#simulationtechnology

Explore tagged Tumblr posts

Text

The Gregory Poole Equipment Company took its Cat® Simulators trailer to Sandhills Community College (SCC) to provide students in their heavy equipment operator training program with an opportunity to practice various jobsite applications. Students experience a safe learning environment, hands-on training, and skill development that directly translates to jobsites when they train with Cat Simulators. With the construction industry facing a skilled labor shortage, investments in simulation training like this ensure students are job-ready, confident and capable from day one. Kudos to Gregory Poole Equipment Company and SCC for prioritizing workforce development! https://simformotion.com/

#WeAreCatSimulators#SimformotionTraining#HeavyEquipmentOperatorProgram#ConstructionTraining#WorkforceDevelopment#SimulationTechnology#FutureOfWork#SFMK12

0 notes

Text

Integrating CAD and FEA: Advancing Engineering Design and Analysis

In the realm of modern engineering, the fusion of Computer-Aided Design (CAD) and Finite Element Analysis (FEA) has revolutionized the product development landscape. This integration enables engineers to create detailed digital models and rigorously analyze their performance under various conditions, leading to optimized designs and reduced reliance on physical prototypes.

Understanding Computer-Aided Design (CAD)

CAD refers to the use of computer software to create, modify, analyze, and optimize designs. It facilitates the development of precise 2D and 3D models, allowing engineers to visualize components and assemblies before manufacturing. Popular CAD tools include AutoCAD, Inventor, SolidWorks, and Creo. These platforms support 3D solid modeling, geometric dimensioning and tolerancing, and functional validation through animations. Additionally, CAD models can be integrated with FEA software for comprehensive analysis and with controllers for Hardware-in-the-Loop (HIL) testing visualization.

Delving into Finite Element Analysis (FEA)

FEA is a computational technique used to predict how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. By breaking down complex structures into smaller, manageable elements, FEA allows for detailed analysis of stress, strain, and deformation. This method is integral to modern engineering, providing insights that inform design decisions and enhance product reliability.

The Synergy Between CAD and FEA

The integration of CAD and FEA creates a seamless workflow from design to analysis. Engineers can develop a digital model in a CAD environment and directly import it into FEA software for simulation. This synergy offers several advantages

Seamless Data Transfer: Direct importation of CAD models into FEA software ensures accuracy and reduces manual data entry errors.

Iterative Design Process: Engineers can quickly iterate between CAD modifications and FEA analyses, fine-tuning designs to meet performance goals.

Enhanced Accuracy: Utilizing detailed CAD models in FEA simulations improves the precision of analysis results, leading to better-informed design decisions.

The FEA Analysis Process

Conducting an FEA involves three primary stages:

Pre-Processing:

Geometry Definition: Creating the 3D model of the component or system.

Material Properties Assignment: Specifying material characteristics such as elasticity, density, and thermal conductivity.

Loads and Boundary Conditions Application: Defining external forces, pressures, temperatures, and constraints acting on the model.

Discretization and Mesh Generation: Dividing the model into finite elements and generating the mesh, considering element shapes and sizes.

Solution:

Physics and Assumptions: Selecting the type of analysis—structural, thermal, vibration, etc.—and defining relevant assumptions.

Equation Generation and Solving: Constructing and solving the mathematical equations governing the system's behavior.

Post-Processing:

Result Evaluation and Interpretation: Visualizing and analyzing results through contour plots, graphs, and animations to assess performance and identify potential issues.

This structured approach ensures comprehensive analysis and facilitates informed decision-making throughout the design process.

Applications of CAD and FEA Integration

The combined use of CAD and FEA spans various industries and applications:

Automotive Engineering: Designing and analyzing vehicle components for safety, durability, and performance.

Aerospace Engineering: Ensuring structural integrity and optimizing weight in aircraft and spacecraft designs.

Civil Engineering: Assessing the strength and stability of structures like bridges and buildings.

Consumer Products: Enhancing the design of everyday items for improved functionality and user experience.

By leveraging CAD and FEA, engineers can predict and mitigate potential failures, optimize material usage, and innovate more effectively.

Advantages of Integrating CAD with FEA

Integrating CAD with FEA offers numerous benefits:

Reduced Development Time: Early detection of design flaws minimizes the need for extensive prototyping, accelerating the development cycle.

