#single stage watering vacuum pump

Text

Make Easy Maintenance A Reality - Choose a Vacuum Pump From Eject System for Maximum Efficiency

If you're in need of industrial vacuum pumps or water chillers, then you've come to the right place. Here at Eject System, we are a leading manufacturer of these types of products in Ahmedabad. We believe in providing high-quality equipment for our customers to help them achieve their industrial needs.

When it comes to industrial vacuum pump manufacturers, you'll want to make sure you're getting the best quality for your money. Two of the top manufacturers in Ahmedabad are us at Eject System, and PPI Pumps. At Eject System, we offer a variety of vacuum pumps, including oil sealed rotary vane vacuum pumps and single-stage watering vacuum pumps. Our products are designed to be energy efficient, durable, and easy to use. PPI Pumps also offers a range of vacuum pumps, from single stage watering vacuum pump to multi-stage pumps. They are known for their exceptional quality and reliability.

Water chillers are another essential industrial product that you'll want to invest in. Here at water chiller manufacturer in Ahmedabad, we manufacture a variety of chillers, including air-cooled and water-cooled chillers. Our chillers are made from high-quality materials and are designed to be energy-efficient. We offer water-cooled and air-cooled chillers and are known for their excellent customer service.

#industrial vacuum pump manufacturers#oil sealed rotary vane vacuum pumps#single stage watering vacuum pump#water chiller manufacturer in Ahmedabad

0 notes

Text

Trusted Vacuum Pump Solutions for Demanding Industrial Environments

In the world of industrial applications, the importance of reliable vacuum pump solutions cannot be overstated. Meekaj Vacuum Systems Pvt Ltd stands out as a leader, committed to delivering superior quality and innovative vacuum pump technologies to businesses across various sectors. With a focus on durability and efficiency, Meekaj ensures that their products not only meet but exceed industry standards, making them an ideal choice for businesses seeking dependable vacuum solutions.

Meekaj's expertise in manufacturing a wide array of vacuum pumps is evident in the precision engineering of their products. The company's dedication to innovation has led to the development of advanced systems that cater to the unique needs of their clients. Among their offerings is the two-stage liquid ring vacuum pump, known for its robust performance and ability to handle demanding applications with ease. This pump is particularly suited for environments where consistent vacuum levels and reliability are crucial.

Most Reliable vacuum pump suppliers in Gujarat

As one of the leading vacuum pump suppliers in Gujarat, Meekaj Vacuum Systems has built a reputation for excellence and customer satisfaction. Their commitment to quality is reflected in their comprehensive product range, which includes the single-stage water ring vacuum pump. This model is designed to provide efficient and reliable operation, making it a preferred choice for industries requiring stable and effective vacuum solutions.

Moreover, Meekaj Vacuum Systems is recognized among the top water ring vacuum pump manufacturers, offering products that are engineered to ensure optimal performance and long-term reliability. Their pumps are tailored to meet the diverse needs of industries, ensuring minimal downtime and enhanced operational efficiency.

Choosing Meekaj means partnering with a company that values innovation, reliability, and customer satisfaction. Their expert team is dedicated to providing solutions that match the specific requirements of their clients, ensuring that each product supports optimal industrial operations. Explore Meekaj Vacuum Systems' offerings today and experience the transformative impact of their cutting-edge vacuum pump solutions on your business.

#water ring vacuum pump manufacturers#vacuum pump suppliers in Gujarat#single-stage water ring vacuum pump#two-stage liquid ring vacuum pump

0 notes

Text

"WE CHOOSE TO GO TO THE MOON..."

What's wild to think about is the short amount of time between the Wright flyer at Kittyhawk and man walking on the moon.

1903-1969. Totally plausible for someone to have been alive for both.

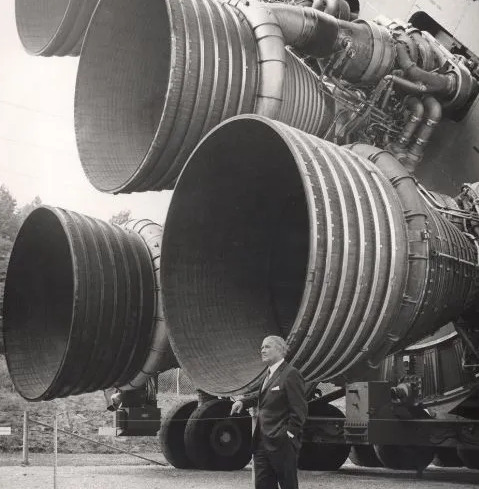

Rocketry as a science is a marvel. From Robert Goddard crashing the first liquid fueled rocket in his aunt's garden in 1926 to the F1 engine (five of them in the first stage) powering the Saturn V rocket with fuel pumps strong enough to empty an olympic sized swimming pool in 2.5 minutes.

And then the physics behind getting things up there in the first place. Orbit. Going from stationary on a launchpad to fast enough to orbit the earth every ~90 minutes. Dealing with atmospheric pressure and drag all the way up there. Every component needing to be meticulously engineered to keep the thing together the whole time. You've got a controlled explosion constantly going off behind you, it's gonna rattle the vehicle a bit. You even need baffles in the fuel tanks so that the sloshing fuel doesn't throw the balance off. Try balancing a bowl of water on your fingertip while walking down a hall.

