#sensorless control system

Explore tagged Tumblr posts

Text

Boost Efficiency in HVAC & Fan Systems with Variable Frequency Drives

Across commercial and industrial facilities, variable frequency drives (VFDs) are key to optimizing HVAC and fan performance by offering precise speed, torque, and airflow regulation. Instead of running at full speed constantly, VFDs adjust motor output to match building demand in real-time, delivering significant energy savings and lower operating costs. Built-in features like sensorless vector control, PID feedback, and automatic sleep/wake functions allow HVAC systems to perform efficiently across all load conditions.

Modern VFDs support a wide range of motors, including induction, permanent magnet, and synchronous reluctance, and typically offer BACnet and Modbus RTU communication as standard, enabling seamless BMS integration. With low harmonic design, internal EMC filtering, and high switching frequencies for quiet operation, VFDs ensure optimal comfort and system reliability. We help facility managers and contractors unlock energy efficiency and operational excellence in their air handling and ventilation systems.

#variablefrequencydrives#vfd#acdrives#industrial#commerical#hvac#controls#automation#airhandling#fans#pumps#motorcontrols#bmsintegration

0 notes

Text

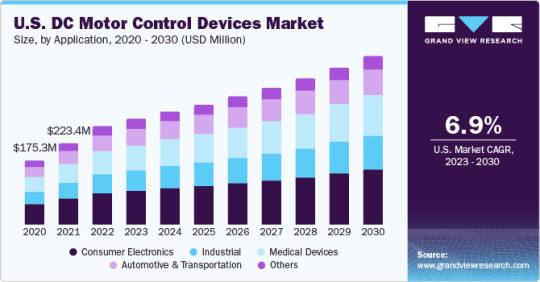

DC Motor Control Devices Market To Reach USD 2.13 Billion By 2030

DC Motor Control Devices Market Growth & Trends

The global DC motor control devices market size is expected to reach USD 2.13 billion by 2030, exhibiting a CAGR of 6.5% from 2023 to 2030, according to a study conducted by Grand View Research, Inc. DC electric motors are being widely used in modern systems, whether in consumer electronics, or industrial, automotive, and transportation industries. Improved performance of these motors in such applications is a result of the underlying electronic controls that are able to rapidly execute sophisticated control algorithms. Thus, increasing demand for motors in such applications, coupled with improved motor performance, is anticipated to drive the market over the forecast period.

Sensorless motor control devices are generally used to reduce overall cost of actuating devices. However, with advancements in sensor control techniques, the market for DC motor control devices is anticipated to gain traction over the forecast period. Furthermore, recent market requirements, such as compatibility with IE3 motors, and changes in motor control systems in several application areas such as industrial, consumer electronics, and medical devices are expected to favor market growth over the coming years.

The market is expected to witness significant demand from the automotive industry owing to introduction of vehicle safety standards to control fuel emissions and increasing adoption of engine control units (ECUs) in modern automobiles. Additionally, growing R&D activities to improve energy efficiency of electric motors are anticipated to boost market growth. For instance, the U.S. Department of Energy invested a substantial amount in 13 R&D projects pertaining to technological advancements in electric motors. These advancements are expected to positively impact the efficiency and performance of motor devices when used in various end-use industries.

However, factors such as uncertainties in raw material prices, limited availability of components, and reduction in overall production of raw materials are contributing to increased product costs, thereby negatively impacting market growth. In order to overcome these challenges, major companies are undertaking several measures to maintain consistency in prices and availability of raw materials. These companies have been entering into long-term supplier contracts to mitigate risks associated with quality and quantity of materials.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/press-release/global-dc-motor-control-devices-market

DC Motor Control Devices Market Report Highlights

Asia Pacific accounted for the largest market share of 41.8% in 2022 and is expected to capture the largest CAGR of 7.8% during the forecast period. Increasing government investments in manufacturing electric vehicles and controlling fuel emissions are anticipated to boost market growth in the region over the forecast period.

The COVID-19 pandemic had a mixed impact on the market for DC motor control devices. The global supply chains for these devices were significantly disrupted, leading to delays in production and distribution.

The medical devices segment is expected to grow at the fastest CAGR of 9.8% over the forecast period. Unprecedented technological advances, coupled with baby boomers' retirement, have created growth potential for companies supplying components for medical applications.

DC Motor Control Devices Market Segmentation

Grand View Research has segmented the global DC motor control devices market based on application, and region:

DC Motor Control Devices Application Outlook (Revenue, USD Million, 2017 - 2030)

Consumer Electronics

Smart motorized devices

High-end toys

Social robots

Others

Automotive & Transportation

Marine outboard motors

Others

Industrial

ATM machines

Pan tilt zoom cameras

Water pump

Actuators & other robotic devices

Others

Medical Devices

CPAC machines

Oxygen concentrator machines

Breast pump

Electronic spoons

Others

Others

DC Motor Control Devices Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

List of Key Players in DC Motor Control Devices Market

ABB

Eaton

General Electric

KB Electronics, Inc.

