#tcp/ip

Explore tagged Tumblr posts

Text

sweet jude, you are my dearest punishment

just finished this piece that took so. fckn. long. btw did i mention my commissions are open? 😼

#jurdan#cardan greenbriar#prince cardan#cardan fanart#cardans tail#jude duarte#jude x cardan#high queen jude#tcp/ip#tcp fanart#tcp#the cruel prince#the wicked king#the queen of nothing#holly black#elfhame#the folk of the air#fae folk#folk of the air#tfota series#tfota fanart#tfota#the stolen heir#cardan my beloved#high king cardan#i love cardan#cardan#high queen of elfhame#jude greenbriar#the cruel prince fanart

1K notes

·

View notes

Text

Wireshark: Unravel the secrets of your network with this essential packet analyzer

Have you ever wondered what exactly is happening on your network? Do you want to understand how your devices communicate and how data flows? If so, you need to know about Wireshark! This powerful, open-source package analyzer is a must-have tool for anyone who works with networks. What is Wireshark? Wireshark is a protocol analyzer that allows you to capture and examine network traffic in…

0 notes

Text

A Review of 1969: A Year of Defining Moments, Month by Month

Apart from being my birth year, 1969 was a pivotal one, full of cultural, scientific, and political milestones that left an indelible mark on human history. Photo by Pixabay on Pexels.com I will take you along a journey through this year, one month at a time, highlighting a significant event from each. January: The Concorde’s First Flight On January 21, the Concorde, the world’s first…

View On WordPress

#1969#1969 Stonewall#ARPANET#dailyprompt#dailyprompt-2161#Internet#LGBT#LGBTQ+#Moon Landing#Raffaello Palandri#Solar Eclipse#Stonewall Uprising#TCP/IP#UNICEF#UNICEF Nobel Peace Prize#Woodstock

0 notes

Text

#standards#developer#tcp/ip#http#oauth#sql#html#css#ecmascript#iso#data#format#openapi#development#software#web#bytebytego

1 note

·

View note

Text

What Are the Key Components of Socket Programming?

Socket programming involves key components such as sockets, which establish endpoints for communication, and protocols like TCP or UDP. Other crucial elements include IP addresses and port numbers for identifying devices and services, socket functions for data transmission and reception, and error handling mechanisms to manage communication issues.

Read more :https://themediumblog.com/what-are-the-key-components-of-socket-programming/

0 notes

Text

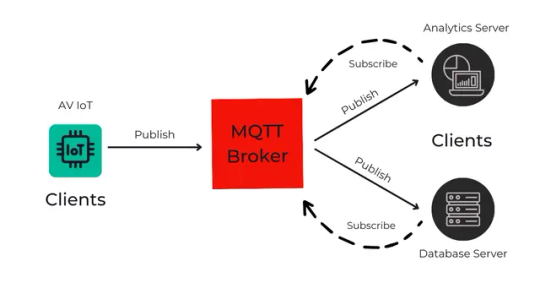

Empowering EVs: How MQTT is Highly Abstracted for IoT Communication

The Internet of Things (IoT) has taken center stage in the rapidly evolving landscape of interconnected devices. Industries have transformed with the ability to share data over the internet seamlessly. Thus, utilizing the right communication protocol becomes one of the cornerstones of optimization. MQTT (Message Queuing Telemetry Transport) has emerged as the catalyst, outperforming traditional TCP/IP protocols. While TCP/IP is the most widely used internet communication protocol, it lacks some key capabilities required in IoT applications. In this blog, we’ll dissect the capabilities of MQTT, exploring how it influences the communication, efficiency, and performance of electric vehicles way more than TCP/IP protocols can.

TCP/IP: The Conventional Choice

TCP/IP, the foundational communication protocol of the internet, has played an indispensable role in connecting the world for decades. Its robustness and reliability have made it the go-to choice for various networking applications. However, when it comes to the unique demands of the Internet of Things (IoT), TCP/IP may not be the complete solution. TCP/IP relies on direct point-to-point connections, predominantly focusing on the accuracy of data transfer over the internet. Meanwhile, IoT requires protocols that efficiently handle many interconnected devices, often with limited resources. Thus, TCP/IP needs additional capabilities to make it suitable for the web of communication in EVs. Achieving the same level of adaptability offered by MQTT while building an application on TCP/IP is possible, although it will incur additional computational overhead and meticulous application design. Moreover, with the availability of a categorically designed protocol, engaging in building one seems redundant.

