#ribbon blender mixer

Explore tagged Tumblr posts

Text

Ribbon blenders are a cornerstone of industrial mixing, achieving consistency, efficiency, and precision. These versatile machines are widely used in industries such as pharmaceuticals, food processing, chemicals, and construction materials. Choosing the right ribbon blender can significantly improve product quality and operational efficiency.

#ribbon blender#Ribbon blender machine#ribbon blender mixer#best ribbon blender#ribbon blenders#ribbon blender manufacturer

0 notes

Text

High-Quality Ribbon Blenders

Mecworks Innovations specializes in designing and manufacturing high-quality Ribbon Blenders tailored to meet your mixing needs. Our innovative solutions ensure efficient, uniform blending for industries ranging from food processing to pharmaceuticals. With cutting-edge technology and expert engineering, Mecworks Innovations delivers reliable, durable equipment that enhances your production process, ensuring consistency and superior performance every time.

#Ribbon Blender#Mecworks Innovations#Industrial Mixers#Powder Blending#Food Processing#Efficient Mixing

0 notes

Text

Ribbon Blender Mixer

youtube

A double helical ribbon agitator that rotates within is part of the Ribbon Blender Mixer (ribbon blade mixer), which also includes a Horizontal U-trough mixer. A double helical ribbon agitator is a ribbon agitator that has an inner and an outer helical ribbon set. Depending on the application, the distance between the ribbon’s outer border and the container’s interior wall might be anywhere from 3 to 6 mm.

The foundation of vertical powder mixers is a tried-and-true agitator design that offers a triple mixing action for quick, effective blending. Ribbon dimensions and arrangement are precisely calibrated to facilitate material circulation within the container, preventing dead spots and enabling quick product discharge.

Paddle agitators represent an alternative design. The paddles are arranged to move the material both radially and in opposing lateral directions. When blending friable materials and mixing batches as tiny as 15% of the blender’s entire capacity, the paddle design is typically used in these situations.

Ribbon blenders with capacities ranging from 5 liters for small ribbon blenders to 15000 liters for industrial ribbon blenders are made by Adinath. Both mild steel and stainless steel are used in the production of mixers. We offer validation and extended support for ribbon blender parts. We supply a ribbon blender equipped with a screw conveyor to automatically feed powdered raw materials.

0 notes

Text

Top Manufacturing Solutions for Pharma & Cosmetic Industries

In the dynamic world of pharmaceutical and cosmetic manufacturing, quality, efficiency, and precision are paramount. At Pharmachem Cosmetics, we understand the importance of using state-of-the-art equipment to ensure top-tier products. Whether you're producing ointments, oral liquids, or other cosmetic formulations, having the right machinery is crucial for success. In this blog, we'll highlight essential equipment and machinery that every manufacturer in the pharmaceutical and cosmetic industries should consider.

