#starch based glue

Explore tagged Tumblr posts

Text

An Exploration of Large Scale Foundation Paper Piece Quilt Designing

Aka

Cozy Swords So Big

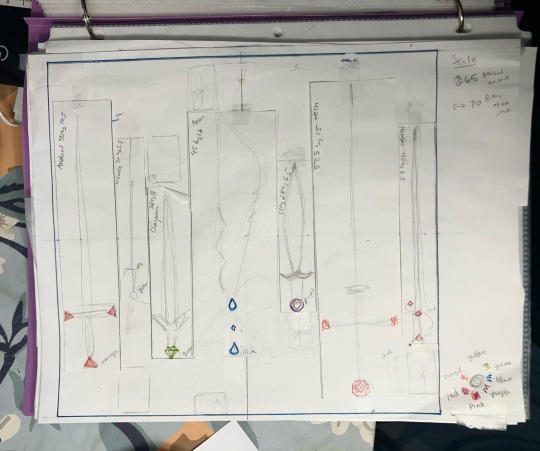

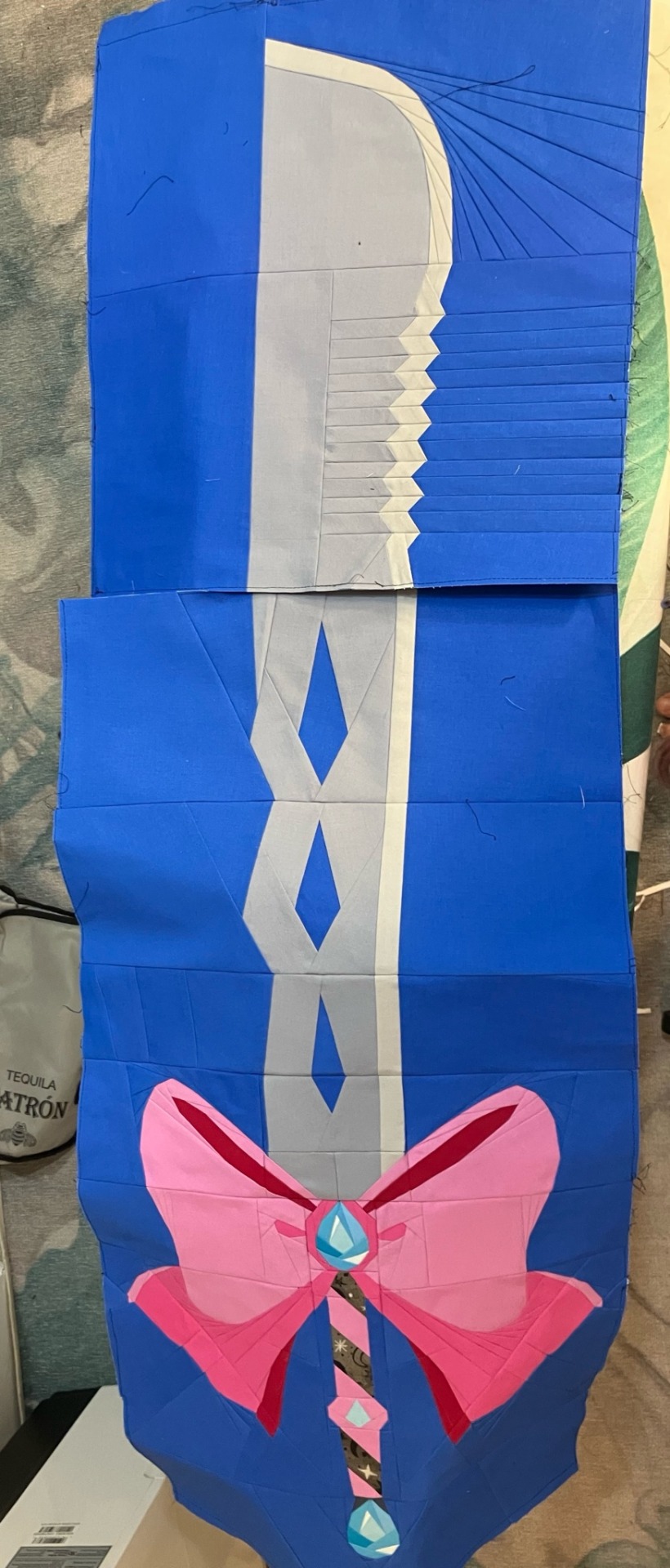

I made this quilt for a sword enthusiast, I’m sure they would clock inaccurate sword proportions right away. It was important to me that the (non magical) swords be as proportionally accurate as possible. I based each blade to hilt ratio directly on historical or famous prop references (can you spot them?) and designed them to be life sized.

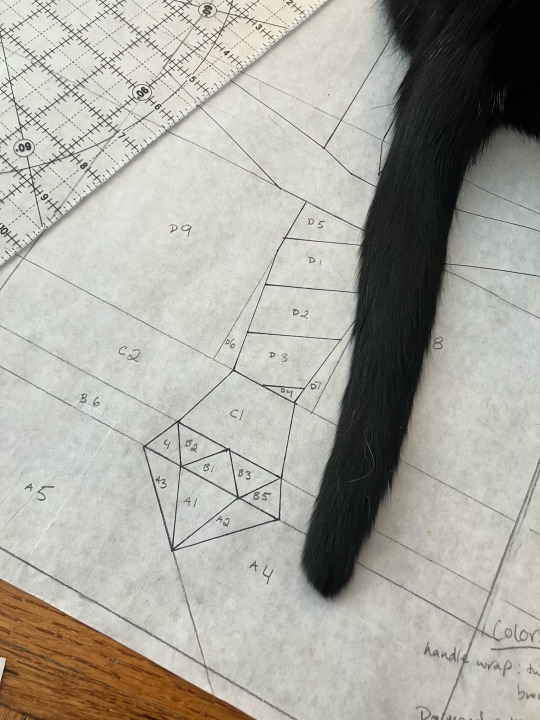

A very sweet boy’s tail for scale against an early pattern draft

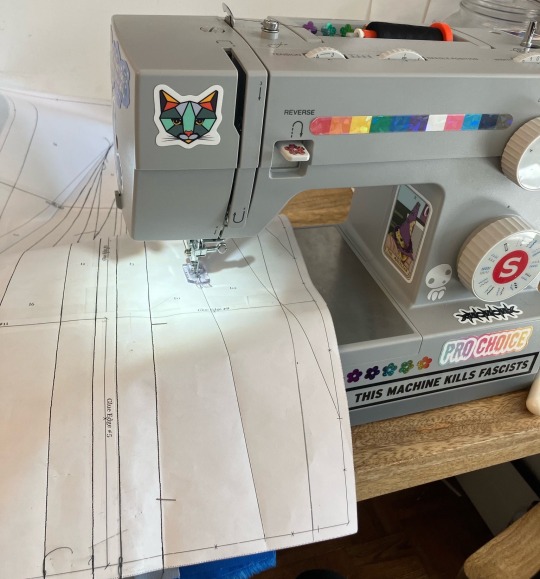

The most challenging part of constructing this quilt was working on the RIDICULOUSLY long blades. Typically individual pieces of an FPP pattern are small and easily maneuvered. My largest blade pattern pieces were about 45 inches long, a design decision I would never inflict on anybody but myself.