Then there's a need for radios strong enough to transmit through the atmosphere, thousands of miles into space and back. Building antennas and relays to put in orbit to extend radio range. The math behind it. Making the electronics strong and resilient enough to survive vacuum, solar radiation, accumulating heat(there's not enough atmosphere for heat to adequately radiate the way it does on Earth, so you gotta get rid of the heat somehow)for years.

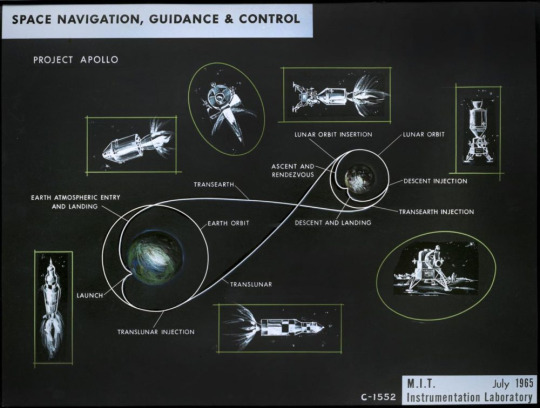

Now you've got to learn docking.

Matching orbital velocities between you and your target. Learning it's not as simple as burning your engines while you're facing your target, but more like … both targets are in free fall and need to maneuver so that their trajectories match each other. Slowly. Carefully. Spacecraft need to be lightweight, so collisions, even small ones, can be catastrophic. Computer-controlled docking computers were not a thing. So they had to do it by hand. Using RCS thrusters to maneuver the craft to its target just right so the hatches connect strongly and airtight.

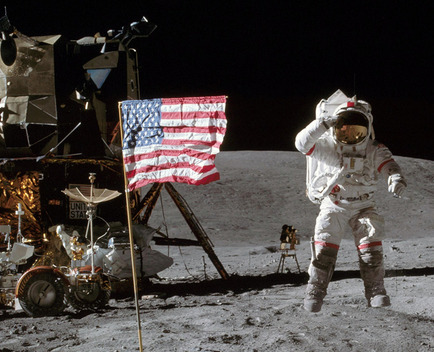

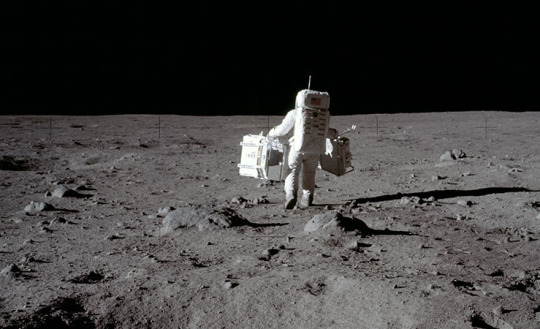

Put all of that together and you have the Apollo program. Launching a 110 meter rocket into space, flinging it at the moon, docking with the lander, sliding into orbit around the moon. Disconnecting the lander. Landing it with a very small fuel tank with no chance of rescue if something goes wrong. Realizing the landing site that was picked was actually rockier than it was supposed to be, while you're about to set down. Having mission control telling you you're almost out of fuel while you literally have to eyeball the landing. The computing power back then was miniscule. A calculator is more complicated than the computers that powered Apollo. Then the blessed touchdown in your tissue paper craft(if you drop a wrench while you're inside the lunar lander on Earth, it will literally punch a hole in the floor). Stepping out of the vehicle to mind-bending, magnificent desolation. Black sky. No stars. The sunlight off of the surface of the moon is too bright to allow starlight. Gray ultra fine 'soil' as far as the eye can see, pockmarked by eons of meteorite collisions older than life itself. Farther from home than anyone's ever been. Where no one's ever set foot.

And then. Leaving on the horse you rode in on. Doing the ballet of orbital rendezvous and docking again. Timing the burn of the engines to get you home. Hoping your math is right and you don't hit the atmosphere at too shallow an angle, skipping off of it like a stone on water. Or too steep, punching into it too fast for the heat shields and parachutes to handle. While you're burning through the atmosphere hoping no superheated gasses find a weak spot in your capsule to punch into, you can't even talk to mission control. The plasma fucks with comms too much so there are minutes of total silence where nobody knows if the other party is still alive. Then, if every single part of this crazy mission worked correctly and you're still alive, parachutes deploy. You hit the waters of the ocean. And wait for someone to pick you up.

That's not even mentioning Apollo 13. Where the command module suffered an explosion during flight, in a fuel tank that fucked their oxygen supply.

Spaceflight is, was, always will be, crazy. Foolhardy. Deadly. Exhilarating.

136 notes

·

View notes

Text

Why Tekman is the Top Choice for Industrial Vacuum Pumps

In the industrial sector, the efficiency and reliability of vacuum pumps are crucial for various processes. Tekman has emerged as a top choice for industrial vacuum pumps Manufacturer, thanks to its exceptional product range and innovative solutions. This article explores why Tekman stands out in the market and how its products, including the Dry Vacuum Pump, Helium Leak Testing Machine, and Single Stage Rotary Vane Pump, offer unparalleled performance.