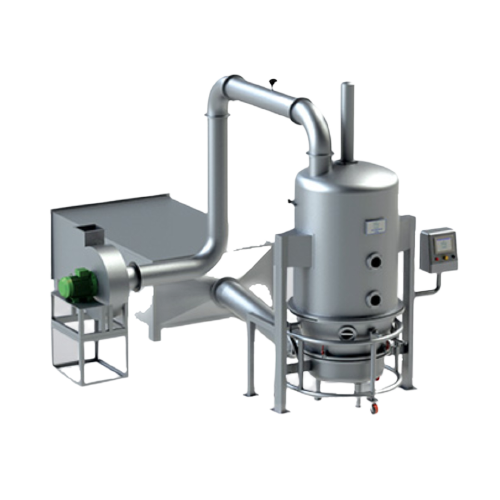

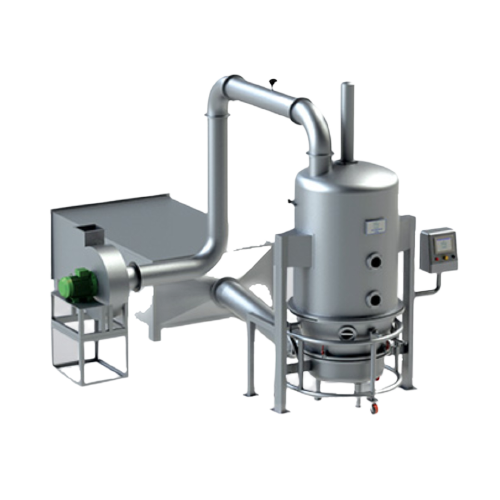

1. Fluid Bed Dryer Manufacturers: Enhancing Product Drying Efficiency

When it comes to drying powders, granules, or other materials in the pharmaceutical and cosmetic industries, Fluid Bed Dryers are indispensable. These dryers operate on the principle of fluidization, where hot air flows through the material, reducing moisture content quickly and efficiently. Fluid Bed Dryer Manufacturers like Pharmachem Cosmetics offer equipment designed for consistency, high-quality results, and energy efficiency, making them ideal for drying sensitive products such as powders, granules, and even some ointments.

Choosing the right Fluid Bed Dryer can significantly impact production timelines and product quality. At Pharmachem Cosmetics, we offer advanced Fluid Bed Dryers that meet industry standards and are customizable for different batch sizes and material types. Our equipment ensures uniform drying, preventing clumping and enhancing the overall product stability.

2. Ribbon Blender Mixer in Maharashtra: Optimal Mixing for Uniform Results

Uniformity in mixing is crucial for the success of any pharmaceutical or cosmetic product. The Ribbon Blender Mixer, a common choice in manufacturing plants, provides an efficient solution for blending powders and granules. This versatile equipment ensures thorough mixing of dry ingredients, resulting in uniform consistency throughout the batch.

Pharmachem Cosmetics, based in Maharashtra, is a leading provider of Ribbon Blender Mixers known for their precision and reliability. Whether you are blending active pharmaceutical ingredients (APIs) or cosmetic powders, our Ribbon Blender Mixers are designed to handle a wide range of formulations with ease. By providing a homogeneous blend, these mixers help in achieving the desired product quality, reducing waste, and optimizing production time.

3. Liquid Oral Manufacturing Plant Suppliers: The Backbone of Liquid Formulations

The demand for liquid oral medications and cosmetic products is on the rise. Whether it’s syrups, tonics, or oral gels, the liquid formulation process requires specialized manufacturing plants equipped with the latest technology. Liquid Oral Manufacturing Plant Suppliers like Pharmachem Cosmetics provide cutting-edge equipment for the smooth production of liquid formulations.

From raw material mixing to bottling and packaging, our liquid oral manufacturing plants are designed to ensure safety, hygiene, and efficiency. With automated systems and robust machinery, we help streamline your liquid production process, reducing contamination risks and ensuring consistent product quality. As a trusted supplier in the industry, Pharmachem Cosmetics ensures that your plant meets regulatory standards and operates at peak performance.

4. Ointment Manufacturing Plant Dealers: Producing High-Quality Ointments

Ointments are among the most widely used formulations in both the pharmaceutical and cosmetic industries. From topical treatments to skincare products, the right manufacturing process is essential to ensure the effectiveness and safety of the ointment. Pharmachem Cosmetics offers high-quality Ointment Manufacturing Plants, designed to produce consistent and reliable ointments for a variety of applications.

Our ointment manufacturing plants are equipped with advanced machinery such as mixers, homogenizers, and filling machines, designed to handle both small and large batches. As leading Ointment Manufacturing Plant Dealers, we provide you with everything you need to produce high-quality ointments while adhering to strict regulatory guidelines.

5. Multi Mill Manufacturers: Versatile and Efficient Milling Solutions

The Multi Mill is one of the most versatile machines used in the pharmaceutical and cosmetic industries. Capable of performing a range of functions such as grinding, milling, shredding, and crushing, the Multi Mill is an essential tool for reducing the size of materials for further processing. Whether you are working with APIs, herbal ingredients, or cosmetic raw materials, the Multi Mill ensures uniform particle size reduction, improving product consistency and performance.

At Pharmachem Cosmetics, we are proud to be recognized as leading Multi Mill Manufacturers, offering equipment that guarantees high throughput, durability, and ease of maintenance. Our Multi Mills are designed with user-friendly controls and are highly adaptable to different production needs.

