#tensile testing machines

Text

Guide To choose the Right Tensile/Compression Strength Testing Machine

Despite the fact that Tensile/Compression strength testing machines are and utilized pretty much in every industry there is still absence of information with regards to buying the right machine. Given the scope of items, the features and the variations in cost getting one can be a bit overwhelming and this becomes especially true for non -standard applications.

One of the inquiries we get posed to by our clients is whether to pick a manually operated machine or motorized one and if motorized is chosen, would it be a good idea for us we pick a machine with Computer Control and inclusive of data acquisition. So, we should check out at this according to a point of view of a spring manufacturer.

There are two elements which go with this choice simpler. The first and most clear one is the price. Manually operated machines are less expensive obviously, then motorized lastly computerized. In any case, in the event that you are taking a heavier spring which are utilized in train bogies or airplanes, then, at that point, motorized ones must be utilized no matter what the budget. Imaging putting a pressure power of 5000 kg on a spring, (for example, the ones utilized under the train bogies) with a hand wheel. Indeed, even with utilization of a geared 3 train it's diligent effort.

Whenever that is chosen, the other element which is significant is the volume of testing. A spring manufacturer can let out a huge number of springs a day. The question then is whether to do batch testing or 100% testing. Batch testing is where you pick a couple of tests from the batch, test them and assuming all are good you say that the entire batch is good. In such cases a manual machine would be satisfactory. However, if one wants to test several thousand springs a day it's smarter to go for a motorized machine and reduce the burden of manual labour on the machine operator.

So, we decided on a manual or motorized machine. Subsequent stage in the development is whether to get a computer-controlled machine. These are machines operated straightforwardly from the computer and give the testing output as a force versus displacement chart. This imagines the way of behaving of the spring constantly. Regularly these software’s also provide a statistical report for all the tests, so min, max, standard deviation etc. and so forth. Are accessible as reports. Any large organizations where the report should be imparted to the higher ups who just need an outline of the production quality, these machines are a good decision. Any new product requiring data for approval must be tested on such machines. In many cases the client request that the manufacturer present the report online or in pdf format to avoid any possibility of manipulation. The best way to avoid from this is to utilize a computerized machine.

In specific cases the product you manufacture dictates the type of machine, there are ASTM, IS norms which settle on the decision for you. Be that as it may, for situations where it’s a non-standard product, we trust this article assists you with choosing what's best for you.

#utm#tensile#compressiontesting#stm#spring#universal testing machine manufacturers#mechanical engineering#manufacturer#springtesting#tensile testing machines

0 notes

Text

The Basics of Universal Tensile Testing Machine: A Comprehensive Guide

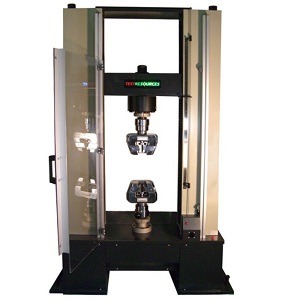

Tensile testing machines, also known as pull testers or universal testing machines (UTMs), are electromechanical systems used to evaluate the tensile strength and deformation behavior of a material until it reaches its breaking point.

0 notes

Text

0 notes

Text

Top Tensile Testing Machine Manufacturer | Indian Trade Bird

IndianTradeBird offers a variety of Tensile Testing Machines, catering to different testing needs. Some options include tabletop models ideal for basic testing in labs [1]. They might be suitable for quality control or production line purposes. Other machines might be computerized, offering greater precision and data analysis capabilities. Our Tensile Testing Machine is equipped with state-of-the-art technology to provide precise measurements of force, elongation, and deformation. This machine is ideal for testing metals, polymers, textiles, and other materials, making it a versatile solution for your testing needs. The robust construction and high-quality components ensure durability and long-term performance, even under heavy usage. At Indian Trade Bird, we are committed to providing top-notch products and exceptional customer service. Our Tensile Testing Machine is backed by comprehensive support, including installation, training, and maintenance services. Our team of experts is dedicated to helping you maximize the performance and efficiency of your testing processes.

For more details clicks here - https://www.indiantradebird.com/product/tensile-testing-machine-

0 notes

Text

Automatic horizontal tensile tester

An automatic horizontal tensile tester is a machine used to measure the tensile strength of materials by subjecting them to a controlled pulling force. Automatic horizontal tensile testers offer efficient and accurate testing of materials, making them essential tools in various industries such as manufacturing, quality control, and research and development.

