#torque sensor blog

Explore tagged Tumblr posts

Photo

New Post has been published on https://www.vividracing.com/blog/139824-2/

In 2022, car enthusiasts all over the United States were anxiously awaiting the arrival of the Nissan Z. In the new Z, not 400Z, it seems Nissan answered all of our prayers. Equipped with a 3.0L VR30DDTT Twin Turbo V6 and a 6 speed FS6R31 manual transmission, the new Z34 (Kouki Z34) seemed to fill all the gaps Nissan left in the Zenki Z34 and R35 that left true drivers wanting more. With a power output at an even 400hp (298kw; 406ps) and 350 ftlbs (475 N-m 48 kg-m) of torque, the new Z34 was unlike any of its predecessors and a breath of fresh air in the middle of the ‘Sports Car Electrification Movement’. Nissan then broke some hearts, mine included, when they announced the 420hp, 384ftlb Z34 Nismo would be equipped with a rebadged Mercedes 9G-Tronic automatic transmission manufactured under Jatco as the JR913E and that there would be no manual option for the Nismo Z. Their reasoning: Even with more power, the automatic sport model would be faster in the ¼ mile than a manual Nismo, and they feared consumers would care.

Fast forward to release day, and the reasonably priced Nissan Z saw dealer markups of over $70,000 over MSRP on what could be Nissan’s final true sports car. Somehow, clout and fear of missing out beat common sense and they sold like hotcakes. So much so, that as of the writing of this article, the least expensive USED Nissan Z on the market is being offered at $7,000 above NEW MSRP. Now to bring it all into perspective, if you were an early buyer of a Nissan Z, you’re punching in Audi RS5 Coupe, BMW M4 Competition xDrive, and C8 Corvette territory price-wise, except you likely have cloth seats, less power, and are a good deal slower from 0-60 than your newly priced out competition… and the EFI scientist here at Vivid Racing just can’t let you go out like that.

Interested in this Nissan Z Tuning Box? Order Here

While we have options for your interior woes, and styling upgrades that make the car look the part of the markup, we were focused on two things and two things only: horsepower and torque… and drivability (I’m aware that’s three things). When this Two-tone Ikazuchi Yellow Tricoat / Super Black Kouki Z34 rolled into our dyno lab, we were impressed. It put down an underrated 405hp and 475ftlbs of torque through the automatic transmission, which was more than we all expected. Immediately wanting to unlock the ECU and start our flash process, the customer let us know the factory warranty was very important to him and that he would like to keep it. Luckily here at VR Tuned, we have developed a Warranty-safe tune with our VR Tuned Tuning Box. Basically, this system acts as a piggy back. It requires no cutting or splicing and does not modify the way any of the factory sensors work. Instead, through science and electrical engineering and magic, it provides safe, modified data to the factory ECU, allowing us modify boost, fuel and spark strategies that ultimately results in a 65hp increase over stock and 85 more ftlbs or torque through our VR Forged wheels.

To make it more user-friendly for the driver, we included optional Bluetooth control for both iOS and Android platforms, allowing the user to quickly change between 7 performance maps, or simply turn the tuning box off for emissions purposes from their phone. With 3 active drive modes (Race, Sport, and Eco) included, and German tuning box construction, we feel Vivid Racing has crafted the ultimate tuning solution for Nissan Z owners looking to retain their factory warranty. We also found the best exhaust system for making big power, and the best suspension system to keep it all under control, so there’s no need to take it one step at a time. The next stop for us and the Z should be a track day, so subscribe if you want to see more.

So whether you want to be the talk of the town at the next local cars and coffee, or you want to take a few hot laps around the track in extreme comfort, shoot me an email at [email protected] to get your Z right.

Product Featured: VR Tuned ECU Tuning Box Kit V2 Nissan Z | 400Z

2 notes

·

View notes

Text

Hi, before I explain my post, I want to say something important.

• What you see my blog has become a major overhaul. And despite the changes, I decided that my 2nd account will be now my artwork blog with a secret twist.

⚠️NEW RULE! (W/ BIGGER TEXT!)⚠️

⚠️ SO PLEASE DO NOT SHARE MY 2nd ACCOUNT TO EVERYONE! THIS SECRECY BLOG OF MINE IS FOR CLOSES FRIENDS ONLY!⚠️

• AND FOR MY CLOSES FRIENDS, DON’T REBLOG IT. INSTEAD, JUST COPY MY LINK AND PASTE IT ON YOUR TUMBLR POST! JUST BE SURE THE IMAGE WILL BE REMOVED AND THE ONLY LEFT WAS THE TEXT.

⚠️ SHARING LINKS, LIKE POSTS, REBLOG POSTS, STEALING MY SNAPSHOT PHOTOS/RECORDED VIDEOS/ARTWORKS (a.k.a. ART THIEVES) OR PLAGIARIZING FROM UNKNOWN TUMBLR STRANGERS WILL IMMEDIATELY BE BLOCKED, RIGHT AWAY!⚠️

😡 WHATEVER YOU DO, DO NOT EVER LIKED & REBLOG MY SECRET POST! THIS IS FOR MY SECRET FRIENDS ONLY, NOT YOU! 😡

Okay? Capiche? Make sense? Good, now back to the post…↓

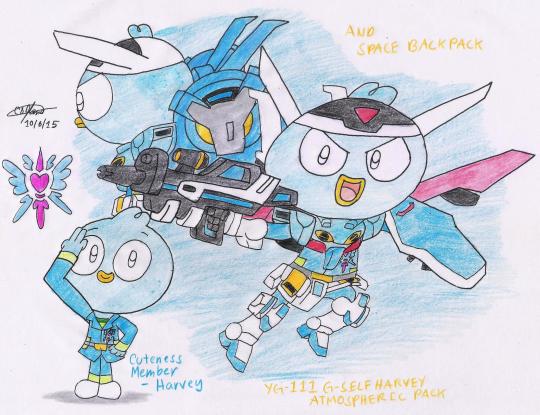

#Onthisday: Oct 6th, 2015

Title: Cuteness Member - Harvey Beaks

A remake from my 1 year ago artwork before they renamed and premiering on Nick a month ago (year 2015).

Anyways, just a little recap. The first Nickelodeon character has joined the "Cuteness Defender Academy" was none other than Harvey Beaks, and his "Cuteness Mecha Armor" of choice? The armored "G-self"! 😁🤖🐤

I have so many differentiate color strip uniforms for Harvey and this is my final color. Including his difference compared to my old ones. And yet I have 2 packs left for Harvey and I hope I could drew it someday.

So now let's focus on my remake. I've also saw some updates for his armaments, so I'll retype again for a full info. 🙂

YG-111 G-Self Harvey (Atmospheric and Space backpack)Came from the original: Gundam G-Self, Atmospheric Pack & Space Pack

• Gundam G-Self - [CLICK ME!] • G-Self Atmospheric Pack - [CLICK ME!] • G-Self Space Pack - [CLICK ME!]

Armament(s):

• Beam Saber G-Self has a pair of beam saber stored near its shoulders. It can spin them so fast for defensive purpose in fashion similar.

• Beam Rifle G-Self actually uses two models of beam rifle with two brands. The original one is the most powerful, and other model is easier to maintain.

• Shield G-Self uses three models. The 1st (blue) and 2nd (red) shield are multipurpose, the 3rd (glow blue) shield is from the Perfect backpack. The 2nd (red) model shield has built-in vulcan guns, sliding beam absorbing reflectors, and is capable of generating a photon shield to protect allies.

Special Equipments and Feature(s):

• Atmospheric Pack The atmospheric pack is the original pack built by Towasanga, G-Self's colors remain the same as the standard colors. On the main wings there are a pair of laser pod, double as radar sensor.

• BPAM-02 Space Pack Built by Amerian Army, the Space Pack are simple boosters to improve the G-Self's mobility in space.

(Other packs:) • Assault Pack • Tricky Pack • Reflector Pack • High Torque Pack • Perfect Pack

Harvey Beaks - Harvey Beaks © Nickelodeon, C.H. Greenblatt Armors (Gundam Reconguista in G) - Gundam Series © Bandai Namco Filmworks/SUNRISE, Sotsu

2 notes

·

View notes

Text

Enhancing Industrial Efficiency: The Role of Motors, Adapters & Circuit Breakers

In the age of Industry 4.0, automation is no longer just about moving parts—it’s about intelligent power management, secure connectivity, and system safety. At Dropship Automation Solutions, we supply the essential components that support high-performance industrial systems and resilient infrastructures.

