#remote PLC programming

Explore tagged Tumblr posts

Text

Global Force Sensors Market Set to Grow at ~7% CAGR Through 2031

The global force sensors market is on track to grow at a CAGR of about 6.96% through 2031, driven by increased industrial automation, booming automotive innovation, widespread IoT adoption, and growing presence in medical, wearable, and consumer device applications.

To Get Sample Report: https://www.datamintelligence.com/download-sample/force-sensors-market

Key Market Drivers & Opportunities

A. Industrial Automation & Robotics Rapid uptake of Industry 4.0 and automation in manufacturing, driven by robotics performing tasks like grinding, assembly, and precision handling, is a major catalyst. Force sensors enable accurate control and detection in real-time, minimizing errors and increasing production reliability.

B. Automotive & ADAS Force sensors are increasingly essential in automotive systems used in brake pressure control, seat occupancy detection, steering systems, and occupant safety in autonomous vehicles. EV and ADAS development are fueling strong adoption in the automotive sector.

C. IoT & Smart Sensor Trends IoT and smart manufacturing require connected sensors capable of condition monitoring, predictive maintenance, and remote diagnostics. Force sensors integrated with digital outputs and communication protocols deliver real-time insights across applications.

D. Miniaturization & Wearables Emerging wearable tech and compact medical devices rely on MEMS-based, ultra-thin, accurate force sensors. Miniaturization supports integration in prosthetics, haptic-feedback gadgets, fitness trackers, and robotics, expanding market use cases.

E. Medical & Healthcare Applications Medical devices from prosthetic hands to rehabilitation robots demand precise force measurement. An aging population and chronic disease growth are increasing adoption, enabling safer surgical tools and effective patient rehabilitation systems.

Restraints & Challenges

Miniaturization Difficulties: Making sensors small without losing sensitivity is technically complex, limiting use in ultra-compact devices.

Development Lead Time: Designing, prototyping, and testing high-precision force sensors is time-consuming.

Volatile End-Use Demand: Fluctuations in sectors like automotive or industrial automation can impact sensor demand and production planning.

Regional Trends

North America: Currently holds the largest market share, driven by its automotive, defense, and consumer electronics sectors. Asia‑Pacific: The fastest growing region, supported by rising automotive and electronics manufacturing in China, India, Japan, and South Korea. Strong EV growth and IoT innovation bolster demand. Europe: Growth supported by aerospace, defense, water and gas infrastructure automation, and smart industry initiatives.

Latest Industry News & Trends from Key Regions

United States: Manufacturers are introducing new smart mini-force sensors with IO-Link integration, enabling predictive maintenance and PLC compatibility in automotive assembly lines. Japan: Japan’s industrial smart sensor market reached about USD 2.26 billion in 2024 and is expected to grow at a 12.7% CAGR through 2033, driven by AI-enabled sensing in manufacturing and demand in electric/hybrid vehicle programs.

Technology Trends & Innovation

Smart Mini Force Sensors: Compact, digitally-enabled products are integrating signal processing, offering real-time monitoring and predictive analytics in tight spaces.

Stretchable & 6-Axis Force Sensing: Cutting-edge academic research into flexible, multi-axis sensors supports tactile robotic control and soft robotics applications.

Optical, Piezoresistive & Ultrasonic Technologies: Non-contact sensing methods are gaining traction in applications requiring high precision or hygienic operation.

Competitive Landscape

The market is highly fragmented with global and regional players competing through innovation, acquisitions, and product extensions. Key companies include Tekscan, TE Connectivity, Texas Instruments, Sensitronics, ATI Industrial Automation, Kistler, FUTEK, Omron, and others, each focusing on niche technologies or application-focused solutions.

Strategic Outlook & Growth Opportunities

Expand Smart Sensing Solutions: Offer force sensors with advanced features smart communication, analytics, predictive alerts to support Industry 4.0 deployments.

Invest in Miniaturization R&D: Target wearable and medical sectors by developing highly accurate, compact MEMS-based devices.

Localize Production in Asia-Pacific: Tap into high-growth automotive and electronics sectors with regional manufacturing and localized partnerships.

Promote Cross-Sector Adoption: Target adjacent markets such as consumer electronics, biotech, aerospace, and smart appliances.

Collaborate with Robotics and EV Innovators: Align with emerging sectors like robotics, EVs, and autonomous systems for early-stage integration.

Conclusion

The global force sensors market is positioned for sustained growth, powered by industrial automation, automotive innovation, smart sensor adoption, and expanding applications in healthcare and wearables. Despite technical challenges around scaling down and product development cycles, demand remains strong across global industries. Market leaders who invest in smart sensing platforms, miniaturization, and regional expansion will emerge as industry frontrunners.

0 notes

Text

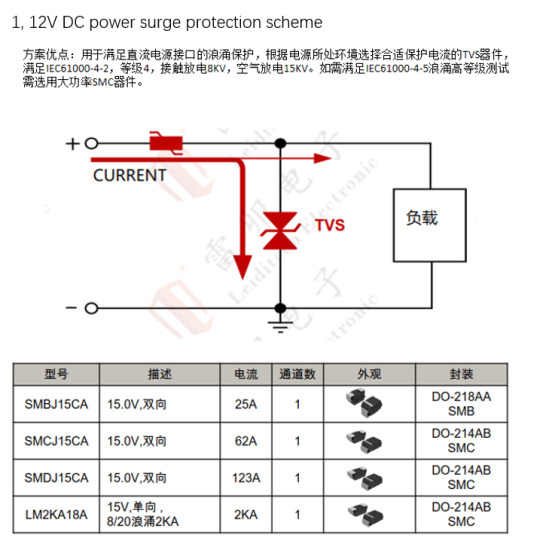

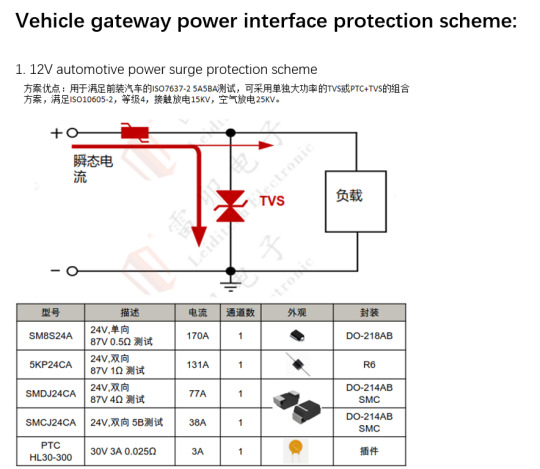

Interface protection design for edge computing gateways

With the rise of the Internet of Things and the popularity of cloud services, a new computing paradigm — edge computing — is beginning to appear in our field of vision. Edge computing advocates processing data at the edge of the network, thereby reducing system response time, protecting data privacy and security, extending battery life, and saving network bandwidth. Current applications are divided into industrial and automotive applications.