Cost Efficiency: Identifying and addressing issues during the design phase reduces expenses associated with late-stage modifications and recalls.

Improved Product Quality: Comprehensive analysis leads to designs that meet performance criteria and regulatory standards.

Enhanced Collaboration: A unified platform facilitates communication among design, analysis, and manufacturing teams, promoting a cohesive development process.

Challenges and Considerations

While the integration of CAD and FEA presents significant advantages, it also poses certain challenges:

Learning Curve: Proficiency in both CAD and FEA software requires training and experience.

Computational Resources: Complex simulations demand substantial computational power and time.

Model Accuracy: The precision of analysis results depends on the quality of the CAD model and the appropriateness of the FEA setup, including mesh quality and boundary conditions.

Addressing these challenges involves investing in training, utilizing advanced computing resources, and adhering to best practices in modeling and analysis.

Conclusion

The integration of Computer-Aided Design and Finite Element Analysis at servotechinc has become a cornerstone of modern engineering, enabling the development of innovative, reliable, and efficient products. By harnessing the strengths of both methodologies, engineers can navigate the complexities of design and analysis with greater precision and confidence.

#CADDesign#FEAAnalysis#EngineeringDesign#FiniteElementAnalysis#ProductDevelopment#StructuralAnalysis#MechanicalEngineering#3DModeling#SimulationTechnology#InnovativeEngineering

0 notes

Text

youtube

Learn how cavitation affects fluid flow, engine performance, and component wear and see how CFD helps engineers predict and mitigate these effects. Whether you’re working on fuel injectors, centrifugal pumps, or high-speed nozzles, this video provides critical insights into the Volume of Fluid (VoF) approach for multiphase flow simulations.

🔥 Key Highlights: ✅ Understanding cavitation & its impact on fuel injectors 🚗⛽ ✅ Introduction to the Winklhofer Nozzle case study 📊 ✅ Setting up cavitation modeling in CONVERGE CFD 🖥️ ✅ How pressure changes drive vapor formation 💨 ✅ Importance of adaptive mesh refinement (AMR) for accuracy

#youtube#skilllync#mechanicalengineering#engineering#automotiveengineering#turbo#machinery#simulationtechnology#simulation