Conclusion: Quality Equipment for Exceptional Products

At Pharmachem Cosmetics, we are committed to providing the highest quality manufacturing equipment for the pharmaceutical and cosmetic industries. Whether you are in need of Fluid Bed Dryers, Ribbon Blender Mixers, Liquid Oral Manufacturing Plants, Ointment Manufacturing Plants, or Multi Mills, we offer cutting-edge solutions to meet your production requirements.

Partner with Pharmachem Cosmetics today and elevate your manufacturing process to new heights. Our equipment ensures precision, efficiency, and safety in every batch, helping you deliver exceptional products to your customers.

#Multi Mill Manufacturers#Ribbon Blender Mixer in Maharashtra#Fluid Bed Dryer Manufacturers#Liquid Oral Manufacturing Plant Suppliers#Ointment Manufacturing Plant Dealers

1 note

·

View note

Text

Ribbon Blender Manufacturer: Hexamide Agro Tech Inc., Mumbai

Hexamide Agro Tech Inc., located in Mumbai, is a premier manufacturer of Ribbon Blenders. With over 25 years of experience, Hexamide Agro Tech has earned a reputation for delivering high-quality, reliable, and efficient blending solutions tailored to the needs of various industries, including pharmaceuticals, chemicals, food processing, and cosmetics. Our Ribbon Blenders are designed to provide optimal mixing of dry powders and granules, ensuring consistency and uniformity in every batch.

Product Overview

Ribbon Blenders

Hexamide Agro Tech’s Ribbon Blenders are engineered to deliver efficient and homogeneous mixing of a wide variety of materials. These blenders are designed with precision to handle different bulk densities and particle sizes, making them versatile for numerous industrial applications.

Key Features and Benefits

Robust Construction:

Manufactured using high-grade materials such as stainless steel (SS 304, SS 316) and mild steel (MS), ensuring durability, corrosion resistance, and long service life.

Efficient Mixing Mechanism:

Equipped with a double-helix ribbon agitator designed to move materials both radially and laterally, ensuring thorough and uniform mixing.

Customizable Designs:

Offering tailor-made solutions to meet specific client requirements, including different sizes, shapes, and configurations. Additional features like heating or cooling jackets, discharge valves, and advanced control systems can be integrated.

Enhanced Mixing Performance:

Designed to handle a wide range of mixing tasks, providing efficient blending of powders, granules, and other bulk materials.

Ease of Operation and Maintenance:

User-friendly designs that facilitate easy operation, cleaning, and maintenance, reducing downtime and operational costs.

Safety and Compliance:

Manufactured in compliance with stringent industry standards and safety regulations, ensuring safe and reliable operation in various industrial environments.

Technical Specifications

Material: High-quality stainless steel (SS 304, SS 316) or mild steel (MS)

Capacity: Available in various sizes to accommodate different batch volumes

Agitator Types: Double-helix ribbon agitator for efficient mixing

Drive System: Robust motor and gearbox for reliable performance

Discharge Options: Various discharge valves and mechanisms to suit specific process needs

Control Systems: Advanced control systems for monitoring and adjusting mixing parameters

Applications

Hexamide Agro Tech’s Ribbon Blenders are suitable for a variety of industrial applications, including:

Pharmaceuticals: For blending active pharmaceutical ingredients (APIs) with excipients and other compounds.

Chemicals: For mixing various chemical powders and granules, ensuring uniformity and consistency.

Food and Beverage: For the preparation of spices, baking mixes, nutritional supplements, and other food products requiring homogeneous mixing.

Cosmetics: For blending ingredients used in the production of creams, lotions, and other personal care products.

Plastic and Rubber: For mixing additives and fillers with plastic and rubber compounds.

Manufacturing Excellence

Hexamide Agro Tech’s manufacturing facility in Mumbai is equipped with state-of-the-art machinery and technology. Our team of skilled engineers and technicians is dedicated to producing Ribbon Blenders that meet the highest standards of quality and performance. We implement rigorous quality control processes and continuous improvement practices to ensure that every blender delivered is reliable, efficient, and durable.