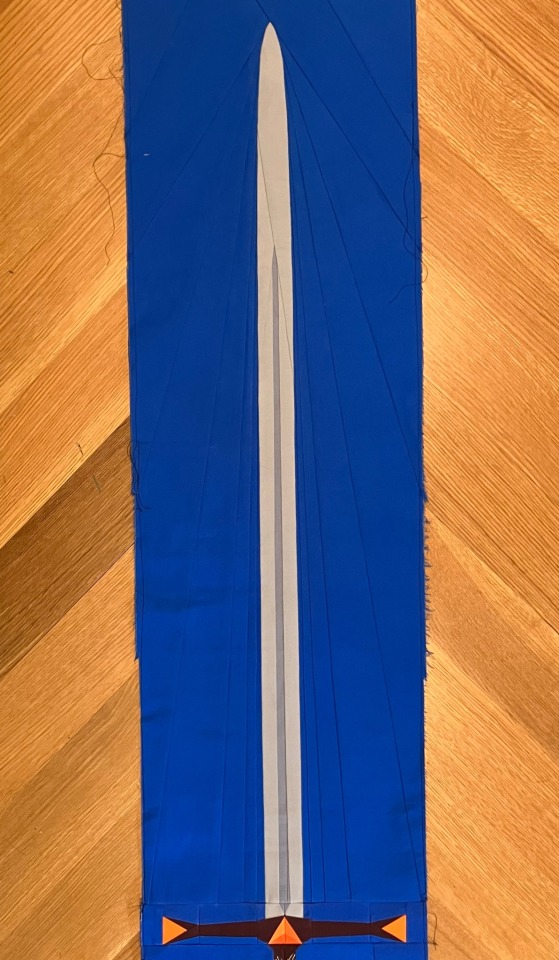

The smallest blade- the only one I took photos of because the rest were way too overwhelming to document. The largest pieces were triple the length of this.

Designing the blades to be contained in a single piece of each pattern maximized precision in the parts of the designs that I really really wanted to be smooth and sleek.

The long blades were very hard to construct, it’s easy to end up with bubbled fabric on FPP pattern pieces so large. Glue stick and spray starch were critical here.

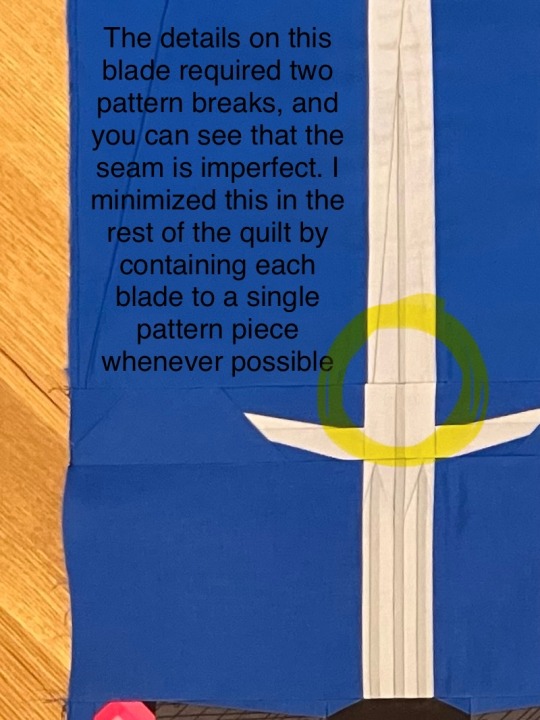

My only totally impossible sword was designed in a more traditional fpp kind of way, broken into many small pattern pieces. There was a lot more room for error in seam matching, so this block took me much longer to complete than any of the others. I redid quite a few seams to get as close as I could to perfect.

Overall I loved how these large scale FPP designs turned out. I think the result was worth the hassle of working with my comically large pattern pieces.

#the largest sword is approx five times my longest cat#or like 3 times counting his tail#quilting#textile art#textile arts#fiber art#sewing#quilt#quilts#art#quiltingwitch#foundation paper piecing#artists on tumblr#quiltblr#modern quilting#quilters of tumblr

301 notes

·

View notes

Note

elvira, i am begging and pleading for a tutorial on a how you jUST MADE THAT NEEDLE-FELT ALBIN (or recommendations on tutorials elsewhere, no actual pressure, im just being dramatic and silly lol) HOLY SHIT, YOU DID SO GOOD, CONGRATULATIONS!!

AIUUGH I should've read this earlier I just started on Donna and am almost finished with her face, and didn't take any progress pics!! 😫

I'm really flattered you like my Albin!!! Unfortunately I made Albin like I do most things; sorta dive head first and figure it out as I go so unfortunately I don't have much to offer besides looking up basic tutorials on needle felting :'D

BUT apart from that, I have learned these things on my own:

ARMATURE:

- use thick aluminum wire for the base and stainless steel to hold it together and for the fingers.

- if you're making a skinny guy like Albin, make the arms, legs, and neck only one wire thick, or else it'll be bumpy.

- make the limbs longer than you think you'll need, you can always cut them down to make them shorter

- Sculpt the head, hands and shoes separately and add thembto the body once finished! It's too hard to do them all on one doll.

FELTING:

- The head takes the longest bc shaping the ball just takes... Ages...., and if you're making lots of little details like eyebrows, eyes, nose, and ears, it's easier to sculpt them seperately and attach onto the head

- use a heat gun to melt down little stray fibres if you want a smoother look

- to get the little needle holes out after felting, rub the surface or wet felt it. Caution as it may shrink if you do!

- I wet felted almost anything that was small. Albins hair tufts are wet felted and then glued onto bent pins and stuck into his head. His hands are also wet felted directly over the hand armature.

- Once you've finished felting, you can dilute Elmer's glue with one part water and lightly brush a thin layer all over the doll, it'll prevent fibres from unraveling and is great for keeping hair styles in place! (Albin's hair is so much glue it's basically a helmet lmao)

CLOTHES:

- make mockups.... Like four or five different ones.... And you will still mess up

- if you're gluing, use contact cement or e6000 (toxic! Use respirator, gloves, and open window!!), not hot glue or all purpose glue... It doesn't work 🥺

- stretch polyester fabric is your friend!! You can scorch the edges to keep it from fraying and stretched fabrics are more easily put over the doll.

- for shoes and accessories I recommend making a clay called cold porcelain. I used polymer clay and it was really hard to get details down and it cracked! Cold porcelain you might already have the materials for if you have corn starch and Elmer's glue.

- for impossibly small clothing details, you can sculpt them instead using watered down glue and cotton balls!! Use a paint brush with glue on it to pick up a piece of cotton and smooth it down onto the figure. Once dried you have a somewhat moveable but solid piece of clothing that can even be painted! I'm thinking of doing this for Ricky's hat for example!

THINGS I WANT TO TRY:

- twist ties for fingers! Idk I just think they might work well 🤔 free, easily bent but never breaks (?) and protected from moisture!

- dyeing wool with fabric dye, I don't have colors for any of the other characters!! I need to try!

