#solar panel connectors

Text

What is Solar Connectors: What to Know About Solar Connectors

In order to ensure a secure and efficient flow of electricity throughout your system, short solar connectors join various solar components together. The most prevalent connector on brand-new solar panels is the MC4 connector, which has a plug and socket design.

Connectors and Cables for Solar Panels: The majority of contemporary high-power solar modules are made with wire leads that have MC4 connectors on the ends. The back of solar modules used to have a junction box, so the installer had to manually connect the wires to the positive and negative terminal posts. Even though this method is still used, it is slowly becoming obsolete. Because they simplify and speed up the process of wiring your solar array, modern solar modules typically make use of the MC4 connectors. Both male and female versions of the connectors, which are intended to snap together, are available. They are UL-certified, conform to the National Electric Code, and electrical inspectors favour this connection method. The locking mechanism of the MC4 connectors ensures that they cannot be unplugged, making them ideal for use in outdoor settings. A specific MC4 unlocking tool is needed to separate the connectors.

PV cable connectors, branch connectors, module junction boxes, and PV wire harness solutions are all examples of solar connectors. They are utilized extensively in a wide range of solar power projects.

In order to produce solar panel connectors of the highest possible quality, India's renowned PV connector manufacturers have developed advanced engineering design capabilities and specialized manufacturing technology knowledge.

The fact that solar panel connectors of a high quality require less upkeep and produce less heat when in use helps rule out the possibility of an accidental fire. Because of these advantageous features, PV connectors are an excellent choice for the majority of industrial applications used by large businesses.

PV Connectors of high quality save more energy, work more efficiently, and last for longer. The connectors for the solar panels can be easily assembled with common tools and equipment that are readily available in the market. The solar connector's audible click sound helps ensure the stability and safety of the connection within the connectors when establishing connections. Solar connectors that are connected in the right places have low contact resistance and exponentially increase the performance of the entire system.

Over the course of the product's lifespan, robust solar panel connectors deliver dependable performance when utilized in actual industrial and commercial settings under a diverse range of weather conditions. The solar connectors can also be used outdoors for a long time because they are made of great housing materials that are resistant to UV light.

Connectors for solar cables can be used in business. Because they use a snap-in safety locking tabs system to lock two mating solar connectors, branch connectors ensure strong and secure connections. Two mating solar connectors can be prevented from being accidentally disconnected thanks to the snap-in safety locking tabs. By preventing dust and water from entering the mating contents, these measures increase the level of protection.

One of the most important types of solar connectors is the PV branch connector. The ESP-PC-X (plus branch connector), the ESP-TC SERIES (t branch connector), the ESP-YC (y branch connector), the ESC-BC-S3P1, the ESC-BC-S1P3 (3-way branch connector), the ESC-BC-S1P2, and the ESC-BC-S2P1-(2-way branch connector) are all examples of PV branch connectors. Other types of solar connectors include the PV cable connector and the PV

Solar cable connectors of high-quality aid in the efficient management, control, and connection of electrical energy.

If you're looking for high-efficiency solar panel connectors, solar cable connectors, or PV connectors, you should buy them from Elcom, a well-known manufacturer in India.

This article throws light upon What is Solar Connectors: What to Know About Solar Connectors.

0 notes

Text

The Advantages of Panel-Mounted Terminal Blocks with Spring Clamps

Panel-mounted terminal blocks with spring clamps are an essential component in electrical and electronic systems, offering numerous advantages over traditional screw-type terminal blocks. Panel mounted terminal blocks spring clamps in India, manufactured and supplied by Elmex Controls Pvt. Ltd. are gaining popularity around the world due to their reliability, ease of use, and time-saving capabilities.

These clamps have become increasingly popular in India due to their numerous advantages over traditional wiring methods. In this article, let’s explore the importance of using panel-mounted terminal blocks with spring clamps, including enhanced reliability, improved safety, and superior performance.

Importance:

Firstly, their reliability is crucial for ensuring the smooth operation of electrical systems. Loose connections or faulty wiring can lead to interruptions in the power supply, equipment malfunction, or even safety hazards. Panel mounted terminal blocks spring clamps in India provide secure and stable connections, reducing the risk of such issues. This reliability is particularly vital in industries where downtime can result in substantial financial losses.

Secondly, the safety features offered by these terminal blocks play a significant role in protecting both equipment and personnel. Loose connections and short circuits can lead to electrical arcing, overheating, or electrical shocks. The spring clamps and clear separation between conductors in panel-mounted terminal blocks minimize these risks, making them a safer alternative to traditional wiring methods.

Moreover, the performance benefits of panel-mounted terminal blocks contribute to the overall efficiency and productivity of electrical systems. By maintaining optimal contact and reducing electrical resistance, these terminal blocks minimize power loss and voltage drops. This improves the performance of equipment, reduces energy consumption, and lowers operating costs.

Additionally, the ease of installation and maintenance provided by terminal blocks saves time and effort. Troubleshooting becomes simpler due to organized wiring and easy accessibility. Wiring errors are minimized, leading to quicker identification and resolution of issues. Furthermore, the flexibility and adaptability of terminal blocks allow for system modifications or expansions without the need for extensive rewiring, providing cost-effective solutions.

Reliability:

Reliability is a crucial aspect of any electrical system, and panel-mounted terminal blocks with spring clamps offer notable advantages in this regard. These terminal blocks provide secure and stable connections, ensuring consistent and uninterrupted electrical flow. The spring clamps exert constant pressure on the conductors, maintaining a reliable connection even in demanding environments with vibrations or temperature variations. This feature reduces the risk of loose connections, which can lead to electrical faults, downtime, and costly repairs.

Furthermore, panel-mounted terminal blocks simplify maintenance and troubleshooting processes. With traditional wiring methods, locating and fixing faulty connections can be time-consuming and challenging. However, with terminal blocks, the wiring is organized and easily accessible, allowing quick identification and resolution of issues. This enhances the overall reliability of the system, minimizing downtime and optimizing productivity.

Safety:

Safety is of utmost importance in electrical installations, and panel-mounted terminal blocks with spring clamps offer significant safety benefits. These terminal blocks have built-in features that help prevent electrical hazards. The spring clamps ensure a secure and vibration-resistant connection, reducing the risk of loose connections that can cause electrical arcing or overheating. Additionally, terminal blocks provide a clear separation between conductors, minimizing the chances of accidental contact and short circuits.

Panel-mounted terminal blocks also simplify installation and reduce the risk of wiring errors. The spring clamps allow for easy and tool-free wiring, eliminating the need for twisting and soldering wires. This reduces the chances of human error, such as loose connections or crossed wires, which can compromise safety. The clearly labelled and organized terminals make it easier to identify and verify correct wiring, ensuring proper circuit configurations.

Moreover, terminal blocks are designed to withstand high voltages and currents, offering excellent electrical insulation. They are manufactured using high-quality materials that provide resistance to heat, chemicals, and other environmental factors. These attributes enhance the overall safety and durability of the electrical system.

Performance:

Panel mounted terminal blocks spring clamps in India offered by Elmex Controls, deliver superior performance compared to traditional wiring methods offered by other companies. The spring clamps provide consistent pressure, maintaining optimal contact between the conductors. This ensures low electrical resistance, minimizing power loss and voltage drops. The reliable connection offered by terminal blocks improves the overall efficiency of the system, resulting in better performance and reduced energy consumption.

Additionally, panel-mounted terminal blocks facilitate easy customization and flexibility. They allow for quick and hassle-free reconfiguration or expansion of the electrical system, without the need for rewiring. This feature is particularly advantageous in industrial settings where frequent changes and upgrades are common.

Furthermore, terminal blocks offer compatibility with a wide range of wire sizes and types. They can accommodate various conductor materials, such as solid, stranded, or flexible wires. This versatility allows for greater flexibility in system design and installation.

Final Thoughts:

Panel mounted terminal blocks spring clamps in India have revolutionized electrical installations in India, offering reliability, safety, and superior performance. Their secure connections, simplified troubleshooting, enhanced safety features, and flexibility make them the preferred choice for a wide range of applications, from industrial automation to building installations. Embracing these terminal blocks supplied by Elmex Controls Pvt. Ltd. can significantly improve electrical systems in terms of efficiency, durability, and overall performance.