Tekman: Leading the Vacuum Pump Industry

Tekman is well-known for its cutting-edge vacuum pump solutions, which are made to satisfy a variety of industrial application requirements. By emphasizing innovation, longevity, and quality, Tekman has become a market leader in the vacuum pump sector. Their extensive product line, which includes the Helium Recovery System and Helium Leak Detection Service, demonstrates their dedication to quality.

Superior Performance with Dry Vacuum Pumps

The Dry Vacuum Pump is a product of note from Tekman. Dry vacuum pumps function without the need for oil or water, which makes them more ecologically friendly and requires less maintenance than conventional liquid-sealed pumps. These pumps provide dependable and constant vacuum levels and are suited for high-performance applications. They are perfect for procedures where contamination from water or oil is a problem because of their dry operation.

Precision and Reliability in Helium Leak Testing

A further example of Tekman's dedication to accuracy and dependability is their Helium Leak Testing Machine. Testing for helium leaks is an essential procedure in several sectors, including the aerospace, automotive, and pharmaceutical industries. The Helium Leak Testing Machine from Tekman is engineered to precisely identify even the tiniest leaks. Ensuring the integrity and safety of delicate equipment and components requires this skill.

Innovative Solutions with Helium Recovery Systems

The Helium Recovery System from Tekman is a shining example of their creative use of vacuum technology. Due to its high value and high cost, recovering helium is essential for both financial and environmental reasons. By effectively recovering and recycling helium, Tekman's Helium Recovery System lowers waste and operating expenses. This technique is very useful in fields like semiconductor manufacture and scientific research, where helium is widely used.

Efficiency of Single-Stage Rotary Vane Pumps

Applications needing a sturdy and dependable vacuum source are intended for the Tekman Single Stage Rotary Vane Pump. This kind of pump is renowned for being straightforward and effective, offering reliable performance in a range of industrial environments. The one-step design guarantees a small and economical solution without sacrificing functionality. Rotating vane pumps from Tekman are a flexible option for numerous industries because of their ability to handle a wide range of applications, from mild to heavy-duty use.

Comprehensive Helium Leak Detection Services

Apart from its cutting-edge merchandise, Tekman also offers extensive Helium Leak Detection Services. For sectors where stringent leak testing is necessary to guarantee the dependability and safety of their products, these services are vital. In order to preserve the integrity of their systems and components, clients can benefit from Tekman's proficiency in helium leak detection by identifying and resolving such problems before they become serious.

The Advantages of Choosing Tekman

Tekman’s reputation as a top choice for industrial vacuum pumps is built on several key advantages:

Innovation: To incorporate cutting-edge technology into their products, Tekman consistently invests in research and development. Their dedication to innovation guarantees that their vacuum pumps adhere to the most recent regulations and specifications in the industry.

Quality: The highest quality requirements are met during the manufacturing of every Tekman product. This emphasis on quality ensures dependable operation and longevity, which lowers the requirement for regular upkeep and replacements.

Customer Service: Tekman provides outstanding customer service, offering knowledgeable guidance and support to assist customers in choosing the ideal vacuum pump for their requirements. Their assistance goes above and beyond the first purchase to guarantee that customers are provided with continuous support.

Environmental Responsibilities: Tekman takes environmental concerns into account while designing products like the Helium Recovery System and Dry Vacuum Pump. Through cutting waste and emissions, Tekman supports more environmentally friendly industrial processes.

Applications across Industries

Tekman's vacuum pumps and associated components are used in a wide range of sectors. Their Helium Leak Testing Machine in the pharmaceutical sector guarantees the quality of medicine transportation and packaging systems. Tekman's Single Stage Rotary Vane Pump helps with equipment maintenance and manufacturing processes in the automobile industry. By lowering helium usage and operating expenses, their Helium Recovery System helps the semiconductor production industry.

Tekman is the best option when it comes to industrial vacuum pumps because of its cutting-edge products, dedication to excellence, and first-rate customer service. Tekman provides solutions that match the highest requirements of performance and dependability, whether you need a single-stage rotary vane pump, dry vacuum pump, helium leak testing machine, or helium recovery system. Their all-encompassing approach to vacuum technology guarantees that businesses everywhere may attain maximum efficiency in their operations and procedures. You are investing in state-of-the-art technology and a partner committed to your success when you choose Tekman.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Industrial Vacuum Pump Manufacturers#Vacuum Furnace

0 notes

Text

How to Choose the Right Equipment for Water Damage Restoration

Water damage restoration is a critical process that requires specialized equipment to effectively handle and mitigate the damage caused by water intrusion. Whether you’re a homeowner tackling minor issues or a professional dealing with extensive damage, selecting the right equipment is crucial for a successful restoration. This article provides a comprehensive guide on how to choose the right equipment for water damage restoration, ensuring that you can manage the process efficiently and effectively.

Understanding the Types of Equipment Needed

The first step in choosing the right equipment is understanding the types of equipment required for various stages of water damage restoration. The process generally involves several key phases: water extraction, drying, cleaning, and dehumidification. Each of these phases requires specific tools to ensure thorough and efficient restoration.

Water Extraction Equipment: This includes high-powered pumps and wet vacuums designed to remove standing water from affected areas. For minor water damage, a portable wet vacuum may suffice. However, for more extensive damage, especially in commercial settings or large residential areas, industrial-grade pumps are necessary. These pumps are capable of handling large volumes of water quickly and efficiently.