0 notes

Text

Tensile strength testing is a crucial procedure in various industries, ensuring the quality and durability of materials. A Tensile Strength Tester is a specialized equipment designed to measure the force required to pull a material until it breaks.

A Tensile Testing Machine is a precision instrument comprising various components such as a load cell, grips, and a testing chamber. Selecting the appropriate tensile strength tester involves considering factors such as material type, testing frequency, and required accuracy. Practical tips will be provided to aid in making an informed decision.

Emphasizing the need for regular tensile strength testing in different industries to ensure ongoing quality, safety, and compliance with standards. You can email us at [email protected] or call us at +91 9555515525 for additional information about the tensile testing machine's price, uses, or applications.

#tensile strength tester#tensile testing machine#tensile tester#tensile test equipments#tensile tester manufacturer

0 notes

Text

What is the purpose of a Compression Testing Machine?

Universal Tensile Testing Machine Systems give strength capacities that cover from 1,000 pounds to 100,000 pounds force. The Testing Machine is a very usual testing method that is used to set up the compressive force or crush resistance of a material and the capacity of the material to get back after a particular compressive force is applied and even held over a defined period of time by measuring fundamental variables.

https://compressiontestingmachineusa.blogspot.com/2022/04/what-is-purpose-of-compression-testing.html

0 notes

Text

Measure the Breaking Force of Materials with a Tensile Machine

Tensile Machine is one of the finest lab testing instruments ever made due to its ergonomic design and universal versatility which comes together in a complete package. This test machine is also known as the Tensile Strength Tester, and as the name indicates it is used for measuring the strength or the force required to break the specimen.

The machine is offered universally in all the manufacturing industries as a manufacturer would tend to buy Tensile Tester rather than a load of other machinery and instruments.

It becomes highly important to meter the breaking strength of your material before utilizing the material in the final product. The Tensile Machine Tester is henceforth designed to regulate and make certain changes at the manufacturer level and deliver a flawless final product.

Read More -- https://www.testing-instruments.com/blog/measure-the-breaking-force-of-materials-with-a-tensile-machine/

#tensile strength tester#tensile strength tester manufacturer#tensile strength tester price#tensile strength tester supplier#digital tensile testing machine

0 notes

Text

Unveiling the Strength within the Irresistible Allure of Tensile Testing Machines

Are you one of those who are unable to decide on procuring the right Tensile testing machine? Let your search end right here! Keeping in view the hassle involved, a useful guide has been provided for you. In the realm of materials testing, a tensile testing machine stands as a great asset, quietly unraveling the secrets hidden within various materials. Whether you are a materials engineer, a quality control professional or a researcher pushing the boundaries of innovation, the acquisition of a reliable tensile testing machine is an investment that can redefine your approach to materials analysis.

0 notes

Text

Tensile Testing Machines Role in Improving Quality of Material Testing

The tensile testing machine is also called as a lab testing machine, is one of the most important tools in the field of material science and engineering. When it comes to comprehending and assessing the mechanical properties of materials, accuracy and quality are important.

0 notes

Text

Tensile Strength Testing Machine

The Tensile Testing Machine is a highly efficient and reliable device designed for testing the strength and durability of various materials. It is equipped with advanced technology that allows for precise and accurate measurements of tensile strength, elongation, and other mechanical properties. This machine is widely used in industries such as manufacturing, construction, and research laboratories to ensure the quality and performance of materials.

The Tensile Testing Machine provides:

# Advanced technology for accurate, precise measurements

# Testing capabilities for tensile strength, elongation, and more

# Reliable results you can count on

# User-friendly interface requires minimal training

# Ideal for manufacturing, construction, and research industries

#Tensile Testing Machine#Material Testing#Quality Control#Mechanical Testing#Strength Testing#Engineering#Testing Equipment#Industrial Testing#Material Science#Manufacturing

0 notes

Text

0 notes

Text

Tensile Testing Machine Manufacturer in India

A tensile tester or tensile testing machine is used to determine the strength and deformationbehavior of a material up to the point of fracture. It is used to find out how strong a material is and also how much it can be stretched before it breaks. This test method is used to determine yield strength, ultimate tensile strength, ductility, strain hardening characteristics, Young's modulus and Poisson's ratio. To perform a tensile test, an operator will load a specimen into the two specimen grips of the machine. After loading the specimen, the operator selects the correct rate of movement for the material type. The tester then pulls the specimen apart until failure. The data obtained by tensile testing ensures the integrity and safety of materials, components and products. It helps manufacturers to ensure the quality of their final product and are fit-for-purpose.