In this blog, we explore three foundational elements of automation hardware: electric motors, industrial adapters, and circuit breakers—each playing a vital role in energy transfer, system compatibility, and operational safety.

1. Motors: Driving Industrial Motion

What Motors Do

Electric motors convert electrical energy into mechanical motion, making them fundamental in powering conveyor belts, pumps, fans, and more. Their reliability and precision keep operations running smoothly across countless industries.

Types & Applications

Types: AC motors, DC motors, servo motors, stepper motors

Applications: Conveyor systems, HVAC units, manufacturing robots, elevators

Benefits: High efficiency, consistent torque, reduced manual labor

Why Motors Matter

Motors are the force behind physical movement in automated systems. With high energy efficiency and precise control, modern motors minimize downtime and optimize mechanical output.

2. Adapters: Connecting Systems Seamlessly

What Adapters Do

Adapters serve as connectors that allow two otherwise incompatible devices or systems to work together. In industrial settings, they enable cross-device compatibility for data, power, or signal transmission.

Common Adapter Types & Uses

Types: Electrical plug adapters, signal adapters, communication protocol converters

Applications: Sensor integration, PLC expansion, international power conversion

Benefits: Device compatibility, simplified upgrades, reduced wiring complexity

Why Adapters Matter

Industrial adapters bridge gaps between old and new technologies, allowing systems to scale without costly replacements. They’re key to maintaining flexible and future-proof automation architectures.

3. Circuit Breakers: Safeguarding Electrical Systems

What Circuit Breakers Do

Circuit breakers protect electrical circuits from overloads or short circuits by interrupting power flow when abnormal conditions are detected. They ensure both equipment and personnel safety.

Types & Use Cases

Types: Miniature circuit breakers (MCB), molded case circuit breakers (MCCB), ground fault circuit interrupters (GFCI)

Applications: Control panels, power distribution, renewable energy systems

Benefits: Overcurrent protection, system isolation, fire prevention

Why Circuit Breakers Matter

Without circuit breakers, electrical faults could lead to equipment damage, fires, or system-wide failures. These devices serve as first-line defenders, ensuring your facility operates within safe power limits.

Building a Safer, Smarter Industry

Imagine an automated facility where:

Motors drive production lines with precision,

Adapters ensure seamless system connectivity,

Circuit breakers protect everything from faults and overloads.

This combination supports efficiency, safety, and adaptability—all key ingredients in modern industrial success.

Conclusion: Power Your Automation with Confidence

Smarter factories rely on trusted components for performance, safety, and scalability. At Dropship Automation Solutions, we provide robust motors, versatile adapters, and reliable circuit breakers to help build your next-gen industrial environment.

Empower your automation strategy—today.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Traction Control Systems and Chassis Control Logic

Introduction

Performance and safety are two constant cornerstones that drive innovation and design in the ever-changing field of automotive engineering. Automakers are always trying to find a balance between these fundamental components. Systems that guarantee the best possible traction and stability are becoming increasingly important as cars get quicker and smarter. In this context, Traction Control Systems (TCS) and Chassis Control Logic (CCL) play a vital role.

These technologies are essential parts of modern car architecture, not only accessories. They actively work to enhance safety, handling, and control in a range of driving scenarios. This blog examines the fundamentals, elements, features, advantages, and drawbacks of TCS and CCL — as well as how Dorleco is leading the way in these fields.

The Grip Guardian: Traction Control Systems (TCS)

What is Traction Control?

The Importance of Traction Control Systems

Wheel slippage is more likely with modern engines’ increased torque and power, especially on wet, gravel, or snowy conditions. By identifying and addressing wheel spin in real-time, TCS lowers this danger and promotes a safer and more comfortable driving experience.

Important Elements of Traction Control Systems

1. Sensors for Wheel Speed

Wheel rotation is continuously monitored by these sensors, which are installed on each wheel. TCS can identify traction loss in milliseconds by analyzing each wheel’s rotational speed.

2. Unit of Electronic Control (ECU)

The ECU serves as the system’s brain. It analyses sensor data and decides on repairs like cutting engine power or applying the brakes.

3. System of Brake Actuation

To regain traction balance, TCS selectively delivers braking force to one or more wheels that spin more quickly than the others.

4. Controls for Throttle and Ignition

To stop additional wheel spin in cars with electronic throttle control, TCS may lower engine torque by modifying ignition timing or throttle input.

How TCS Works?

lowering engine output (through ignition timing or throttle control) It reacts in one of two ways if it notices that one or more wheels are spinning significantly faster:

Lowering engine output (through ignition timing or throttle control)

Braking the wheels that are sliding

The driver is frequently unaware of the quick and smooth action, which significantly improves vehicle stability.

The Coordinator of Stability: Chassis Control Logic (CCL)

What is Control Logic for Chassis?

How Other Systems Connect with CCL

ESC stands for Electronic Stability Control. To prevent skidding, ESC recognizes and lessens understeer or oversteer. To maintain the vehicle’s intended course, it applies braking to individual wheels and lowers engine power.

ABS (Anti-lock Braking System)

ABS prevents the wheels from locking when braking abruptly, allowing the driver to maintain steering control.

Distribution of Brake Force Digitally (EBD)

EBD improves braking economy by dynamically adjusting braking power across all four wheels based on driving conditions and vehicle load.

System of Adaptive Suspension

Adaptive suspension, which is seen in high-end or performance cars, automatically modifies damping rates to strike a balance between road sensation and comfort.

Steering control and torque vectoring

In order to maximize power delivery and steering effort for increased agility and safety, CCL may incorporate torque vectoring and variable steering systems.

The Execution of CCL

CCL gathers information from a vast array of sensors, such as:

Accelerometers

Gyroscopes

Wheel-speed sensors

Sensors for steering angle

It continuously analyses this data and modifies the torque output, steering input, suspension stiffness, and brake distribution to maintain vehicle handling and balance.

Principal Advantages of TCS and CCL

Traction control systems’ (TCS) advantages

Improved Traction

keeps traction on slick conditions, such as wet roads, snow, or ice.

Enhanced Speed

Allows for smoother and more effective acceleration by preventing wheel spin.

Consistency When Turning

Controls torque delivery to lessen the chance of losing control when cornering.

Improved Off-Road Management

provides substantial advantages in rough terrain by efficiently controlling wheel slide.

Automated Intervention

TCS enhances overall safety and confidence by operating in the background without requiring driver engagement.

Chassis Control Logic’s (CCL) advantages

Excellent Car Handling

Uses synchronized system inputs to improve lane changing, turning, and cornering behaviour.

Increased Braking Effectiveness

EBD and ABS work together to prevent wheel lock and shorten stopping distances.

Modes Selectable by the Driver

Enables the driver to customize the dynamics of the car by choosing between comfort, sport, or eco modes.

Decreased Tire Damage

Uneven tire wear can be lessened by distributing force evenly across the wheels.

Reduced Risk of Rollover

regulating lateral dynamics, CCL, which is essential for SUVs and trucks, helps avoid rollovers.

Challenges and Limitations

Limitations of the Traction Control System (TCS)

Decreased Engine Performance In performance automobiles, a drop in engine power during intervention may feel slow.

Not Suitable for Every Off-Road Situation

Intentional wheel spin is required in certain off-road situations — TCS can hinder advancement.

Inaccurate Positive Results

may turn on unnecessarily when driving aggressively but carefully.

Increased Expense and Difficulty

increases the cost of the vehicle and the amount of maintenance needed because of the extra hardware.

Limitations of Chassis Control Logic (CCL)

Complexity of the System

The complexity of diagnosis and repair is increased when numerous systems are integrated.

Dependency on Sensors

Curve of Driver Adaptation

System interventions could be too obtrusive or foreign to certain drivers.

Energy usage

Particularly in non-EV cars, electronic technologies may result in higher fuel or battery consumption.

Applications in the Real World

From sedans and SUVs to sports cars and commercial vehicles, TCS and CCL technologies are becoming more and more commonplace in most contemporary automobiles. These devices complement autonomous driving capabilities in premium and performance cars to improve control in challenging circumstances.

Regenerative braking in EVs provides even more traction and stability by seamlessly integrating with TCS and CCL.

These solutions improve operational safety in commercial fleets by lowering accident rates and vehicle downtime.

