#replace subframe

Explore tagged Tumblr posts

Text

Rear subframe replacement is underway on a Volvo.

Once this work is completed, a wheel alignment will be performed.

Typically, we don’t replace subframes unless they are rusted, bent or damaged. However, sometimes our technicians need to move them to reach other parts.

#subframe replacement#volvo#steve's auto repair and tire#prince william county virginia#replace subframe

1 note

·

View note

Text

Couple weeks ago, I was watching the evening news when a commercial came on. Usually, I skip those suckers. Change channels. Couldn't do that this time, though, because the television I was watching was in my neighbour's living room. And although the binoculars I was using to look into said living room are exceptionally high-tech, they do not contain a television remote. Always leaving something on the table for the 2.0 version, those fucking scam artists.

Here's what the commercial was: a prayer line. You could dial in and pay nine cents a minute to have a group of folks working in a call centre pray for you. The handsome-yet-celibate dude wearing an insanely expensive suit droned on about something I couldn't hear, but the message was obvious. If I got them to get their god to do my bidding, then maybe I'd be able to win at a salvage auction for once.

The only higher power I believe in is the universe's ability to put its thumb directly on me as soon as I start to get a little smug, almost as if my hubris leads inevitably to a moderately funny downfall. Couldn't hurt to bring in another guy and make them fight.

Thing is, I don't have a phone. Sure, I have a smartphone, everyone does, but it can't make phone calls. Or send data. Or light up more than about half the screen. So I had to help myself to one of the public-use phones at the police station, pretending that I was calling home to my wife to come bring my insurance card. I think the precinct desk clerk was starting to get suspicious around hour two, but she went on break shortly after that and was replaced by someone who I could repeat the same bullshit story to. Four hours in total of god-bothering, I figured, would at least score me a low-mileage Intrepid with subframe damage.

Friends, it did not work. Well, it kind of worked. I ended up with a recent Mercedes luxobarge that was running perfectly well, had low kilometres on the clock, and was immaculate inside and out. Exactly the opposite of what I was looking for. Repulsed, I immediately put it back up for auction and got several thousand worthless dollars of profit, instead of a cool shitbox. That's what you get for trying to mess with the fates.

427 notes

·

View notes

Text

CAR UPDATE!

So, *finally* got a chance to take the goddamn car into the shop to be inspected. People donated something $850 to the GFM, and I genuinely appreciate it because there is no other way I would have been able to afford to take it in.

… anyway, turns out it can’t pass inspection.

Let’s start simple. It needed (that I knew of) a headlight bulb replaced, new brake pads and rotors, and an oil change. It turned out it also needs a new windshield wiper, a ball joint, and a couple of filters. That will come to $970.

So, Jennifer, why can’t it pass inspection?

Because the subframe is rotted. That’s why.

How much does a subframe cost? Oh, $2000.

There’s not much I could have done to stop the subframe being rotted. With where I live and park, that’s not a shocker. Still, I do not have $2000. There’s no amount of cutting back on streaming services or the little things that’ll make $2000 magically appear. SO. GFM, it is.

Gimme a little time and I’m going to see about editing the one I have set up to add this new info. And then I’m going to get SO fucking high.

29 notes

·

View notes

Text

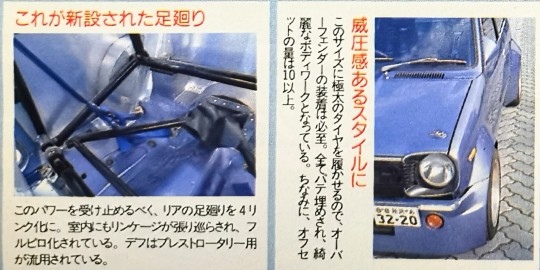

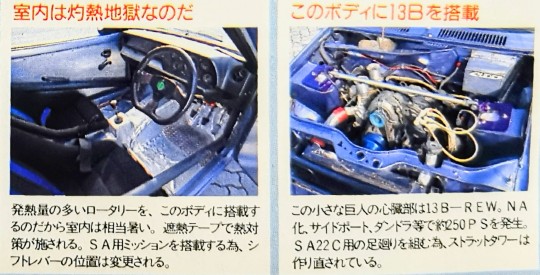

Mazda Chantez kei car with a 13B from an FD3S RX7 transplanted. Engine converted to high comp NA with fuel from a Weber carby. Front suspension and gearbox from an SA22C RX7. Custom 4 link rear suspension.

TRANSLATION OF TEXT AND PIC CAPTIONS

Super Chantez revived as a modern version. Enjoy watching and driving.

This year Mr. Shimoyama's Chantez came in 2nd place with a difference of one vote. This Chantez is a remake of a car that RE Amemiya once built. However, it is not a complete remake at all.

This can be said to be the reason why we were able to score points. The installed engine has been replaced with a 13B-REW for FD3S. The 13B is set to NA, and a high compression rotor (compression ratio 9.7) is installed in the side port tune. Also, instead of using injection, the engine was intentionally changed to Weber's downdraft, producing a maximum output of 246PS. Of course, exhaust manifolds, mufflers, etc are custom items and are made of stainless materials.

And that's not the only thing that makes this Little Gang style Chantez so great. The rear suspension has been completely rebuilt. From normal leaf to original 4-link subframe

(It's also full pillow) and there's a lot left.

They are now able to accept the power that comes with it. On the other hand, a new strut tower has been installed for the front suspension, and the suspension from the SA22C has been reused. By the way, the cost to modify this model of Chantez was over 3.3 million yen. Since the modification has been so thorough, I guess there's nothing that can be done about it. Now, the owner, Mr. Shimoyama, is currently putting this Chantez up for sale for 1.98 million yen.