OMRON Corporation

Rockwell Automation

Schneider Electric

STMicroelectronics

TOSHIBA CORPORATION

Browse Full Report: https://www.grandviewresearch.com/press-release/global-dc-motor-control-devices-market

#DC Motor Control Devices Market#DC Motor Control Devices Market Size#DC Motor Control Devices Market Share#DC Motor Control Devices Market Trends

0 notes

Text

Benefits of PowerFlex 525 AC Drive

The PowerFlex 525 AC Drive has a small, modular design that saves panel space and makes maintenance and installation easier. Integrated EtherNet/IP allows for smooth integration with PLC and SCADA systems, and a USB programming port allows for quick parameter configuration without requiring power. Sensorless Vector Control (SVC) and optional closed-loop operation are two examples of advanced motor control features that guarantee accurate speed and torque regulation. With Safe Torque Off (STO), the drive improves safety by lowering the requirement for external safety relays. In order to optimize power consumption and lower operating costs, its energy-efficient design also supports a variety of motor control modes.

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#allen bradley#rockwell automation#plc#PowerFlex#PowerFlex525#acdrive

1 note

·

View note

Text

Dimensional Measurement Market Revenue Trends and Growth Drivers – 2030

Dimensional measurement systems enhance the quality and accuracy of manufacturing processes by detecting defects and inconsistencies early in production. Dimensional measurement refers to determining an object's geometric characteristics, including size, shape, and form. It plays a critical role in quality control and manufacturing processes by ensuring that products meet precise specifications and regulatory standards. This market encompasses tools, technologies, and systems such as coordinate measuring machines (CMMs), laser trackers, vision systems, and portable measurement devices. Major industries utilizing dimensional measurement include automotive, aerospace, electronics, medical devices, and consumer goods.

Advanced systems such as non-contact measurement solutions also enable the evaluation of delicate or complex components without risking damage. Additionally, these tools support reverse engineering and rapid prototyping by providing precise 3D models of existing parts. Overall, dimensional measurement enhances productivity, ensures compliance with international standards, and fosters product design and development innovation.

Impact of AI on the Dimensional Measurement Market

Artificial Intelligence (AI) has emerged as a transformative force in quality control, providing manufacturers with advanced tools to enhance the efficiency, scalability, and accuracy of dimensional analysis. In sensorless dimensional analysis, AI offers innovative solutions for processing large volumes of sensor data to extract dimensional information from products. Traditionally, dimensional measurements were conducted using physical sensors or through direct contact with the object being measured. However, AI enables sensorless measurement techniques by processing data from non-contact sources such as 3D scanners, analyzing this information to infer the product's dimensions. These technologies outperform traditional methods by offering better learning, real-time, and improved accuracy, while also reducing the costs associated with physical sensors and measurement devices.

Technological advancements like AI-powered optical measurement driving the dimensional measurement market

Technological advancements have played a pivotal role in driving the growth of the dimensional measurement market, particularly with the emergence of high-precision technologies such as laser interferometers and advanced coordinate measuring machines (CMMs). These innovations have significantly enhanced measurement accuracy and efficiency, making them essential in complex manufacturing environments where precision is critical. Laser interferometers, for instance, utilize the interference of light to measure displacement with remarkable accuracy, while advanced CMMs provide automated, high-precision measurements of physical objects in three dimensions. These technologies have paved the way for more effective and consistent quality control in the aerospace, automotive, and electronics industries. Furthermore, newer innovations like AI-powered optical measurement systems and Light Detection and Ranging (LADAR) technology have expanded dimensional measurement capabilities. AI-powered optical systems integrate machine learning algorithms to analyze and interpret measurement data in real time, enhancing speed and accuracy while reducing human error.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=104240004

High costs of advanced dimensional measurement systems

One significant challenge in the dimensional measurement market is the high initial investment costs associated with advanced systems such as coordinate measuring machines (CMMs) and laser scanners. While offering unparalleled precision and efficiency, these systems require a substantial financial outlay, making them inaccessible for many small and medium-sized enterprises. This financial constraint can deter these businesses from adopting such technologies, even when they could significantly enhance quality control and production accuracy. Consequently, the high costs limit the market’s growth potential, especially in regions with a prevalence of cost-sensitive industries.

Some players in the dimensional measurement market includes Hexagon AB (Sweden), Carl Zeiss AG (Germany), FARO Technologies (US), Mitutoyo Corporation (Japan), Nikon Metrology NV (Belgium), KEYENCE CORPORATION (Japan), and Renishaw plc (UK).