Advanced TCS and CCL Solutions from Dorleco

Furthermore, Dorleco’s next-generation chassis control logic and traction control systems are revolutionizing vehicle dynamics.

Our products use clever algorithms and smoothly interface with vehicle control units (VCUs) for:

Wheel slip detection in real time

Improvements to predictive control

Improved aid for drivers

Adaptable driving modes

Why opt for Dorleco?

Strong E/E Software Proficiency

In addition, our own development team creates control systems that are both scalable and modular.

Superior CAN Interfaces

Our CAN keypads and CAN displays provide efficient human-machine communication with vital control systems.

Worldwide R&D Assistance

Dorleco produces innovation that is both locally relevant and globally compliant through teams in the US, India, Germany, and Canada.

With every vehicle, Dorleco enables OEMs and Tier 1s to provide unmatched safety, comfort, and control.

Conclusion

Advanced control systems are becoming more and more necessary as vehicle technology advances. Today’s drivers want safety, performance, and dependability, and traction control systems and chassis control logic are no longer optional equipment.

Although there are certain difficulties with these technologies, they are greatly outweighed by their advantages. The foundation of intelligent vehicle control is made up of Traction Control Systems and CCL, which reduce tire wear, improve off-road capabilities, and minimize skidding and cornering.

We at Dorleco are honoured to be a part of this development. Our cutting-edge technology , Engineering services, Engineering Staffing Solutions not only fulfil but also surpass contemporary performance and safety requirements, propelling the development of intelligent, dependable, and superior cars in the future.

#Dorleco#TractionControl#ChassisControl#VehicleDynamics#AutomotiveInnovation#VCU#CANDisplay#ElectricVehicles#ADAS#MobilityTech#SmartDriving#EngineeringExcellence

0 notes

Text

Bottle Cap Torque Tester for Accurate Torque Testing

Source of Info: https://www.perfectgroupindia.co.in/blog/bottle-cap-torque-tester-for-accurate-torque-testing

Introduction

A helpful equipment to identify the force needed to open or close bottle caps and guarantee they are not too tight or too loose is a Bottle Cap Torque Tester. Maintaining packaging standards is important for the beverage and cosmetics industries. This device is supported by Perfect Group India and allows businesses to test cap torque correctly, reducing the risk of leaks and unhappy customers. Its reliable performance and user-friendly design make it suitable for manufacturing processes and quality control labs, helping brands in following product safety and trust across various packaging methods.

How does a Bottle Cap Torque Tester work? An accurate tool called a Bottle Cap Torque Tester is used to identify how much force is needed to open or close bottle caps. Torque is the rotational force applied to a cap. If the torque is too low the bottle can break. The product can be damaged or the customer might find it difficult to open if it is too high. Manufacturers can achieve the perfect balance between sealing the product tightly enough to avoid breakage or user complaints by using torque testers.

This tester allows manufacturers to check every cap’s tightness during quality control processes and even helps in setting torque standards for different bottle and cap types.

Why Torque Testing Matters When it comes to sealing bottles achieving the correct torque is a delicate balance. It directly affects:

Product Safety: Incorrect sealing can lead to damage or leakage.

Shelf Life: Proper sealing maintains product freshness for a longer period.

Brand Image: Easy to open and properly sealed bottles reflect positively on brand quality.

Customer Experience: Customers can become irritated with a bottle that is difficult to open.

Regulatory Compliance: Certain industries require specific sealing torque levels for health and safety compliance.

In short the Bottle Cap Torque Tester is not just an optional tool it's important in maintaining product quality.

Industries Using Bottle Cap Torque Tester

Food and Beverage: To keep liquids fresh and avoid leaks.

Pharmaceutical: To guarantee that child-resistant and tamper-evident caps function as planned.

Cosmetics: For lotions, creams and serums that come in sealed bottles.

Chemicals: To stop dangerous exposures or spills.

Household Products: Ensuring the safety of cleaning liquids and sprays.

In each of these sectors torque testing supports not just quality control but also consumer trust and brand value.

Features of a Reliable Bottle Cap Torque Tester A good tester should offer more than just torque measurement. What to look for is as follows:

Digital Display: Makes reading values easy and error free.

User-Friendly Interface: Suitable for testing productivity and providing quick training.

High Accuracy Sensors: Guarantees reliable test results every time.

Compact Design: Saves space in your lab or manufacturing process.

Memory Storage: Stores test results for quality audits or future reference.

Customizable Range: It works with a variety of bottle and cap sizes.

These features simplify the testing process while delivering dependable outcomes, making it easier for industries to meet quality standards.

How the Tester Works The work of a Bottle Cap Torque Tester is simple. The bottle is placed securely into the holding clamp. Then the cap is manually turned or sometimes rotated using a motorized system, while the torque sensor records the force. The device captures both the opening torque, how much force is needed to remove the cap and the closing torque force required to tighten the cap during manufuring..

The measured data is then displayed and can be stored or printed for further analysis. The results help in adjusting capping machines and maintaining uniformity in production.

Common Types of Torque Testers

Manual Torque Testers: Hand-operated best for small batches or lab settings.

Digital Torque Testers: Provide improved accuracy and digital results.

Motorized Torque Testers: Completely automated perfect for manufacturing processes with high speeds.

Key Benefits of Using a Bottle Cap Torque Tester

Improves Packaging Quality

Decrease Product Wastage

Reduce Leakage Complaints

Ensures Better Shelf Presence

Helps in Calibration of Capping Machines

Supports Regulatory Audits and Documentation

These benefits make Bottle Cap Torque Tester a wise investment for manufacturers who care about product reliability and market reputation.

Perfect Group India Your Partner in Packaging Solutions The Bottle Cap Torque Tester is one of Perfect Group India's premium options for companies searching for reliable testing equipment. Their device is user-friendly designs and advanced technology help manufacturers to maintain high quality control across packaging processes. Having the right testing equipment is important for durability in competitive markets and no matter the size of the company.

Maintenance Tips for Better Performance To ensure durability use of your torque tester:

Calibrate Regularly: Regular calibration maintains testing accuracy.

Clean After Use: Avoid buildup that can affect grip or readings.

Store in a Safe Area: Avoid damage from dust, heat or moisture.

Train Operators: Ensure your team uses the equipment correctly for best results.

Conclusion The Bottle Cap Torque Tester helps industries maintain proper sealing and avoid product leakage by providing reliable torque testing. It is important for maintaining packaging security, freshness and safety for storage and transportation. Its reliable performance and simple use help manufacturers meet quality standards. This device is trusted in industries such as chemicals, beverages and medication. It increases productivity and improves testing requirements by using advanced features. This equipment is the best option for people who want quality and packaging safety. Perfect Group India is a reputable company that provides this testing solution and is well-known for providing reliable testing equipment to a variety of industries.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester

0 notes

Text

Smart Peristaltic Pumps and IoT Integration in Modern Industries

We are in a fast-paced industry landscape where efficiency, precision, and adaptability are the need of the hour. This can be a more critical process than ever, so including smart peristaltic pumps with the Internet of Things should be a perfect choice.

Joining this might be crucial in this shift, as their cutting-edge fluid handling system would allow real-time monitoring. Coupled with this, they need predictive maintenance, which might lend itself to energy-efficient operation in various industries.

Smart peristaltic pump uses are versatile in that they can be applied in either pharmaceuticals or food processing. These Internet of Things-enabled pumps are making their space in a new era of fluid management. This blog is all about peristaltic pumps and how its going smart, so let’s catch up with the pace.

What is a Peristaltic Pump and Why is it Going Smart?

Fundamentally, a peristaltic pump is a form of positive displacement pump that conveys fluids in a flexible tube by squeezing the tube using revolving rollers or shoes. The reason it is special is that it operates contamination-free because the fluid only touches the tubing.

Now imagine that same streamlined process with sensors, real-time data, and remote control. That's exactly what IoT integration offers with control, increased security, and smarter decision-making.

Real-Time Monitoring and Remote Control

One of the most intelligent advantages of smart peristaltic pumps is real-time monitoring. Sensors embedded within monitor important parameters like:

Flow rate

Internal pressure

Fluid temperature

Motor speed

Tubing wear

These real-time data streams over IoT networks into dashboards accessible on any device, anywhere. Operators can remotely change flow settings or react to alarms without being there, a godsend for companies with multiple operating locations.