Drying Equipment: After extracting water, the next step is drying out the affected area. This is done using air movers and dehumidifiers. Air movers, or fans, help to circulate air and accelerate the evaporation process. Dehumidifiers remove moisture from the air, preventing secondary damage such as mold growth. Both types of equipment work together to thoroughly dry out water-damaged materials.

Cleaning and Sanitizing Equipment: If the water damage involves contamination, such as from sewage or floodwater, cleaning and sanitizing become critical. Equipment in this category includes steam cleaners, scrubbers, and disinfectants. These tools help to remove contaminants, eliminate odors, and ensure that the affected areas are safe and hygienic.

Assessing Your Needs

Choosing the right equipment involves assessing the extent of the water damage and your specific needs. For smaller, localized issues, basic equipment such as a wet vacuum and small air movers might be sufficient. However, for larger or more severe damage, particularly in commercial or multi-story buildings, you’ll need more powerful and specialized equipment.

Severity of Damage: Evaluate the severity of the water damage to determine the size and type of equipment required. For minor leaks or spills, residential-grade equipment may be adequate. For major flooding or significant damage, industrial-grade equipment will be necessary to handle the volume and ensure thorough restoration.

Size of the Area: The size of the affected area also impacts equipment choice. For small rooms or single areas, portable equipment may be sufficient. For larger spaces or entire buildings, you’ll need equipment with higher capacities and capabilities, such as larger dehumidifiers and high-output air movers.

Type of Water Damage: The type of water involved (clean, gray, or black) will influence the choice of cleaning and sanitizing equipment. Contaminated water requires more advanced cleaning and disinfecting tools to ensure proper sanitation and safety.

Quality and Efficiency

When selecting equipment, quality and efficiency are paramount. High-quality equipment not only performs better but also lasts longer, offering better value over time. Look for equipment from reputable brands known for their durability and performance. Additionally, efficient equipment can speed up the restoration process, reducing downtime and minimizing further damage.

Brand and Reliability: Choose equipment from trusted manufacturers with a reputation for reliability and performance. Investing in high-quality tools can lead to better results and fewer issues during the restoration process.

Energy Efficiency: Consider the energy efficiency of the equipment. Energy-efficient models can save on operating costs and are better for the environment. Look for equipment with energy-saving features and certifications.

Training and Maintenance

Proper use and maintenance of restoration equipment are essential for optimal performance. Ensure that you or your team are trained in the operation of the equipment to maximize its effectiveness and avoid potential damage. Regular maintenance and servicing of the equipment are also crucial to ensure its longevity and reliability.

Training: Ensure that operators are trained in the correct use of the equipment. Proper training helps in efficient operation and prevents misuse or damage.

Maintenance: Regularly maintain and service your equipment to keep it in good working condition. Follow the manufacturer’s guidelines for maintenance and address any issues promptly. Also check this post https://friscodamagerepair.tumblr.com/post/759588169666740224/water-damage-restoration-myths-debunking-common

Conclusion

Choosing the right equipment for water damage restoration is essential for effective and efficient recovery. By understanding the types of equipment needed, assessing your specific needs, and focusing on quality and efficiency, you can ensure that you are well-equipped to handle water damage effectively. Whether you are dealing with minor issues or extensive damage, selecting the appropriate tools will significantly impact the success of your restoration efforts and the overall condition of your property.

0 notes

Text

"China offer valve HED 8 OP-20/350K14AS for Electric Company

"China offer valve HED 8 OP-20/350K14AS for Electric Company

Dongfang Yoyik perennial supply spare parts of steam turbine, turbine generator, EH oil system filter, fluorine rubber O-ring, EHC system various types of pumps, valves, power plant automatic control components, water turbine generator, all kinds of bearings, electrical insulation materials, and other power plant spare parts accessories. The quality is quite worthy of buying.

Yoyik can offer many spare parts for power plants as below:

DF-valve HED 8 OP-20/350K14AS-DF

EH oil main pump PVH131Q1C.RSF.10.C25

screw pump diagram HSNH80Q-48NZ

piston plunger pump PVH131R13AF30B252000002001AB010A

IPSV/valve stem E1-T2-M4172-01

AST solenoid valve HQ16.12Z

Dc Motor Driven Emergency Oil Pump 125LY 23-4

Manual test valve cod.224.32.9.1/1x PMAX 10bar,tf -5℃ +70℃

O-ring C8689029

single screw pump SNH280R54E6.7W21

vacuum cleaner P1764-1

pump screw HSNH280-46NZ

vertical centrifugal pump IHF80-50-200

solenoid valve AS32060b-G220

variable vane pump F3.SV10.4.1.A

BFP LP MSV solenoid directional valve ZD.02.004

cylinder CDA2F63-400-A54

piston pump parts A10V100R-31R-PPA12N00

vacuum pump parts P-1758

screw pump working HSNSQ3440-46

axial piston variable pump PD060PS02SRS5AC00S0000000

twin screw pump ACG 052K7 NVBP

screw pump manufacturer ACF070

oil pump replacement 50PWF-25A

electric centrifugal pump head DFB-100-80-230

vacuum pumps PVH098R01AJ30A250000002001AB010

vacuum pump KZ100-WS

Oil pump PVH74QIC-RSMIS-10-C25-31

servo valve SM4-20 (15)57-80/40

axial piston pump PVH740ICRSF-IS-10-1

bellows globe valve KHWJ10F-1.6P

gear oil transfer pump 3GR25*4-2.0/1.0

globe throttle check valve KJC50-2.5P

water pump DFB-80-80-240

lubrication pump 7318ACM

electric centrifugal pump head DFB 80-50-220

motor 65-250B

valve HED 8 OP-20/350K14AS

Angle joint EW-L06-SS

vacuum pump oil HSND280-54

multi stage centrifugal pump 65-250

pressure hose S100-AC-FC-0250

screw pump stainless HSNH280-43Z

Accumulator NXQB-L20/10LNXQB-L20/10L

dc centrifugal pump 125-80-260

oil pump C9602005

stator cooling water pump impeller DFB100-80-230

pressure hose SMS-12/15-610-C

flexible shaft coupling HSNH-280-43NZ

vane pump working F3-V20-1S8S-1C11

thrust collar nut FK5G32-03-11

centrifugal pump DFB100-80-250

screw pump manufacturer HSNH280-43Z

oil vacuum pump P-1764-1

centrifugal pumps head LK45/CZ65-250-4

bellows Pressure relief valve BXF-40F

mechanical seal pdf N.D.E L270

AST solenoid valve GS061600V+CCP230D

screw pump stainless DLZB820-R64A-2

china hydraulic pump 56AY50X9

Hydraulic control valve(Complete assembly) 1K2213

pump shaft 2S-185

gear oil transfer pump 80AYZ-55

pump vacuum KZ/RP100WS

piston pump parts PV046R1K1T1NMF1

sealing gasket HZB253-640-03-07

vacuum pump 30-WSRP

sealing ring HB4-56J8-147

end suction centrifugal pump 65-250A

hydraulic pump piston PVH074R01AA(AB)10A250000002001AB0

shaft seal mechanical A108-45B/BX1

pressure hose SMS-12/15-1829mm-B

three screw pump DLZB820-R64A-19

High pressure ball valve RKH20S164465-EG W.01.A.0087

valve HED 8 OP-20/350K14AS

DFYLSYC-2024-7-8-A

"

0 notes

Text

What to do if the fine sand recycling machine produces unclean sand? How to improve recycling rate?

In the later stage of the sand making production line, (Stone crusher)for sand with a large mud content or a sand-water mixture with a large sand content, only a sand washing machine may not meet the requirements for the final finished sand, so a fine sand recovery machine is required. , it has become the standard equipment in the sand making production line, and its importance is self-evident. When the equipment is used for a long time, some problems will inevitably occur, such as: the sand is not clean. In order to solve the problem of unclean sand produced by the fine sand recovery machine, we must first find out the cause of the problem before we can prescribe the right medicine to solve the problem. Xingao Nai Heavy Industry has summarized the following 5 reasons.(Xingaonai group , Stone crusher)

Reasons and solutions for unclean sand production

1. The discharge port is blocked

If the sand and gravel particles in the slurry in the fine sand recovery machine are too fine, and the single feeding amount suddenly increases, causing material to accumulate at the discharge port, the sand discharge will be unclean.

Solution: Stop feeding immediately, open all discharge openings, rinse with clean water before continuing the operation. When starting the operation again, be sure to feed the material evenly.

2. The pressure of the cyclone is too large

During operation, if the pressure given by the cyclone is too high, it will cause water to spray and splash from the cyclone. Eventually, the sediment cannot be completely separated when the material passes through the vibrating screen. If the pressure is too small, the fine sand cannot be completely separated. Recycling, resulting in low fine sand recovery rate.

Solution: Properly configure the cyclone and provide appropriate pressure.

3. The vacuum high-pressure pump is clogged

If debris enters the mud, causing the vacuum high-pressure pump to become clogged, it will result in unclean sand production.

Solution: During operation, try to prevent debris from entering the mud. You can directly connect the outlet of the dewatering screen to the feed port of the fine sand recovery machine to prevent debris from entering and clogging the high-pressure pump.

4. Sieve plate

When the screen mesh of the screen plate is too large and the particle size of the recovered fine sand is small, there will definitely be no sand. If the mesh size is too small and the particle size of the sand is too large, it will easily cause the dewatering fine sand recovery machine to become clogged. This will also cause it to not produce sand.

Solution: Choose the appropriate screen according to the fine sand particle size in the production line.

5. Vibration motor

If the motor power is too small, the motor will not be able to drive the equipment, resulting in no sand production. If the motor power is too large, electricity will be wasted, making the investment uneconomical.

Solution: Choose the appropriate vibration motor according to your actual situation.

0 notes

Text

Our Vacuum Pumps Give Long Lasting Performance

Looking for a vacuum pump manufacturer in India? Look no further than the experts at Eject System. We have years of experience manufacturing high-quality vacuum pumps that meet the needs of our customers. Our precision manufacturing process ensures accuracy and reliability, and we offer a variety of customization options to make sure you get the perfect pump for your needs. Our oil sealed rotary vane vacuum pump is widely used in many industries. It is a reliable and efficient way to evacuate air or gas from a system. This pump can be used in both low and high vacuums, making it the perfect choice for many applications. Thanks to its compact size and easy-to-use design, our oil sealed rotary vane vacuum pump is ideal for use in a variety of settings. Contact us today to learn more about oil lubricated vacuum pump!