0 notes

Text

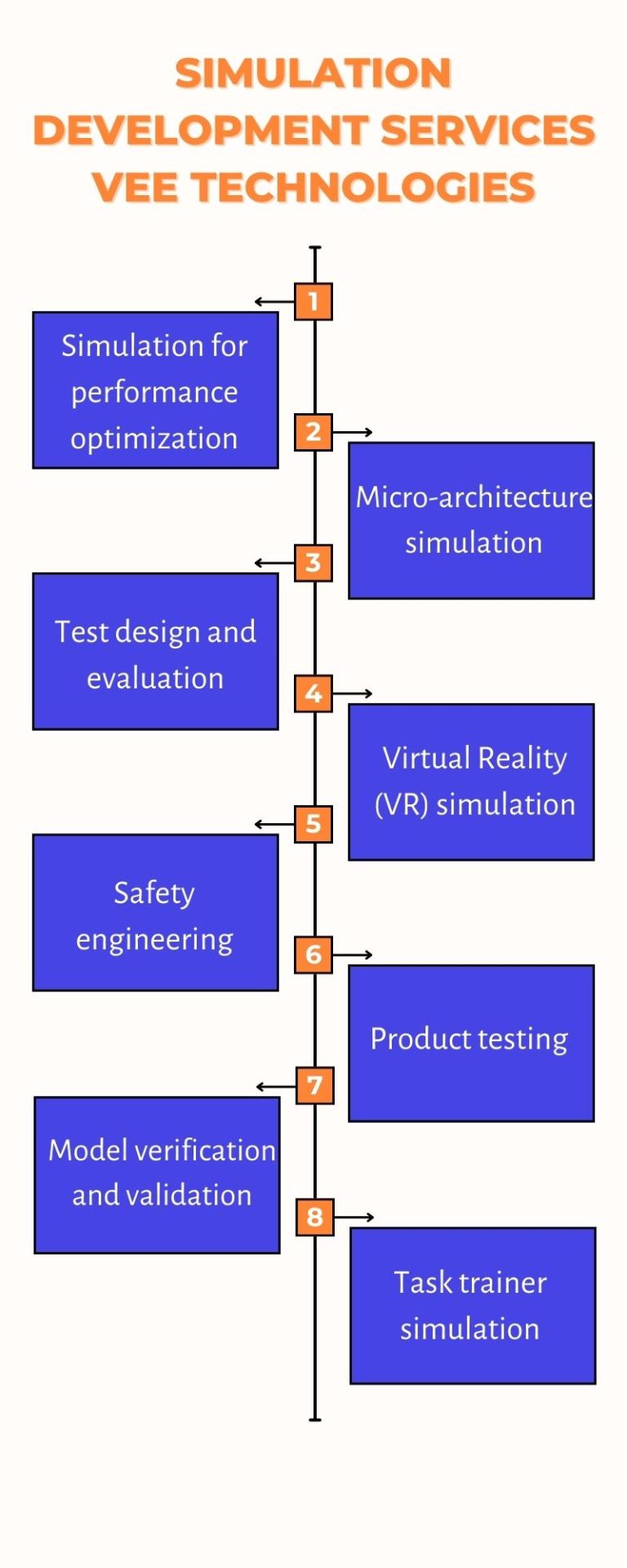

Vee Technologies' Simulation Development Services

At Vee Technologies, They provide simulation development services for both technical and non-technical learning requirements. Our high-quality, lightweight, and instant-loading videos make it easy for your target audience to learn on the go.

Explore More: https://www.veetechnologies.com/industries/animation-services/simulation-development.htm

#SimulationDevelopment#Simulations#3DModeling#VirtualSimulation#SimulationSoftware#TrainingSimulations#ModelingAndSimulation#DataVisualization#SimulationServices#InteractiveSimulations#SimulationDesign#EngineeringSimulations#SimulationTechnology

0 notes

Text

Vee Technologies' Simulation Development Services

At Vee Technologies, They provide simulation development services for both technical and non-technical learning requirements. Our high-quality, lightweight, and instant-loading videos make it easy for your target audience to learn on the go.

Explore More: https://www.veetechnologies.com/industries/animation-services/simulation-development.htm

#SimulationDevelopment#Simulations#3DModeling#VirtualSimulation#SimulationSoftware#TrainingSimulations#ModelingAndSimulation#DataVisualization#SimulationServices#InteractiveSimulations#SimulationDesign#EngineeringSimulations#SimulationTechnology#veetechnologies

0 notes

Text

Virtual Reality Company in India | Simulanis

At Simulanis Solutions, we’re at the forefront of innovation as a premier Virtual Reality Company in India. Based in Delhi, we create immersive experiences that transform training, education, and product development.

Join us on this exciting journey and see how we can elevate your projects with cutting-edge Virtual Reality technology!

#VirtualReality#VRCompany#SimulanisSolutions#ImmersiveExperiences#VREducation#VTraining#SimulationTechnology#InteractiveLearning#VRSolutions#VirtualTours#HealthcareVR#EnterpriseVR#VRDevelopment#3DModeling#VirtualRealityIndia#Innovation#TechForGood#DigitalTransformation#FutureOfLearning#virtual reality company india#virtual reality company near me

0 notes

Text

3D Simulation Software Market Dynamics: Trends, Innovations, and Future Prospects| GQ Research

The 3D Simulation Software market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global 3D Simulation Software market showcased a significant presence, boasting a valuation of US$ 14.54 billion. This underscores the substantial demand for 3D Simulation Software technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-3d-simulation-software-market/

Projected Growth: Projections suggest that the 3D Simulation Software market will continue its upward trajectory, with a projected value of US$ 39.63 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 15.4%, reflecting a steady and robust growth rate for the 3D Simulation Software market over the coming years.

Technology Adoption:

The adoption of 3D simulation software has experienced a remarkable surge across industries, driven by its transformative potential in virtual prototyping, product design, and process optimization. From manufacturing and architecture to healthcare and entertainment, industries are embracing 3D simulation as a means to visualize, analyze, and refine complex systems and environments. As businesses seek to mitigate risks, reduce costs, and accelerate innovation, the demand for 3D simulation software continues to grow, with widespread adoption expected to continue as the technology evolves.