Predictive Maintenance: No Guesswork Needed

Conventional maintenance practices have the potential of being based on periodic servicing or repair. But that's not the case with IoT-enabled pumps.

Sophisticated machine learning algorithms and analytics interpret sensor data to forecast failure prior to occurrence. For instance, once a peristaltic pump dispenser indicates abnormal pressure, the system can provide a choice to alert the operator in advance of its impact on the process.

Predictive approach:

Reduces unplanned downtime

Reduces repair costs

Extends pump life

Enhances safety

Optimising Performance and Energy Consumption

Smart peristaltic pumps respond to changing conditions. Whether setting up a flow rate for delicate biotech materials or boosting throughout a bottling operation, they provide optimal performance with minimal user input.

The systems assist:

Prevent excessive energy usage

Reduce wear on pump components

Balance performance for changing viscosities and materials

Particularly, a peristaltic pump for high viscosity fluids becomes more efficient through intelligent feedback loops and adjustable torque settings.

Industry Use: Where Smart Pumps Shine

Smart peristaltic pumps serve across industries:

Pharmaceutical: Sterile, contamination-free processing of fluids for drug manufacture

Biotechnology: Precise dosing and reagent transfer

Water Treatment: Chlorine or pH adjustment with remote diagnostics

Food and Beverage: Hygienic transfer of syrups, sauces, or dairy

Manufacturing: Faultless dosing in automated assembly lines

Need mobility? An intelligent, portable peristaltic pump is ideal for application in remote locations or on-site measurement. It provides excellent performance without compromising portability.

Sustainable, Scalable, and Future-Ready

Along with control and efficiency, smart pumps are also sustainable. By not wasting, optimising energy use, and saving the application of excessive chemicals, they are also in concordance with the environmental goals of this time.

Intelligent peristaltic systems also provide easy scalability. With changing industries, the addition of additional pumps or adaptation of parameters involves a negligible adjustment of infrastructure from cloud-based interfaces and universal IoT protocols.

Conclusion: Smarter Pumps for Smarter Industries

As the Industrial Age welcomes digitisation, intelligent peristaltic pumps are proving to be an actual valuable gem. Because they can monitor, predict, and optimise, their performance is not only improved, but reliability, cost savings, and eco-efficiency are also fostered.

From sterile labs to sprawling production lines, the impact of IoT integration in peristaltic systems is undeniable, and we’re just scratching the surface.Want to take your fluid handling processes to the next level with intelligent peristaltic technology? Discover Microlit's portfolio of cutting-edge dispensing technologies for the industry of tomorrow. Let's pump smarter, not harder.

#peristaltic pumps#peristaltic pump#peristaltic pump uses#peristaltic pump for high viscosity fluids#liquid handling#pipettes#liquid handling instruments#portable peristaltic pump

0 notes

Text

Bottle Cap Torque Tester for Accurate Torque Testing

Source of Info: https://www.perfectgroupindia.co.in/blog/bottle-cap-torque-tester-for-accurate-torque-testing

Introduction

A helpful equipment to identify the force needed to open or close bottle caps and guarantee they are not too tight or too loose is a Bottle Cap Torque Tester. Maintaining packaging standards is important for the beverage and cosmetics industries. This device is supported by Perfect Group India and allows businesses to test cap torque correctly, reducing the risk of leaks and unhappy customers. Its reliable performance and user-friendly design make it suitable for manufacturing processes and quality control labs, helping brands in following product safety and trust across various packaging methods.

How does a Bottle Cap Torque Tester work?

An accurate tool called a Bottle Cap Torque Tester is used to identify how much force is needed to open or close bottle caps. Torque is the rotational force applied to a cap. If the torque is too low the bottle can break. The product can be damaged or the customer might find it difficult to open if it is too high. Manufacturers can achieve the perfect balance between sealing the product tightly enough to avoid breakage or user complaints by using torque testers.

This tester allows manufacturers to check every cap’s tightness during quality control processes and even helps in setting torque standards for different bottle and cap types.

Why Torque Testing Matters

When it comes to sealing bottles achieving the correct torque is a delicate balance. It directly affects:

• Product Safety: Incorrect sealing can lead to damage or leakage.

• Shelf Life: Proper sealing maintains product freshness for a longer period.

• Brand Image: Easy to open and properly sealed bottles reflect positively on brand quality.

• Customer Experience: Customers can become irritated with a bottle that is difficult to open.

• Regulatory Compliance: Certain industries require specific sealing torque levels for health and safety compliance.

In short the Bottle Cap Torque Tester is not just an optional tool it's important in maintaining product quality.

Industries Using Bottle Cap Torque Tester

• Food and Beverage: To keep liquids fresh and avoid leaks.

• Pharmaceutical: To guarantee that child-resistant and tamper-evident caps function as planned.

• Cosmetics: For lotions, creams and serums that come in sealed bottles.

• Chemicals: To stop dangerous exposures or spills.

• Household Products: Ensuring the safety of cleaning liquids and sprays.

In each of these sectors torque testing supports not just quality control but also consumer trust and brand value.

Features of a Reliable Bottle Cap Torque Tester

A good tester should offer more than just torque measurement. What to look for is as follows:

• Digital Display: Makes reading values easy and error free.

• User-Friendly Interface: Suitable for testing productivity and providing quick training.

• High Accuracy Sensors: Guarantees reliable test results every time.

• Compact Design: Saves space in your lab or manufacturing process.

• Memory Storage: Stores test results for quality audits or future reference.

• Customizable Range: It works with a variety of bottle and cap sizes.

These features simplify the testing process while delivering dependable outcomes, making it easier for industries to meet quality standards.

How the Tester Works

The work of a Bottle Cap Torque Tester is simple. The bottle is placed securely into the holding clamp. Then the cap is manually turned or sometimes rotated using a motorized system, while the torque sensor records the force. The device captures both the opening torque, how much force is needed to remove the cap and the closing torque force required to tighten the cap during manufuring..

The measured data is then displayed and can be stored or printed for further analysis. The results help in adjusting capping machines and maintaining uniformity in production.

Common Types of Torque Testers

• Manual Torque Testers: Hand-operated best for small batches or lab settings.

• Digital Torque Testers: Provide improved accuracy and digital results.

• Motorized Torque Testers: Completely automated perfect for manufacturing processes with high speeds.

Key Benefits of Using a Bottle Cap Torque Tester

• Improves Packaging Quality

• Decrease Product Wastage

• Reduce Leakage Complaints

• Ensures Better Shelf Presence

• Helps in Calibration of Capping Machines

• Supports Regulatory Audits and Documentation

These benefits make Bottle Cap Torque Tester a wise investment for manufacturers who care about product reliability and market reputation.

Perfect Group India Your Partner in Packaging Solutions

The Bottle Cap Torque Tester is one of Perfect Group India's premium options for companies searching for reliable testing equipment. Their device is user-friendly designs and advanced technology help manufacturers to maintain high quality control across packaging processes. Having the right testing equipment is important for durability in competitive markets and no matter the size of the company.

Maintenance Tips for Better Performance

To ensure durability use of your torque tester:

• Calibrate Regularly: Regular calibration maintains testing accuracy.

• Clean After Use: Avoid buildup that can affect grip or readings.

• Store in a Safe Area: Avoid damage from dust, heat or moisture.

• Train Operators: Ensure your team uses the equipment correctly for best results.

Conclusion

The Bottle Cap Torque Tester helps industries maintain proper sealing and avoid product leakage by providing reliable torque testing. It is important for maintaining packaging security, freshness and safety for storage and transportation. Its reliable performance and simple use help manufacturers meet quality standards. This device is trusted in industries such as chemicals, beverages and medication. It increases productivity and improves testing requirements by using advanced features. This equipment is the best option for people who want quality and packaging safety. Perfect Group India is a reputable company that provides this testing solution and is well-known for providing reliable testing equipment to a variety of industries.

0 notes

Text

Roller speed test

Roller Speed Test: Evaluating Performance, Efficiency, and Safety

The term "roller speed test" encompasses a variety of assessments designed to measure the performance and operational speed of roller-based systems. These tests are critical in industries ranging from manufacturing and logistics to sports and automotive engineering. Whether you're testing conveyor rollers, inline skates, or the speed of tires on roller dynamometers, the roller speed test is essential for ensuring efficiency, quality, and safety.

What is a Roller Speed Test?

A roller speed test typically involves using rollers—cylindrical components that rotate to facilitate movement or transfer of materials or objects—to determine how fast and efficiently a system operates. Depending on the context, the test may involve mechanical rollers (such as those in conveyor belts or machinery), rollers used in fitness or sports (like inline skates or treadmills), or roller dynamometers in automotive testing.

Applications of Roller Speed Tests

1. Manufacturing and Logistics

In production lines and warehouses, conveyor rollers move goods from one point to another. Roller speed tests in this context are used to:

Optimize production speeds.

Detect faulty or underperforming rollers.

Ensure synchronization with other parts of the assembly line.

2. Automotive Industry

Roller dynamometers are used to measure the performance of vehicle wheels, engines, and drivetrains. In a controlled environment, cars or motorcycles are placed on rollers that simulate road conditions. These tests help:

Assess horsepower and torque.

Monitor emissions under load.

Test braking systems at different speeds.

3. Sports and Recreation

In the world of roller sports (like skating or cycling training), roller speed tests are used to:

Measure an athlete’s speed and stamina.

Assess skate or wheel performance.

Fine-tune equipment for optimal race conditions.

Key Components of a Roller Speed Test

Sensors and Timers: For accurate speed readings.

Data Acquisition Systems: To log and analyze results.

Control Systems: To maintain consistent test conditions.

Safety Mechanisms: Especially important in high-speed or high-torque environments.

Benefits of Conducting Roller Speed Tests

Performance Optimization Regular testing helps identify mechanical inefficiencies, ensuring systems operate at peak capacity.

Preventive Maintenance Early detection of worn-out rollers or misaligned components reduces downtime and costly repairs.

Quality Assurance Products passing through rollers (such as on conveyor belts) experience consistent handling and reduced risk of damage.

Enhanced Safety In vehicles and sports, speed tests can expose faults in equipment that may lead to accidents if left unchecked.

Conclusion

The roller speed test is a critical evaluation tool across multiple sectors, ensuring that roller-based systems function effectively, safely, and efficiently. As automation and precision continue to define modern industry and sport, the importance of such testing will only grow. With proper implementation and regular monitoring, roller speed tests not only enhance performance but also drive innovation and reliability in equipment and systems.

Would you like this adapted for a technical report, school project, or SEO-optimized blog post?

1 note

·

View note

Text

Ford Expedition XLT 2015 usada—Ford Expedition en venta

Si busca una SUV espaciosa, potente y confiable, la Ford Expedition XLT 2015 podría ser justo lo que busca. Conocida por su comodidad, excelente rendimiento y amplia capacidad de asientos, la Ford Expedition ha sido durante mucho tiempo una de las favoritas tanto de familias como de aventureros. Ya sea que transporte un bote, lleve a los niños a la práctica de fútbol o se vaya de viaje por carretera, esta SUV de tamaño completo cumple con lo que promete.

En este blog, exploraremos las características, el rendimiento y los beneficios de comprar una Ford Expedition usada, especialmente la versión XLT 2015. También compartiremos por qué es una opción inteligente si busca una Ford Expedition en venta.

¿Por qué elegir la Ford Expedition XLT 2015?

La Ford Expedition XLT 2015 forma parte de la cuarta generación de Expeditions y presenta varias mejoras con respecto a sus predecesoras. Uno de los cambios más significativos para este modelo es el cambio de un motor V8 a un V6 turboalimentado. Este cambio ofrece una mejor eficiencia de combustible sin sacrificar el rendimiento.

Estas son algunas razones por las que la Expedition XLT 2015 destaca:

1. Rendimiento potente

Bajo el capó, la Expedition XLT 2015 está impulsada por un motor EcoBoost V6 de 3.5 litros, que genera 365 caballos de fuerza y 420 lb-pie de torque. Esto significa una gran potencia para remolcar y transportar. La capacidad de remolque alcanza hasta 9,200 libras con el equipamiento adecuado, ideal para remolques, botes o casas rodantes.

El motor está acoplado a una transmisión automática de 6 velocidades y está disponible con tracción trasera y tracción en las cuatro ruedas, lo que brinda a los conductores flexibilidad según sus necesidades.

2. Interior espacioso

Una de las principales razones por las que la gente elige la Ford Expedition es el espacio, y el modelo 2015 no decepciona. Tiene capacidad para ocho pasajeros en tres filas, con amplio espacio para las piernas y la cabeza en todas ellas. Ya sea que viaje con una familia numerosa o un grupo de amigos, todos pueden viajar con comodidad.

Además, los asientos traseros se pliegan para abrir un amplio espacio de carga. Si necesita aún más espacio, la versión Expedition EL (Longitud Extendida) ofrece espacio de almacenamiento adicional detrás de la tercera fila.

3. Características de comodidad y conveniencia

La versión XLT 2015 está bien equipada con características que mejoran la experiencia de conducción. Las características estándar incluyen:

Cámara de visión trasera

Sensores de estacionamiento traseros

Sistema de sonido de 6 bocinas

Sistema de control de voz SYNC

Conectividad Bluetooth

Puertos USB y entradas auxiliares

Las mejoras disponibles incluyen asientos de cuero, navegación, asientos delanteros con calefacción y refrigeración, y un sistema de sonido premium. Muchos modelos usados en el mercado vienen con paquetes opcionales ya instalados, por lo que es posible encontrar excelentes ofertas en vehículos bien equipados.

¿Qué hace de la Ford Expedition una excelente SUV usada?

Comprar una Ford Expedition usada puede ofrecer una excelente relación calidad-precio. Estas son las razones:

1. Durabilidad y fiabilidad

Ford es conocido por fabricar vehículos robustos y duraderos, y la Expedition no es la excepción. El modelo 2015 está fabricado sobre una estructura de camioneta, lo que lo hace muy resistente para el uso diario y las tareas pesadas. Con un mantenimiento adecuado, una Expedition usada puede superar fácilmente los 320.000 kilómetros.

2. Menor depreciación

Al comprar un vehículo nuevo, su valor se deprecia rápidamente. Un vehículo usado, especialmente uno de 2015, ya ha sufrido la mayor parte de su depreciación. Esto significa que obtienes un mejor vehículo por tu dinero. Puedes disfrutar de los mismos beneficios y características que una SUV más nueva, a una fracción del precio.

3. Mantenimiento asequible

Las piezas para la Ford Expedition están ampliamente disponibles y muchos talleres están familiarizados con el modelo. Esto hace que el mantenimiento y las reparaciones regulares sean más asequibles que los de la competencia, especialmente las SUV de lujo. Qué buscar en una Ford Expedition XLT 2015 usada.

Si está buscando una Ford Expedition en venta, aquí tiene algunos consejos para asegurarse de encontrar un vehículo de alta calidad:

1. Revise el historial del vehículo.

Solicite siempre un informe del historial del vehículo. Este mostrará cualquier accidente previo, registro de servicio e historial de propiedad. Un historial limpio con mantenimiento regular es una buena señal de que la SUV ha recibido un buen cuidado.

2. Inspeccione el estado.

Revise el interior y el exterior para detectar signos de desgaste, óxido o daños. Preste especial atención a la parte inferior del vehículo, el compartimento del motor, las llantas y los frenos.

3. Prueba de manejo

Pruebe la SUV. Preste atención a ruidos inusuales, pruebe los frenos y todas las funciones. Asegúrese de que la transmisión cambie con suavidad y que el motor responda bien a la aceleración.

4. Pregunte sobre el uso para remolcar.

Si la Expedition se usó con frecuencia para remolcar, pregunte sobre el mantenimiento de la transmisión y revise si hay signos de desgaste excesivo.

Preguntas frecuentes sobre la Ford Expedition usada

P: ¿Es la Ford Expedition XLT 2015 ideal para familias?

R: ¡Por supuesto! Tiene capacidad para ocho personas, ofrece excelentes características de seguridad y amplio espacio de carga para carriolas, equipaje o equipo deportivo.

P: ¿Cuál es el consumo de combustible?

R: El modelo 2015 rinde alrededor de 15 mpg en ciudad y 20 mpg en carretera. Si bien no es la SUV más eficiente en consumo de combustible, es razonable considerando su tamaño y potencia.

P: ¿Puedo remolcar con una Ford Expedition usada?

R: Sí. Con una capacidad de remolque de hasta 9200 lb, es ideal para botes, remolques y más.

P: ¿Cuánto cuesta una Ford Expedition XLT 2015 usada?