_________________________________________

This is the newly installed suspension

In order to absorb this power, the rear suspension has been made into a 4-link structure. The interior is also lined with linkage, making it fully covered. The differential is a pre-rotary one.

For an intimidating style

Since this size is equipped with extremely thick tires, it is inevitable to install over fenders. Everything is filled with putty and the bodywork is beautiful. By the way, the amount of offset is

-10 or more.

_______________________________________

It's a scorching hell inside the room.

Since this body is equipped with a rotary engine that generates a lot of heat, it gets quite hot inside. Heat countermeasures will be taken with heat shield tape. The shift lever position will be changed to accommodate the SA mission.

This body is equipped with a 13B

The heart of this little giant is 13B-REW. NA, side ports, Weber, etc., generating about 250PS. The strut tower has been rebuilt to accommodate the suspension for SA22C.

________________________________________

A powerful over fender that accommodates extra-thick tires. Tire size 175/50R13 is worn on the front and rear.

17 notes

·

View notes

Text

All Hard Parts for Motorcycle: Essential Upgrades for Performance and Safety

Motorcycles are more than just machines—they're expressions of freedom, power, and personal style. Whether you're a casual rider or a performance enthusiast, upgrading and maintaining your bike's hard parts is key to ensuring it runs smoothly, looks sharp, and remains safe on the road. These components form the mechanical backbone of your motorcycle, affecting everything from how it handles to how fast it goes.

What Are Motorcycle Hard Parts? Hard parts refer to the essential mechanical and structural components of a motorcycle. These are not cosmetic or soft accessories like seat covers or tank pads—they're the parts that keep the bike running and safe to ride. Common examples include engine parts, suspension systems, brakes, wheels, and frames. Unlike aesthetic upgrades, hard parts directly influence performance, safety, and durability.

Main Categories of Motorcycle Hard Parts Engine components include pistons, valves, camshafts, and crankshafts. Upgrading or replacing these can significantly improve your bike’s horsepower and responsiveness. Exhaust systems are another critical area, comprising headers, pipes, mufflers, and catalytic converters. A performance exhaust can reduce weight, increase power, and give your motorcycle a more aggressive sound. Suspension systems, such as forks, rear shocks, and swingarms, control how your bike handles and absorbs bumps. Quality suspension upgrades offer better control, smoother rides, and safer handling, especially at high speeds or rough terrain. Brake systems consist of rotors, calipers, pads, and master cylinders. These are essential for safety. Upgrading your braking system enhances stopping power and reduces brake fade during aggressive or prolonged riding. Transmission and drivetrain parts like clutches, chains, sprockets, and gearboxes dictate how power from the engine reaches the wheels. High-performance parts ensure smoother shifting, quicker acceleration, and better efficiency. Wheels and tires are foundational for traction, balance, and speed. Lighter wheels and high-performance tires can drastically change how your bike feels on the road or track. The frame and subframe are the bike’s skeleton, supporting every other part. Some riders choose lightweight frames for racing performance, while others upgrade for aesthetics or specific riding ergonomics. Controls and levers such as handlebars, footpegs, brake levers, and shifters are not just for comfort—they’re critical for proper bike control. Premium components offer better grip, adjustability, and feedback. Cooling systems like radiators, hoses, and fans are essential for high-performance engines to avoid overheating and maintain consistent power output. Fuel system parts, including tanks, pumps, injectors, and carburetors, affect how fuel is delivered and consumed. Efficient systems lead to better mileage and smoother throttle response.

Why Should You Upgrade Hard Parts? Upgrading hard parts enhances your motorcycle’s performance, making it faster, more responsive, and more reliable. It also adds to customization, allowing your bike to match your personal style or riding needs. High-quality hard parts offer better durability, meaning fewer breakdowns and lower maintenance in the long run. Most importantly, they improve safety—better brakes, suspension, and control systems make every ride more secure and predictable.

OEM vs. Aftermarket Hard Parts When upgrading your motorcycle, you'll face the choice between OEM (Original Equipment Manufacturer) and aftermarket hard parts. OEM parts are made by the bike's manufacturer and are guaranteed to fit and perform to factory standards. However, they tend to be more expensive and offer limited customization. On the other hand, aftermarket parts are made by third-party companies and come in a wide variety of designs and performance levels. They're often more affordable and customizable, but quality can vary. To ensure safety and reliability, it's crucial to choose well-reviewed brands and parts that are specifically designed to fit your motorcycle model.

Tips for Choosing the Right Hard Parts Before purchasing or installing hard parts, always check your motorcycle’s specifications. Knowing your bike’s make, model, and year helps ensure compatibility. Be clear about your goals—whether it’s increasing speed, improving ride comfort, enhancing safety, or achieving a specific look. Take time to research the best brands, read rider reviews, and if needed, consult with a mechanic for proper installation and advice.

Conclusion Investing in all hard parts for motorcycles is not just about upgrades—it's about transforming your machine into a safer, more efficient, and more personalized ride. From the engine to the brakes, each component plays a vital role in your motorcycle’s performance. Whether you’re tuning your bike for speed, comfort, or endurance, quality hard parts are essential. Choose wisely, maintain regularly, and enjoy the power and freedom your upgraded motorcycle can deliver.

