#flange manufacturer in india

Text

Top-Quality Pipe Fittings by Pearl Pipe Fittings

Pearl Pipe Fittings is a reputed Pipe Fittings Manufacturer in India specializing in various comprehensive solutions. These products are carbon steel fittings and flanges used in severe service applications. Pearl is also committed to precision engineering, using only the finest materials to lead industries including oil/gas construction.We are also the best Flange Manufacturer in India and CS Flanges Manufacturers in India

Contact us

Website: https://pearlpipefittings.com

Call us at +91 91723 33437

Product Source: Carbon Steel Pipe Fittings Manufacturer in India and Copper Nickel Flange Manufacturer in India

You may also like: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

#carbon steel pipe fittings manufacturer in india#pipe fittings manufacturer in india#flange manufacturer in india#cs flanges manufacturers in india#cristiano ronaldo#stainless steel flanges manufacturer in india#copper nickel flange manufacturer in india#business#industrial#ss pipe fittings manufacturers in india

0 notes

Text

Advantages of Sourcing Pipes and Tubes from Manufacturers in India

Sagar Steel Corporation is a leading Pipes & Tubes Supplier in India. Pipes and Tubes Manufacturers in India are leaders in the manufacturing industry, providing the foundation for a variety of sectors. India has emerged as a major player in the global manufacturing sector, and pipes and tubes are no exception. For those looking to source these products, India offers a number of advantages, but it's important to weigh them against potential drawbacks to make an informed decision.

Cost-effectiveness: One of the biggest advantages of sourcing pipes and tubes from India is the competitive pricing.expand_more Labor costs in India are generally lower than in many developed countries, which can translate to significant savings.expand_more Additionally, the Indian government offers various incentives for manufacturers, further reducing production costs.

Manufacturing Expertise: The Indian pipe and tube industry boasts a well-established infrastructure and a skilled workforce. Manufacturers have expertise in producing a wide range of pipes and tubes, catering to various industries like construction, automotive, and oil & gas.expand_more They are adept at meeting international quality standards, ensuring you receive products that meet your specifications.

Diverse Product Range: Indian manufacturers offer a vast selection of pipes and tubes in various materials, including steel, copper, PVC, and more. You'll find products in different sizes, shapes, and thicknesses to suit your specific needs. This one-stop-shop approach can simplify your sourcing process.

Challenges to Consider:

Distance and Logistics: Depending on your location, transporting pipes and tubes from India can add to the overall cost. Lead times can also be longer due to factors like customs clearance and ocean freight. Careful planning and negotiation with logistics providers are crucial to mitigate these challenges.

Quality Control: While India has a strong manufacturing base, ensuring consistent quality can be a concern. It's vital to partner with reputable manufacturers with a proven track record of quality control. Visiting their facilities or hiring a third-party inspection agency can provide peace of mind.

Minimum Order Quantities: Some Indian manufacturers may have minimum order quantities (MOQs) that might be too high for smaller businesses. Negotiating or exploring options with smaller manufacturers can be helpful.

Communication and Cultural Differences: Effective communication can be a hurdle when working with international suppliers. Clear communication regarding specifications, timelines, and expectations is essential. Building a strong working relationship with your supplier can help bridge any cultural gaps.

Impact Considerations:

Environmental Impact: Manufacturing processes can have an environmental impact. Researching the sustainability practices of potential suppliers is important. Look for manufacturers who use recycled materials or have energy-efficient production processes.

Social Impact: Labor practices are another consideration. Ensure your chosen supplier adheres to ethical labor standards and fair wages.

Premier Pipes and Tubes - Crafted by the Best in India

Explore the vibrant world of Pipes and Tubes Suppliers, where precision meets innovation. Discover how these industry leaders craft quality products, shaping the infrastructure for a sustainable future. Sagar Steel Corporation is one of the greatest Pipes and Tubes Suppliers in India. In the field of manufacturing excellence Pipes and Tubes Manufacturers in India stand tall, crafting the backbone of various industries.

In the dynamic landscape of India's industrial prowess, Pipes and Tubes Manufacturers play a pivotal role in shaping the nation's progress. From the seamless flow of water to the robust structures of buildings, these manufacturers are the unsung heroes behind the scenes. Let's delve into the intricate world of Pipes and Tubes manufacturing in India, where excellence is not just a goal but a tradition.