R: Los precios varían según el kilometraje, el estado y la ubicación, pero la mayoría oscila entre $15,000 y $25,000. La Ford Expedition XLT 2015 es una sólida opción para quienes buscan una SUV potente, espaciosa y asequible. Ya sea para uso diario, para el transporte familiar o para una aventura de fin de semana, este vehículo lo tiene todo.

Si busca una Ford Expedition en venta, no pase por alto la XLT 2015. Con su equilibrio entre rendimiento, comodidad y valor, es una compra inteligente en el mercado de Ford Expeditions de segunda mano. Así que, si está listo para mejorar su experiencia de manejo, eche un vistazo a la Ford Expedition XLT 2015; quizás descubra que es la opción perfecta para su estilo de vida.

0 notes

Text

Explore Delta Industrial Automation Products at Aeliya Marine – Reliable, Precise, and Proven

Introduction: A Legacy of Precision with Delta

Delta is a well-known international brand within the industrial automation sector, renowned for its cutting-edge technology, rugged products, and reliable performance in marine, industrial, and factory automation applications. For maintenance engineers, technical buyers, and maintenance experts searching for high-performance automation products, Delta has become synonymous with trust. At Aeliya Marine Tech, we are honored to carry an expansive range of original Delta products that are perfectly suitable for a vast range of industrial and marine control applications.

In this blog, we dive deep into the Delta product lines found at Aeliya Marine’s Delta Collection, discuss their specifications, applications, and what they have to offer for mission-critical operations.

Why Choose Delta?

Delta Electronics was established in 1971 and has developed into one of the world’s most recognizable power and energy management product companies. Their products are renowned for:

Precision engineering

Long operational lifespan

Energy efficiency

Easy integration with automation systems

Proven performance in rugged environments

Delta’s solutions are preferred by manufacturing, marine, oil & gas, pharma, and other industries.

Delta Product Categories on Offer at Aeliya Marine

Below is a glimpse into some of the trending categories of Delta products available on our website:

1. Delta VFD (Variable Frequency Drives)

Delta’s VFDs are one of the most popular AC motor controllers in industries. They enable motor speed and torque control with no jerks, yielding greater energy efficiency and smoother operation.

Features :

Compatibility with wide voltage range (200V to 480V)

Built-in PLC and PID control

Protection against overload and fault diagnosis

Space-saving design for handy installation

Application Areas :

Conveyor belts

HVAC systems

Pumps and compressors

Industrial mixers

Some of the most sought-after models available include the Delta VFD007EL43A, VFD037EL21A, and VFD015M21A.

2. Delta PLC (Programmable Logic Controllers)

Delta PLCs offer rugged, programmable control for demanding automation applications. Their DVP series stands out for compact size and high-speed processing.

Features :

Modular construction for adaptability

High-speed counters and timers

Ethernet and Modbus communication ports

Ladder logic programming

Ideal For :

Machine control

Building automation

Packaging and printing equipment

Automated storage devices

Shop for models such as DVP14SS211R, DVP32ES00R, or DVP60ES2 in our Delta product catalog.

3. Delta HMI (Human Machine Interface)

Delta HMIs offer easy-to-use interfaces for operators to use with automation systems effectively.

Key Features :

Touchscreen interface

Availability of wide screen sizes (4.3" to 15")

Simple integration with Delta and third-party PLCs

Real-time data visualization and diagnostics

Applications :

Monitoring production lines

Operator control panels

Industrial dashboards

Watch out for units such as the Delta DOP-B07S411 or DOP-107BV available at discounted prices.

4. Delta Servo Systems

Delta servo drives and motors provide accurate motion control, suitable for those applications where speed, position, and torque must be controlled with a high degree of accuracy.

Features :

Real-time auto-tuning

Integrated positioning and velocity modes

Absolute and incremental encoder feedback

Low inertia and compact design

Applications :

CNC machinery

Robotics

Textile and printing machines

Our range comprises systems like ASD-B2–0421-B Servo Drive and ECMA-C20604RS Servo Motor.

5. Delta Temperature Controllers and Timers

These compact controllers are widely used in process control systems to maintain desired temperature levels, providing reliability and efficiency.

Key Benefits :

PID and ON/OFF control modes

Multi-sensor compatibility

User-configurable alarms and settings

Fast response time

Used in :

Furnaces and ovens

Industrial dryers

Refrigeration systems

You’ll find models like DTB4848CR and DTD4848R0 in stock.

Why Buy Delta Products from Aeliya Marine?

We do more than just list Delta products here at Aeliya Marine Tech — we verify that every component is tested, confirmed, and competitively priced. Here’s why we stand out :

Extensive Range : From VFD to Servo Motors, discover the entire range of Delta solutions.

Tested Parts : Each item is condition-checked (new or refurbished), and properly marked.

Quick Dispatch : Fast, secure delivery in India and worldwide.

Committed Support : Our support team is here for technical consultation and post-sales support.

Respected by Thousands : Aeliya Marine is a name respected by thousands of engineers and buyers from industries.

Who Should Consider Delta Products?

If you are :

A systems integrator in need of automating your process line,

A maintenance engineer searching for fast replacements,

A procurement specialist requiring high-quality components for your factory floor,

Or a marine technician working with onboard control systems,

Delta products provide the reliability, compatibility, and value you require.

Don’t wait until downtime hits you upgrade or replace your control components now with Delta’s reliable range.

Buy Delta Products Now

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#DELTA#products#marineautomation#automationparts

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-10-bmw-aftermarket-parts-upgrades-that-actually-deliver-results/

Top 10 BMW Aftermarket Parts Upgrades That Actually Deliver Results

To the BMW enthusiast, the idea of blending style, performance, capability, and power into one vehicle is always the goal. BMW has been manufacturing high-performance coupes and sedans for decades, and they now even offer some of the hottest SUVs available. They’re fast, handle beautifully, and look amazing.

But that doesn’t mean they’re complete masterpieces. BMW enthusiasts also have a penchant for upgrading their cars, finding areas they can squeeze just a bit more capability out of for a bit more untapped potential. BMW performance parts are the perfect option, as they can help produce more power, reduce weight, and generally personalize your Bimmer.

In this guide, we’ll go over the top 10 upgrades that actually deliver real results. We’re talking beyond simple accessories or genuine BMW parts–these are true BMW aftermarket parts to improve handling, increase power, sharpen response, and turn your BMW into a true performer.

1. Cold Air Intake Systems

When it comes to getting the biggest bang for your buck, a high-quality cold air intake is one of the most cost-effective upgrades for your BMW. These BMW aftermarket parts improve airflow by replacing the restrictive factory airbox with a wider, smoother system with a high-flow filter and materials that dissipate heat effectively. This allows your engine to breathe better and draw in cooler air, improving horsepower and throttle response, especially in turbocharged BMW models.

Finding BMW parts that add performance is one thing, but the sound that a cold air intake offers is another. That high-flowing filter doesn’t muffle sound, meaning these systems are louder and provide a throatier, more visceral experience. And if you’re worried about weight, they’re typically more lightweight, helping shed a few valuable pounds for track day.

Boosts: Horsepower, engine sound, intake efficiency, throttle feel

2. ECU Tuning (Flash Tunes & Piggybacks)

The one upgrade that does outperform a cold air intake in terms of performance for value is an ECU tune. An ECU tune works by reprogramming the way your engine’s software and control points work, essentially changing the way it thinks. It adjusts fuel mapping, ignition timing, and turbo boost levels. In some cases, a simple tune can increase an engine’s output by over 100 horsepower, depending on the vehicle and existing mods.

Piggyback systems are also available for some BMW series, allowing you to enhance performance without modifying the factory ECU. Instead of changing the way your car thinks, piggyback systems essentially intersect the signal from different sensors and send a new signal to the ECU, boosting performance. These can be an excellent choice for those who would like to switch between smooth daily driving or track-ready power.

Boosts: Horsepower, torque, acceleration

3. Performance Exhaust Systems

Everyone likes a deep, throaty exhaust note. But, upgrading your BMW’s exhaust system is about more than just sound. Cat-back or axle-back systems reduce backpressure, improve exhaust flow, and add a throatier tone that makes your car feel more alive. And, they offer a huge boost for turbocharged vehicles (no pun intended).