Application Diversity:

The application diversity of 3D simulation software spans a myriad of industries and use cases, reflecting its versatility and utility across various domains. In manufacturing, these software solutions are utilized for virtual prototyping, production line optimization, and predictive maintenance, enabling manufacturers to streamline operations and enhance efficiency. In architecture and construction, 3D simulation facilitates architectural visualization, structural analysis, and urban planning, empowering designers and planners to create immersive, lifelike environments. Moreover, in healthcare, automotive, aerospace, and gaming industries, 3D simulation software is leveraged for training, simulation, and immersive experiences, showcasing its broad applicability and impact.

Consumer Preferences:

Consumer preferences in the 3D simulation software market are influenced by factors such as usability, functionality, compatibility, and support services. Businesses prioritize software solutions that offer intuitive interfaces, robust features, and seamless integration with existing workflows and systems. Additionally, reliability, accuracy, and scalability are critical considerations, particularly for enterprises seeking to deploy 3D simulation software across diverse projects and teams. As businesses demand greater flexibility, customization options, and responsive customer support, software providers are focusing on enhancing user experiences and delivering value-added services to meet evolving consumer preferences.

Technological Advancements:

Continuous technological advancements drive innovation in the 3D simulation software market, enabling providers to push the boundaries of realism, interactivity, and performance. Advances in computer graphics, physics simulations, and artificial intelligence algorithms enable more realistic and immersive simulations, blurring the lines between virtual and physical environments. Furthermore, the integration of cloud computing, big data analytics, and machine learning capabilities enhances simulation accuracy, scalability, and predictive capabilities. As software providers invest in research and development, the latest generation of 3D simulation software offers unprecedented levels of realism, efficiency, and versatility, empowering businesses to unlock new insights and opportunities.

Market Competition:

The 3D simulation software market is characterized by intense competition among established players and emerging contenders seeking to differentiate themselves through innovation and market positioning. Leading software providers invest heavily in product development, partnerships, and marketing efforts to maintain their market leadership and expand their customer base. Meanwhile, startups and niche players focus on specialized applications or disruptive technologies to carve out their market niche. As competition intensifies, software providers are exploring new markets, industries, and use cases to capitalize on the growing demand for 3D simulation solutions.

Environmental Considerations:

Environmental considerations are increasingly important in the 3D simulation software market, with providers and users alike seeking sustainable solutions that minimize environmental impact. Software providers prioritize energy-efficient algorithms, optimized code, and cloud-based deployments to reduce energy consumption and carbon emissions. Additionally, by enabling virtual prototyping and simulation, 3D simulation software helps businesses minimize material waste, energy consumption, and environmental footprint associated with physical prototypes and testing. Moreover, remote collaboration and telecommuting enabled by 3D simulation software contribute to reducing transportation-related emissions and fostering a more sustainable work environment.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Autodesk, Inc.

Dassault Systèmes

Siemens Digital Industries Software

ANSYS, Inc.

Altair Engineering, Inc.

Bentley Systems, Incorporated

PTC Inc.

MSC Software Corporation

COMSOL, Inc.

Synopsys, Inc.

MathWorks

ESI Group

Blender Foundation

Unity Technologies

The AnyLogic Company

The research report provides a comprehensive analysis of the 3D Simulation Software market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-3d-simulation-software-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Hire Us!

https://www.fiverr.com/s/EGj4vD

#SimulatedWorlds#ImmersiveSim#VirtualLearning#3DInteractive#VRDesign#SimulationTechnology#AugmentedExperience#DigitalSimulationLab#VirtualEnvironments#SimulatedTraining#3DModelSimulation#VRVisualization#SimulatedRealityTech#VirtualSandbox#ImmersiveTraining#3DRenderings#VirtualExperiences#SimulatedEnvironments#VRModeling#3DExperienceDesign#3d#3d relapse#3d render#blender 3d#design#Visual Components#VisualComponents

0 notes

Text

Driving Simulator Market 2024 Is Set to Fly High in Years to Come with Top Countries Data

The qualitative report published by Exactitude Consultancy research on the “Driving Simulator Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Driving Simulator market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Driving Simulator Market from a Global and Regional perspective.

