#sheet metal fabrication company

Text

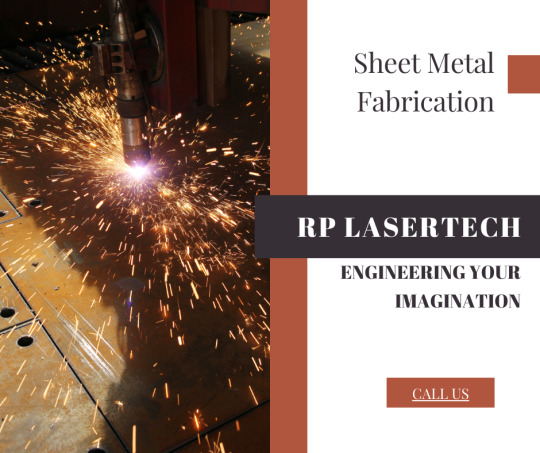

Laser Cutting and Sheet Metal Fabrication Services - RP Lasertech

At RP Lasertech, we believe a great product is a result of an in-depth understanding of the customer’s requirements, transforming imaginations into practical realities, and manufacturing products that set the benchmark of innovative engineering.

#cnc metal cutting#stainless steel fabricators#metal manufacturing company#sheet metal fabrication company#sheet metal enclosure

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

EQUAL - Robotic TIG Welding

youtube

Unique Power Technologies is the top sheet metal manufacturing company that uses the latest technology in Robot Welding Services to bring you the highest level of Finishing. UPT has been known for quality sheet metal fabrication services since 2020. No matter what service you’re looking for, we guarantee to not only meet but exceed your expectations and ensure your full satisfaction. Our Fabrication Services deliver clean finishing and long life with completely repeatable results. Our system is ideal for high-volume production. As a result, projects can reach optimum material utilization, increasing manufacturing accuracy and efficiency.

#Fabrication Services#home improvement#ladders#weighing machine#shoe rack#Unique Power Technologies#sheet metal manufacturing#manufacturing company#top sheet metal#highest level of Finishing#quality sheet#metal fabrication services#manufacturing accuracy#accuracy and efficiency#high-volume production#clean finishing#long life#repeatable results#Youtube

0 notes

Text

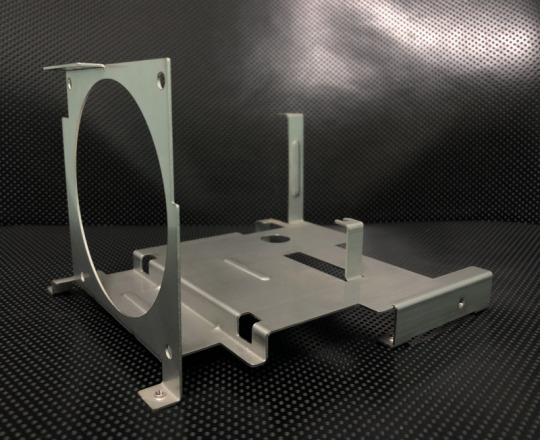

Custom Sheet Metal Fabrication Company takes pride in delivering top-notch quality and precision in every project we undertake. With a team of skilled professionals, we strive to exceed our clients' expectations by providing innovative solutions tailored to their specific needs. From concept to completion, our commitment to excellence ensures that each piece we fabricate meets the highest industry standards.

0 notes

Text

Know About the Science of Sheet Metal Fabrication

The process of transforming flat metal sheets into beautiful and useful structures is called sheet metal fabrication, and it involves a complex tango between creativity and precision engineering. For decades, the core of manufacturing has been this dynamic process, which has developed in tandem with advances in design and technology. The history of sheet metal manufacture began in antiquity when…

View On WordPress

#Online Sheet Metal Fabrication#Sheet Metal Fabrication#Sheet Metal Fabrication Companies#Sheet Metal Fabrication services#Sheet Metal Fabrication Techniques

1 note

·

View note

Text

For an outstanding finished product, work with a trusted fabrication company. Promark Tool and Manufacturing is a leader among sheet metal fabrication companies.