#Panel mounted terminal blocks spring clamp India#Component housing block spring clamp#Spring loaded terminal blocks#Plug & socket terminal block spring clamp#Micro terminal block spring clamp#spring loaded terminal connector#spring type terminal block#solar pv panel junction box India#solar pv branch connector India

2 notes

·

View notes

Text

0 notes

Text

Solar Panel Alarm Products South Africa

Secure your solar investment with Solar-Cop's advanced alarm solutions. Explore our cutting-edge solar panel alarm products in South Africa to protect your solar energy investment with relief. Our advanced solutions are designed and engineered to protect your solar panels from theft or tampering and ensure the security of your solar panels. With advanced features such as fire alert, tamper detection, and seamless integration options, our alarm products provide reliable protection and peace of mind. Invest in the best defense for your solar panels with Solar-Cop's trusted alarm products. Visit solar-cop.com now to learn more and secure your solar energy assets today!

#Solar Panel Alarm Products South Africa#Solar Panel Security System South Africa#Solar Panel Security Alarm System South Africa#Solar Panel Alarm Connector South Africa

1 note

·

View note

Text

Solar Panels & inverters - Sunline Energy - Melbourne Australia

Best quality panels and inverters etc.. sold or installed in Australia at low prices. For more information visit our website sunlineenergy.com.au

#risen solar panels vs canadian solar#longi panels and sungrow inverter#canadian solar australia#sunline energy solar#solar energy melbourne australia#jinko solar panels melbourne#goodwe inverter warranty#solar panel inverter melbourne#longi panels australia#risen solar#tesla wall connector vs wallbox#inverters east melbourne#sunline energy australia#goodwe inverters

0 notes

Link

Edac is a leader in the card edge and rack and panel industries. Edac has also expanded its line to include one of the widest ranges of interconnect solutions in the world.

0 notes

Text

Polycab DC solar cables

We are leading as the best solar panels, solar inverters distributors which providing the complete range of solar bos products like Solar DCDB, Solar ACDB, Solar AJB, Also, You can get polycab DC solar cables at reasonable price in Jaipur with Wholesolar. For more details, visit now. https://wholesolar.co.in/solar-bos/

#polycab DC solar cables#polycab solar cable#dc wire for solar panels#Elmex MC4 Connector#Elmex Y-Connector#Elmex Inline Fuse Connector

0 notes

Text

HW Electro Puzzle, 2025. A Japanese start-up has revealed a prototype small electric van they say will go into production in 2025. With a design inspired by Origami, the Puzzle is 3,395 mm long, 1,475 mm wide and has a wheelbase of 2,480 mm. The panels at the front open up, giving access to the charging port as well as connectors for charging gadgets and a first aid kit. There are solar panels on the roof to supplement charging and the lithium-iron-phosphate battery provides a range of 200 km.

watch a video here

#HW Electro#HW Electro Puzzle#micro van#EV#electric van#electric vehicle#2025#prototype#boxy#Origami#video#start-up#new vehicle#Puzzle

250 notes

·

View notes

Text

Happy Solarpunk Aesthetic Week and Winter Solstice! ❄️

While we do celebrate here, we don't actually experience winter in my region, or any of the classic four seasons! The weather here is basically a coin toss between searing heat and torrential rain lol. So while I was musing over how to adapt a solarpunk aesthetic to a tropical lifestyle, I came up with this!

Lengthy explanations and chaotic ideas below:

Disclaimer: I am not a science-y person, so I'm not sure how any of these would technically work or what materials would go into making them. Hopefully one day someone could figure it out, but I'm just having fun sharing these ideas for now :)

-----

What works well both in harsh sunlight and heavy downpours, plus is already something that people here use everyday? Umbrellas! How cool would it be to have an umbrella that absorbs sunlight during the day, and turns it into a personal spotlight at night? Or perhaps it could absorb and store large amounts of rainwater, to be re-used later or released somewhere more useful?

My main inspiration for this is the bamboo. This plant already plays a huge role in our lives here -- culturally, economically, and from what I recently learned, ecologically too! Our region suffers from floods often, and bamboo can help to control the flow of water, for example through their roots providing a barrier against soil erosion, or their ability to store large amounts of water and release it gradually during drier seasons. (And that's just one of the many reasons why bamboos are awesome and solarpunky!) I thought it would be cool to have water stored in the 'bamboo nodes' of the umbrella shaft, which could then be detached and used individually, or as components in other tech!