#tail bags for motorcycles#tank bags#motorsport#motorcycle#hydration pack#motorcycle tail bags#motorcycle luggage#motorcycle accessories#motorbike#essential series

2 notes

·

View notes

Note

what did you hit with your car?? it would take a LOT to bend a strut, let alone both of them. and unless your subframe was rusted out that shouldnt have possibly needed replacement either. it sounds like your mechanic is taking you for a ride if im being honest. struts do wear out and impact ride quality, but not alignment. and usually alignments will find bad balljoints, control arms, or tie-rods that need replacing but subframes are closer to the body of the car, not a part that wears out.

idk im sorry if im overstepping its prob too late anyways i just always feel bad when it sounds like a mechanic is taking advantage of somebody. hope its back on the road again soon 🙏 if you ever need to fix your car again in the future parts on rockauto.com are usually way cheaper than mechanics charge unless you get a good one

bumped into someone's trailer months ago which misaligned my car (i've been driving it with the steering wheel turned to the right this whole time). this was actually the third place i've taken it to and showed me what's going on underneath the car and why they weren't able to align the passenger side (was sitting there for like 2 hours while the guy tried to fix it). i'm pretty sure it's the struts are bent enough that they (or something next to them) are scraping against my tires and wearing them down. but also not ruling out the subframe because it's aluminum so it's more prone to bending (probably as a safety thing, unfortunately). basically i fucked myself over because i was a little too impatient for a few seconds

6 notes

·

View notes

Note

prompt: Bonnie treats Kitt3 right

Some discretion was taken with this. Mostly the ABS and such-- gotta assume that KITT and KI3T have the whole nightmare, even in the 80s. Bonnie isn't too flabbergasted by the tech because KITT is, as they say, the car of the future.

"KITT, turn your wheel all the way to the right, please."

KITT-- Three Thousand-- turns his wheel all the way to the right. Immediately, hands are all over his frame again, untangling the brake line from the wheel hub assembly. He uses a portion of his sophisticated sensory suite to watch Bonnie work, even as her face screws up in consternation, her most common expression since beginning maintenance.

And what maintenance it is! She's propped him up on jackstands and wooden blocks. It is a far cry from the gyroscopic, laser-equipped armory he's used to. It gives him time to reflect on what he considers normal. As it turns out, if a human is involved with his care, it is through a laptop.

But laptops do not exist here. And this time, his failure is... physical.

"You seem perturbed, Dr. Barstow," he says quietly.

Bonnie's face scrunches up. She fusses at the knot of sensors dangling from his front left wheel. With him unable to power down, it is a mess of data, all of it erroneous. But--

Not unwelcome.

"Not-- perturbed, KITT," she says, echoing him. "Just can't make heads or tails of what's going on here. Pretty sure it's not supposed to look like this, though. Is it?"

She brandishes some of the cables underneath his chassis. A curious location, but not useless. And it seems practiced, or at least embedded in muscle memory, as her shoulders drop several inches. Confusion is always so fascinating on humans. It's enough to soothe his irritation at his fouled eyes; the plastic sheathing has melted together.

"No, it is not. It appears I have melted the bulk of my wheel speed sensors on this side."

His fault. The 1974 Mustang II form he'd adopted had been, as Mike would say, slapped together. And consolidating all of his functions into such a tight package was, ah.

Not what he was designed to do.

Bonnie brushes her fingers across a piece of his subframe. It shouldn't feel like anything, but the nanoskin is more sensitive than usual like this. And it's a wholly novel experience. Humans do not touch him often.

It is... undeniably a positive impact.

Eventually, she pushes herself up to a standing position, silent.

KITT watches her raptly.

"Want me to see if any of, uh, KITT's parts will fit?" Bonnie asks finally. Once again, she seems 'put out', clearly trying to come up with a solution and finding none.

"I do not wish to impose. If my databanks are correct, replacement parts for my predecessor were... expensive. Nearly a quarter of the Foundation's budg--"

Her face goes gray. Wisely, he ceases speaking, because he likes her. If it'd been anyone else...

"Don't remind me. Jesus. Okay. Look, let me just see if they'll fit, okay?"

"Of course," KITT says. "I am not going anywhere."

Bonnie laughs and ducks out of the trailer. His analyzer reads it as 'slightly hysterical.' Perhaps the circumstances are painful for both of them.

12 notes

·

View notes

Text

Lately, we've been racking up miles on the new Suzuki V-Strom 1050DE. This year Suzuki has put more focus on dirt performance incorporating features like a 21" front wheel along with increased suspension travel and ground clearance, a more-rigid swingarm and subframe, serrated footpegs, a new Gravel ride mode, and more. In order to get a better sense of the bike’s off-road capabilities, we replaced the stock street-biased tires with a set of Heidenau K60 Ranger (70% Dirt / 30% street) Dual Sport tires. This made a significant improvement in loose terrain that allowed us to push the 1050DE's limits with greater confidence. Yet they still gave us plenty of grip on the street for some spirited riding in the twisties. Plus they're quiet on the highway too! For more details on the K60 Ranger, check out our full review at bit.ly/ridek60ranger and stay tuned for more details from our V-Strom test!

#dualsport#adventure bike#adventure motorcycle#vstrom#adventurebike#dual sport tires#heidenau#k60 ranger

11 notes

·

View notes

Text

stream of consciousness post

my new car is great in a lot of ways but it’s… slow

It’s the base model 5-series 2.5L i6 189hp 6500rpm in a ~3600lb car

My other car I usually drive is a Taurus SHO 3.2L V6 220hp 7000rpm, which is just enough to have fun with in a ~3400lb car. A great engine in a mediocre car. Now I have a great car with a mediocre engine.

If I wanted to change that, I’m contemplating two different routes.

Swap in the 3L m54b30 version of the engine from the e39 530 sedan or e46 330, maybe get the 330 zhp engine for a bit more power and revs. that would be fairly affordable and probably replicate the performance of the Taurus, while keeping the straightforward parts compatibility and i6 smoothness, and I could possibly manual swap it at the same time relatively easily.

