#sheet metal market

Text

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

8 notes

·

View notes

Text

STRAWBERRIES?? YEAH STRAWBERRIES. I WISH I COULD EAT SHEET METAL.

#the last of us#tlou show#tv shows#bill and frank#episode 3#strawberries#i’m cryign#i love gay people#old men#ignore this#as a whole#sheet metal market#i’m so normal

7 notes

·

View notes

Text

Organ Farmers Market

#artists on tumblr#animated illustration#animated gif#illustration#my art#what if we ate eyeballs at the organ farmers market and we were both cattheys#so this started as a DTIYS like SO long ago i just went fuck it im redesigning the character and idk how i landed on jars of eyeballs#i like the idea of a necromancer depot situation... like... get all the parts for your homonculous here. but it was no thoughts head empty#anyway my favorite part is how the eyeball looks like how a sheet of metal being waggled around sounds. wubba wubba wubba#weirdly eyeball on a stick is something i drew alot as a kid so. this is for you 6th grade geo. heads up your trans

322 notes

·

View notes

Text

Meticulous Research® recently released a report titled “Galvanized Steel Market by Product Type, Application, and Geography - Global Forecast to 2031,” predicting that the galvanized steel market will reach $216.2 billion by 2031 with a CAGR of 9.9% from 2024 to 2031, and in volume, it is expected to hit 240.8 million tons at a CAGR of 9.2% during the same period. This growth is primarily driven by increasing infrastructure investments and heightened demand from the construction sector. However, market expansion may be hindered by fluctuations in raw material prices and the complexities of regulatory compliance. On the positive side, technological advancements in the manufacturing process are anticipated to present growth opportunities, despite the challenge of high manufacturing costs.

#Galvanized Steel Market#Galvanized Steel#Galvanized Sheet Metal#Galvanized Steel Sheet#Galvanized Roofing#Galvanised Pipe#Galvanized Metal Roofing#Galvanized Coil#Galvanized Metal#Galvanized Steel Plate

0 notes

Text

#Galvanized Steel Market#Galvanized Steel#Galvanized Sheet Metal#Galvanized Steel Sheet#Galvanized Roofing#Galvanised Pipe#Galvanized Metal Roofing#Galvanized Coil#Galvanized Metal#Galvanized Steel Plate

0 notes

Text

Don't settle for just any metal roofing system. Choose LCP LYCORSEAM® for a high-quality, customizable solution that adds value to your structure. With its superior durability and aesthetic appeal, you won't regret choosing LYCORSEAM®. LCP LYCORSEAM is the best roofing sheet supplier in Gujarat.

For More Information:-

Contact us: (+91) 87545 50260

Mail us: [email protected]

Visit Us: https://lcpindia.com/gujarat/curved-standingseam-profile

#Don't settle for just any metal roofing system. Choose LCP LYCORSEAM® for a high-quality#customizable solution that adds value to your structure. With its superior durability and aesthetic appeal#you won't regret choosing LYCORSEAM®. LCP LYCORSEAM is the best roofing sheet supplier in Gujarat.#For More Information:-#Contact us: (+91) 87545 50260#Mail us: [email protected]#Visit Us: https://lcpindia.com/gujarat/curved-standingseam-profile

0 notes

Text

Building Panels Market to Witness Rapid Expansion with Growing Urbanization

Building panels are prefabricated components used to construct a building’s walls, floors, and roofs. They are made of various materials such as wood, steel, concrete, and masonry. Building panels are lightweight, durable, and easy to transport, making them an appealing option for developers and builders. Building panels are becoming more popular as developers and builders recognize their low…

View On WordPress

#Building Panels#Building Panels Industry Analysis#Building Panels Market#Building Panels Market Forecast#Building Panels Market Growth#Building Panels Market Share#Building Panels Market Size#Building Panels Market Trends#Building Panels Price#corrugated metal paneling#corrugated metal sheets#foam insulation board#Global Building Panels Market#home depot wood fence panels#metal roofing sheets#structural insulated panels#Structural Insulated Panels Market

0 notes

Text

Stainless Steel Uses and Applications in Aviation and Aerospace Industry - SPP Metals & Alloys

Stainless steel is a highly versatile metal that is widely used in various industries due to its exceptional properties. Among these industries, aviation and aerospace are among the most prominent users of stainless steel. This metal is used extensively in the manufacturing of aircraft components and parts due to its high strength, durability, and resistance to corrosion.