Why MQTT?

Electric vehicles represent the mobility innovation paradigm of the 21st century, filled with intricate systems comprising sensors, control units, and batteries. These systems require seamless information exchange with analytical and database servers via the Internet. Some critical decisions are made based on the data received from the vehicles, making infallible and efficient communication, often using limited resources, extremely vital. TCP/IP protocol does meet these requirements with design customizations. However, MQTT, the protocol in our spotlight, is custom-designed to cater to these exacting demands.

Let’s see how-

1. Real-time Data Flow: Harmonizing EV Communication

Visualize an EV as an orchestra of components—batteries, motors, sensors—all attuned to real-time performance. The data from this intricate system needs to be efficiently acquired and stored so that post-analytics, intelligent insights can be drawn from it. MQTT’s publish/subscribe model facilitates seamless bidirectional communication between vehicles and servers. A central MQTT broker hosts topics (data sources, in this case, EVs) and servers without direct links. Clients can subscribe to relevant topics, keeping communication fast and efficient rather than overloading with information. MQTT also keeps communication bidirectional, allowing servers to publish back to the topics when required.

2. Lean, Green, and Efficient

In the realm of EVs, efficiency is non-negotiable. MQTT protocol utilizes a shorter data packet compared to other protocols. Moreover, the data is stored as binary bytes, leading to a much smaller data footprint. This lightweight architecture minimizes computational overhead, conserving precious power drawn from the battery. It also keeps the servers clear from data overload.

3. Quality of Service (QoS): Precision Delivery

EVs demand precision in data transmission. MQTT offers three Quality of Service (QoS) levels—0, 1, and 2—that ensure data arrives exactly when required.

QoS 0 (At most once): This level ensures that messages are delivered but provides no acknowledgment or guarantee of receipt. It’s suitable for scenarios where some message loss is acceptable.

QoS 1 (At least once): This level guarantees that messages are delivered at least once but may be delivered multiple times. It suits applications where message duplication is acceptable, but message loss isn’t.

QoS 2 (Exactly once): This is the highest level of assurance, ensuring that messages are delivered exactly once. It’s suitable for applications where message duplication is unacceptable, such as critical control systems.

4. Adept with Multiple Data Types

With systems of various sensors, motor controllers, battery packs, and more, the data from EVs comes in all shapes, sizes, and formats. The communication must be adept with multiple data types to ensure the assured data communication from each system. MQTT currently offers a spectrum of data types ranging from two-bit and four-bit integers to UTF-8 string pairs.

5. Scaling for EV Fleets

The surge in electric vehicle fleets requires scalability. MQTT can seamlessly accommodate a flourishing array of vehicles and components because of its application layer architecture. The ease of setup and scale-up makes it an ideal choice for efficient fleet management. It adapts to your evolving needs, whether managing a handful of vehicles or an entire fleet.

Putting MQTT into Action

Let’s delve into a brief exposition of the level of abstraction the MQTT protocol offers within the context of electric vehicles.

1. Lightweight Design

TCP/IP is more resource-intensive than MQTT due to its comprehensive nature. While MQTT stores control units as binary bytes, TCP/IP uses bulky text strings. This extra resource consumption can affect the overall efficiency of EVs.

2. Data Reliability

While TCP/IP does provide reliability in data transfer, it may not offer the same flexibility and customization as MQTT regarding data delivery. Without QoS, the surety of re-transmission and loss-less data delivery becomes extremely tough and undesirable for EVs. Whether for battery management, charging control, or firmware updates, MQTT’s QoS guarantees reliability while maintaining communication efficiency.

3. Bidirectional Communication

TCP/IP intrinsically prevents servers from initiating communication and publishing messages. MQTT allows servers to initiate communication, increasing vehicle and server data flow flexibility and adaptability, enabling a list of additional services specific to EVs, like remote locking and unlocking.

4. Superior Data Handling Capability

Unlike MQTT, TCP/IP natively only supports ASCII characters. Although handling multiple data types can be achieved with TCP/IP, it may not be as effortless as MQTT. This capability empowers sourcing data from different devices in the EV.