Recent Developments The dimensional measurement market has experienced significant advancements in recent years, with portable and wireless measurement devices gaining popularity due to their flexibility and convenience. Non-contact measurement technologies, such as 3D laser scanners and structured light systems, have further transformed the market by enabling faster and more precise data acquisition. For instance, in December 2024, Nikon Metrology NV introduced the NEXIV VMF-K Series, a next-generation video measuring system developed to address growing inspection needs in the semiconductor and electronics industries. The VMF-K Series ensures stable micron-level measurements while enhancing throughput, supporting stringent quality control in semiconductor manufacturing.

0 notes

Text

Avail of the best Eaton Dm1 | Seagatecontrols.com

Searching for the best Eaton Dm1 ? Seagatecontrols.com is your trusted source for top-quality industrial control solutions. These drives are compact yet powerful, offering advanced motor control features such as sensorless vector control, precise speed regulation, and integrated safety functions. The DM1 drives are designed for versatility, capable of handling various applications from HVAC systems to industrial machinery. Visit our site for more info.

eaton DM1

0 notes

Text

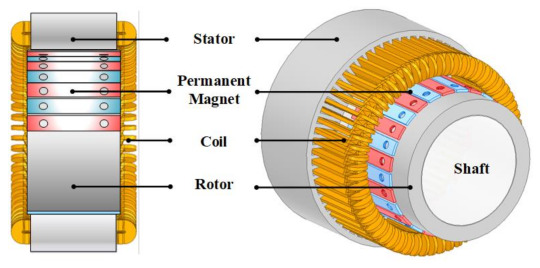

Optimizing Performance & Efficiency by Advanced Techniques in 3-Phase PMSM Motor Control

In the contemporary EV realm, advanced techniques and methodologies aimed at elevating the performance and efficiency of 3-phase PMSM motor controllers, aligning with the evolving landscape of industrial automation.

Sensorless Control

Sensorless control techniques, such as observer-based methods and back-EMF estimation, offer alternatives to traditional sensor-based control, addressing challenges while enhancing reliability and reducing cost.

Advanced Control Algorithms

Exploring sophisticated control algorithms like Model Predictive Control (MPC) and Adaptive Control, which leverage computational intelligence to enhance dynamic response and robustness, ensuring precise motor control in dynamic environments.

Power Factor Correction (PFC)

Power Factor Correction techniques play a vital role in improving the efficiency and power quality of PMSM motor drives. Active and passive PFC methods optimize power utilization, reducing harmonic distortion and enhancing overall system efficiency.

Fault Diagnosis and Protection

Efficient fault diagnosis methods, coupled with fault-tolerant control strategies, safeguard PMSM motor systems against various faults, ensuring uninterrupted operation and prolonging system lifespan in critical industrial applications.

Future Trends and Emerging Technologies

Anticipating the future of PMSM motor control, we delve into emerging trends such as AI integration, digital twin simulations, and advanced semiconductor devices like SiC/GaN, which promise to reshape the landscape of industrial automation with unprecedented efficiency and intelligence.

#PMSM Motor Control#PMSM motor controllers#motor controllers#motor controller EV#EV motor controller#PMSM motor drives

0 notes

Text

Unleashing Precision in Motion: The Dynamics of BLDC Motor Driver Technology

Embark on a journey into the heart of motion control as we delve into the intricacies of BLDC Motor Driver technology. As a distinguished distributor of electronic components, Millennium Semiconductors is your guide to understanding how BLDC Motor Drivers play a pivotal role in powering and controlling Brushless DC Motors with unparalleled precision.

Decoding BLDC Motor Controllers Technology: Precision in Every Revolution

Brushless DC (BLDC) Motors are renowned for their efficiency and longevity, and behind their seamless operation lies the sophistication of BLDC Motor Drivers. These electronic powerhouses are designed to precisely control the speed, direction, and torque of BLDC Motors, making them indispensable in a myriad of applications, from automotive systems to industrial automation.

Key Features and Functions of BLDC Motor Drivers:

1. Precise Speed Control: BLDC Motor Drivers enable precise speed control, ensuring that the motor operates at the desired speed with minimal fluctuations. This level of precision is crucial in applications where consistent and accurate speed is paramount.

2. Sensorless Operation: Many modern BLDC Motor Drivers offer sensorless operation, eliminating the need for external sensors. This not only simplifies the motor design but also enhances reliability by reducing potential points of failure.

3. Efficient Commutation: BLDC Motor Drivers facilitate efficient commutation, ensuring that the motor's magnetic field is synchronized with the rotor's position. This optimized commutation enhances motor efficiency, reduces heat generation, and extends the motor's lifespan.

4. Regenerative Braking: Some BLDC Motor Drivers support regenerative braking, a feature that recovers energy during braking and feeds it back into the power supply. This not only improves overall system efficiency but also reduces energy consumption.