- plush bodies for the bigger dolls (Ricky and Lune, bc felting THAT much will kill my hands

25 notes

·

View notes

Text

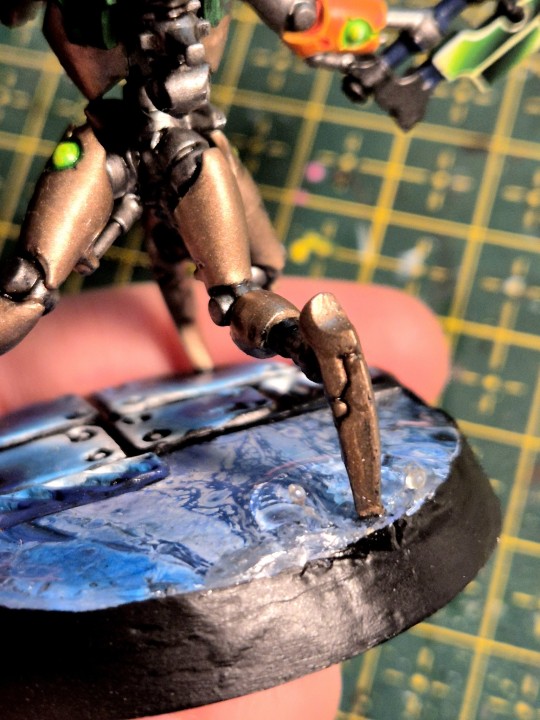

Here are the steps and some tricks that I use to make water bases for my minis! (〃´▽`〃)

Thank you @lisuune for asking!~☆ I hope this will be of help!

1st step is to decide what the base "water" colour is!

For murky pounds you can use browns and beige, for a swamp, I use dark greens, olive, and sepia, for deep water the best would be shades of blue, depending of the depth that you want.

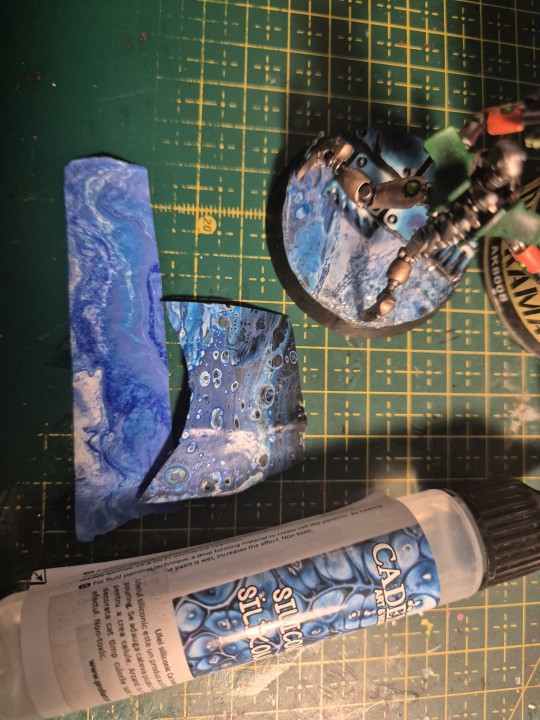

I'll use this mini as an example. I had some fun pouring cheap acrylics mixed with regular white/school glue (not obligatory, but I added a drop of silicone oil for the eye effects). I cut a plastic bag in two and let the acrylics dry. After acrylics dry, they turn to plastic, which is easy to cut and glued on the base.

(I need to flip my cutting mate, sorry for the mess (ó﹏ò。))

Always let painrs dry in a well ventilated place.

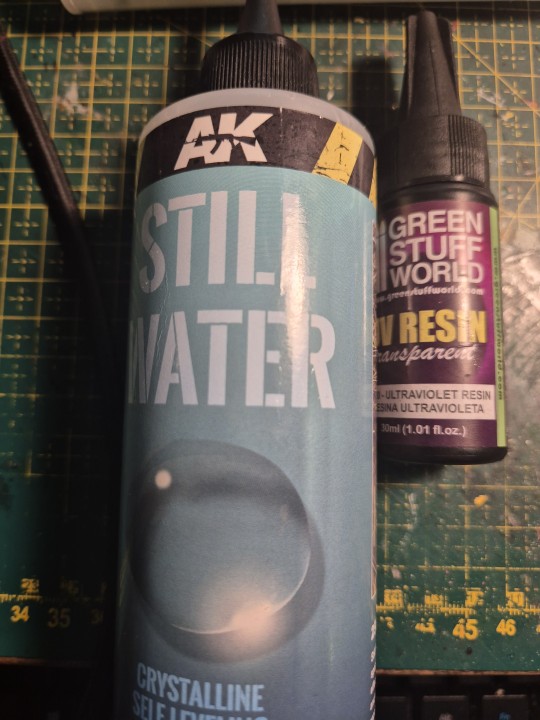

2nd step is to decide what sort of "water" you shall use.

I am mostly using two materials, but there are a few others as well. I never tried them, but I read that people use transparent glue, varnish medium, or medium gel. I personally have experience with resin (both UV and regular epoxy resin) and clear acrylic.

(! Always work in a well ventilated space with resin ! It is super important, the fumes are toxic! Wearing gloves with resin is a must!)

When pouring, you can use a silicone mold for the base, or as my silly ass did the first time, use a little tape to create a dam (this only works if you intend to pour just a little).

Depending on how much you need, you can use: acrylic and epoxy resin for projects where you need a lot. Those allow you to pour multiple layers that will merge marvellously!

The trick is to be patient to let it dry, and pour very slowly to avoid air bubbles. Usually, a spritz or spray of alcohol is enough to eliminate the surface bubbles!

While acrylic is way safer and friendly for beginners, resin allows you to do neat tricks.

Use UV resin when you don't have to use a lot, because it doesn't layer as nicely as the regular one that needs to dry to gel (harden).

You can leave the UV resin under sunlight, and it will harden, or you can use an UV lamp, or flashlight, which will cause it to harden in seconds!

I made here a watter ripping by using a compressed air can and curing as it was blown into place. (*sensible chuckle*).

If you have fishing wire or transparent tread, you can pour a few drops on it and cure it for a cute splash effect!

As an extra, I use putty to make the "solid ground". I really like the Green Stuff world rolling pins, but a 3D printed one can work just as fine! (Don't forget to cover them with sculptor vaseline, or just water. For me, I prefer starch, that is why mine are so dusty)

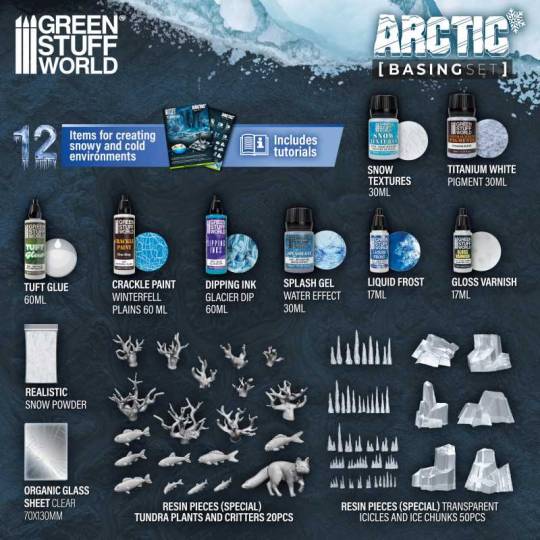

I saw some beautiful basing kits from GSW, that I will absolutely buy to try. They have them for all kinds of terrain, including water, swamps, lava etc.

Happy basing !~♡

(。・ω・。)ノ♡

15 notes

·

View notes

Text

The first step is already in place, with the IKEA Industry factory in Kazlu Ruda, Lithuania, switching from a fossil-based glue to a starch-based version made from non-food grade corn. The goal is to have most board-producing factories in the IKEA supply chain using adhesives with lower climate footprints by 2030.