In this article, we will discuss stainless steel and the applications stainless steel uses in the aviation & aerospace Industries

Definition of Stainless Steel:

Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium by mass. The addition of chromium to the steel creates a passive layer of chromium oxide on the surface of the metal, which gives it excellent corrosion resistance properties. This layer also helps to prevent staining, rusting, and other types of surface degradation.

Properties of Stainless Steel:

Stainless steel has a unique set of properties that make it an ideal material for use in the aviation and aerospace industry.

Here are some of the most notable properties:

High strength and durability

Excellent corrosion resistance

Resistance to high and low temperatures

Non-magnetic

Easy to fabricate and weld

Hygienic and easy to clean

Types of Stainless Steel grades that are available:

At SPP Metal & Alloys we provide stainless steel in various types such as

Flanges

Fittings

Fasteners

Plates

Coils

Sheets,

Pipes,

Tubes & Round Bars.

Welded Tubes

Seamless Pipes

Sheets, Plates and Coils

Advantages of Stainless Steel in the Aviation and Aerospace Industry

Stainless steel offers many benefits in the aviation and aerospace industry, including:

Reduced maintenance costs

Longer service life

Improved safety and reliability

Enhanced resistance to corrosion, erosion, and fatigue

Lower weight compared to other metals

Easy to sterilize and maintain hygiene

Types of Stainless Steel

There are several types of stainless steel that are used in the aviation and aerospace industry. The most commonly used types are:

Austenitic stainless steel

Martensitic stainless steel

Ferritic stainless steel

Duplex stainless steel

Precipitation hardening stainless steel

Applications of Stainless Steel in the Aviation and Aerospace Industry:

Stainless steel is used in various applications in the aviation and aerospace industry, including:

Stainless Steel Uses in Aerospace:

Stainless steel is used in the aerospace industry in a variety of applications, including spacecraft components, satellites, and missiles.

Spacecraft components, such as fuel tanks and rocket engines, require high strength, durability, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of satellite components, including antennas, reflectors, and structural supports. These components must be able to withstand extreme temperatures and harsh space environments, and stainless steel provides excellent resistance to both.

In addition, stainless steel is used in the manufacture of missile components, including guidance systems and rocket motor casings. These components require high strength and durability, which stainless steel provides.

· Aircraft Structures

Stainless steel is used in the manufacture of aircraft structures, including wings, fuselage, landing gear, and engine components. It is highly resistant to corrosion and fatigue, which makes it an ideal material for use in these critical parts.

· Aircraft Interiors

Stainless steel is also used extensively in the manufacture of aircraft interiors, including cabin fittings, lavatories, and galleys. Its easy-to-clean and hygienic properties make it a popular choice for these applications.

· Aerospace Fasteners

Stainless steel is used in the manufacture of aerospace fasteners, including bolts, screws, and rivets. These fasteners require high strength and resistance to corrosion, and stainless steel provides both.

· Aerospace Exhaust Systems

Stainless steel is used in the manufacture of aerospace exhaust systems, which must withstand high temperatures and corrosive gases. Its high-temperature resistance and corrosion resistance make it an ideal material for these applications.

· Aircraft Engine Components

Stainless steel is used in the manufacture of aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades. These components require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

· Aircraft Hydraulic Systems

Stainless steel is used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

· Aircraft Fuel Systems

Stainless steel is also used in the manufacture of aircraft fuel systems, including tanks, pipes, and fittings. These components must be able to withstand the corrosive effects of fuel, and stainless steel provides excellent resistance to fuel corrosion.

Stainless Steel Uses in Aviation:

Stainless steel is used in the aviation industry in a variety of applications, including aircraft engine components, hydraulic systems, and fuel systems.

Aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades, require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

Conclusion

Stainless steel is an essential material in the aviation and aerospace industry due to its exceptional properties, including high strength, durability, and resistance to corrosion. SPP Metals & Alloys is a leading stainless steel products manufacturer and supplier in India, providing high-quality stainless steel products for use in the aviation and aerospace industry.