Pipes and Tubes Manufacturer in India have earned accolades and recognition on both the national and global stages. Awards serve as a testament to their commitment to excellence and innovation. The strategic global presence of these manufacturers ensures that their products reach and benefit diverse industries around the world.

As an industry pioneer, we believe that our unique products, such as Round Bars Manufacturer and Fasteners Manufacturer in India, should thoroughly benefit our clients.

Sourcing pipes and tubes from India can be a strategic decision, offering cost savings, a wide product range, and a skilled manufacturing base. However, it's important to weigh the potential challenges of distance, quality control, and minimum order quantities. Carefully considering these factors alongside your specific needs and priorities will help you make an informed decision. By partnering with a reputable Indian manufacturer and establishing clear communication, you can leverage the many advantages this market offers.

For More Detail

Website: sagarsteel.net

Product: Pipes and Tubes Supplier in IndiaOther Product: Flange Manufacturer In India.

#Pipes and Tubes Manufacturers in India#Pipes and Tubes Manufacturers#Flange Manufacturer In India#Pipes and Tubes

0 notes

Photo

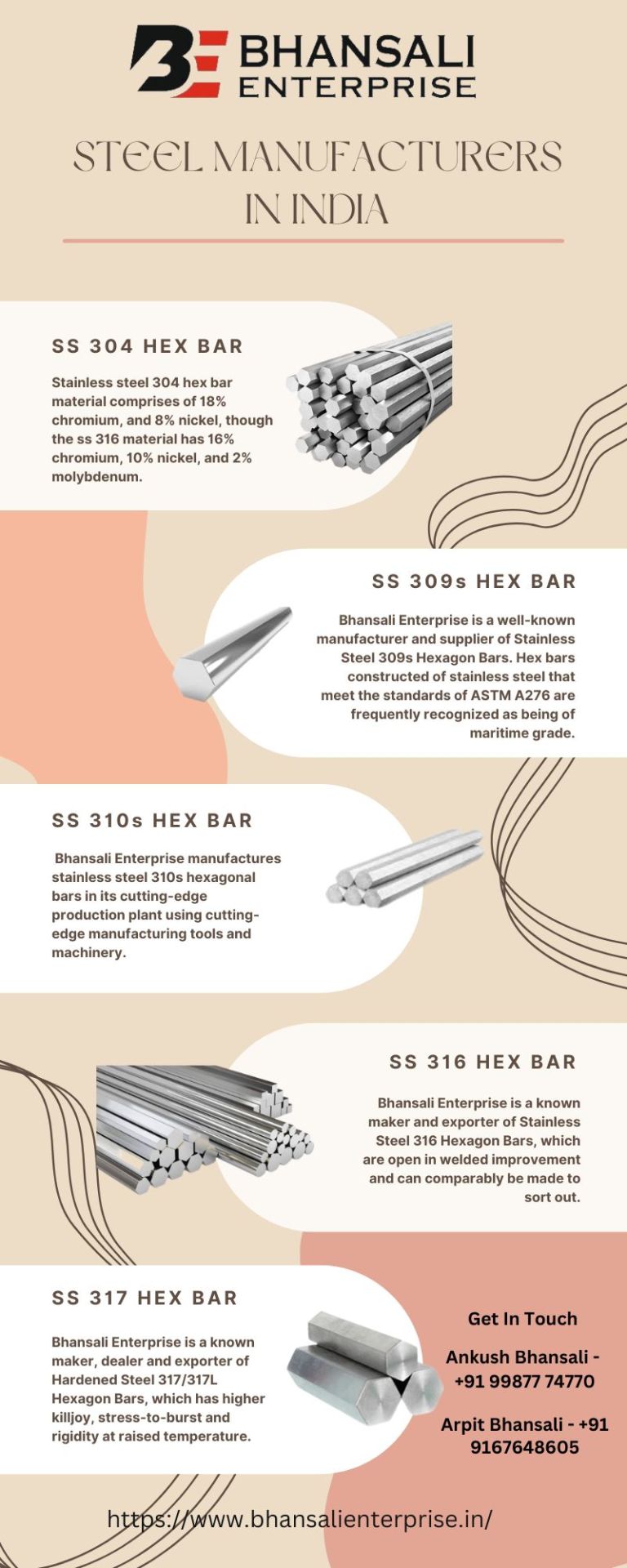

"SS Hex Bars Manufacturers & Exporter."

The Stainless Steel Hex Bars have improved strength and for that reason they are utilized in many applications. The extra strength is because of the mathematical state of the hex bars. On the off chance that the hex bar is made of austenitic treated steel, they have more prominent strength and higher erosion opposing properties. The Stainless Steel Hex Bars can be altered to various shapes and sizes as per the particular necessities. Bhansali Enterprise manufactures ASME SA276 Stainless Steel 309s Hex Bars using state-of-the-art tools and machinery to guarantee complete dimensional accuracy. Customers can choose from a variety of ASTM A276 SS 309s Hexagon Bars at Bhansali Enterprise. We produce 310 stainless steel hexagonal bars that fulfil national and international quality standards using only the best raw materials. Bhansali Enterprise is known in the business for the reliability of the goods we offer. Bhansali Enterprise is a known maker and exporter of Stainless Steel 316 Hexagon Bars, which are open in welded improvement and can comparably be made to sort out. SS 316 Hexagon Bar is utilized in blend process gear; tank trucks; propeller screws, and spent atomic fuel part recuperation. Bhansali Enterprise is a known maker, dealer and exporter of Hardened Steel 317/317L Hexagon Bars, which has higher killjoy, stress-to-burst and rigidity at raised temperature. SS 317 Hex Bars doesn’t respond to warm treatment, which can be additionally solidified by chilly working.

#stainless steel round bar#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#steel grades#round bar#polished stainless steel#stainless steel 304 price per kg in delhi#stainless steel manufacturers in india#flange manufacturer in india

0 notes

Text

Everything about flange and their various types

What exactly are Flange?

A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Types of Flanges

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flange have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

Dalmine Flanges is a well-known Flange Manufacturer in India.We are one of the largest Flange Manufacturers. Our flanges can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

0 notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Specification and Uses of Forged Fittings

Top Quality Forged Fittings Manufacturers in India

Regent Steel Inc is the leading Forged Fittings Manufacturers in India. Our products, which are made in accordance with international standards, are extensively used by the petrochemical, chemical, oil and gas, and other industries. We are the top Molybdenum Rod Manufacturers and Carbon Steel Flanges Manufacturers in India.

Forged Fittings Specification

Material: Stainless steel, carbon steel, alloy steel, etc.

Size Range: 1/8" to 4" or larger

Pressure Ratings: 3000#, 6000#, 9000# or custom

Types: Elbows, tees, couplings, unions, crosses, caps, plugs, reducers, etc.

Design Standards: ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, etc.

Applications of Forged Fittings

Water Treatment Plants

Fertilizers Industry

Marine & Industrial

Oil and Gas Industry

Aircraft Industry

India’s leading Flanges Manufacturer

Regent Steel Inc is a top Forged Fittings Manufacturers in India.We appreciate how crucial having trustworthy and durable flanges are for your piping systems, thus we are committed to offering flanges that adhere to the highest standards of quality and performance. We are the top Flange Manufacturer in Pune and Flange Manufacturer in Kolkata.

Contact us:

Website: forgefittings.com

Mail: [email protected]

Product source: Forged Fittings Manufacturers in India and Carbon Steel Flanges Manufacturers in India.

You may also like: Flanges Manufacturers in India

#Forged Fittings Manufacturers in India#Forged Fittings Manufacturers#Carbon Steel Flanges Manufacturers#Carbon Steel Flanges Manufacturers in India#Flanges Manufacturers in India#Molybdenum Rod Manufacturers

3 notes

·

View notes

Text

SS Flange End Ball Valve Manufacturer from Ahmedabad - Gold Techno Casting

Gold Techno Casting Company is a leading manufacturer of high-quality ball valves in Ahmedabad, Gujarat. Our range includes SS flange end ball valves, stainless steel ball valves, and SS gate valves, perfect for various industrial applications. Contact us today!

Google Map:--> https://maps.app.goo.gl/LUnHirgkXMPNPJ1V7

SS Flange End Ball Valve Manufacture in Ahmedabad, Ball Valve, SS Flange End Ball Valve, Ball Valve Manufacture in Ahmedabad, SS Ball Valve, Stainless Steel Flanged Valve, SS Gate Valves, Stainless Steel Globe Valve, Kheda, Ahmedabad, Gujarat, India, Gold Techno Casting

#SS Flange End Ball Valve Manufacture in Ahmedabad#Ball Valve#SS Flange End Ball Valve#Ball Valve Manufacture in Ahmedabad#SS Ball Valve#Stainless Steel Flanged Valve#SS Gate Valves#Stainless Steel Globe Valve#Kheda#Ahmedabad#Gujarat#India#Gold Techno Casting

0 notes

Text

Inconel 718 Flanges Exporters

Inconel 718 Flanges

Inconel 718 is a nickel-based superalloy widely known for its superior strength, corrosion resistance, and high-temperature performance. Flanges made from Inconel 718 are used in some of the most demanding environments, including aerospace, chemical processing, and power generation industries. Due to their robust properties, Inconel 718 flanges can withstand extreme pressure and temperature conditions while maintaining excellent mechanical performance. These flanges play a crucial role in connecting pipes, valves, and other components in piping systems while ensuring a leak-proof seal, making them essential for critical applications.

Key Properties of Inconel 718 Flanges

Inconel 718 flanges offer several unique properties that set them apart from other materials:

High-Temperature Resistance: Inconel 718 can withstand temperatures up to 1300°F (700°C) without losing its mechanical integrity. This property makes it ideal for high-heat applications.

Corrosion Resistance: The alloy exhibits exceptional resistance to corrosion, especially in harsh environments where chemicals, acids, and high salinity are present.

Excellent Mechanical Strength: Inconel 718 is precipitation-hardened, giving it superior tensile strength and fatigue resistance.

Oxidation Resistance: It has high resistance to oxidation, even at elevated temperatures, preventing surface degradation over time.

Creep and Rupture Strength: The alloy maintains its structural integrity under prolonged stress and high temperatures, minimizing the risk of material failure.

Weldability: Inconel 718 has good weldability compared to other nickel alloys, making it easier to fabricate complex flange designs without cracking.

What Are Inconel 718 Flanges?

Inconel 718 flanges are components made from Inconel 718 material, designed to connect pipes, valves, pumps, and other equipment in high-pressure or high-temperature environments. These flanges are typically used in industries where the operating conditions demand extreme strength and durability, such as oil and gas, power generation, aerospace, and chemical processing.

The most common types of Inconel 718 flanges include:

Weld Neck Flanges: Known for their long tapered hub, these are ideal for high-pressure applications, ensuring smooth fluid flow.

Slip-On Flanges: These are designed to slip over the pipe and are typically welded in place. They are easier to align but not as strong as weld neck flanges.

Blind Flanges: These are used to close the end of a pipe or a valve.

Socket Weld Flanges: These flanges are ideal for small-diameter, high-pressure pipes, ensuring a smooth bore flow.

Threaded Flanges: Often used for lower-pressure systems, these flanges can be screwed onto pipes without welding.

Specifications of Inconel 718 Flanges

Specifications: ASTM B564 / ASME SB564

Size: 1/2″NB TO 60″NB

Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Benefits of Inconel 718 Flanges

Durability in Harsh Environments: The material's high resistance to heat, pressure, and corrosive substances ensures long-term performance in the most challenging conditions.

Reduced Maintenance: Due to its strength and corrosion resistance, equipment with Inconel 718 flanges requires less frequent maintenance or replacement, saving operational costs over time.

Versatility: Inconel 718 flanges are suitable for a variety of industries, including aerospace, marine, nuclear, and chemical processing, because of their adaptability to different environmental demands.

Cost-Efficiency in Critical Applications: Although Inconel 718 is more expensive than conventional materials, its long life cycle and reliability in critical applications result in cost savings by reducing downtime and repairs.

High-Pressure Tolerance: These flanges can handle extreme pressure and stress without deforming, which is crucial for systems in industries like oil & gas and aerospace.

Conclusion

Inconel 718 flanges are indispensable components in industries that require materials capable of enduring harsh environments. Their combination of high-temperature resistance, corrosion resistance, and mechanical strength makes them one of the best choices for critical applications. While the upfront cost of Inconel 718 flanges may be higher than that of standard materials, the long-term benefits such as durability, reliability, and reduced maintenance needs make them a cost-effective solution for the most demanding applications. Whether it's a high-pressure pipeline in a chemical plant or an aerospace component exposed to extreme conditions, Inconel 718 flanges deliver unmatched performance and reliability.