5. Retained Messages

A retained message is stored in the broker with its corresponding QoS for the topic. Each client will receive this retained message as soon as it subscribes to that topic. Retained messages are essential in the EV domain, as some data points are critical for the vehicle’s health. This functionality of the MQTT protocol makes it stand apart from other protocols.

The Road Ahead for MQTT:

MQTT offers a compelling set of advantages for IoT-based communication, making it a preferred choice for many IoT deployments. As the electric vehicle landscape continues its steep ascent, MQTT will play an increasingly pivotal role. MQTT is the protocol of choice for EVs due to its lightweight design, real-time capabilities, efficiency, and scalability. Embracing MQTT will empower EV OEMs to optimize and streamline data transfer from edge to cloud, where efficient communication is key to success. Don’t stand on the sidelines— adopt MQTT today and position yourself at the forefront of the electric vehicle revolution.

0 notes

Text

What is TCP/IP and How Does it Work? 2023

TCP IP stands for Transmission Control Protocol Internet Protocol It is a set of communication protocols that are used to connect computers

0 notes

Text

youtube

0 notes

Text

a garden you never got to see

[ALT ID: A digital illustration of a man with his eyes closed and head tilted up toward the light. An embroidered red scarf is draped over his head and ghostly hands appear to be pulling on it.]

#the ascension to IP is skimmed over pretty lightly in tcp but it brings me joy to imagine callebero#stoned out of his mind and seeing ghosts#anyway i never know if ppl actually want the bg details on these things#but the gist is that red is associated with victory in arradine and one of anharad's (the founder of arradine who's believed to have been#the god of death incarnate) epithets is ~'scarlet-mantled'#which by the time of tcp (callebero's era) has created great discord in the historian community#between the camp that believes it's because she actually had red hair#and the camp that believes it's more like 'adorned by victory' and metaphorical#callebero is the second person to ever achieve that title#which was his maman's great dream#so all in all this is basically the ghost of his maman straightening the mantle of victory after callebero is crowned/etc.#my art#story: tcp#ch: callebero#ch: alir#at least in hallucination form!

4 notes

·

View notes

Text

fast forward a year from now (hopefully) when I'm taking the comptia security+ exam. anyone who reads my mind that day is just gonna hear the chant "a pussy so tight no dick penetrates" over and over again

#all the mnemonic devices out there for tcp/ip and it's only the crudest one that sticks in my brain#gitta.txt

5 notes

·

View notes

Text

ah sim, os protocolos de redes de internet... SMT, FDP, VTNC, FDS, PPRT.... a internet é linda...

#qrevo.txt#estudando os protocolos de internet e como caralhos eu vou decorar todas essas letras#SMTP?? FTP?? TCP/IP?? não podiam ter dado nomes melhores??#vou escrever letras aleatórias e esperar que eu acerte um dos protocolos na sorte

6 notes

·

View notes

Text

Wireshark: Desentraña los secretos de tu red con este analizador de paquetes esencial

¿Te has preguntado alguna vez qué sucede exactamente en tu red? ¿Quieres entender cómo se comunican tus dispositivos y cómo fluyen los datos? Si es así, ¡necesitas conocer Wireshark! Este potente analizador de paquetes de código abierto es una herramienta imprescindible para cualquier persona que trabaje con redes. ¿Qué es Wireshark? Wireshark es un analizador de protocolos que te permite…

0 notes

Text

#QuizTime Best protocol for secure web browsing?

A) HTTPS 🔐 B) HTTP 🌍 C) FTP 📤 D) TCP/IP 📡

Comments your answer below👇

💻 Explore insights on the latest in #technology on our Blog Page 👉 https://simplelogic-it.com/blogs/

🚀 Ready for your next career move? Check out our #careers page for exciting opportunities 👉 https://simplelogic-it.com/careers/

#quiztime#testyourknowledge#brainteasers#triviachallenge#thinkfast#protocol#secure#webbrowsing#https#http#ftp#tcp#ip#quizmaster#knowledgeIspower#mindgames#funfacts#makeitsimple#simplelogicit#simplelogic#makingitsimple#itservices#itconsulting

0 notes

Text

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes