severe economic shock as a result of the COVID-19 epidemic. Numerous industrial sectors have been severely impacted by the decreased worker force and the restricted access to the raw materials used in manufacturing. However, the demand for food and drinks as well as the pharmaceutical sector was rising, which aided in the sustainable packaging sector's overall expansion.

The global Sustainable Packaging Material market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on process, the market is segmented into recycled, reusable, and degradable. The recycled category witnessed a higher CAGR during the forecast period. Increased use of recycled content packaging by companies aiming to demonstrate environmental sustainability and differentiate their products, combined with increased collection and processing capacity, would promote gains in recycled content packaging.

On the basis of end-users, the market is categorized as pharmaceutical & healthcare, food & beverage, and others. Among these, the food & beverage segment to hold a significant share in the market in 2020. The expansion is attributable to the appeal of environmentally friendly packaging, which has led to the large adoption of compostable and moulded pulp packaging by fast food chains, casual dining establishments, and restaurant chains. Moreover, the growing demand for sustainable packaging from FMCG goods, dairy products, beverages, and other items is adding pace to the market growth.

Sustainable Packaging Material Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

APAC is anticipated to grow at a substantial CAGR during the forecast period. The initiatives from the e-commerce sectors in the Asia-pacific region are also propelling the sustainable packaging market value in recent years. For instance, a leading e-commerce organization named SF express which is based in China was determined to reuse the packaging materials for overtimes and support the growth of the sustainable packaging market growth. The e-commerce sector has started to adopt packaging cartons from the urban regions and 1st tier and 2nd tier cities.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25977

The major players targeting the market include

BASF SE

Amcor Plc

Westrock Company

Sonoco Products Company

TetraPak International SA

Sealed Air Corporation

Mondi PLC

Ball Corporation

Ardagh Group SA

Smurfit Kappa Group PLC

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Sustainable Packaging Material market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the sustainable packaging material market?

• Which factors are influencing the sustainable packaging material market over the forecast period?

• What are the global challenges, threats, and risks in the sustainable packaging material market?

• Which factors are propelling and restraining the sustainable packaging material market?

• What are the demanding global regions of the sustainable packaging material market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Flat Glass Market: SWOT Analysis [2023-2028]

Anti-Wear Additives Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

A folded box, also known as a carton or a paperboard box, is a type of packaging that is made from paperboard or corrugated fiberboard. It is commonly used for shipping, storage, and display of a wide range of products. Here are some key points about folded boxes: 1. Material: Made from paperboard, which can be single-wall, double-wall, or multi-wall depending on the strength required. 2. Design: Can be designed in various shapes and sizes to fit the product it is meant to hold. 3. Function: Used for protection during shipping, as well as for marketing and display purposes. 4. Printing: Often printed with logos, product information, and graphics to attract customers. 5. Assembly: Typically comes flat and is folded into shape for use. 6. Environmental Impact: Generally considered eco-friendly as they are made from paper products and are recyclable. 7. Customization: Can be customized with different finishes, such as gloss, matte, or textured surfaces. If you have a specific question or need information about a particular type of folded box, feel free to ask! #retailpackaging #displaybox #mailingbox #packaging #paperbox #foldingbox #corrugatedbox #shippingbox #online #recycle #kraftbox #cardboardbox #packing #foodbox #cosmeticbox #pizzabox #windowbox

0 notes