For More Information:

Visit Our Website - https://www.sankalpalloys.com/

Call Us : +91-88283-69483

E-mail - [email protected]

#Inconel 718 Flanges Exporters#Inconel 718 Flanges Manufacturers#Inconel 718 Flanges Manufacturers in India#Inconel 718 Flanges Exporters in India#Inconel 718 Flanges#Inconel Flanges#Sankalpalloys

0 notes

Text

Top 3 Applications of Pipe Fittings

What are Pipe Fittings?

Pipe fittings are essential in many industries and systems where the handling of fluids-one form or other-is involved. Pipe Fittings are used for connecting, changing the direction of, controlling, and stopping the flow of a liquid, gas, or slurry inside a piping system. Their versatility and functionality make them indispensable across several fields. Some common applications and usages of pipe fittings are discussed below. Pearl Pipe Fittings is the leading Pipe Fittings Manufacturer in India and Flange Manufacturer in India.

Top 3 Applications of Pipe Fittings

1. Plumbing Systems

Probably the most common plumbing pipe fitting used serves to connect various sections of pipe in residential, commercial, and industrial buildings for water distribution and sewage systems. Standard elbows, tees, and couplers allow the flow of water to divert around obstructions or corners, while reducers change pipe sizes to comprehend any variation in pressure. We are also the best Carbon Steel Pipe Fittings Manufacturer in India and CS Flanges Manufacturers in India

2. Oil and Gas Industry

The oil and gas industry-operated pipe fittings are highly important to guarantee that crude oil, natural gas, or refined products are being moved around safely. Applications involving fittings under high-pressure conditions and requirements for corrosion resistance call for materials to be manufactured from carbon steel, stainless steel, or alloy for this purpose. Such fittings play an indispensable role in the process of connecting pipelines, flow rate control, and leak-proof applications at the stage of extraction, refining, and distribution.

3. Chemical and Pharmaceutical Industry

The chemical and pharmaceutical industries are one of the prime concerns in terms of precision with safety. The pipe fitting deployed within this industry needs to be resistant to corrosion and thereby not chemically reactive. Thus, this is used for transporting liquids, gases, and powders so that the substance being conveyed retains its integrity. Flanged connections, valves, and special fittings such as fittings for sanitary appliances ensure the process remains clean and free from contamination.

You may also like: Copper Nickel Flange Manufacturer in India

Product Source: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

#Pipe Fittings Manufacturer in India#Flange Manufacturer in India#Carbon Steel Pipe Fittings Manufacturer in India#CS Flanges Manufacturers in India#Copper Nickel Flange Manufacturer in India#Stainless Steel Flanges Manufacturer in India#SS Pipe Fittings Manufacturers in India

0 notes

Text

Understanding the Importance of Stainless Steel Flanges in Industrial Applications

Riddhi Siddhi Metal Impex is one of the top Stainless Steel Flanges Manufacturers In India. Stainless steel flanges play a crucial role in various industries, from petrochemicals to power plants. These essential components connect pipes, valves, and pumps, ensuring seamless and secure flow within a system. India has emerged as a leading hub for stainless steel flange manufacturing, producing world-class products for global markets.

Why Stainless Steel Flanges Are Essential

Stainless steel flanges offer several advantages over other materials. Some of these include:

Corrosion Resistance: Stainless steel’s ability to resist corrosion makes it ideal for harsh industrial environments where exposure to chemicals, moisture, and extreme temperatures is common.

Durability: These flanges have a long service life, ensuring cost savings over time for industries where equipment downtime can be costly.

Strength: Stainless steel flanges are known for their high tensile strength, ensuring structural integrity under pressure.

Versatility: They can be used across various industries, from oil and gas to food processing, making them highly versatile.

Applications of Stainless Steel Flanges

Oil and Gas Industry

In this industry, stainless steel flanges are used extensively in pipelines and refineries. Their ability to resist corrosion and withstand high pressure makes them perfect for transporting oil and gas over long distances.

Chemical Processing Plants

Stainless steel flanges are often used in chemical plants, where they are exposed to harsh chemicals and extreme temperatures. Their corrosion resistance and strength ensure the safe transport of volatile and hazardous substances.

