#stainless steel 316l

Text

In this blog, we will take a closer look at three of the most popular grades of stainless steel: 316, 316L, and 316Ti. These grades are known for their high strength, excellent resistance to corrosion and staining, and their ability to withstand high temperatures and pressure.

0 notes

Photo

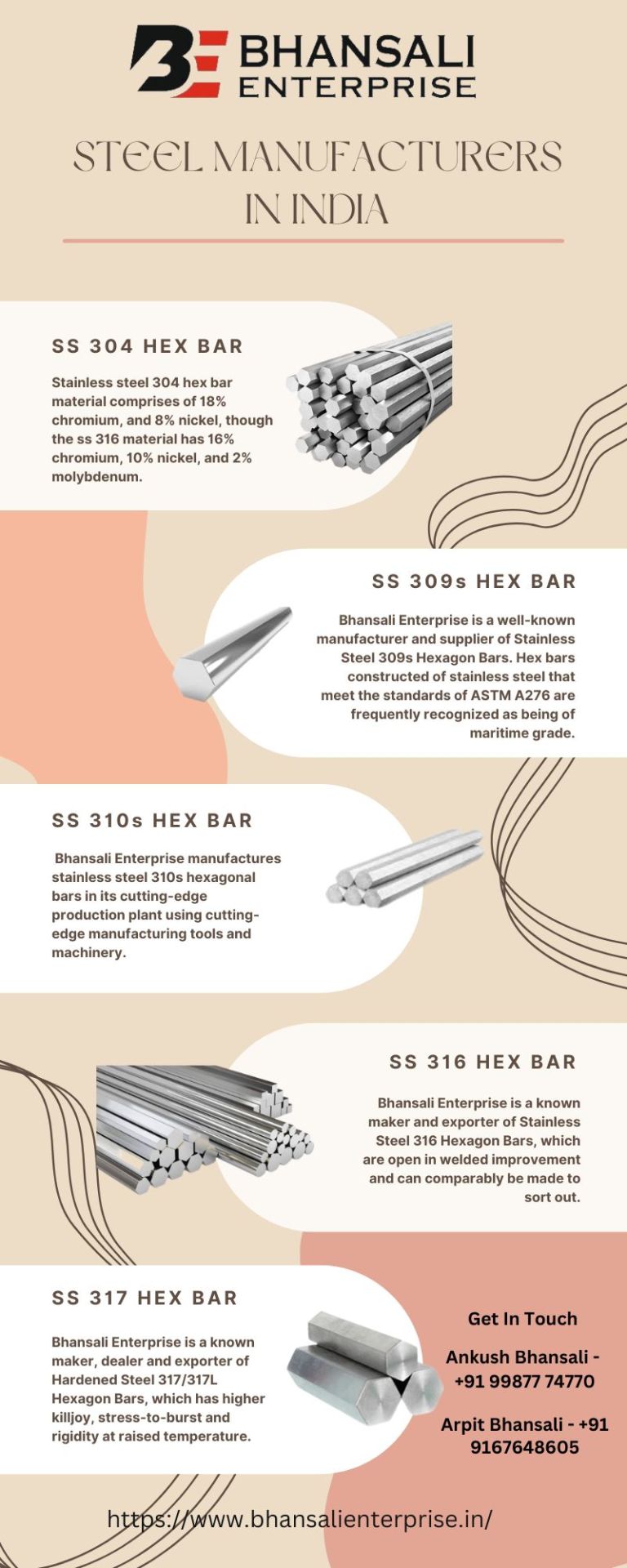

"SS Hex Bars Manufacturers & Exporter."