Industrial gateways

Industrial gateway is an indispensable device of the industrial Internet of Things, it is like the nerves of the human body, the perceived various types of information to the brain for processing, the brain through the operation to determine what kind of response to do, and then transmitted by the nerves to the limbs of the whole body. The gateway can collect PLC data, do remote maintenance and download programs, and has the functions of edge computing and protocol parsing. Industrial communication gateways can perform message conversion between various network protocols, and their functions can be implemented by a chip, an embedded device or board, or a stand-alone device.

Industrial Edge Computing Gateway Features:

1. Rich interface, support Ethernet, serial port, CAN port, IO port and other equipment access and Ethernet, 2G/3G/4G full Netcom network access;

2. Embedded hundreds of industrial protocols, supporting more than 99% PLC and the vast majority of industrial equipment access;

3. 8GB local storage + SD card support, support local data cache and offline application;

4. Three-in-one serial port, support RS485/RS232/RS422 three kinds of electrical interfaces;

5. Support edge computing, realize data optimization, real-time response, agile connection, model analysis and other services in the edge node of the Internet of Things, and effectively share cloud computing resources to support simultaneous access of multiple devices;

6. Support DC9~36V wide voltage input, adapt to a variety of complex industrial sites;

Each interface protection design of the industrial gateway

D-C power supply

Features of the on-board gateway

Due to the particularity of the on-board power supply, all the product power ports taken from the car need to pass the surge load-dump test, Leiditech Electronics provides a professional protection solution for the load-dump test, compared with the industrial gateway, the on-board power supply protection needs are greater.

summary

The interface protection of electronic products needs to use overvoltage protection devices, many engineers realize that they want to use protection devices, but due to improper selection or failure to follow the ESD circuit PCB design principles, resulting in product electrostatic testing or EMC testing does not pass, product verification tests many times, waste of manpower and financial resources, causing product delays to market Things always occur, or over-design, resulting in cost pressure.

Leiditech Electronics specializes in providing customers with EMC design services for electromagnetic compatibility, providing laboratories to do thorough tests, from customers efficient, easy to complete the design, hoping that more customers can quickly pass EMC’s projects and improve product reliability. Leiditech Electronic Electromagnetic Compatibility Laboratory, which provides peripheral electrostatic surge protection reference circuits.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

EdgeComputing #IndustrialIoT #EMCDesign #ESDProtection #AutomotiveGateway #SmartFactory #IoTDesign #HardwareEngineering #EmbeddedSystems #SurgeProtection #InterfaceDesign #TechBlog #EngineeringLife #ProductDevelopment #DesignTips

0 notes

Text

0 notes

Text

Why Siemens SIMATIC S7-1200 PLC is Ideal for Modern Industries

In today’s rapid-paced manufacturing environment, the roles of automation are the improvement in productivity, quality, and efficiency. At the core of many intelligent automation systems, there is the versatile and powerful PLC SIMATIC S7-1200 developed by Siemens.

Learn more about, Top 10 Features of the SIMATIC S7 1200 That Makes It a Game Changer

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a compact and modular PLC designed for small to medium automation tasks. It is scalable in nature and comes with integrated communication and user-friendly programming using the TIA Portal (Totally Integrated Automation). Be it a simple machine or a highly complex process; the Siemens SIMATIC S7-1200 strikes a perfect balance between performance and affordability.

Key Features of Siemens SIMATIC S7-1200 PLC

Packed with features, the Siemens SIMATIC S7-1200 PLC can adapt perfectly to a variety of industrial applications.

Modular Design: Easily expand your system by attaching different signal modules, communication modules, or signal boards.

Integrated Communication: Provides a built-in PROFINET interface.

High-Speed Processing: Operation with precise control and response.

Web Server: Access to the system diagnostics remotely through a web-based interface.

Security Functions: Protect with a password and access control security functions.

Energy Monitoring: Optimizes power usage in the production processes.

This makes the SIMATIC S7-1200 a perfect fit to be a controller for packaging, HVAC, conveyor systems, and other applications.

Why Choose Siemens SIMATIC S7-1200 for Automation?

Scalability:

Automation needs grow with Siemens SIMATIC S7-1200; start small and work your way up along with your processes.

Programming Flexibility:

This system supports ladder diagrams, function block diagrams, and structured text, allowing both newbie and seasoned programmers to use them.

Robust Performance:

Operating under harsh industrial conditions, the Siemens SIMATIC S7-1200 PLC looks after consistent performance even when challenged by environmental conditions.

Integrated System Diagnostics:

Diagnose and fix problems immediately without the aid of external tools to minimize system downtime and maximize operational efficiency.

Learn more, Why Siemens PLC S7-1200 is the best choice for Compact Automation System

Applications of SIMATIC S7 1200

The SIMATIC S7-1200 finds applications in several industrial fields, including:

Automotive: Automated assembly lines and robotics are controlled.

Food & Beverage: Packaging and processing lines are handled with precision.

Textile: Improves control of dyeing and printing machines.

Water treatment: Monitoring and control of pumps and filters are performed.

Material Handling: Smart conveyors and warehouse automation present a challenging application.

Because of its versatility, the Siemens SIMATIC S7-1200 PLC continues to be a very reliable solution in the industrial automation world.

Conclusion

Whether updating an existing automation system or embarking on a brand-new project, the S7-1200 affords the performance, flexibility, and reliability you need. Its intelligence and easy integration make it a wise choice in any industrial setting.

If you are considering procurement or implantation of Siemens SIMATIC S7-1200 PLC, Naksh Technology Solutions LLP is your trusted partner. With years of experience in the field of industrial automation coupled with a sturdy portfolio of Siemens products, Naksh Technology ensures the development of seamless solutions that fit your business needs.

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

Decentralized Power, Central to Progress: The Small Modular Reactor Revolution

Small Modular Reactor (SMR) Market Growth & Trends

The global small modular reactor (SMR) market was valued at USD 6.14 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.3% from 2024 to 2030. This growth is fueled by the increasing demand for flexible, cost-efficient, and low-carbon energy solutions, especially as global economies transition toward more sustainable energy systems.