Look for BMW performance parts made from stainless steel or titanium, and make sure they’re street legal if you plan to use them on the street. Some systems are track-legal only, as they’re loud and don’t typically include the necessary emissions requirements. You’ll also shed weight compared to stock components, which is a performance win.

Boosts: Power, tone, weight reduction, style

4. Suspension Upgrades – Springs, Coilovers & Dampers

Factory BMW suspension is generally pretty good, so it’s often one of the most overlooked opportunities for BMW upgrades. Still, some upgraded gear here can deliver some of the most noticeable performance gains. Upgrading to lowering springs, coilovers, or sport dampers dramatically improves handling, cornering balance, and ride quality, while coilovers can change your ride height and center of gravity.

Not only does it give your BMW a more aggressive stance, it also tightens body roll and makes the vehicle more responsive on twisty roads. From daily driving to autocross, suspension mods pay off, and really help take a BMW to its full potential.

Boosts: Grip, confidence, cornering precision

5. Upgraded Intercoolers

Turbocharged BMW models like the 335i or M340i generate a lot of heat under boost, and heat is the enemy of performance. As genuine BMW parts, the stock intercooler helps but can get heat-soaked under hard driving conditions, reducing power. A larger aftermarket intercooler helps dissipate heat more effectively, keeping intake temps cooler and letting your engine perform consistently—even on hot days or back-to-back pulls.

Pairing an intercooler with an ECU tune, intake, and exhaust system is a proven recipe for power and reliability. It also increases the longevity and life of your turbo system, making an intercooler one of the best performance parts for your BMW.

Boosts: Power stability, intake temp management, engine longevity

6. Big Brake Kits (BBKs) or Performance Pads and Rotors

Speed is great—stopping safely and controllably from those speeds is better. Hard braking creates heat and brake fade, robbing a BMW of reliable performance and stealing the driver’s confidence lap after lap. But brake upgrades can restore both.

Upgrading your braking system is crucial if you’ve already enhanced your engine’s output. Performance rotors, pads, and stainless lines enhance stopping power and eliminate fade during aggressive driving. For track enthusiasts, full big brake kits with larger calipers and slotted rotors offer serious bite. Even spirited street drivers will benefit from upgraded BMW parts in this category.

Boosts: Stopping distance, pedal feel, fade resistance

7. Lightweight Performance Wheels

BMW fans have been upgrading their wheels for decades. Factory wheels are often heavy and uninspired, and reducing rotational weight can offer huge performance gains. Upgrading to lightweight, forged or flow-formed wheels reduces that weight, which improves acceleration, braking, and cornering.

Plus, wheels are one of the most noticeable accessories in the car world. Choose styles that fit your BMW series, match your style, and won’t break the bank. The right wheel setup can completely transform the way your BMW feels and performs. Plus, anytime you see a BMW with a set of performance wheels, you know it’s a sign that the owner takes their ride seriously.

Boosts: Handling, acceleration, looks

8. Limited-Slip Differential (LSD)

Many modern BMW models—especially non-M variants—lack a mechanical limited slip differential (LSD). That’s a shame, because a proper LSD adds massive performance benefits in terms of speed and control. You’ll see better traction, especially in wet or uneven conditions, and more predictable behavior when accelerating out of corners.

For spirited or track driving, this upgrade is a game-changer. BMW owners who want to perform at the next level should consider this once they’ve added power and suspension mods.

Boosts: Grip, performance, fun factor

9. Short Shifter Kits & Transmission Mounts

For those who drive a manual, a short shifter kit is one of the most satisfying upgrades. It reduces shift throw, increases mechanical feel, and helps you shift faster and more accurately. As long as your clutch work can keep up, you’ll be able to shift faster and continue putting power to the wheels.

Combine your short shifter with performance transmission mounts to reduce drivetrain slop, and you’ll feel more connected to your BMW. It’s a small mod that makes a big difference in driving satisfaction.

Boosts: Shift speed, feel, driving satisfaction

10. Strut Tower Braces & Chassis Bracing

BMWs are generally pretty firm from side to side, but a bit of bracing can make them much more responsive. These parts improve structural rigidity by tying the front strut towers together and rear strut towers together with a stiff bar. Less flex means sharper handling, especially under heavy cornering or braking.

It’s a subtle mod that doesn’t add horsepower, and in fact does add more weight—but it does make the car feel tighter and more composed. Some BMW aftermarket parts in this category even enhance style under the hood.

Boosts: Stability, handling, steering feedback

Final Thoughts: Build Your BMW the Right Way

The BMW performance parts and accessories above aren’t just hype—they deliver real results. Whether you’re trying to improve performance, handling, or style, each of these upgrades brings measurable improvements and helps you build a vehicle that stands out from the crowd.

And remember: not all BMW parts carry the same weight in terms of quality and value. Stick to trusted industry brands, select components that work together, and don’t forget the importance of support from experienced experts when planning your build. The Vivid Racing warehouse and shop are full of great BMW aftermarket parts that can change your vehicle’s entire feel and performance.

0 notes

Text

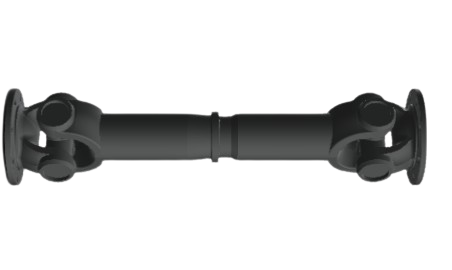

Cardan Shafts in UAE: Driving Industrial Progress Through Innovation

As the United Arab Emirates continues to evolve as a global hub for industry and technology, one mechanical component is quietly playing a vital role in this transformation: the Cardan shaft. Commonly used in systems requiring torque transmission between misaligned shafts, Cardan shafts in UAE have become essential in a wide range of applications—from heavy machinery and transport vehicles to oil & gas infrastructure and renewable energy systems.

In this blog, we explore how Cardan shafts are supporting the UAE's industrial growth and where innovation in this technology is heading.

What Are Cardan Shafts?

A Cardan shaft (also called a universal shaft or drive shaft) is a mechanical device designed to transmit rotational power from one point to another where the shafts are not in a straight line. They offer flexibility, strength, and reliability—qualities that are crucial for high-performance environments like the UAE’s expanding industrial, construction, and transportation sectors.

Why Cardan Shafts Matter in the UAE

The UAE’s ambitious infrastructure projects, massive transportation networks, and energy sector initiatives demand durable and efficient mechanical components. Cardan shafts in UAE are particularly suited to this demand for several reasons:

High load capacity: Perfect for heavy vehicles, cranes, drilling machines, and other industrial equipment.

Operational flexibility: Ideal for systems with changing shaft alignments and angular movements.

Resilience in extreme conditions: Built to perform under the UAE's harsh desert climate and demanding work cycles.

Key Industries Using Cardan Shafts in UAE

1. Oil and Gas

In Abu Dhabi and across the Emirates, Cardan shafts are widely used in pumps, compressors, and other rotating equipment. Their ability to handle high torque and resist wear makes them essential in both upstream and downstream operations.

2. Logistics and Transportation

From commercial trucks to port cranes, Cardan shafts ensure reliable motion across multiple load-bearing vehicles. Dubai’s extensive logistics infrastructure depends on such technology for uninterrupted operations.

3. Manufacturing and Heavy Industry

With the UAE pushing its “Make it in the Emirates” initiative, Cardan shafts are integral in automated production lines, conveyor systems, and industrial robotics.

Innovation in Cardan Shaft Technology

The future of Cardan shafts in UAE is tied to innovation. Companies are developing advanced shaft designs that offer better performance, efficiency, and lifespan.

● Advanced Materials

New composite materials like carbon fiber-reinforced polymers are reducing weight while maintaining strength—ideal for transport and aerospace industries.

● Smart Monitoring Systems

Integration with IoT sensors enables predictive maintenance. This minimizes downtime and improves safety—key priorities in high-stakes industries.

● Custom and Modular Designs

Tailored Cardan shaft solutions allow industries to select shaft systems that meet exact performance specifications, improving compatibility and reliability.

Local Manufacturing and Supply Chain Growth

As part of the UAE’s economic diversification and localization goals, there is increasing support for domestic production of mechanical components like Cardan shafts. This shift offers multiple advantages:

Reduced lead times and logistics costs

Greater quality control and customization

Economic value added to the national industrial sector

Local manufacturers now have opportunities to invest in advanced Cardan shaft production lines, supported by government-backed programs and free zone incentives.