The Stainless Steel Hex Bars have improved strength and for that reason they are utilized in many applications. The extra strength is because of the mathematical state of the hex bars. On the off chance that the hex bar is made of austenitic treated steel, they have more prominent strength and higher erosion opposing properties. The Stainless Steel Hex Bars can be altered to various shapes and sizes as per the particular necessities. Bhansali Enterprise manufactures ASME SA276 Stainless Steel 309s Hex Bars using state-of-the-art tools and machinery to guarantee complete dimensional accuracy. Customers can choose from a variety of ASTM A276 SS 309s Hexagon Bars at Bhansali Enterprise. We produce 310 stainless steel hexagonal bars that fulfil national and international quality standards using only the best raw materials. Bhansali Enterprise is known in the business for the reliability of the goods we offer. Bhansali Enterprise is a known maker and exporter of Stainless Steel 316 Hexagon Bars, which are open in welded improvement and can comparably be made to sort out. SS 316 Hexagon Bar is utilized in blend process gear; tank trucks; propeller screws, and spent atomic fuel part recuperation. Bhansali Enterprise is a known maker, dealer and exporter of Hardened Steel 317/317L Hexagon Bars, which has higher killjoy, stress-to-burst and rigidity at raised temperature. SS 317 Hex Bars doesn’t respond to warm treatment, which can be additionally solidified by chilly working.

#stainless steel round bar#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#steel grades#round bar#polished stainless steel#stainless steel 304 price per kg in delhi#stainless steel manufacturers in india#flange manufacturer in india

0 notes

Text

Stainless Steel 316L Sheets Manufacturers in India

One of the top exporters, suppliers, and stockists of a variety of metal works is Shree Venktesh Wires and Steels Pvt Limited. We've been offering our services all around the world. SS 316L sheets are a part of our product line. In many different manufacturing industry divisions, this commodity is among the most sought-after steel grades. This product has an exceptional amount of nickel components, which offers remarkable corrosion-proofing characteristics. We collaborate with Jindal Stainless Limited to manufacture sheets made of stainless steel in grades 316 as well as additional stainless steel grades. To satisfy our customers' needs, we offer the best jindal ss sheet price and 316L sheets in a variety of sizes, dimensions, and thicknesses.

Characteristics of jindal ss 316L sheet:

Higher creep resistance

Excellent formability.

Rupture and tensile strength at high temperatures

Corrosion and pitting resistance

Standards of Jindal ss 316L sheets:

Standards: ASTM A240 / ASME SA240

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness: 4mm-100mm

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, hairline, sand blast, Brush, etching, Hot rolled coil (HR), Cold rolled coil (CR), SATIN (Met with Plastic Coated), etc

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Form: Coils, Foils, Rolls, Plain Coil, Shim Coil, strips, Flats, Blank (Circle), Ring (Flange), etc.

Applications of Jindal ss 316L sheets:

A wide range of applications and industries use jindal stainless steel 316 sheets.

Below are a few of them:

Petrochemical Industry

Oil and Gas Industry

Chemical Industry

Power Plant Industry

Energy Industry

Pharmaceuticals Industry

Pulp & Paper industry

Food Processing Industry

Aerospace Industry

Refining Industry and many more.

Uses and Purpose of Jindal ss 316L sheets:

Jindal ss 316L sheets have a high tolerance to corrosion, outstanding resistance to oxidation, and exceptional grade strength thanks to their high chromium and nickel content. The maximum melting point of stainless steel 316L sheets is 1399 degrees Celsius (or 2550 degrees Fahrenheit). They have incredible yield and tensile strength ranges. Its range of elongation is the widest, at 35%. They also contain the elements carbon, manganese, silicon, phosphorus, sulfur, chromium, molybdenum, nitrogen, and nickel because they are a member of one of the 300 families.

Jindal steel dealers provide perforated sheets made of Jindal ss 316L sheets that are extensively used in the welding, electrochemical, mechanical, and construction industries. Hot rolled sheets made of Jindal ss 316L sheets are specifically created to have features like unprecedentedly high withstanding resistance to corrosion brought on by liquids, hardness, and temperature fluctuation resistance.