0 notes

Text

Precision Metal Forming Services for Sheet & Roll Forming- LSW

In the intricate world of metal fabrication, precision and efficiency are paramount. Lasercut Steelworks stands at the forefront of this industry, offering a comprehensive suite of metal forming services that caters to diverse needs. Specializing in sheet metal forming and metal roll forming services, Lasercut Steelworks has earned a reputation for excellence and innovation.

Sheet metal forming is a crucial process in metal fabrication, transforming flat sheets of metal into complex shapes and structures. This method is employed in various industries, from automotive to aerospace, where precision and durability are non-negotiable. Lasercut Steelworks leverages cutting-edge technology and a team of skilled professionals to provide top-notch sheet metal forming services.

One of the key advantages of sheet metal forming is its ability to create intricate designs and geometric shapes with a high degree of accuracy. Lasercut Steelworks utilizes advanced machinery and computer-aided design (CAD) software to ensure that every project meets the exact specifications of its clients. Whether it's prototyping a new product or mass-producing components, the sheet metal forming services at Lasercut Steelworks are tailored to deliver precision and consistency.

Metal roll forming is another expertise that sets Lasercut Steelworks apart. This process involves continuously bending and shaping a metal coil to create a desired cross-section. The result is a product with uniform dimensions and excellent structural integrity. Metal roll forming is widely used in the construction and manufacturing industries, and Lasercut Steelworks excels at providing custom solutions to meet the unique requirements of each project.

The efficiency of metal roll-forming services lies in their ability to produce large quantities of components with minimal material waste. Lasercut Steelworks optimizes this process to offer cost-effective solutions without compromising on quality. Whether it's producing roof panels, automotive components, or structural elements, the metal roll-forming services at Lasercut Steelworks contribute to the seamless realization of diverse projects.

The commitment to quality extends beyond the manufacturing floor at Lasercut Steelworks. Rigorous quality control measures are integrated into every step of the metal-forming process to ensure that the final products meet or exceed industry standards. This dedication to excellence has earned Lasercut Steelworks the trust of clients across various sectors.

In addition to its technological prowess, Lasercut Steelworks places a strong emphasis on customer collaboration. The team works closely with clients to understand their unique requirements, providing valuable insights and recommendations to enhance the efficiency and cost-effectiveness of each project. This collaborative approach, combined with the expertise in sheet metal forming and metal roll forming, positions Lasercut Steelworks as a reliable partner for businesses seeking top-tier metal fabrication solutions.

In conclusion, Lasercut Steelworks stands as a beacon of innovation in the realm of metal forming services. With a focus on sheet metal forming and metal roll forming, the company blends cutting-edge technology with a commitment to precision and quality. As industries continue to evolve, Lasercut Steelworks remains at the forefront, ready to shape the future of metal fabrication through its unparalleled expertise and customer-centric approach.

METAL SHEEET FORMING

0 notes

Text

Embark on a journey of discovery as you delve into the intricacies of sheet metal on Indgirka's informative platform. Uncover the versatile applications and manufacturing processes that define this essential material. Whether you're a novice or industry professional, this insightful resource offers a detailed exploration of what sheet metal is and how it shapes the world around us. Expand your knowledge and gain valuable insights into the diverse world of sheet metal on Indgirka.

#Sheet metal#Sheet Metal Parts Manufacturers in India#Sheet Metal Manufacturing Companies#auto parts#fabrication parts

1 note

·

View note

Text

Industrial Sheet Metal Fabrication manufacture & supplier in India

Spp Alloy is provide best industrial sheet metal fabrication. These sheet offer exceptional corrosion resistance and durability, making them ideal for various industrial applications. Available in a range of sizes and configurations, Industrial Sheet Metal Fabricationare a top choice for projects requiring superior performance and reliability

#sheet metal manufacturing companies#sheet metal production#industrial sheet metal fabrication#ss sheet metal fabrication#sheet metal factory

0 notes

Text

Leading Metal Fabrication Industry in commercial, electronic and aerospace around the world.