Conclusion

Hexamide Agro Tech Inc. stands as a leading manufacturer of Ribbon Blenders in Mumbai, offering high-performance blending solutions tailored to meet the diverse needs of various industries. Combining advanced engineering with superior materials, Hexamide Agro Tech delivers Ribbon Blenders that ensure exceptional performance, reliability, and efficiency. Whether for pharmaceuticals, chemicals, food processing, cosmetics, or other industries, Hexamide Agro Tech’s Ribbon Blenders are designed to provide consistent and optimal mixing results in every application.

1 note

·

View note

Text

#conical screw mixer#vertical ribbon mixer#ribbon blender#ribbon mixer#machine#equipment#industrial#powder mixer#mixer#blender

0 notes

Note

So, I've been writing a blind character who cooks. So far, I've written him as being someone who relies a lot on routine and habit, who navigates the kitchen by touch and by memory. He's a bit rigid, and insists on using his own tools, which are color coded (he can see them up close with what residual vision he has) and marked with braille, but I was wondering what other tools a blind person might use when cooking.

A Bunch of Stuff For Blind People Who Want to Cook

I don’t know where and when your story takes place, so what is used might change depending on the character. Here are some options to get you started. There are many tools and techniques devoted to making cooking easier. I don’t know as much about the subject, so I’ll do my best. Please add any other ideas in the notes.

First, the creator @canseecantsee on YouTube and TikTok is an excellent resource. She has lots of videos showcasing how she cooks and does various daily tasks. She demonstrates the use of many tools, such as heat resistant gloves and high contrast items. Here is a video in which she demonstrates chopping vegetables.

Notice the high contrast items such as the yellow chopping board and purple knife. In the video, she demonstrates use of the towel or a place mat beneath the cutting board to prevent slipping. As she cuts a cucumber, tomatoes, and onions, she also uses a technique that allows her to feel the edge of the item so that she knows where she wants to cut and how thick the slices will be.

Here is a video by TheBlindLife showcasing his accessible kitchen. He has excellent points on the importance of contrast, from color contrast to shape contrast. The video includes

bump dots

labels

high contrast colors of tools

high contrast plates and bowls

talking scale and thermometer

heat resistant gloves

and alternatives for glass cups

High contrast is important and can be created by being mindful of the kind of countertops or tables used. For example, in the video, there is a triangular plate that is decorated like a pizza slice. Eating on this plate might cause food to get lost visually, especially food that has the same colors as the plate. Much like the plate, counters or tablecloths with busy patterns might cause items to be harder to see due to lack of contrast. Plain counters, tables, or tablecloths make items stand out more.

Additionally, creating contrast between surfaces and the items on them is helpful. The table is a dark wood? Light plates, bowls, and cups it is. The counter is plain white? The plates and bowls are a dark color.

For glass cups, the video offers solid, colorful plastic cups that offer better contrast. The fact that glasses are clear makes them even more of a challenge and colorful plastic alleviates that concern. However, if someone wants to use glass cups, they can use some that are either made with colorful glass or have color somewhere on them. This might help depending on the contrast and lighting.

In addition to memory, your character can also use labels and various markers. Sharpie, different colors and shapes, textural elements like bump dots, actual Braille or large print labels, tape, stickers, string, or ribbon. Label makers are great, but plenty of other options exist, particularly considering the aesthetic the kitchen has. He may also enjoy decorating this way since he has residual vision. Ribbons tied around containers of sugar, salt, and flour can be cute and functional.

A few other ideas after searching cooking stuff:

talking items, such as a blender, rice cooker, or microwave oven

marking speed on electric mixers or other devices

talking, high contrast, or large print timers

funnel or liquid level indicator

Braille or large print labeled measuring cups

individual bowls for portions, such as soup, rice, sauces, proteins, etc. Different shapes, sizes, or color could also indicate what food item typically goes in what bowl.

You can also come up with other ideas by thinking about what your character would use and how that might be done more easily. While I prefer characters use blindness techniques and assistive devices, people also naturally make things easier for themselves through organization and creating their own labels. A person who cooks might also be able to distinguish certain ingredients by smell or texture.

Another tip I have is to watch blind content creators on social media. Chances are, some of them show themselves cooking or discuss how they do it.

Lighting is also going to be a big deal. The kitchen will need good lighting, both overhead and under cabinets. Natural lighting is also great, although this is not as reliable or constant.