5. Compact and Lightweight Design: BLDC Motor Drivers are often designed to be compact and lightweight, making them suitable for applications where space is limited. This characteristic is particularly beneficial in the automotive and aerospace industries.

Why Choose Millennium Semiconductors?

As a trusted distributor of electronic components, Millennium Semiconductors is committed to providing cutting-edge solutions for BLDC Motor controller. Our extensive portfolio includes a diverse range of BLDC Motor Drivers sourced from reputable manufacturers, ensuring reliability, efficiency, and innovation.

For more enquiry click here!

0 notes

Text

2024's Motor Movements: Mapping the Evolution of Energy-Efficient Technologies in UAE

In the realm of industrial machinery and automation, induction motors have long been the workhorses, driving efficiency and productivity across various sectors. In the United Arab Emirates (UAE), a hub of technological innovation and industrial growth, the demand for induction motors continues to rise. As we delve into 2024, the UAE Induction Motor Market is poised for substantial growth, driven by factors such as industrial expansion, infrastructure development, and the emphasis on energy-efficient solutions. This article delves into the key trends, market dynamics, and factors shaping the UAE Induction Motor Market in 2024.

Market Overview:

The UAE Induction Motor Market is experiencing robust growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 6% from 2022 to 2024. This growth is fueled by factors such as the expansion of manufacturing sectors, increasing investments in infrastructure projects, and the demand for energy-efficient motors in various applications.

Key Factors Driving Growth:

Industrial Expansion: The UAE's industrial sector is experiencing significant growth, driven by diversification initiatives and investments in key industries such as manufacturing, construction, and logistics. Induction motors are essential components in industrial machinery, driving processes such as pumping, ventilation, and material handling.

Infrastructure Development: Infrastructure development projects, including construction of buildings, airports, ports, and transportation networks, require a wide range of electrical equipment, including induction motors. As the UAE continues to invest in infrastructure projects, the demand for induction motors for HVAC systems, pumps, and compressors is expected to increase.

Energy Efficiency Regulations: The UAE government has implemented regulations and initiatives to promote energy efficiency and sustainability across sectors. Induction motors with high energy efficiency ratings, such as IE3 and IE4 motors, are increasingly preferred in industrial and commercial applications, driving the market for premium efficiency motors.

Technological Advancements: Technological advancements in motor design, materials, and control systems have led to improvements in the performance and efficiency of induction motors. Features such as variable speed drives, sensorless control, and condition monitoring capabilities enhance motor reliability, reduce maintenance costs, and improve overall system efficiency.

Challenges and Opportunities:

While the UAE Induction Motor Market presents significant growth opportunities, challenges such as price competition, supply chain disruptions, and the need for skilled workforce remain. However, these challenges also present opportunities for industry players to innovate, invest in research and development, and collaborate on sustainable solutions to address evolving market demands.

For More Info@ https://www.gmiresearch.com/report/uae-induction-motor-market/

Conclusion:

In 2024, the UAE Induction Motor Market stands as a key enabler of industrial progress and energy efficiency, driving productivity and sustainability across sectors. As the UAE continues its journey towards economic diversification and technological innovation, the market's growth is not just about induction motors; it is about powering efficiency and progress in the nation's industrial landscape. The UAE Induction Motor Market is not merely a segment of the electrical equipment industry; it is a cornerstone of industrial automation and efficiency in the UAE. In embracing industrial expansion, infrastructure development, and energy efficiency initiatives, the UAE Induction Motor Market is not just powering machinery; it is powering a future where efficiency, sustainability, and innovation drive success in the United Arab Emirates.

0 notes

Text

Optimizing Efficiency and Performance: Advancements in Permanent Magnet Machines

Permanent magnet machines, including motors and generators, have become integral components in various industries, owing to their high efficiency, reliability, and compact design. Enhancing the efficiency and performance of these machines is crucial for achieving energy savings, reducing environmental impact, and ensuring optimal operation across diverse applications.

Optimizing the efficiency and performance of permanent magnet machines involves a multi-faceted approach that encompasses design, materials, control systems, and thermal management strategies.

Magnetic circuit design stands at the forefront of optimizing the performance of permanent magnet machines. The design of the magnetic circuit significantly influences the machine's efficiency. Engineers focus on maximizing magnetic flux density in the air gap while minimizing losses caused by magnetic resistance and eddy currents. Advanced simulation tools aid in modeling and optimizing magnetic circuits, ensuring optimal design parameters for achieving higher efficiencies.

Additionally, the selection and utilization of permanent magnet materials play a pivotal role in enhancing machine performance. The continuous advancement of magnet materials, such as neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), has led to magnets with higher energy densities and improved magnetic properties. These materials allow for stronger magnetic fields and higher operating temperatures, contributing to improved overall machine efficiency.