Sustainability and Efficiency

In alignment with UAE’s sustainability vision, particularly the UAE Net Zero 2050 initiative, there is a growing focus on:

Energy-efficient shaft designs

Long-life components with lower environmental impact

Recyclable materials and eco-friendly production processes

Cardan shafts that deliver high performance while supporting green industry standards are becoming increasingly important.

0 notes

Text

Best EMC Solution Provider

We offer the same capabilities to customers. We develop and supply the latest technology and instrumentation, designed to gauge compliance with each customer’s defined goals. A full range of measurement approaches fulfill the quality assurance needs of manufacturers of high precision round parts and related products, as well as grease testing for the grease industry - EMC Testing and Measurement.

We are proficient in co-creating supernormal growth for clients across the globe. We also provide instrument calibration services to maintain accuracy and functionality. We are the measurement insight company committed to performance, and compelled by possibilities. Our designs and manufactures test and measurement solutions to break through the walls of complexity, and accelerate global innovation. Customized training programs are designed by experienced equipment specialists and tailored to fit customer needs. We automated and manual testing systems measure rotational device torque for many devices, including bottle caps, knobs, window latches, switches, and night vision sensors - Electronic Solutions.

We are the measurement insight company committed to performance, and compelled by possibilities. Our designs and manufactures test and measurement solutions to break through the walls of complexity, and accelerate global innovation. Our designs and manufactures test and measurement solutions to break through the walls of complexity, and accelerate global innovation.

Beyond technologically-advanced, precise instruments, our customers seek the competitive advantage of measurement insights, domain expertise and applications expertise. To make this more accessible, you’ll find around the world at trade shows, seminars, and conferences offering the latest technologies, techniques and standards. We look forward to problem-solving with you. We have a persistent curiosity and sense of possibilities. Our blog is filled with insights from our technical experts and thought leaders designed to help you and even entertain you on occasion. Join the discussion now and connect with our experts. For more information, please visit our site https://www.westek.com.au/

0 notes

Text

Choose Genuine NGK Spark Plugs for Optimal Engine Performance – Trusted Worldwide

At Smart Parts Exports, we realize that when it comes to engine performance, every small part assembles a big difference. Among these constituents, spark plugs play a vital role in delivering featureless ignition, fuel orderliness, with well entrenched power. That's why we proudly supply Genuine NGK Spark Plugs – trusted by professional workers as well as car producers worldwide for their higher quality and accuracy engineering.

Whether you're looking for OE replacement or presentation upgrades, NGK has a spark plug to meet your needs. In this blog, we’ll search the key well-being of NGK spark plugs, including their iridium variants, and guide you through how to choose the right model using the NGK spark plug chart.

Why Choose NGK Spark Plugs?

NGK Spark Plugs are globally recognized for their reliability, longevity, and production. initiated in 1936, NGK has become a supreme manufacturer of spark plugs, glow plugs, and sensors for internal kindling engines. With decades of revolution and OEM partnerships, NGK remains the preferred brand for many automotive brands, including Maruti Suzuki, Toyota, Honda, and more.

Here’s why NGK spark plugs stand out:

Exceptional Durability: Built to withstand extreme temperatures with constraint in the inner part of the combustion auditorium.

Consistent Performance: Engineered for optimal spark, assemble better ignition reliability as well as fuel kindling.

Wide Compatibility: Covers a broad range of makes and models, ensuring easy replacement and fitment.

Environmental Efficiency: Enhances fuel economy and reduces harmful emissions.

When you install NGK spark plugs in your vehicle, you subsidize long-label engine health besides showing.

NGK Iridium Spark Plugs: Advanced Technology for Modern Engines

For vehicle owners seeking premium presentation, NGK iridium spark plugs are a game-changer. Iridium is one of the inflexible with most corrosion-resistant metals on earth, manufacturing it ideal for high-recital spark plugs.

Key Benefits of NGK Iridium Spark Plugs:

Longer Life Span: Thanks to their extremist-fine center electrode (typically 0.6mm), these plugs offer unusual wear aversion..

Improved Ignition: The iridium tip impart an additional combined spark, ensuring faster combustion and better throttle response.

Enhanced Fuel Efficiency: Iridium spark plugs promote absolute kindling of the air-fuel mixture, most significantly to improve mileage.

These spark plugs are especially beneficial for high-performance and modern vehicles that demand precise ignition control.

Find the Right Fit: Use the NGK Spark Plug Chart

Choosing the correct spark plug for your vehicle is critical. NGK simplifies this process with their detailed NGK spark plug chart, which matches spark plug models to engine types and vehicle specifications. This chart includes information such as:

Thread diameter and reach

Heat range

Electrode design

Recommended torque settings

Whether you're an industrial unit owner, mechanic, or car expert, the NGK spark plug chart is an essential gadget for quick and precise spark plug selection.

At Smart Parts Exports, we assist our clients in navigating this chart to ensure they receive the exact spark plug for their application. Whether it's a close-packed hatchback or a business SUV, we’ve got you covered.

Why Buy Genuine NGK Spark Plugs from Smart Parts Exports?

As an experienced exporter of auto components from India, Smart Parts Exports is a trusted source for genuine NGK spark plugs. We stock a wide range of spark plugs, including:

NGK Standard Spark Plugs

NGK Iridium Spark Plugs

NGK Laser Iridium Spark Plugs

Our Promise:

100% Genuine Products: Sourced directly from authorized suppliers to ensure authenticity.

Competitive Prices: Affordable rates for bulk and individual orders.

Worldwide Shipping: Fast, reliable delivery to over 80 countries.

Expert Guidance: Our team helps you select the right plug using the NGK spark plug chart and technical data.

Whether you're a distributor, retailer, or vehicle owner, Smart Parts Exports delivers premium NGK products tailored to your requirements.

Conclusion

Spark plugs may be small, but their impact on your machine performance is extensive. By choosing NGK spark plugs, mostly the NGK iridium spark plugs and NGK laser iridium spark plug, you’re manufacturing a smart financing in power, reliability, as well as fuel efficiency.

Let Smart Parts Exports be your trusted partner for sourcing genuine NGK spark plugs from India. Backed by our devotion to quality and consumer satisfaction, we ensure your motor keeps firing on all cylinders – no matter where you are in the world.

Get in touch with us today to travel over our NGK range or to petition assistance with the NGK spark plug chart

0 notes

Text

Sports biomechanics unveiled: A physiotherapy perspective

Introduction

Welcome to our latest blog post where we delve into the fascinating world of sports biomechanics from a physiotherapy perspective. Join us as we uncover the intricacies of human movement within the realm of sports and explore how physiotherapists utilize biomechanical principles to enhance athletic performance, prevent injuries, and facilitate rehabilitation.

Foundation of Understanding

Physiotherapists lay the groundwork by delving into the fundamental principles of biomechanics, examining how forces, torques, and motion influence the human body during sports activities. This integration with physiology forms the basis for targeted physiotherapeutic interventions.

Performance Optimization

Leveraging biomechanical principles, physiotherapists fine-tune athletes’ movements to optimize form, muscle activation, and joint mechanics. Through understanding motion intricacies, practitioners aim to maximize efficiency and boost performance best physiotherapy center in Delhi.

Injury Prevention

By examining biomechanics, physiotherapists identify potential stressors and risk factors contributing to injuries. This proactive approach enables the development of targeted interventions and exercise programs to minimize injury risks.

Rehabilitation Strategies

Biomechanics plays a pivotal role in tailoring rehabilitation programs for athletes recovering from injuries. Physiotherapists analyze movement patterns and joint mechanics to design personalized exercises promoting optimal recovery best physiotherapy for sports rehab.

Gait Analysis

Detailed analysis of an individual’s gait aids in diagnosing and treating conditions related to the lower extremities. Bio-mechanical insights facilitate a more targeted and effective rehabilitation process.

Functional Movement Assessments

Incorporating biomechanical assessments allows for comprehensive evaluations of an athlete’s functional movements. This approach guides tailored interventions to improve overall movement patterns.

Technology Integration

Embracing advanced technologies enhances therapeutic interventions and accelerates the rehabilitation process. Motion capture systems and wearable sensors provide real-time feedback, improving effectiveness.

Collaboration with Coaches

Collaboration with coaches ensures a holistic approach to athlete development, integrating biomechanical insights into training regimens and injury prevention strategies best physio center in Delhi.

Conclusion