With its wide range of applications, stainless steel will continue to play a crucial role in the growth and advancement of the aviation and aerospace industry for many years to come.

If you are looking for high-quality stainless steel products for use in the aviation and aerospace industry, look no further than SPP Metals & Alloys. Contact us today to learn more about our products and services.

#flange types#steel pipe manufacturing company#metal sheet manufacturer#aerostructures market#aerospace#airplain

0 notes

Text

The report "Building Panels Market by Type (Concrete Panels, VIP, SIP, Wood Panel), Raw Material (Concrete, Plastic, Metal, Wood, Silica), End Use (Floors & Roofs, Walls, Columns & Beams, Staircase), Application (Residential & Non-Residential) - Forecast to 2021", The building panels market size is projected to grow from USD 170.83 Billion in 2016 to USD 230.93 Billion by 2021, at a CAGR of 6.21% from 2016 to 2021

The global building panels market is driven by factors such as rapid development in the construction technology, modular/precast/prefabricated building systems, and rising demand in the residential and commercial sectors. The market for building panels market is driven by its rising demand for new construction and transportation facilities. The rising population and increasing disposable income of consumers in emerging economies are expected to drive the demand for these industries, which would in turn increase the application of this type of construction components and techniques.

The floors & roofs segment is projected to be the largest market in 2021. The demand for building panels for floors and roofs is expected to experience a higher growth rate, mainly because of the growing demand from the residential and commercial sectors. The Asia-Pacific region is projected to be the fastest-growing market for the floors & roofs segment owing to its increasing emphasis on building construction activities.

#Building Panels Market#Structural Insulated Panels Market#metal roofing sheets#foam insulation board#corrugated metal paneling#structural insulated panels#home depot wood fence panels#corrugated metal sheets#structural insulated panels market#COVID 19 impact on Building Panels Market#Global Building Panels Market#Building Panels Industry Analysis#Building Panels Market Size#Building Panels Market Share#Building Panels Market Growth#Building Panels Market Trends#Building Panels Market Forecast

0 notes

Text

Despite our limited awareness of it, sheet metal fabrication is a vital technology in the manufacturing industry. It allows us to have a wide range of products, from automobiles to electronic devices, all of which rely on the contributions of sheet metal fabrication. Therefore, let us appreciate this unsung hero of manufacturing, as it plays a crucial role in our lives, driving technological advancements and innovation.

#sheet metal fabrication#cars#lamborghini#sheet metal design#sheet metal manufacturing#sheet metal market#robots

1 note

·

View note

Text

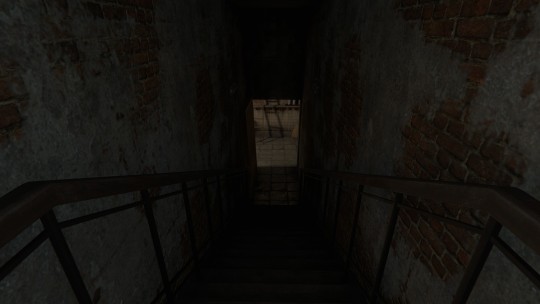

I'm so jealous of Daniil. Having only played the Haruspex route so far in both game, each time I'm invited to the Bachelor's place I turn green with envy at how he resides at an actual proper house with a real room and a real bed.

A real bed with a whole bedframe. A pillow with an actual pillowcase!! His bed even has sheets!

He has WINDOWS. His house is in a nice neighbourhood, and his roommate is a very attractive woman. There is actual furniture in his room. Not one hint of fungus growing on the walls or rust!

Can you imagine living there as your lair? Spending the whole game knowing you have a real house with a real bed to go back to at the end of each night? Seeing Eva's face every day before leaving to do quests?

Meanwhile, Artemy is stuck in this dumpster room of an abandoned factory. Cuddling with rats on his makeshift bed, held by nothing but a wooden panel, some boxes and a dream.

A pillow so yellow it has its own ecosystem where bugs established real estate. Is that even a pillow or is it some random rock Artemy found and chucked in there? Is it a stale loaf of bread?? Why is it hard looking?