Power Generation

In power plants, especially those using steam and high-pressure systems, stainless steel flanges help maintain the integrity of piping systems that carry high-temperature fluids and steam.

Water Treatment

Stainless steel flanges are also widely used in water treatment plants. Their non-reactive properties ensure that they do not contaminate the water, and their resistance to corrosion is vital when dealing with chemical-laden water or seawater.

Food and Beverage Industry

Hygiene and cleanliness are crucial in this sector. Stainless steel flanges are used to connect pipes in food processing facilities because they are easy to sanitize and do not react with food products or beverages.

Excellent Quality SS Flanges Suppliers in India

Our high-quality stainless steel flanges and other commodities are thoroughly inspected before shipment. We have a ready supply of stainless steel flanges in a range of sizes and shapes to fulfil our clients' needs.

Stainless steel flanges are milled using solid forged. Due to its dependability and performance, Riddhi Siddhi Metal Impex is the leading stockholder, manufacturer, supplier, importer, and exporter in India.

Our objective has been to supply our clients with high-quality stainless steel flanges and pipe fittings, rather than EIL Approved Pipe Fittings Manufacturer in India & IBR Approved Pipe Fittings Manufacturer in India.

For More Detail

Website: riddhisiddhimetal.com

Product: Stainless Steel Flanges Suppliers in India

Other Product: EIL Approved Pipe Fittings Suppliers in India & IBR Approved Pipe Fittings Suppliers in India.

#Stainless Steel Flanges Manufacturer in India#EIL Approved Flanges Manufacturers#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges

0 notes

Photo

"SS 304 Round Bars Manufacturer & Exporter."

Bhansali Enterprise is specialized in manufacturing Stainless Steel 304 Bar that are in high demand in many applications such as Chemical Processing, Marine, Navy, Petrochemical & Refining and Oil & Gas markets. We have a comprehensive inventory of 304 Stainless Steel Favorized Bar, 304 Stainless Steel Round Bar, 304 Stainless Steel Nerf Bar & Stainless Steel 304 Round Bar in a large variety of types, schedules, sizes, and pressures. The company plant is equipped with a range of machines and advanced processing facilities that give tremendous flexibility to meet the exact needs of our clients. We have Become No 1 Stainless Steel 304 Cold Finish Round Bar Exporter in India, We are Largest Stainless Steel 304 Cold Drawn & Polished Square Bars Distributors. We are Known as Stainless Steel 304 Hexagonal Bar Stockist.

#stainless steel round bar#stainless steel 304#stainless steel rod 304 price per kg in india#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributorsteel manufacturers in india#polished stainless steel#stainless steel manufacturers in india#stainless steel 304 price per kg in delhi#flange manufacturer in india

0 notes

Text

Metalica Forging Inc, a prominent Flanges Manufacturer in India, offers a wide selection of flanges ranging from 12 inches to 48 inches. These flanges are crucial components that connect pipes to vital accessories like tees, elbows, reducers, and valves, enabling seamless integration within piping systems.

As one of the largest Flange Suppliers in India. is recognized for meeting the global demands of its clients, serving customers across five continents and nearly 80 countries. This achievement reflects the company's dedication to providing high-quality and durable products.

Metalica Forging Inc. is a trusted name in the Indian flanges market, supplying ASTM A105 flanges known for their ability to withstand high-pressure and high-temperature environments. As a leading provider of JIS Flanges, the company continues to expand its range of services to cater to the growing needs of its diverse customer base.

We Lead flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

For more details, please visit: metalicaforginginc.com

Product Information: Flange manufacturer

#flanges#flanges manufacturer in india#flanges manufacturer#jis flanges#jis flanges manufacturer#jis flanges manufacturer in india

0 notes

Text

Top ASTM A234 WPB Pipe Fittings Exporters in India: Your Global Supply Partner

India has become a major hub for exporting high-quality ASTM A234 WPB Pipe Fittings, widely used in industries such as oil & gas, petrochemical, and power generation. These fittings are essential for applications that require toughness, durability, and corrosion resistance in both low and high temperatures.

What are ASTM A234 WPB Pipe Fittings?

ASTM A234 WPB is a standard specification for carbon steel pipe fittings designed for moderate and high-temperature service. These fittings are primarily used in pressure systems and offer excellent performance in harsh environments.

