#robotic automation solution

Explore tagged Tumblr posts

Text

Unlocking Productivity with Robotic Process Automation

In an era where efficiency is critical, Robotic Process Automation (RPA) has emerged as a game-changer for businesses aiming to unlock new levels of productivity. RPA allows organizations to automate repetitive, rule-based tasks by deploying software bots that work around the clock with speed and precision. This not only accelerates processes but also reduces operational costs and minimizes human error.

By taking over tasks such as data extraction, report generation, invoice processing, and customer onboarding, Robotic Process Automation frees employees from mundane workloads. This enables teams to shift their focus to strategic, high-value activities like innovation, decision-making, and customer engagement. As a result, businesses experience higher output, improved accuracy, and faster service delivery.

One of RPA's strongest benefits is its ability to scale—bots can be quickly deployed across departments without requiring major changes to existing IT infrastructure. This makes implementation fast, cost-effective, and low-risk.

From finance and HR to supply chain and customer service, RPA is transforming how work gets done. Organizations that adopt RPA early are not just improving productivity—they’re gaining a competitive edge. Unlocking productivity with RPA isn't just about doing things faster—it's about working smarter and laying the foundation for digital transformation.

#robotic automation solution#software testing#automation testing#qa testing services#qa consulting services#test management tool#automated system testing#rpa test automation#end to end testing

0 notes

Text

Pushing my 'Ride The Cyclone could easily be reintepreted as horror' agenda

#like c'mon#fortune telling robot that is implied to have done this before#and a bunch of kids who died on a rollercoaster due to the automated messgae#and now are pupeteered against their will to do choreo and backings for their choir mates#+ the fact that he probably did read her fortune#but he couldn't remember it so for some reason his solution was to take her doll's head and smack in on her body#ride the cyclone#rtc

49 notes

·

View notes

Text

Exploring the Best Robot Vacuum for Pet Hair.

I've recently invested in a Smart Home setup, and I'm excited to share my experience with the SwitchBot brand. After researching various options, I decided to try their robot vacuum, which is often touted as the best robot vacuum for pet hair. I have two furry friends at home, and I was looking for a solution that would help keep my floors clean without too much effort on my part.

After using the SwitchBot vacuum for a few weeks, I am thrilled with the results! It efficiently picks up pet hair, dander, and dirt, leaving my floors spotless. I love that I can schedule cleaning times through the SwitchBot app, which makes it incredibly convenient.

I'm also impressed with its ability to navigate around furniture and avoid obstacles, ensuring that it covers every corner of my home. The suction power is fantastic, and it even has a self-charging feature that means I don't have to worry about it running out of battery.

If you're a pet owner looking for an effective cleaning solution, I highly recommend checking out SwitchBot's robot vacuum. It has truly made my life easier, and I can't imagine going back to manual cleaning. If you have any questions about my experience or the product, feel free to ask!

#robot vacuum#pet hair#SwitchBot#smart home#cleaning solution#suction power#self-charging#home automation#pet owner#convenience

2 notes

·

View notes

Text

Unlocking Efficiency and Innovation: The Role of Robotic Process Automation (RPA)

In today's fast-paced and competitive business environment, organizations are constantly seeking ways to improve efficiency, reduce costs, and increase productivity. Robotic Process Automation (RPA) has emerged as a powerful tool that can help businesses achieve these objectives.

What is Robotic Process Automation (RPA)?

Robotic Process Automation (RPA) is a technology that allows businesses to automate repetitive, rule-based tasks. It uses software robots, also known as "bots," to mimic human actions and interact with digital systems. These bots can log into applications, navigate through screens, input data, and complete tasks just like humans would.

The Role of RPA in Business:

RPA can be used to automate a wide range of tasks across various industries and departments. Here are some examples:

Finance and Accounting: Automating tasks such as accounts payable and receivable, invoice processing, and financial reporting.

Customer Service: Automating tasks such as answering FAQs, resolving customer inquiries, and processing orders.

Human Resources: Automating tasks such as onboarding new employees, processing payroll, and managing benefits.

IT: Automating tasks such as provisioning accounts, managing user access, and deploying software updates.