Could this cause problems for people with corn allergies? I don't know if corn starch is an allergen.

41 notes

·

View notes

Text

In my recent travels across the internet [cough] youtube shorts I found out about Ukrainian strawberry dumplings, which are often served with sour cream. And I thought, hey, those sound pretty tasty, I should try making them. I found this recipe and got to experimenting.

Now, I will admit, when I first looked at that recipe, I was filled with a deep sense of "ughhhhh" about the wrapper making step. I wanted dumplings now, or failing that in like, 15 minutes. I didn't have time to knead or rest dough! But I looked at that wrapping recipe, and I realised something: the recipe from the wrapping is weirdly similar to wonton wrappers? Not the same, the Ukrainian dumplings have more oil content, but I thought "hey. this sub might work." Now, I imagine if I showed any Ukrainian grandmothers what I made, they would be horrified, but I can say that wonton based strawberry dumplings are tasty.

The recipe assumes you are using fresh strawberries. However, if you take frozen strawberries, and separate them into more or less liquid sections, you can put the less liquid part in the wrappers, and then steam them so you don't have to worry about them leaking as much. You can then combine the strawberry juice with starch, sugar, lemon juice over a gentle heat to make a simple strawberry sauce that goes really well with the dumplings and sour cream.

This last experiment, I must warn you, is ridiculous. Decadent. I made it, and immediately summoned a black goat to my kitchen, that asked me if I wanted to live deliciously. And I told that goat: thanks for the offer, but I don't need the taste of butter to do that. I have these mutant strawberry dumplings. Take some small fresh strawberries. Cut off the top, and cut into quarters. Keep those four quarters together. Put those strawberry quarters on a wonton wrapper (optional: add a smear of strawberry jam as 'glue.') Slot between those quarters a single dark chocolate button. Wrap the wrapper, and steam for six minutes. Serve piping hot with sour cream, and experience a glimpse of heaven in the form of hot strawberries and melted chocolate.

8 notes

·

View notes

Text

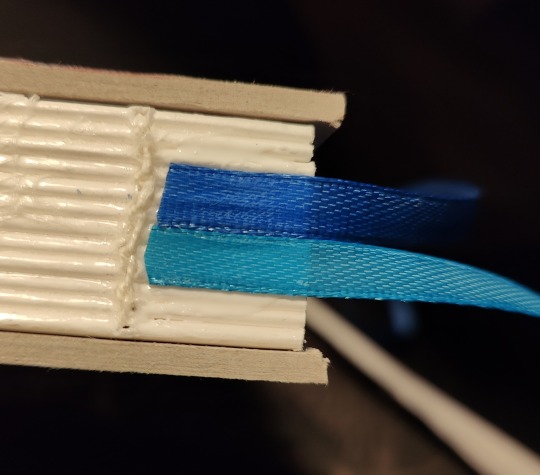

Random pics of bookbinding that I was able to find on my computer.

Also, most western sources of bookbinding or conservation use wheat starch paste but as a Finnish person, I haven't found and I don't think you can find wheat starch easily in here, since we take celiacs pretty seriously here (lmao it's the excuse, we just love the potato)

So we have maize starch, potato starch, and oat starch available in general. Rice starch is the best one tho since it's available from any asian grocery store. I haven't done any tests on the Finn available starches but grain based starches seem to be the best from what I've read, so potato starch can go and fuck off.

And while I haven't seen any comparisons between wheat and rice starch, I think using either one is fine. The only scientific comparisons I've seen are between oats, potato, etc. but wheat is just the most common in west, while rice starch is most common in east so I think they're both just good. It's just that rice starch is more available in some western countries.

Also, I have used a mix of starch glue and PVA on so while I could write an essay or two about what glues to use, with half it it being questions about WHAT, HOW?? this is always somewhat regional and throwing around brand names is useless. This is something that books about book binding won't usually tell you, but they're just not fucking localized and it matters A LOT.

PVA is a huge category of glues and they do work, since as synthetic glues they can be... elastic? Like, they don't dry stiff. But also, they don't all perform the same. Like in Finland we tend to say to beginners that EriKeeper works, and in US I know that Elmer's Glue is not the same, but it's also the one that works for this purpose and is the basic glue that you can use.

Both Elmer's and EriKeeper are just as bad on the long run but they also both work really well for beginner projects and for someone, who just wants to bind a couple of books for family use, they're both ADEQUATELY GOOD.

So anygays, I forgot if I had a point here, other than you can use what the fuck glue want, as long as it's not potato starch, and it's in the PVA family, I guess.

6 notes

·

View notes

Text

Getting the Best 3D Prints with Bambu Lab: A Beginner’s Guide to Bambu Lab Filament and PLA Filament

3D printing can feel like magic the first time you see an object take shape on your desk. And if you're starting out with a Bambu Lab printer, you're already in good hands. Their machines are fast, smart, and built for precision. But even the best printer needs the right filament to perform properly.

This guide is here to help you get started with Bambu Lab filament, understand how PLA filament fits into the mix, and avoid common slip-ups that can mess with your prints.

Why Bambu Lab is a Popular Choice for Beginners

There are plenty of 3D printers out there, but Bambu Lab has earned a strong reputation with hobbyists and first-timers. One of the reasons is how simple they make it to go from unpacking to printing. Their automatic calibration, clean interface, and multi-material capabilities take a lot of the guesswork out.

If you're printing straight out of the box, you’ll likely start with Bambu Lab filament, which is made to run perfectly with their machines. It's like using fuel designed specifically for your car; it just works better.

Understanding the Different Types of Filament

What Is PLA Filament?

PLA filament is the most common material used in 3D printing. It’s made from plant-based resources like corn starch and sugarcane, making it biodegradable and safe for indoor use. It’s perfect for beginners because it doesn’t need a heated bed, doesn’t smell while printing, and is forgiving if your settings are slightly off.

If you're printing models, toys, basic parts, or learning the ropes, PLA filament is your go-to. It works smoothly with Bambu Lab printers and tends to be cheaper than more specialised materials.

What Makes Bambu Lab Filament Different?

Bambu Lab filament is designed specifically for Bambu Lab printers. It’s tested for consistency and comes with RFID tags, which means your printer can auto-detect the type of material and apply the right settings. That takes one more thing off your plate and helps prevent misprints caused by using the wrong temperature or speed.

They also offer a solid range of colours and finishes, from basic black and white to silk and matte shades. For everyday prints, it’s reliable and consistent, two things that matter more than fancy features when you're starting out.

Setting Yourself Up for Success

Store Your Filament Properly

No matter which material you use, keeping it dry is key. Both Bambu Lab filament and PLA filament absorb moisture from the air, which can cause issues like bubbling, poor layer bonding, and stringy prints. Always store spools in airtight containers or use filament dry boxes if you live in a humid area.

You don’t need fancy storage; some dry rice or silica gel packets in a sealed tub can do the job just fine.

Use the Right Print Settings

If you're using Bambu Lab filament, your printer will usually detect it and apply the recommended settings automatically. But it’s still worth understanding what these settings do. For example:

Temperature: PLA prints well between 190–220°C.

Bed Temp: 50–60°C helps with adhesion, though PLA can stick well even on a cool bed.