What he uses might also depend on various factors such as income; how often a character cooks; amount of available space; time period and setting; cultural practices around cooking, eating, and utensils used; access to the blind community; willingness to use assistive devices for blind people; any internalized ableism or ableism from family; and level of vision.

Hope that helps.

#blind#blind characters#writing blind characters#accessibility#disability#ableism#kitchen#cooking#accessible cooking#labeling#ask

287 notes

·

View notes

Text

Ribbon Blender Machine Manufacturers

Ribbon Blender is a high speed, high capacity batch mixer for the homogeneous blending of dry, free-flowing solids. It comprises a U-shaped horizontal trough and a specially designed double helical ribbon agitator rotating within. Ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast and efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide movement of material within the container that avoids dead spots and gives rapid product discharge. The mixer is available in machine sizes ranging from 100 to 5000 liters.

INSTECH Pharma is a leading ribbon blender machine manufacturers & supplier in India. We manufacture customized ribbon blenders as per the requirement of the customer or the industry. It is mainly applied in processing industries such as food, feed, chemicals, petrochemicals, plastics and flour milling for blending premixes and ready-made mixes.

Website: https://www.pharmaceutech.com/ribbon-blender-machine-manufacturers/

0 notes

Text

Top Benefits of Using a Drum Mixer Blender for Bulk Mixing

A drum mixer blender offers several key benefits for bulk mixing, making it ideal for industries requiring large-scale production. Its efficient design ensures uniform blending of powders, granules, or liquids, reducing mixing time. Drum mixer blenders are highly versatile, accommodating a variety of materials while maintaining consistency. Their ease of use and minimal maintenance requirements help optimize production processes. Additionally, they improve safety by minimizing manual labor and the risk of contamination. Investing in a drum mixer blender enhances productivity, reduces waste, and ensures high-quality results in large batch operations.

Understanding the Functionality of a Drum Mixer Blender

A drum mixer blender is an industrial-grade machine designed for efficient and uniform mixing of bulk materials such as powders, granules, and liquids. Its rotating drum action ensures that all components are mixed thoroughly, creating consistent blends in large batches. The design of these machines allows for smooth material flow, ensuring that even dense or heavy substances are mixed effectively. Whether used in the food, pharmaceutical, or chemical industries, drum mixer blenders offer versatility for a wide range of mixing needs.

Key Benefits of Using a Drum Mixer Blender for Large-Scale Operations

Drum mixer blenders provide significant benefits for large-scale manufacturing operations. They are designed to handle high volumes of materials, making them ideal for industries that require bulk mixing. The consistency of the mixture is maintained, which is crucial for product quality. Additionally, these machines reduce mixing time and labor, improving operational efficiency. The large capacity of drum mixers also ensures a continuous flow of materials, minimizing downtime during production.

How Drum Mixer Blenders Improve Consistency in Bulk Mixing?

One of the most significant advantages of drum mixer blenders is their ability to produce highly consistent blends. The rotating drum ensures thorough mixing, preventing any segregation of materials. This is essential in industries where even minor variations in product composition can impact quality. Whether you're mixing dry ingredients for a food product or chemicals for industrial applications, a drum mixer blender helps achieve uniformity in every batch, ensuring product integrity and reliability.

Types of Drum Mixer Blenders and Their Applications

Drum mixer blenders come in various designs, each tailored to specific types of materials and industries. For example, horizontal drum mixers are commonly used for powders and granules, while vertical drum mixers are ideal for liquids and slurries. Additionally, some models are equipped with specialized features, such as ribbon agitators or paddle designs, to enhance mixing efficiency. By choosing the right type of drum mixer, businesses can optimize their mixing process for different applications, from food production to pharmaceutical manufacturing.

Energy Efficiency and Cost-Effectiveness of Drum Mixer Blenders

Drum mixer blenders are designed with energy efficiency in mind. Their high-performance mixing capabilities reduce the need for excessive energy consumption, making them a cost-effective option for large-scale production. Moreover, because they can handle large volumes of materials with minimal labor, businesses can save on both energy and labor costs. The durability and long lifespan of these machines also contribute to long-term savings, as they require fewer repairs and replacements compared to other mixing equipment.