Control algorithms and systems also contribute significantly to optimizing permanent magnet machine performance. Advanced control strategies, including field-oriented control (FOC) and sensorless control techniques, enable precise control of motor parameters such as torque, speed, and flux. These algorithms maximize efficiency by minimizing losses and improving dynamic response, particularly in variable speed applications.

Moreover, thermal management plays a critical role in maintaining the efficiency and reliability of permanent magnet machines. Heat generated during operation can degrade magnet properties and reduce machine efficiency. Effective cooling techniques, such as liquid cooling systems or improved ventilation designs, help dissipate heat efficiently, preventing thermal degradation and ensuring stable performance over extended operational periods.

Furthermore, the integration of innovative materials and manufacturing techniques contributes to improved performance. Advances in magnetization processes, such as magnet shaping and segmenting, enable enhanced utilization of magnetic materials, reducing losses and improving efficiency. Moreover, the use of advanced composite materials for structural components can reduce weight, enhancing machine dynamics and overall efficiency.

Despite significant advancements, challenges persist in the quest to further optimize the efficiency and performance of permanent magnet machines. Demagnetization risks due to high temperatures, material costs, and production scalability remain areas of concern. Researchers and engineers continually explore novel magnet designs, alternative materials, and manufacturing methods to address these challenges and further enhance machine performance.

Looking ahead, the future of permanent magnet machines revolves around pushing the boundaries of efficiency and performance. Emerging trends, such as the development of rare-earth-free magnets, magnetocaloric materials, and advancements in computational modeling for precise design optimization, hold promise for even greater advancements in efficiency and performance.

In conclusion, optimizing the efficiency and performance of permanent magnet machines is a continuous endeavor driven by advancements in design, materials, control systems, and thermal management. As technological innovations continue to evolve, the pursuit of higher efficiencies, improved reliability, and sustainable solutions remains at the forefront, ensuring the widespread adoption and continued advancement of these machines across various industries.

0 notes

Text

Frequency Inverter Meets Your Needs

As a professional frequency inverter supplier, our company takes quality as its premise and produces general inverters, solar inverters, and other main products, as well as inverter parts, reactors, filters, and a series of related products. Our inverters not only support single phase or three phase input but also have a wide range of wattage. It minimum kilowatt rating is 0.75 kw, and its maximum kilowatt rating is 800 kw. There are two types of it: 220v and 380v, and it is extensively employed in industry, agriculture, and daily life.

Our company has been established for 10 years, and thanks to our high quality, our products have a great competitive advantage in the frequency converter industry. The technical procedures for our drives are written by a team of top senior engineers with more than 40 protection procedures. Our products use imported chips, good-brand modules, large radiators, and a variety of high-quality materials to ensure the stable operation of the inverter and high efficiency output. We have rich experience in the production of variable frequency inverters and can provide customers with a range of customized services.

Types of Anchuan Frequency Inverters

Important Components of Frequency Inverters

Frequency Inverters vs Traditional Motor Control MethodsFrequency Inverters vs Traditional Motor Control Methods

Frequency inverters, also known as variable frequency drives (VFD), have revolutionized motor control methods and offer several advantages over traditional control methods.

One key difference is that traditional methods, such as on/off control or direct-on-line (DOL) starters, provide only fixed-speed operation. In contrast, frequency inverters provide variable-speed control, allowing for precise motor speed regulation. This flexibility offers several benefits, including improved motor efficiency, reduced energy consumption, and enhanced process control.

Frequency inverters achieve variable-speed control by adjusting the frequency of the electrical input to the motor, which in turn adjusts the motor's rotational speed. This allows the motor to operate only at the speed required for the particular load or application, eliminating the energy wastage associated with running at full speed constantly.

Furthermore, frequency inverters offer smooth and gradual motor acceleration and deceleration, reducing mechanical stress on the motor and associated equipment. This can extend the lifespan of the motor and reduce maintenance costs.

Traditional motor control methods also lack advanced protection features found in frequency inverters. Frequency inverters often include built-in overload protection, short-circuit protection, and phase loss detection. These safety features contribute to increased system reliability and offer greater protection against motor damage or failure.

Additionally, frequency inverters provide advanced control features such as torque control, position control, and sensorless vector control. These capabilities enable precise control over motor operations, allowing for optimized performance and enhanced process efficiency.

In summary, frequency inverters offer significant advantages over traditional motor control methods. They provide variable-speed control, increased energy efficiency, improved motor protection, and advanced control features. As a result, frequency inverters have become the preferred choice for motor control in a wide range of industrial applications.

0 notes

Text

Precision Testing Starts with Intelligent Motor Control

In applications such as dynamometer systems, test stands, and industrial load testing, variable frequency drives (VFDs) offer precise control over motor speed, torque, and load simulation. VFDs support a wide output frequency range (up to 500Hz or higher) and enable fine-tuned adjustments, making them ideal for replicating complex, real-world operating conditions. With features like sensorless vector torque control, encoder-based closed-loop feedback, and real-time analog/digital inputs, VFDs deliver the responsiveness and accuracy required in advanced testing environments.