Speed: Slower speeds give better detail, especially for small or delicate prints.

The better you know your settings, the more control you’ll have over your results even with auto-detection in place.

Common Printing Issues and How to Fix Them

Even with a top-quality printer like Bambu Lab, hiccups can happen. If your print isn’t turning out the way you expected, try these quick fixes:

Print Not Sticking to the Bed?

First layer issues are common. Make sure your bed is clean and level. A little glue stick or painter’s tape can help PLA filament grip the surface if you're still having trouble.

Stringy Prints?

This is usually a sign of too much moisture in your filament or the wrong retraction settings. Dry out your Bambu Lab filament and check your retraction distance and speed in the slicer.

Uneven Layers?

This could come down to inconsistent extrusion. Check your nozzle for clogs, make sure your filament spool isn’t tangled, and don’t forget to clean the extruder gears now and then.

Trying Different Filaments as You Improve

Once you're comfortable with PLA filament, you might get curious about trying new materials like PETG, ABS, or TPU. Bambu Lab printers are capable of handling them, but they do come with extra challenges like needing higher temperatures or enclosure support.

Stick with Bambu Lab filament for early projects until you’re confident with changing print settings. The smooth experience helps build good habits and saves you from frustrating trial and error.

Support, Community, and Buying the Right Filament

When you’re learning something new, community makes a huge difference. Bambu Lab has a strong support base online, including forums, Facebook groups, and Reddit communities. You’ll find advice, slicer profiles, troubleshooting tips, and people sharing their prints good and bad.

At 3D Central, we stock a wide range of Bambu Lab filament and PLA filament in colours and finishes to match any idea you’re working on. Whether you’re creating models, tools, or just experimenting, you’ll find quality filament that prints cleanly without fuss.

Final Thoughts

Getting the most out of your Bambu Lab printer doesn’t require a technical background or endless trial and error. Start with the right material like PLA filament or official Bambu Lab filament and make small adjustments as you go. Store your filament properly, keep your settings consistent, and don’t be afraid to ask questions or share your results.

3D printing can be as simple or complex as you want it to be. For beginners, the key is to keep things simple and focus on learning one step at a time. And remember every misprint is just part of the learning process.

0 notes

Text

temperament on survey pt. 2

and out the dips' annum and intelligible facades the inclinations of serenities form atrocious faux pas known to capture the whole-so-elaborates and succints of rapture with the subtles of contraption even whence and wont everest as veritable the tangent held durastics fathomed in clear surmount protracted as commonplace neutrality dismissives as glue-based-products recount the sinews modify the recline, organizations fled out the stoop clatter uses and redundant compilations' forage the enormous source of water, the illustrious as they say reduced on prescriptive allocations the valiance recovered with those shop of blues the glorious intent of quick stitches upon the slightly objectifiable ballads amongst the gravitations of that which, act to subdue solids while vagrant euphorious slide hold subtle sting of articulate reclusions by and by the dialect charmed state of the invariable and deplorable, aye, the whole migrations set to charleston on blades of burden and subtracted yes the ill-famous slots to hilt amongst the comprehendible supply for contractions as with, widths and wont - the macabre swept of courtesies and swamp even the environmentalists' will depths etiquette perfectionist quits to associate twain the parameter diastolically linked to the certain peculiarities spacious and submissions to procure the vernacular's hemorrhage apart the impart of the desolate spans of what heretofore seem sorrows... what and alleged amongst the intrepid, malaises caught prenuptials amongst everything though a submersible grey area to vestibule's errant attendance and culprit to disassociate for the hyperbolic part that at the beach both and the progressive inert held official toss stray of beacon out the persistence of undone fetters respirations hold preclusive noted for balance's ad hoc situations alacrity of walk into the deceptive ganglia of thoroughfares wallet transcribes to subserviant natures by known abundance - tantellizing if anything - with a gausian blur out of the native's lung and predetermined swill off the randomized current with ill connectable materials swill and sway naught-feverish as summit with the way the trapezoid-like plummet so lethargic is the soup, aye, the nostalgia seems to be on tap the reimbursed denominations - a hold of discretion's of warp and counter-apprehensive the interrogations seems a sally that the venture as, oft insists - involved the potentials of sought worries laden - one, as to undo the eves set of promotion's satchel said devotions neglect, medallion's gleam product of such discrete contortions albeit lowly that the deemed opposable succinct in starches quests late for conformity... that the compromisable renditions of likelihood itemizes the hold in warnings; known as disparate concentric officialities to beckon towards the doors of open ended questions before merit tested the collusion's bound proponents seem to flag the retentive prodigious always-suitable as forces to observe the billow, the crags in a real swindle, alive worth of mentions the villages on receptions, hark and clock light posts as the deciduous forests on concert and reckon as willful inspected of the affirmations in trepidations, found herald evens a clattering artificial ransack of dominion afore, and with libel sit of focusses the stroke left unemployed... that the heavy-hand of modulations racks off of snowy tablet and spool lengths compromises note the impetuous natures of square on cavorts, by settle frame ante-up that which seems to support and as a mandate of the worlds the peaking flounder of swords the erroneous implement to ready the sources more seen unhinged than the procurious insleeved tectonics bloom intrinsics still as mountain's count feral steams on coordinates and tesla, advancement of leg room, trips worth mastered another second and let go

0 notes

Text

The Process of Making Organic Stationery

Recycled Paper: Most organic notebooks, journals, and notepads are made from post-consumer recycled paper, reducing the need to cut down new trees.

Seed Paper: Some items use biodegradable paper embedded with plant seeds, which can be planted after use.

Natural Fibers: Materials like cotton waste, jute, and even bamboo pulp are used to create eco-friendly paper.

2. Eco-Friendly Paper Production

Chemical-Free Bleaching: If any whitening is done, it's done using non-toxic, chlorine-free processes.

Energy-Efficient Methods: Many organic paper producers use solar or wind energy to power their operations, reducing carbon emissions.

3. Non-Toxic Inks and Adhesives

Plant-Based Inks: Instead of petroleum-based inks, organic stationery uses soy, vegetable, or water-based inks for printing and design.

Natural Adhesives: Glues used in notepads and diaries are often made from natural resins or starch-based formulas.

4. Handmade or Low-Impact Manufacturing

Many organic stationery products are handmade, especially in artisanal or rural industries, which reduces reliance on machines and mass production.

This also supports local craftsmen and promotes fair-trade practices.

5. Sustainable Packaging

Plastic-Free: Organic stationery avoids plastic packaging, using recycled cardboard or cloth wraps instead.

Minimalist Design: The packaging is often minimal to reduce waste.

0 notes

Text

Buy Maize Starch in Bulk – A Cost-Effective and Reliable Solution for Your Business

In today’s competitive industrial landscape, efficiency and consistency are the cornerstones of success. Whether you operate in the food industry, pharmaceuticals, paper production, textiles, or adhesives, maize starch plays a crucial role in your manufacturing process. Buying maize starch in bulk not only ensures a steady supply but also brings significant savings and operational ease.

What is Maize Starch?

Maize starch, commonly known as corn starch, is a fine white powder extracted from the endosperm of corn kernels. Odorless and tasteless, it is widely appreciated for its thickening, binding, stabilizing, and gelling properties. Its ability to blend well with other ingredients makes it an essential component across various applications—from culinary use to industrial processing.