Maintenance and Longevity of Drum Mixer Blenders

Proper maintenance is essential for ensuring the longevity and optimal performance of drum mixer blenders. Fortunately, these machines are designed with ease of maintenance in mind. Regular cleaning, lubrication of moving parts, and inspection of the drum and motor are essential for maintaining efficiency. Additionally, some models come with self-cleaning features, further reducing maintenance efforts. By following the manufacturer’s guidelines for upkeep, businesses can extend the life of their drum mixer blender and maintain smooth, uninterrupted production.

Choosing the Right Drum Mixer Blender for Your Business Needs

Selecting the right drum mixer blender is crucial for maximizing its potential. Factors to consider include the volume of materials to be mixed, the types of substances involved, and the specific industry requirements. Businesses should assess whether they need a stationary or portable model, and choose a blender that offers the appropriate capacity and mixing action. It’s also important to evaluate the machine's ease of use, safety features, and warranty. A well-chosen drum mixer blender can greatly enhance productivity, improve consistency, and reduce costs.

Conclusion

In conclusion, drum mixer blenders offer numerous advantages for large-scale operations across various industries. Their ability to produce consistent, high-quality mixes in a short amount of time helps streamline production and reduce costs. With a wide range of designs to meet different mixing needs, they provide flexibility and efficiency. By investing in a drum mixer blender and choosing the right model for your business, you can ensure smoother, more effective operations while maintaining the highest standards of product quality. Proper maintenance and smart usage of these machines can also lead to significant long-term savings and productivity gains.

0 notes

Text

Ribbon Blender Mixer, Vibro Sifter Machine, Conveyor System For Plant Manufacturer

Godman Automation is the Manufacturer & Supplier of Robotics, Control Systems, AI Technology, & Conveyor Belt Systems in Delhi, Mumbai, Bangalore, Tamil Nadu, Hyderabad, Bihar, Haryana

0 notes

Text

Among the most versatile and widely used mixing equipment, ribbon blenders stand out for their ability to deliver exceptional performance across diverse industries.

#ribbon blender#ribbon blender mixer#lab ribbon blender#ribbon blender manufacturer#best ribbon blender machine

0 notes

Text

Comparing Different Types of Conical Mixers: Which One Is Right for You?

Conical mixers are a type of industrial mixing equipment used in various industries, including food, pharmaceutical, and chemical processing. They are designed to efficiently mix and blend materials of different densities and viscosities, ensuring a uniform product. With several types of conical mixers available, selecting the right one for your specific application can be challenging. In this article, we will compare different types of conical mixers, highlighting their features, advantages, and conical mixer to help you make an informed decision.

Tumble Blenders: A Popular Choice

Tumble blenders are a common type of conical mixer used for blending dry powders, granules, and small particles. They consist of a rotating drum with a conical shape, which creates a tumbling action that mixes the materials. Tumble blenders are known for their simplicity, ease of use, and low maintenance costs. They are ideal for applications where gentle blending is required, such as in the food and pharmaceutical industries. However, they may not be suitable for mixing materials with high viscosity or large particle sizes.

Ribbon Blenders: Efficient and Versatile

Ribbon blenders are another type of conical mixer that uses a rotating ribbon or agitator to mix materials. They are designed for blending a wide range of materials, including powders, granules, and liquids. Ribbon blenders are known for their high efficiency and versatility, making them suitable for various applications, including food, chemical, and pharmaceutical processing. They are also easy to clean and maintain, reducing downtime and increasing productivity. However, they may require more energy than tumble blenders and can be more expensive.

Paddle Mixers: Ideal for High-Viscosity Materials

Paddle mixers are a type of conical mixer that uses a rotating paddle or blade to mix materials. They are designed for blending high-viscosity materials, such as thick pastes, gels, and slurries. Paddle mixers are known for their ability to handle tough mixing applications, making them ideal for industries such as cosmetics, adhesives, and sealants. They are also easy to clean and maintain, reducing the risk of contamination. However, they may require more energy than other types of conical mixers and can be more expensive.