SMRs are innovatively designed nuclear reactors that are factory-built, modular, and transportable, offering considerable advantages over traditional large-scale nuclear plants. These advantages include reduced construction times and costs, as well as greater deployment flexibility, especially in remote locations or smaller electrical grids where conventional reactors are impractical.

In addition to their adaptability, SMRs incorporate advanced passive safety features, enhancing operational safety and reducing the risks traditionally associated with nuclear energy. Their ability to complement renewable energy sources by providing stable baseload power makes them a critical asset in decarbonizing the energy sector while maintaining grid stability.

However, despite these benefits, several challenges hinder market expansion. The high upfront capital costs associated with developing and deploying SMRs can deter investors when compared with alternative energy technologies such as solar, wind, or natural gas. Moreover, the complex and rigorous regulatory environment for nuclear technology can cause significant delays and increase compliance costs, adding further uncertainty for project developers. Public apprehensions around nuclear safety and radioactive waste management also remain significant barriers to widespread acceptance and deployment.

Market Strategies and Industry Dynamics

To overcome these barriers and gain a competitive edge, key industry players are engaging in:

Strategic partnerships and public-private collaborations aimed at securing funding, accelerating approvals, and increasing public trust.

A strong focus on modularity and scalability, which allows for easier site integration, phased capacity expansions, and cost control.

Emphasis on enhanced safety and reliability, leveraging state-of-the-art design features to reduce operational risks and improve system resilience.

These strategies are collectively shaping the roadmap for broader adoption and long-term viability of SMRs in the global energy mix.

Get a preview of the latest developments in the Small Modular Reactor Market? Download your FREE sample PDF copy today and explore key data and trends

Global Small Modular Reactor Market Segmentation

Grand View Research has segmented the small modular reactor market on the basis of product type, application, and region:

Product Type Outlook (Revenue, USD Million, 2018 - 2030)

Heavy Water Reactors

Light Water Reactors

High-temperature Reactors

Others

Application Outlook (Revenue, USD Million, 2018 - 2030)

Power Generation

Desalination

Industrial

Hydrogen Production

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Asia Pacific

China

Japan

India

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Key Small Modular Reactor Companies

The small modular reactor market is led by several prominent companies, including:

Fluor Corporation – A U.S.-based engineering and construction firm that provides nuclear and energy solutions across diverse sectors including infrastructure, energy transition, and technology through three key business segments: Energy Solutions, Urban Solutions, and Mission Solutions.

Rolls-Royce plc – A global manufacturer specializing in propulsion and power systems. Rolls-Royce is advancing its role in the SMR space through innovation in civil nuclear applications

and is a key player in the UK’s SMR program.

Other major companies shaping the industry include:

Brookfield Asset Management

Moltex Energy

General Electric Company

ULTRA SAFE NUCLEAR

X Energy LLC

Westinghouse Electric Company LLC

Terrestrial Energy Inc.

General Atomics

These players collectively represent a significant share of the market and are actively influencing SMR design, commercialization, and policy frameworks.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Parry Romberg Syndrome Market Forecast and Growth Analysis

The Parry Romberg Syndrome Market industry is experiencing a critical shift driven by escalating R&D investments in biologic therapies and diagnostic imaging. With industry size expanding beyond historical expectations and industry share gravitating towards novel regenerative modalities, detailed market analysis underscores accelerating business growth. Current market dynamics and market drivers point to a competitive landscape focused on high-value orphan drug development. Market Size and Overview

The Parry Romberg syndrome market is estimated to be valued at USD 455.8 Mn in 2025 and is expected to reach USD 827.9 Mn by 2032, growing at a compound annual growth rate (CAGR) of 8.9% from 2025 to 2032.

According to the Parry Romberg Syndrome Market report released in Q1 2025, biologic therapeutics and diagnostic imaging segments account for over 40% of Parry Romberg Syndrome Market revenue in 2024, driven by immunomodulators and stem cell interventions. Market trends in targeted gene therapy and advanced imaging are unlocking substantial market opportunities, while reimbursement gaps present notable market challenges. Annual capacity expansions and new labeling approvals are projected to bolster overall market size through 2030. The Parry Romberg Syndrome Market trends underscore a shift towards integrated therapeutic platforms and precision diagnostics by 2027. Use Case Scenarios

• Late 2024 saw a Phase II trial by Novartis using adipose-derived stem cell injections at the Mayo Clinic, achieving a 30% improvement in facial volume and validating a key Parry Romberg Syndrome Market share shift toward regenerative medicine. Recent market research and market insights reveal such outcomes reinforce targeted cell therapy pipelines. • In Q1 2025, Roche deployed its AI-based diagnostic imaging suite across three Paris hospitals, reducing diagnostic turnaround by 20% and illustrating market growth strategies for precision diagnostics in rare facial atrophy cases. • Mid-2024 partnership between Sanofi and remote telehealth providers in rural India improved patient adherence by 25%, overcoming significant market challenges related to access and infrastructure in emerging regions. Policy and Regulatory Impact

• In May 2024, the U.S. FDA expanded the Rare Pediatric Disease Priority Review Voucher Program to include progressive facial atrophy syndromes, serving as a key market driver by de-risking clinical approvals. • A 2024 EU regulatory market report emphasized strengthened post-marketing surveillance under the Orphan Medicinal Products Regulation, introducing tighter market restraints and adding complexity to trial design and compliance. • Japan’s Ministry of Health 2024 subsidy program for rare disease therapies increased reimbursement coverage, unlocking new market opportunities across APAC and shaping regional market dynamics. Key Players

Key market players include: • Pfizer Inc. • Novartis AG • Roche Holding AG • Sanofi S.A. • GlaxoSmithKline plc. • AbbVie Inc. • Johnson & Johnson • Eli Lilly and Company • Takeda Pharmaceutical Company Limited • Merck & Co., Inc. • AstraZeneca plc • Biogen Inc. • Novo Nordisk A/S • Amgen Inc. • Bristol Myers Squibb

‣ Get More Insights On: Parry Romberg Syndrome Market

‣ Get this Report in Japanese Language: パリー・ロンバーグ症候群市場

‣ Get this Report in Korean Language: 파리롬버그증후군시장

0 notes

Text

Embedded Control Software Systems: Powering Intelligent Automation

Embedded control software systems are the unseen brains behind many of today’s most advanced technologies. From industrial machines and automotive systems to consumer electronics and medical devices, these systems ensure that everything operates efficiently, safely, and reliably. Embedded control software is a combination of software and hardware engineered to perform dedicated control functions within larger systems, often with real-time constraints and minimal user interaction.

This article explores what embedded control software systems are, how they work, their architecture, applications, benefits, and challenges.