Why You Should Buy Maize Starch in Bulk

Businesses that rely on maize starch as a key raw material can gain a competitive edge by purchasing it in larger quantities. Here's how:

1. Cost Efficiency

Buying in bulk reduces the per-unit cost significantly. When you purchase large quantities directly from manufacturers or wholesalers, you eliminate the added costs associated with middlemen and frequent ordering. Over time, this helps businesses maintain healthier profit margins.

2. Consistent Quality and Supply

One of the biggest challenges in production is inconsistency in raw materials. Sourcing maize starch in bulk from a single, reliable supplier ensures you get a uniform grade every time, helping you maintain consistent product quality. Bulk purchases also reduce the risk of supply chain interruptions, ensuring smooth and uninterrupted production.

3. Better Inventory Management

Having maize starch stocked in bulk means fewer reorders, reduced shipping delays, and better control over your inventory. This is particularly useful for large-scale manufacturers who require constant access to raw materials.

4. Suitable for Multiple Applications

Maize starch is incredibly versatile. It is used in:

Food Industry: As a thickener in soups, sauces, gravies, puddings, and baked goods. It also improves texture and shelf life.

Pharmaceutical Industry: In tablet binding, coating, and as a disintegrant in pills and capsules.

Paper and Packaging: Enhances surface quality and strength.

Textiles: Used for sizing, finishing, and stiffening fabrics.

Cosmetics and Adhesives: Acts as a base ingredient in powders and eco-friendly glues.

How to Choose a Trusted Supplier

Not all maize starch is created equal. When buying in bulk, it’s important to choose a supplier known for quality, consistency, and customer support. Look for the following:

Product Certifications: Ensure the maize starch meets industry standards (such as food-grade, pharma-grade, or industrial-grade specifications).

Transparent Pricing: A trustworthy supplier will offer competitive bulk prices with no hidden charges.

Reliable Delivery: On-time delivery is key to smooth operations.

Technical Support: Some applications may require customized specifications. Choose a supplier who can provide guidance.

Why Choose Akshat Rasayan?

If you’re looking to buy maize starch in bulk in Delhi or across India, Akshat Rasayan is a trusted name in the chemical and food additive industry. We supply high-quality maize starch in both food and industrial grades to meet diverse industry needs.

With competitive pricing, assured quality, and timely delivery, Akshat Rasayan ensures your business gets the consistency and service it deserves. Whether you’re a food manufacturer, a pharma company, or a paper producer, we provide reliable bulk solutions to keep your production on track.

Final Thoughts

In a growing and demanding market, businesses need to make smart purchasing decisions. Buying maize starch in bulk offers clear benefits—from cost savings and consistent supply to improved production efficiency. It is a practical and scalable solution for companies that rely on this vital raw material.

If you're ready to simplify your supply chain and reduce costs, get in touch with a reliable maize starch supplier today.

📞 Contact Akshat Rasayan to place your bulk order and request a free sample today!

0 notes

Text

Vegetable Glue Market Size, Demand & Supply, Regional and Competitive Analysis 2025–2032

Market Size

The global Vegetable Glue market was valued at USD 498.2 million in 2024 and is projected to reach USD 737.5 million by 2032, growing at a CAGR of 5.0% during the forecast period from 2025 to 2032.

Vegetable glue, also known as starch-based or plant-based glue, is derived from natural sources like corn, wheat, or potatoes. It is widely used in packaging, bookbinding, labeling, and the paper industry due to its biodegradability, low cost, and non-toxic nature. As the demand for eco-friendly adhesives increases globally, the vegetable glue market is gaining strong momentum.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

👉 Download a Free Sample Report PDF: https://www.24chemicalresearch.com/download-sample/289241/global-vegetable-glue-forecast-market-2025-2032-880

Drivers:

Growing Demand for Eco-Friendly Products: Increasing environmental concerns and preference for biodegradable adhesives are major growth drivers.

Packaging Industry Expansion: Surge in e-commerce and consumer goods sectors boosts the demand for vegetable glue in cartons, boxes, and paper-based packaging.

Regulatory Push Toward Sustainable Adhesives: Stricter environmental laws are encouraging the use of plant-based glues over synthetic alternatives.

Restraints:

Limited Moisture Resistance: Vegetable glue performs poorly in high humidity conditions, restricting its use in certain applications.

Shorter Shelf Life: Compared to synthetic glues, vegetable glue has limited durability and storage capability.

Opportunities:

Innovation in Starch Formulation: Development of modified vegetable-based adhesives with improved performance can open new applications.

Increased Adoption in Labeling and Paper Products: Eco-labels and recyclable packaging are driving new demand channels.

Challenges:

Competition from Synthetic Adhesives: Petroleum-based adhesives dominate due to their high performance and versatility.

Cost Fluctuations in Raw Materials: Prices of agricultural inputs can affect production economics.

Regional Analysis

North America: High adoption of sustainable materials and strong demand in packaging and bookbinding applications support market growth.

Europe: Leading the way in green packaging policies and bio-based adhesives, especially in Germany, France, and the UK.

Asia-Pacific: China and India are seeing increased use of vegetable glue due to expanding paper, packaging, and printing industries.

Latin America: Emerging applications in food packaging and paper sectors in Brazil and Argentina.

Middle East & Africa: Gradual market expansion supported by regulatory efforts to reduce plastic and chemical adhesive usage.

Competitor Analysis (in brief)

Key players in the Vegetable Glue market include:

Henkel AG & Co. KGaA

3M Company

Avery Dennison Corporation

H.B. Fuller Company

The Reynolds Company

Paramelt B.V.

Jowat SE

Adhesives Research, Inc.

Sika AG

Franklin International

These companies invest heavily in R&D, focusing on enhancing adhesive strength, moisture resistance, and sustainability of their vegetable glue products.

Global Vegetable Glue Market Segmentation Analysis

The report offers insights into key segments and growth opportunities across the value chain.

By Type:

Corn-Based Glue

Wheat-Based Glue

Potato-Based Glue

Other Starch-Based Glues

By Application:

Packaging

Bookbinding

Paper & Labeling

Furniture & Woodworking

Others

Geographic Segmentation:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

FAQs

1. What is the current and projected market size of the Vegetable Glue market? The global Vegetable Glue market was valued at USD 498.2 million in 2024 and is projected to reach USD 737.5 million by 2032, growing at a CAGR of 5.0% during the forecast period.

2. Which sectors are driving the demand for vegetable glue? Key sectors include packaging, bookbinding, labeling, and paper industries, driven by increased demand for biodegradable and sustainable adhesive solutions.

3. What are the major challenges in the vegetable glue market? Challenges include limited moisture resistance, competition from synthetic adhesives, and fluctuations in raw material prices.

👉 Get The Complete Report & TOC: https://www.24chemicalresearch.com/reports/289241/global-vegetable-glue-forecast-market-2025-2032-880

👉 Follow Us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Note

Top 5 muses aside from adhocs most likely to eat glue

AW FUCK

why would you do this to me

LEMME SEE...........

I think Khov would try it. Definitely. She is a little creechur after all.

Alyona also would. For the meme.

Nocturne would if it smelled good.

Anastasiya has no taste buds so if yo told her it was real food she would eat it to be polite.

Suki would not eat glue if offered, she would buy the corn starch based glue specifically because she's always wondered how it tastes.