The Driving Simulator Market is expected to grow at 7.02% CAGR from 2024 to 2030. It is expected to reach above USD 2.77 billion by 2030 from USD 1.5 billion in 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/13099/driving-simulator-market/

#DrivingSimulator#SimulatorTechnology#DrivingSimulation#VirtualReality#SimulatorTraining#AutomotiveTechnology#DriverTraining#DrivingExperience#VirtualDriving#SimulationTechnology#DrivingSkills#AutomotiveInnovation#DriverSafety#RoadSafety#SimulatorDevelopment#FutureOfDriving#DriverEducation#VehicleSimulation#DrivingPerformance#SimulatorSystems

0 notes

Text

The next evolution in ECG simulation: Dive into the advancements with SIM2, setting new standards in accuracy and realism.

#ecgsimulation#MedicalTraining#cardiachealth#SIM2#medicalsimulation#InnovationInMedicine#healthtech#simulationtechnology#ecgmodel

1 note

·

View note

Text

Wind Tunnel Market Gains Momentum – Expected to Hit $5.8B by 2034! 🌬️🏎️

Wind Tunnel Market is projected to expand from $3.2 billion in 2024 to $5.8 billion by 2034, growing at a CAGR of 6.1%. As industries push for aerodynamic efficiency, fuel optimization, and technological advancements, wind tunnel testing is becoming more critical than ever.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS10476 &utm_source=SnehaPatil&utm_medium=Article

Key Market Trends:

✈ Aerospace Leads — Aircraft manufacturers rely on wind tunnels for precision aerodynamic testing. 🚗 Automotive on the Rise — With the surge in electric vehicles (EVs), optimizing aerodynamics is a game-changer. 🏗 Expanding Applications — Wind tunnels are now used in sports performance analysis, civil engineering, and energy solutions.

Regional Insights:

🌎 North America — Leads with high R&D investments in aerospace and automotive sectors. 🌍 Europe — Strong demand from automakers and sustainable transportation initiatives. 🌏 Asia-Pacific — Rapid industrialization, infrastructure growth, and EV adoption fuel demand.

Competitive Landscape:

Top industry players like Boeing, Lockheed Martin, Honda R&D, and Aerolab are innovating with cutting-edge CFD integration, AI-based flow visualization, and high-speed data acquisition. The future of wind tunnel technology will be driven by automation, real-time analytics, and enhanced efficiency.

#windtunnel #aerodynamicdesign #aircrafttesting #aviationtechnology #evinnovation #aerospacetechnology #electricvehicles #sustainabledesign #vehicleperformance #researchanddevelopment #engineeringtech #computationalfluiddynamics #fluidmechanics #transportationinnovation #energysector #sportstechnology #racecartesting #windengineering #airflowtesting #futureofmobility #spaceexploration #automotivetesting #smartmanufacturing #climatewindtunnel #hypersonictech #aeroacoustics #dragreduction #airflowoptimization #nextgenvehicles #flightdynamics #smartcities #speedoptimization #turbulencetesting #industrialinnovation #racingtechnology #infrastructuredevelopment #defensetechnology #energyresearch #technologytrends #simulationtechnology #engineeringexcellence #aviationnews #scienceandtech #advancedmaterials #greenmobility #performanceengineering

0 notes

Text

See what we’ve been up to in our January/February issue of Simformed, which includes: ▪️ Tennessee College of Applied Technology Knoxville Includes Heavy Equipment Operator Apprenticeship Training ▪️ Canada Heavy Equipment Operators in the Workforce Infographic ▪️ Maintenance Tips for Maximum Uptime Series: Mining Truck ▪️ Caterpillar’s 2025 Global Operator Challenge to Feature Cat® Simulators Systems We’re committed to pushing the boundaries of what’s possible in simulation and bringing cutting-edge tools to our clients. Stay tuned for more exciting developments and thank you for being part of the Simformotion journey! Check out our latest highlights here: Simformed - January/February 2025 - SIMFORMOTION LLC

#Simformotion#CatSimulators#SimulationTechnology#Innovation#TechUpdates#Simformed#NewRelease#ConstructionTech#SFMK12

0 notes

Text

youtube

In this episode, we dive deep into the results of our turbocharger simulation 🏎️💨.

We analyze the velocity, pressure, and torque variations to understand how the impeller behaves under exhaust gas flow. We also break down key convergence criteria and explain why simply looking at fluid angular velocity isn’t enough for assessing simulation stability.