Metal Dynamics is the top choice for all your metal fabrication needs in Chatsworth. As a leading company in the industry, they offer a comprehensive range of services, including custom sheet metal fabrication, catering to the commercial, electronic, and aerospace sectors. With their extensive experience and expertise, Metal Dynamics excels in delivering high-quality and precision-crafted products, meeting the stringent requirements of these industries. Our commitment to excellence is evident in their advanced manufacturing processes, cutting-edge technology, and adherence to strict quality control standards. By choosing us, you can expect exceptional craftsmanship, attention to detail, timely delivery, and outstanding customer service. Whether you need enclosures, chassis, brackets, or other metal components, Metal Dynamics is the trusted partner that will exceed your expectations and provide you with top-notch solutions for your metal fabrication projects. Our Metal fabrication services are available all over Chatsworth.

#fabrication industries#Metal Cutting Industries#fabrication company#metal fabrication industries#custom sheet metal fabrication#aerospace sheet metal fabrication companies#fabrication services#precision sheet metal#sheet metal stamping#metal fabrication services#precision sheet metal fabrication#metal fabrication

1 note

·

View note

Text

Finding reliable heavy fabricators in India, specifically in Gujarat, for your school project requires thorough research, recommendations, attending trade shows, contacting industry associations, requesting quotations, checking credentials, visiting facilities, and reviewing contracts. By following these steps, you can ensure a successful collaboration with a reputable heavy fabrication company in Gujarat and achieve the desired results for your school project.

#top fabrication company#commercial fabrication fabricators india#sheet metal fabrication#heavy fabrication company in gujarat

0 notes

Text

Flanges: Types and applications in Industries

Flanges are essential for forming a pipe work structure by connecting valves, tubes, pumps, and other machines. Flanges are usually welded or fastened together and then joined by screwing them together with washers.

SPP Metals and Alloys offers many types of flanges, such as Slip On, Weld-neck, Blind flanges, Socket weld flanges, and Threaded flanges. Flanges are a crucial part of plumbing systems and come in a variety of shapes and sizes.

In this article, We will discuss various types of flanges and their Uses/Applications in industries!

Types of Flanges

Slip-on flanges

A Slip-On Flange is a band that fits over the end of a tube, with a flange's surface extending from the end of the pipeline to the point where a weld bead can be applied to the inside of the pipe. These flanges are termed "Slip-On" because they can be quickly placed on a conduit by simply sliding them onto the tube. The Slip-On-Flanges internal size is slightly larger than the pipe's external dimension, enabling it to be welded quickly onto the pipe at both its top and bottom. It is used for slipping into the inner hole of the flange. If working with low pressure, Slip On Flanges can be a suitable choice.

Application of Slip-On-flanges

Oil, Natural gas, and refined hydrocarbon (steam lines)

Petrochemical Facilities

Cryogenic services

Pump Industries

Plant engineering

Wastewater recycling plant

Paper and pulp Industries

Chemical Industries and many more

Weld Neck Flanges

Weld Neck Flanges are also known as High Hub Flanges or Tapered Hub Flanges. The movable neck of the Weld Neck Flange (WN Flange) relieves pressure that has built up at the base of the flange and can be used for high-pressure, high-temperature pipelines.

Applications of Weld Neck Flanges

Chemical Industries

Power/electricity Industries

Aerospace

Food processing industry and many more.

Marine industry

Water waste management

Mechanical engineering

Food Processing industries and many more

Threaded flanges

A threaded flange looks similar to a slip-on flange, but it has a bore that matches the internal diameter of a pipe. Threaded flanges can be used in piping systems where no welding over the pipe is allowed, such as in highly explosive locations. Threaded flanges are used with galvanized and cast-iron piping. With smaller diameters, threaded flanges can be fitted without welding.

Application of Threaded Flanges

Here are a few of the Industries where Threaded Flanges are been Used. They are used in explosive areas Such as petrol stations, hexane plants, stores with flammable fluids, etc.

Additionally, Threaded flanges are also used in various industries such as

Shipbuilding

Power Generation

Petrochemical plants

Oil refineries

Wastewater treatment plants

Paper mills

Pharmaceutical plants, and so on.

Socket-welded flanges

A socket is welded onto this type of flange, allowing the flange to be attached to the pipe with an inserted bolt, rather than welding the flange to the pipe. These flanges are often used when welding is not possible due to high temperatures or when protection from corrosion caused by water or oil is needed.