#Stainless Steel 316L Sheets Manufacturers in India#Stainless Steel 316L Sheets Suppliers in India#Stainless Steel 316L Sheets Stockists in India#Stainless Steel 316L Sheets Exporters in India

0 notes

Text

Stainless steel 316l pipes & tubes manufacturers in saudi arabia | Bhagya laxmi Industrial

Bhagya Laxmi Industrial specializes in the manufacturing of high-quality stainless steel 316L pipes and tubes in Saudi Arabia. Renowned for their exceptional corrosion resistance and durability, these products are ideal for various industrial applications, including chemical processing, marine environments, and food production. The company's commitment to precision engineering and adherence to international standards ensures that clients receive reliable and long-lasting solutions tailored to their specific needs. With a focus on innovation and customer satisfaction, Bhagya Laxmi Industrial stands out as a trusted partner in the stainless steel industry.

0 notes

Text

Stainless Steel 316/316l Round Bars Manufacturer in Saudi Arabia | Anand steels

Anand steels specializes in the manufacturing of high-quality Stainless Steel 316/316L Round Bars in Saudi Arabia, designed to meet the rigorous demands of various industrial applications. These round bars are crafted from premium-grade stainless steel, ensuring exceptional corrosion resistance, durability, and strength. Ideal for use in marine environments, chemical processing, and food production, our products adhere to international standards, providing reliability and performance. With a commitment to excellence, we offer a range of sizes and finishes to cater to diverse customer requirements, ensuring timely delivery and superior service.

0 notes

Text

#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Hastelloy C276 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Text

#Stainless Steel 316L Round Bars#Stainless Steel 316L Round Bars Suppliers#Stainless Steel 316L Round Bars Manufacturer#Stainless Steel 316L Round Bars Exporter#Stainless Steel 304 Round Bars#Stainless Steel 304 Round Bars Suppliers#Stainless Steel 304 Round Bars Exporter#Stainless Steel 304 Round Bars Manufacturer

0 notes

Text

Comparing Different Grades of Stainless Steel: 304 vs. 316 vs. 316L

Stainless metal is generally composed of iron, with at least 10.5% chromium content cloth, which works as a protective oxide layer that prevents corrosion. Different grades of stainless steel vary through their alloy composition, influencing their mechanical properties, corrosion resistance, and packages. When deciding on among 304, 316, and 316L stainless-steel grades, recording their properties is vital for making an informed preference.

Understanding Grade 304 Stainless Steel

Grade 304 is the most common sort of stainless steel and money is owed for more than 50% of the area’s stainless-steel manufacturing. It is also referred to as 18/8 stainless steel because of its composition of 18% chromium and 8% nickel. This composition offers first-rate corrosion resistance and ease of fabrication, making it suitable for a huge type of program.

Key Properties:

Corrosion Resistance: Grade 304 stainless steel gives accurate resistance to quite a few environmental factors and is extensively implemented in applications in which the risk of corrosion is mild.

Mechanical Strength: It has immoderate tensile power, making it appropriate for structural packages.

Weldability: Grade 304 is noted for its ease of welding and forming.

Cost Efficiency: It is much less expensive in contrast to 316 and 316L, making it a rate-effective desire for general-reason packages.

Common Applications of Grade 304:

Kitchen devices (sinks, refrigerators, cooking utensils)

Chemical packing containers

Automotive and aerospace systems

Building facades and architectural trim

Limitations of Grade 304:

While 304 stainless steel is a wonderful all-purpose cloth, it does have boundaries, particularly at the same time as exposed to chloride environments. In such situations, the cloth is prone to pitting and crevice corrosion, decreasing its lifespan.

This leads us to the subsequent grade in our Stainless Steel Grades Comparison: 304 vs. 316 vs. 316L.

Understanding Grade 316 Stainless Steel

Grade 316 stainless steel builds upon the advantages of 304 however enhances its trendy traditional overall performance in greater corrosive environments by means of a long facet of 2-3% molybdenum. This small addition drastically improves its corrosion resistance, particularly in the direction of chlorides and specific commercial solvents.