Reputed Industrial Chiller Manufacturer

As a professional industrial chiller manufacturer, we are always striving to provide our customers with the best possible products and service. Our chillers are some of the most reliable on the market, and we have a variety of options to choose from so that you can find the perfect one for your needs. We also offer excellent customer support, so you can rest assured that you're in good hands. A vacuum pump is a device that removes gas molecules from a sealed volume in order to create a vacuum. There are many different types of vacuum pumps, but the most common are the rotary vane and the scroll pump. Here, we will discuss the single stage water ring vacuum pump, which is used mainly in industries such as agriculture, biotechnology, and food processing.

#single stage water ring vacuum pump#industrial chiller manufacturer#oil lubricated vacuum pump#oil sealed rotary vane vacuum pump

0 notes

Text

Compact and Reliable Single Stage Vacuum Pumps for Consistent Industrial Vacuums

Meekaj Vacuum Systems Pvt Ltd stands as a premier provider of advanced vacuum pump solutions, catering to the industrial sector in India with a diverse range of high-performance products. As a reputable industrial vacuum pump supplier in India, we specialize in delivering reliable and efficient vacuum pump systems that are essential for a wide range of industrial applications, ensuring optimal performance and productivity.

Discover innovation and precision engineering with Meekaj Vacuum Systems, one of the leading water ring vacuum pump manufacturers in Ahmedabad. Our water ring vacuum pumps are designed to meet the rigorous demands of industrial processes, offering robust performance, energy efficiency, and durability for seamless operation in challenging environments.

Enhance Your Industrial Efficiency with Meekaj’s Two Stage Liquid Ring Vacuum Pumps

Experience the power and efficiency of single stage water ring vacuum pumps from Meekaj Vacuum Systems, engineered to deliver exceptional performance and reliability in various industrial settings. Our single-stage pumps are known for their compact design, low maintenance requirements, and high suction capacity, making them an ideal choice for applications that demand consistent vacuum levels.

Meekaj Vacuum Systems two stage liquid ring vacuum pump, designed to handle demanding industrial processes with precision and efficiency. Our two-stage pumps offer increased vacuum levels, reduced energy consumption, and enhanced reliability, making them the preferred choice for applications that require higher vacuum capabilities and optimal operational efficiency.

Meekaj Vacuum Systems prioritizes customer satisfaction and technical excellence, ensuring that our vacuum pump solutions meet the highest standards of quality and performance. Whether you require an industrial vacuum pump supplier in India, water ring vacuum pump manufacturers in Ahmedabad, single-stage pumps, or two-stage models, Meekaj Vacuum Systems is your trusted partner for cutting-edge vacuum solutions that drive success in your industrial operations.

#two stage liquid ring vacuum pump#single stage water ring vacuum pumps#water ring vacuum pump manufacturers in Ahmedabad#industrial vacuum pump supplier in India

0 notes

Video

youtube

SOUZ VACUUM -Roots-liquid ring vacuum system

SOUZ VACUUM offers vacuum system solutions. This means we don’t just ship you a vacuum pump,We work together on each step to create a fully sustainable, custom-fit system. No matter your location, no matter your application, whether it is standardized or customized. SOUZ VACUUM will help you find the solution that is perfect for you and your needs. Liquid ring vacuum pumps are frequently used, in particular in the chemical industry. Besides water, other sealing liquid also can be used as operating medium. In combination with Roots vacuum pumps, vacuum pumping units with high pumping speeds and good ultimate vacuum are thus created. Ultimate pressure: 0.5Pa Liquid ring vacuum pump from SOUZ VACUUM: 1. 2BV monoblock vacuum pump 2. 2BE series big vacuum pump 3. 2SK two stage vacuum pump 4. SK single stage vacuum pump

Welcome to visit our web, www.souzvac.com

Also look forward to hearing you through [email protected]

0 notes

Text

Sludge pump rental in India | Power Rental ----- Book Now.....

Sludge pump rental in India | Power Rental ----- Book Now.....

Well-Point Dewatering Pumps on Rent in India

Well points are smaller diameter tubes with slot near the bottom that are inserted into the ground from which water is drawn by a vacuum generated by a dewatering pump. System consist of number of well points spaced along a trench, all connected to common header, which is attached to one or better points pump.

Dewatering is an important step in any construction process. To have a solid and strong basement, it is very important to vacate the soil of that site of the water.

If the construction site is near a water body, then dewatering becomes even more important. In these days this dewatering is done by a special type of device called submersible pump or well-points dewatering pump. This device has a hermetically sealed motor close-coupled to the motor body. This structure is then submerged into the water to be pumped.

This avoids a big problem of pump cavitation. As water is pumped from the deep soil, a hydraulic gradient is formed which removes water from the neighboring soil pores. Water simply flows into the well forming a cone of depression around the well so that there is no space left in the pore spaces of the soil in and around the neighboring soil.