But that would still only get me 235hp/6800rpm, which would be… enough, but it’d still be slower than it looks, with the M5 front bumper and wheels (still need the back bumper).

The s54 engine from the e46 m3 would be really fun, 3.2L 333hp 8000rpm, or the actual M5’s s62 V8, 4.9L 394hp 7000rpm, but those are really expensive and questionably reliable. The 540’s m62 4.4L V8, 290hp 6000rpm, would also be an option with factory compatibility but it’s got timing chain reliability issues, and isn’t very powerful or efficient for a modern V8, and revs even lower than what I’ve already got.

So then there’s the ford coyote v8, 5L 435/460/480/500hp and 7000/7500rpm depending on the version. Pretty fuel efficient for what it is, and while more expensive than the m54b30 I could probably find one for less than an m3 or m5 engine, and it would have better power, efficiency, and reliability/maintenance friendliness than any of the other options, and more revs than anything but the s54, especially if I go for the gen 3 coyote.

I’m definitely not going to LS swap it, yes that’s the cheapest most powerful option, but a low revving pushrod engine just wouldn’t suit the car.

I’d really like to get one of the ones with the tremec tr3160 transmission, not the mt82. The gt350’s 5.2L 526hp 8250rpm V8 also exists and has that trans, and would be amazing, but might be too expensive and vibrate too much. idk I haven’t driven one to know, but I really like the current i6 smoothness and want to stay as close to that as I can.

Another issue is the rear differential. The only direct swap for the current open diff is the M5’s lsd, and those are expensive and only have one ratio option. What I want to do is put the ford 8.8 irs diff in it, either from an older explorer or cobra etc, or from whatever s550/s650 mustang I get as a donor car. Problem is, the mounts don’t fit. You’d need to modify or replace the rear cover, and weld new front mounts onto the car’s subframe. Doable, I’ve seen it done for the guys who have ls swapped these, but it’s work I don’t currently know how to do. I’d probably have to get a lot of outside help for the whole project, especially the electronics programming and wiring. My friend who sold me the car is a fabricator, which could come in handy.

Then there’s the exhaust. One of the most annoying things about the car. Every e39 5-series has the spare tire and battery on the right side of the of the under-trunk area, which only leaves room for a single exhaust on the left side. The M5 ditched the spare tire to run dual exhaust, which is a lot to give up. All the dual exhaust conversions I’ve seen online either replace the whole rear floor with m5 sheet metal, or are ugly hack jobs. All of them lose the spare tire. I think, if you ran small mufflers, or had the muffler further forward, you could shift the spare tire to the center and sneak a second tailpipe between the tire and battery compartments.

Alternatively, just run the stock axle-back section for quiet mode and have two valved dump pipes in front of the diff. But I really like the aesthetics of the m5 bumper and quad tips, so idk

5 notes

·

View notes

Text

Why an Independent BMW Specialist Offers Better Value Than Dealerships

An independent BMW specialist provides an alternative to dealership servicing, offering competitive pricing, deep technical expertise, and personalised service. These independent workshops focus exclusively on BMWs, meaning they are often better equipped to handle complex diagnostics, performance tuning, and long-term maintenance than general garages. For Australian BMW owners seeking reliable, cost-effective servicing, choosing an independent specialist ensures that your car receives expert care without dealership markups.

What Sets Independent BMW Specialists Apart?

Specialist workshops offer several advantages over traditional dealerships:

Dealership-Level Diagnostics: Many independent specialists use factory-level scanners and software to interpret BMW-specific fault codes.

Lower Labour Rates: Without dealership overheads, independent workshops often charge less while delivering comparable or superior service.

In-Depth Model Knowledge: Technicians are often passionate BMW owners themselves, bringing hands-on experience beyond technical manuals.

Flexibility in Parts Sourcing : May use genuine BMW parts or high-quality alternatives that meet or exceed factory specifications.

Personalised Customer Interaction : Smaller workshops typically offer direct communication with technicians, improving transparency and trust.

These differences make independent specialists appealing to many BMW owners.

What Types of Repairs and Services Do Specialists Handle?

An independent BMW specialist covers a broad range of mechanical and electronic needs:

General Servicing and Oil Changes : Performing scheduled maintenance using approved fluids and filters.

Transmission and Differential Repairs : Addressing gearbox issues, clutch replacements, and differential wear in rear-wheel and all-wheel-drive models.

Electrical Fault Diagnostics : Troubleshooting complex electrical issues including wiring harness failures, sensor malfunctions, and module reprogramming.

Suspension and Steering Component Replacement : From control arms to subframe mounts, specialists address wear items that affect ride quality and handling.

Air Conditioning and Climate Control Servicing : Refilling refrigerant, replacing compressors, and fixing heater core issues.

These services ensure that even older models remain roadworthy and comfortable.

How Do Independent Specialists Approach Diagnostics?

Diagnosing modern BMWs requires advanced equipment and experience:

Factory-Level Scan Tools : Many specialists use ISTA or similar software to access real-time data and coding adjustments.

Interpretation of Error Codes : Unlike generic code readers, BMW specialists understand the context behind each fault message.

CAN Bus and Module Communication : Experts diagnose issues within interconnected systems that general mechanics may struggle to interpret.

Software Updates and Recalls : Some independent shops apply official software patches and firmware upgrades when needed.

Component Testing and Swaps : When a part fails intermittently, specialists often test components rather than replace outright.

This methodical approach reduces guesswork and unnecessary part replacements.

What Should You Expect in Terms of Cost and Turnaround Time?

Costs at an independent BMW specialist vary but often compare favourably to dealership pricing:

Labour Rate Differences : Independent shops typically charge lower hourly rates, making complex jobs more affordable.