Application of Socket-Weld Flanges

A socket weld fitting is suitable for applications requiring low- to medium-pressures in limited spaces.

Moreover, these Socket Weld flanges are been used in various Industries such as

Power generation

Shipbuilding

Boilers

Automotive and Aerospace Industries

Pressure vessels

Petrochemical plants

Oil refineries

Wastewater treatment plants

Paper mills, pharmaceutical plants, and so on.

Blind Flanges

A blind flange is a type of flange that has no bore center and is used to terminate or seal the end of a piping system. Due to system pressure and the necessary fastening forces, these flanges are put under a lot of mechanical stress. Due to this, they are suitable for high-pressure applications and testing gas or liquid flow through pipes. Blind flanges allow easy access to the pipeline since they can easily be unbolted by the operator.

Applications of Blind Flanges such as,

Vacuum Systems

Pipeline and ports.

Removal of impurities from water.

Systems for conveying materials.

Plants and refineries process chemicals.

Production of electricity and so on.

With SPP Metal & Alloys materials and grades in which these flanges are available.

Super Duplex: S32750/S32760/F55/F53

Duplex: S31803/S32205/SMO 254

Nickel Alloys: Alloy 400, 625, 800, 825

Stainless Steels: 304, 316L, 321, 904L & 310S

Steel: A105

LTCS: A350 LF2

Alloy Steel: F9/F11/F12/F22/F91

Final words

SPP Metals and Alloys is one of the leading manufacturers of flanges in Mumbai, India. Additionally, we export our products overseas. With an international standard, SPP Metals and Alloys provide these flanges in different grades. These flanges are used in plenty of industries with different purposes.

#Sheet Metal Fabrication#welded tubes suppliers#sheet metal manufacturing companies#stainless steel pipe suppliers#stainless steel furnace parts#sheet metal parts manufacturer

0 notes

Text

Powder Coating Services With Highest Level of Finishing | EQUAL

youtube

Unique Power Technologies is the top sheet metal manufacturing company that uses the latest technology in Powder Coating Services to bring you the highest level of Finishing. UPT has been known for quality sheet metal fabrication services since 2020. No matter what service you’re looking for, we guarantee to not only meet but exceed your expectations and ensure your full satisfaction. Our Powder Coating Services deliver clean finishing and long life with completely repeatable results. Our system is ideal for high-volume production. As a result, projects can reach optimum material utilization, increasing manufacturing accuracy and efficiency.

#Youtube#Fabrication Services#home improvement#ladders#weighing machine#shoe rack#Unique Power Technologies#sheet metal manufacturing#manufacturing company#top sheet metal#highest level of Finishing#quality sheet#metal fabrication services#manufacturing accuracy#accuracy and efficiency#high-volume production#clean finishing#long life#repeatable results

0 notes

Text

#Sheet Metal Fabrication Services#Heavy Steel Fabrication Companies#Stainless Steel Sheet Metal Fabricators near Me

0 notes

Link

The process of fabricating custom metal work singapore uses a wide range of industrial tools and equipment that can be used to cut, bend, roll, and join metal into complicated shapes and assemblies. Metals that are commonly used include carbon steel, stainless steel, aluminum, and copper. Basically, custom fabrication metal involves manufacturing raw materials along with machine parts and structural components.

#metal fabrication singapore#metal fabrication company in singapore#metal fabrication companies#sheet metal fabrication

0 notes

Text

Battery electric vs hydrogen — which is the future for electric vehicles?

Battery electric vehicles (BEVs) rely on rechargeable batteries for power, offering established infrastructure and growing range. Hydrogen fuel cell vehicles (FCVs) use hydrogen to produce electricity, with potential for quick refueling. The future balance depends on technological advancements, infrastructure development, cost-efficiency, and sustainability considerations. BEVs currently dominate the market, but FCVs may find a niche in specific applications, like heavy-duty transport. Future trends will be influenced by advancements in both technologies and sustainable energy solutions.

https://www.lsw.co.in/hello-world/

0 notes