But no, you don't even get to keep the rock roach pillow because in P2, they take it away.

Fuck you Artemy, you had it good for too long. No pillow now because what are you gonna do about it?. Fold your mattress instead to have a resemblance of a faux sense of protection under your most vital organ during the long hours of death rehearsal that you call sleep.

Somehow, they made the bed even more unstable looking. As if that thin panel in the middle could hold Artemy's weight without caving in. Oh, and apparently, I ran out of boxes to use for furniture because the bed and the table have to share custody of the same box.

We have downgraded into barrels now, as you can see :) No, I don't know what they used to contain inside.

Waking up every day to Sticky's snotty face telling me not to spit in the wind and nagging me about cleaning up the week-old human organs thrown around that are stinking up the place.

THERE IS MOLD GROWING ON MY WALLS. RUST FLAKES FALL FROM THE EXPOSED METAL PIPES DOWN INTO MY CEREAL EACH BREAKFAST.

This single wall holds so much mold and fungus that they started crossbreeding and evolved into new, never seen before types of bacteria. Satan's asscrack is more hygienic than whatever biohazard plagues of Egypt this slab of concrete contains.

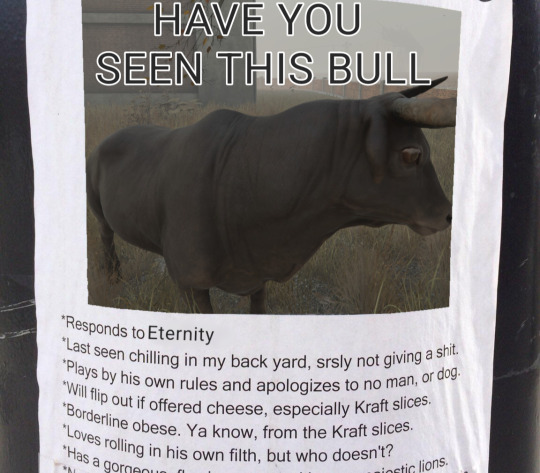

I live in the gutters. My only neighbours are an illegal gang of minors with a hatred for furries and another illegal gang but of adults this time who sell me bullets way above the market price. A dangerous neighbourhood where you can't have shit because SOMEONE STOLE MY BULL.

The basement I reside in has no windows, the smell is pungent and fucking vile down here. There isn't even a space for a bathroom.

This is my kitchenette/bathroomette/showerette/cupboardette/surgery tools disinfection stationette/sinkette/watercoolerette/toilette/fridge.

also my buckets yk.

One bucket for the makeshift bathroom, another for holding important organs and loose guts during surgery, a third one as a cooking pot for making tasty meat grub soup and the final one for murky water after sweeping the floor.

What do I use to tell them apart? Oh nothing :) I just mix em up every now and then, oppsie daisy.

Oh and the floors are CONSTANTLY wet for some reason. Yeah sticky slipped and almost broke his neck the other day so watch your steps.

There is also this eerie room with literal garbage and broken furniture right next to the entrance. Don't worry about it, sometimes I hear someone crying and screaming for help when I'm trying to go to sleep but it's just the factory being silly lol.

Now this? This is where the M A G I C happens. This is where Artemy the Menkhu makes his famous herbal remedies and natural mixtures. This is where the Panacea for the infamous sand plague gets made!

In a rusty empty food can.

Falling into a bucket with shit stains.

MEDICINE BABBYYY. GET YOUR WEAK SOFT BONED ASS BACK TO THE CAPITAL BITCH, THIS IS HOW REAL MEN MAKE REAALLL MEDICINE!! RAWRRRRR🦅🦅💥💥

Meanwhile, dickovsky has the view of the cathedral and polyhedron just around the corner from where he resides. He has a backyard with a lake, and all I have is a swamp behind my basement. I trudge through the mud each night, collecting weeds and herbs to mix and trade so I and the two orphans who adopted themselves into my life don't go starving.

Not to mention the gaggles of herb brides loitering outside and giving me a false bad reputation.

That dandy douchbag has a pharmacy, a grocery, and a tailor right next door. The closest establishment to my shrekcore place of resident is a dingy basement bar with shady drinks and no bouncer to check for ID, I saw two kids in there once.