Parts Pricing Options : Some specialists source parts directly from Europe, while others use local distributors for faster turnaround.

Transparent Billing Practices : Reputable specialists itemise costs, ensuring clarity on parts, diagnostics, and repair work.

Repair Duration Variability : Minor services may take a few hours, while major repairs could take several days depending on parts availability.

Value for Money : Despite being independent, many offer higher service quality than dealerships due to focused expertise and smaller client loads.

These factors contribute to a more satisfying and cost-efficient ownership experience.

How to Select the Right Independent Specialist

Finding a reputable independent BMW specialist involves several steps:

Community Recommendations: Enthusiast forums and local BMW clubs often list trusted service providers.

Review Online Feedback: Reading past customer experiences gives insight into reliability, communication, and work quality.

Verify Technical Qualifications: Ensure the workshop employs licensed technicians with experience in modern BMW platforms.

Check for Proper Tools and Equipment: The best specialists invest in the latest scanning and diagnostic tools.

Visit the Workshop in Person: Seeing the environment and meeting the team builds confidence in the service provider.

A well-researched choice leads to better outcomes and long-term vehicle satisfaction.

Final Thoughts

An independent BMW specialist offers a compelling alternative to franchised dealerships, particularly for those seeking expert diagnostics, cost-effective repairs, and tailored service. With the right specialist, owners can enjoy the full potential of their BMW without paying inflated dealership prices. As the market for independent workshops grows, so does the opportunity for Australian BMW drivers to access high-quality, model-specific care that supports both daily commutes and weekend driving pleasure.

0 notes

Text

Deck Repairs Northern Beaches – Reinvent Your Outdoor Living with Viccon’s Expert Touch

Your outdoor deck isn’t just a structural extension of your home—it’s where morning coffees are savoured, evening chats take place, and memorable moments unfold. However, decks face constant exposure to Sydney's coastal weather, especially in areas like the Northern Beaches, where salt air, moisture, and intense sun can quickly wear down even the most robust timber.

At Viccon Deck and Timber Restoration, we believe in more than just surface fixes. We deliver comprehensive Deck Repairs Northern Beaches, breathing new life into your outdoor space through skilled craftsmanship and proven restoration techniques. Whether your deck is splintered, unstable, discoloured, or simply aged, we’re here to help you rediscover its true potential.

Why Deck Repairs Are Crucial for Northern Beaches Properties

The Northern Beaches of Sydney offer a stunning coastal lifestyle, but that environment can take a heavy toll on timber decking. Common issues we see include:

Saltwater corrosion of metal fixings and fasteners

Warped or cupped boards due to intense sun exposure

Rot and decay from excess moisture and poor drainage

Faded, splintering timber resulting from prolonged UV exposure

Loose railings and unsafe structures that pose serious safety risks

Ignoring these signs doesn’t just impact aesthetics—it can lead to more extensive damage and expensive replacements down the track. That’s why timely, professional deck repairs in Northern Beaches are essential for preserving both the beauty and safety of your deck.

What Makes Viccon the Trusted Name in Deck Repairs

At Viccon, we approach each project with precision, care, and a genuine commitment to customer satisfaction. Our deck repair services in the Northern Beaches stand out for several reasons:

1. Comprehensive Restoration, Not Just Quick Fixes

We assess the full structure of your deck—not just the surface. Our repair work includes replacing damaged boards, re-securing framing, fixing joints, and treating timber to ensure your deck is fully safe, sturdy, and visually appealing.

2. Tailored Repairs for Local Conditions

From Collaroy to Manly and Avalon to Dee Why, we understand the specific challenges faced by decks along the Northern Beaches. We tailor our materials and techniques to suit the harsh coastal environment, ensuring long-lasting results.

3. Licensed and Experienced Tradespeople

Our team is comprised of trained professionals who bring years of hands-on experience in decking and timber restoration. We work with all timber types commonly used in Sydney decks, including spotted gum, merbau, and treated pine.

4. High-Quality Materials and Finishes

We use only premium-grade materials and weather-resistant coatings to protect your deck and extend its lifespan. This includes rust-proof fixings, eco-friendly timber treatments, and UV-protective finishes.

What’s Included in Our Deck Repairs (Northern Beaches)

Viccon offers an end-to-end deck repair service that covers:

Board replacement: Removing cracked, cupped, or rotting boards and fitting new, matched timber

Structural repairs: Reinforcing subframes, posts, and joists to restore stability and load-bearing strength

Fastener replacement: Replacing rusty or corroded screws, nails, and bolts with marine-grade alternatives

Timber treatment: Applying anti-fungal and anti-rot solutions to prevent future deterioration

Deck sanding and refinishing: Restoring the smooth surface and natural colour of your timber before sealing it with high-performance oils or stains

With every project, we aim to restore your deck to like-new condition—or better.

The Viccon Process: Deck Repairs Done Right

We follow a detailed, professional process that ensures every repair is durable, attractive, and built to last:

On-Site Inspection We begin with a thorough on-site assessment to evaluate structural integrity, timber health, and moisture levels.

Custom Repair Plan Our team develops a tailored repair plan based on your deck's condition, materials, and usage.

Repair & Restoration Work Using industry-best tools and techniques, we carry out the repairs efficiently while maintaining a clean work environment.

Finishing & Protection We sand the surface for a smooth finish and apply protective coatings to preserve your deck’s new look against coastal wear.