What is an Embedded Control Software System?

An embedded control software system consists of three main components:

Embedded Hardware (Microcontroller or Microprocessor) – This is the processing unit that executes the control logic.

Control Algorithms (Software) – Written in programming languages like C or C++, these define the behavior of the system based on inputs and desired outputs.

Sensors and Actuators – Sensors provide feedback from the environment (e.g., temperature, speed), while actuators carry out control actions (e.g., motor movement).

These systems are “embedded” because they are integrated into larger products, and they typically perform one or more specific control functions rather than general-purpose computing tasks.

Key Features of Embedded Control Software

Real-Time Operation: Embedded control software often operates in real time, meaning it must respond to inputs within a strict time frame.

Determinism: The system must behave in a predictable manner, particularly in safety-critical applications like automotive or aerospace.

Low Power and Resource Constraints: Many embedded systems are deployed on hardware with limited processing power, memory, and energy.

Reliability and Robustness: Since embedded systems are often deployed in harsh environments, they must be stable and resistant to failure.

Minimal User Interaction: Most embedded control systems are designed to operate with limited or no user interface.

Architecture of Embedded Control Systems

Input Interface: Collects data from sensors or communication channels.

Control Software: Applies algorithms (e.g., PID, fuzzy logic, model predictive control) to decide what action should be taken based on inputs.

Output Interface: Sends control signals to actuators (motors, valves, lights, etc.).

Feedback Loop: Ensures the system continuously adjusts itself based on output performance.

For example, in an automotive cruise control system:

Input: Speed sensor measures vehicle speed.

Control Software: Compares current speed with desired speed.

Output: Sends signals to the throttle actuator to maintain or change speed.

Feedback: Adjusts continuously as road conditions or driver input change.

Applications of Embedded Control Software Systems

1. Automotive Industry

Engine control units (ECUs)

Anti-lock braking systems (ABS)

Adaptive cruise control

Lane-keeping assistance

Airbag deployment systems

2. Industrial Automation

Programmable logic controllers (PLCs)

Robotic arms

Process control in manufacturing lines

Condition monitoring systems

3. Consumer Electronics

Smart thermostats

Washing machines

Microwave ovens

Smart TVs and remote controllers

4. Aerospace and Defense

Flight control systems

Missile guidance

Radar systems

UAV navigation

5. Healthcare

Medical infusion pumps

MRI and imaging equipment

Wearable health monitors

Automated ventilators

Development Process for Embedded Control Software

Requirement Analysis: Define functional and non-functional requirements, such as timing constraints and energy consumption.

System Design: Select hardware platform and define software architecture.

Algorithm Development: Create control logic using mathematical models or empirical rules.

Implementation: Code the algorithms using languages like C, C++, or model-based tools such as MATLAB/Simulink.

Simulation and Testing: Validate performance through simulation, hardware-in-the-loop (HIL) testing, and real-world trials.

Deployment and Maintenance: Deploy code to the embedded hardware and ensure updates or bug fixes are managed safely.

Model-Based Design in Embedded Control

A growing trend in embedded control software development is model-based design (MBD). Engineers use graphical models to design, simulate, and automatically generate code for control algorithms. Tools like Simulink allow for rapid prototyping, reduced coding errors, and quicker time to market. This is especially useful for systems that require frequent iterations or are highly complex.

Benefits of Embedded Control Software Systems

Efficiency: Optimizes system performance, energy use, and functionality.

Precision: Ensures accurate control in critical applications like medical devices and aerospace.

Cost-Effectiveness: Minimizes the need for manual intervention and large hardware setups.

Scalability: Can be tailored for use in simple household gadgets or complex industrial machinery.

Safety and Reliability: Especially in automotive and aviation, embedded control systems contribute to increased safety through reliable automation.

Challenges in Embedded Control Software Development

Real-Time Constraints: Meeting strict timing requirements can be difficult.

Resource Limitations: Must operate on hardware with limited memory and processing capabilities.

Debugging Complexity: Difficult to test systems in real-time without disrupting performance.

Cybersecurity Risks: Increased connectivity (IoT integration) exposes systems to potential attacks.

Maintenance and Upgrades: Embedded systems often need to be updated securely, especially in remote or critical applications.

Future Trends in Embedded Control Systems

AI and Machine Learning Integration: Adaptive systems that learn from data for more intelligent control.

Edge Computing: Processing control logic closer to the source (sensors/actuators) to reduce latency.

Wireless and IoT Connectivity: Embedded systems communicating via 5G or other wireless protocols.

Open-Source Platforms: Tools like Arduino and Raspberry Pi are making embedded control development more accessible.

Conclusion

Embedded control software systems by Servotechinc are the cornerstone of modern intelligent automation. By integrating sensors, control algorithms, and actuators into compact, efficient packages, these systems bring intelligence to machines across countless industries. Whether improving the safety of vehicles, the precision of medical devices, or the efficiency of industrial processes, embedded control systems play a pivotal role in shaping a smarter, more connected world.