Built-in data logging, torque limiting, and dynamic braking functions give engineers the tools to monitor system behavior under a range of stress conditions. Whether you're conducting R&D, endurance testing, or quality control, VFDs offer repeatable performance and precise load profiling, essential for today’s high performance industrial testing applications.

The VFD Exchange

#dynamometer#testing#motorcontrol#vfdapplications#industrialtesting#speedcontrol#torquecontrol#vfds#variablefrequencydrives#electricmotorcontrols#automation#braking#flux#voltage#current#phase#invertek#optidrive#USA

0 notes

Text

Brushless DC Motors in Robotics: Powering the Future of Automation

Control algorithms are at the heart of optimizing the performance of brushless DC motors (BLDC), enabling these motors to deliver precise speed regulation, torque management, and smooth operation. Whether it's sensorless control or closed-loop feedback systems, the choice of control method significantly impacts the motor's efficiency, responsiveness, and overall effectiveness. In this exploration, we delve into the world of control algorithms that drive BLDC motors to their peak performance.

One of the most prominent control techniques for BLDC motors is sensorless control. Traditionally, position sensors were employed to provide real-time feedback about the rotor's position, allowing the controller to commutate the motor accurately. However, sensorless control methods have emerged as an alternative, eliminating the need for additional hardware and potential points of failure. These algorithms rely on the back electromotive force (EMF) generated by the motor to estimate the rotor position, thus achieving commutation without external sensors. Sensorless control is particularly advantageous in applications where adding sensors might be impractical or cost-prohibitive.

Closed-loop control systems, on the other hand, utilize sensors to provide real-time feedback and adjust the motor's operation accordingly. This type of control is known for its precision and accuracy. By constantly monitoring variables such as speed, current, and position, the controller can make rapid adjustments to maintain the desired performance. Closed-loop control is vital in applications that require high levels of accuracy and responsiveness, such as robotics and industrial automation.

Another important consideration in control algorithms is the choice between trapezoidal and sinusoidal commutation. Trapezoidal commutation is simpler and often used in applications where the motor doesn't need to operate at very low speeds. Sinusoidal commutation, on the other hand, provides smoother torque delivery and is suitable for applications requiring precise speed control across a wide range of speeds.

Advancements in microcontroller technology and digital signal processing have paved the way for more sophisticated control algorithms. Field-oriented control (FOC), for instance, offers precise torque and speed control by transforming the three-phase AC currents and voltages into a two-coordinate system. This method allows for independent control of torque and flux, resulting in smoother performance and reduced torque ripple.

In the realm of robotics and automation, brushless DC motors (BLDC) are emerging as the driving force behind precision motion control, high torque-to-weight ratios, and quiet operation. From collaborative robots (cobots) to unmanned aerial vehicles (drones), BLDC motors are playing a pivotal role in shaping the future of automation by providing the efficiency and performance required for a wide range of applications.

Collaborative robots, or cobots, are designed to work alongside humans in industrial settings. They require motors that are not only powerful but also safe and responsive. BLDC motors fit the bill perfectly. Their ability to deliver high torque at low speeds makes them well-suited for tasks that require precise and controlled movements, such as picking and placing objects on a production line. Moreover, their compact size and lightweight nature are advantageous for integrating into cobots without compromising their overall agility and safety.

Drones, another rapidly advancing area of robotics, heavily rely on BLDC motors for propulsion and maneuverability. The lightweight design and high power-to-weight ratio of BLDC motors enable drones to achieve impressive flight times and carry payloads effectively. Additionally, the precise speed control and rapid response of these motors allow drones to navigate tight spaces and execute complex aerial maneuvers with ease. Whether it's aerial photography, surveillance, or package delivery, BLDC motors are the workhorses that keep drones airborne and operational.

Industrial automation is yet another domain benefiting from the capabilities of BLDC motors. From conveyor belts to robotic arms, these motors provide the necessary muscle for machines to move, lift, and manipulate objects efficiently. The ability to precisely control speed and position enhances production processes, minimizes errors, and improves overall productivity. The quiet operation of BLDC motors is an added advantage, contributing to a more conducive and less noisy working environment.

The application of BLDC motors in robotics and automation isn't limited to just these examples. From exoskeletons that assist in rehabilitation to robotic surgical instruments that demand precision beyond human capabilities, the versatility of BLDC motors continues to expand the possibilities of what robots can achieve.

In conclusion, brushless DC motors are ushering in a new era of robotics and automation. Their combination of power, precision, and efficiency makes them indispensable for tasks ranging from delicate maneuvers in cobots to high-speed flight in drones. As technology advances and robots become increasingly integrated into our lives, BLDC motors will remain at the forefront of innovation, driving the automation revolution forward.

The choice of control algorithm significantly influences the performance of brushless DC motors. Whether opting for sensorless or closed-loop control, trapezoidal or sinusoidal commutation, or even more advanced techniques like field-oriented control, engineers must carefully consider the specific requirements of their applications. By mastering these control algorithms, engineers unlock the full potential of BLDC motors and ensure their optimal performance across a wide range of industries and applications.

1 note

·

View note

Photo

Speed Control System for BLDC Motor by using Direct Back EMF Detection Mathod

by Soe Sandar Aung | Thet Naing Htun ""Speed Control System for BLDC Motor by using Direct Back EMF Detection Mathod""

Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-5 , August 2019,

URL: https://www.ijtsrd.com/papers/ijtsrd26624.pdf

Paper URL: https://www.ijtsrd.com/engineering/electrical-engineering/26624/speed-control-system-for-bldc-motor-by-using-direct-back-emf-detection-mathod/soe-sandar-aung

call for paper health science, ugc approved engineering journal, social science journal

BLDC motors are used in many industrial and traction applications due to high efficiency, low maintenance and high torque. For good performance of BLDC motors, the accurate knowledge of the rotor position is required. The need for the rotor position information in BLDC motors have been satisfied by use of some form of rotor position sensors. But to reduce cost, complexity and also to improve reliability of the system, sensor less drive system is preferred. In this paper, the development of sensor less control system for BLDC motor using a direct back EMF detection method is presented and simulation for proposed system is done with the help of MATLAB SIMULINK.

0 notes

Text

How to choose dehumidifier heat pump air conditioner

Japan dehumidifier, dehumidifier, dehumidifier, dehumidifier, pipeline dehumidifier, industrial dehumidifier and temperature regulating dehumidifier series all adopt heat pump air conditioner, air to air heat pump supplier advanced high-efficiency rotary famous brand compressor, high gold plating heat exchange system, low noise and large air volume external rotor fan. Nikkei dehumidifier adopts the second generation motion control chip specially designed for dehumidifier by American IR company to realize sensorless vector control By running the control algorithm embedded in the chip, the control link of software programming is reduced, the performance of dehumidifier is stable and reliable, and the dehumidification effect of air dryer is in the leading level in the same industry. Japanese ultrasonic humidifier: using 2 million times per second of ultrasonic high-frequency vibration, water atomization into 1-5 micron ultrafine particles and negative oxygen ions, through the pneumatic device, the water mist diffuses into the air to increase the humidity of the surrounding air, so as to achieve the purpose of humidifying the air. Dehumidifier, industrial humidifier, constant temperature and humidity machine have passed the Sino German certification in February 2006, and have opened the integrity service. Dehumidifier, Shanghai dehumidifier, Hangzhou dehumidifier, dehumidifier, dehumidifier price, dehumidifier brand, humidifier price, humidifier brand, humidifier price, humidifier, Beijing humidifier, humidifier principle, Shanghai humidifier, ultrasonic humidifier won the title of 2008 Ali bid. The industrial air dehumidifier uses the principle of mechanical refrigeration and freeze-drying, sucks the moist air, drops it below the dew point temperature through the evaporator, condenses the water in the air into water droplets, and then condenses and heats up by the refrigeration compressor, and then turns into dry air to discharge, so as to achieve the purpose of drying airThis product can effectively remove the moisture in the air, thus reducing the relative humidity of the air, inhibiting the growth of mold, maintaining the humidity balance, and reducing the loss caused by moisture, corrosion and deterioration. The industrial air dehumidifier of Japan industry has an intelligent humidity constant control system, and the user can input the required humidity value into the microcomputer control system of the dehumidifier according to the production needs, Automatic control of dehumidifier work and shutdown, through automatic control to achieve the most effective dehumidification effect, reduce the operating cost of the whole machine. Technical authority, personalized product design, energy efficiency ratio higher than national standards. Careful follow-up service in the whole process of pre-sale and after-sale, To create air humidifier, dehumidifier, industrial dehumidifier, dehumidifier, dehumidifier, air dehumidifier, humidifier, constant temperature and humidity air conditioner and other air dehumidification equipment industry famous brands. Diurnal dehumidifier and humidifier are suitable for precision electronics, optical instruments, bioengineering, textile, medicine, packaging, food, printing industry, underground engineering and national defense, etc In our advanced laboratory, we strictly inspect all kinds of purchased raw materials to ensure that they meet the highest quality requirements of daily dehumidifiers and humidifiers. In the process of product development and production, we carry out strict tests on various spare parts and finished products to avoid possible weaknesses, and more time is spent on the operating conditions of products Due to the strict quality control system, the dehumidifier and humidifier can meet the requirements of ISO9001The highest requirement of international quality standards. The total quality management program creates the highest quality and best reputation of Nippon dehumidifier and mini split heat pump diurnal humidifier. Therefore, engineering authorities around the world (as well as some of our major customers) naturally recognize our model and recognize our production. Nippon dehumidifier and humidifier will continue to pay attention to the development of users, understand the real needs of users, and will continue to research and develop the latest and most cutting-edge technology, and adhere to the use of the most advanced and top-level materials to produce the most excellent and reliable products. To provide users with better solutions, until become a model in the industry. There is no factor that will change the quality of trump we offer to our customers.