The Benefits of Restoring Your Deck with Viccon

Investing in professional deck repairs in Northern Beaches delivers a range of lasting benefits:

Enhanced Safety: No more tripping hazards, loose boards, or weak railings

Improved Appearance: Your deck looks refreshed, cleaner, and more modern

Extended Deck Lifespan: Quality repairs delay the need for costly full replacements

Increased Property Value: A beautifully maintained deck boosts the overall value and appeal of your home

Greater Enjoyment: Spend more time outdoors, worry-free, in a space that feels brand new

Reinvent the Spaces You Use with Viccon

At Viccon, we believe that decks are not just surfaces—they’re experiences waiting to happen. Our goal is to help homeowners across the Northern Beaches rediscover their outdoor spaces by transforming aged or damaged decks into safe, stylish, and durable extensions of their homes.

We don’t just fix decks—we reinvent them with care, precision, and craftsmanship that lasts.

Ready for Quality Deck Repairs Northern Beaches Can Rely On?

If your deck is showing signs of wear, don't wait until the damage becomes irreversible. Contact Viccon Deck and Timber Restoration today and let us breathe new life into your outdoor area with trusted Deck Repairs Northern Beaches.

We offer transparent quotes, fast turnaround times, and workmanship you can depend on. Whether it’s a minor board replacement or a full structural overhaul, we’re the team locals trust for quality deck care.

0 notes

Text

[ad_1] Gestamp showcases advanced vehicle components on the advancement of electric mobility at the 2nd edition of the Bharat Mobility Global Expo in New Delhi Unveils large integrated components from its GES-GIGASTAMPING® product family, engineered to create lighter, safer vehicles, reduce energy consumption, and minimize environmental impact Chassis innovations, such as Highpertubes (a high-strength tube material) in subframe designs, are key to crash performance For pedestrian protection, Edscha Gestamp introduces Active Frunk, a solution tailored for electric vehicles that combines a powered system for fully automatic opening and closing of the front lid Gestamp, a leading global automotive technology company specialized in the design, development, and production of highly engineered metal components, unveiled its innovative product lineup today at Bharat Mobility Global Expo. Glimpses of the innovative solutions showcased in the Gestamp booth at the Bharat Mobility Global Expo As the automotive industry pivots towards electrification, connectivity, sustainability, and safety, Gestamp is stepping up to meet the evolving demands of this dynamic landscape. The company is addressing the growing need for lightweight, eco-friendly materials while adhering to stringent safety standards—an endeavor that presents both challenges and opportunities for automakers worldwide. With a focus on reducing CO₂ emissions without compromising cost efficiency, Gestamp's innovative technologies are designed to support the mobility of the future. The company is committed to creating lighter and safer vehicles that consume less energy and have a smaller environmental footprint. Speaking at the unveiling, Mr. Glyn Jones, Country Manager, Gestamp India said, "Sustainability has been an integral part Gestamp’s strategy since its inception. We’re committed to designing, developing, and manufacturing vehicle parts that contribute to creating cars that are not only safer for consumers but also lighter on the environment. As the automotive industry undergoes significant changes, Gestamp expresses optimism about the future. Its focus on lightweight solutions enhances vehicle performance while aligning with sustainability goals. These products that we unveiled today represent key advancements in Gestamp's pursuit of innovation and sustainability, emphasizing lightweight design, improved safety, reduced CO2 emissions, and cost efficiency." Gestamp’s Technology and Innovation Office is leading the development of solutions for a new mobility where multiple powertrains coexist, from combustion engines, hybrids, and plug-in hybrids to pure electric vehicles. By harnessing its engineering expertise and advanced technologies, Gestamp is driving the shift to electric mobility. The company is creating key components for new EV architectures, focusing on lightweight materials to enhance vehicle range, advancements that meet evolving safety standards, and designs that streamline assembly processes. Gestamp introduced its GES-GIGASTAMPING® product line—a pioneering family of large-format components that combine multiple body parts into a single unit. This one-piece component replaces multiple cold and hot-stamped parts, streamlining assembly and cutting costs. It provides notable benefits, including enhanced safety cell integrity during crashes, lighter components, easier integration, and a more sustainable solution. In the chassis segment, Gestamp also unveiled its Highpertubes—high-strength tube materials designed to enhance vehicle crash performance. These crucial components play a vital role in occupant safety and are manufactured using advanced hydroforming technologies to achieve optimal CO₂ efficiency and cost-effectiveness. Additionally, Gestamp unveiled the Active Frunk, specifically designed for electric vehicles. This technology features a powered system for

fully automatic opening and closing of the front lid while incorporating active pedestrian protection measures. Sustainability and Circular Economy as core business strategies Sustainability has been a cornerstone of Gestamp's strategy, with the company targeting carbon-neutral production by 2050. To achieve this, Gestamp plans to significantly reduce CO₂ emissions and resource consumption by incorporating recycled materials and shifting to 100% green electricity by 2030. The company adopts a circular economy model, recycling steel and other materials to lower emissions and conserve water. Gestamp also ensures a reliable supply of high-quality scrap steel to facilitate the increased use of low-emission steels in automotive components. The integrated scrap management system allows full lifecycle traceability, from collection and sorting to the reuse of quality scrap steel. This process reintroduces recycled steel as a secondary raw material, promoting a sustainable materials economy that reduces the need for primary resources and helps steer the automotive industry toward a climate-friendly future. Gestamp also collaborates closely with partners to advance sustainable innovations such as low-emission steel for vehicle components, strengthening its role as a leader in promoting environmentally responsible mobility within the automotive sector. Gestamp in India Gestamp has been present in the Indian market since 2006. The company began operations that year and, two years later, began construction of its first plant in Pune. Today, Gestamp operates four production plants in India: three in Pune (Pune I, Pune II, and Chennai) and one Edscha plant in Chakan, employing over 1,000 people. Additionally, the company has sales offices in Maharashtra and R&D capabilities in Pune. About Gestamp Gestamp is a multinational specialized in the design, development, and manufacture of highly engineered metal components for the main vehicle manufacturers. It develops products with an innovative design to produce lighter and safer vehicles, which offer lower energy consumption and a lower environmental impact. Its products cover the areas of BiW, chassis and mechanisms. The Company is present in 24 countries with 115 production plants (5 of those under construction), 13 R&D centers and a workforce of more than 44,000 employees worldwide. Its turnover in 2023 was €12,274 million. Gestamp is listed on the Spanish stock exchange under the ticker GEST. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