Sumps Dewatering Pumps OR Sludge pump rental in India

System involve excavation of temporary pit & installation of sumps within the excavation, from which water entering into the excavation can be pumped. The number of location of sump pit should be determined & place on the erosion & sedimentations control plan.

Apart from this, sumps dewatering pumps are also used in the horizontal drainage system to remove excess water from the drains. In this case, the electric submerged pumps are fitted into the drains. Dewatering pumps are also used in the well points which are used to extract water from sandy soils. There are some dewatering pumps which are designed solely for the sandy soils. They may not be that effective in sandy soil or rocky conditions. Single stage dewatering pumps are used in the sewage pumping, industrial pumping, and slurry pumping. This process helps in cleaning out the environment.

Not only to draw are water, but these submersible electric pumps also used in the oil wells. But the pumps which are being used in the electrically hazardous sites or that of combustible liquids should be so designed so that not to ignite the combustible liquid.

Dewatering pumps are highly priced owing to their variety of applications. If you want it for a small time venture, for e.g. to dig a well in your own home then buying a dewatering pump will not be a good idea.

Perennial provides Sumps Dewatering Pumps Rental Service in India

1 note

·

View note

Text

Unlike traditional single-stage purifiers, the ZJA Double Stage Transformer Oil Filtration Machine is a two-stage system. This translates to an intensified purification process, tackling contaminants with exceptional finesse. Here's how it works:

Stage 1: Roughing the Seas: The initial stage employs a primary filter and a high-flow vacuum pump. This duo works in tandem to swiftly remove larger particles and water vapor, laying the groundwork for deeper purification.

Stage 2: Deep Dive into Purity: The second stage deploys a multi-pronged attack. Precision filters eliminate even the tiniest impurities, while a high-vacuum dehydration system meticulously extracts residual moisture. Additionally, degassing technology whisks away dissolved gases, leaving the oil pristine and ready for action.

0 notes

Text

Lab Lubricated Rotary Vane Vacuum Pump - Pattons Medical USA

Pattons Medicals Rugged, single stage, oil sealed lubricated rotary vane vacuum pumps Low cost, high efficiency, outstanding reliability, requires no water.

0 notes

Text

China offer Pump shaft FA1D56-01-03A for power plant

China offer Pump shaft FA1D56-01-03A for power plant

Dongfang Yoyik Engineering Co., Ltd is specialized in producing, manufacturing and selling industrial spare parts, as well as providing products of famous brands. Since 1989, our products have being widely used in various industries from power, oil, chemical, electronic, gas to environmental protection, fire-fighting equipments and nuke industry.

Yoyik can offer many spare parts for power plants as below:

#DF-Pump shaft FA1D56-01-03A-DF

mechanic seal water pump A108-45B/BX1

vane pump parts F3-V10-IS6S-IC-20

rotary piston pump 2.5CY14-1B

magnetic coupling centrifugal pump YCZ50-25

vacuum pump P-1931A

roots vacuum pump WS-30

piston hydraulic pump A10VS045DR/31R-PPA12N00

Corrosion resistant Single stage centrifugal pump 65-250A

Gasket 03506-300/311/415

sealing ring HB4-56J8-79

PRESSURE REDUCING VALVE DB15G-2-L5X/5/2 ,L05-23031-00003, REVISION:2

vacuum pump WSRP-30

transfer pump oil 50AYZ-50

Seal assembly of high pressure accumulator NXQB-40/20-L-A

Globe valve IV14MBW316H/416-10-GP-ST-0C

manual vacuum pump P-1607

AC lube pump 125LY-35-4

Packing as-stop valve 2-1/2"B09-5076Z-06TS

electric transfer oil pump SDH125-100-200C

piston plunger pump PV29-2R50-000

pressure joint Z103-01-14.00HD

vacuum cleaner P-1964-1

O ring HY.SO.0051.V

pumps centrifugal DFB80-50-20

INTEGRATED BLOCK 0508.919T0301.AW001

radial piston pump 5MCY14-1B

pump vacuum ZS-185

differential pressure valve 514D098-06 2.5"

Lubrication Oil Pump 125LY-36-20

dongfang Nitrogen reducer YQD-II

STC shutdown trip AST solenoid valve CCP115D 115VAC 19W

pumps parts hydraulic 50YW32-250A

dc centrifugal pump YCZ65-250B

vacuum cleaner WSRP-30

electric motor centrifugal water pump YNKN300/200-20Y/J

solenoid valve AW2110A-220VDC-VITON

Pump shaft FA1D56-01-03A

mechanical seal FIJ125-100-315

piston vacuum pump PD060PC02SRS5AC00E1200000

vacuum pump rotary vane F3-V10-1S6S-1C20

pressure hose SMS-12/15-610mm-C

piston pump PVH074R01AB10A250000002001AB010A

Pressure relief valve AR925-20\DN20

level oil thermometer YWZ-500T

vickers vane pump F3-V10-1S6S-1C20

oil transfer gear pump SDH65-50-160

OPC Solenoie valve seat OPC G130519

O-ring HZB253-640-03-09

globe valve HY-SHV6.01Z

Shaft sleeve Coupling XB08VI-86-1.6-0

globe throttle check valve KJC65C-4.0P

AC sealing oil pump KF80KZ/15F4

Shaft end baffle JB/ZQ4724

bellows globe valve core WJ50F1.6P.03

vacum pump air vacuum P-1751

EH oil pump outlet hose 16G2AT-HMP (DN25)-DK025-1600

self-locking pipe joint dn40/q/d9111g-77

vacuum oil pump P-545

mechanical seal in pump CM104-45

vacuum filter YCZ50-250

screw QD9403

fuel pump 80AY-50X10

balanced vane pump F3-SV10-1P5P-00

600MW turbine AC Auxiliary oil pump (TOP)coupling driving pin 125LY-36

piston plunger pump PVH131Q1C.RSF.10.C25

solenoid trip valve F3DG5S2-062A-220VAC-50-DFZK-V/B08

reciprocating piston pump PVHD74R01AA10A250000001ABO1OA

PluginsLC25DB20E-7xgasket 03506-300/311/415 part no.:93

solenoid valve 300AA00126A

screw pump diagram ACG060N7NVBP

vacuum pump price P-1764-1

vacuum cleaner 30-WS

Pump shaft FA1D56-01-03A

DFYLSYC-2024-4-1-A

0 notes

Text

Pfeiffer Vacuum Presents New Two-Stage Rotary Vane Pump

Pfeiffer Vacuum Presents New Two-Stage Rotary Vane Pump

With the new Pascal 2021 HW, Pfeiffer Vacuum presents the two-stage rotary vane pump with the highest vapor capacity in its class. It is optimally suited for all applications where water vapor is expected, such as low temperature sterilization and drying. An optimized design and gas ballast system allows to pump large volumes of vapor without condensation inside the pump. This prevents accumulation of fluid that would adversely affect the service life of the pump and the oil.Get more news about Two Stage Rotary Vane Vacuum Pump Seller,you can vist our website!

Thanks to the materials used, the Pascal 2021 HW also resists aggressive chemicals such as hydrogen peroxide. The pump is ready to deliver vapor in just a few minutes due to a customized temperature management. It has a safety device that impedes the ingress of water into functional sections if the steam capacity is inadvertently exceeded.

With accessories such as oil mist filter and inlet traps, the pump can be ideally adapted to most processes. Thanks to its compactness, the Pascal 2021 HW is also ideal for installation into equipment. An oil drain valve simplifies the maintenance in confined spaces. The single-phase universal motor allows for operation almost everywhere in the world.

The proven service concept of the Pascal series makes maintenance predictable and ensures a constantly high availability. The maintenance intervals can be extended by using different operating fluids.

0 notes

Text

Efficient Dewatering System

DEWATERING SYSTEM

What is dewatering?

Dewatering is the process of removing surface or groundwater from a particular location. It can also be known as the process of draining rainwater or groundwater. Every construction site's technique for dewatering will be different from others.

Methods of dewatering?

Construction dewatering system methods refer to unique techniques such as well points, deep wells, bypass, flood control, etc. Everyone has a different procedure for dewatering. Here are the different methods of dewatering which is as follows.

Wellpoint

Deepwells

Bypass Dewatering

Flood control

Tunneling Dewatering

Wellpoint

In wellpoint dewatering, the well will be drilled around the excavation area with submersible pumps installed in the good shaft. These pumps are connected to a header pipe allowing the groundwater to be drawn up by the pumps into the Wellpoint and then discharged. There are three types of well-point systems:

Single-stage system

Multiple-stage system

Vacuum System

Deepwells

In deep well dewatering system it consists of bored wells in series fitted with submersible pumps at the bottom. Each well will be capable of creating a cone of depression around itself while drawing water to the surface.

Bypass Dewatering

When sewer lines need maintenance, the sewage flow is pumped around the damaged pipe section using dewatering water pumps. The pumps are installed upstream of the maintained pipe section. The bypass technique is also common in irrigation and construction projects.

Flood Control

Flood control refers to all methods used to reduce or prevent the harmful effects of flooding.

Tunneling Dewatering

Tunnel constructions are complex worksites where many variables should be considered first. Significant volumes of water from the construction site need to be removed to stabilize the ground or prevent flooding of the work area.

Necessity of dewatering:

Dewatering is the safety of the structure around the pit in the following conditions:

Ease of concreting or masonry in the foundation

To protect concrete

To prevent soil erosion

Deep excavation

Construction in a water-logged area

Docks

Pile Foundation

Tips of Dewatering System:

Choose the proper discharge area

Check the signs of instability or erosion in the area during dewatering system

Shouldn't pump water directly into slopes

Channels used for dewatering system must be safe

Avoid dewatering under heavy rain

Water contamination with any chemical products must be solved before starting the project

Don't discharge contaminated water

Enquire about the permit details and requirements for dewatering

Analyze the conditions of water in the project area

CONCLUSION:

Selecting a dewatering method will be based on soil conditions and the water stability. Here we discussed complete dewatering system so that you can get some knowledge about it choose the right method for dewatering. We Prasanth De-watering contractor always concentrates on the quality, safety and stability of the project management and provide you efficient work in affordable price. Grab the opportunity and join with us.

#Prasanthdewatering#wellpointdewateringsystem#deepwelldewatering#surfacedewatering#wellpointdewateringcontractors#dewateringservices

0 notes