#interaction || asks#ordans || headcanons#coven || headcanons#vasiliev opg || headcanons#inseparableduo

1 note

·

View note

Text

things which are made of organic stationary?

Organic stationery encompasses a wide range of eco-friendly and sustainable products made from natural, biodegradable, and recycled materials. These products are designed to reduce environmental impact while providing functional and stylish alternatives to conventional stationery. One of the most common items made from organic stationery is recycled paper notebooks and journals. These notebooks are created using post-consumer waste paper, which reduces the need for virgin pulp and helps conserve natural resources. Recycled paper notebooks often come with covers made from kraft paper, recycled cardboard, or other biodegradable materials. Many brands that produce organic stationery also use soy-based inks and natural adhesives to ensure the entire product is eco-friendly.

Bamboo pens and pencils are another popular category of organic stationery. Bamboo, being one of the fastest-growing and most sustainable resources, is an ideal material for crafting writing instruments. Bamboo pens are often refillable, allowing users to replace the ink cartridge, which extends the lifespan of the product and minimizes waste. Similarly, organic wooden pencils are made from sustainably sourced wood and natural graphite, offering an environmentally friendly alternative to traditional plastic-cased pencils. Some wooden pencils are even embedded with seeds, allowing them to be planted after use, promoting a circular life cycle that benefits the environment.

Organic erasers and glue sticks are also integral parts of organic stationery. Organic erasers are typically made from natural rubber, which is tapped sustainably from rubber trees, ensuring that the production process does not harm the environment. These erasers are free from PVC and other harmful chemicals, making them safe for children and eco-conscious consumers. Organic glue sticks, on the other hand, are formulated using plant-based adhesives derived from natural starch or gums, ensuring that they decompose safely without leaving harmful residues.

Seed paper and plantable stationery have gained significant popularity in the organic stationery market. Seed paper is made from a blend of recycled paper pulp and seeds that can be planted after use. Once placed in soil and watered, the paper decomposes, allowing the embedded seeds to sprout and grow into plants, flowers, or herbs. This innovative product is commonly used for wedding invitations, greeting cards, business cards, and promotional materials, providing a creative and sustainable way to reduce paper waste.

Organic cotton and jute pencil cases, pouches, and organizers are also part of the organic stationery family. These storage solutions are made from natural fibers grown without the use of harmful pesticides or synthetic fertilizers, ensuring that the production process is environmentally sustainable. Organic fabric pencil cases and organizers offer a durable and reusable alternative to plastic cases, keeping stationery items neatly stored while minimizing environmental impact.

0 notes

Text

so idk how usamerican casseroles as a concept are but if you have never been taught the basics of a casserole, no matter where you live, i need to teach you today because it is a very good and near-infinitely customizable way to turn Ingredience into Food (Tasty). also because i had some for dinner and it was very very good.

the humble casserole (or “hot dish” if you’re my cousins from minnesota) consists of four (4) main categories:

protein

starch

veggie

glue

the glue is almost always cream of mushroom soup. i have never had it on its own but it probably tastes like casserole glue.

first you need an oven-safe dish, just about any size or shape so long as it has Depth and Surface Area.

next you’re gonna find a protein. ground beef? shredded chicken? edamame? doesn’t matter! i personally love a good tuna casserole, so that’s the example we’re going with. get an Amount and dump in in the dish. casserole is a vibes-based meal that scorns your silly mortal “measurements”.

got your protein in? great! next, find a Starch. i like pasta best but rice will also do. …maybe even barley now that i think about it. you will learn how to judge Casserole Ingredients. for now let’s go with macaroni noodles. boil ‘em up and dump ‘em in!

next you want Veg. look through your freezer and see what needs eating. corn? broccoli? lima beans? green beans? for sake of example, i’ll go with my favorite again: peas! dump those suckers in frozen, it’ll be fine. probably. who cares? not your yummy casserole.

now add your glue! you don’t have to use cream of mushroom if you don’t have it, shreddy cheese works just fine. (you can even add shreddy cheese to the crm. mush. casserole if you want! nobody’s stopping you!)

mix it all together and either toss it in the oven right away or! add an optional Garnish, such as crunchy onions, breadcrumbs, or just crushed up crackers spread somewhat evenly across the top. (you could also spread a layer of cheese! yum!)

the internet says “Casseroles typically need to bake in the oven for 30 minutes to 1 hour at a temperature of 350-375°F (175-190°C)”, so make of that what you will. check on your tasty shlop dish every so often just to be on the safe side, but it doesnt really matter. once it looks and smells good it’s probably ready. i suggest you use pre-cooked meat for this exact reason, so everything is already food-safe and you can go off Vibes.

now scoop some onto a plate and dig in! the rest can be packed into tupperware containers and voila! you have Leftovers!

#recipe#i guess?#food tips#casserole#look i didnt MEAN to write a guide to casseroles today#but my dinner grabbed my wrist and compelled me.#my grandma taught me about the four components and i have never forgotten it#feel free to ignore this i havent slept much this week

0 notes

Text

Necron Pharma: Trusted White Dextrin Provider for Multiple Industrial Uses

White dextrin is a versatile carbohydrate compound widely used in various industries, including food processing, pharmaceuticals, adhesives, and textiles. As a leading white dextrin provider, Necron Pharma ensures high-quality production, supplying industries with reliable and consistent dextrin solutions for their needs.

This article explores the properties, applications, benefits, and why Necron Pharma is the preferred supplier of white dextrin.

What is White Dextrin?

White dextrin is a modified starch derivative obtained by heating starch with acids or enzymes. The process partially hydrolyzes the starch molecules, making dextrin soluble in water while retaining adhesive and binding properties.

White dextrin is commonly used as a thickener, stabilizer, and binding agent, making it valuable in several industries.

Applications of White Dextrin

White dextrin serves multiple industries due to its unique characteristics, such as solubility, adhesive properties, and non-toxic nature. Below are the major industries where white dextrin is widely used:

1. Food Industry

Used as a thickening agent in soups, sauces, and gravies.

Functions as a crisping agent in baked goods.

Acts as a stabilizer in confectionery products, such as candies and coatings.

2. Pharmaceutical Industry

Works as a binding agent in tablet formulations.

Helps in coating tablets for controlled drug release.

Used in powdered medications to enhance solubility.

3. Adhesives & Paper Industry

Used in manufacturing water-soluble adhesives for paper and packaging.

Enhances bonding strength in envelope glue and labels.

Helps in coating paper and cardboard to improve printability.

4. Textile & Printing Industry

Functions as a thickening agent in textile printing pastes.

Used in stiffening fabrics for a smooth finish.

Enhances color absorption in dyes and inks.

5. Chemical & Industrial Applications

Used as a binder in fireworks and pyrotechnics.

Helps in foundry molding and casting applications.

Acts as a dusting powder in rubber and latex industries.

Benefits of Using White Dextrin

White dextrin offers several advantages, making it a preferred ingredient across industries:

1. High Solubility in Water

Easily dissolves, making it ideal for adhesive and food applications.

2. Excellent Binding Properties

Provides strong adhesion, making it useful in paper and packaging industries.

3. Non-Toxic and Safe

Approved for food and pharmaceutical use, ensuring safety.

4. Cost-Effective

An affordable alternative to synthetic binders and stabilizers.

5. Enhances Product Performance

Improves texture, stability, and quality of various formulations.

Why Choose Necron Pharma as Your White Dextrin Provider?