Key Properties:

Superior Corrosion Resistance: The presence of molybdenum complements resistance to pitting, crevice corrosion, and merciless chemical environments, making it notable for marine and coastal programs.

High-Temperature Resistance: 316 can resist higher temperatures, making it suitable for packages related to warmth publicity.

Versatility: It has a massive shape of applications, from medical devices to marine hardware.

Common Applications of Grade 316:

Marine environments (boat fittings, dock hardware)

Chemical processing and storage tool

Medical implants and surgical equipment

Food and beverage production device

Limitations of Grade 316:

The primary disadvantage of 316 stainless steel is its price. It is higher priced than 304 due to the addition of molybdenum. However, at the same time as superior corrosion resistance is needed, the benefits often outweigh the greater price.

Introduction to Grade 316L Stainless Steel

316L is a low-carbon model of 316 stainless steel. The “L” stands for “low carbon,” which means that it has the most carbon content material of 0.03%. This small exchange makes a large distinction in positive applications.

Key Properties:

Improved Weldability: The decreased carbon content material fabric minimizes carbide precipitation sooner or later of welding, decreasing the risk of corrosion at weld joints.

Corrosion Resistance: While 316 and 316L have similar corrosion resistance, 316L’s lower carbon content material fabric makes it greater suitable for environments wherein welding is worried.

Durability: The mechanical houses of 316L are barely lower than 316, but it gives advanced resistance to sensitization (grain boundary carbide precipitation).

Common Applications of Grade 316L:

Pharmaceutical and scientific industries

Chemical processing environments

Welded systems in marine applications

Oil and gasoline tool

Limitations of Grade 316L:

Although 316L is terrific for welded programs and corrosive environments, it's far typically more expensive than each 304 and 316. Additionally, its mechanical strength is slightly decreased than that of 316, making it a whole lot much less appropriate for excessive-pressure environments.

304 vs. 316 vs. 316L: Detailed Stainless Steel Grades Comparison

Recognize how those grades compare, permits to spoil down their key variations.

Corrosion Resistance:

304 Stainless Steel: Good regular corrosion resistance however prone to pitting in chloride environments.

316 Stainless Steel: Superior resistance to pitting and crevice corrosion because of the addition of molybdenum.

316L Stainless Steel: Similar corrosion resistance to 316 however excels in welded applications due to decreased carbide precipitation.

Mechanical Strength:

304 Stainless Steel: High tensile electricity, suitable for structural applications.

316 Stainless Steel: Slightly stronger than 304, supplying higher regular typical overall performance in excessive-strain environments.

316L Stainless Steel: Slightly decreased strength than 316 however with higher resilience in corrosive environments.

Weldability:

304 Stainless Steel: Easily welded and commonplace, however also can be thru corrosion at welded joints if not nicely dealt with.

316 Stainless Steel: Better relevant for immoderate-temperature welding however even though it calls for proper put up-weld treatment.

316L Stainless Steel: Ideal for welding, as its low carbon content material cloth fabric reduces the danger of carbide precipitation.

Cost:

304 Stainless Steel: Most charge-effective opportunity, suitable for cutting-edge-day-reason packages.

316 Stainless Steel: More high priced due to molybdenum, ideal for especially corrosive environments.

316L Stainless Steel: Slightly greater pricey than 316, especially valuable in environments requiring immoderate weldability and corrosion resistance.

Choosing the Right Grade for Your Application

When considering the Stainless Steel Grades Comparison of 304 vs. 316 vs. 316L, deciding on the super grade is based upon elements like surroundings, budget, and unique necessities.

1. General-Purpose Applications:

For duties in which corrosion isn't a massive state of affairs, which encompass kitchen gadgets or fundamental structural additives, 304 is often the remarkable choice. It is rate-powerful and bendy, making it first-rate for non-important packages.

2. Corrosive Environments:

If the environment includes exposure to chlorides, harsh chemical materials, or saltwater, 316 is the recommended grade. Its introduced molybdenum content material fabric presents more appropriate corrosion resistance, making it appropriate for disturbing situations like coastal installations or chemical processing flora.