0 notes

Text

Buraq Integrated Solutions

Buraq Integrated Solutions is a premier system integration, professional services, and software development company, offering cutting-edge technology solutions across multiple industries. Specializing in Industrial Automation, Automatic Weather Stations, Flood Early Warning Systems, PLC/SCADA, and IT Consultancy, Buraq Integrated Solutions provides tailored services to government bodies, financial institutions, telecom providers, energy sectors, healthcare, and educational institutions. With a commitment to delivering reliable, rapid, and robust solutions, Buraq Integrated Solutions has established itself as a trusted partner for businesses and government organizations seeking to enhance efficiency through automation and advanced technology. Comprehensive Solutions for Various Industries As a technology-intensive company, Buraq Integrated Solutions offers a diverse portfolio of services designed to meet the evolving needs of its clients. The company specializes in: 1. Industrial Automation & Control Systems - PLC Programming & SCADA Systems – Advanced industrial automation solutions for seamless control and monitoring. - HMI (Human-Machine Interface) – Intuitive systems for process control and operational efficiency. - Telemetry Systems – Real-time data acquisition and remote monitoring solutions. 2. Automatic Weather Stations & Flood Early Warning Systems - Environmental Monitoring Systems – Providing accurate weather data for improved forecasting. - Flood Early Warning Systems – Enhancing disaster preparedness through real-time flood detection technology. - GIS Survey & Mapping – Geographic Information Systems (GIS) for land and infrastructure analysis. 3. IT Consultancy & Software Development - Custom Software Solutions – Tailored applications for financial services, government institutions, and enterprise operations. - Cybersecurity & Data Protection – Ensuring the integrity and security of IT infrastructure. - Cloud-Based Solutions – Scalable and efficient cloud computing services for businesses. Industries We Serve Buraq Integrated Solutions delivers advanced technological solutions to a broad range of industries, ensuring efficiency, security, and automation in key sectors: Government (Local & Central): We provide digital transformation solutions that enhance the efficiency and effectiveness of local and central government operations. Financial Services: Our solutions help banks, insurance companies, and clearing houses streamline operations, reduce risks, and improve customer service. Telecommunications: We enable telecom companies to optimize their networks, improve service delivery, and stay competitive in a rapidly evolving industry. Energy & Utilities: Our solutions help energy providers and utilities improve operational efficiency, reduce costs, and enhance sustainability. Healthcare: We deliver technology solutions that improve patient care, streamline operations, and ensure compliance with regulatory requirements. Education: Our solutions help educational institutions enhance learning experiences, improve administrative efficiency, and prepare students for the future. Why Choose Buraq Integrated Solutions? ✔ Proven Expertise – A team of highly skilled professionals with vast industry experience. ✔ Innovative Technology – Implementation of the latest advancements in industrial automation and IT solutions. ✔ Custom-Tailored Solutions – Designed to meet the unique needs of each client. ✔ Reliable & Scalable Systems – Ensuring long-term efficiency and adaptability. ✔ Commitment to Excellence – Delivering quality-driven solutions that maximize performance. Get in Touch Buraq Integrated Solutions is your trusted partner for advanced technology solutions. Whether you need automation, IT consultancy, or environmental monitoring, we have the expertise to deliver state-of-the-art solutions that work. For inquiries, consultations, or collaborations, contact us today! Read the full article

0 notes

Text

Global Women’s Health Market Set for 5.5% CAGR Growth Through 2031

The global women’s health market was valued at US$ 77.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2031, reaching an estimated US$ 130.9 billion by the end of the forecast period. Increasing prevalence of biological health issues among women, coupled with rising awareness and improved access to healthcare services, has fueled consistent market expansion. The broad scope of women’s health spans from reproductive and hormonal therapies to oncology, cardiology, and mental health, underscoring a multidisciplinary approach to improving women’s well-being.

Market Drivers & Trends

Aging Female Population: The number of menopausal and postmenopausal women worldwide is anticipated to reach 1.2 billion by 2030, with 47 million women entering menopause each year. This demographic shift drives demand for hormonal therapies, bone health supplements, and targeted treatments for menopause-related conditions.

Rising Prevalence of Women-Specific Cancers: Cervical, ovarian, breast, and uterine cancers continue to pose significant morbidity and mortality risks. Early detection programs and novel targeted therapies are reshaping treatment paradigms.

Nutritional Deficiencies: Iron, calcium, vitamin D, folate, and omega-3 deficiencies are common among women. Healthcare professionals increasingly recommend natural dietary supplements, with an emphasis on herbal and plant-based formulations to minimize side effects.

Digital Health Integration: Adoption of telemedicine, mobile health applications, and wearable devices facilitates remote monitoring of menstrual cycles, fertility, and chronic conditions such as osteoporosis and hypothyroidism.

Latest Market Trends Manufacturers are investing heavily in research and development to expand natural and personalized supplements portfolios. Partnerships between nutraceutical companies and academic institutions are driving clinical validation of botanicals and probiotics for women’s health. Additionally, artificial intelligence and machine learning are being applied to predict disease risk and tailor interventions, from menstrual health tracking to cancer therapy optimization.

Key Players and Industry Leaders Prominent companies shaping the global women’s health landscape include:

Eli Lilly and Company

Novartis AG

Pfizer, Inc.

Merck & Co., Inc.

Novo Nordisk A/S

Amgen, Inc.

AstraZeneca

F. Hoffmann-La Roche Ltd.

Sanofi

Allergan plc

GlaxoSmithKline plc

Lupin Pharmaceuticals, Inc.

These industry leaders leverage advanced pipelines, strategic mergers and acquisitions, and collaborations to broaden their product offerings and strengthen global footprints.

Explore the highlights and essential data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=214

Recent Developments

On November 17, 2023, AstraZeneca received U.S. FDA approval for Truqap, a breast cancer drug used in combination with Faslodex. Clinical data demonstrated a 50% reduction in risk of disease progression and mortality.

On June 1, 2023, Nykode and F. Hoffmann-La Roche Ltd. announced a collaboration to evaluate VB10.16 combined with Tecentriq for advanced cervical cancer patients.

Market Opportunities and Challenges

Opportunities: Growth in preventive health screening, expansion of OTC and prescription supplement categories, and breakthroughs in targeted oncology and gene therapies offer significant upside.

Challenges: High R&D costs, stringent regulatory pathways, and pricing pressures in key markets may hinder rapid adoption of novel therapies. Disparities in healthcare access across emerging economies further constrain market penetration.

Future Outlook Analysts project sustained growth driven by innovation in biologics and personalized medicine, alongside heightened government and private sector investment in women’s health programs. Integration of digital health platforms will accelerate early diagnosis and monitoring, while holistic wellness approaches—including mental health and lifestyle management—will gain prominence.

Market Segmentation

By Treatment Type

Hormonal Treatment (Estrogen therapy, Progestin therapy, Combination therapy, Thyroid replacement, Parathyroid hormone therapy, Others)

Non-hormonal Treatment (Targeted therapy drugs, Antibiotics, Bisphosphonates, Others)

By Disease Indication

Cancer (Breast, Cervical, Ovarian)

Hypothyroidism

Post-menopausal Syndrome

Osteoporosis

Contraception

Uterine Fibroid

Urinary Tract Infection

Others

Regional Insights

North America: Dominant market share driven by high breast cancer prevalence, robust insurance coverage, and extensive R&D investments. Government initiatives and awareness campaigns bolster early diagnosis and treatment uptake.

Europe: Strong demand for biologics and digital health solutions, supported by comprehensive healthcare frameworks in Germany, the U.K., and France.

Asia Pacific: Rapidly growing elderly female population and rising healthcare expenditure in Japan, China, and India. Market expansion hampered by access disparities and affordability concerns.

Latin America & MEA: Emerging markets with improving healthcare infrastructure, increasing public–private partnerships, and growing focus on women’s wellness.

Why Buy This Report?

Comprehensive analysis covering market drivers, restraints, opportunities, and emerging trends.

Detailed profiling of leading companies, their strategies, product pipelines, and financial performance.

In-depth market segmentation and regional forecasts up to 2031.