I chose the Amazonian lily pad as the canopy design because 1) it looks big enough to cover a person, 2) it has a wide surface for solar panels to 'photosynthesize' energy, 3) its container-like shape looks as though it could hold rainwater like a funnel while it trickles into the shaft, and 4) it just looks really pretty! Realistically, this canopy might not be able to do everything at once, so I'm hoping for this tech to be modular and highly customizable -- as in, you could replace this 'lily pad' with something else that serves a different function! I did play around with some other designs, here they are hehe

Hibiscus: Our national flower! Have these bad boys growing in my yard so I thought why not. Not sure what functions it would have yet... perhaps the pistil could be a sensor for gathering weather data? Or maybe the anthers are little lights? Maybe it attracts BEES???

Mushroom: Not familiar with the fungi in my area yet so I went with the classic Amanita. Though now I'm kinda regretting because! Wouldn't it be so cool and lunarpunky to design it based on a bio-luminescent mushroom, so it would make sense for the umbrella to glow in the dark? AGH missed opportunities ;;

-----

Anyway while I was designing the umbrella I thought about giving the model a cool fit too, so tadaaa! A customizable pair of pants that can be worn as a shorts + half-skirt/sarong combo during hot weather, or extended to become a full pair of jeans during colder/rainy times! I used zippers as the connectors because they seem easy to sew on and I like the punky vibe it adds to the outfit. HOWEVER, I'm realising that might be inconvenient or way too time consuming for some people. Maybe buttons, magnets or hook-and-loop fasteners would be easier?

As for the shirt, idk that was just for fun. Maybe it changes colour/design based on the surrounding temperature?

-----

So YEAH that was my longer-than-expected idea dump for this week! Thank you for reading <3 If you have any thoughts or ways of expanding on these ideas please please please share them with me I'm just really excited to see what people think waaaaa!!! ok bye stay hydrated

#art#artists on tumblr#solarpunk#solarpunk aesthetic week#winter solstice#no im not late im not I M NOT#fashion#roobiedoodle#tl simmer#i did not intend for it to be her but she looks similar enough! should use my OCs as models more often actually