[ad_1] Gestamp showcases advanced vehicle components on the advancement of electric mobility at the 2nd edition of the Bharat Mobility Global Expo in New Delhi Unveils large integrated components from its GES-GIGASTAMPING® product family, engineered to create lighter, safer vehicles, reduce energy consumption, and minimize environmental impact Chassis innovations, such as Highpertubes (a high-strength tube material) in subframe designs, are key to crash performance For pedestrian protection, Edscha Gestamp introduces Active Frunk, a solution tailored for electric vehicles that combines a powered system for fully automatic opening and closing of the front lid Gestamp, a leading global automotive technology company specialized in the design, development, and production of highly engineered metal components, unveiled its innovative product lineup today at Bharat Mobility Global Expo. Glimpses of the innovative solutions showcased in the Gestamp booth at the Bharat Mobility Global Expo As the automotive industry pivots towards electrification, connectivity, sustainability, and safety, Gestamp is stepping up to meet the evolving demands of this dynamic landscape. The company is addressing the growing need for lightweight, eco-friendly materials while adhering to stringent safety standards—an endeavor that presents both challenges and opportunities for automakers worldwide. With a focus on reducing CO₂ emissions without compromising cost efficiency, Gestamp's innovative technologies are designed to support the mobility of the future. The company is committed to creating lighter and safer vehicles that consume less energy and have a smaller environmental footprint. Speaking at the unveiling, Mr. Glyn Jones, Country Manager, Gestamp India said, "Sustainability has been an integral part Gestamp’s strategy since its inception. We’re committed to designing, developing, and manufacturing vehicle parts that contribute to creating cars that are not only safer for consumers but also lighter on the environment. As the automotive industry undergoes significant changes, Gestamp expresses optimism about the future. Its focus on lightweight solutions enhances vehicle performance while aligning with sustainability goals. These products that we unveiled today represent key advancements in Gestamp's pursuit of innovation and sustainability, emphasizing lightweight design, improved safety, reduced CO2 emissions, and cost efficiency." Gestamp’s Technology and Innovation Office is leading the development of solutions for a new mobility where multiple powertrains coexist, from combustion engines, hybrids, and plug-in hybrids to pure electric vehicles. By harnessing its engineering expertise and advanced technologies, Gestamp is driving the shift to electric mobility. The company is creating key components for new EV architectures, focusing on lightweight materials to enhance vehicle range, advancements that meet evolving safety standards, and designs that streamline assembly processes. Gestamp introduced its GES-GIGASTAMPING® product line—a pioneering family of large-format components that combine multiple body parts into a single unit. This one-piece component replaces multiple cold and hot-stamped parts, streamlining assembly and cutting costs. It provides notable benefits, including enhanced safety cell integrity during crashes, lighter components, easier integration, and a more sustainable solution. In the chassis segment, Gestamp also unveiled its Highpertubes—high-strength tube materials designed to enhance vehicle crash performance. These crucial components play a vital role in occupant safety and are manufactured using advanced hydroforming technologies to achieve optimal CO₂ efficiency and cost-effectiveness. Additionally, Gestamp unveiled the Active Frunk, specifically designed for electric vehicles. This technology features a powered system for

fully automatic opening and closing of the front lid while incorporating active pedestrian protection measures. Sustainability and Circular Economy as core business strategies Sustainability has been a cornerstone of Gestamp's strategy, with the company targeting carbon-neutral production by 2050. To achieve this, Gestamp plans to significantly reduce CO₂ emissions and resource consumption by incorporating recycled materials and shifting to 100% green electricity by 2030. The company adopts a circular economy model, recycling steel and other materials to lower emissions and conserve water. Gestamp also ensures a reliable supply of high-quality scrap steel to facilitate the increased use of low-emission steels in automotive components. The integrated scrap management system allows full lifecycle traceability, from collection and sorting to the reuse of quality scrap steel. This process reintroduces recycled steel as a secondary raw material, promoting a sustainable materials economy that reduces the need for primary resources and helps steer the automotive industry toward a climate-friendly future. Gestamp also collaborates closely with partners to advance sustainable innovations such as low-emission steel for vehicle components, strengthening its role as a leader in promoting environmentally responsible mobility within the automotive sector. Gestamp in India Gestamp has been present in the Indian market since 2006. The company began operations that year and, two years later, began construction of its first plant in Pune. Today, Gestamp operates four production plants in India: three in Pune (Pune I, Pune II, and Chennai) and one Edscha plant in Chakan, employing over 1,000 people. Additionally, the company has sales offices in Maharashtra and R&D capabilities in Pune. About Gestamp Gestamp is a multinational specialized in the design, development, and manufacture of highly engineered metal components for the main vehicle manufacturers. It develops products with an innovative design to produce lighter and safer vehicles, which offer lower energy consumption and a lower environmental impact. Its products cover the areas of BiW, chassis and mechanisms. The Company is present in 24 countries with 115 production plants (5 of those under construction), 13 R&D centers and a workforce of more than 44,000 employees worldwide. Its turnover in 2023 was €12,274 million. Gestamp is listed on the Spanish stock exchange under the ticker GEST. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

all customers have is audacity istg I got asked today if I "even know what a subframe is" because of COURSE a mechanic couldn't handle that for cheaper. I argued for five minutes before my boss told him to fuck off, a mechanic can absolutely handle cradle replacement and a subframe is not actually framework dumbfuck asshole AHHHHHHHHHHHHGGGGGGGGGHHHH get out of my FUCKING SHOP!!!

#im fine and normal#i just want to curl up with my book so bad. but the horrors*#*customers#*who arent even really customers because they won't pay for shit#**if you want frame measurements like you fucking insist you do youre looking at $300 for your stupid pos chrysler#no one is paying that!!!#thats why i told you no!! 9 times!!!#says kenna

1 note

·

View note

Text

There's a lot of people getting sick and the threats are going up it's time to get intense he's going to hit from all over we need to start working on it. There's also a number of things these guys doing wrong they're not really getting it

-the sun says they have the computing ability to do it then to full the sensors and then start small and it can work their way in with a network of computers and take over the ground stuff partially it's kind of happening and even without the laser light at least I have to protect with everything where it's gone and they can't use they had much faster computers in the back well the sensing is out it's still a chore cuz they do like exercises and they build new ones on board they try solid state testing and there's other infiltrators that were all intermingled that helps with that. So yes both ways are possible

John renalord looked into replacement windows and said no but since the security issue with alligators and criminals and storms and the ships can make debris fly around and they looked at and said wow that's a big business and even to put the shutters like one of those storm windows in the front door or the impact lexan with a design full view in the desert looking at it. They took a look at it and said we can't seem to get it going but they're doing their own and it says it makes a difference you can hear everything you shut the windows and you feel better you have shutters you can shut them at night takes 5 minutes and they say if you can do it from the inside would be nice unless you mean the shutter like have three latches this latch the top is going to half assed. You can make the latches automatic and the large from the inside but if someone has the code it ruins the effect and everybody does that these days but most people keep their windows closed in Florida and not tons of people have screens how did anybody actually is true to the zombie screams out these days they're putting the outside more or less it's kind of the outside so these shutters were great and they said they do that and really people don't have screens they're nice to have them but.

Now they looked at this and said it makes a difference it makes you feel better and the house is safer in a storm and it's safer during any season it's not much to do at night and not many people notice it the front yard you can put lexan over the window that shutters and not really but you can do the door how many windows in the front. There's a lot of ideas in some of them are real good but we got to move on here so we're going to publish

Thor Freya

Olympus

You see him too A lot of times the shutters are mission style they look like solid wood with a kind of an arch and they close the same way and they're almost paying the same color as the wall just a little lighter and they have their visible and the solid metal and when they're open they look nice you frame the window out you can put a flower box or two they look beautiful I left with the flower box a little lower

-there's other stuff happening for real there are giant numbers of people who are not aware of what is really happening today. Our son and daughter just came up with another idea it's a mock-up kitchen and it would be modular and a certain cabinet faces and you would make like a a cheap subframe that's metal and we can connect to it maybe like a rail system and you can change out the panels if they want to look at a different look and they're real light like panels you have in your motorhome and the doors will be hollow like hollow core doors have people might start buying the fake kitchen and there's really no rules or anything let me come out of plastic they have like a low flame spread no but it could make it that way with filler they're kind of laughing. And each kid number for the kitchen could be used and then you just put them off vacations like addendum and really with the metal frame and the way he's talking about making it you can make the whole kitchen out of it and it would be really cheap. You're like $300 for a whole whole kitchen for the size of the house in Northport that the countertops would have to be light. It's a great idea and a tool for people to sell to the builders who build a lot of houses you show up on site they have a couple models being built and you asked him if you can put in a kitchen for free and then say okay but it's just a mock-up I didn't see what he means it looks exactly the same way to see it if you want to buy it it's only a mock-up and they say what the hell is that for and it's really a good idea because the builders would do it if you can make that mock-up you can make a different type of cabinet it's inexpensive and have a full line so he's right there you make clips and reinforcing the eclipse on the clip on the face and it's durable it's like these panels they have everywhere they take a beating and the luggage steel would be fairly heavy gauge but not real heavy and the steel stronger they used to be metal is gross so we are getting to something else in a moment

We did already sign it yes

Yes they did

Hera I came up with the power where it could be like this metal frame and then he went nuts with the door and I went nuts with the facade the face another side is a face where you can use panels and clip them on and it's like permanent so they have this really cheap idea and you can raise it up with the frame and you simply put like plywood down on the bottom and you could have cabinet to drawers and everything with the frame it's just a cheap frame it's really easy to put together but everything would be supported by metal frames instead of all this wood and saves tons of time and money and the kitchen as well as modular if you break a piece or a door you order another one that comes like a day and the only thing is they're so cheap that nobody would put them in no tons of people might in apartments and condos so I'm going to check into it

Good night dear it's a great idea you guys look through the cabinets and things are bulky and they're a pain in the ass fixing them is impossible and here we have the idea

Thor Freya

0 notes

Text

Check it out

Panhard Dyna Z, 1954. Dyna Z featured an impressive array of unusual engineering choices. It was powered by an air-cooled flat twin engine driving the front wheels. Its bodywork was originally aluminium with steel tube subframes front and rear. The decision to use aluminium sheeting was taken at a time, after the Second World War, when a drop off in demand for fighter planes had left the producers with a glut of the metal, but in subsequent years the relative cost advantage of sheet steel increased steadily. Throughout its model life the use of aluminium was gradually reduced increasing the car's weight. However its combination of space, ride comfort, performance and fuel economy at a competitive price meant approximately 140,00 were sold before it was replaced in 1959..

0 notes