1 note

·

View note

Text

Estimation of Tool-Tissue Forces in Robot-Assisted Minimally Invasive Surgery

The advent of robots in surgery started in 1994 when the first AESOP (voice-controlled camera holder) prototype robot was used clinically in 1993. AESOP was then marketed as the first surgical robot ever in 1994 by the US FDA. Since then Robot-assisted minimally invasive surgery (RAMIS) has gained immense popularity over the last two decades. Statistics show that more than 50% of errors performed by surgical trainees are due to excessive force. This may often lead to irreparable damage. RAMIS reduces the error percentage of tool-tissue interaction forces significantly, it is much more accurate than an open surgery or laparoscopic minimally invasive surgery. Although it may seem like this approach saves the patient from excessive trauma this method is limiting. This is because the surgeon is not directly controlling the machine. Which means the tool might lose direct contact with the surface of surgery, i.e. loss of tactile information for the surgeon. This entire process of relaying tool-tissue force information to the surgeon is the haptic feedback or force feedback. The tool-tissue interaction forces affect the efficacy of the surgery to a great extent, so it is imperative for RAMIS to overcome this obstacle to reach its full potential.

This disparity in information is the main reason RAMIS has not reached its apogee. The lack of haptic feedback, tactile sensing, and tool tissue force-sensing contributes to this method’s dubiousness. Several attempts have been made over the years for the sensorization of surgical instruments but even the most of developed sensory systems required to alter the standard shape of the surgical tool (as it may affect the handling of the surgical tool and possibly the amount of tool-tissue interaction forces), are not suitable in terms of size or the installation place, require the filtration of noise signals, or have an unsuitable range of measurement. In addition to that they make the instruments bulky and complicate the process of sterilization. The size of force sensors, and incision ports, the sterilization of tools at high temperature and the disposable nature of surgical tools have so far prevented the integration of end-effector/tissue force sensing in RAMIS.

Scientists soon understood that sensors are definitely not the way to go.

There have been multitudes of research solutions for this problem. None of the methods seemed to provide a complete remedy. However, a recent research brings forth an answer to this long-lasting issue by proposing a new algorithm to estimate the tool-tissue force interaction in robot-assisted minimally invasive surgery in a way that it does not require the use of external force sensing (sensor-less). This incredible feat was achieved by applying a neural network method to estimate the tool-tissue force interaction during a grasp manoeuvre in RAMIS for future application in providing haptic feedback to surgeons. Its distinctive features reside in the fact that it considers a black box approach regarding the whole mechanism, thus rendering the analysis of the grippers mechanism unnecessary. The proposed method is based on utilization of the current of the gripper-actuating motors as well as a detailed examination of the various stages of a grasping motion. In contrast to existing algorithms in literature, this model does not require external sensors or equipment such as vision systems, predicting sufficiently both small and large forces.

This model was tested online and offline to check its feasibility and feedback system. The results showed that the developed algorithm can estimate the tool-tissue interaction force during the grasp online and could thus allow haptic feedback in robotic surgery to be provided. This model can predict both large and relatively small forces which was an issue in the algorithm developed by Zhao and Nelson (2015). The model developed by Zhao and Nelson used motor current and was the first model to tackle the existing problems of RAMIS without the use of sensors. Their model utilized the Gaussian Process Regression, which unfortunately failed when the target went out of range. This research tactfully handles the problem of GPR not being able to predict the outcomes when the target goes out of the range of the dataset. This problem was combated with the help of neural networks. This approach was inspired by Yu et al. (2018) who proposed a cable tension based method to estimate external forces and utilized a back propagation (BP) network to estimate resistance parameters such as friction to aid in the force estimation. Along with Yu, Aviles et al. (2015, 2015) also inspired this algorithm with his seminal paper on combined vision based methods with recurrent neural networks to estimate tool-tissue interaction.

Source:

https://www.frontiersin.org/articles/10.3389/frobt.2019.00056/full

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2699074/

https://asmedigitalcollection.asme.org/medicaldevices/article-abstract/9/4/041012/376819/Sensorless-Force-Sensing-for-Minimally-Invasive?redirectedFrom=fulltext

1 note

·

View note