Impact of RPA on Businesses:

Implementing RPA can offer numerous benefits to businesses, including:

Increased efficiency and productivity: RPA can automate time-consuming and tedious tasks, freeing up employees to focus on more strategic and value-added activities.

Reduced costs: RPA can help businesses save money on labor costs, as well as reduce errors and compliance risks.

Improved accuracy and compliance: RPA bots are programmed to follow specific rules and procedures, which can help to improve accuracy and compliance with regulations.

Enhanced process visibility and control: RPA provides businesses with a clear view of their processes, which can help them identify and address bottlenecks.

Improved customer satisfaction: RPA can help businesses improve customer satisfaction by automating tasks such as order processing and customer service interactions.

RPA Services:

Implementing RPA successfully requires a partner with expertise in the technology and a deep understanding of business processes. A comprehensive RPA solution should include the following services:

Document AS-IS Process: This involves mapping out the existing process to identify areas for automation.

Design & Development of Bots, workflows, and forms for process automation: This includes designing and developing the software robots that will automate the tasks.

Bot license (We will use the appropriate underlying technology): This provides access to the software robots and the underlying technology platform.

Infrastructure: This includes setting up the necessary infrastructure to support the Robotic Process Automation (RPA) solution.

Production Deployment of the Bots: This involves deploying the bots to production and monitoring their performance.

RPA support: This includes ongoing support for the RPA solution, such as troubleshooting and maintenance.

Test & Deploy bots to production: This involves testing the bots in a production environment and making any necessary adjustments before they are deployed to full production.

Configuration data changes: This involves making changes to the configuration data of the bots as needed.

Password updates: This involves updating the passwords of the bots as needed.

Errors in executing the Bots: This involves resolving errors that occur during the execution of the bots.

Determining the “root cause” of a recurring issue or incident & recommendations: This involves identifying the root cause of a recurring issue or incident and recommending solutions to prevent it from happening again.

Infrastructure/application related issues: This involves resolving issues with the infrastructure or applications that the bots are interacting with.

Conclusion:

RPA is a powerful technology that can have a significant impact on businesses of all sizes. By automating repetitive tasks, RPA can help businesses improve efficiency, reduce costs, and increase productivity. However, it is important to choose a reputable Robotic Process Automation (RPA) companies with the expertise and experience to help you implement a successful RPA solution.

Ready to embrace the power of RPA?

Contact us today to learn more about how RPA can help your business achieve its goals.

#robotic process automation#robotic process automation rpa#rpa automation#robotic process automation software#rpa software#robotic process automation companies#robotic process automation technology#robotic process automation in healthcare#robotic process automation in banking#rpa solution#robotic process automation for finance#process automation solution#robotic process automation services#robotic process automation for insurance#rpa system#what is rpa automation#robotic process automation solution#robotic process automation benefits#robotic process automation consulting#robotic process automation consultant#rpa service provider#rpa consulting services

2 notes

·

View notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.

10-Voice and Wearable Technologies: Wearable devices and voice-guided picking systems can provide workers with real-time information and instructions, improving accuracy and efficiency.11-Automated Packaging Solutions: These systems automate the packaging process by selecting the appropriate box size, sealing packages, and applying labels, reducing manual labour and ensuring consistent packaging quality.

1 note

·

View note

Text

For the last fucking time, the mech is *SUPPOSED* to look fuckable

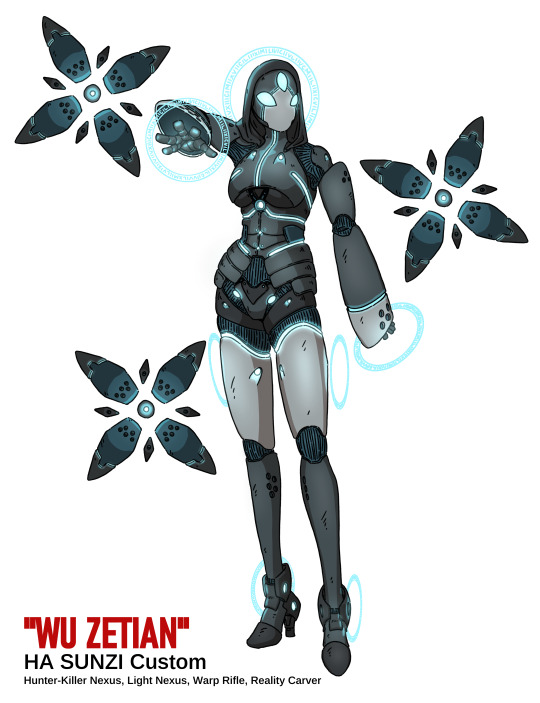

Lancer RPG commission of the Wu Zetian, a nexus-based (and tron-based) Sunzi build.

#lancer rpg#autos automated solutions#HOW THE FUCK DO YOU EVEN EXPECT LANCERS TO WORK IF THEY DONT WANT TO FUCK THE ROBOT

478 notes

·

View notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

For Smarter Manufacturing Choose Advanced Robotic Automation Solutions https://bigskyeng.com/robotic-integrators/ - We create intelligent robotic automation systems that streamline operations and reduce manual labor. At Big Sky Engineering, Inc., we deliver flexible, innovative, and scalable solutions designed to boost productivity and adapt to evolving manufacturing challenges. For more information visit our website Bigskyeng.com.

0 notes

Text

Gantry Robot manufacturers in India

Strategi automation solutions is a leading Gantry robot manufacturer in India that offers advanced automation solutions designed for high-precision material handling and industrial applications. These systems feature multi-axis movement, robust construction, and customizable designs, making them ideal for industries such as automotive, electronics, packaging, and heavy engineering. With a focus on efficiency, reliability, and integration flexibility. Strategi automation provide cost-effective solutions that boost productivity, reduce manual labor, and support seamless workflow automation.

#gantry#robot#manufacturers#india#bangalore#mysore#strategiautomation#companies#automation solutions

0 notes

Text

The Ultimate Guide to Self-Cleaning Cat Litter Box: In-Depth Review of the PETKIT PuraMax 2, Pros, Cons, FAQs, and Comparisons

As a cat owner, you know the daily grind of scooping litter boxes—it’s a chore that’s messy, time-consuming, and often unpleasant. Enter the self-cleaning cat litter box, a revolutionary solution that automates the scooping process, reduces odors, and gives you more time to enjoy with your furry friend. After extensive research and hands-on testing, I’m excited to share a comprehensive review of…

#automatic litter box#cat care automation#cat health tracking#cat litter box review#cat litter solutions#cat owner convenience#clumping litter#litter box comparison#Litter-Robot 4#low-maintenance litter box#multi-cat litter box#Neakasa M1#Odor control litter box#pet technology#PETKIT PuraMax 2#PetSafe ScoopFree#self-cleaning cat litter box#smart litter box#smart pet products#WiFi cat litter box

0 notes

Text

Test Management Tools Compared: Features, Pricing, and Use Cases

Choosing the right test management tool can make or break your QA process.

We’ll break down essential features such as test case creation, requirement traceability, integration with CI/CD pipelines, real-time reporting, and collaboration support. Some test management tools excel in Agile environments, while others are better suited for traditional test cycles or large enterprises.

Next, we explore pricing models—from subscription-based to one-time licenses and open-source alternatives—highlighting what small teams vs. enterprises should consider.

Finally, we include use case examples from different industries (finance, healthcare, SaaS) to show how these tools fit into unique QA workflows. Whether you're looking for a lightweight solution or an enterprise-grade platform, this comparison will help you make a confident choice.

#qa services#qa software#qa testing services#qa testing software#automated software testing#software testing#automated system testing#robotic automation solution#rpa testing#test automation#test management tools

0 notes

Text

Transforming Business Operations with RPA in Dubai Process Automation

In today's fast-paced digital landscape, businesses face increasing pressure to optimize operations, enhance efficiency, and drive productivity. Robotic Process Automation (RPA) emerges as a transformative technology that leverages intelligent software robots to automate repetitive, rule-based tasks—enabling organizations to streamline workflows, reduce errors, and achieve significant cost savings. With our expertise in robotic process automation and deep industry knowledge, Centelli empowers businesses in Dubai to unlock their full potential through the implementation of cutting-edge RPA process automation solutions.

With the UAE’s ongoing push to bolster its status as a global business hub, AI and automation are set to play a pivotal role. The adoption of these technologies has gained steady traction in recent years—and it’s expected to accelerate further as the government rolls out ambitious innovation and digital transformation plans.

The evolution isn’t limited to the public sector alone. It’s actively reshaping businesses across various industries. Moreover, as use cases, tools, and solutions continue to advance, many exciting new concepts are emerging.

Top Automation AI Trends to Know in 2025

In a market like the UAE—driven by ambition and innovation—staying ahead of the curve is crucial!

Whether you’re a business, an organization, a leader, or part of the workforce, the following AI automation trends are worth noting. And they’re making waves worldwide:

AI-Enhanced RPA

Intelligent Automation

Digital Workers

Hyperautomation

Agentic AI

If You’re a UAE Business Looking to Leverage AI / Automation

Whether you seek operational efficiency, real-time decisions, an empowered workforce, or streamlined costs, please understand: AI and automation aren’t one-size-fits-all solutions. Every organization should approach them based on its own complexity, resources, and goals.

As trusted partners of UiPath (Automation) and Soroco (AI), we at Centelli provide custom-crafted solutions that deliver real results. Book a free, no-obligation online meeting with us today.

#AI Solutions#Intelligent Automation#Robotic Process Automation#Digital Worker#Dubai#Centelli#UAE#RPA in Dubai#UiPath

0 notes

Text

Emerging Energy Technologies: Data, AI, and Digital Solutions Reshaping the Industry

The energy industry is undergoing a revolutionary transformation, driven by cutting-edge technologies that are reshaping how energy operations are managed. With advancements like autonomous robotics, AI, and real-time data analytics, these innovations are solving key challenges and setting new benchmarks for efficiency and sustainability.

Key Developments in Emerging Energy Technologies

Energy Digital Transformation is more than just a trend — it’s a necessity. The integration of advanced tools and strategies is enabling energy companies to overcome barriers, optimize processes, and unlock new possibilities for growth and sustainability. Below, we outline key developments that are shaping this transformation.

Learn more on Future of Oil & Gas in 2025: Key trends

1. Automation and Real-Time Insights

Advanced automation and real-time data solutions are transforming energy operations. These innovations are making operations safer, faster, and more efficient.

Autonomous Robotics: Tools like ANYbotics are automating inspections in hazardous environments, reducing the risk of human error.

Edge Computing: Solutions like IOTech (AcuNow) enable faster and more responsive decision-making by processing data at the edge.

Key Statistics:

The automation adoption in the energy sector is projected to increase by 15–20% in 2025.

Autonomous robotics in hazardous environments is expected to reduce inspection time by 30%.

2. Harnessing the Power of Data

Energy Data Analytics is becoming increasingly critical for energy companies. By harnessing real-time data, companies can optimize performance and make better decisions.

Digital Twin Technology: The KDI Kognitwin integrates with AcuSeven to offer predictive maintenance and improve operational efficiency.

Data Analytics: Platforms like Databricks, AcuPrism enable real-time data analysis to drive better decision-making.

Key Statistics:

Energy sector spending on data analytics is expected to grow by 10–15% annually over the next five years.

The implementation of digital twins is expected to improve maintenance efficiency by 20–25%.

Watch the Webinar Recording

To explore these innovations in more detail, watch the recorded version of SYNERGY FOR ENERGY. Gain exclusive insights into how these trends and technologies are shaping the future of the energy sector.

Click here to watch

3. AI-Driven Energy Optimization

Artificial Intelligence is transforming how energy companies manage operations in the Energy Sector, from predictive maintenance to forecasting. AI is predicted to play a central role in optimizing energy usage and reducing costs.

Generative AI: AI-driven applications enhance forecasting, predictive maintenance, and optimization of energy consumption.

Energy Efficiency Tools: AI-based tools help organizations achieve sustainability goals by reducing waste and optimizing consumption.

Key Statistics:

AI-driven solutions are expected to account for 25–30% of energy management by 2025.

Energy efficiency tools can reduce consumption by 15% across industries.

4. Streamlining Digital Transformation

The shift to digital tools is vital for staying competitive in the fast-evolving energy industry. Digital transformation is helping companies modernize legacy systems and enhance data management.