Conical Screw Mixers: Gentle and Efficient

Conical screw mixers are a type of conical mixer that uses a rotating screw to mix materials. They are designed for blending sensitive materials, such as powders, granules, and small particles. Conical screw mixers are known for their gentle mixing action, which preserves the integrity of the materials. They are also energy-efficient and easy to maintain, reducing costs and increasing productivity. However, they may not be suitable for mixing materials with high viscosity or large particle sizes.

Double Cone Mixers: High-Capacity Blending

Double cone mixers are a type of conical mixer that uses two rotating cones to mix materials. They are designed for high-capacity blending applications, such as in the food, pharmaceutical, and chemical industries. Double cone mixers are known for their ability to handle large batches and blend materials quickly and efficiently. They are also easy to clean and maintain, reducing downtime and increasing productivity. However, they may require more energy than other types of conical mixers and can be more expensive.

Conclusion: Choosing the Right Conical Mixer

Selecting the right conical mixer for your specific application requires careful consideration of several factors, including the type of materials being mixed, the desired level of blending, and the available budget. By understanding the features, advantages, and disadvantages of different types of conical mixers, you can make an informed decision that meets your needs. Whether you choose a tumble blender, ribbon blender, paddle mixer, conical screw mixer, or double cone mixer, ensure that it is designed for your specific application and provides the desired level of blending efficiency and product quality.

0 notes

Text

Ribbon Blender R&D Lab Model

youtube

Ribbon Blender R&D Lab Modal (small ribbon blender) including small powder mixer comprises double helical ribbon agitator that rotates within. Ribbon Agitators consists of set of inner and outer helical ribbons, it is referred to as a double helical ribbon agitator. The gap between the ribbon’s outer edge and the internal wall of the container ranges between 3 to 6 mm depending on the application.

Small powder blender is based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

An alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender.

Adinath is leading ribbon blender machine manufacturer in capacity ranging from 5 liters small ribbon blender to 15000 liters industrial ribbon blender. We produce mixer in mild steel as well as stainless steel materials. We provide extended support for ribbon blender parts and validation. We provide ribbon blender with screw conveyor for auto feeding of powder raw material.

0 notes

Text

0 notes

Text

Equipment Used in the Pharmaceutical Industry

The pharmaceutical industry relies on a vast range of specialized equipment to ensure that the production processes for medicines, vaccines, and other health products are safe, efficient, and compliant with regulatory standards. From raw material handling to the packaging of the final product, equipment plays a crucial role in ensuring quality and sterility. This article explores the essential equipment used in pharmaceutical manufacturing, highlighting the importance of each category and its application in the production process.

1. Mixing and Blending Equipment

Mixers and blenders are critical in combining raw materials and active pharmaceutical ingredients (APIs) into homogeneous mixtures. This equipment ensures that the components are evenly distributed, which is vital for dosage consistency in tablets, capsules, and other pharmaceutical forms. Different types of mixing equipment are used depending on the properties of the ingredients:

Ribbon Blenders: Used for dry powder mixing, commonly in tablet production.

High-Shear Mixers: Ideal for wet granulation processes where liquid binding agents are added to powders.

2. Granulation Equipment

Granulation is a key step in the production of tablets. This process converts fine powders into larger, free-flowing granules, making it easier to compress them into solid dosage forms. The two main types of granulation processes are wet granulation and dry granulation. Equipment used for this purpose includes:

Fluid Bed Granulators: Used in wet granulation to spray binder solutions onto powder particles.

Roller Compactors: Used in dry granulation, where powders are compacted between rollers to form granules without adding liquids.

3. Tableting and Encapsulation Machines

Tableting and encapsulation are the processes of converting granules into solid dosage forms. Specialized machines are required to compress powders into tablets or encapsulate them in capsules:

Tablet Presses: These machines compress powders or granules into tablets of uniform size and weight. Single-punch or rotary tablet presses are commonly used, depending on production scale.

Capsule Fillers: Capsule filling machines automatically fill empty gelatin or HPMC capsules with powders, granules, or liquid formulations, ensuring precise dosage in each capsule.

4. Coating Machines

Pharmaceutical tablets often require coatings for several reasons, such as improving taste, protecting the active ingredients, or controlling drug release. Coating machines apply a thin layer of polymer or sugar-based coating onto the tablet's surface. The most common equipment used for this purpose includes:

Pan Coaters: These machines rotate tablets in a pan while spraying the coating solution.

Fluidized Bed Coaters: Used for applying coatings to particles or small tablets by suspending them in an air stream while applying the coating material.

5. Sterilization Equipment

In pharmaceutical production, sterility is paramount, especially in the manufacturing of injectable drugs, vaccines, and other sterile products. Sterilization equipment ensures that any microbial contamination is eliminated. The common sterilization methods and equipment include:

Autoclaves: Use steam under pressure to sterilize equipment and pharmaceutical products. They are widely used for sterilizing surgical instruments, glassware, and some types of media.

Dry Heat Sterilizers: Ideal for sterilizing equipment that can withstand high temperatures but not moisture, such as glass bottles and metal equipment.

Gamma Irradiation: Used for sterilizing pharmaceutical products that are sensitive to heat or moisture.

6. Filtration Systems

Filtration is critical in ensuring that liquids and gases used in pharmaceutical manufacturing are free from particulates, bacteria, and other contaminants. Filtration systems are essential in the production of injectable drugs, vaccines, and sterile products:

Membrane Filters: Used to remove bacteria and particulates from liquid formulations. These filters are commonly used in the preparation of sterile solutions.

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are used in cleanrooms and HVAC systems to ensure the air is free from particulates and microorganisms.

7. Water Purification Systems

Water is a fundamental ingredient in the pharmaceutical industry, used in various forms, such as Purified Water (PW), Water for Injection (WFI), and Ultra-Pure Water (UPW). Water purification systems ensure that the water used in pharmaceutical production meets strict purity standards:

Reverse Osmosis (RO) Systems: Remove dissolved solids, bacteria, and organic impurities from water.

Electrodeionization (EDI) Systems: Used for the continuous production of ultra-pure water by removing ionic contaminants.

Water for Injection (WFI) Systems: Produce highly purified, sterile water used in the production of injectables and other sterile pharmaceutical products.

8. Packaging Equipment

Pharmaceutical packaging must ensure the product’s safety, integrity, and compliance with regulatory requirements. The packaging process also protects the product from contamination, tampering, and environmental factors. Common types of packaging equipment include:

Blister Packaging Machines: Used for packaging tablets and capsules in pre-formed cavities made of plastic or aluminum.

Bottle Filling Machines: Automatically fill liquid pharmaceuticals into bottles or vials, ensuring precise measurement and sealing.

Labeling Machines: Apply labels to pharmaceutical containers, ensuring that they contain the correct product information and batch details.

9. Quality Control Equipment

Pharmaceutical production requires stringent quality control to ensure that products meet regulatory standards. Quality control equipment is used for testing various attributes of the product, such as potency, purity, dissolution rate, and more:

HPLC (High-Performance Liquid Chromatography): Used to analyze the chemical composition of drugs and ensure that they contain the correct concentrations of active ingredients.

Dissolution Testers: Measure the rate at which tablets or capsules dissolve in liquids, ensuring that they meet specified release profiles.

Spectrophotometers: Analyze the absorbance of light in drug samples, helping to identify impurities or verify the concentration of active ingredients.

10. Cleanroom Equipment

Pharmaceutical manufacturing often takes place in cleanrooms, which are controlled environments designed to minimize contamination from airborne particles. Cleanroom equipment includes:

Air Showers: Used at the entrances to cleanrooms to blow off dust and contaminants from personnel before entering the sterile environment.

Laminar Flow Hoods: Ensure a sterile working environment by providing a stream of filtered air over work surfaces, minimizing the risk of contamination.

Conclusion

The pharmaceutical industry relies on a wide variety of specialized equipment to ensure the safe, efficient, and compliant production of medicines and other health products. From mixing and granulation to sterilization, packaging, and quality control, every stage of pharmaceutical manufacturing is supported by advanced technologies designed to maintain product integrity and meet the highest purity standards. With the demand for pharmaceuticals constantly increasing, the role of equipment in ensuring product safety, quality, and regulatory compliance cannot be overstated.

SWJAL PROCESS Pvt. Ltd. offers high-quality pharmaceutical equipment to ensure safe, efficient, and compliant production processes across the pharmaceutical industry.

0 notes