Actionable insights for stakeholders, including investors, manufacturers, healthcare providers, and policymakers.

Frequently Asked Questions

What is driving the growth of the global women’s health market? The market growth is fueled by demographic trends, rising prevalence of cancers and menopausal issues, and increasing adoption of dietary supplements and digital health tools.

Which region holds the largest share? North America leads the market due to high disease awareness, advanced healthcare infrastructure, and strong investment in R&D.

Who are the top players in this market? Key players include Eli Lilly, Novartis, Pfizer, Merck, Novo Nordisk, and AstraZeneca, among others.

What are the major challenges? Challenges include regulatory complexities, high development costs, and disparities in healthcare access in emerging economies.

How will the market evolve by 2031? The market is expected to reach US$ 130.9 billion by 2031, driven by personalized medicine, biologics, and integration of digital health solutions.

Explore Latest Research Reports by Transparency Market Research: Revenue Cycle Management Market: https://www.transparencymarketresearch.com/revenue-cycle-management-market-report.html

Anaphylaxis Market: https://www.transparencymarketresearch.com/anaphylaxis-market.html

Corporate Wellness Market: https://www.transparencymarketresearch.com/corporate-wellness-market.html

Otoscopes Market: https://www.transparencymarketresearch.com/otoscopes-market-report.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Nvent Hoffman AC Drives Dealers in Rajasthan

As Nvent Hoffman AC drives dealers in Rajasthan, we specialize in offering high-performance drives that are ideal for controlling the speed, torque, and direction of electric motors. These drives are essential in applications requiring precise motor control for energy savings, reduced maintenance, and extended equipment life. Our AC drives are built to withstand the harsh conditions of industrial environments while providing optimal energy efficiency. Nvent Hoffman VFD Dealers in Rajasthan Variable Frequency Drives (VFDs) are vital for controlling the speed and performance of motors in various industrial applications. As Nvent Hoffman VFD dealers in Rajasthan, we provide state-of-the-art VFDs that help in improving system efficiency, reducing energy consumption, and enhancing motor control. These VFDs are designed to handle a wide range of applications, from simple to complex automation systems. We also offer expert advice on selecting the right VFD for your specific requirements. Nvent Hoffman HMI Dealers in Rajasthan Human-Machine Interface (HMI) systems are crucial for efficient communication between operators and industrial machines. As Nvent Hoffman HMI dealers in Rajasthan, we offer innovative HMI solutions that allow operators to monitor and control complex processes with ease. Our HMIs provide intuitive touchscreen interfaces, real-time data display, and remote access capabilities, ensuring smooth and efficient operation in industrial environments. Whether for simple or advanced control systems, our HMI products are tailored to enhance usability and productivity. Nvent Hoffman PLC Dealers in Rajasthan Programmable Logic Controllers (PLCs) are at the heart of industrial automation, and as Nvent Hoffman PLC dealers in Rajasthan, we provide robust, reliable, and scalable PLC systems for a wide range of applications. From controlling machinery to automating processes, our PLCs ensure seamless integration with other industrial systems. With advanced features such as real-time control, remote diagnostics, and easy programming, our PLC solutions are designed to improve operational efficiency and reliability across various industries.

0 notes

Text

Underwater Communication System Market Size, Share, Analysis, Forecast, and Emerging Growth Opportunities by 2032

The Underwater Communication System Market was valued at USD 4.2 Billion in 2023 and is expected to reach USD 9.7 Billion by 2032, growing at a CAGR of 9.68% from 2024-2032.

The Underwater Communication System market is rapidly evolving, driven by growing demands across diverse sectors such as defense, oil & gas exploration, marine research, and offshore construction. As underwater activities increase in complexity and scope, reliable communication becomes crucial for safety, data transmission, and operational efficiency. Innovations in acoustic, optical, and electromagnetic communication technologies are transforming how information is exchanged beneath the ocean surface, fostering new opportunities for real-time underwater networking and exploration.

Underwater Communication System market advancements are reshaping subsea operations worldwide. Emerging applications in autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs), and environmental monitoring have heightened the need for robust, long-range, and low-latency communication systems. The integration of IoT and AI into underwater networks further propels the market, enabling smarter and more adaptive communication solutions that meet stringent underwater environmental challenges.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/6080

Market Keyplayers:

Sonardyne International Ltd. – BlueComm Optical Modem

Teledyne Technologies Incorporated – Teledyne Benthos Acoustic Modems

Ultra Electronics Holdings plc – UnderSea Acoustic Communication System

EvoLogics GmbH – S2C Acoustic Modems

Kongsberg Gruppen ASA – cNODE Modems

Thales Group – BlueScan Acoustic System

L3Harris Technologies, Inc. – UUV Acoustic Communication System

Sea and Land Technologies Pte Ltd – Seatext Underwater Modems

Aquatec Group Ltd. – AQUAmod Acoustic Modems

DSIT Solutions Ltd. – PointShield Diver Detection System

Hydroacoustic Inc. – HLF-5000 Underwater Acoustic Transceiver

Ocean Technology Systems (OTS) – Aquacom SSB-2010 Wireless Communicator

Zebra-Tech Ltd. – Hydro-Wireless Acoustic Modems

Mistral Solutions Pvt. Ltd. – Tactical Underwater Communication System

Japan Radio Co., Ltd. – JHS-800S Submarine Communication System

Market Analysis

The market is characterized by a diverse range of communication technologies, including acoustic communication, which remains dominant due to its long-range capabilities, alongside growing adoption of optical and radio frequency systems for short-range, high-speed data transfer. Increasing investments from defense agencies and energy sectors, alongside rising marine research activities, have significantly contributed to market expansion. Furthermore, regional growth is driven by enhanced offshore exploration and naval modernization programs in North America, Europe, and Asia-Pacific.

Market Trends

Rising integration of IoT and AI for underwater communication enhancement

Increasing use of autonomous and remotely operated underwater vehicles

Development of hybrid communication systems combining acoustic, optical, and electromagnetic technologies

Growing demand for real-time underwater data transmission and monitoring

Expansion of offshore oil & gas and renewable energy projects fueling demand

Focus on miniaturization and energy-efficient communication devices

Advancements in underwater sensor networks for environmental and defense applications

Market Scope

Enhanced safety and operational efficiency across subsea industries

Broad applications spanning defense, marine research, oil & gas, and offshore wind farms

Emergence of multi-modal communication technologies for diverse underwater environments

Growing emphasis on reducing latency and increasing data bandwidth underwater

Increasing collaborations between tech developers and marine research institutes

Rising adoption of underwater wireless sensor networks to monitor oceanographic parameters

The Underwater Communication System market encapsulates an expansive scope, touching various sectors that depend on seamless underwater connectivity. Its growth is fueled by technological breakthroughs and an increasing need to monitor and manage underwater activities effectively.