For more details clicks here - https://www.indiantradebird.com/product/tensile-testing-machine-

0 notes

Text

Best Tensile Testing Machine Manufacturers

Peak Technology is established in the year 2010 and we are trusted and reputed Tensile Testing Machine Manufacturers which is located in New Delhi. Our offered machines are equipped with advance techniques & tools and Tensile Testing Machine is widely used to tensile tester machine, a pulling force or tension is applied to a material until it fails or breaks and its response to the stress is measured.

Visit Here: - https://peaktest.in/tensile-test/

0 notes

Text

Types of tests conducted under UTM in the electronics sector.

Tensile testing is a mechanical test widely used in various industries to evaluate the mechanical properties of materials. The primary focus of tensile testing is to measure the strength and performance characteristics of materials when subjected to tensile (tension) forces. During the test, a sample of the material is pulled in opposite directions until it fractures or reaches its breaking point. The data obtained from tensile testing helps engineers and manufacturers understand material behaviour under tension and design products that meet specific requirements. Here are some key industries where tensile testing is prominently used:

Manufacturing Industry: Tensile testing is extensively used in the manufacturing industry to assess the mechanical properties of raw materials and finished products. It is crucial for quality control, ensuring that materials meet the required strength, ductility, and elongation properties for their intended applications.

Aerospace Industry: In the aerospace industry, tensile testing is employed to evaluate the performance of materials used in aircraft components, such as metals, composites, and alloys. It ensures the materials can withstand the high stresses and forces experienced during flight.

Automotive Industry: Tensile testing is essential in the automotive industry to evaluate the strength and reliability of various automotive materials, including steel, aluminium, and plastics. It helps ensure the safety and durability of vehicle components.

Construction Industry: Tensile testing is used to assess the strength and performance of construction materials, such as concrete, steel, and other building materials. It ensures the materials can withstand the stresses and loads experienced in construction projects.

Materials Research and Development: In research and development laboratories, tensile testing is used to study and understand the mechanical properties of new materials, such as advanced composites, polymers, and nanomaterials.

Medical Devices and Biomedical Industry: Tensile testing is utilized to evaluate the mechanical properties of materials used in medical devices, implants, and prosthetics. It ensures the safety and reliability of these products for patient use.

Plastics and Polymers Industry: Tensile testing is critical for evaluating the tensile strength, elongation, and flexibility of plastics and polymers used in various applications, including packaging, consumer goods, and industrial components.

Electronics Industry: Tensile testing is applied to evaluate the mechanical integrity of electronic components and solder joints to ensure their reliability under stress and temperature variations.

Textile Industry: In the textile industry, tensile testing is used to assess the tensile strength and elongation properties of fabrics and fibers. It helps determine their suitability for various applications, such as apparel, technical textiles, and industrial fabrics.

Tensile testing is a fundamental mechanical testing method that plays a crucial role in various industries, helping ensure the quality, safety, and performance of materials and products. It aids in material selection, product design, quality control, and research and development efforts across different sectors.

Material testing in the electronic industry is essential to ensure the reliability, performance, and safety of electronic components and devices. The electronic industry relies on various material testing methods to assess the mechanical, electrical, thermal, and environmental properties of materials used in electronic products. Electrical testing is performed to evaluate the electrical properties of materials, such as conductivity, resistivity, dielectric strength, and insulation properties. These tests are crucial for selecting suitable materials for conductive traces, insulators, and other electronic components. Thermal testing assesses the thermal properties of materials, including thermal conductivity, coefficient of thermal expansion (CTE), and heat resistance. It is essential for ensuring that materials can withstand temperature variations during operation without failure. Mechanical testing involves evaluating the mechanical properties of materials, such as tensile strength, hardness, flexural strength, and modulus of elasticity. These tests help determine the material's ability to withstand mechanical stresses and mechanical failure points. Solderability testing evaluates the ability of electronic components and materials to be effectively soldered during the assembly process. It ensures proper bonding and reliability of solder joints. Environmental testing exposes materials and electronic components to various environmental conditions, including temperature extremes, humidity, salt spray, and vibration. This testing assesses how the materials perform in real-world conditions and helps identify potential failure mechanisms. Corrosion testing is crucial for assessing the material's resistance to corrosion, which is essential for electronic components used in harsh or corrosive environments. Surface analysis techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are used to examine the surface morphology and microstructure of materials and electronic components. Flammability testing evaluates the material's response to fire and determines its fire resistance properties. It is particularly important for materials used in electronics, as they must comply with safety standards to prevent fire hazards. These material testing methods ensure that the materials used in electronic components and devices meet the required specifications, standards, and performance expectations. Effective material testing helps improve product quality, reduce manufacturing defects, and enhance the reliability and safety of electronic products. In the context of electronic testing, UTM stands for Universal Test Machine, which is a versatile testing equipment used for conducting various mechanical tests on materials and electronic components. UTM can perform different types of electronic testing to evaluate the mechanical properties of materials used in electronic products.