188 notes

·

View notes

Text

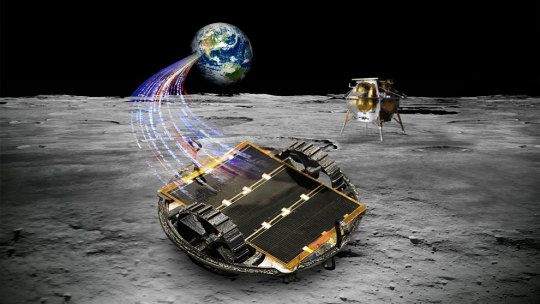

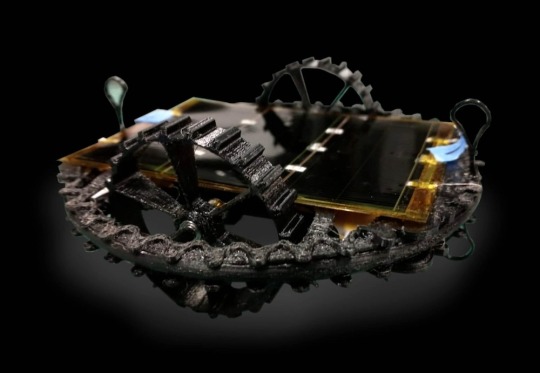

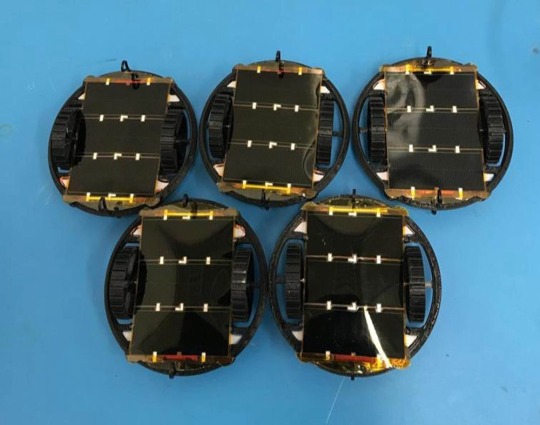

Colmena or "Hive" (2024) by Gustavo Medina Tanco plus a team of 200 students, from the National Autonomous University of Mexico (UNAM). This will be the first Mexican mission to the moon, carried aboard Astrobotic's Peregrine Lunar Lander launched on January 8th 2024, arriving on February 23rd. "The COLMENA Project, or “hive” in English, will involve a self-organized swarm of five robots, each weighing less than 60 grams and measuring just 12 centimeters in diameter, each equipped with a small solar panel. Inside the robots is a single, flexible PCB containing power conditioning, control, communications, monitoring, interface connector, arming and tripping, trip mechanism and grounding and bonding subsystems. The robots will autonomously navigate themselves to achieve electrical connectivity by joining their panels together to make a larger solar panel. The project will demonstrate how feasible it may be to build structures on planetary surfaces with robot swarms." – UNAM researchers to send micro-robots to the moon, The Robot Report, Brianna Wessling.

UPDATE: The Peregrine Lander began venting fuel soon after launch, making it difficult for Astrobotic to stabilise the spacecraft. The resulting loss of fuel means that it cannot attempt a moon landing.

20 notes

·

View notes

Text

Yay! The Drake is relocated to her new location in Nottingham. This is them coming into Shardlow Marina yesterday, which is where the new mooring is until April next year.

Sadly I am not great at making video and looking at things at the same time. Every time I look with my actual eyes, I lose control of the camera. Murderbot would be horrified.

The eel on the side really showing up here.

On this journey, the canal was blocked by a landslide for two months. The solar panel connector fell out and Son drained the batteries as a result. Also the bilge pump stopped working and the engine compartment filled with water. But apart from that it all went surprisingly smoothly.

Gongoozlers (people who walk down the towpath and look at the boats but otherwise have nothing to do with them) often say, wistfully, "it must be such an idyllic life!" "So relaxing!"

But the truth is it is definitely no life for the anxious. There is no end to what can go wrong, and the possibility of the boat filling with water, sinking, and you drowning in your bed can never fully be ruled out.

2 notes

·

View notes

Text

What material is PVDF?

PVDF is a very important high-performance engineering plastic. It has excellent chemical stability, heat resistance, weather resistance and mechanical properties, so it is widely used in various fields. The full name of PVDF is polyvinylidene fluoride, which is a thermoplastic fluoroplastic with excellent chemical corrosion resistance and electrical insulation properties. PVDF has attracted much attention due to its unique properties. Let’s take a closer look at what material PVDF is.

First, PVDF has excellent chemical resistance. PVDF has excellent acid and alkali resistance and good corrosion resistance to most organic solvents, acids, alkali and salts, so it is widely used in chemical pharmaceuticals, electroplating and other fields. In the chemical industry, PVDF is often used to manufacture pipes, pumps, valves and other equipment because it can effectively resist acid and alkali corrosion and ensure the stable operation of equipment.

Secondly, PVDF has excellent heat resistance. The melting point of PVDF is about 165°C, the long-term use temperature can reach 140°C, and the short-term use temperature is even higher. This allows PVDF to maintain stable performance in high temperature environments, so it is widely used in aerospace, automotive, electronics and other fields. For example, in the aerospace field, PVDF is often used to manufacture aircraft parts, such as pipes, connectors, etc., because it can maintain stable performance in high-temperature and high-pressure environments.

In addition, PVDF also has good weather resistance. PVDF has excellent UV resistance and anti-aging properties, so it can maintain stable performance for a long time in outdoor environments and is not prone to aging, discoloration, etc. Therefore, PVDF is often used to manufacture exterior wall panels in the fields of construction, billboards, solar energy, etc. , billboards, solar panels and other products to ensure their long-term stable performance in outdoor environments.

Finally, PVDF has excellent mechanical properties. PVDF has high strength and stiffness, as well as good toughness and impact properties, so it is widely used in machinery manufacturing, electrical equipment and other fields. In the field of machinery manufacturing, PVDF is often used to manufacture bearings, gears, seals and other products because it can maintain stable performance under high-speed, high-load working conditions.

To sum up, PVDF is a very important high-performance engineering plastic with excellent chemical stability, heat resistance, weather resistance and mechanical properties. Therefore, it is widely used in chemical industry, aerospace, construction, machinery manufacturing and other fields. It is believed that with the continuous advancement of technology, the application fields of PVDF will continue to expand, bringing more convenience and possibilities to all walks of life.