⚙️ What You’ll Learn: ✅ How fluid forces impact turbine rotation ✅ Understanding pressure distribution on the impeller ✅ Why convergence analysis is critical 📉 ✅ How to check mass flow rate stability ✅ The importance of extended simulation time for rotational convergence

#youtube#skilllync#mechanicalengineering#engineering#automotiveengineering#turbo#machinery#simulationtechnology#simulation

0 notes

Text

Breaking Boundaries: The Destructive Testing Market

The destructive testing market is witnessing steady growth as industries across sectors such as manufacturing, aerospace, automotive, and construction prioritize quality assurance and product reliability.

Destructive testing involves subjecting materials and components to extreme conditions to assess their strength, durability, and performance characteristics. With the increasing complexity of products and the need for stringent safety standards, the demand for destructive testing solutions with advanced capabilities and accuracy is driving innovation in the market.

Advancements in testing methodologies, equipment, and data analysis techniques are driving innovation in the destructive testing market, enabling manufacturers to perform comprehensive evaluations of materials and components. These advancements have led to the development of specialized testing instruments and techniques for assessing the mechanical properties, fatigue life, and failure modes of materials under various conditions. Moreover, the integration of digital imaging, non-destructive evaluation (NDE), and simulation technologies is enhancing testing efficiency and enabling predictive modeling of material behavior, empowering industries to optimize product designs and manufacturing processes.

#DestructiveTesting #QualityAssurance #ProductReliability #Manufacturing #Aerospace #Automotive #Construction #MaterialTesting #SafetyStandards #TestingTechnology #InnovationInIndustry #MechanicalProperties #DataAnalysis #NDE #SimulationTechnology #QualityControl

0 notes

Text

SIMULATION TECHNOLOGY AND ITS IMPACT TO SAFETY ENGINEERING

Simulation has become a vital part of modern engineering. The need for experiments, pro-active occurrences and corrections before real hardware productions, had been the main factors projecting engineers to embark on simulation engineering. Read the full article

#Computersimulation#safetyanalyses#safetyengineering#simulationtechnology#softwaredesigning#softwaremodeling

0 notes

Text

Driving Simulator Market: $3.5B to $7.2B by 2033 | 7.2% CAGR

Driving Simulator Market focuses on developing simulation systems designed to replicate real-world driving conditions for purposes such as driver training, vehicle research, and entertainment. These simulators offer immersive experiences that enhance driver skills, improve safety, and enable realistic virtual driving environments, supporting advancements in automotive technology and training methodologies.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS20021 &utm_source=SnehaPatil&utm_medium=Article

Market Growth and Drivers

The market is experiencing robust growth, driven by technological innovations and an increased focus on driver safety training. The professional training simulator segment is the leading sub-segment, fueled by rising demand from automotive manufacturers and transport companies seeking advanced solutions to train skilled drivers. The entertainment segment, powered by the growing popularity of immersive gaming experiences, follows closely behind.

Regional Dynamics

North America is the market leader, owing to the presence of key industry players and a strong focus on road safety.

Europe follows as the second-largest market, benefiting from stringent regulatory standards and a growing interest in virtual reality applications.

Asia-Pacific is emerging as a significant growth area, driven by urbanization and increasing investments in simulation technologies.

Technological Innovations

The driving simulator market is enhanced by cutting-edge technologies such as Virtual Reality (VR), Augmented Reality (AR), Mixed Reality (MR), Artificial Intelligence (AI), and Machine Learning (ML). These innovations are revolutionizing the market by offering real-time simulation, scenario-based training, and performance analysis, making simulations more interactive and educational.

Market Segmentation

Type: Compact Simulator, Full-Scale Simulator, Advanced Driving Simulator

Product: Software, Hardware, Accessories

Services: Training, Consultation, Maintenance, Customization

Applications: Driver Training, Research and Testing, Entertainment

Market Outlook

In 2023, the market was valued at $1.2 billion, with projections to reach $2.5 billion by 2033. The professional training segment holds the largest share at 45%, driven by increasing safety regulations and demand for skilled drivers.

#DrivingSimulator #VirtualReality #DriverTraining #AutomotiveResearch #VehicleTesting #SimulationTechnology #RoadSafety #AIinDriving #CarSimulation #ImmersiveGaming #AdvancedSimulation #DriverSafetyTraining #TechInnovation #AutomotiveTechnology #AerospaceSimulation #MixedReality #SimulationBasedLearning #VirtualTraining #AutomotiveIndustry #EntertainmentTech #SmartDriving

0 notes