Key Features of ASTM A234 WPB Pipe Fittings:

Durability: These fittings provide excellent resistance to wear and tear, ensuring a long service life.

High-Temperature Resistance: Ideal for applications requiring performance in both high and low temperatures.

Corrosion Resistance: Manufactured with superior-quality carbon steel, these fittings can resist corrosion, making them ideal for oil & gas pipelines.

Cost-Efficiency: With a balance of durability and affordability, ASTM A234 WPB fittings offer a cost-effective solution for various industries.

Why India is a Leading Exporter of ASTM A234 WPB Pipe Fittings?

India has a growing reputation as a key exporter of pipe fittings thanks to its:

Advanced Manufacturing: State-of-the-art manufacturing processes ensure consistent quality and adherence to global standards.

Cost Competitiveness: Indian exporters offer high-quality products at competitive prices, making them a preferred choice for global buyers.

Compliance with Standards: Indian exporters adhere to stringent quality standards, ensuring that the ASTM A234 WPB pipe fittings meet international specifications.

Leading Exporters of ASTM A234 WPB Pipe Fittings in India:

Manilaxmi Industrial: A leading supplier and exporter, Manilaxmi Industrial is known for delivering superior-quality ASTM A234 WPB pipe fittings to various global markets. They ensure fast shipping and top-notch service to countries across the globe, including the USA, UAE, and Europe.

XYZ Industries: With a large inventory of ASTM A234 WPB fittings, XYZ Industries has become a key player in exporting to international markets, particularly in the oil and gas sectors.

ABC Fittings Co.: Specializing in custom fittings, ABC Fittings Co. provides ASTM A234 WPB fittings to meet specific client requirements across industries.

Exporting to Global Markets:

Indian exporters have established a strong network worldwide, with key markets including:

Middle East (UAE, Saudi Arabia): For oil & gas applications.

North America (USA, Canada): In industries requiring pressure and heat-resistant pipe fittings.

Europe: Serving power plants, chemical industries, and petrochemical sectors.

Conclusion:

India’s reputation as a reliable exporter of ASTM A234 WPB pipe fittings continues to grow, thanks to high-quality manufacturing, competitive pricing, and a strong commitment to international standards. For industries requiring robust, long-lasting pipe fittings, Indian suppliers provide an unmatched blend of quality and affordability.

Looking for reliable ASTM A234 WPB Pipe Fittings exporters? Explore our full range of products and get in touch for a quote today.

Learn more here.

#industrial#manufacturer#suppliers#exporters#flanges#innovation#pipeaccessories#india#manilaxmi industrial#manufacturers

1 note

·

View note

Text

Tantalum Sheets & Plates Exporters

All the material used for manufacturing of fittings are tested for chemical & mechanical properties.

1. Overview of Tantalum and the Industry

Tantalum is a highly corrosion-resistant metal widely used in various industries, including electronics, aerospace, medical, and chemical processing, due to its excellent conductivity and durability. Tantalum sheets and plates are essential components in the manufacturing of capacitors, reactors, heat exchangers, and other high-performance equipment.

India has emerged as a significant player in tantalum products manufacturing, with companies like Navneet Metal Corporation standing out as leading suppliers of tantalum sheets and plates. Navneet Metal Corporation offers high-quality tantalum products to meet the increasing global demand across multiple sectors. The company’s commitment to precision, quality, and customer service has allowed it to solidify its position as one of the top manufacturers in this niche market.

2. Current Trends in Tantalum Sheets & Plates Manufacturing

The demand for tantalum sheets and plates is rising, driven by the following trends:

Increased Use in Electronics: Tantalum capacitors are critical for the electronics sector, particularly in smartphones, computers, and medical devices. The growing electronics market is boosting the demand for tantalum products.

Adoption in Aerospace and Defense: Tantalum’s ability to withstand extreme temperatures makes it a preferred material for aerospace and defense applications, contributing to an increase in demand for tantalum sheets and plates.

Advancements in Manufacturing Technology: Companies like Navneet Metal Corporation are adopting advanced production techniques, including precision rolling and heat treatment, to ensure the highest quality in tantalum sheets and plates. This enhances their durability, consistency, and performance in critical applications.