Pov: a qt3.14 surgeon says his dad isn't home and invites you over.

#♡otherfandoms#♡pathologic 2#♡pathologic#artemy burakh#daniil dankovsky#pathologic 2#pathologic classic hd#the haruspex#pathologic

622 notes

·

View notes

Text

SAVE A HORSE, RIDE A COWBOY

pairings ; boothill x fem! reader

warnings ; smut smut smuuuuut, size kink if you squint real hard, robo dick, ooc boothill (made before release), censored cussing from his side, you call him "sir", use of pet names (sugar, girlie, pretty thing), he has normal human cum for some reason okay don't question me it's smut, you wear his hat (mentioned like...once), he's a huge tease, clit smacking, breeding kink, dumbification, degradation and praise???, he calls you a pillow princess, and more stuff...

a/n: i know he just got drip marketing but i need MORE- also i was thinking of sloppy seconds (ick pt2) by lay bankz while writing this so do with that what you will.

"c'mon sugar, you can do better, can't ya?" the cowboy mumbles mockingly, circling patterns into your inner thigh as you ride him tirelessly, tears staining your puffy cheeks as you try your hardest to cum.

"aw, is my pretty thing such a pillow princess that she can't do nothin unless her big strong cowboy does it for her?" he coos, smacking your clit before gripping onto your hips, still not moving, "didn't you want this? i never told you to, but you thought you could do it, dumb little girl."

you sob, grinding down on him, "sir— wanna cum s'bad sir— nghaa!— it hurts, fuck—" he smiles up at your teary face, back resting against the headboard of the bed as he looks at you, teeth bared.

"oh girlie, you want me that bad? you want me to fill that pussy up so good until you can't think no more?" he coos, thrusting up into you, and for the first time tonight, you feel good, his cock touching that spot in your cunny.

"boothill—" he slaps your clit as a warning, and you whine, "sir! sir, it feels good! please, please make me feel good sir, please! fill me up, make me cum, anything!"

he grins at you, sharp teeth glinting under the dim light of the bedroom as he grabs you by the waist and pushes you down on the bed, metal-plated hands cold against your body. you squeak out, gripping onto the sides of the sheets as he flips you over.

"since ya asked so nicely, it would be too mean to say no to ya, girlie," he groans out, using his thumbs to spread your leaky cunt apart, humming at the way it glistens before he thrusts his cock back into you, eliciting a scream from your lips.

"sir! yes, sir— fu- hahnghh! it feels so good, sir, hah~ s-so good—" he doesn't respond, letting out a low growl as he thrusts into you harder and faster, feeling you tighten around him deliciously. You whimper and whine, feeling so full with his cock.

"such a good girl, my good little cutie," he clicks his tongue in annoyance when he can't call you what he wants to; when he can't call you his little slut. but you seem to get the memo, hole tightening around him before you squirt, cum gushing all over him as you fall limp, but he's not stopping, still thrusting into your sensitive hole.

"sir— sir, wait, 'm still sensitive, sir— nghyaa!??" he presses you down on the bed fully, cock thrusting deep until it kisses your cervix, and you let out a broken whimper. He lets out a delightful chuckle, a hand going around your neck until he brings you into a choke hold in his arm, squishing your cheeks until you can only let out babbles from the struggle to breathe. but it still feels so good, better even.

"sir— sir, 'm gonna cum again— sir— mphyaaa!" you gush around his cock once more and he finally spills into your hole, cum thick and creamy. he lets you out of the criminally sexy chokehold before putting his hat on you with a chuckle, admiring your fucked out face.

"that's my pretty girl, heh."