Market Forecast

The Underwater Communication System market is poised for remarkable growth, driven by continuous technological innovation and expanding applications. As global subsea operations intensify, demand for more reliable, faster, and energy-efficient communication systems will surge. Integration with digital transformation trends such as AI, machine learning, and IoT will unlock new dimensions in underwater data management, expanding possibilities for exploration, surveillance, and environmental protection. Market players focusing on R&D and strategic collaborations will spearhead future advancements and market penetration.

Access Complete Report: https://www.snsinsider.com/reports/underwater-communication-system-market-6080

Conclusion

The Underwater Communication System market stands at the cusp of a technological revolution that promises to redefine subsea connectivity. For stakeholders, this market offers exciting prospects fueled by innovation and expanding industry demands. Investing in advanced underwater communication technologies will not only enhance operational safety and efficiency but also unlock unprecedented opportunities in marine exploration and monitoring. As the ocean becomes the next frontier for digital transformation, the underwater communication ecosystem is set to become a cornerstone of global maritime strategy and sustainable underwater operations.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Underwater Communication System Market#Underwater Communication System Market Scope#Underwater Communication System Market Trends#Underwater Communication System Market Growth

0 notes

Text

https://anadiautomation.com/schneider-electric/TM200CE40T

Product Overview: TM200CE40T Controller

The TM200CE40T is part of Schneider Electric’s Modicon M200 series, designed to meet the automation needs of modern industries. It features a combination of 24 digital inputs and 16 digital transistor outputs, making it ideal for various I/O-intensive applications.

🔧 Key Specifications:

Part Number: TM200CE40T

Brand: Schneider Electric

Controller Type: Programmable Logic Controller (PLC)

Digital Inputs: 24

Digital Outputs: 16 (Transistor type)

Communication Ports: Built-in Ethernet

Mounting: DIN Rail

Power Supply: 24V DC

Program Memory: Expandable

Warranty: 1 Year (provided by Anadi Automation)

Availability: In stock at Anadi Automation, Nashik, India

Top Features of Schneider Electric TM200CE40T

The TM200CE40T offers a variety of features that enhance its appeal to system integrators and OEMs alike. Here’s why it stands out:

✅ High Input/Output Capacity

With 24 digital inputs and 16 digital outputs, the controller provides ample I/O support for mid-size automation systems.

✅ Compact and Modular Design

Despite its powerful capabilities, the TM200CE40T has a compact footprint. It supports modular expansion, allowing you to scale your system as needed.

✅ Integrated Ethernet Port

The built-in Ethernet port enables high-speed communication, remote monitoring, and easy integration into industrial networks using Modbus TCP/IP protocol.

✅ High-Speed Counter and Pulse Outputs

It includes high-speed counters and pulse output functions that are essential for motion control and fast process operations.

✅ DIN Rail Mounting

Ease of installation with standard DIN rail mounting ensures a secure and accessible setup.

✅ Advanced Programming Environment

Compatible with Schneider Electric's EcoStruxure Machine Expert – Basic (SoMachine Basic) software for intuitive programming, simulation, and troubleshooting.

0 notes

Text

Leading Automation Solutions and Robotic Welding Fixture Manufacturers in Pune and India

In this blog, we’ll explore how these technologies work and which companies are leading the way in Pune and across India.

Automation Solutions Companies in Pune

Pune is home to some of India’s best automation solutions companies. These companies help factories reduce human error, increase speed, and improve safety.

From assembly lines to material handling, automation plays a crucial role in modern manufacturing. PLC programming, SCADA systems, robotics integration, and sensor-based automation are now widely adopted.

Why choose automation solutions in Pune?

Skilled engineering talent

Strong IT and mechanical ecosystem

Cost-effective and scalable solutions

Some automation companies in Pune also offer complete turnkey projects. These include electrical control panels, robot cells, and HMI-based systems.

Whether you are in automotive, packaging, or FMCG, automation helps save time and reduce costs. Many companies in Pune now focus on Industry 4.0 technologies and smart factory integration too.

BIW Projects Design & Manufacturing Solutions Provider

BIW (Body-in-White) is a key phase in vehicle manufacturing. It involves the design and welding of the car body structure before painting. Companies that offer BIW project design and manufacturing solutions focus on both accuracy and speed.

What is BIW design?

BIW design involves:

Weld spot planning

Fixture design

Simulation for strength and rigidity

Robotic path planning

Leading providers ensure the entire BIW assembly line is optimized. From conveyors to clamps, every part is designed with precision.

Services provided by BIW solutions providers:

3D modeling and simulations

Robotic cell integration

Process validation

Fixture and gripper manufacturing

Turnkey BIW lines

The demand for BIW solutions is high in Pune due to the presence of top automotive OEMs and Tier-1 suppliers. Companies in this domain work with global quality standards and provide support from concept to commissioning.

Welding SPMs Design & Manufacturing in Pune

SPM (Special Purpose Machines) are custom machines designed for specific tasks. In welding, Welding SPMs are widely used for high-volume, repetitive jobs. Pune has many experienced players in designing and manufacturing welding SPMs.

These machines are tailored for:

Spot welding

MIG welding

TIG welding

Seam welding

Welding SPMs increase production efficiency and ensure consistent weld quality. Most machines are semi-automatic or fully automatic and can be integrated with robotic arms.

Benefits of Welding SPMs:

Reduced cycle time

Improved safety

High repeatability

Custom tooling options

Pune-based SPM manufacturers use CAD/CAM software and simulate the entire process before production. From fixture design to final assembly, everything is handled in-house.

They also offer after-sales service, control panel integration, and remote troubleshooting. That’s why industries in Pune trust local SPM makers for high-performance and durable welding machines.

Robotic Welding Fixtures Manufacturers in India

For robotic welding to work effectively, the fixtures holding the parts must be perfectly designed. This is where robotic welding fixtures manufacturers in India come into play.

What is a robotic welding fixture?

It is a tool used to:

Secure the components to be welded

Maintain alignment and accuracy

Allow easy loading and unloading

Minimize operator involvement

These fixtures are made with high-strength steel and use pneumatic or hydraulic clamping systems. Some also have sensors to detect part placement and alignment.

Leading Indian manufacturers offer:

Design and simulation of fixtures

Integration with robotic arms

Support for different weld processes

Customization based on component geometry

Robotic welding fixtures made in India are exported globally. These are used in industries like automotive, aerospace, defense, and construction machinery.