3. Welded Structures:

For welded structures that require excessive resistance to corrosion, 316L is frequently the popular alternative. Its low carbon content material minimizes the threat of carbide precipitation, ensuring an extended lifespan in environments like pharmaceutical production or meal processing.

Real-World Industry Usage

Companies like Vishal Tube Industries apprehend the importance of selecting the proper stainless steel grade for their applications. Engaged in the production of Stainless Steel Seamless Tubes, Welded Tubes, and U-Tubes, Vishal Tube Industries caters to a big range of industries, from chemical processing to marine engineering.

Their current facilities make sure that they will be able to produce stainless-steel products that meet stringent tremendous necessities. By offering a number of grades, they empower clients to pick out the right fabric for their precise desires. Whether it’s 304 for famous applications or 316L for specialized obligations, Vishal Tube Industries ensures top-terrific answers.

Conclusion

When evaluating Stainless Steel Grades: 304 vs. 316 vs. 316L, it’s clear that every grade has its particular strengths. Grade 304 remains a famous, charge-effective opportunity for fashionable programs. Grade 316 gives advanced corrosion resistance for harsh environments, at the same time as grade 316L gives extra average standard performance in welded systems.

In industries wherein material choice is crucial to conventional overall performance and sturdiness, it’s crucial to understand those variations. By considering factors which include corrosion resistance, mechanical electricity, weldability, and fee, you could decide which stainless steel grade exceptionally fits your undertaking’s requirements.

Vishal Tube Industries, with its willpower to be first-rate and innovative, offers a great shape of stainless steel merchandise to fulfill the numerous desires of worldwide industries. Their expertise in production guarantees that irrespective of which grade you select, you get maintenance of a product that exceeds expectancies.

Understanding the variations among those stainless steel grades not only helps in making a knowledgeable choice but also ensures that your projects have the sturdiness and reliability needed to achieve achievement. Whether you select 304, 316, or 316L, the proper software is the critical issue to maximizing regular fashionable overall performance.

0 notes

Text

#Super Duplex Steel UNS S32760 Round Bars#Super Duplex Steel UNS S32760 Round Bars supplier#Super Duplex Steel UNS S32760 Round Bars exporter#Monel 400 Round Bars#Monel 400 Round Bars supplier#Monel 400 Round Bars exporter#Stainless Steel 304 Round Bars#Stainless Steel 304 Round Bars Suppliers#Stainless Steel 304 Round Bars Exporter#Stainless Steel 304 Round Bars Manufacturer#Stainless Steel 316L Round Bars#Stainless Steel 316L Round Bars Suppliers#Stainless Steel 316L Round Bars Manufacturer#Stainless Steel 316L Round Bars Exporter

0 notes

Text

Stainless Steel 316L Perforated Flat Bars are durable metal components crafted from high-quality stainless steel alloy. Featuring evenly spaced perforations along their length, they facilitate enhanced ventilation, drainage, or filtration.

These flat bars come in various dimensions, customizable to specific project requirements, including thickness, width, and length. Surface finishes like polished, brushed, or mill finish cater to both functional and aesthetic preferences.

#Stainless Steel 316L Perforated Flat Bars#Stainless Steel 316L Perforated Flat Bars Manufacturers#Stainless Steel 316L Perforated Flat Bars Suppliers#Stainless Steel 316L Perforated Flat Bars Stockists

0 notes

Text

Jay Steel-The Ultimate Guide to the Manufacturing Process Stainless 316L Sheet, Plates

Stainless metal 316L is a flexible and sought-after fabric prized for its top notch corrosion resistance, electricity, and formability. It's extensively used at some stage in various industries, from chemical processing and construction to food and beverage production. But how precisely are the ones sheets and plates introduced to life? This weblog delves into the charming international of Stainless Steel 316L Sheet Manufacture exploring each critical step:

1. Raw Material Selection:

The journey starts off with choosing wonderful uncooked substances. Reputable producers, like the ones you'll find at Inshora Group, a main Stainless Steel 316L Sheets Stockist In India, use particular grades of chromium, nickel, molybdenum, and unique elements to collect the preferred properties of 316L stainless steel.