#boothill#hsr smut#boothill smut#i am down bad as shit#honkai star rail smut#boothill is plaguing my brain gvnqenrgvwievbgw#hsr boothill#hsr boothill smut

660 notes

·

View notes

Text

Galvanized Steel Demand Surge: Key Drivers and Market Insights for 2024–2031

Meticulous Research®, a leading global market intelligence and consulting company, has released a new report titled "Galvanized Steel Market by Product Type (Hot-dipped Galvanized Steel, Electro-galvanized Steel), Application (Building and Construction, Automotive, White Goods, Shipbuilding, and Other Applications), and Geography - Global Forecast to 2031." According to this comprehensive analysis, the global galvanized steel market is projected to grow significantly, reaching $216.2 billion by 2031 at a CAGR of 9.9% from 2024 to 2031. In terms of volume, the market is expected to expand to 240.8 million tons by 2031, with a CAGR of 9.2% during the same period.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5846?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=24-09-2024

This robust growth is largely driven by a surge in infrastructure investments and increasing demand for galvanized steel in the construction sector. However, the market faces several challenges, including the volatility of raw material prices and regulatory compliance issues, which may constrain growth. Despite these obstacles, technological advancements in manufacturing processes are poised to unlock new opportunities, while high manufacturing costs remain a significant challenge for market players.

Market Overview: Key Drivers and Restraints

The galvanized steel market is expanding rapidly as several industries increasingly adopt galvanized steel for its superior corrosion resistance, cost-effectiveness, and durability. Several factors are contributing to the growth of this market:

1. Growing Infrastructure Investments

Infrastructure investments, particularly in emerging economies, are one of the main drivers behind the rising demand for galvanized steel. Governments around the world are investing heavily in infrastructure projects, including roads, bridges, railways, and residential and commercial buildings. Galvanized steel is highly preferred in these projects because of its longevity and resistance to environmental factors such as moisture and extreme weather conditions.

2. Increasing Demand from the Construction Industry

The construction industry accounts for the largest share of galvanized steel consumption, primarily due to its structural benefits. Galvanized steel is used extensively in building frameworks, roofing, trusses, and decking, where its corrosion-resistant properties help extend the life of critical building components. The use of galvanized steel not only protects against rust but also ensures low maintenance, making it a cost-effective option for long-term infrastructure.

3. Technological Advancements in Manufacturing

Technological advancements in the galvanizing process are also playing a crucial role in market growth. Improved hot-dipped galvanizing technologies have enhanced the durability and flexibility of steel coatings, leading to increased adoption in a variety of industries. Advances such as laser welding, resistance welding, and arc welding are also making galvanized steel more attractive by improving ease of fabrication without compromising corrosion protection.

4. Challenges: Raw Material Price Volatility

While demand for galvanized steel is growing, fluctuating prices of raw materials such as steel and zinc are impacting profit margins for manufacturers. Additionally, regulatory compliance related to environmental standards adds a layer of complexity, as companies must balance between meeting these standards and keeping production costs low.

5. High Manufacturing Costs

Manufacturing galvanized steel, especially through advanced methods, can be capital-intensive. The high initial costs of setting up galvanized steel production facilities and the need for regular maintenance and inspections can deter smaller players from entering the market. However, for established firms, the return on investment remains promising due to the durable and low-maintenance nature of galvanized steel products.

Product Segmentation: Hot-dipped vs. Electro-galvanized Steel

The galvanized steel market is segmented into two primary product types:

1. Hot-dipped Galvanized Steel

The hot-dipped galvanized steel segment is expected to dominate the market, accounting for over 75% of the total share in 2024. Hot-dipped galvanized steel provides numerous environmental and economic benefits, particularly in achieving sustainable designs. By tightly bonding the zinc coating with the steel, hot-dip galvanizing creates a robust layer of protection that can last for decades without the need for frequent maintenance or corrosion inspections. This type of steel is widely used in construction, automotive manufacturing, and other heavy-duty applications due to its resilience against rust and ability to withstand harsh environments.

One of the standout advantages of hot-dipped galvanized steel is its ductility. Even after being heavily formed or fabricated, it retains its full corrosion protection capabilities. This makes it a preferred material for industries that require both strength and flexibility. Additionally, hot-dipped galvanized steel is easily welded using various methods, making it a versatile material for complex manufacturing processes.

The hot-dipped galvanized steel segment is projected to register the highest CAGR during the forecast period, driven by increasing demand across several industries, particularly in the construction and automotive sectors.

2. Electro-galvanized Steel

While the hot-dipped segment leads the market, electro-galvanized steel is also gaining traction, particularly in specialized applications such as white goods and electronics. Electro-galvanized steel is commonly used for products where aesthetic appeal is crucial, as it provides a smooth, consistent finish. It is widely utilized in the manufacture of refrigerators, washing machines, and other household appliances. Moreover, advancements in electro-galvanizing processes have made this type of steel more corrosion-resistant, enhancing its performance in high-humidity environments.