Why Pune and India Are Ideal for Automation and Welding Solutions

Pune and other Indian cities are now global players in the field of industrial automation and welding technologies. Here's why:

Skilled workforce: Engineers with mechanical, electrical, and automation expertise.

Cost-effective manufacturing: High quality at lower cost.

Technology integration: Use of advanced CAD tools, simulation software, and robotics.

Global supply chain: Export-ready capabilities with strong logistics support.

Whether you're setting up a new plant or upgrading an old one, Pune-based companies offer end-to-end solutions. From automation and SPMs to BIW systems and robotic fixtures, everything is locally available and globally reliable.

FAQs

Q. What are automation solutions in manufacturing? Automation solutions involve using machines, sensors, and software to run industrial processes with minimal human input.

Q. What is BIW in the automotive sector? BIW stands for Body-in-White, the stage in car manufacturing where the vehicle frame is assembled before painting.

Q. How do SPMs improve productivity? Welding SPMs are designed for speed, accuracy, and repetitive tasks. They cut down manual work and increase efficiency.

Q. Are robotic welding fixtures expensive? Not necessarily. Indian manufacturers offer cost-effective fixtures that meet international standards.

Q. Can I get custom automation solutions in Pune? Yes, many Pune-based companies offer customized automation systems based on your industry needs.

Final Thoughts

If you are searching for:

Automation solutions companies in Pune

BIW projects design & manufacturing solutions provider

Welding SPM’s design & manufacturers in Pune

Robotic welding fixtures manufacturers in India

— then Pune is the place to explore top-tier engineering and manufacturing partners.

These companies not only offer cutting-edge products but also partner with you through the entire journey—from design to delivery.

#automation solutions pune#BIW projects india#welding SPMs pune#robotic welding fixtures india#industrial automation#smart manufacturing#automotive manufacturing india#special purpose machines#robotics integration#pune engineering companies#robotics welding

0 notes

Text

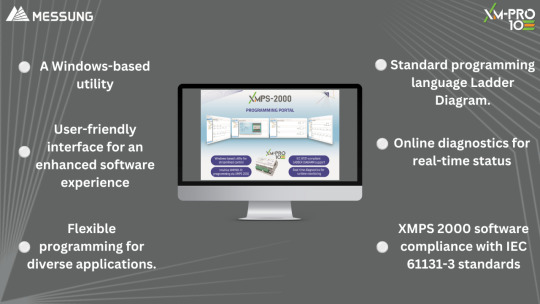

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

What Is PLC and SCADA? 2025 Beginners Guide

In the modern industrial world, automation is key to ensuring efficient, reliable, and safe operations. Two of the most important technologies behind industrial automation are PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). These systems are widely used across various industries, including manufacturing, power generation, oil and gas, water treatment, and transportation. This guide provides a clear understanding of what PLC and SCADA are, how they function, and how they work together to streamline industrial operations.

Understanding PLC: The Core of Industrial Automation

A Programmable Logic Controller (PLC) is a rugged digital computer designed specifically for controlling industrial machines and processes. It replaces traditional relay-based control systems and offers flexibility, reliability, and ease of programming.

PLCs are used to automate repetitive tasks. They receive input signals from sensors, process those signals according to a programmed logic, and then trigger appropriate outputs. These outputs can be used to control motors, solenoids, alarms, or other machinery.

One of the main advantages of PLCs is their ability to withstand harsh industrial environments. They are resistant to vibration, electrical noise, extreme temperatures, and dust, making them ideal for use in factories and processing plants.

Components of a PLC System

A basic PLC system includes the following components:

CPU (Central Processing Unit): The brain of the PLC that executes the control logic.

Power Supply: Provides the necessary voltage to the PLC system.

Input/Output Modules: Interface with field devices like sensors and actuators.

Programming Device: Used to write and transfer the logic to the CPU.

Communication Ports: Allow the PLC to connect with SCADA or other PLCs.

Introduction to SCADA: Centralized Monitoring and Control

While PLCs perform local control, SCADA (Supervisory Control and Data Acquisition) provides centralized supervision. SCADA is a software-based system that monitors and controls industrial processes from a central location.

SCADA systems collect data from PLCs and other control devices, display it in a user-friendly graphical format, and store it for future analysis. Operators can monitor equipment status, receive alarms, and send control commands from a SCADA interface.

SCADA is essential in large-scale operations where physical presence at every machine or sensor is not feasible. It allows industries to maintain control over complex systems spread across multiple locations.

Key Features of SCADA Systems

Real-Time Data Acquisition: Gathers data from field devices continuously.

Graphical User Interface (GUI): Displays process visuals for operators.

Alarm Management: Notifies operators of abnormal conditions.

Data Logging and Reporting: Stores historical data for audits and performance evaluation.

Remote Control: Enables operators to control equipment from a distance.

How PLC and SCADA Work Together

In most industrial setups, PLCs are responsible for direct control of machinery. They process sensor data and control outputs based on pre-defined logic. SCADA, on the other hand, acts as a higher-level system that collects data from multiple PLCs, analyzes it, and presents it to operators.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while SCADA provides a dashboard showing water levels, chemical dosages, and system status in real-time. If there is a problem, SCADA alerts the operator, who can then take corrective action remotely.

Applications of PLC and SCADA

The combined use of PLC and SCADA systems is common in many sectors:

Manufacturing: For managing automated assembly lines.

Power Plants: For monitoring turbines, generators, and safety systems.

Water Treatment: For controlling pumps, valves, and chemical dosing.

Oil and Gas: For pipeline monitoring, storage management, and leak detection.

Transportation: For traffic signal control and railway automation.

Benefits of Integrating PLC and SCADA

Improved Efficiency: Automation reduces human error and increases throughput.

Remote Monitoring: Operators can control systems from central control rooms.

Reduced Downtime: Quick response to system failures minimizes interruptions.

Data-Driven Decisions: Real-time and historical data support informed planning.

Cost Savings: Optimized operations lower operational and maintenance costs.

Conclusion

PLC and SCADA systems are foundational technologies in industrial automation. PLCs handle the core control functions at the equipment level, while SCADA provides real-time monitoring and centralized management. Together, they create a powerful system that improves reliability, safety, and efficiency in complex industrial environments.

As industries continue to evolve with Industry 4.0 and smart technologies, the integration of PLC and SCADA will become even more critical. Understanding these systems is essential for engineers, technicians, and anyone aspiring to work in the field of automation.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes