#reprap

Explore tagged Tumblr posts

Text

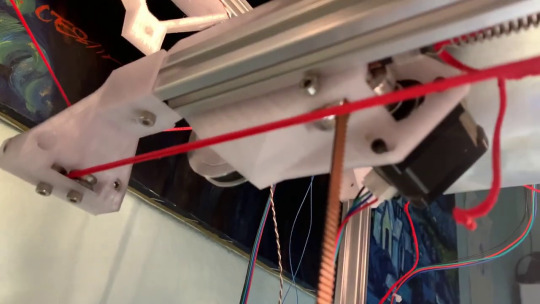

starting my 3d printer build, it's a voron 2.4 from formbot, self printing the parts in glow green and purple!

I managed to get minimal warping on my printer! with ABS!!

4 notes

·

View notes

Text

Cómo la Impresión 3D Está Revolucionando la Industria

La Impresión 3D, una tecnología que está marcando un antes y después en la creación de artefactos de todo tipo.

La tecnología avanza a pasos agigantados, y una de sus maravillas más impresionantes es, sin duda, la impresión 3D. Lo que antes parecía sacado de una película de ciencia ficción, hoy es una realidad que está revolucionando industrias enteras. Desde la fabricación de piezas mecánicas y prótesis médicas hasta la posibilidad de imprimir comida en el espacio, esta tecnología ha demostrado ser tan…

#Adrian Bowyer#Charles Hull#estereolitografia#impresion 3d#impresora 3d#imprimir#internet#Nieves Cubo#redes#RepRap

0 notes

Text

The Marionette 3D Printer

View On WordPress

0 notes

Text

This day in history

I'm on tour with my new novel The Bezzle! Catch me TONIGHT in SALT LAKE CITY (Feb 21, Weller Book Works) and TOMORROW in SAN DIEGO (Feb 22, Mysterious Galaxy). After that, it's LA, Seattle, Portland, Phoenix and more!

#15yrsago Parent of gamer asks his son to honor the Geneva Conventions https://memex.craphound.com/2009/02/21/parent-of-gamer-asks-his-son-to-honor-the-geneva-conventions/

#15yrsago UAE plans ban on negative economic reporting https://www.nytimes.com/2009/02/12/world/middleeast/12dubai.html

#15yrsago UK’s top snoop gets finked out by her neighbours https://www.theguardian.com/commentisfree/2009/feb/22/jacqui-smith-expenses-inquiry

#15yrsago Stimulus bill requires RSS feeds of how the money is spent http://www.aaronsw.com/weblog/rssstimulus

#10yrsago Conservative western bloggers: Ukraine strongman’s pay-for-play useful idiots https://www.buzzfeednews.com/article/rosiegray/exclusive-how-ukraine-wooed-conservative-websites

#10yrsago I am a Ukrainian: powerful, viral video about Euromaidan https://www.youtube.com/watch?v=Hvds2AIiWLA

#10yrsago Kansas lawmaker introduces bill to permit teachers to hit children hard enough to bruise https://slate.com/human-interest/2014/02/kansas-spanking-bill-new-legislation-allows-parents-and-teachers-to-hit-kids-harder.html

#10yrsago Canadian court rules on copyright trolls: letters can go ahead, under strict supervision https://www.michaelgeist.ca/2015/03/defending-privacy-doesnt-pay-federal-court-issues-ruling-in-voltage-teksavvy-costs/

#10yrsago Mall cops freak out over steampunk meetup, call the real cops https://www.kpbs.org/news/2014/feb/19/steampunk-carousel-outing-cut-short-security-guard/

#10yrsago Openknit: a Reprap-inspired open source knitting machine http://openknit.org

#5yrsago Beyond “more copyright”: how do we improve artists’ lives and livelihoods through policy? https://www.youtube.com/watch?v=0294Y6Lv3Eo

#5yrsago Iowa’s electricity monopolist Midamerican Energy has written a bill to let it “monopolize the sun” https://www.bleedingheartland.com/2019/02/20/new-bill-is-clear-attempt-by-midamerican-to-monopolize-the-sun-in-iowa/

#5yrsago Tucker Carlson thought anti-elite historian would be an easy interview, but ended up telling him “go fuck yourself” https://www.theguardian.com/society/2019/feb/20/historian-who-confronted-davos-billionaires-leaks-tucker-carlson-rant

#5yrsago As sports company abandons support for “smart” basketball, Nike pushes a software update that bricks its self-tying shoes https://mashable.com/article/nike-app-connected-shoe-bricked#duGbFcvYdsqa

#5yrsago The TRUE Fees Act: legislative proposal to force cable/ISP companies to advertise the true cost of their services, inclusive of surcharges https://www.vice.com/en/article/j57ddb/new-bill-would-stop-internet-service-providers-from-screwing-you-with-hidden-fees

#1yrago Matt Ruff's "Destroyer of Worlds" https://pluralistic.net/2023/02/21/the-horror-of-white-magic/#anti-lovecraftian

2 notes

·

View notes

Text

Thanks to Richard Hirst Hirsty3D's contribution, we updated the SMRRF post with new highlights: https://3dwithus.com/smrrf-sanjay-mortimer-reprap-festival-highlights

1 note

·

View note

Link

Want to start 3D printing? Click here to get your discount in the Prusa shop!

0 notes

Text

Appena qualche anno prima, il senato accademico aveva cercato in tutti i modi di bloccare la nomina di [Emmy] Noether, tanto che Hilbert dovette intervenire in sua difesa: «Non vedo come il sesso della candidata sia un argomento contro la sua ammissione. Questa è un'università, non un bagno pubblico». _______________ «Dall'inizio della guerra, un passo dopo l'altro, ero arretrato da una posizione morale a un'altra, e alla fine non ne avevo più nessuna» [Freeman Dyson] _______________ Quando von Neumann tornò in Europa nel 1949, la sua fiducia nell'umanità era del tutto svanita. «Provo l'opposto della nostalgia per l'Europa,» scrisse a Klári «perché ogni angolo mi ricorda … il mondo che non c'è più, e le rovine non sono di conforto. La seconda ragione per cui non amo l'Europa è il ricordo di quando persi per sempre le mie ultime illusioni sul rispetto dei valori umani tra il 1933 e il settembre 1938». _______________

La teoria dei giochi - e il dilemma del prigioniero in particolare - divenne presto lo strumento di analisi preferito della politica estera americana nell'atmosfera febbrile di paura e paranoia che persistette fino alla fine del ventesimo secolo. «La guerra fredda» scrisse lo storico Paul Erickson «finì per essere considerata il gioco più importante che la teoria avrebbe dovuto analizzare». Questo approccio era così onnipresente, aggiunge, che «la storia di molti eventi chiave della guerra fredda … si potrebbe riesaminare in questa prospettiva, al punto da rendere l'analisi post hoc di un gioco e lo studio storico difficili da distinguere». _______________ La controforza esprimeva il vero spirito della Rand [progetto "Research And Development" e poi Rand Corporation, organizzazione per lo studio di nuovi strumenti bellici e poi per lo studio di teorie generali della guerra] , era la ricerca di «modi più ragionevoli di usare la violenza», nelle parole di [Herman] Kahn. _______________ Nel giugno 2019 il Pentagono ha pubblicato per sbaglio sul suo sito web le linee guida dell'esercito statunitense per la pianificazione e l'esecuzione di una guerra nucleare su piccola scala. Il documento di sessanta pagine, contrassegnato dal codice JP 3-72 e intitolato Joint Nuclear Operations (Operazioni nucleari della Joint), è stato rapidamente rimosso, ma è rimasto online abbastanza a lungo da essere scaricato dalla Federation of American Scientists, un'associazione non profit fondata nel 1945 dai ricercatori del Progetto Manhattan, che promuove gli usi pacifici dell'energia atomica. Il rapporto si concentra sugli scenari peggiori e pone l'accento sulla guerra combattuta piuttosto che sulla deterrenza. I critici obiettano che l'evocazione di una guerra nucleare limitata incoraggia i nemici degli Stati Uniti a pensare che gli americani sono pronti a usare la bomba - aumentando il rischio che qualcun altro lo faccia davvero. Se pensiamo sempre al peggio, il peggio diventa un po' più reale. _______________

«L'evento più clamoroso dell'ultimo mezzo secolo è quello che non si è verificato» disse [Thomas] Schelling nel 2005, due giorni prima di ritirare il premio Nobel. «Per sessant'anni abbiamo prosperato senza che le armi nucleari esplodessero in tutta la loro rabbia». Schelling attribuì la nostra «sbalorditiva fortuna» a un tacito tabù contro l'uso di ogni bomba, anche la più piccola. Ma se l'orrore di Hiroshima e Nagasaki dovesse svanire dalla coscienza collettiva, e se altre nazioni o addirittura gruppi terroristici dovessero acquisire armi nucleari, non c'è alcuna garanzia che questa «repulsione quasi universale» contro il loro uso sarà ancora condivisa. Non sappiamo se ci resta molto tempo. _______________

«Snappy» è una RepRap (Replicating Rapid Prototyper), una stampante 3D autoreplicante in grado di stamparsi da sé circa l'80 per cento delle proprie parti. [...] L'ingegnere e matematico Adrian Bowyer ha concepito l'idea di quello che chiama «marxismo darwiniano» nel 2004: in futuro ogni casa sarà una fabbrica in grado di produrre tutto ciò di cui abbiamo bisogno (purché si possa fare in plastica). Gli ingegneri della Carleton University di Ottawa stanno lavorando per annullare anche quel 20 per cento che oggi resiste, e creare una stampante in grado di replicare sé stessa interamente, senza la necessità di andare a comprare qualche pezzo in un negozio di ferramenta. In particolare, stanno pensando di utilizzare solo materiali che si trovano sulla superficie della Luna. [...] Una volta stabilitesi sulla Luna, le macchine di [Alex] Ellery potrebbero moltiplicarsi per formare una fabbrica spaziale semi-autonoma in grado di ampliarsi e di costruire�� praticamente tutto. Per esempio, potrebbero stampare basi pronte ad accogliere i coloni umani, o persino, come spera Ellery, aiutare a mitigare il riscaldamento globale creando sciami di satelliti in miniatura che ci proteggeranno dalle radiazioni solari o irradieranno energia verso la Terra. Tutte queste idee, e altre ancora, si ispirano a un'opera intitolata Theory of Self-reproducing Automata (Teoria degli automi autoreplicanti) il cui autore non è altro che John von Neumann. _______________

Al gruppo non sfuggivano le implicazioni sociali e filosofiche del progetto. Si aspettavano che le fabbriche si evolvessero, proprio come i replicatori biologici. Lasciate a sé stesse nello spazio, queste macchine avrebbero potuto diventare coscienti? Se sì, sarebbero state ancora felici di soddisfare le nostre esigenze piuttosto che le loro? Alle macchine si poteva insegnare quel che era «giusto» e «sbagliato», ma ciò non garantiva che si comportassero bene, proprio come avviene per gli esseri umani. Questa conclusione inquietante li ha portati a chiedersi: saremo sempre in grado di spegnere le fabbriche autonome nel caso in cui diventassero pericolose? potremmo sempre staccare la spina? «A un certo punto la profondità dell'analisi e la sofisticazione delle azioni possibili per un sistema robotico possono superare le capacità della mente umana di sconfiggerlo» sostengono. Come evitare che tali macchine diventino «non-scollegabili»? [...] Alcuni futurologi ipotizzano che un'intelligenza artificiale sovrumana potrebbe trasformare la società fino a renderla irriconoscibile. Oggi si parla di questa evenienza come della «singolarità» - un termine usato per la prima volta da chi ne aveva previsto la possibilità molti anni prima: John von Neumann. _______________

Can We Survive Technology?, apparso nel giugno del 1955 sulla rivista «Fortune», inizia con un sinistro avvertimento: «In senso letterale come in senso figurato, ci mancherà lo spazio». I progressi in campi come gli armamenti e le telecomunicazioni, continua von Neumann, hanno notevolmente ridotto i tempi di una escalation dei conflitti e ne hanno ingigantito la portata. Una disputa regionale può in breve estendersi e inghiottire l'intero pianeta. «Cominciamo ad avvertire in modo drammatico gli effetti della dimensione reale, limitata, della Terra». [...] Ma tutto il progresso tecnologico, avverte, sarà inevitabilmente sfruttato anche a scopi militari. Tecniche sofisticate di controllo del clima, per esempio, potrebbero «prestarsi a forme di guerra climatica oggi inimmaginabili». La prevenzione delle catastrofi richiederà l'invenzione di «nuove forme di politica e nuove procedure». [...] «Le stesse tecniche che portano a pericoli e instabilità sono di per sé utili, o strettamente correlate all'utile». In un paragrafo dal titolo inquietante, «Sopravvivere - una possibilità», scrive: «Non c'è cura per il progresso. Qualsiasi tentativo di trovare modi automatici per incanalare su strade sicure l'attuale esplosiva quantità di progressi porta alla frustrazione. L'unica sicurezza possibile è relativa, e sta nell'esercizio intelligente, giorno per giorno, del nostro discernimento». Non esiste una «ricetta pronta per l'uso» - una panacea - per evitare l'estinzione per mano della tecnologia. «Possiamo solo specificare le qualità umane richieste: pazienza, flessibilità, intelligenza». ________________

[nel giugno del 1941 il "comitato Maud" (un gruppo di eminenti scienziati messo insieme dal governo britannico) era giunto alla conclusione che la bomba atomica fosse realizzabile in breve tempo, addirittura entro la fine del 1943] Il nome del comitato non era un acronimo. Un suo membro, John Cockcroft, aveva ricevuto un telegramma criptico da Lise Meitner tramite un suo amico inglese: «incontrati di recente niels e margrethe, in buona salute ma scontenti degli eventi, si prega informare cockcroft e maud ray kent». Cockcroft era perplesso. Isolando le ultime tre parole, mettendo una «i» al posto della «y» e anagrammando si otteneva radium taken, cioè «radio catturato». I tedeschi stavano accumulando quella sostanza radioattiva per lavorare a un reattore o a una bomba? Il comitato fu tanto galvanizzato dall'ingegnoso avvertimento di Meitner, che decise di battezzarsi come la prima parola della misteriosa tripletta: Maud. Molti anni dopo saltò fuori che il messaggio di Meitner non era per nulla un allarme e un invito ad agire, ma era indirizzato all'ex governante dei figli di Bohr. Il suo nome era Maud Ray e viveva nel Kent. Meitner, pacifista convinta, aveva inavvertitamente contribuito a dare una spinta alla ricerca sulla bomba atomica in due paesi.

Ananyo Bhattacharya, L'uomo venuto dal futuro. La vita visionaria di John Von Neumann

0 notes

Link

Want to start 3D printing? Click here to get your discount in the Prusa shop!

0 notes

Text

3D printing technology has been part of the discussion for at least a couple of decades, and about ten years ago the first 3D printer was designed and released. This machines have amazing capabilities and can print almost everything from hardware and toys to food and housing. Today, 3D printers occupy relatively small niches and are mainly used to print product prototypes, custom phone cases, detailed toys and figurines, various cosplay materials, figures for board games (Warhammer 40000, for instance), etc. And after hearing about astonishing 3D printers capacities, you decided to buy one or just planning to use this technology to print some product or simply want to know more about 3D printers, then this article is for you. Today, we unveil the curtain of what stands behind additive manufacturing and introduce you to ten things which are necessary to know before dealing with three-dimensional printing. 1. Different Types Of 3D Printers Use Different Technology Modern market is full of a variety of 3D printers with diverse specifications and requirements that work under different technologies. Let's discuss three the most common approaches to additive manufacturing. Fused Deposition Modeling (FDM) It's the most popular 3D printing process which works on a principle of placing material layer by layer. FDM printers use a thermoplastic or metal spool of filaments and apply heating to release the filament of a material to put down layers that echoing the shape of the model. Fused Filament Fabrication (FFF) is also a widely used term that literally means the very same method of 3D printing and was invented by the RepRap initiative in order to patent and legally used this technology. It's also known as Plastic Jet Printing (PJP). FDM printers are universally available and considered to be relatively not high priced. Stereolithography (SLA) Such printers involve using photosensitive liquid substances as a basic material and work with ultraviolet light in order to release molecules and link them together, forming a solid 3D object. Stereolithography is also called Optical Fabrication or Rapid Prototyping. It's suitable for prototyping, creating models or patterns since SLA is distinguished by the amazing precision of all the details. On the other hand, it allows using a very narrow range of possible materials and is unsuitable for printing organic and metal. Moreover, stereolithography printers are at least twice more expensive than FDM ones and a bit more difficult to found. Selective Laser Sintering (SLS) SLS is slightly different from SLA printing technique in choosing the basic working material which in turn leads to the use of other 3D printing technology. SLS printers engage a laser as a source of power that is focused on a specific place in space according to the 3D model parameters. Such printers work with powder materials, mainly metals, and use a laser to melt the powder and bind its molecules into a solid model. This technology is mainly used to print metal objects. The choice of technology depends on a desirable material and the amount of funds that you are willing to spend on manufacturing. Besides, despite the fact that 3D printing features high details accuracy, some devices in more or less degree do not allow you to print fine details. That's why before choosing a 3D printer for further purchasing or printing, you should consider the points made above. Let's pay a bit more attention to the prices and materials used to print objects. 2. Printers Can Cost As Much As Your House This point will be mainly interesting for the ones who are going to buy a 3D printer or just interested in its pricing policy. Well, the prices of three-dimensional printers depend, for the most part, on a quality of the end-product. Generally, professional and the most expensive ones can produce the higher-quality objects and their price mainly starts from $2,000. However, the price also depends on the type of raw material and the printing technology.

FDM printers are the easiest to find at the market and use at home or in a small office. In general, the lower the price is the more limitations the printer has in terms of the size of final object and materials involved. But, if you don't want to spend a lot of money and prefer to purchase a relatively cheap printer as an introductory device, you can easily find a small printer that will cost you about $100. Nevertheless, the 3D printing technology gains more and more popularity among consumers, and thanks to that prices on 3D printers went down while the printing quality enhances. In addition, do remember that printing devices don't come along with the materials used in a printing process. These components should be purchased or collected separately according to printer and model requirements. 3. There Aren't So Many Materials Fit For 3D Printers Despite the fact that innovators found a way to think-out-of-the-box and print chocolate and pasta, today the devices available for customers have a comparatively narrow range of materials to use. Most popular models involve FDM technology and use different thermoplastics to print solid objects. We would like to examine plastic as an example, so you can see what dangers await you at this step. One of two most popular materials is Poly Lactic Acid (PLA). This material is derived from corn starch and possesses good temperature characteristics (can be cooled or heated quickly). PLA is eco-friendly and presented in solid and translucent colors. This material is perfect for newbies to deal with. However, since it possesses low melting characteristics, the output can contort under high temperatures. Besides, it's not the best options for models that have joints or moving parts. The second material we would like to mention is Acrylonitrile Butadiene Styrene (ABS), a petroleum-based thermoplastic that became popular thanks to its flexibility and durability. Moreover, ABS won't likely be deformed under heat because it's resistant to high temperatures. Furthermore, it can be used to produce a solid object with interlocking parts. On the other hand, at the output, ABS-based models take longer to cool after printing. It's obligatory to know decide on a suitable material before buying a printer or choosing one for future printing. Some printers can work with a range of materials, some, on the other hand, accept only one type. 4 Nozzles Size Is Important When it comes to preferred filament size, it's really up to the printer specifications, 3D model quality, and personal preferences. Most printers go with 1.75 mm filament size, however, 3 mm is also quite common and more tolerant with hardware shortcomings. But you need more force to push 3mm filament into the hot end. The nozzle size affects the horizontal resolution of the print. The most popular nozzle diameters are 0.34 mm and 0.4 mm. Each size is better in some situations. For example, if you need to print the 3D object fast, it's better to choose bigger nozzle since it reduces the overall number of layers thanks to thicker string. Smaller nozzles, on the other hand, ensures the smoother finish of the final prototype. 5 3D Modeling For Different 3D Printers Has Its Peculiarities It's possible to create a 3D model in a wide range of software both free and commercial like Maya, 3ds max or Zbrush. Besides, as you already know the type of raw material is also important and affects the modeling process. When it comes to 3D modeling, you should pay attention to many details and limitations. For instance, take into consideration printer type, printing technology, and physical qualities of the raw material. This also means that you should create a 3D model with physically correct characteristics. If you are not familiar with modeling processes and material guidebooks, you should better entrust this work to professionals who are experienced in 3D modeling for 3D printing. Just provide them with all necessary information about printer type and model,

material that you are going to use while printing and the outlines of the overall idea (sketches, pictures, photos). 6. STL Is A Universal File Format For All Printers The name of .STL file extension does not come from stereolithography printing technique. It stands for Standard Triangle Language and became a worldwide format supported by all 3D printers. Basically, the term 'Standard Triangle Language' means expansion of the modeled object into triangles in three-dimensional coordinates. STL file is required in order to print any 3D model. This file with full information about the model can be uploaded, recognized and proceeded by the printer in a matter of seconds if everything is done according to industry standards. The printer inspects the information received from the STL file and places the pin of the printer which moves along X, Y and Z axes in order to create an object layer by layer to the appropriate point in space according to the model coordinates. In addition, professionals don't recommend to exceed the 100MB file size. 7. You Should Have A Special Software Even if you make everything right with a 3D modeling and compile the correct STL file of the model, you will still need an appropriate software installed. Such programs known as 'slicing software' will explain the printer how to produce the model you uploaded on the language it understands. This software provides exhaustive information about the number of layers, the solid parts of the prototype and hollows, and also the starting position of the print bed. Some companies produce printers that have an inbuilt slicing software or such program come along with the printer. For other printers, you should choose the right software on your own or consult with a community what the best choice is. 8. Different Printers Provide Different Print Quality This point should be noted by the ones who are going to buy a printer or looking for a 3D printing services. Printing quality is one more point that should concern you in three-dimensional printers. To receive a high-quality prototype, you should take into account resolution and printing speed. Print resolution indicates to the level of detail that printer can ensure. The smaller this parameter is, the more detailed object you can create. Print speed refers to the speed of extruder movements. Generally, printers with high print speed characteristics print faster than others. Moreover, there are other factors that may affect the print quality, for instance, slow down the print speed or change the output. These elements can include the material characteristics (some materials cool slower that can cause deformation or blur the details) or default settings when a change of speed is required and printer reacts by acceleration to higher speed and vice verse. Eventually, the best way to judge about the print quality of a specific printer is to carefully examine the final output. If you are going to buy the printer, you should better Google some images and photos of a final product. If you're just looking for the printing services, consult the representatives and look at company portfolio to determine the most suitable printer. 9. 3D Printers Require Careful Care To Prevent Safety Issues Three-dimensional printers as any other manufacturing devices are fraught with specific safety problems to which you should pay special attention. When it comes to working with any 3D printer, precautions must be taken to avoid accidents. For this reason, before purchasing the printer examine all available instructions and possible problems that may arise and follow the rules of operation. We prepared a small brief description about some notable issues. One of the most important things you should pay attention to is high temperatures of materials you are working with. Due to the fact that a majority of 'domestic' printers work with heated plastic, some external parts of the printer can get extremely hot. For instance, print bed, extruders and the plastic itself.

These parts can be a cause of dangerous burns in cases when you aren't careful. Most large printers have an inbuilt protective glass around the print area, however, many small ones have an open area. That's why with that type of 3D printers, you should take extra precautions. Moreover, 3D printers require a well-ventilated space due to the fact that during the printing process some printers accumulate fumes, especially when ABS plastic has been taken as a raw material. There is no much research about the impact of these fumes on general health and there is no final option on that matter. Still, it's better to protect personal health and safety by taking extra precautions. In addition, the plastic you use can be dangerous for your well-being and welfare. Think about it, 3D printing industry has reached the point when three-dimensional printers are used to create many household hardware and kitchenware, in particular. The two most popular thermoplastics mentioned in this article Poly Lactic Acid and Acrylonitrile Butadiene Styrene are considered to be safe, however, it's only in case they are of a good quality. If you buy a substandard plastic no matter on purpose or accidentally, this material can include additives that may be unsafe. Another problem is that most printers work under FDM technology and can produce the items with not smooth enough surface that is a perfect condition for collection of bacteria. In some cases, this problem can be solved by coating an item, however, it's still not completely safe to use printed kitchenware. 10. The Technology Is Everywhere We guess it's not a secret for everyone that 3D printing industry is a field for investment. The world considers three-dimensional printing as the future of manufacturing and even humanity. Thirty years ago people didn't even think about having printed hardware, but now it's everywhere. The majority of 3D printers use plastic or metal material to produce items, but it's also possible to use a generous amount of other primary products, including food. Such devices are capable of creating almost every dish from cookie to pizza. These machines use fresh components that were prepared just before printing. 3D printers is also an area of interest of a Health Care industry. For example, this technology can be used in prosthetics to create custom prostheses that will be individual and fix perfectly for a specific patient and in surgery to conduct operations that now seem impossible. Moreover, humanity organized a housing initiatives in order to provide poor families with relatively cheap houses in countries like China and Netherlands. Besides, in areas where natural disasters have happened, such as a tornado or earthquake, and people lost their homes, such shelters will be a perfect option. In addition, Science and Education are particularly interested in implementation of 3D-printed models and print devices in order to improve educational and research process. 3D printing apps are recommended for children as a part of their study process. Finally, 3D printing can play a significant role in further space exploration, for example in long-term space missions as a part of a spaceship 3D printer can produce and replace the damaged or lost part of the ship according to the design sent from the control center. Although 3D printers aren't very common like PCs, people can observe an express grow in the technology and quantity of devices itself. Many industry experts name 3D printing industry one of the most perspective trends for the upcoming years. While it's easy to predict the areas where 3D printers will become a usual device or a part of a process, some industries are still keeping themselves aloof and probably wait for some kind of a revolution to include 3D printers in their techniques. 3D printers have all chances to revolutionize manufacturing (actually, they have already started doing this) and become one of the most important inventions of a human being. Victor Terekhovskyi is a marketing specialist at Program-Ace.

It is an R&D company that provides a full circle of IT services located in Kharkov, Ukraine. Our team specializes in development of 2D/3D games and apps, custom web solutions and mobile applications. The qualified experts of Program-Ace combine a unique experience in complex web systems and 3D related fields.

0 notes

Text

The 3D Printing Revolution: When the Printer Built Itself (Almost)

Remember when 3D printers were the exclusive toys of giant corporations? Back then, the idea of bringing one into your garage was about as likely as building a rocket ship in your backyard. But then came RepRap, the brainchild of a daring professor named Adrian Bowyer. His radical idea? A 3D printer that could... print itself!

Imagine the scene: Bowyer, probably wearing a slightly bewildered expression, watching his first RepRap printer, lovingly named "Darwin," slowly extrude its own plastic parts. It was like witnessing a robot giving birth to a smaller, slightly less impressive robot. Did he print a tiny screwdriver first? A miniature teacup? No, of course not. He printed more printer parts, because priorities.

RepRap wasn't just about self-replication; it was about democratizing 3D printing. By open-sourcing the designs, Bowyer unleashed a wave of tinkering and collaboration. Suddenly, hobbyists were building their own printers in garages, basements, and even, I kid you not, on kitchen tables. The internet buzzed with discussions about filament types, failed prints, and the occasional triumphant post of a perfectly printed gear.

The impact of RepRap is undeniable. It sparked a global movement, fueling the rise of affordable desktop printers that are now commonplace. From personalized gadgets to life-saving medical implants, 3D printing is transforming industries. So, the next time you marvel at a 3D-printed creation, remember the quirky professor and his self-replicating dream. It may not have been perfectly self-sufficient (who needs a self-printing teacup anyway?), but it revolutionized how we create.

0 notes

Text

This day in history

Tomorrow (July 30) at 1530h, I’m appearing on a panel at Midsummer Scream in Long Beach, CA, to discuss the wonderful, award-winning “Ghost Post” Haunted Mansion project I worked on for Disney Imagineering.

#20yrsago Briefing the court on Fuck https://www.thesmokinggun.com/documents/crime/passionate-defense-f-word

#15yrsago UK’s ISP-record industry deal won’t stop infringement, but will make it harder for the record industry to cash in https://www.theguardian.com/technology/2008/jul/29/internet.digitalmusic

#15yrsago TSA destroys the RepRap’s first child http://blog.reprap.org/2008/07/tsa-really-wreck-reprap-child.html

#10yrsago MIT report on Aaron Swartz’s prosecution is out, and it’s a “whitewash” https://tarensk.tumblr.com/post/56881327662/mit-report-is-a-whitewash-my-statement-in

#10yrsago Rotolight sends fraudulent takedown notice to censor unfavorable review https://notesonvideo.blogspot.com/2013/07/using-copyright-infringement-claim-to.html

#10yrsago US spies supplied intelligence on investigative journalist to NZ military http://www.stuff.co.nz/national/8972743/US-spy-agencies-eavesdrop-on-Kiwi

#10yrsago Kill City Blues: Sandman Slim versus the elder gods of the dead mall https://memex.craphound.com/2013/07/30/kill-city-blues-sandman-slim-versus-the-elder-gods-of-the-dead-mall/

#5yrsago Quiet Skies: Air Marshals are following thousands of random Americans through airports and on planes, for no articulatable purpose https://apps.bostonglobe.com/news/nation/graphics/2018/07/tsa-quiet-skies/?p1=HP_SpecialTSA

#5yrsago Sacha Baron Cohen confronts Roy Moore with a beeping “pedophile detector” https://www.youtube.com/watch?v=3kaJaDx51iw

#5yrsago Universal, having learned nothing from its “dancing baby” ass-kicking, is once again attacking Prince fans https://www.techdirt.com/2018/07/30/universal-right-back-it-issuing-dmca-reporters-video-prince-fans-singing-purple-rain/

#5yrsago Wall Street landlords are slumlords https://www.reuters.com/investigates/special-report/usa-housing-invitation/

#5yrsago GOP candidate who campaigned with a white supremacist condemned for Bigfoot erotica https://www.huffpost.com/entry/bigfoot-porn-house-race-virginia_n_5b5ec4f5e4b0de86f4988800

#5yrsago John Oliver’s scorching debullshitification of Facebook’s apology ads https://www.vice.com/en/article/bjb745/john-oliver-facebook-ads-last-week-tonight

4 notes

·

View notes

Text

كيفية الطباعة ثلاثية الأبعاد بألوان متعددة

أول طابعة رأيتها في الحياة الواقعية كانت طابعة منزلية نقطية من إبسون يمكنها عرض صور بالأبيض والأسود بتفاصيل رهيبة. هذا هو ما كانت عليه الطباعة ثلاثية الأبعاد حتى الآن، ولكن من الممكن هذه الأيام أن تكون أقل أحادية اللون.

ارسمها

إن أبسط طريقة لإضفاء اللون على الطباعة ثلاثية الأبعاد هي رسمها يدويًا. قم بالطباعة بلون أساسي جيد، مثل الفتيل الأبيض، ثم استخدم دهانات الأكريليك لإنهاء النموذج الخاص بك. هذه هي الطريقة الأرخص للحصول على نماذج رائعة كاملة الألوان، لكنك لن تصنع الكثير من النماذج بهذه الطريقة، وبالطبع فهي تتطلب عمالة كثيفة. ناهيك عن أنه إذا لم تكن لديك موهبة الرسم، فقد تكون النتائج أقل جاذبية!

وقف ومبادلة خيوط

إذا كنت تريد طباعة نموذج واحد بألوان متعددة، فإن الطريقة الأسهل للقيام بذلك هي عن طريق تبديل الخيوط في منتصف الطباعة. من الواضح أن هذا سيؤدي إلى تغيير الألوان والمواد على طول المحور Z، حيث ستضع الفتيل الجديد فوق الفتيل القديم. هناك العديد من الطابعات وأنظمة تشغيل الطابعة وبرامج التقطيع المختلفة، وبالتالي فإن الطريقة الدقيقة للقيام بذلك ستعتمد على الإعداد لديك والبرامج والأجهزة التي تستخدمها. لحسن الحظ، يجب أن يكون الأمر سهلاً مثل البحث عن اسم الطابعة الخاصة بك مع مصطلح "مبادلة الفتيل" للحصول على تفاصيل دقيقة حول كيفية إجراء هذه الطباعة في منتصفها. تتيح لك معظم برامج التقطيع أيضًا تعديل رمز G (التعليمات المرسلة إلى الطابعة) لإدراج أمر تبديل الفتيل. بمجرد وصول الطابعة إلى الطبقة الصحيحة، ستتوقف وتنتظر حتى تضع فتيلًا جديدًا قبل طباعة الباقي. بالطبع، تحتاج طابعتك إلى دعم هذه الوظيفة أيضًا. إذا كان الإعداد الخاص بك لا يسمح بهذه الطريقة الدقيقة والمعتمدة والأنيقة لتبديل الخيوط، فبدلاً من ذلك، يمكنك استخدام طريقة مقلة العين المجربة والمختبرة. ما عليك سوى الضغط على زر الإيقاف المؤقت على طابعتك عندما تبدو وكأنها في المكان الصحيح تقريبًا، ثم تبديل الفتيل قبل الاستئناف. بعض خبراء الطباعة ثلاثية الأبعاد ذوي الخبرة لا يكلفون أنفسهم عناء إيقاف الطباعة مؤقتًا. إنهم يقومون فقط بقطع الفتيل الحالي ثم إدخال فتيل جديد يدويًا في الطابعة دون فقدان أي إيقاع.

الطباعة في جلستين منفصلتين

بالنسبة للنماذج التي لم تتم طباعتها في قطعة واحدة (أو التي يمكنك تقطيعها إلى قطع مختلفة)، فإن الإجابة السهلة هي طباعة القطع في جلسات مختلفة باستخدام خيوط مختلفة أو على طابعات مختلفة. على سبيل المثال، إذا كنت تطبع نموذج دبابة، فيمكنك طباعة الجسم بخيط أخضر عسكري، وطباعة المداسات باللون الأسود. يمكنك أيضًا إضافة اهتمام أساسي إلى النماذج التي يجب تجميعها عن طريق طباعة مجموعة واحدة من الأجزاء بلون واحد وأخرى بلون ثانٍ، ثم تبديل الأجزاء بين المجموعات.

استخدم خيوط متعددة الألوان

إذا كنت لا تهتم بأن تكون أجزاء معينة من النموذج الخاص بك ذات لون معين، فيمكنك أيضًا تجربة خيوط متعددة الألوان. على سبيل المثال، يتغير لون خيوط قوس قزح كل بضعة أقدام، مما يعني أنه إذا قمت بطباعة نسخ متعددة من نفس النموذج، فستحصل على اختلافات ألوان فريدة في كل واحدة. هناك أيضًا خيوط تحتوي على شريطين من الألوان يعملان بالتوازي، مما يوفر أيضًا مزيجًا مثيرًا للاهتمام متعدد الألوان. إنها ليست طباعة ملونة حقيقية تمامًا، ولكنها تتفوق على وجود لون واحد فقط للنموذج بأكمله. شراء طابعة ثلاثية الأبعاد متعددة الألوان لقد قطعت الطابعات ثلاثية الأبعاد شوطًا طويلًا منذ الأيام الأولى لـ RepRap، وهناك الآن طابعات ثلاثية الأبعاد متعددة الألوان ومتعددة المواد يمكنها إنتاج كائنات معقدة تنافس المنتجات المصنوعة تقليديًا. كما يمكنك أن تتخيل، فإن القدرة على الطباعة بألوان متعددة لها ثمن. على سبيل المثال، يبلغ سعر طابعة Bambu X1 Carbon Combo ثلاثية الأبعاد حوالي 1500 دولار حتى كتابة هذه السطور، وهو جزء كبير من التغيير. ومع ذلك، هذا ليس بعيدًا عن الطابعات الأحادية ثلاثية الأبعاد الرائدة مثل Creality K1 Max. لذلك، إذا كنت تريد حقًا القدرة على طباعة الأشياء بدقة بألوان ومواد متعددة، فهذا ليس بعيد المنال.

استخدم خدمة طباعة متعددة الألوان

الطابعات ثلاثية الأبعاد باهظة الثمن، والحصول على أقصى استفادة منها يتطلب خبرة كبيرة. لذلك ليس من المستغرب أن تظهر خدمات الطباعة ثلاثية الأبعاد في كل مكان. تمامًا مثل خدمة طباعة الورق، يمكنك إرسال نماذجك ثلاثية الأبعاد إلى هذه الخدمات، وسوف يرسلون لك مطبوعاتك. تتمتع بعض المجموعات الأكبر حجمًا بإمكانية الوصول إلى طابعات ثلاثية الأبعاد ملونة "غير مباشرة" متقدمة حقًا، حيث ستقوم الطابعة بشكل أساسي برسم النموذج باستخدام بخاخات فوهة دقيقة بألوان CMYK تمامًا مثل الطابعة الاحترافية. على الرغم من أنه من المرجح أن يكون لدى معظم الطابعات الملونة "المباشرة" فقط والتي تستخدم خيوط ملونة، وبالتالي لن تقدم سوى عدد قليل من الألوان في وقت واحد. تميل خدمات الطباعة ثلاثية الأبعاد عبر الإنترنت مثل Sculpteo وXometry إلى بيع خدماتها إلى شركات أخرى، وليس لمهام الطباعة الصغيرة مثل متجر الطباعة ثلاثي الأبعاد المحلي الخاص بك، ولكن أعتقد أنه مع انخفاض تكاليف الطابعات متعددة الألوان، هناك فرصة جيدة أن يقدم المحلي بعضًا منها من هذه الخيارات قريبا، إذا لم تكن قد فعلت ذلك بالفعل. Read the full article

0 notes

Photo

#167 Adrian Bowyer tells the story of the 3D printing RepRap movement

0 notes

Text

Multi Color Printing! Explaining what this current build is and how it works. Join Part 2 of the Livestream build today (1-30) at 3PM EST. Link is below. See you all there!

https://www.youtube.com/live/q8z0JPECvBo?si=Rg3tg6GXiDG_HYtC

#ercf #ams #multicolor #leemerie3d #reprap #youtube #tiktok #fun #live

#ender 3#leemerie3d#prusa#tech#voron#x1c#3dprint#fyp#subscribetomychannel#pc build#mr beast#mark rober#diy

0 notes

Text

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

New Post has been published on https://thedigitalinsider.com/the-next-frontier-how-3d-printing-is-revolutionizing-manufacturing-technology-org/

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

3D printing, also known as additive manufacturing, has gained significant popularity in recent years, revolutionizing the manufacturing industry. The concept of 3D printing dates back to the 1980s when it was first introduced as a rapid prototyping technology. However, it is only in the past decade that 3D printing has gained widespread recognition and adoption in various industries.

The growing popularity of 3D printing can be attributed to its ability to create complex and customized objects with ease. Traditional manufacturing methods often involve multiple steps and processes, which can be time-consuming and costly. 3D printing simplifies the manufacturing process by directly creating objects layer by layer from a digital design, eliminating the need for molds or tooling.

The central piece of a 3D printer – illustrative photo. Image credit: Christian Englmeier via Unsplash, free license

The History of 3D Pringting

The concept of additive manufacturing has existed since the 1940s. In 1945, sci-fi author Murray Leinster described a machine that could “make drawings in the air” and output plastic parts layer-by-layer in his short story “A Logic Named Joe.” However, it took a few more decades for this vision to become reality.

1980s: Early Prototyping

In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute invented one of the first working rapid prototyping systems. It used photopolymers that could be cured by UV light to build parts additively.

In 1984, Charles “Chuck” Hull filed a patent for stereolithography (SLA), which described an additive manufacturing process using photopolymers cured layer-by-layer by UV lasers. He later co-founded the company 3D Systems to commercialize SLA 3D printers.

In 1986, Carl Deckard, an undergraduate at the University of Texas, filed a patent for selective laser sintering (SLS), another 3D printing process that used a laser to fuse powder material. Deckard’s patent was licensed by DTM corporation, which released the Sinterstation 2000, the first SLS machine, in 1992.

In 1989, S. Scott Crump invented fused deposition modeling (FDM) and patented the technology. This process used a heated nozzle to extrude thermoplastic filament material layer by layer. Crump later commercialized it through the company Stratasys, which he co-founded.

1990s: Industry Growth

In 1992, 3D Systems released the SLA-250, which was the first commercially available 3D printer. Meanwhile, Stratasys introduced their first commercial FDM 3D printer in 1992 as well.

Through the 1990s and 2000s, the industry saw rising adoption and usage of additive manufacturing for rapid prototyping across automotive, aerospace, medical, consumer goods and other industries. Both established corporations and startups expanded the capabilities of 3D printing during this period.

2000s: Patent Expiration, Desktop 3D Printers

A significant milestone came in 2009 when key SLA patents expired, opening up the technology. This allowed for the rise of desktop SLA 3D printers like the Form 1, developed by startup Formlabs in 2012.

The expiration of FDM patents around 2010 similarly saw a wave of open source FDM/FFF desktop 3D printers like the RepRap, inspiring companies like MakerBot. This drove increased adoption of desktop 3D printing.

The Basics of 3D Printing: How it Works and its Advantages

The process of 3D printing involves several steps. First, a digital design of the object is created using computer-aided design (CAD) software. This design is then converted into a format that can be read by the 3D printer. The printer then builds the object layer by layer using various materials such as plastic, metal, or even biological materials.

One of the key advantages of 3D printing is its ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. Traditional methods often involve subtractive processes, where material is removed from a larger block to create the desired shape. In contrast, 3D printing is an additive process, where material is added layer by layer to create the final object.

Another advantage of 3D printing is its ability to create customized products. With traditional manufacturing methods, producing customized products can be expensive and time-consuming. However, with 3D printing, each object can be easily customized by simply modifying the digital design before printing.

From Prototyping to Production: How 3D Printing is Changing the Manufacturing Process

One of the key roles of 3D printing in manufacturing is in the prototyping stage. Traditionally, prototyping involved creating molds or tooling, which can be expensive and time-consuming. With 3D printing, prototypes can be created quickly and cost-effectively, allowing for faster iteration and refinement of designs.

However, 3D printing is not limited to prototyping alone. It has the potential to replace traditional manufacturing methods in certain applications. For example, in industries such as aerospace and automotive, where complex geometries are often required, 3D printing can offer significant advantages over traditional methods. By eliminating the need for molds or tooling, 3D printing can reduce costs and lead times while enabling the production of lightweight and optimized components.

Customization and Personalization: The Power of 3D Printing in Meeting Customer Demands

One of the key advantages of 3D printing is its ability to create customized products. Traditional manufacturing methods often involve producing large quantities of identical products, which may not meet the specific needs or preferences of individual customers. With 3D printing, each product can be easily customized to meet the unique requirements of each customer.

This ability to create customized products has a significant impact on the customer experience. Customers today are increasingly looking for personalized products that reflect their individual tastes and preferences. By offering customized products, companies can differentiate themselves from their competitors and build stronger relationships with their customers.

Reducing Costs and Waste: The Economic Benefits of 3D Printing in Manufacturing

One of the key advantages of 3D printing is its potential to reduce manufacturing costs. Traditional manufacturing methods often involve multiple steps and processes, each adding to the overall cost of production. In contrast, 3D printing simplifies the manufacturing process by directly creating objects from a digital design, eliminating the need for molds or tooling.

By reducing the number of steps and processes involved in manufacturing, 3D printing can significantly reduce costs. This is particularly beneficial for small and medium-sized enterprises (SMEs) that may not have the resources to invest in expensive molds or tooling. With 3D printing, SMEs can compete with larger companies by offering customized products at a lower cost.

In addition to reducing costs, 3D printing also has the potential to reduce waste. Traditional manufacturing methods often result in significant material waste, as excess material is removed during the production process. With 3D printing, only the required amount of material is used, minimizing waste and reducing environmental impact.

Sustainability and Environmental Impact: How 3D Printing is Helping to Reduce Carbon Footprint

In addition to reducing waste, 3D printing also has the potential to reduce carbon footprint. Traditional manufacturing methods often involve transporting raw materials and finished products over long distances, resulting in significant carbon emissions. With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering carbon emissions.

Furthermore, 3D printing enables the use of more sustainable materials. For example, bio-based materials can be used in 3D printing, reducing reliance on fossil fuels and minimizing environmental impact. Additionally, 3D printing allows for the optimization of designs, resulting in lighter and more efficient products that require less energy to produce and use.

The Role of 3D Printing in Industry

The impact of 3D printing on various industries is significant. In the healthcare industry, 3D printing has revolutionized medical device manufacturing by enabling the production of customized implants and prosthetics. In the aerospace industry, 3D printing has been used to create lightweight components that improve fuel efficiency and reduce emissions.

The potential for 3D printing to disrupt traditional manufacturing industries is also significant. For example, in the automotive industry, 3D printing has the potential to transform the production of spare parts. Instead of maintaining large inventories of spare parts, manufacturers can simply 3D print the required parts on demand, reducing costs and lead times.

The Future of Manufacturing

The potential for 3D printing to revolutionize the manufacturing industry is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in various industries. The ability to create complex and customized objects with ease will continue to drive the growth of 3D printing in manufacturing.

However, there are also challenges and opportunities associated with 3D printing in manufacturing. One of the key challenges is the need for skilled operators who can design and operate 3D printers effectively. Additionally, there are regulatory challenges that need to be addressed, particularly in industries such as healthcare where safety and quality standards are critical.

The Challenges of 3D Printing in Manufacturing: Overcoming Technical and Regulatory Hurdles

One of the key technical challenges of 3D printing in manufacturing is the limited range of materials that can be used. While 3D printing has made significant advancements in recent years, there are still limitations in terms of the types of materials that can be used. For example, metals such as titanium and aluminum are commonly used in traditional manufacturing methods but are more challenging to 3D print.

Another technical challenge is the need for post-processing and finishing. While 3D printing can create complex geometries with ease, the surface finish of 3D printed objects is often rough and requires additional processing to achieve the desired quality. This can add time and cost to the manufacturing process.

In addition to technical challenges, there are also regulatory challenges associated with 3D printing in manufacturing. In industries such as healthcare, where safety and quality standards are critical, there is a need for regulatory frameworks to ensure that 3D printed products meet the required standards. This includes the need for validation and certification processes to ensure the safety and efficacy of 3D printed medical devices.

The Impact of 3D Printing on Supply Chain Management: Opportunities and Challenges

The potential for 3D printing to disrupt supply chain management is significant. With traditional manufacturing methods, products are often manufactured in one location and then transported to various distribution centers or retail stores. This can result in long lead times and high transportation costs.

With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering lead times. This has the potential to transform supply chain management by enabling companies to produce products on demand, reducing inventory costs and improving responsiveness to customer demands.

However, integrating 3D printing into supply chain management also presents challenges. For example, companies will need to invest in 3D printing infrastructure and develop new processes and workflows to support on-demand manufacturing. Additionally, there may be challenges in terms of intellectual property protection and ensuring product quality and consistency across different manufacturing locations.

The Future of 3D Printing in Manufacturing: Emerging Trends and Technologies

The future of 3D printing in manufacturing is promising, with several emerging trends and technologies driving its growth. One of the key trends is the development of new materials that can be used in 3D printing. Researchers are exploring the use of materials such as graphene, carbon fiber, and biodegradable polymers, which offer improved strength, durability, and sustainability.

Another emerging trend is the development of multi-material and multi-color 3D printing technologies. Currently, most 3D printers can only print objects using a single material or color. However, researchers are working on developing printers that can print objects using multiple materials or colors simultaneously, opening up new possibilities for complex and customized designs.

The Promise of 3D Printing in Revolutionizing Manufacturing

3D printing has the potential to revolutionize the manufacturing industry. Its ability to create complex and customized objects with ease, reduce costs and waste, and promote sustainability makes it an attractive option for manufacturers across various industries.

While there are challenges and opportunities associated with 3D printing in manufacturing, the promise of this technology is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in manufacturing, leading to a more efficient, sustainable, and customer-centric manufacturing industry.

3D printing is transforming manufacturing across industries in revolutionary ways. Its ability to rapidly prototype designs, create complex geometries, enable mass customization, reduce waste, and distribute production is disrupting traditional processes. Companies are adopting 3D printing to accelerate product development, unlock new design possibilities, produce specialized components, and manufacture goods on-demand. While the technology does have some limitations currently, advancements around speed, materials, and costs are helping address these.

Overall, 3D printing provides unmatched flexibility that is spurring a manufacturing revolution. It allows for more sustainable production methods with less waste and emissions. As the capabilities of 3D printing continue to advance, its applications will expand even further. Forward-thinking companies that leverage this technology now will gain key competitive advantages. Adoption is still in early phases, signaling immense room for growth. 3D printing is undoubtedly redefining manufacturing as we know it and enabling the factories of the future.

#1980s#250#3d#3D printing#additive manufacturing#aerospace#aerospace industry#air#aluminum#applications#automotive#automotive industry#biodegradable#Biodegradable Polymers#carbon#carbon emissions#carbon fiber#carbon footprint#certification#challenge#Chemistry & materials science news#Color#colors#Companies#computer#customer experience#dates#Design#desktop#development

0 notes

Text

SMRRF – Sanjay Mortimer RepRap Festival Highlights

The Sanjay Mortimer RepRap Festival (SMRRF) is an annual event that celebrates the innovative and community-driven spirit of the 3D printing world.

1 note

·

View note