2. Melting and Refining:

The selected raw substances are meticulously weighed and measured earlier than being loaded into an electric powered arc furnace or an induction furnace. Intense heat melts the combination, and precise controls ensure a homogeneous molten metal. During this stage, impurities are eliminated via refining techniques, resulting in a smooth and regular melt.

3. Casting:

The molten steel is then poured into a mildew hollow space designed for the preferred very last form – each a thick slab for plates or a thinner sheet shape. As the metallic cools and solidifies, it takes the form of the mold.

4. Hot Rolling:

The strong slab or sheet is reheated to a particular temperature, making it greater malleable. It's then surpassed between a couple of rollers below huge pressure, step by step lowering its thickness and enhancing its grain shape. This warm rolling gadget plays a critical function in shaping the very last product and improving its mechanical homes.

5. Annealing:

After warm rolling, the sheet or plate undergoes annealing, a warmness treatment gadget that entails controlled heating and next sluggish cooling. Annealing softens the metal, improves its ductility (the functionality to be deformed without breaking), and relieves any inner stresses added at some level within the rolling method.

6. Cold Rolling (Optional):

For applications requiring very specific thicknesses and advanced surface finishes, cold rolling is probably employed. Here, the sheet or plate is rolled at room temperature to attain the favored final dimensions. Cold rolling imparts a smoother surface end and enhances the fabric's power but reduces its ductility in comparison to hot-rolled merchandise.

7. Pickling and Passivation:

Pickling entails cleansing the floor of the sheet or plate with the aid of immersing it in an acidic manner to eliminate any floor contaminants like oxides or mill scale left inside the again of the rolling approach. Passivation follows, wherein the sheet is treated with a moderate acid way to form a thin chromium oxide layer at the ground. This chromium oxide layer is what gives 316L stainless steel its tremendous corrosion resistance.

8. Cutting and Inspection:

The finished sheets or plates are then cut to specific sizes using numerous techniques like shearing, sawing, or waterjet decreasing. Finally, the products undergo rigorous nice manipulation inspections to make sure they meet the desired specs for thickness, surface end, and mechanical houses.

Stainless Steel 316L Sheets and Plates: A Reliable Choice

By know-how the manufacturing gadget, you have a deeper appreciation for the great and overall performance of 316L chrome steel sheets and plates. As a distinguished Stainless Steel 316L Sheets Stockist, Inshora Group prioritizes the use of excessive-grade substances and adhering to stringent production practices. We offer a significant choice of 316L stainless-steel sheets and plates in numerous thicknesses and sizes, without a problem to be had to cater to your project requirements.

Looking for a Reliable 316 Stainless Steel Plates Exporter?

Inshora Group is your one-prevent shop for all of your 316L chrome steel goals. We offer:

Unmatched Quality: Our 316L sheets and plates are synthetic, use of pinnacle-grade substances and meet the very first-rate enterprise standards.

Extensive Inventory: We keep a massive stock of numerous thicknesses and sizes to fulfill your specific mission necessities.

Competitive Prices: We are dedicated to supplying aggressive pricing on all our merchandise.

Expert Support: Our knowledgeable institution is right here to assist you in choosing the right 316L stainless steel product in your application and answer any questions you may have.

At Inshora Group, a leading Stainless Steel 316L Sheets Stockist In India, we pass beyond simply providing the material. Our team of professionals has in-depth knowledge of the manufacturing tactics and various grades of 316L stainless-steel. We can help you in selecting the right product for your software, thinking about factors like floor finishes, strength necessities, and enterprise regulations.

Contact Inshora Group in recent times! We'll be glad to help you locate the great 316L stainless-steel sheets or plates for your next task.