Tensile testing is conducted using a UTM to evaluate the tensile strength, elongation, and other mechanical properties of materials. In the electronic industry, tensile testing is commonly performed on components like connectors, cables, and wires to ensure they can withstand mechanical stress without failure.

Compression testing is used to assess the compressive strength and resistance of materials. Electronic components, such as connectors, sockets, and enclosures, may undergo compression testing to determine their structural integrity and ability to withstand external forces.

Flexural testing, also known as bending testing, evaluates the bending strength and modulus of materials. It is important for assessing the rigidity and flexibility of components like circuit boards, PCBs, and thin electronic devices.

Shear testing is conducted to evaluate the shear strength and deformation behaviour of materials under shear stress. In the electronic industry, shear testing may be performed on solder joints and adhesive materials to assess their reliability and performance.

Peel testing is used to measure the adhesion strength of materials and adhesive bonds. This type of testing is relevant for electronic components with adhesive backing or bonded structures.

Fracture toughness testing assesses the resistance of materials to crack propagation. It is important for evaluating the reliability and durability of materials used in electronic components subjected to dynamic stresses.

Fatigue testing is used to determine the fatigue life and fatigue strength of materials. In the electronic industry, fatigue testing is relevant for connectors, solder joints, and other components that may experience cyclic loading during use.

Impact testing evaluates the impact resistance and toughness of materials. It may be applied to electronic components to assess their ability to withstand mechanical shocks and impacts.

Hardness testing measures the hardness of materials, which is crucial for assessing wear resistance and deformation characteristics. Electronic components and materials may undergo hardness testing to ensure their durability and performance.

These electronic testing methods conducted under a Universal Test Machine (UTM) play a vital role in evaluating the mechanical properties of materials and ensuring the reliability, safety, and performance of electronic components and devices. The results obtained from these tests aid in material selection, quality control, and design optimization for various electronic applications. Tensile testing services in the electronic industry are provided by specialized testing laboratories and facilities that have the necessary equipment and expertise to conduct mechanical testing on electronic components and materials. These services play a crucial role in ensuring the mechanical reliability and performance of electronic products. Some common types of tensile testing services offered in the electronic industry include:

Cable and Wire Testing:

Tensile testing of cables and wires is essential to assess their tensile strength, elongation, and breaking point. These tests help determine the mechanical properties of conductive materials used in cables and wires, ensuring they can withstand mechanical stress during installation and use.

Connector and Contact Testing:

Connectors and contacts in electronic devices may undergo tensile testing to evaluate their mechanical strength and integrity. Tensile tests help identify potential weaknesses or failure points in connectors, ensuring they can withstand repeated plugging and unplugging.

Adhesive Bond Testing:

Tensile testing is used to assess the adhesion strength of adhesive bonds in electronic components. This testing ensures that adhesives used in bonding components together can withstand mechanical forces without delamination or failure.

PCB (Printed Circuit Board) Testing:

Tensile testing of PCBs is important to evaluate their flexural strength and bending properties. It helps determine the mechanical reliability of PCBs, especially in applications where they may be subjected to bending or flexing.

Solder Joint Testing:

Tensile testing of solder joints is performed to assess their mechanical strength and reliability. Solder joints are critical in electronic assembly, and tensile testing ensures their ability to withstand mechanical stress and temperature variations.

Component Testing:

Tensile testing is used to evaluate the mechanical properties of various electronic components, such as resistors, capacitors, inductors, and semiconductors. These tests help ensure the components can withstand mechanical stresses during assembly and operation.

Material Characterization:

Tensile testing is performed on various materials used in the electronic industry to determine their tensile strength, elongation, and other mechanical properties. This information aids in material selection and quality control.

Failure Analysis:

In cases of product failure or defects, tensile testing may be used as part of the failure analysis process to identify the root cause of the failure and assess the mechanical reliability of the components involved.

Tensile testing services are typically offered by accredited testing laboratories with experienced technicians and engineers who follow standardized testing procedures and industry specifications. The results obtained from these tests provide valuable data for product development, quality assurance, and compliance with industry standards in the electronic industry.

1 note

·

View note