Custom Digital Applications: Acuvate’s solutions streamline the deployment of digital tools to enhance operational efficiency.

Modernizing Legacy Systems: Solutions like Microsoft Fabric and AcuWeave simplify the migration from outdated systems, improving scalability and performance.

Read more about Top 4 Emerging Technologies Shaping Digital Transformation in 2025

Key Statistics:

Digital adoption in the energy sector is expected to increase by 20% by 2025.

The use of Microsoft Fabric has reduced migration costs by 20–30%.

Looking Ahead: Key Trends for 2025

As we are in 2025, several key trends will further influence the energy sector:

Increased Focus on Renewable Energy: The International Energy Agency predicts that over a third of global electricity will come from renewable sources.

AI’s Growing Demand: The computational needs of AI will significantly drive electricity demand, necessitating a focus on sustainable energy sources.

Nuclear Energy Renaissance: A renewed societal acceptance of nuclear power as part of the energy transition is gaining momentum.

Continued R&D Investment: Ongoing investments in research and development will spur innovation across clean energy technologies.

Conclusion

The ongoing transformation within the energy sector underscores the critical role of innovation in driving efficiency and sustainability. As automation, data analytics, AI, and digital transformation continue to evolve, they will collectively shape a more resilient and environmentally friendly energy landscape. Engaging with these advancements through initiatives like webinars and industry reports will provide valuable insights into navigating this dynamic environment effectively.

For More Insightful Webinars

For more insightful webinars like SYNERGY FOR ENERGY, visit our website. We host a variety of sessions designed to provide in-depth insights into the latest innovations shaping industries worldwide. Stay informed and explore the future of technology and business.

Check out our upcoming webinars here.

#autonomous robots#Advanced automation#real-time data solutions#data analytics#generative ai#Artificial Intelligence#AI-driven applications#Microsoft Fabric#Digital transformation#predictive maintenance

0 notes

Text

Unlocking Robotic Precision with Dynaflex by Dynalog-US

In our rapidly paced world of automation and advanced manufacturing, robotics is continuing to reshape efficiency, precision and innovation. Leading this transformation is Dynalog-US, a well-known name in robotic calibration, inspection, and integration solutions. One of its most innovative products is Dynaflex, an advanced solution focused on robotic flexibility and performance optimization. So, what is Dynaflex, and why is it important to manufacturers and robotics engineers?

Let’s take a look at how Dynaflex by Dynalog is pushing automation prospects further, and why this tool is becoming a "must have" in all sectors.

Why Dynaflex?

Dynaflex is an advanced robotic measurement and diagnostic tool developed by Dynalog-US, specifically to measure and improve the dynamic flexibility of robotic systems. In laymen's terms, Dynaflex measures the amount of flex or deformation a robot experiences while under load. This information is vital since flex must be considered to maintain acceptable levels of a robot's precision, repeatability and accuracy.

Most traditional calibration tools are concerned solely with static accuracy. While Dynaflex is also concerned with accuracy, it delves deeper into the dynamic behaviours of the robot which most traditional tools do not incorporate, nor do they offer ways to improve those measures. Whether a robotic arm is welding, assembling, or packaging products, understanding how the robot flexes as it moves about doing its work allows for better programming and ultimately better overall result

Why Robotic Flexibility is Very Important

Robots are amazing machines that can perform a variety of sophisticated tasks accurately and quickly. Robots are limited in their overall performance because they can suffer from tool deflection, joint compliance, and vibrations from their base which degrade positional accuracy. These small variations can have large implications in precision-based industries like automotive manufacturing, aerospace, and medical device manufacturing, where aspects locally must be at millimeter and sometimes sub-millimeter tolerances.

This is where Dynaflex comes into play by Dynalog; Dynaflex gives an accurate and precise measurement of a robot's physical performance under different operating conditions. This information allows engineers to tune robot paths and minimize errors to deliver the right output.

Additional Benefits of Dynaflex

Dynaflex has several differentiating features that provide it with more advanced capabilities compared to other robotic diagnostics tools:

Non-contact laser tracking measurement Real time data recording and actions of the robot and how the load reacts to that Advanced reports on base flexibility, link/joint compliance, and dynamic deflection of the robotCompatible with all leading robot brands including ABB, FANUC, KUKA, and Yaskawa Canny integrate into a current calibration process

These features make Dynaflex a powerful companion for roboticists aiming to enhance the performance of robotic cells or conduct detailed robotic system diagnostics.

Applications in Various Industries

Dynaflex is valuable in any field of application it's required, and it can be used wherever robotic precision is essential.

Automotive Production: increase the accuracy of weld seam, and body panel alignment.

Aerospace Assembly: control tight tolerances in the assembly of components.

Electronics Manufacturing: validate accuracy of PCB handling and soldering.

Medical Devices: maintain consistent quality of assembly of sensitive devices.

Industrial Automation: improve every aspect of a robot’s motion in handling materials, packaging, and inspection.

Wherever a robot is required to consistently provide high accuracy, Dynaflex by Dynalog-US provides unparalleled insights and improvement.

The Dynalog-US Advantage

Dynalog-US was founded and exists for the purpose of bringing intelligence and precision to robotics. For many years they have been at the forefront of robotic calibration and inspection technologies. Dynalog is known for its comprehensive solutions for robotic inspection and calibration that identify and fix issues beyond calibration alone with deeper mechanical or structural information.

Dynalog was successful because of leadership that put customer first and retained an organisation committed to support and provide thorough training on the full use of tools such as Dynaflex without a steep learning curve. Dynalog's standards of measurement have been adopted by global manufacturers and leading research institutes — Definitely an indication of quality they have pioneered in robotic automation.

How Dynaflex Works Alongside the Robot TCP Calibration

Dynalog provides common services for Robot TCP (Tool Center Point) Calibration which ensures that the robot programming accurately matches the location of the tool in the physical world. TCP calibration looks at the static position of the tool while Dynaflex takes it a step further in understanding the static picture from movement and operation under load.

When considered together, they show a full picture, magnetic or static and dynamic, of the performance of a robot, making programming and execution more consistent and reliable.

In Conclusion: Why Investing in Dynaflex Is a Smart Investment

If you are serious about leveraging robotic systems as much as possible Dynaflex from Dynalog-US is more than a tool, it is an investment you make in performance, quality, and work excellence. Dynaflex can help you recognize flexibilities you did not know existed and help improve responsiveness of the robot so you can decrease downtime, reduce product defects, and get your ROI.

With the push for robotic automation as the underpinning of modern manufacturing there is no margin for errors. Let Dynalog help you stay ahead, with it offering Dynaflex as the smarter way to measure, diagnose, and help optimize robotics performance.

Ready to bring precision to your automation? Learn more about Dynaflex and other robotic calibration tools by visiting Dynalog-US.com

#Dynaflex#Dynalog-US#Robotic Flexibility#Robot Calibration#Robotic Inspection Tools#Automation Solutions#Industrial Robotics#Robot Performance Optimization

0 notes

Text

Revolutionize Traditional Operations with Robotic Process Automation

Traditional business models can’t survive in today’s fast-paced economy. Robotic Process Automation (RPA) offers a practical, affordable way to modernize and scale. An RPA solution eliminates manual bottlenecks by automating everyday tasks like data entry, payroll, and customer service. This means faster response times, fewer errors, and lower operational costs. Whether you're in manufacturing, retail, or logistics, RPA helps you adapt and thrive. At ESS, we customize RPA services for real-world business challenges—ensuring a smooth digital transformation. Say goodbye to inefficiencies and hello to a smarter way of working. Discover how RPA can future-proof your operations today.

0 notes

Text

Boosting Efficiency: The Impact of Robots in Mobile Phone Production

Industrial robots are significantly boosting efficiency in mobile phone production. By automating tasks such as assembly, testing, and packaging, robots increase production speed and reduce human error. These machines work tirelessly, ensuring consistent quality and precision in every step of the process. Robots also enhance flexibility, allowing manufacturers to adapt quickly to new models or design changes. As a result, mobile phone manufacturers can meet growing demand while maintaining high standards. With robots driving efficiency, production costs are lowered, and businesses stay competitive in the fast-paced mobile phone industry. Industrial robots are truly transforming mobile phone manufacturing.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#industrial robots#mobile manufacturing#mobile phone manufacturing#robots

0 notes