0 notes

Text

#Stainless Steel 316/316L/316Ti Forged Rings Manufacturers#Stainless Steel 316/316L/316Ti Forged Rings Suppliers#Stainless Steel 316/316L/316Ti Forged Rings Stockists#Stainless Steel 316/316L/316Ti Forged Rings Exporters#Stainless Steel 316/316L/316Ti Forged Rings Manufacturers In India#Stainless Steel 316/316L/316Ti Forged Rings Suppliers In India#Stainless Steel 316/316L/316Ti Forged Rings Stockists In India

0 notes

Photo

"Stainless Steel 316 Wires."

Bhansali Enterprise is a well-known distributor and stockiest of Stainless Steel 316 Wires , which is essentially a standard carbon 316 type with titanium stabilization. It is similar in principle to the titanium stabilization of the 304. Grade 316 Wires is a titanium-stabilized version of Type 316 molybdenum-bearing austenitic stainless steel. Austenitic Stainless Steel Grade 316 Wires is referred to as the stabilized grade of the 316 wires types, and also one of the two 316 wires stainless steel that is recommended for higher temperature situations. We, Bhansali Enterprise designed very high quality of these SS 316 Wires shows some excellent Properties due to its Titanium addition that can be used at elevated sensitization temperatures. Alloy 316 Wires also offer higher creep, stress rupture, and tensile strength at elevated temperatures. This grade contains a small amount, typically a small percent of titanium. While it still possesses many of the characteristics of other 316 wires grades, the addition of titanium allows Stainless Steel wires are to be protected from precipitation at elevated temperatures, even with prolonged exposure.

#stainless steel wire#wire manufacturers#stainless steel 201 cu wire manufactures in mumbai#stainless steel 316l#ss 316 chemical composition#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#manufacturer of stainless steel in india

0 notes

Text

Stainless Steel 316l Pipe Manufacturers in USA

Looking for top-notch Stainless Steel 316L Pipe Manufacturers in USA? Look no further than Siddhigiri Tubes. Renowned for their exceptional quality and durability, their stainless steel pipes meet the highest industry standards. Whether you need pipes for industrial, commercial, or residential applications, we provides unparalleled craftsmanship and reliable delivery times. Trust in their expertise to ensure your projects are equipped with the best materials available in the market. Choose them for your stainless steel 316L pipe needs and experience the difference in quality and service.

1 note

·

View note

Text

Stainless Steel 316l Pipes/Tubes Manufacturer, Supplier in Oman | Bhagya laxmi industrial

Bhagya laxmi industrial is top Stainless Steel 316l Pipes/Tubes Manufacturer, Supplier in Oman. Our company is a leading exporter of high-quality Stainless Steel 316L Pipes & Tubes to Oman. These pipes and tubes are made from durable and corrosion-resistant stainless steel, ensuring long-lasting performance in various industrial applications. With a focus on quality and reliability, our products meet international standards and are available in different sizes and specifications to meet the diverse needs of our customers in Oman. Trust us for all your stainless steel pipe and tube requirements.

0 notes

Text

Nascent Pipe & Tubes is one of the prominent stockiest and dealer for Stainless Steel 316 / 316L Fasteners (Bolts / Nuts), which is being offered at affordable rates and in customized options for our esteemed clients. The welded corners of Stainless Steel 316 Hex Head Bolts typically rust whereas the bulk of the exposed stainless is untouched. Stainless Steel 316L Hex Head Nuts has lower carbon such that when welded the chromium carbide that forms does not deplete the chromium to the point where the corrosion of the stainless is deleteriously impacted.

#Stainless Steel 316 / 316L Bolt/Nut Manufacturers In India#Stainless Steel 316 / 316L Bolt/Nut Suppliers In India#Stainless Steel 316 / 316L Bolt/Nut Stockists In India#Stainless Steel 316 / 316L Bolt/Nut Exporters In India#manufacturers#exporters#trends

0 notes