Focus on Sustainable and Ethical Sourcing: Given the ethical concerns around tantalum mining, many manufacturers, including Navneet Metal Corporation, are focusing on sustainable and responsible sourcing to meet global standards for ethical trade.

3. Impact on the Industry

The increased demand for tantalum sheets and plates is significantly impacting industries such as electronics, medical devices, chemical processing, and aerospace. Navneet Metal Corporation’s high-quality products support critical manufacturing processes in these industries, driving innovation and ensuring reliability.

Electronics Sector: As one of the primary consumers of tantalum, the electronics industry benefits from high-performance capacitors that enhance device efficiency.

Chemical Processing: Tantalum's corrosion resistance is critical in chemical processing plants, where equipment must withstand harsh environments.

Medical Technology: Tantalum’s biocompatibility makes it an essential material for surgical implants and devices, improving the reliability and longevity of life-saving equipment.

Aerospace & Defense: The aerospace sector values tantalum for its strength and heat resistance in high-performance applications, improving safety and efficiency in aviation technologies.

4. Implications and Future Prospects

Growth in High-Tech Sectors: As industries like 5G, electric vehicles (EVs), and medical technology expand, the demand for tantalum sheets and plates is expected to grow. Navneet Metal Corporation is well-positioned to cater to these emerging markets with its quality products.

Rising Importance of Sustainable Practices: As global awareness of ethical mining and environmental concerns increases, manufacturers like Navneet Metal Corporation will need to further emphasize transparency and sustainability in their supply chains.

Innovation in Materials Science: Continued advancements in materials science may lead to the development of new tantalum-based alloys with enhanced properties, increasing the range of applications for tantalum sheets and plates in high-performance sectors.

5. Summary & Recommendations

Navneet Metal Corporation has established itself as a key player in India’s tantalum sheets and plates manufacturing industry. Their commitment to quality, innovation, and sustainability positions them to meet the growing global demand across various sectors such as electronics, aerospace, and chemical processing.

Recommendations for Navneet Metal Corporation:

Expand R&D Capabilities: To stay ahead of competitors, invest in research and development to innovate new tantalum alloys and improve production techniques.

Focus on Ethical Sourcing: Continue prioritizing sustainable and ethical sourcing practices to align with global industry standards and maintain customer trust.

Global Market Expansion: With growing demand worldwide, consider expanding operations to international markets to capitalize on the increasing demand for tantalum products.

Strengthen Partnerships: Building strong partnerships with key players in high-demand sectors such as electronics and aerospace will ensure a steady growth trajectory for the company.

Navneet Metal Corporation’s strong foundation in manufacturing, paired with a strategic focus on innovation and sustainability, ensures a promising future in the tantalum industry.

#Pipes & Tubes#Sheet & Plate#Round Bars#Pipe Fittings#Flanges#Fasteners#Wires#Tantalum Sheets & Plates#Tantalum Sheets & Plates Manufacturers#Tantalum Sheets & Plates Suppliers#Tantalum Sheets & Plates Stockists#Tantalum Sheets & Plates Exporters#Tantalum Sheets & Plates In India#Tantalum Sheets & Plates Manufacturers In India#Tantalum Sheets & Plates Suppliers In India#Tantalum Sheets & Plates Stockists In India#Tantalum Sheets & Plates Exporters In India

0 notes

Text

Best KNPC Approved Flanges Manufacturer, Supplier, and Exporter in India - Mcneil Instrument

At Mcneil Instrument, we are a leading provider of top quality KNPC approved flanges that meet the highest international standards. Our flanges are widely recognized and utilized across various industries in countries such as the USA, Bahrain, Kuwait, Oman, Qatar, Saudi Arabia, UAE, and Canada. With a strong commitment to quality and customer satisfaction, Mcneil Instrument is your go to partner for reliable and durable flanges. At Mcneil Instrument, we serve clients around the globe, offering the Best USA KNPC Approved Flanges, Best Bahrain KNPC Approved Flanges, Best Kuwait KNPC Approved Flanges, Best Oman KNPC Approved Flanges, Best Qatar KNPC Approved Flanges, Best Saudi Arabia KNPC Approved Flanges, Best UAE KNPC Approved Flanges, and Best Canada KNPC Approved Flanges. Our extensive distribution network ensures timely delivery and outstanding customer service, regardless of your location.

0 notes