3 notes

·

View notes

Text

CNC Machining Manufacturers in India: Precision at Its Best

Deccanew is among the top CNC machining manufacturers in India, known for delivering high-precision, customized solutions for various industries. Whether you’re in the automotive, aerospace, electronics, or medical sector, our CNC machining services can meet your unique requirements. For expert CNC machining in India,

The adoption of CNC technology in India dates back to the late 20th century. Early on, Indian manufacturers recognized the potential of CNC machining in improving efficiency, accuracy, and productivity. Over the years, the industry has witnessed significant growth, driven by factors such as government initiatives, technological advancements, and increasing global demand.

Key Players in India's CNC Machining Landscape

India boasts a diverse range of CNC machining manufacturers, each with its unique strengths and specializations. Some of the prominent players include:

Large-Scale Manufacturers: These companies often operate in multiple locations, catering to a wide range of industries. They possess the capacity to handle large-scale projects and offer comprehensive solutions.

Specialized Manufacturers: These manufacturers focus on specific niches, such as aerospace, automotive, or medical components. They have in-depth knowledge and expertise in their respective fields.

Job Shops: Smaller-scale operations that specialize in custom machining jobs. They offer flexibility and can quickly adapt to changing customer requirements.

Applications of CNC Machining in India

CNC machining is essential for producing a wide variety of components across various industries. Some of the most common applications include:

Automotive: Engine blocks, transmission parts, brake components, and other critical components.

Aerospace: Aircraft parts, turbine blades, and precision components for aerospace systems.

Medical: Surgical instruments, implants, dental prosthetics, and medical devices.

Electronics: Precision parts for electronic components, such as circuit boards and connectors.

Energy: Components for wind turbines, solar panels, and other renewable energy systems.

Advantages of CNC Machining in India

Cost-Effectiveness: India offers competitive pricing for CNC machining services, making it an attractive option for businesses seeking to reduce costs.

Skilled Workforce: India has a large pool of skilled engineers and technicians with expertise in CNC machining.

Technological Advancements: Indian manufacturers have invested in modern CNC machines and software, ensuring high-quality output.

Flexibility: CNC machining allows for customization and rapid prototyping, making it suitable for both large and small-scale projects.

Quality Assurance: Indian manufacturers implement stringent quality control measures to guarantee the accuracy and precision of their products.

Challenges and Opportunities

Despite its many advantages, CNC machining in India faces certain challenges, including:

Competition: The global market for CNC machining India is highly competitive, requiring Indian manufacturers to continuously innovate and improve their offerings.

Skill Shortage: While India has a skilled workforce, there may be a shortage of specialized CNC machinists in certain areas.

Infrastructure: In some regions, infrastructure limitations can pose challenges for manufacturing operations.

However, these challenges also present opportunities for growth. By investing in training programs, improving infrastructure, and adopting advanced technologies, India can further strengthen its position in the global CNC machining market.

The Future of CNC Machining in India

The future of CNC machining India looks promising. With ongoing technological advancements, increasing automation, and a growing emphasis on precision engineering, the industry is poised for continued growth. Indian manufacturers are well-positioned to capitalize on emerging trends, such as additive manufacturing and Industry 4.0, to remain competitive and meet the evolving needs of their customers.

CNC machining has played a vital role in India's manufacturing sector. 1 The country's combination of skilled labor, competitive costs, and technological advancements has made it a preferred destination for businesses seeking precision-engineered components. 1 As India continues to invest in research and development, the future of CNC machining in the country looks bright

Discover leading CNC Machining Manufacturers in India with Deccanew. Offering top-notch CNC machining services for precise manufacturing. Contact us at 9657039991 for expert solutions.

Visit: https://www.deccanew.com/cnc-machining-india.php

Contact: 9657039991

0 notes

Text

120W Portable Solar Panel Review

Have you ever found yourself in the middle of a camping trip or a long hike, wishing you had a reliable power source to keep your devices charged? The “120W Portable Solar Panel with MC-4 Connector Foldable Solar Panel for Camping Folding Solar Panel Charger for Portable Power Station Laptops RV” from SOKIOVOLA might just be the solution you’ve been seeking.

Lightweight and Portable

Portability…

1 note

·

View note

Text

How do I disconnect MC4 solar connectors safely?