Application Segmentation: Building and Construction Leads

The galvanized steel market is categorized by application into building and construction, automotive, white goods, shipbuilding, and other sectors. Among these, the building and construction segment is projected to account for the largest share—over 45%—of the global galvanized steel market by 2024. The use of galvanized steel in construction is extensive, covering applications such as structural frameworks, trusses, roofs, walls, and decking. It offers protection against corrosion caused by moisture and environmental factors, making it a cost-effective, durable solution for both commercial and residential buildings.

The automotive sector is another significant consumer of galvanized steel, particularly in the Asia-Pacific region, where automotive production is booming. Galvanized steel is used in vehicle body construction to enhance durability and resistance to rust, which is especially important for cars exposed to harsh weather conditions. Electro-galvanized steel is often favored in this industry due to its superior surface finish and corrosion resistance.

White Goods: High Growth Potential

The white goods segment is expected to register the highest CAGR during the forecast period. This growth is driven by the increasing use of electro-galvanized steel in the production of household appliances such as refrigerators, air conditioners, and washing machines. Steel’s strength and corrosion resistance make it ideal for these appliances, while its recyclability aligns with the growing emphasis on sustainability in consumer goods manufacturing.

Regional Insights: Asia-Pacific Dominates the Market

Geographically, the galvanized steel market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of over 47% of the global market. The rapid industrialization and urbanization in countries such as China, India, and Southeast Asian nations are fueling the demand for galvanized steel in construction and automotive manufacturing. As these countries invest in large-scale infrastructure projects, the demand for durable and low-maintenance building materials like galvanized steel is surging.

In addition to construction, the automotive industry in Asia-Pacific is a major driver of market growth. Countries like Japan, South Korea, and China are leading producers of automobiles, and the use of galvanized steel in vehicle manufacturing ensures the longevity and safety of vehicles. The region's dominance in galvanized steel production is further bolstered by advances in galvanizing technologies, which have improved efficiency and cost-effectiveness, making steel more attractive to various industries.

Key Players and Competitive Landscape

Several key players operate in the galvanized steel market, including:

ArcelorMittal S.A. (Luxembourg)

POSCO (South Korea)

Nippon Steel Corporation (Japan)

JFE Holdings, Inc. (Japan)

ThyssenKrupp AG (Germany)

NS Bluescope Steel Limited (Australia)

These companies are continuously innovating to meet the growing demand for galvanized steel. For instance, in June 2022, Nippon Steel Corporation and ArcelorMittal S.A. announced a joint venture to build advanced steel processing lines in India to tap into the country's burgeoning steel market. Similarly, POSCO began construction of a plant in China to produce galvanized steel sheets for automobiles, further expanding its presence in the region.

Read Full Report :- https://www.meticulousresearch.com/product/galvanized-steel-market-5846?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=24-09-2024

Conclusion

The galvanized steel market is poised for significant growth through 2031, driven by rising infrastructure investments, technological advancements, and increasing demand from key industries such as construction and automotive manufacturing. However, manufacturers must navigate challenges such as fluctuating raw material costs and regulatory hurdles to capitalize on the market's full potential. With major players continuing to innovate and expand their operations, the galvanized steel market is set to remain a vital component of global industrial growth.

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Galvanized Steel Market#Galvanized Steel#Galvanized Sheet Metal#Galvanized Steel Sheet#Galvanized Roofing#Galvanised Pipe#Galvanized Metal Roofing#Galvanized Coil#Galvanized Metal#Galvanized Steel Plate

0 notes

Text

Explore $216.2 Billion Galvanized Steel Market: Get exclusive insights on key market trends, segments, geographical analysis, & competitive analysis!

#Galvanized Steel Market#Galvanized Steel#Galvanized Sheet Metal#Galvanized Steel Sheet#Galvanized Roofing#Galvanised Pipe#Galvanized Metal Roofing#Galvanized Coil#Galvanized Metal#Galvanized Steel Plate

0 notes