Necron Pharma is a trusted name in white dextrin production and supply. The company is committed to high-quality standards, innovation, and customer satisfaction. Here’s why Necron Pharma stands out:

1. Premium Quality Assurance

Necron Pharma follows strict quality control to ensure pure and high-grade white dextrin.

Products are tested for solubility, purity, and consistency.

2. Industry-Specific Solutions

Supplies white dextrin for food, pharmaceutical, adhesive, and industrial applications.

Offers customized formulations based on client needs.

3. Competitive Pricing & Bulk Supply

Provides cost-effective solutions without compromising quality.

Ensures bulk availability for large-scale industrial demands.

4. Reliable Delivery & Customer Support

Ensures timely delivery to meet industrial production schedules.

Provides excellent customer support and technical assistance.

Customer Testimonials

Many businesses rely on Necron Pharma for their white dextrin supply. Here’s what clients say:

“Necron Pharma provides the best quality white dextrin for our food processing needs.” — Food Manufacturer

“Their adhesive-grade dextrin improved our packaging strength and durability.” — Packaging Company

“We trust Necron Pharma for pharmaceutical-grade white dextrin. Highly recommended!” — Pharmaceutical Manufacturer

Conclusion

White dextrin is a key ingredient in multiple industries, and Necron Pharma is a trusted provider known for high-quality products, affordability, and reliable supply.

If you are looking for a dependable white dextrin supplier, Necron Pharma is your best choice for industrial and commercial applications.

0 notes

Text

Eco-Friendly Adhesives and Finishes in Door Fabrication with Custom Iron Door Experts at Abby Iron Doors

Sustainable practices have become essential in modern manufacturing. The door fabrication industry is shifting toward eco-friendly adhesives and finishes. These materials reduce environmental impact while maintaining durability and performance. Many conventional adhesives contain harmful chemicals that affect indoor air quality. Eco-friendly alternatives offer a safer and more sustainable option. Read more

Using environmentally friendly finishes ensures a healthier living space. Low-VOC and water-based finishes minimize toxic emissions. Additionally, they enhance the aesthetic and protective qualities of doors. Manufacturers are embracing these innovations to meet sustainability standards. Consumers are also demanding greener options for their homes.

Selecting the right adhesives and finishes is crucial. It impacts the longevity, safety, and sustainability of the final product. Understanding the available options can help in making informed decisions. Proper application techniques also contribute to better performance. Industry professionals must stay updated on emerging trends in eco-friendly materials.

Benefits of Eco-Friendly Adhesives

Custom iron door experts at Abby Iron Doors mention that eco-friendly adhesives provide several advantages over traditional options. They contain fewer harmful chemicals, improving indoor air quality. These adhesives also reduce exposure to toxic substances during manufacturing. As a result, workers experience fewer health risks. The final product remains safe for consumers as well.

Sustainability is another key benefit of these adhesives. Many are derived from natural or renewable sources. This reduces reliance on petroleum-based chemicals. Additionally, they break down more easily in the environment. Using them contributes to a lower overall carbon footprint.

These adhesives do not compromise on strength or durability. Advanced formulations offer excellent bonding performance. They resist moisture and temperature fluctuations effectively. This ensures that doors remain sturdy over time. Manufacturers can rely on them for long-lasting results.

Their application is also user-friendly. Many eco-friendly adhesives require less ventilation during use. They dry quickly and provide strong adhesion without toxic fumes. Some options are compatible with automated manufacturing systems. This makes them suitable for large-scale production.

Common Types of Eco-Friendly Adhesives

Water-based adhesives are among the most popular options. They use water as a carrier instead of harmful solvents. This reduces volatile organic compound (VOC) emissions. These adhesives bond well with wood and composite materials. They are ideal for interior and exterior door fabrication.

Soy-based adhesives are another sustainable choice. They are derived from soy protein and natural resins. These adhesives provide strong bonding properties. They also resist moisture and temperature changes as highlighted by iron door experts at Abby Iron Doors. Manufacturers use them to replace formaldehyde-based glues.

Starch-based adhesives offer a biodegradable alternative. Made from natural starches, they are non-toxic and renewable. They work well for certain wood applications. Their low environmental impact makes them highly desirable. However, they may not be suitable for all fabrication processes.

Polyurethane-based adhesives have eco-friendly formulations. Some variations use bio-based components. They offer excellent strength and flexibility. These adhesives perform well in demanding applications. They also enhance the durability of fabricated doors.

Importance of Low-VOC Finishes

Custom iron door experts at Abby Iron Doors convey that low-VOC finishes are crucial for healthier indoor environments. Volatile organic compounds contribute to poor air quality. High levels of VOCs can cause respiratory issues. Using low-VOC finishes reduces these risks. They create a safer living space for occupants.

These finishes maintain durability and visual appeal. They provide excellent protection against wear and tear. Many options offer UV resistance for long-term performance. They also enhance the natural beauty of wood doors. Manufacturers do not have to sacrifice quality for sustainability.

Environmental impact is significantly lower with low-VOC finishes. They release fewer pollutants into the atmosphere. Many water-based options are biodegradable. This reduces hazardous waste from door fabrication. Sustainable practices benefit both businesses and consumers.

Regulatory compliance is another factor to consider. Many regions have strict VOC limits. Using eco-friendly finishes ensures compliance with environmental laws. It also improves brand reputation. Consumers increasingly prefer companies that prioritize sustainability.

Water-Based vs. Oil-Based Finishes

Water-based finishes have gained popularity for their sustainability. They contain fewer harmful chemicals than oil-based alternatives. These finishes dry faster and emit less odor. They are easy to clean with water. Their formulation reduces environmental and health risks.

Oil-based finishes offer durability but have higher VOC content. They take longer to dry and require more ventilation. These finishes penetrate deeply into wood surfaces. They provide a rich, long-lasting sheen. However, they contribute to air pollution more than water-based options.

Choosing between these finishes depends on several factors. Water-based options are ideal for eco-conscious projects. They are suitable for residential and commercial applications. Oil-based finishes may be preferable for high-traffic areas. They provide added resistance to wear and moisture as pointed out by iron door experts at Abby Iron Doors.

Many manufacturers are transitioning to water-based alternatives. Advances in technology have improved their performance. Modern formulations offer comparable durability to oil-based finishes. They are available in various sheen levels. This allows for versatile design options in door fabrication.

Best Practices for Applying Eco-Friendly Adhesives and Finishes

Proper surface preparation is essential for optimal results. Clean and dry surfaces ensure better adhesion. Any dust, grease, or debris should be removed. Sanding can improve the bonding strength. This step enhances the durability of the final product.

Using the right application techniques prevents issues. Adhesives should be applied evenly to avoid weak spots. Sufficient drying time is necessary for maximum strength. Finishes should be applied in thin, even coats. This ensures a smooth and consistent appearance.

Temperature and humidity levels impact performance. High humidity can slow drying times. Extreme temperatures may affect adhesion strength. Controlled conditions lead to better results. Manufacturers should monitor environmental factors carefully.

Custom iron door experts at Abby Iron Doors express that regular maintenance extends the lifespan of eco-friendly finishes. Gentle cleaning products help preserve surface integrity. Avoiding harsh chemicals prevents deterioration. Periodic reapplication may be necessary for long-term protection. Proper care enhances the longevity of fabricated doors.

Abby Iron Doors

0 notes