To safely disconnect MC4 solar connectors, first ensure the solar system is turned off to avoid electric shock. Use an MC4 disconnect tool or spanner specifically designed for these connectors. Insert the tool into the slots of the MC4 connectors, gently press, and pull the connectors apart. Avoid pulling the cables directly to prevent damage. Always inspect the connectors after disconnecting to ensure no wear or damage. If unsure, consult a professional for assistance.

0 notes

Text

Enhancing Electrical Connectivity with Electrical Lugs: A Comprehensive Overview

Electrical lugs are essential components in electrical systems used for connecting cables or wires to electrical equipment, devices, or other cables. These lugs play a crucial role in ensuring secure and reliable electrical connections, enabling efficient power transmission and distribution in various applications. This article delves into the functionality, types, applications, advantages, and installation methods of electrical lugs, highlighting their significance in modern electrical systems.

Functionality of Electrical Lugs:

Electrical lugs, also known as cable lugs or wire lugs, serve as interface connectors between cables or wires and electrical equipment. These lugs are typically made of conductive materials such as copper or aluminum and are designed to provide a secure and stable connection that facilitates the flow of electrical current. Electrical lugs come in various shapes and sizes to accommodate different wire gauges and types, ensuring compatibility with a wide range of electrical applications.

Types of Electrical Lugs:

Copper Lugs: Copper lugs are widely used for their excellent conductivity and corrosion resistance, making them ideal for applications requiring high electrical performance.

Aluminum Lugs: Aluminum lugs are lightweight and cost-effective alternatives to copper lugs, suitable for applications where weight and cost considerations are important.

Mechanical Lugs: Mechanical lugs feature a screw or compression mechanism for securing wires, offering a reliable and reusable connection that can withstand mechanical stress.

Solder Lugs: Solder lugs require soldering to create a permanent connection between the lug and the wire, providing a secure and low-resistance electrical joint.

Applications of Electrical Lugs:

Power Distribution Networks: Electrical lugs are commonly used in power distribution networks to connect cables to transformers, switchgear, and distribution panels, ensuring efficient power transmission.

Renewable Energy Systems: In solar power installations and wind turbines, electrical lugs are utilized to connect solar panels, inverters, and battery banks, facilitating the flow of renewable energy.

Industrial Equipment: Electrical lugs are essential in industrial machinery and equipment, providing secure connections for motors, control systems, and electrical enclosures.

Automotive Industry: In automotive applications, electrical lugs are used to connect electrical components, batteries, and wiring harnesses, ensuring reliable performance in vehicles.

Advantages of Electrical Lugs:

Reliable Connectivity: Electrical lugs offer a secure and stable connection between cables and electrical equipment, minimizing the risk of electrical faults and interruptions in power transmission.

Versatility: With a wide range of types and sizes available, electrical lugs are versatile components that can be used in various electrical applications, providing flexibility and adaptability.

Corrosion Resistance: Copper and aluminum lugs are resistant to corrosion, ensuring long-term performance and durability in diverse environmental conditions.

Ease of Installation: Electrical lugs are designed for easy installation, reducing downtime and labor costs associated with connecting cables to electrical equipment.

Installation Methods for Electrical Lugs:

Cable Preparation: Ensure that the cables are stripped, cleaned, and prepared properly before attaching the lugs.

Crimp or Compression: Use crimping tools or compression devices to secure the lug onto the cable, ensuring a tight and reliable connection.

Insulation: Insulate the connection using heat shrink tubing or insulating tape to protect against electrical hazards and ensure safety.

Testing: After installation, conduct testing to verify the integrity of the connection and ensure proper electrical conductivity.

Significance of Electrical Lugs in Electrical Systems:

Electrical lugs play a critical role in ensuring efficient power transmission, reliable connectivity, and safe operation of electrical systems. By providing secure connections between cables and electrical equipment, these components help minimize power losses, reduce downtime, and prevent electrical faults, thereby enhancing the overall performance and reliability of electrical networks.

In conclusion, electrical lugs are indispensable components in the electrical industry, offering secure connectivity, versatility, and ease of installation in various applications. With their importance in facilitating efficient power transmission and safe operation of electrical systems, electrical lugs continue to be essential components in modern power distribution networks, industrial equipment, renewable energy systems, and automotive applications. As the demand for robust and reliable electrical connections grows, the role of electrical lugs in ensuring secure and stable connections remains paramount in maintaining the integrity and efficiency of electrical networks.

0 notes